rod MITSUBISHI ECLIPSE 1990 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 2 of 391

SAFETY NOTICE

CAUTIONALL SERVICE AND REBUILDING INSTRUCTIONS CONTAINED HEREIN ARE

APPLICABLE TO, AND FOR THE CONVENIENCE OF, THE AUTOMOTIVE

TRADE ONLY. All test and repair procedures on components or assemblies in

non-automotive applications should be repaired in accordance with instructions

supplied by the manufacturer of the total product.

Proper service and repair is important to the safe, reliable, operation of all motor vehicles.

The service procedures recommended and described in this publication were developedfor professional

servlTe personnel and are effective methods for performing vehicle

repair.Following these procedures will help assure efficient economical vehicleperformance

and service reliability. Some of these service procedures require the use of

special tools designed for specific procedures. These special tools should be used when

recommended throughout this publication.

Special attention should be exercised when working with spring or tension loaded

fasteners and devices such as E-Clips, Circlips, Snap rings, etc., as careless removal

may cause personal injury. Always wear safety goggles whenever working on

vehicles or vehicle components.

7

It is important to note that this publication contains various Cautions and Warnings.These

should be carefully read in order to minimize the risk of personal injury, or thepossibility

that, improper service methods may damage the vehicle or render it unsafe.It

is important to note that these Cautions and Warnings cover only the situations and

procedures Chrysler Motors has encountered and recommended. Chrysler Motors couldnot possibly know,

evaluate, and advise the service trade of all conceivable ways thatservice

may *be performed, or of the possible hazards of each. Consequently, ChryslerMotors

has not undertaken any such broad service review. Accordingly, anyone who

uses a service procedure, or tool, that is not recommended in this publication, must assure

oneself thoroughly that neither personal safety, nor vehicle safety, be jeopardized bythe service

methods they select.

WE SrjPPORT

VOLUNTARY TECHNICIAN

CERTIFICATION

THROUGH

Page 6 of 391

o-2GENERAL - Technical Features

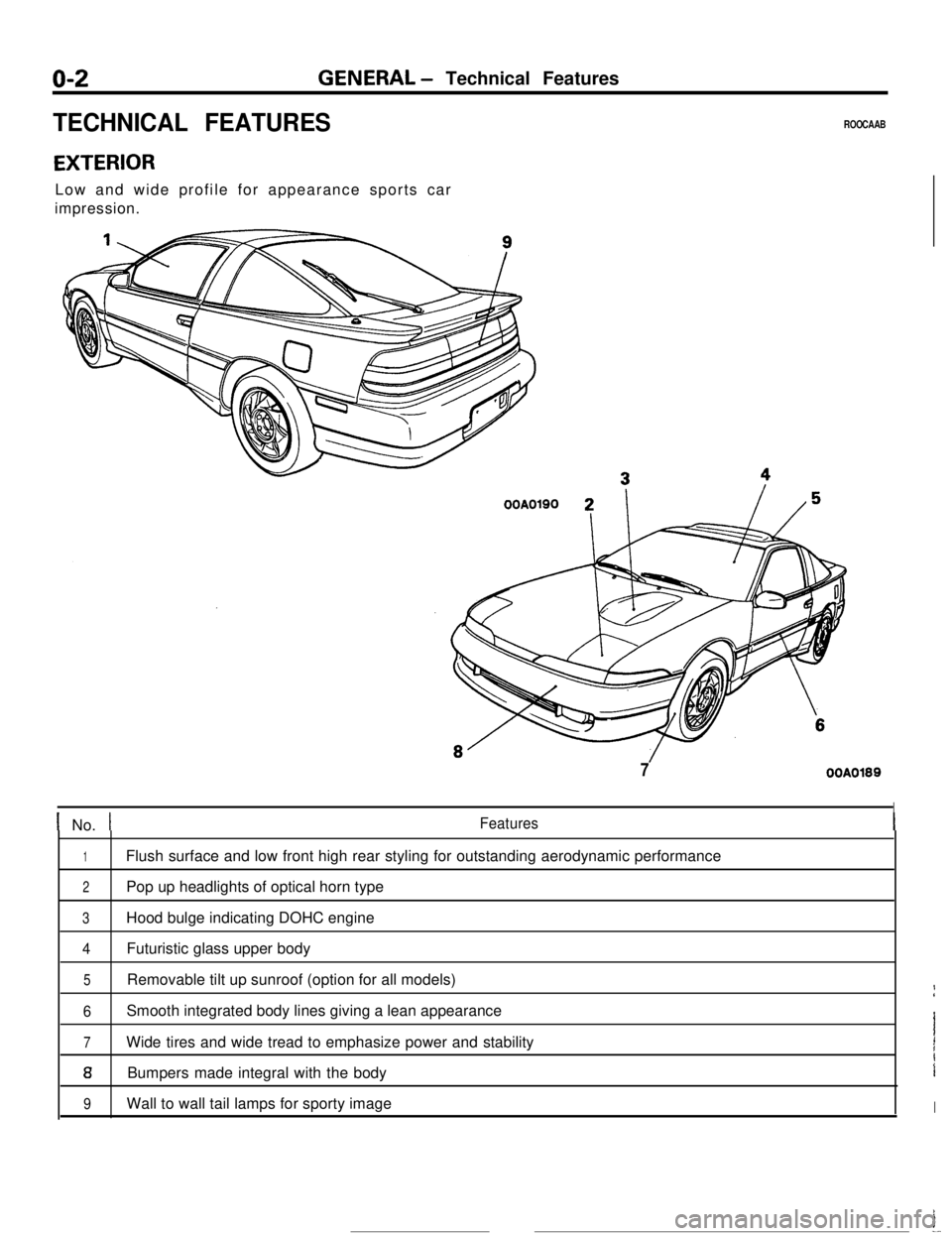

TECHNICAL FEATURESROOCAAB

EXTERIORLow and wide profile for appearance sports car

impression.

OOA0190 2

7OOA0189

I

1 No. tFeatures

1Flush surface and low front high rear styling for outstanding aerodynamic performance

2Pop up headlights of optical horn type

3Hood bulge indicating DOHC engine

4Futuristic glass upper body

5Removable tilt up sunroof (option for all models)If

6Smooth integrated body lines giving a lean appearance

7Wide tires and wide tread to emphasize power and stabilityI1

aBumpers made integral with the bodyi

9Wall to wall tail lamps for sporty imageIi

--

Page 21 of 391

FRONT SUSPENSION - General Information2-3

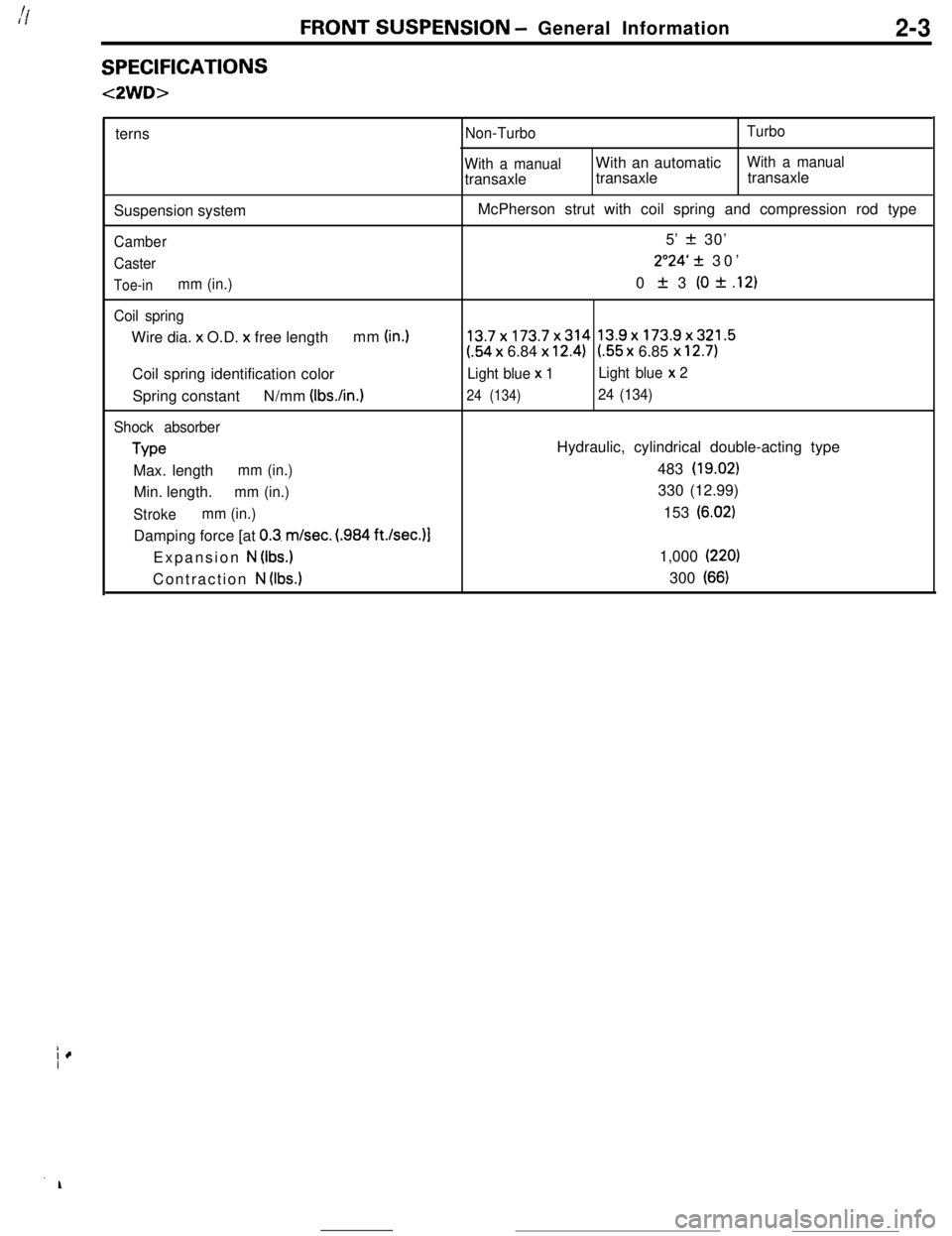

SPECIFICATIONS

<2WD>terns

Suspension system

Camber

Caster

Toe-inmm (in.)

Coil springWire dia. x O.D.

x free lengthmm (in.)Coil spring identification color

Spring constantN/mm (IbsAn.)

Shock absorber

TypeMax. length

mm (in.)Min. length.

mm (in.)

Strokemm (in.)Damping force [at

0.3. m/set. (.984 ft./sec.)l

Expansion

N (Ibs.)Contraction

N (Ibs.)

Non-TurboTurbo

With a manualWith an automatic

With a manualtransaxletransaxletransaxle

McPherson strut with coil spring and compression rod type

5’

z!z 30’

2”24’ 31 30’

0

It 3 (0 * .12)

13.7x173.7x314 13.9x173.9x321.5

(.54 x 6.84 x 12.4)l.55 x 6.85 x 12.7)

Light blue x 1Light blue x 2

24 (134)24 (134)Hydraulic, cylindrical double-acting type

483

(19.02)330 (12.99)

153

(6.02)1,000

(220)300

(66)

Page 22 of 391

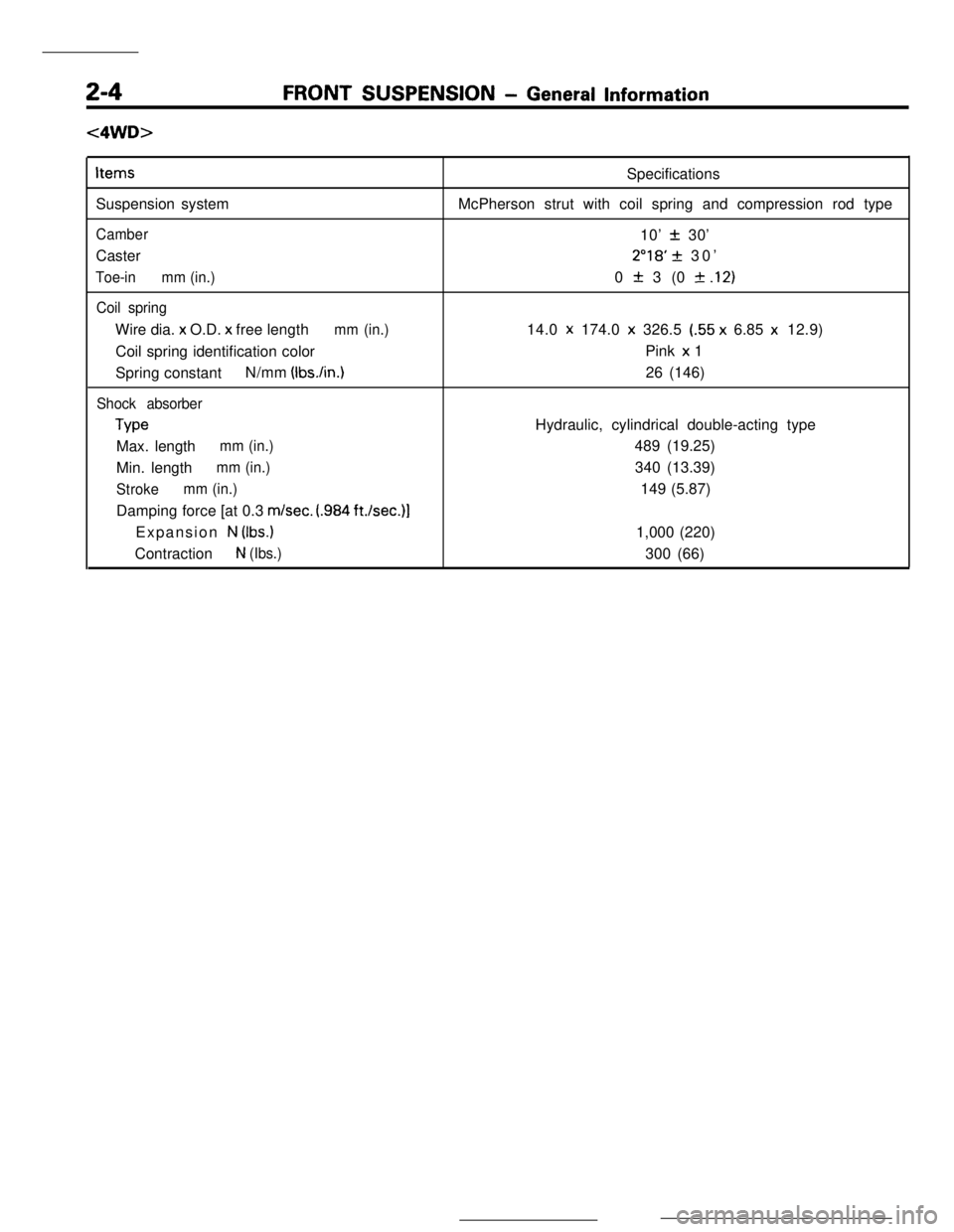

FRONT SUSPENSION - General Information

c4WD>Items

Suspension system

CamberCaster

Toe-inmm (in.)

Coil springWire dia. x O.D. x free length

mm (in.)Coil spring identification color

Spring constantN/mm

(Ibs./in.)

Shock absorber

TypeMax. length

mm (in.)Min. length

mm (in.)

Strokemm (in.)Damping force [at 0.3

m/set. (.984 ft./set.)]Expansion

N (Ibs.)Contraction

N (Ibs.)Specifications

McPherson strut with coil spring and compression rod type

10’

+- 30’

2”18’ + 30’

0

zk 3 (0 f .l2)14.0 x 174.0

x 326.5 (.55 x 6.85 x 12.9)

Pink x 1

26 (146)

Hydraulic, cylindrical double-acting type

489 (19.25)

340 (13.39)

149 (5.87)

1,000 (220)

300 (66)

Page 25 of 391

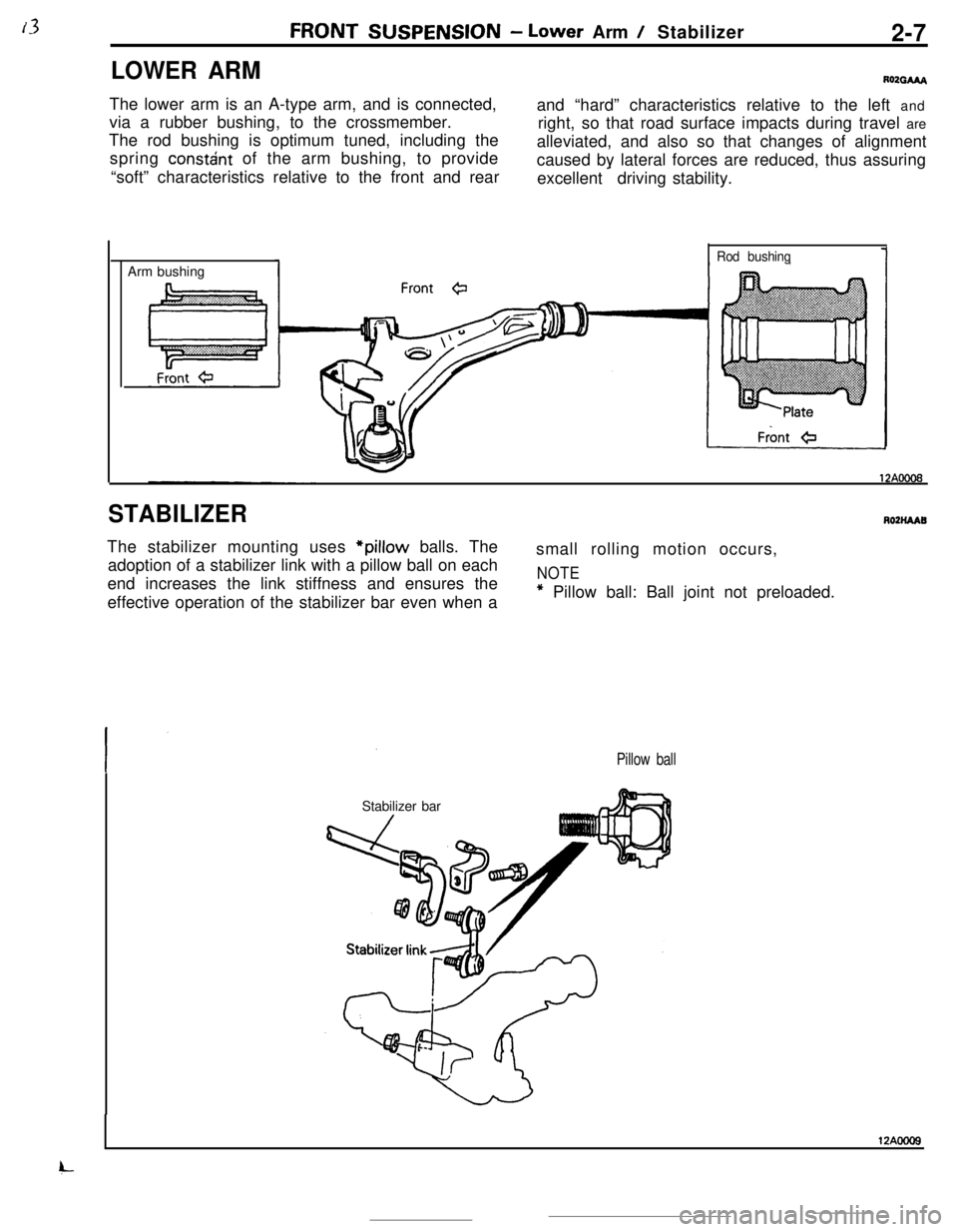

FRONT SUSPENSION- Lower Arm / Stabilizer2-7

LOWER ARM

ROZGAAAThe lower arm is an A-type arm, and is connected,

via a rubber bushing, to the crossmember.

The rod bushing is optimum tuned, including the

spring constant of the arm bushing, to provideand “hard” characteristics relative to the left and

right, so that road surface impacts during travel are

alleviated, and also so that changes of alignment

caused by lateral forces are reduced, thus assuring

“soft” characteristics relative to the front and rear

excellent

I driving stability.

Arm bushing

,m

Rod bushing

STABILIZERROZHAABThe stabilizer mounting uses

*pillow balls. The

adoption of a stabilizer link with a pillow ball on each

end increases the link stiffness and ensures the

effective operation of the stabilizer bar even when asmall rolling motion occurs,

NOTE* Pillow ball: Ball joint not preloaded.

Pillow ballStabilizer bar

12AOOOS

4--

Page 68 of 391

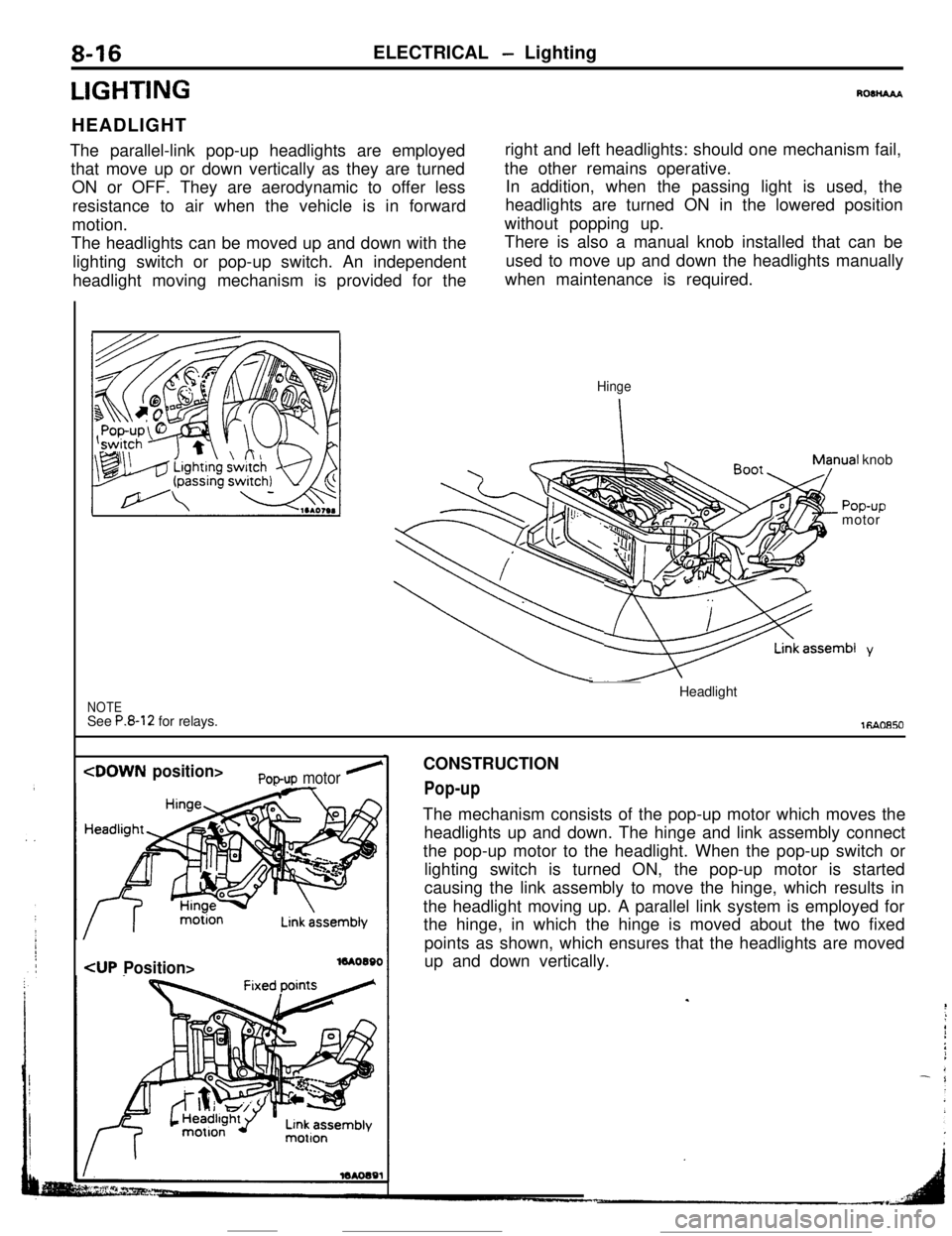

8-16ELECTRICAL - Lighting

LIGHTINGHEADLIGHT

The parallel-link pop-up headlights are employed

that move up or down vertically as they are turned

ON or OFF. They are aerodynamic to offer less

resistance to air when the vehicle is in forward

motion.

The headlights can be moved up and down with the

lighting switch or pop-up switch. An independent

headlight moving mechanism is provided for theRo3liAAAright and left headlights: should one mechanism fail,

the other remains operative.

In addition, when the passing light is used, the

headlights are turned ON in the lowered position

without popping up.

There is also a manual knob installed that can be

used to move up and down the headlights manually

when maintenance is required.

nual knob

POD-UD

NOTESee P.8-12 for relays.

Hinge

-r -rmotor

~ SpsernbI y_Headlight

1RAoa50

Pop-upThe mechanism consists of the pop-up motor which moves the

headlights up and down. The hinge and link assembly connect

the pop-up motor to the headlight. When the pop-up switch or

lighting switch is turned ON, the pop-up motor is started

causing the link assembly to move the hinge, which results in

the headlight moving up. A parallel link system is employed for

the hinge, in which the hinge is moved about the two fixed

points as shown, which ensures that the headlights are moved

up and down vertically.

.

Page 95 of 391

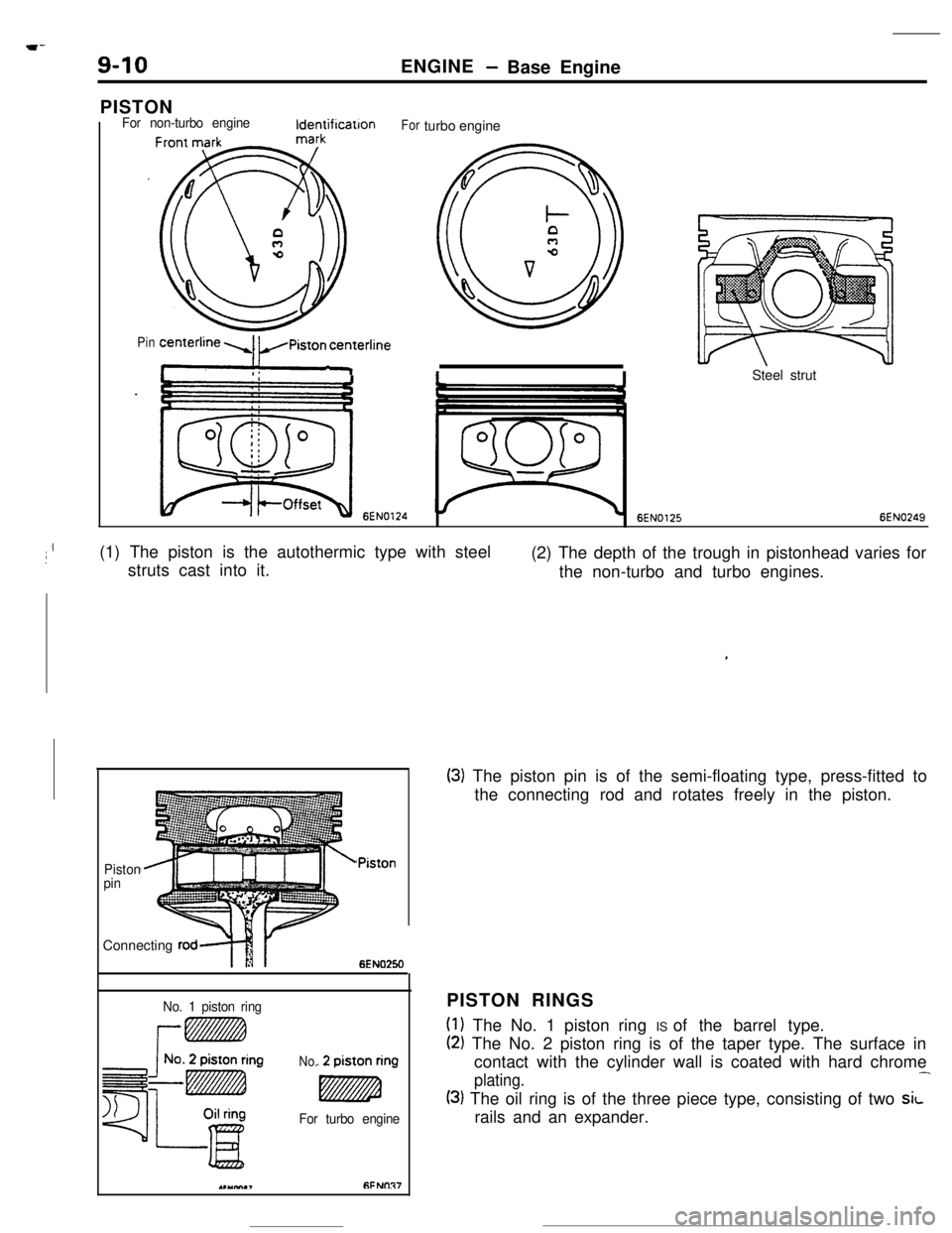

9-10PISTONENGINE- Base Engine

For non-turbo engineldentificatlonForturbo engine

Pin;nterline y FPiston ceyerline

6EN01246EN0125Steel strut6EN0249

Ij(1) The piston is the autothermic type with steel

struts cast into it..(2) The depth of the trough in pistonhead varies for

the non-turbo and turbo engines.

Piston

pinConnecting

rod?\i

~Piston

6EN0250

No. 1 piston ringPISTON RINGS

No.3

For turbo engine

(1) The No. 1 piston ring IS of the barrel type.

(2) The No. 2 piston ring is of the taper type. The surface in

contact with the cylinder wall is coated with hard chrome

plating.-

(3) The oil ring is of the three piece type, consisting of two sLrails and an expander.

.,YM,,fiFNflR7

,

(3) The piston pin is of the semi-floating type, press-fitted to

the connecting rod and rotates freely in the piston.

Page 96 of 391

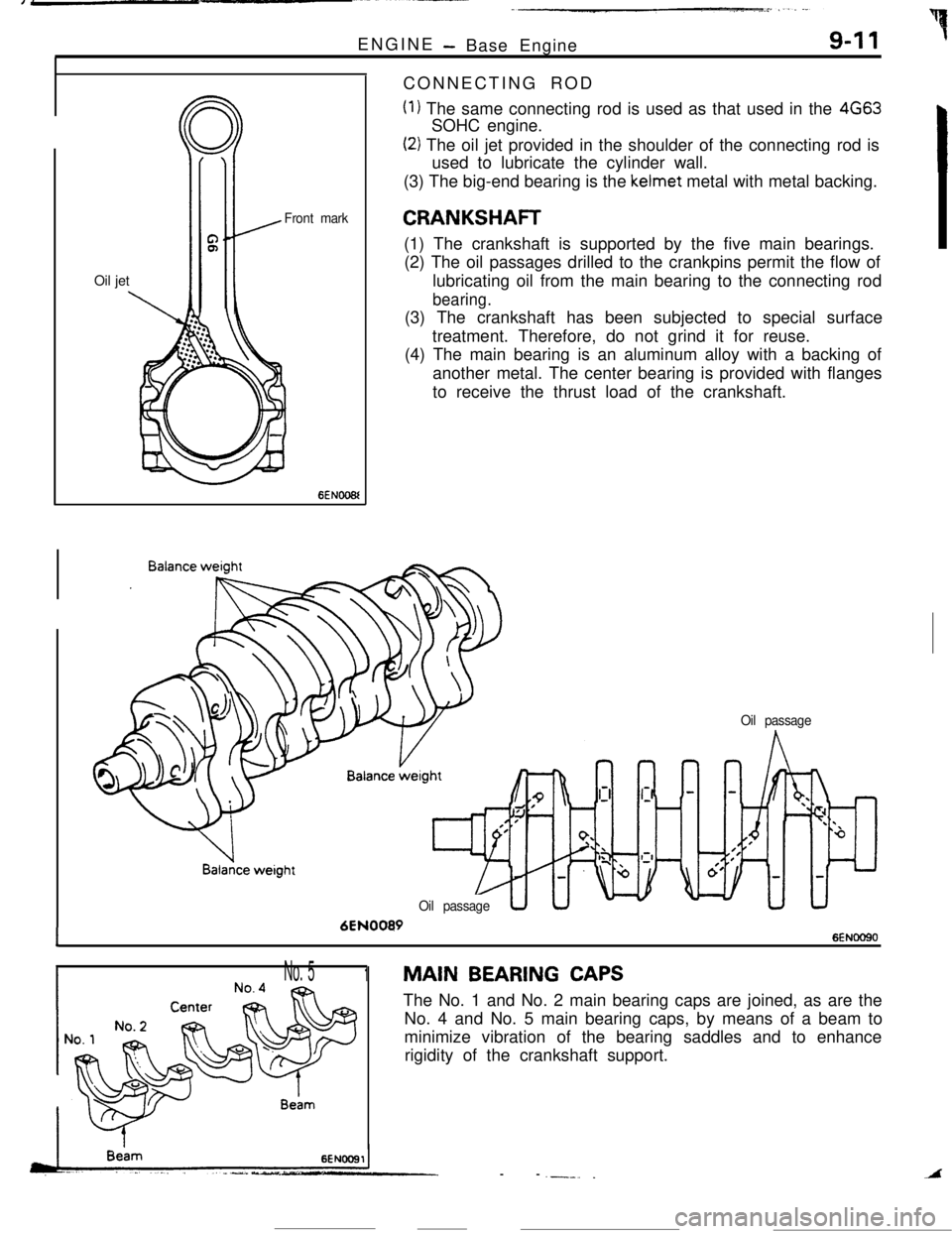

ENGINE- Base Engine9-11 7Oil jet

Front mark

6ENOO6lCONNECTING ROD

(1) The same connecting rod is used as that used in the 4663SOHC engine.

(2) The oil jet provided in the shoulder of the connecting rod is

used to lubricate the cylinder wall.

(3) The big-end bearing is the kelmet metal with metal backing.

CRANKSHAFT(1) The crankshaft is supported by the five main bearings.

(2) The oil passages drilled to the crankpins permit the flow of

lubricating oil from the main bearing to the connecting rod

bearing.(3) The crankshaft has been subjected to special surface

treatment. Therefore, do not grind it for reuse.

(4) The main bearing is an aluminum alloy with a backing of

another metal. The center bearing is provided with flanges

to receive the thrust load of the crankshaft.

Oil passage

6EN0089

16ENOOQO

Oil passage

INo. 51MAIN BEARING CAPSThe No. 1 and No. 2 main bearing caps are joined, as are the

No. 4 and No. 5 main bearing caps, by means of a beam to

minimize vibration of the bearing saddles and to enhance

rigidity of the crankshaft support.

--

.--. _A

Page 199 of 391

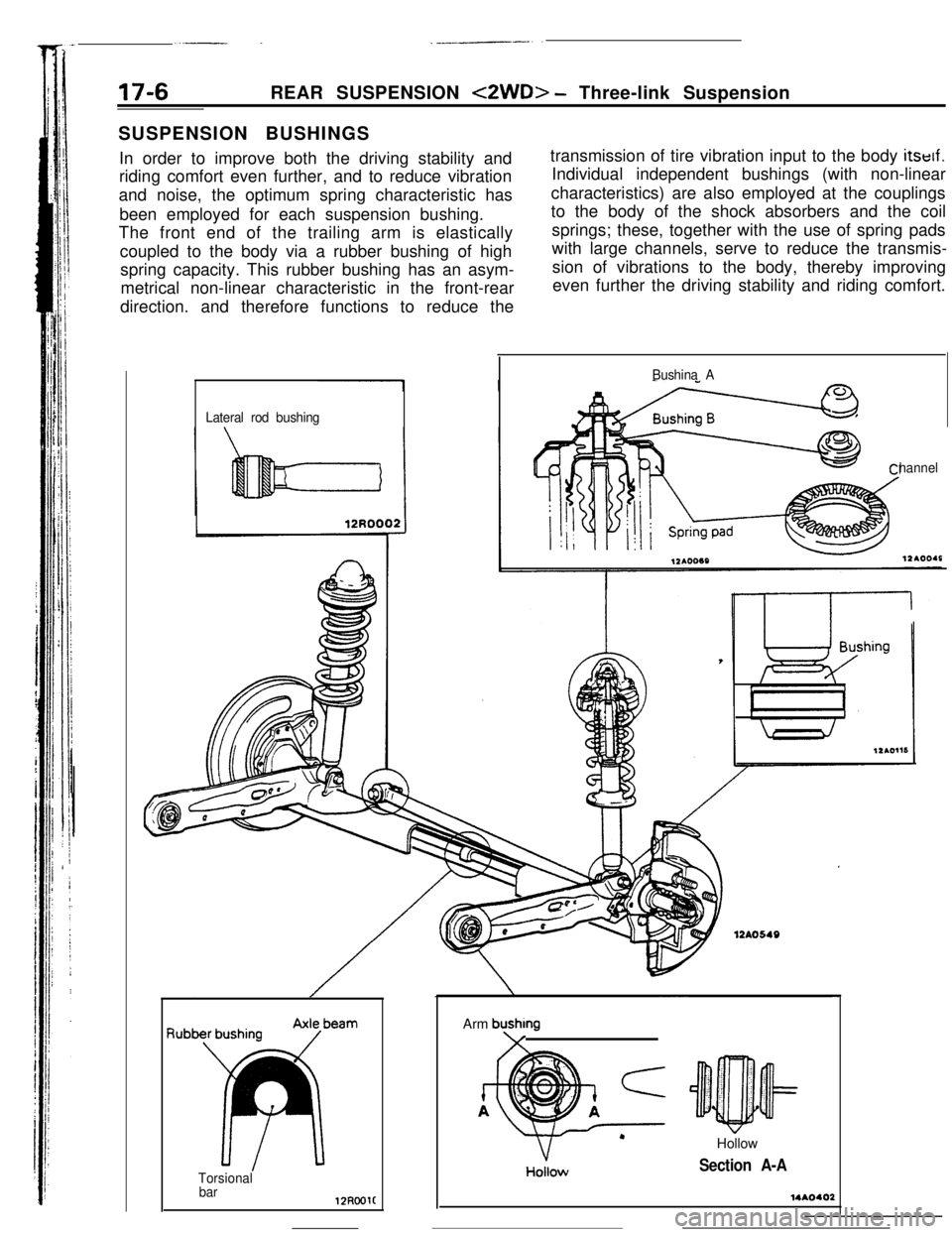

17-6REAR SUSPENSION <2WD> - Three-link Suspension

SUSPENSION BUSHINGS

In order to improve both the driving stability and

riding comfort even further, and to reduce vibration

and noise, the optimum spring characteristic has

been employed for each suspension bushing.

The front end of the trailing arm is elastically

coupled to the body via a rubber bushing of high

spring capacity. This rubber bushing has an asym-

metrical non-linear characteristic in the front-rear

direction. and therefore functions to reduce thetransmission of tire vibration input to the body itself.

Individual independent bushings (with non-linear

characteristics) are also employed at the couplings

to the body of the shock absorbers and the coil

springs; these, together with the use of spring pads

with large channels, serve to reduce the transmis-

sion of vibrations to the body, thereby improving

even further the driving stability and riding comfort.

Lateral rod bushingBushina A

hannel

f3ub

Torsional

barArm

bushmg\/HollowHoilow

Section A-A

Page 208 of 391

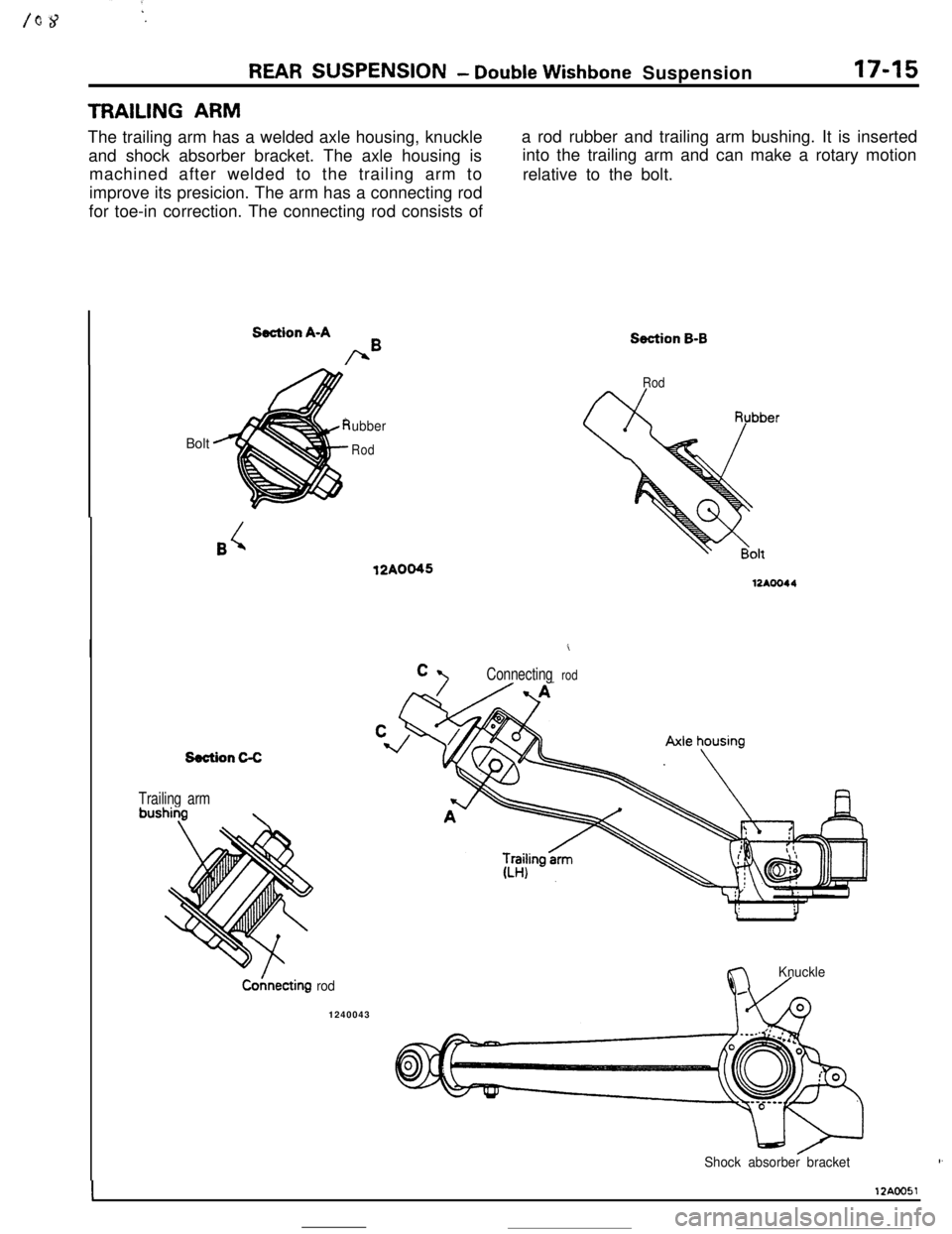

REAR SUSPENSION- Double Wishbone Suspension17-15TRAILING ARM

The trailing arm has a welded axle housing, knuckle

and shock absorber bracket. The axle housing is

machined after welded to the trailing arm to

improve its presicion. The arm has a connecting rod

for toe-in correction. The connecting rod consists ofa rod rubber and trailing arm bushing. It is inserted

into the trailing arm and can make a rotary motion

relative to the bolt.

Section A-A

bBBolt

ubber

RodRod12A0045

Ii

Connecting rod

Section C-C

Trailing armbushiyg

\Co;lnecting

rod1240043

Section B-B

Knuckleii-l /

Shock absorber bracket,,

I12ACO51