service MITSUBISHI ECLIPSE 1990 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 2 of 391

SAFETY NOTICE

CAUTIONALL SERVICE AND REBUILDING INSTRUCTIONS CONTAINED HEREIN ARE

APPLICABLE TO, AND FOR THE CONVENIENCE OF, THE AUTOMOTIVE

TRADE ONLY. All test and repair procedures on components or assemblies in

non-automotive applications should be repaired in accordance with instructions

supplied by the manufacturer of the total product.

Proper service and repair is important to the safe, reliable, operation of all motor vehicles.

The service procedures recommended and described in this publication were developedfor professional

servlTe personnel and are effective methods for performing vehicle

repair.Following these procedures will help assure efficient economical vehicleperformance

and service reliability. Some of these service procedures require the use of

special tools designed for specific procedures. These special tools should be used when

recommended throughout this publication.

Special attention should be exercised when working with spring or tension loaded

fasteners and devices such as E-Clips, Circlips, Snap rings, etc., as careless removal

may cause personal injury. Always wear safety goggles whenever working on

vehicles or vehicle components.

7

It is important to note that this publication contains various Cautions and Warnings.These

should be carefully read in order to minimize the risk of personal injury, or thepossibility

that, improper service methods may damage the vehicle or render it unsafe.It

is important to note that these Cautions and Warnings cover only the situations and

procedures Chrysler Motors has encountered and recommended. Chrysler Motors couldnot possibly know,

evaluate, and advise the service trade of all conceivable ways thatservice

may *be performed, or of the possible hazards of each. Consequently, ChryslerMotors

has not undertaken any such broad service review. Accordingly, anyone who

uses a service procedure, or tool, that is not recommended in this publication, must assure

oneself thoroughly that neither personal safety, nor vehicle safety, be jeopardized bythe service

methods they select.

WE SrjPPORT

VOLUNTARY TECHNICIAN

CERTIFICATION

THROUGH

Page 4 of 391

._._ -_- 1 -.

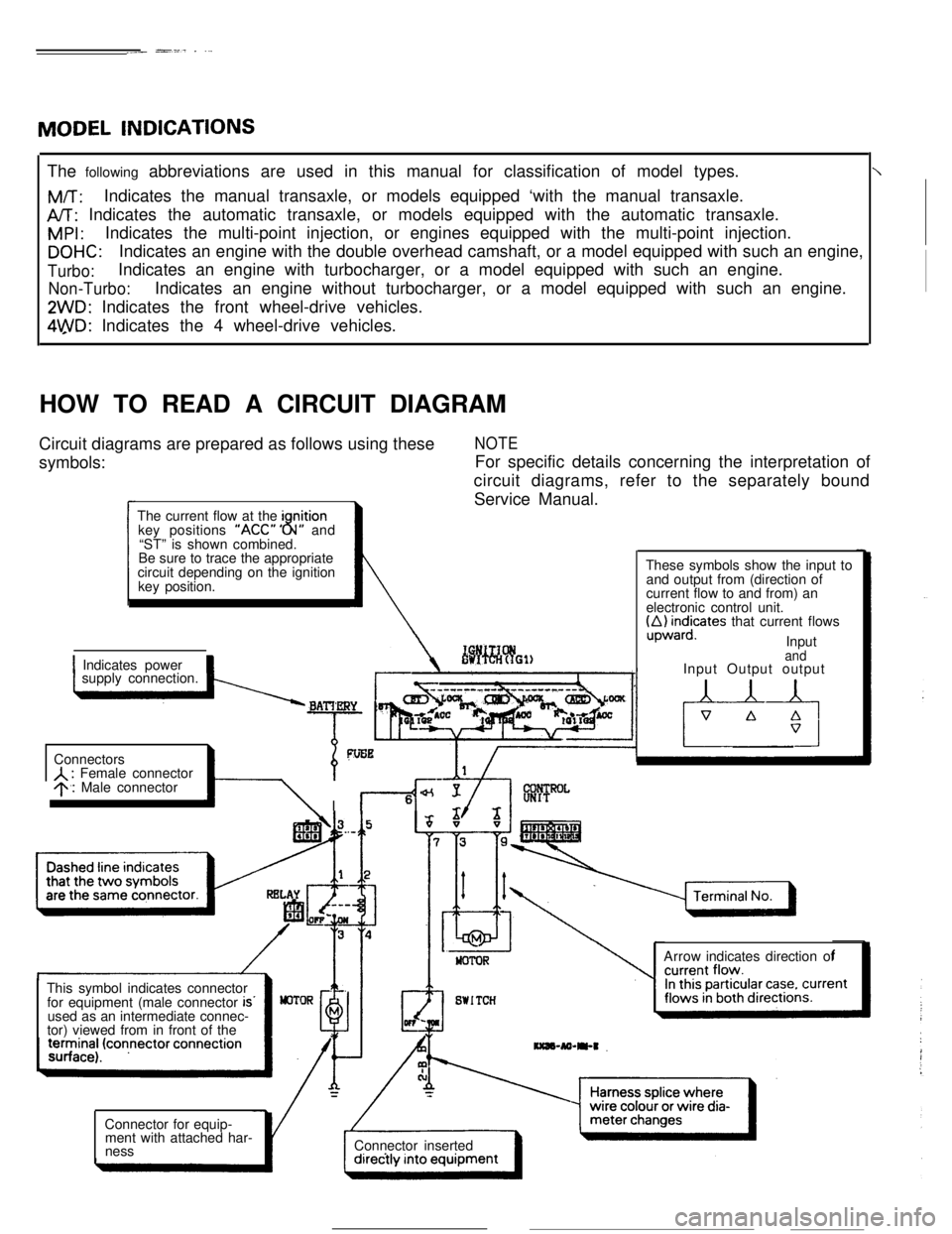

MODEL INDICATIONS

The following abbreviations are used in this manual for classification of model types.\

M/T: Indicates the manual transaxle, or models equipped ‘with the manual t\

ransaxle.

A/T: Indicates the automatic transaxle, or models equipped with the automatic\

transaxle.

MPI: Indicates the multi-point injection, or engines equipped with the multi-\

point injection.

DOHC: Indicates an engine with the double overhead camshaft, or a model equipp\

ed with such an engine,

Turbo: Indicates an engine with turbocharger, or a model equipped with such an \

engine.

2WD: Indicates the front wheel-drive vehicles.

4WD: Indicates the 4 wheel-drive vehicles.

HOW TO READ A CIRCUIT DIAGRAM

initionkey positions “ACC” ” N” and8“ST” is shown combined.

~

Service Manual.

o&ficates that current flows

Input

1 Indicates power1supply connection.

A : Female connector9.1 Male connector

\ Il-4’

Input Output output

is..used as an intermediate connec-

Page 9 of 391

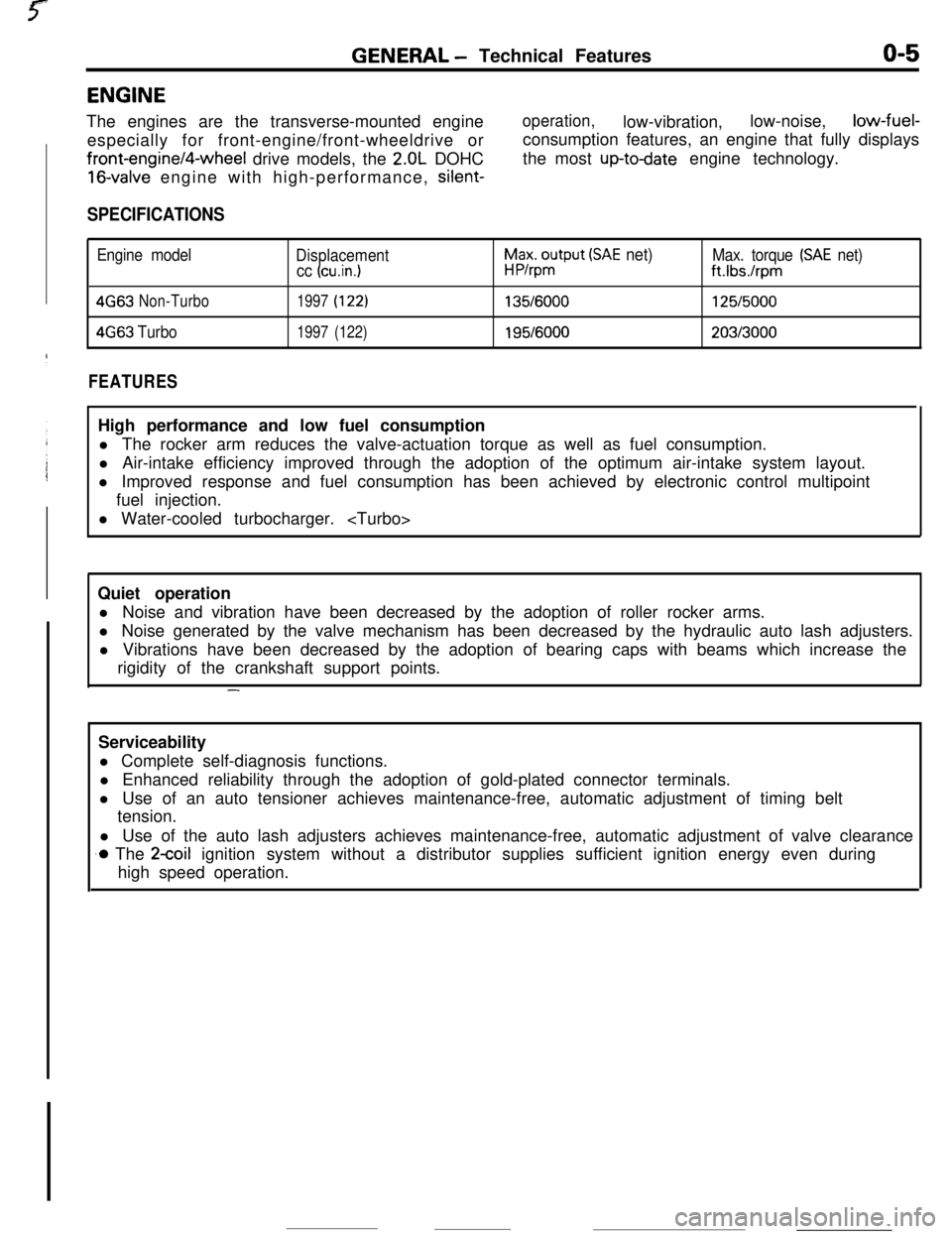

GENERAL - Technical Featureso-5ENGINE

The engines are the transverse-mounted engine

especially for front-engine/front-wheeldrive orfront-engine/4-wheel drive models, the

2.OL DOHC

16-valve engine with high-performance, silent-

operation,low-vibration,low-noise,low-fuel-

consumption features, an engine that fully displays

the most

up-todate engine technology.

SPECIFICATIONS

Engine model

Displacement

cc (cu.in.1

h$xo$put (SAE net)Max. torque (SAE net)

ft.Ibs./rpm

4G63Non-Turbo1997(122)135/6000125/5000

4663Turbo1997(122)195/6000203/3000

FEATURESHigh performance and low fuel consumption

l The rocker arm reduces the valve-actuation torque as well as fuel consumption.

l Air-intake efficiency improved through the adoption of the optimum air-intake system layout.

l Improved response and fuel consumption has been achieved by electronic control multipoint

fuel injection.

l Water-cooled turbocharger.

Quiet operation

l Noise and vibration have been decreased by the adoption of roller rocker arms.

l Noise generated by the valve mechanism has been decreased by the hydraulic auto lash adjusters.

l Vibrations have been decreased by the adoption of bearing caps with beams which increase the

rigidity of the crankshaft support points.

-Serviceability

l Complete self-diagnosis functions.

l Enhanced reliability through the adoption of gold-plated connector terminals.

l Use of an auto tensioner achieves maintenance-free, automatic adjustment of timing belt

tension.

l Use of the auto lash adjusters achieves maintenance-free, automatic adjustment of valve clearance

.o The 2coil ignition system without a distributor supplies sufficient ignition energy even during

high speed operation.

Page 27 of 391

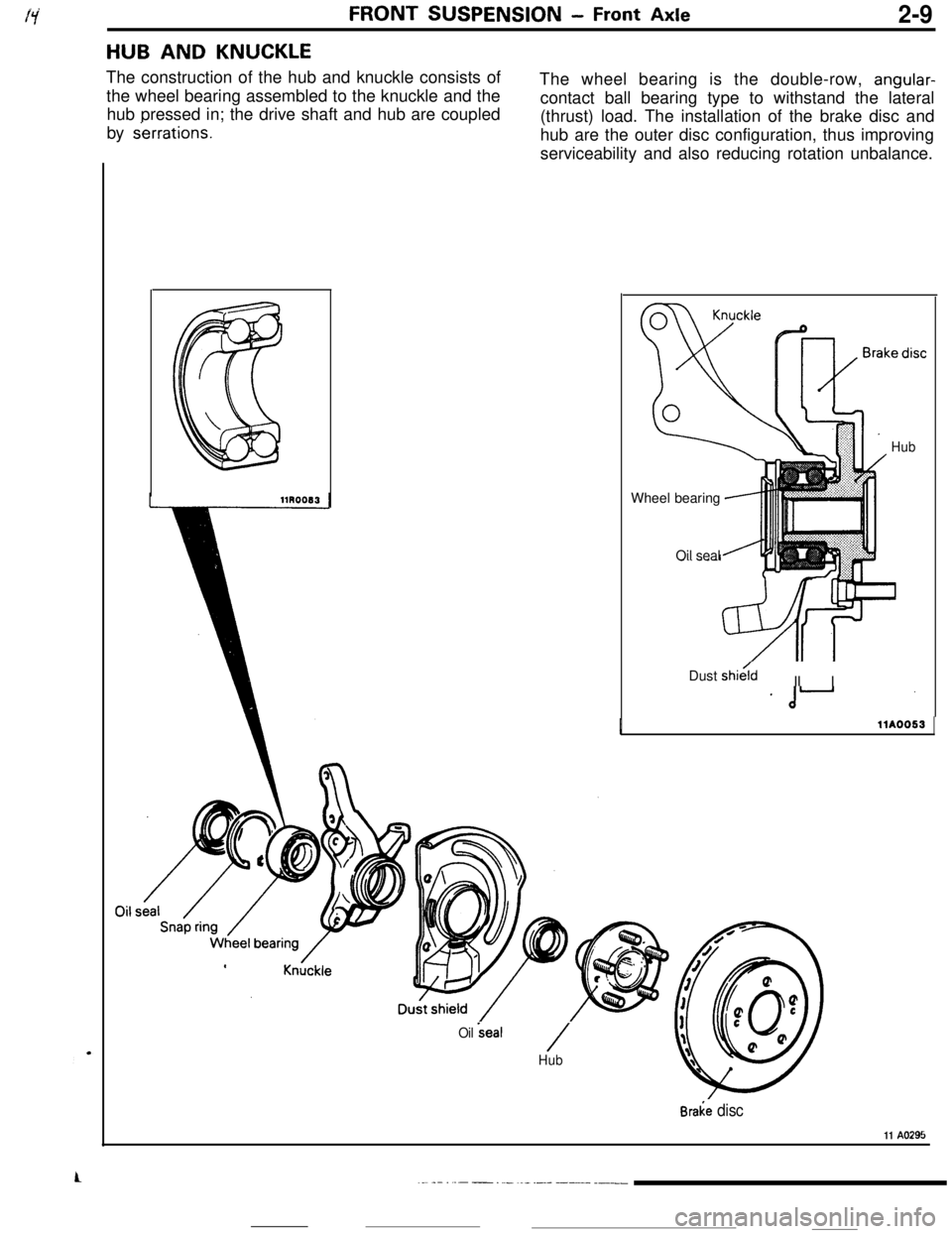

FRONT SUSPENSION - Front Axle2-9

HUB AND KNUCKLEThe construction of the hub and knuckle consists of

The wheel bearing is the double-row,

angular-the wheel bearing assembled to the knuckle and the

contact ball bearing type to withstand the lateral

hub pressed in; the drive shaft and hub are coupled

(thrust) load. The installation of the brake disc and

by

&rations.hub are the outer disc configuration, thus improving

serviceability and also reducing rotation unbalance.

Wheel bearing

Oil seal

HubDust shi&d

II I

IllA0053

Oil seal/HubBraie

disc

11 A0295

..~ -- . ..- - . .._ ~._ __.- ----_ .__

Page 32 of 391

REAR AXLE- Viscous Coupling Type Limited Slip Differential3-a

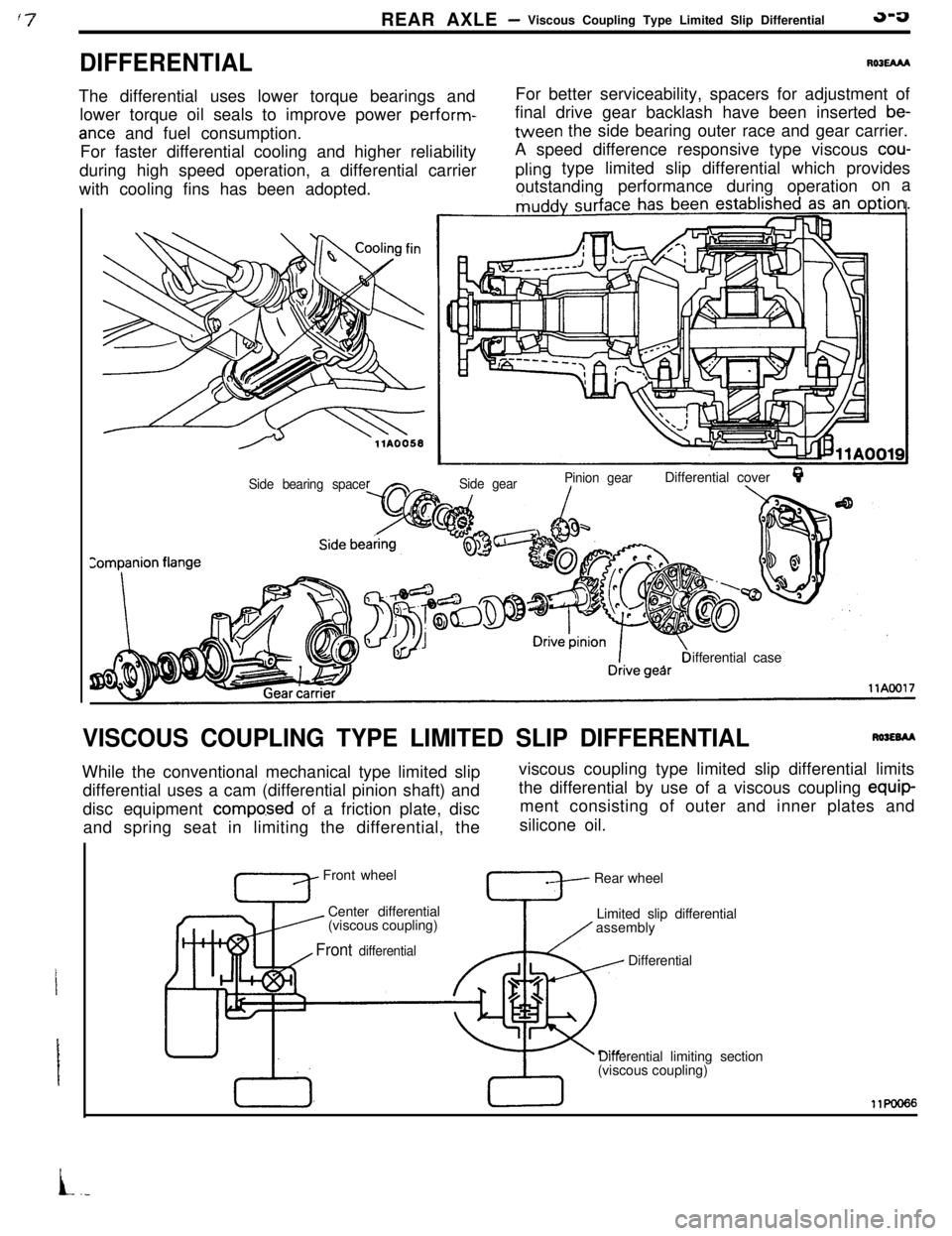

DIFFERENTIALROlEAM

The differential uses lower torque bearings and

lower torque oil seals to improve power perform-

ante and fuel consumption.

For faster differential cooling and higher reliability

during high speed operation, a differential carrier

with cooling fins has been adopted.For better serviceability, spacers for adjustment of

final drive gear backlash have been inserted

be-tween the side bearing outer race and gear carrier.

A speed difference responsive type viscous

cou-

pling type limited slip differential which provides

outstandingperformance during operationon a

Side gearPinion gearDifferential coverQ./\Side bearing spaceifferential case

VISCOUS COUPLING TYPE LIMITED SLIP DIFFERENTIALRWEBAAWhile the conventional mechanical type limited slip

differential uses a cam (differential pinion shaft) and

disc equipment

compo.sed of a friction plate, disc

and spring seat in limiting the differential, theviscous coupling type limited slip differential limits

the differential by use of a viscous coupling equip-

ment consisting of outer and inner plates and

silicone oil.

Front wheel

Center differential

’ (viscous coupling)Rear wheel

Limited slip differential

assembly

Front differential, I

TDifferential

Differential limiting section

(viscous coupling)11KmI66

L.-

Page 39 of 391

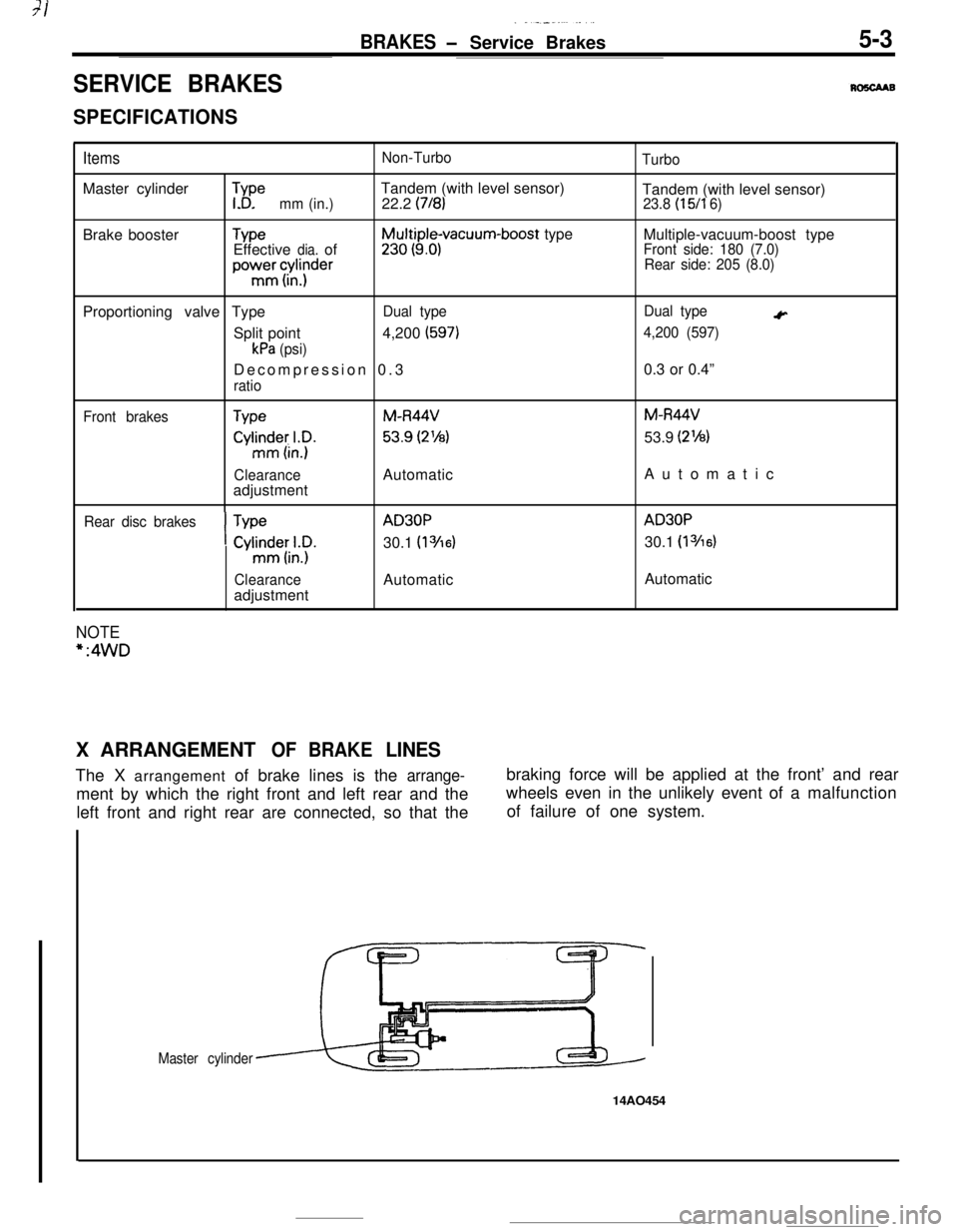

BRAKES - Service Brakes 5-3

$eTandem (with level sensor)

(718)

Brake boosterTYpeEffective dia. of

y3tt$;ivacuum-boost type

powmermc&;der

Proportioning valve Type Dual type

(597)

kPa (psi)

Decompression 0. 3

(15/l 6)

Multiple-vacuum-boost type

c

4,200 (597)

TypeM-R44VM-R44V

cyhnxLy.53.9 (2’/8) 53.9 (2%)

Clearance Automatic Automati

c

I

TypeAD30PAD30P

Cyl~itl;.~. 30.1 (13/16) 30.1 (13/16)

Clearance Automatic Automatic

*:4WD

X

ARRANGEMENT OF BRAKE LINES

Page 41 of 391

7-.

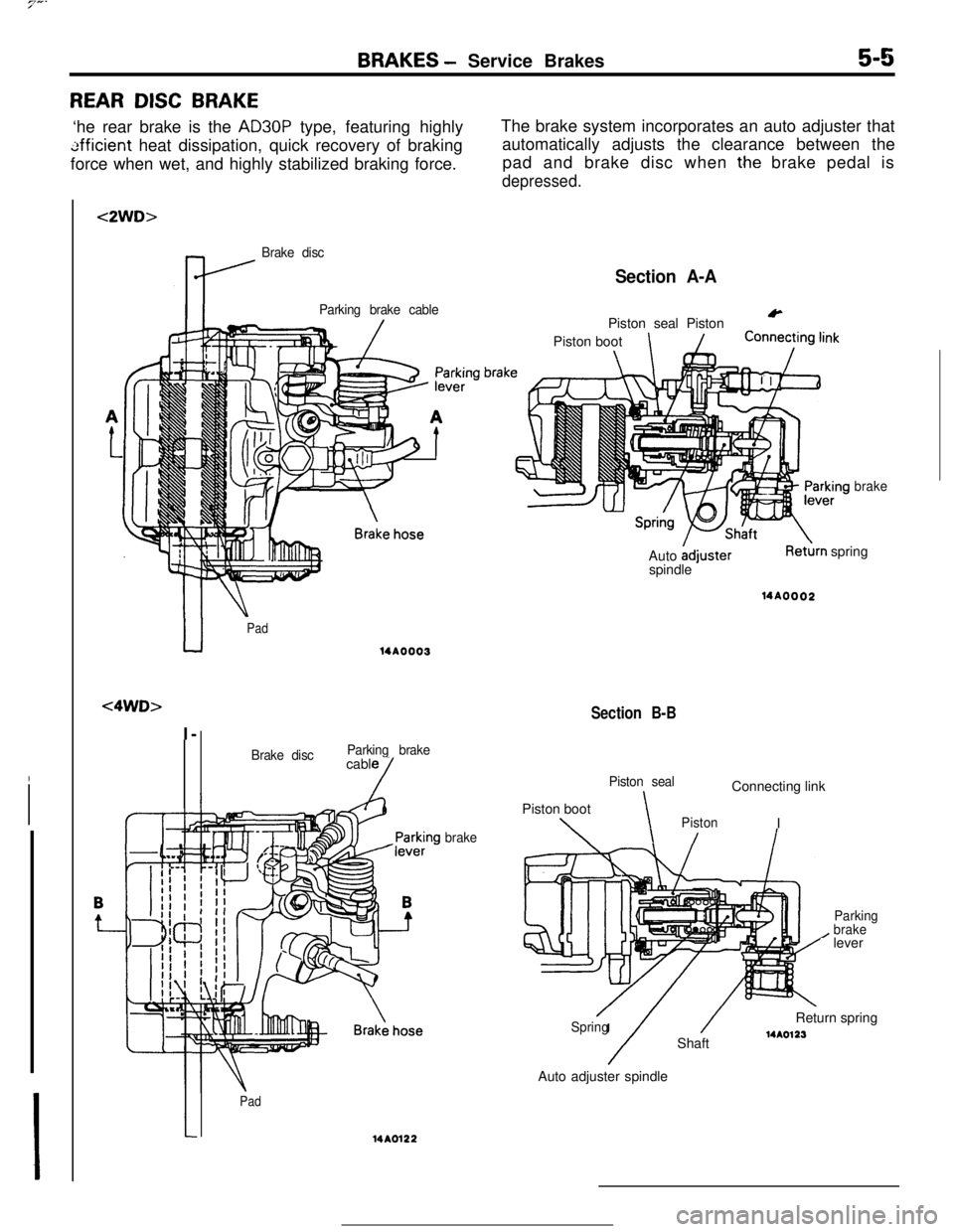

BRAKES - Service Brakes5-5

REAR DISC BRAKE‘he rear brake is the

AD30P type, featuring highly

tifficient heat dissipation, quick recovery of braking

force when wet, and highly stabilized braking force.The brake system incorporates an auto adjuster that

automatically adjusts the clearance between the

pad and brake disc when

t.he brake pedal is

depressed.

<2WD>

Brake disc

Parking brake cable

Section A-A

&

u

Pad

<4WD>I-

14A0003

Brake discParking brakecable

/

Pad14A0122

brake

brakPiston seal Piston

Piston boot

\

brakeAuto

AdjusterspindleRet&n spring14AOOO2

Section B-B

Piston sealConnecting link

Piston boot

\\PistonI

/

Parking

brakelever

/Spring

/

/Return spring

Shaft14A0123Auto adjuster spindle

Page 42 of 391

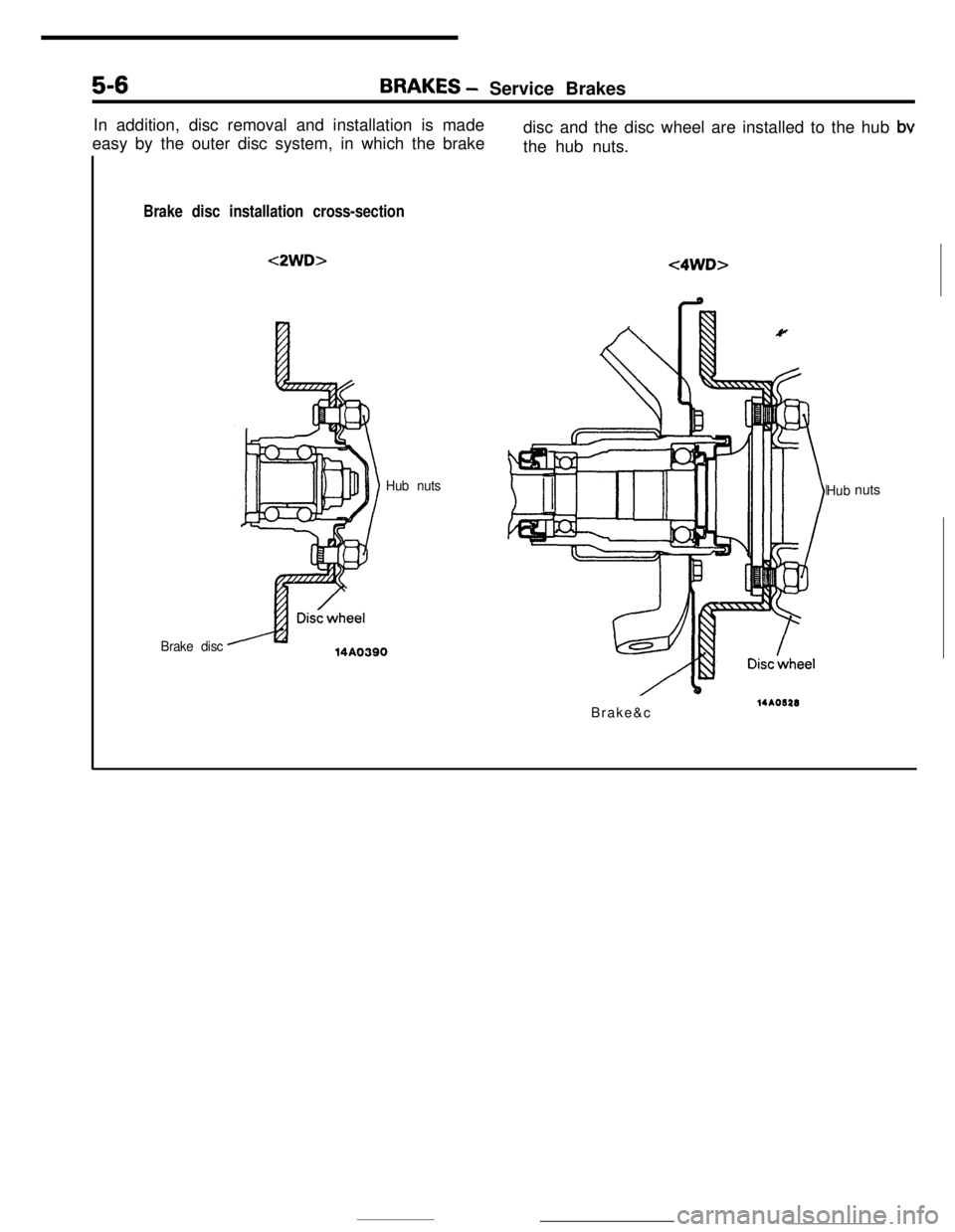

5-6BRAKES - Service Brakes

In addition, disc removal and installation is made

easy by the outer disc system, in which the brakedisc and the disc wheel are installed to the hub

bvthe hub nuts.

Brake disc installation cross-section<2WD>

<4WD>

Hub nuts

Brake disc14AO390Hubnuts

Brake&c

14AO622

Page 43 of 391

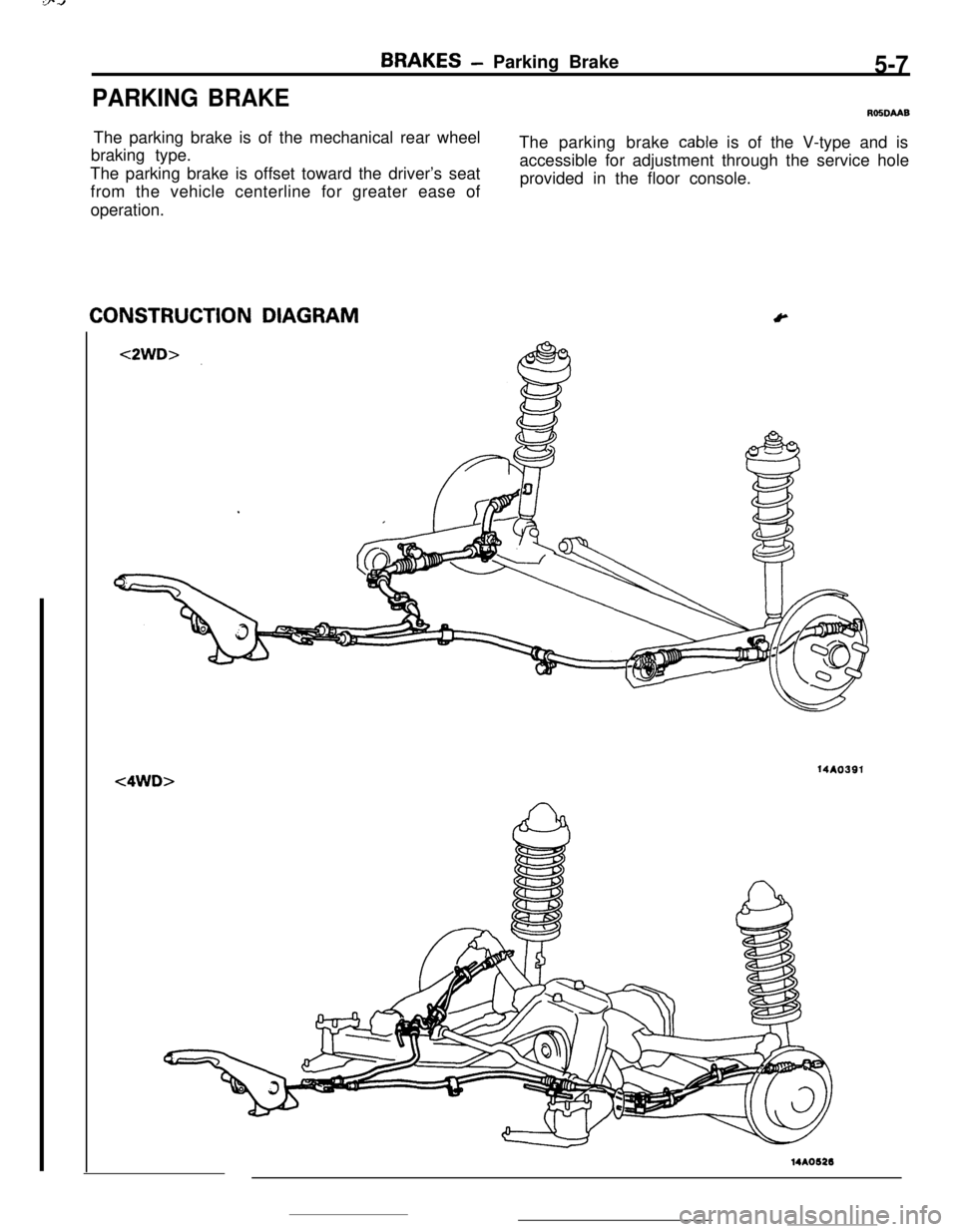

PARKING BRAKE

BRAKES- Parking Brake5-7

ROSDMBThe parking brake is of the mechanical rear wheel

braking type.The parking brake

cable is of the V-type and is

The parking brake is offset toward the driver’s seataccessible for adjustment through the service hole

provided in the floor console.

from the vehicle centerline for greater ease of

operation.CONSTRUCTION DIAGRAM

Y14AO391

<4WD>14A0626

Page 88 of 391

q7 --_-.-ENGINE

- General Information9-3TECHNICAL FEATURES

HIGH PERFORMANCE AND . . .._..............1. The DOHC 16-valve engine ensures excellent intake and exhaust

FUEL ECONOMYefficiency.

2. The rocker arm is of the roller-type-cam-follower design which Iminimizes friction loss.

3. The combustion chamber is of the pentroof type with a squish

area that offers outstanding combustion efficiency.

4. The multipoint fuel injection system is electronically

controlled.5. The intake manifold is the inertia supercharging type which

improves intake efficiency and the dual-type exhaust manifold

offers good exhaust efficiency.

6. The two-coil type electronic control ignition system ensures

good ignition performance.

LOW VIBRATION AND. . . . . . ..I.................1. The hydraulic lash adjuster, together with the roller rocker arm,

LOW NOISEcontributes to reduced operating noise of the valve mechanism.

2. A cogged type belt is used to drive the camshaft.

3. The auto tensioner maintains the optimum timing belt tension.

4. The torsional damper reduces twisting vibration in the crankshaft’

to a minimum.

5. The silent shaft system reduces engine vibration and rolling

’moment to a minimum

SERVICEABILITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1. The self-diagnosis system makes troubleshooting easier.

2. The lash adjuster eliminates the need for valve clearance

adjustment.3. The auto tensioner eliminates the need for timing belt

tension adjustment.

-.--..-. --.-