timing belt MITSUBISHI ECLIPSE 1990 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 9 of 391

GENERAL - Technical Featureso-5ENGINE

The engines are the transverse-mounted engine

especially for front-engine/front-wheeldrive orfront-engine/4-wheel drive models, the

2.OL DOHC

16-valve engine with high-performance, silent-

operation,low-vibration,low-noise,low-fuel-

consumption features, an engine that fully displays

the most

up-todate engine technology.

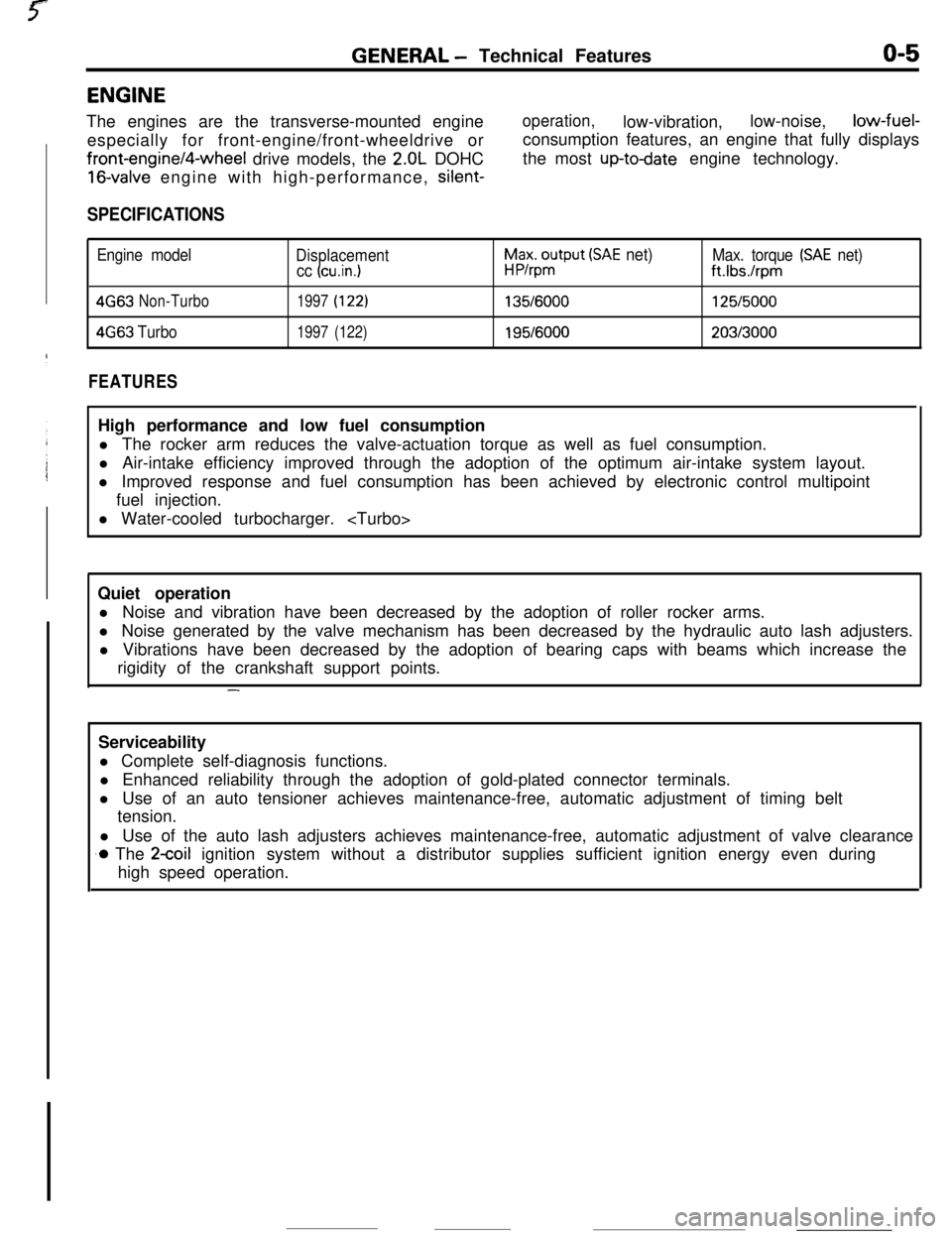

SPECIFICATIONS

Engine model

Displacement

cc (cu.in.1

h$xo$put (SAE net)Max. torque (SAE net)

ft.Ibs./rpm

4G63Non-Turbo1997(122)135/6000125/5000

4663Turbo1997(122)195/6000203/3000

FEATURESHigh performance and low fuel consumption

l The rocker arm reduces the valve-actuation torque as well as fuel consumption.

l Air-intake efficiency improved through the adoption of the optimum air-intake system layout.

l Improved response and fuel consumption has been achieved by electronic control multipoint

fuel injection.

l Water-cooled turbocharger.

Quiet operation

l Noise and vibration have been decreased by the adoption of roller rocker arms.

l Noise generated by the valve mechanism has been decreased by the hydraulic auto lash adjusters.

l Vibrations have been decreased by the adoption of bearing caps with beams which increase the

rigidity of the crankshaft support points.

-Serviceability

l Complete self-diagnosis functions.

l Enhanced reliability through the adoption of gold-plated connector terminals.

l Use of an auto tensioner achieves maintenance-free, automatic adjustment of timing belt

tension.

l Use of the auto lash adjusters achieves maintenance-free, automatic adjustment of valve clearance

.o The 2coil ignition system without a distributor supplies sufficient ignition energy even during

high speed operation.

Page 10 of 391

O-6GENERAL - Technical Features

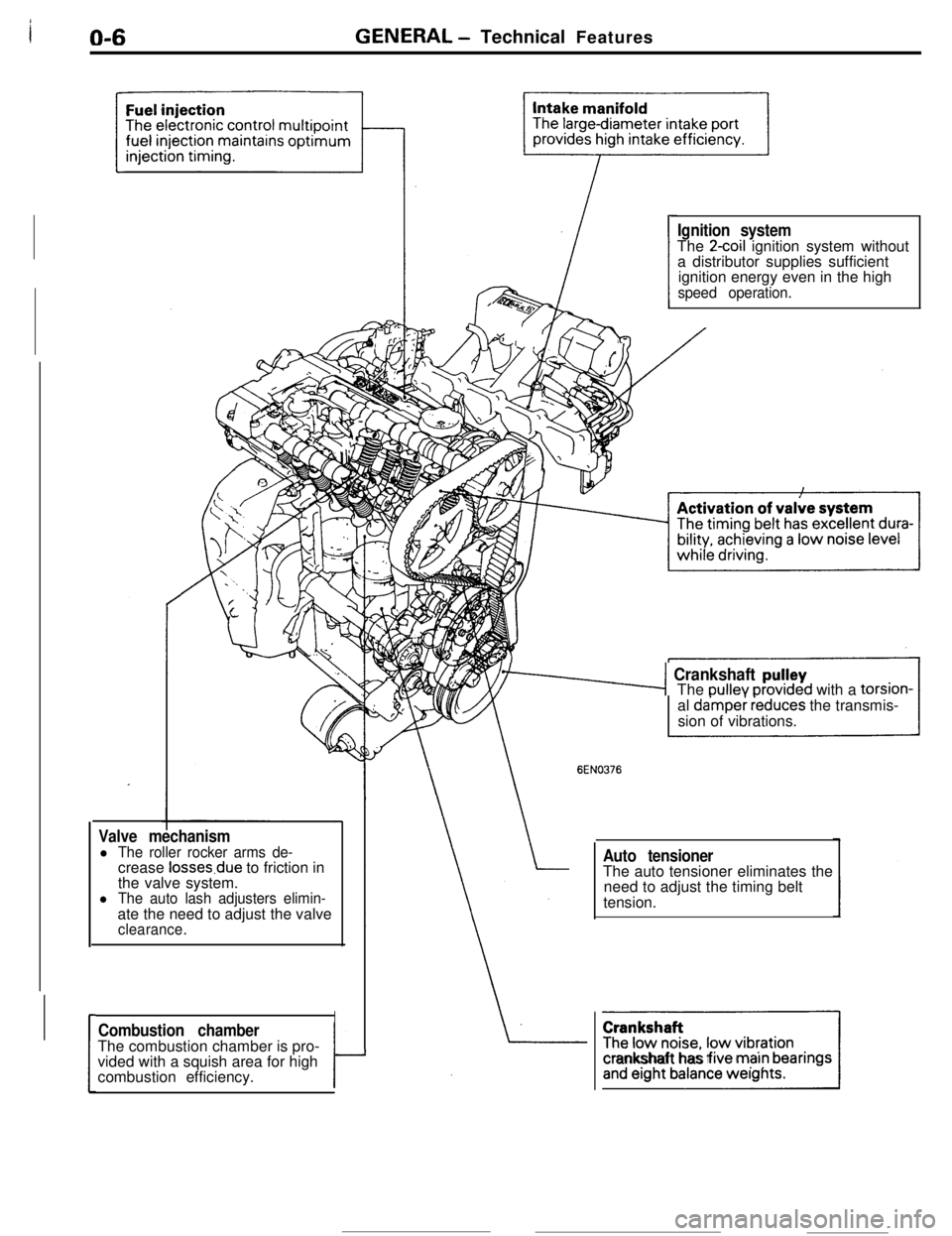

Valve mechanisml The roller rocker arms de-crease losses.due to friction in

the valve system.

l The auto lash adjusters elimin-ate the need to adjust the valve

clearance.

ICombustion chamberThe combustion chamber is pro-

vided with a squish area for high

combustion efficiency.

tJ

Ignition systemThe 2coil ignition system without

a distributor supplies sufficient

ignition energy even in the high

speed operation.

76-4 Crankshaft pu!leyThe oullev orovrded with a torsion-

al

da’mper ieduces the transmis-

sion of vibrations.

EN0376

Auto tensionerThe auto tensioner eliminates the

need to adjust the timing belt

tension.

]Icrankshaft has five marn bearings

Page 88 of 391

q7 --_-.-ENGINE

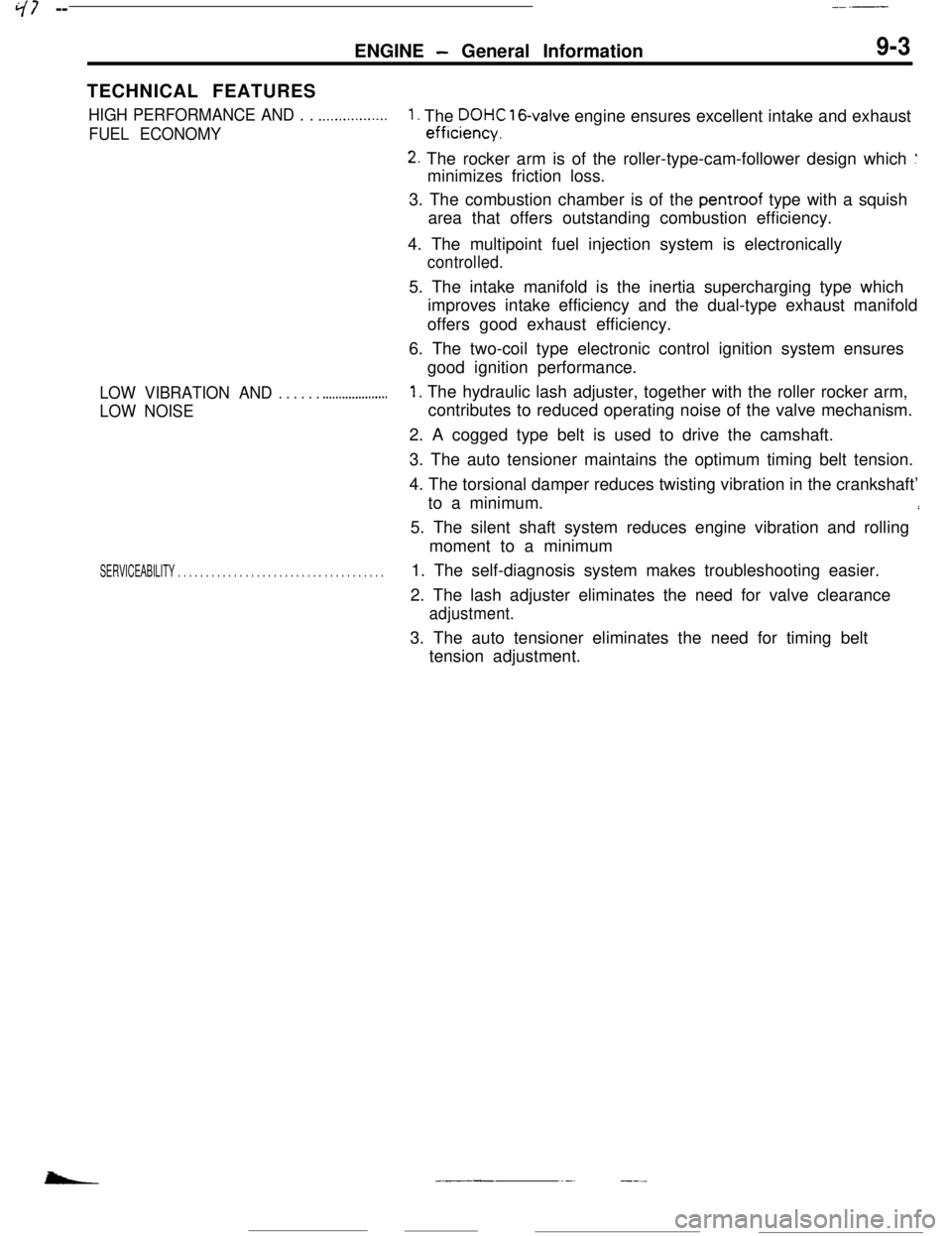

- General Information9-3TECHNICAL FEATURES

HIGH PERFORMANCE AND . . .._..............1. The DOHC 16-valve engine ensures excellent intake and exhaust

FUEL ECONOMYefficiency.

2. The rocker arm is of the roller-type-cam-follower design which Iminimizes friction loss.

3. The combustion chamber is of the pentroof type with a squish

area that offers outstanding combustion efficiency.

4. The multipoint fuel injection system is electronically

controlled.5. The intake manifold is the inertia supercharging type which

improves intake efficiency and the dual-type exhaust manifold

offers good exhaust efficiency.

6. The two-coil type electronic control ignition system ensures

good ignition performance.

LOW VIBRATION AND. . . . . . ..I.................1. The hydraulic lash adjuster, together with the roller rocker arm,

LOW NOISEcontributes to reduced operating noise of the valve mechanism.

2. A cogged type belt is used to drive the camshaft.

3. The auto tensioner maintains the optimum timing belt tension.

4. The torsional damper reduces twisting vibration in the crankshaft’

to a minimum.

5. The silent shaft system reduces engine vibration and rolling

’moment to a minimum

SERVICEABILITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1. The self-diagnosis system makes troubleshooting easier.

2. The lash adjuster eliminates the need for valve clearance

adjustment.3. The auto tensioner eliminates the need for timing belt

tension adjustment.

-.--..-. --.-

Page 97 of 391

9-12

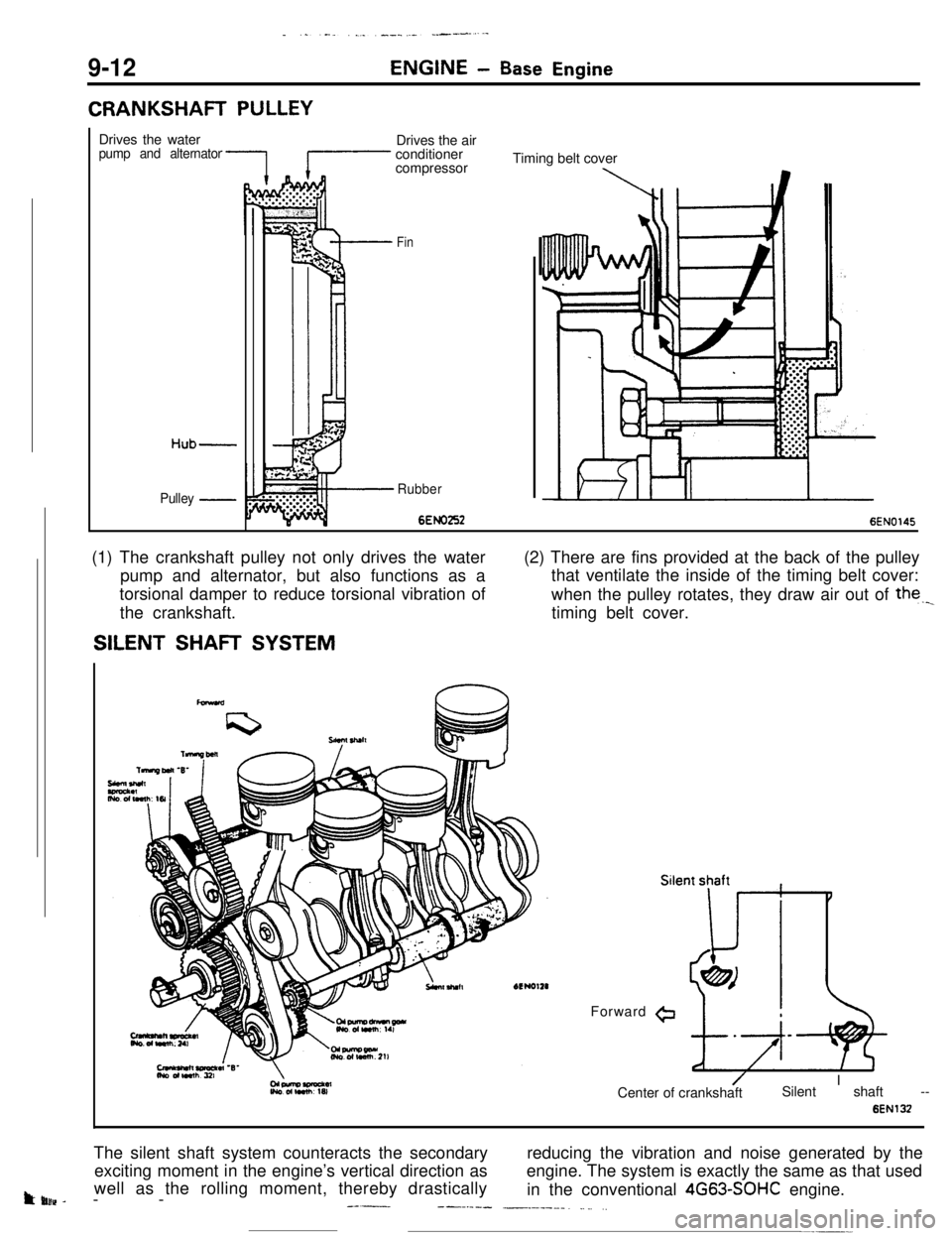

CRANKSHAFT PULLEY

ENGINE- Base EngineDrives the water

pump and alternator

Hub-

Pulley -Drives the air

conditioner

compressor

Fin

Rubber

6EMI2526EN0145 Timing belt cover

(1) The crankshaft pulley not only drives the water

pump and alternator, but also functions as a

torsional damper to reduce torsional vibration of

the crankshaft.

SILENT SHAFT SYSTEM(2) There are fins provided at the back of the pulley

that ventilate the inside of the timing belt cover:

when the pulley rotates, they draw air out of the._

timing belt cover.

Forward

@

/I

Center of crankshaftSilent shaft --

6ENl32The silent shaft system counteracts the secondaryreducing the vibration and noise generated by the

exciting moment in the engine’s vertical direction asengine. The system is exactly the same as that used

t uluv -well as the rolling moment, thereby drastically

in the conventional 4G63-SOHC engine.

-------_---.--- __.----_. _... ,.

Page 102 of 391

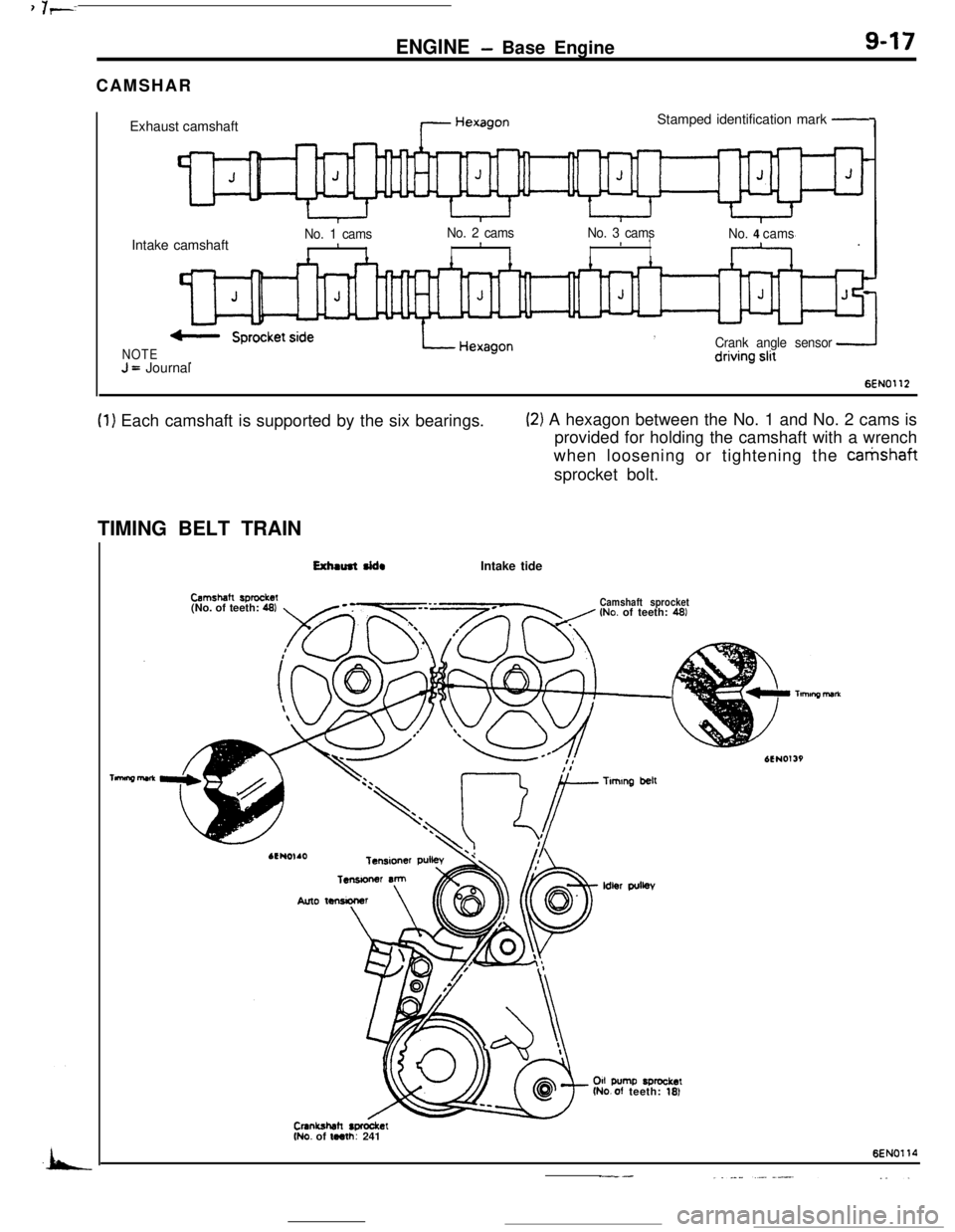

ENGINE- Base Engine9-17CAMSHAR

Exhaust camshaftStamped identification mark

-

-

k--JL---J

No. 1 camsNo. 2 camsNo. 3 cams

No. 4 camsIntake camshaftIt’ II’ II1

NOTEJ = Journal

Crank angle sensor6EN0112

(1) Each camshaft is supported by the six bearings.(2) A hexagon between the No. 1 and No. 2 cams is

provided for holding the camshaft with a wrench

when loosening or tightening the

catishaftsprocket bolt.

TIMING BELT TRAIN

Exhmmt rid.Intake tide

Camshatt sprookec(No. of teeth: 461Camshaft sprocket(No. of teeth: 461

MN0139

6tNOl10

011 Pump stmoket(No. o! teeth: 18)

Crankshatr spmokst(No. of loath: 2416EN0114

Page 103 of 391

9-18ENGINE- Base Engine

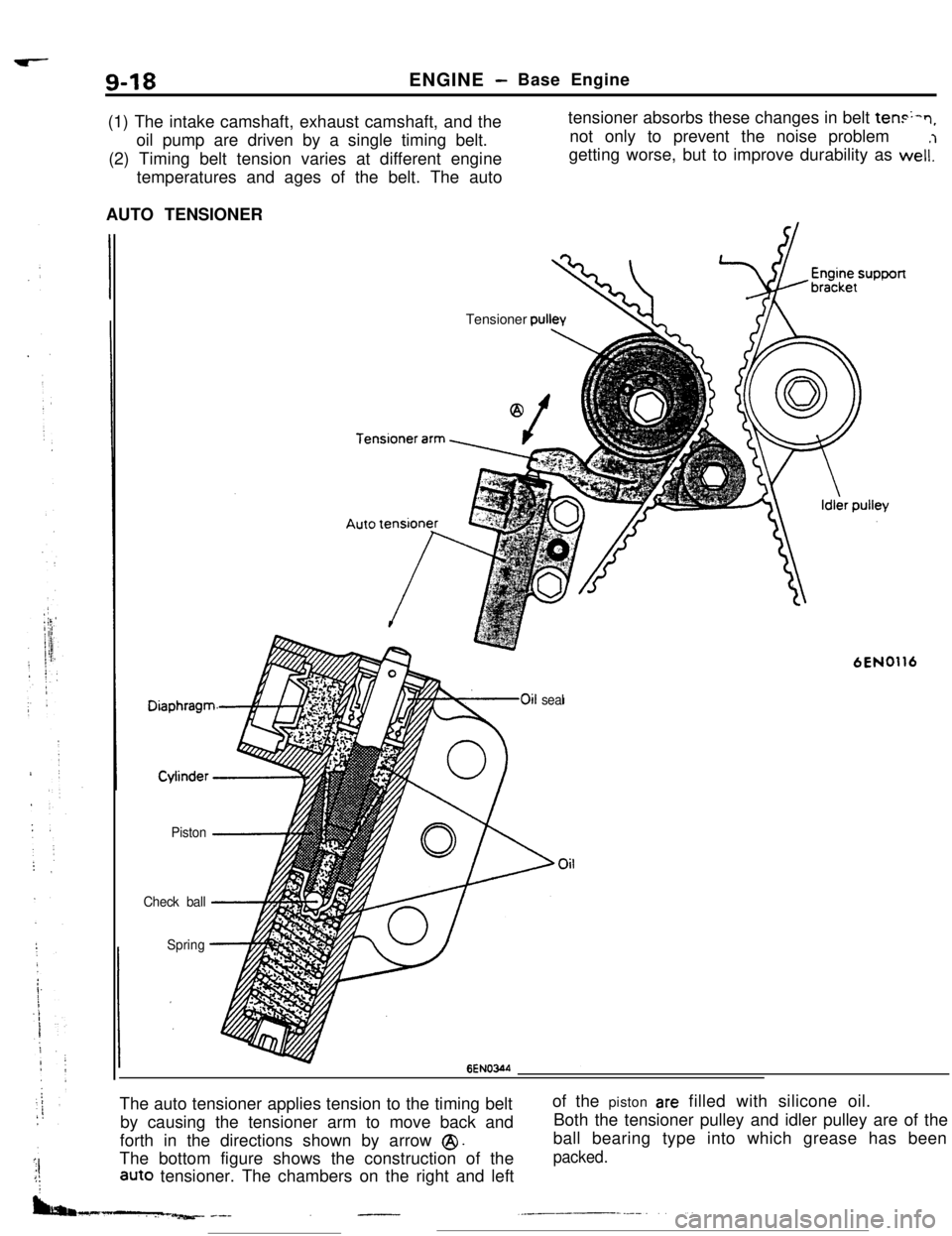

(1) The intake camshaft, exhaust camshaft, and the

oil pump are driven by a single timing belt.

(2) Timing belt tension varies at different engine

temperatures and ages of the belt. The autotensioner absorbs these changes in belt

ten+n,not only to prevent the noise problem

getting worse, but to improve durability as weli’l

AUTO TENSIONER

Piston -1

Check ball-4,

SpringTensioner

cwllev

6EN0116

LOoil seal

6ENOWThe auto tensioner applies tension to the timing belt

by causing the tensioner arm to move back and

forth in the directions shown by arrow

@I.The bottom figure shows the construction of the

aUt0 tensioner. The chambers on the right and leftof the piston

are filled with silicone oil.

Both the tensioner pulley and idler pulley are of the

ball bearing type into which grease has been

packed.