wheel bolts MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 31 of 1216

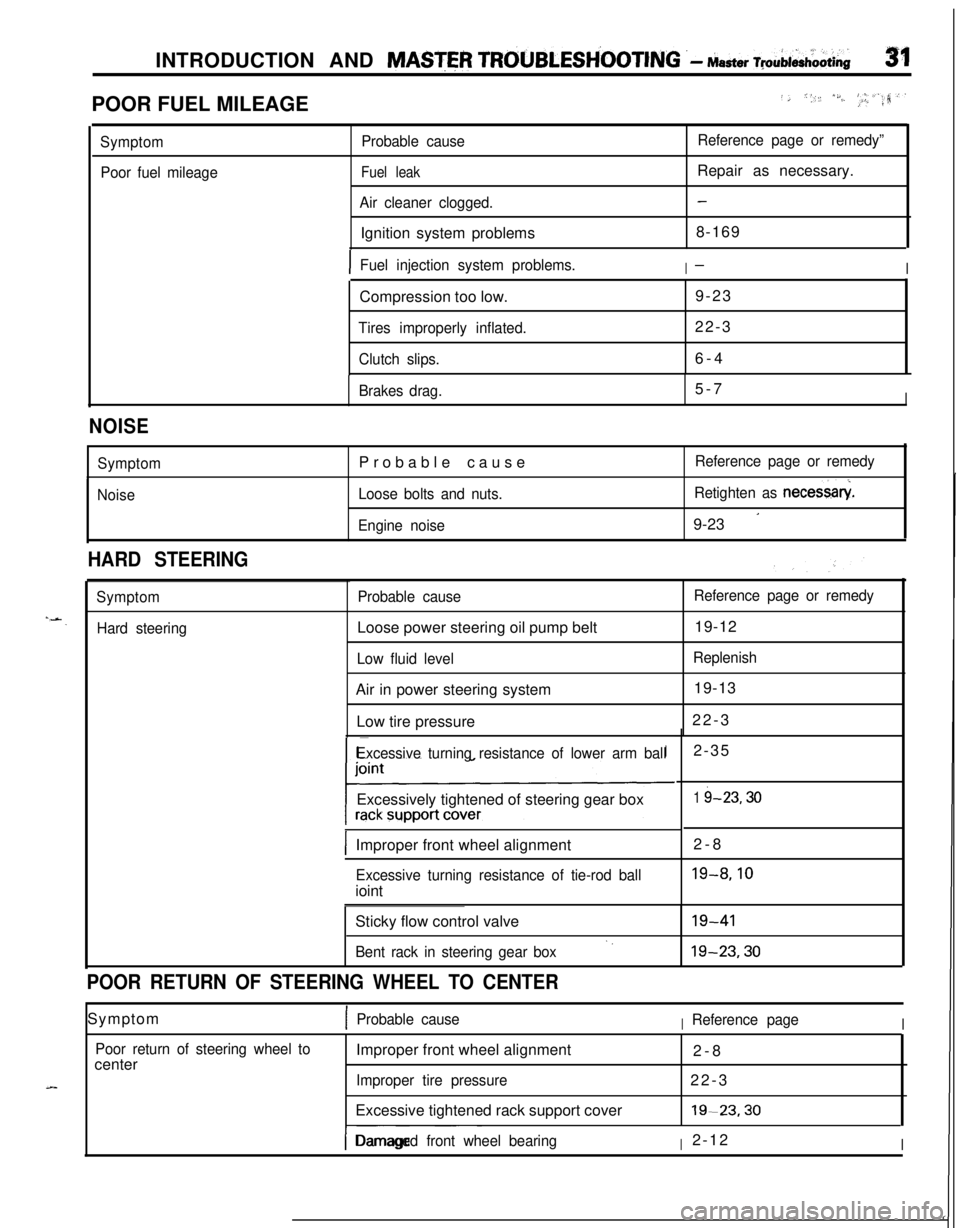

INTRODUCTION AND MASTER TROUBLESH’OOTING .- Master ~pAi&oOti~31POOR FUEL MILEAGE

../, *,, /S./..‘, _I, #_.a,‘.rr?

Symptom

Poor fuel mileageProbable cause

Fuel leak

Air cleaner clogged.Ignition system problems

Reference page or remedy”Repair as necessary.

-8-169

IFuel injection system problems.I-ICompression too low.9-23

Tires improperly inflated.22-3

Clutch slips.6-4

Brakes drag.5-7I

NOISE

Symptom

NoiseProbable cause

Loose bolts and nuts.

Engine noiseReference page or remedy

Retighten as necessary

9-23

’

HARD STEERING

Symptom

Hard steeringProbable causeLoose power steering oil pump belt

Low fluid levelAir in power steering system

Low tire pressure

Reference page or remedy19-12

Replenish19-13

22-3

Excessive turning resistance of lower arm ballExcessively tightened of steering gear box

IImproper front wheel alignment2-8

Excessive turning resistance of tie-rod ballioint2-35

1 i-23.30

19-8.10Sticky flow control valve

Bent rack in steering gear box‘.19-4119-23.30

POOR RETURN OF STEERING WHEEL TO CENTERSymptom

1Probable causeIReference pageI

Poor return of steering wheel tocenterImproper front wheel alignment

2-8

Improper tire pressure22-3

Excessive tightened rack support cover19-23.30

I-- ~~~Damaged front wheel bearingI2-12I

Page 53 of 1216

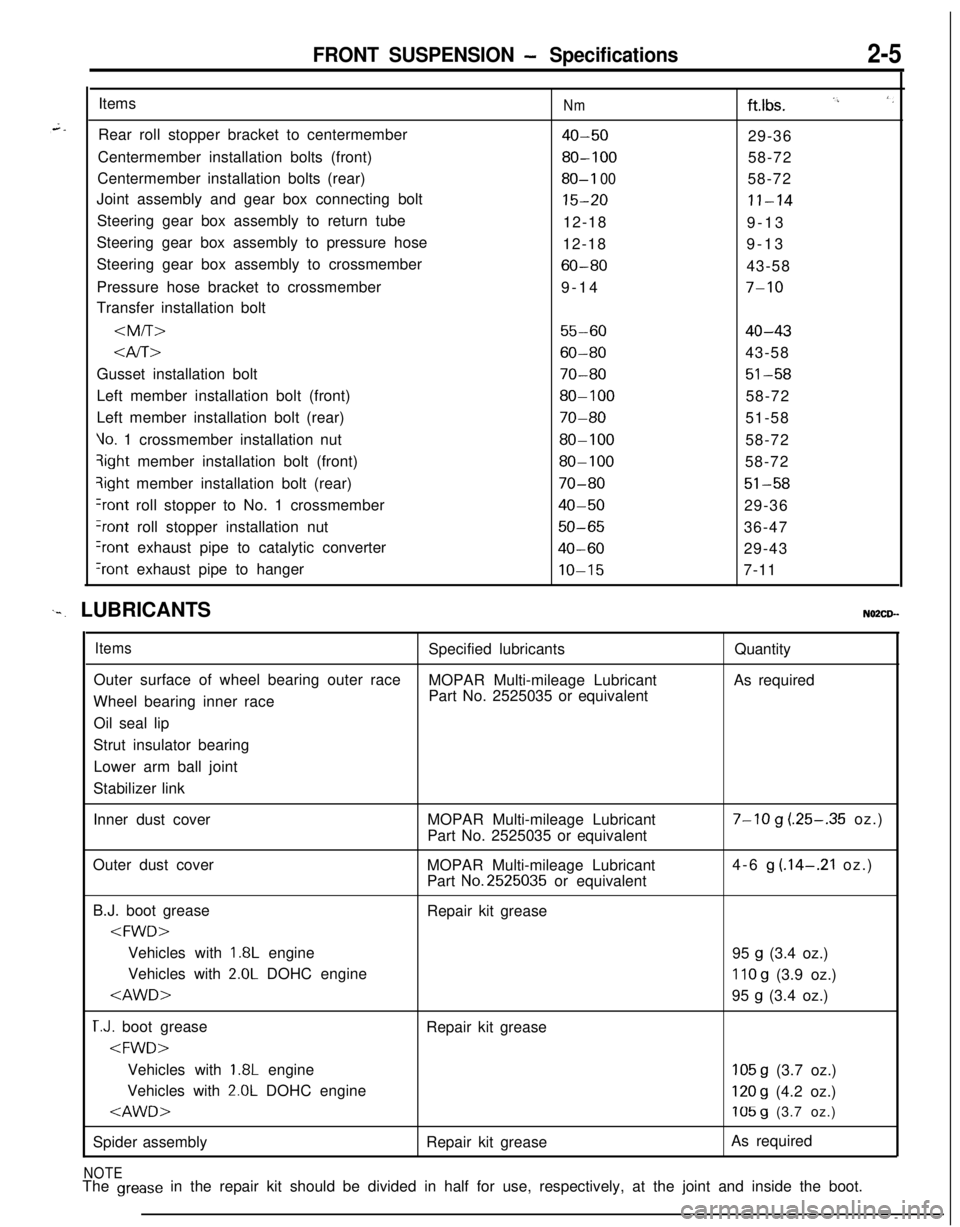

FRONT SUSPENSION - Specifications2-5Items

Rear roll stopper bracket to centermember

Centermember installation bolts (front)

Centermember installation bolts (rear)

Joint assembly and gear box connecting bolt

Steering gear box assembly to return tube

Steering gear box assembly to pressure hose

Steering gear box assembly to crossmember

Pressure hose bracket to crossmember

Transfer installation bolt

Nmftlbs. I’, ‘,

40-5029-36

80-10058-72

80-I 0058-72

15-20II-1412-18

9-13

12-189-13

60-8043-58

9-14

7-10

55-6040-43

Gusset installation bolt

70-8051-58Left member installation bolt (front)

80-10058-72

Left member installation bolt (rear)

70-8051-58

Vo. 1 crossmember installation nut80-10058-72qight member installation bolt (front)

80-10058-72?ight member installation bolt (rear)

70-8051-58

+ont roll stopper to No. 1 crossmember40-5029-36

?ont roll stopper installation nut50-6536-47

Iront exhaust pipe to catalytic converter40-6029-43

‘rant exhaust pipe to hangerIO-157-11

‘-. LUBRICANTSNO2CD--

ItemsSpecified lubricantsQuantity

Outer surface of wheel bearing outer race

MOPAR Multi-mileage LubricantAs required

Wheel bearing inner racePart No. 2525035 or equivalent

Oil seal lip

Strut insulator bearing

Lower arm ball joint

Stabilizer link

Inner dust coverMOPAR Multi-mileage Lubricant

Part No. 2525035 or equivalent

7-10 g (.25-.35 oz.)

Outer dust cover

MOPAR Multi-mileage Lubricant

Part

No.2525035 or equivalent4-6

g (.14-.21 oz.)

B.J. boot grease

Repair kit grease

1.8L engine

95 g (3.4 oz.)

Vehicles with

2.0L DOHC engine110 g (3.9 oz.)

T.J. boot grease

Repair kit grease

1.8L engine105 g (3.7 oz.)

Vehicles with

2.0L DOHC engine120 g (4.2 oz.)

Spider assemblyRepair kit greaseAs required

NOTEThe grease in the repair kit should be divided in half for use, respectively, at the joint and inside the boot.

Page 92 of 1216

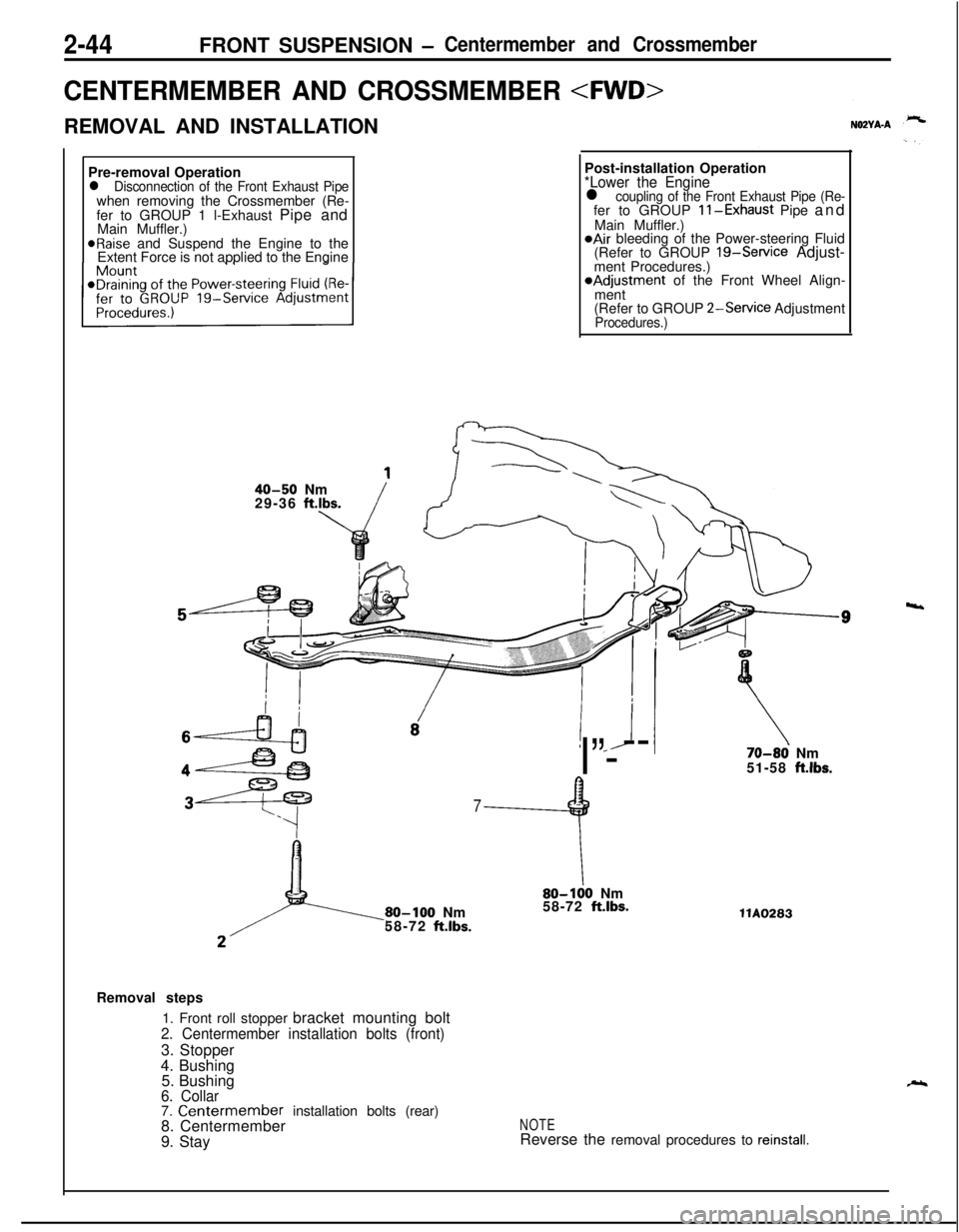

2-44FRONT SUSPENSION -Centermember and Crossmember

CENTERMEMBER AND CROSSMEMBER

REMOVAL AND INSTALLATION

Pre-removal Operation

l Disconnection of the Front Exhaust Pipewhen removing the Crossmember (Re-

fer to GROUP 1 l-Exhaust Pipe and

Main Muffler.)

@Raise and Suspend the Engine to the

Extent Force is not applied to the EnginePost-installation Operation

*Lower the Enginel coupling of the Front Exhaust Pipe (Re-fer to GROUP ll-Exhaust Pipe and

Main Muffler.)

@Air bleeding of the Power-steering Fluid

(Refer to GROUP 19-Service Adjust-

ment Procedures.)*Adjustment of the Front Wheel Align-

ment

(Refer to GROUP

2-Service AdjustmentProcedures.)

40-50 Nm

29-36 ft.lbs.

! *J

I”---

7

9

80-100 Nm

58-72 ft.lbs.

\80-100 Nm

58-72 ft.lbs.

70-86 Nm

51-58 ft.lbs.llA0283

Removal steps

1. Front roll stopper bracket mounting bolt

2. Centermember installation bolts (front)3. Stopper

4. Bushing

5. Bushing

6. Collar7. Centermember installation bolts (rear)

8. Centermember

9. StayNOTEReverse the removal procedures to reinstall.

4

Page 105 of 1216

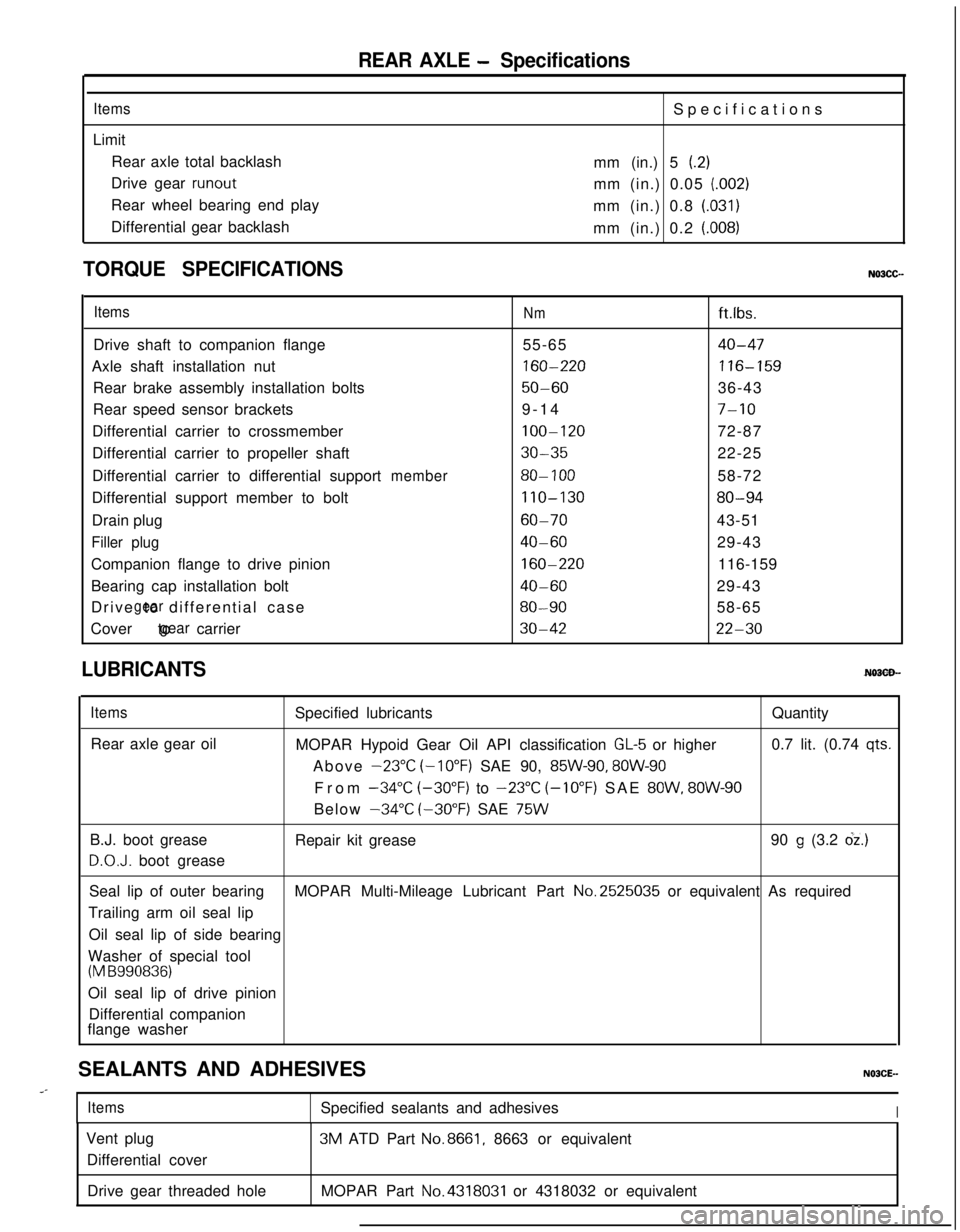

REAR AXLE - Specifications

ItemsLimit

Rear axle total backlash

Drive gear

runoutRear wheel bearing end play

Differential gear backlashSpecifications

mm (in.) 5

(.2)mm (in.) 0.05

(.002)mm (in.) 0.8

(.031)mm (in.) 0.2

(.008)

TORQUE SPECIFICATIONS

ItemsNmft.lbs.

Drive shaft to companion flange55-65

40-47Axle shaft installation nut

160-220116-159Rear brake assembly installation bolts

50-6036-43

Rear speed sensor brackets9-14

7-10Differential carrier to crossmember

100-12072-87

Differential carrier to propeller shaft

30-3522-25

Differential carrier to differential support

member80- 10058-72

Differential support member to bolt

110-13080-94Drain plug

60-7043-51

Filler plug40-6029-43

Companion flange to drive pinion

160-220116-159

Bearing cap installation bolt

40-6029-43

Drive to differential case

gear80-9058-65

Cover to carrier

gear30-4222-30

LUBRICANTS

ItemsRear axle gear oilSpecified lubricantsQuantity

MOPAR Hypoid Gear Oil API classification

GL-5 or higher0.7 lit. (0.74 qts.Above

-23°C (-10°F) SAE 90, 85W-90, 8OW-90From

-34°C (-30°F) to -23°C (-10°F) SAE 8OW, 8OW-90Below

-34°C (-30°F) SAE 75WB.J. boot grease

D.O.J. boot greaseRepair kit grease90

g (3.2 dz.)Seal lip of outer bearingMOPAR Multi-Mileage Lubricant Part No.2525035 or equivalent As required

Trailing arm oil seal lip

Oil seal lip of side bearing

Washer of special tool

(M B990836)Oil seal lip of drive pinion

Differential companion

flange washer

SEALANTS AND ADHESIVES

..-

ItemsSpecified sealants and adhesivesIVent plug

Differential cover3M ATD Part

No.8661, 8663 or equivalent

Drive gear threaded holeMOPAR Part

No.4318031 or 4318032 or equivalent

Page 109 of 1216

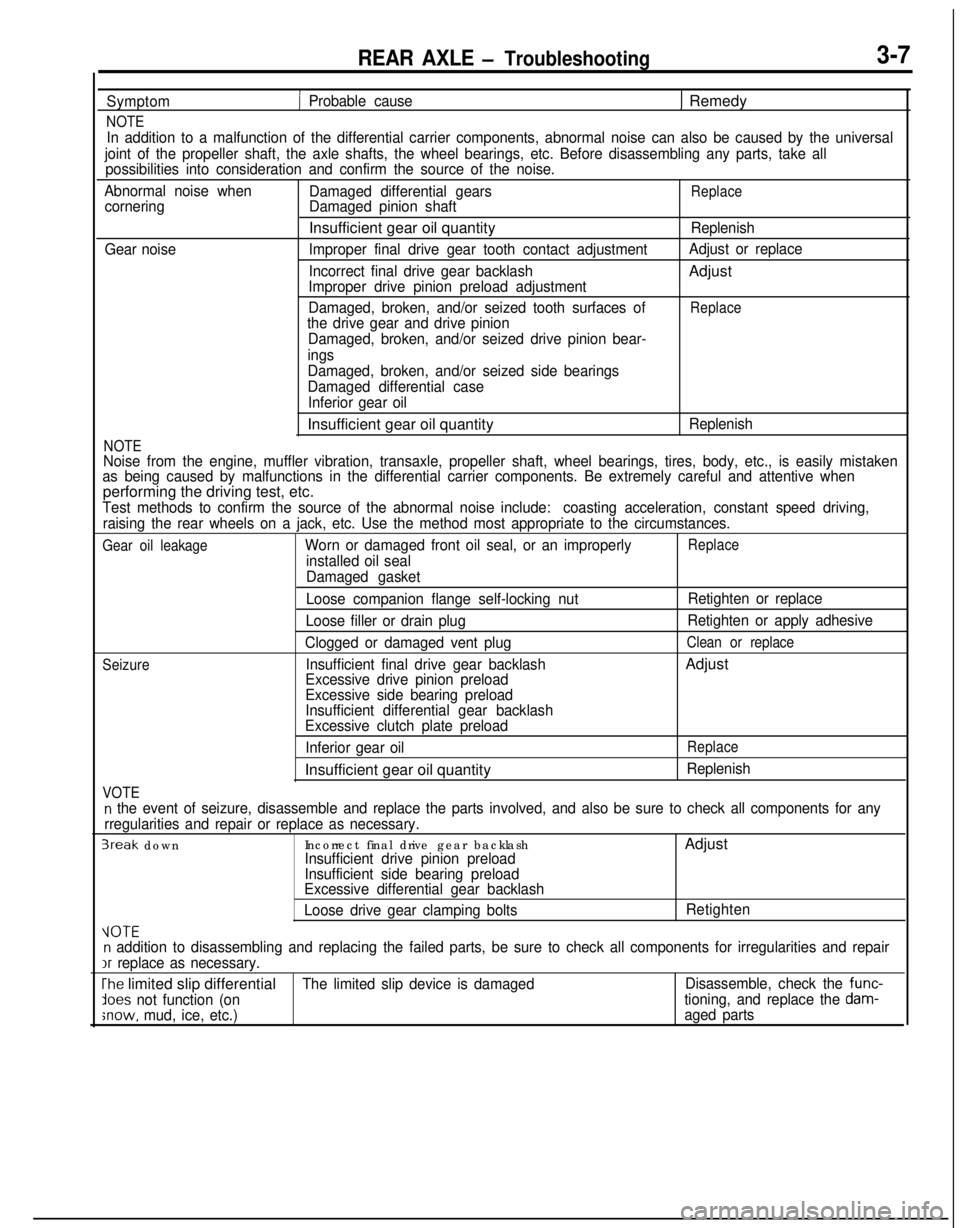

REAR AXLE - Troubleshooting3-7

Symptom

NOTE

1 Probable cause1 Remedy

In addition to a malfunction of the differential carrier components, abnormal noise can also be caused by the universal

joint of the propeller shaft, the axle shafts, the wheel bearings, etc. Before disassembling any parts, take all

possibilities into consideration and confirm the source of the noise.

Abnormal noise when

Damaged differential gears

ReplacecorneringDamaged pinion shaftInsufficient gear oil quantity

Replenish

Gear noiseImproper final drive gear tooth contact adjustmentAdjust or replace

Incorrect final drive gear backlashAdjust

Improper drive pinion preload adjustment

Damaged, broken, and/or seized tooth surfaces of

Replacethe drive gear and drive pinion

Damaged, broken, and/or seized drive pinion bear-

ings

NOTE

Damaged, broken, and/or seized side bearings

Damaged differential case

Inferior gear oilInsufficient gear oil quantity

Replenish

Noise from the engine, muffler vibration, transaxle, propeller shaft, wheel bearings, tires, body, etc., is easily mistaken

as being caused by malfunctions in the differential carrier components. Be extremely careful and attentive whenperforming the driving test, etc.

Test methods to confirm the source of the abnormal noise include:coasting acceleration, constant speed driving,

raising the rear wheels on a jack, etc. Use the method most appropriate to the circumstances.

Gear oil leakageWorn or damaged front oil seal, or an improperlyReplace

installed oil seal

Damaged gasket

Seizure

VOTE

Loose companion flange self-locking nut

Loose filler or drain plug

Clogged or damaged vent plug

Insufficient final drive gear backlash

Excessive drive pinion preload

Excessive side bearing preload

Insufficient differential gear backlash

Excessive clutch plate preload

Inferior gear oilInsufficient gear oil quantityRetighten or replace

Retighten or apply adhesive

Clean or replaceAdjust

Replace

Replenish

n the event of seizure, disassemble and replace the parts involved, and also be sure to check all components for any

rregularities and repair or replace as necessary.

3reak downIncorrect final drive gear backlashAdjustInsufficient drive pinion preload

Insufficient side bearing preload

Excessive differential gear backlash

Loose drive gear clamping boltsRetighten

VOTEn addition to disassembling and replacing the failed parts, be sure to check all components for irregularities and repairIr

replace as necessary.

The limited slip differentialThe limited slip device is damagedDisassemble, check the func-

lees not function (ontioning, and replace the dam-

;now, mud, ice, etc.)aged parts

Page 145 of 1216

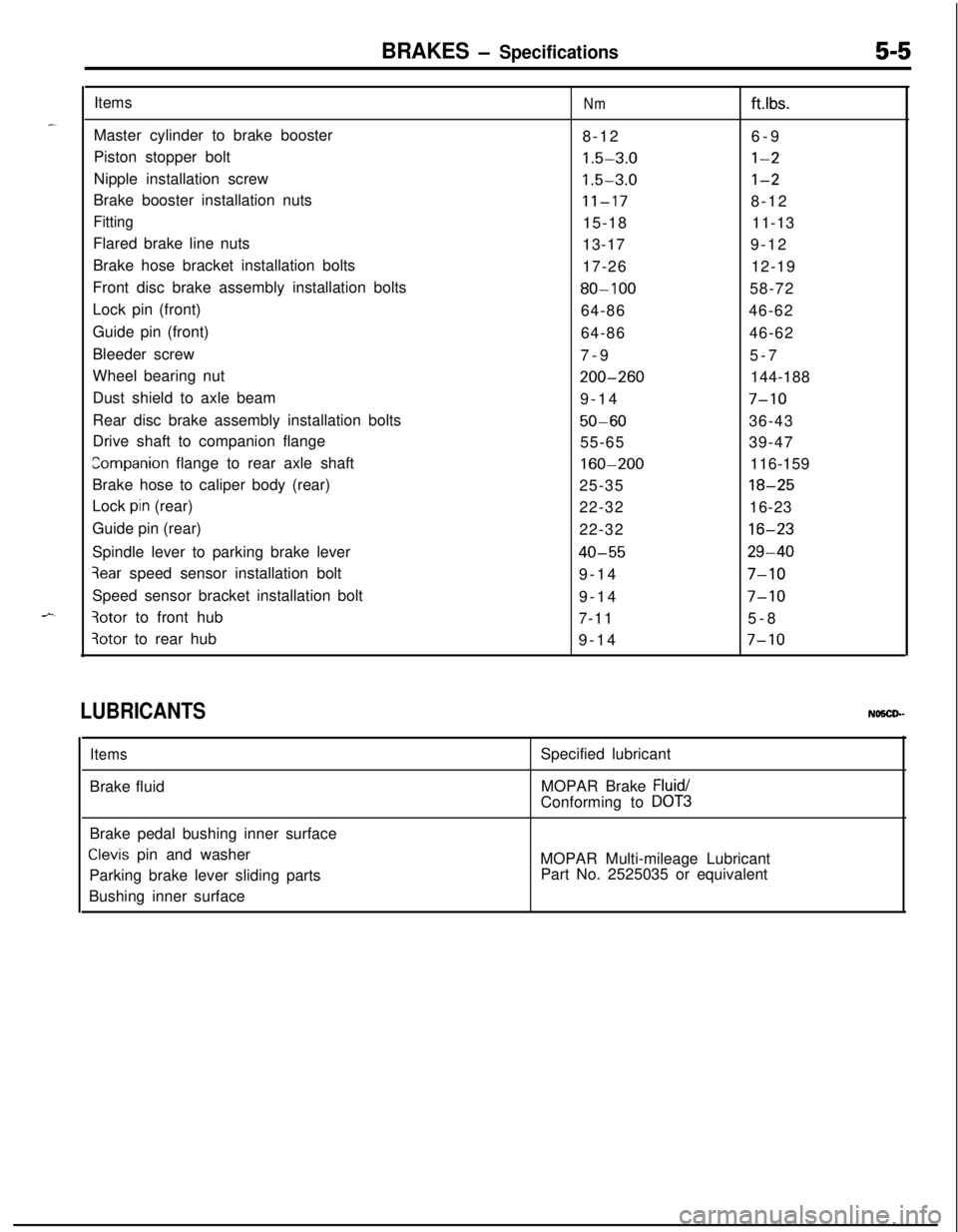

BRAKES - Specifications5-5Items

Nmftlbs.Master cylinder to brake booster

8-126-9

Piston stopper bolt

1.5-3.0l-2Nipple installation screw

1.5-3.0l-2Brake booster installation nuts

11-178-12

Fitting15-1811-13

Flared brake line nuts

13-179-12

Brake hose bracket installation bolts

17-2612-19

Front disc brake assembly installation bolts

80-10058-72

Lock pin (front)

64-8646-62

Guide pin (front)

64-8646-62

Bleeder screw

7-95-7

Wheel bearing nut

200-260144-188

Dust shield to axle beam

9-14

7-10Rear disc brake assembly installation bolts

50-6036-43

Drive shaft to companion flange

55-6539-47

companion flange to rear axle shaft160-200116-159

Brake hose to caliper body (rear)

25-35

18-25Lock

pin (rear)

22-3216-23

Guide pin (rear)

22-32

16-23Spindle lever to parking brake lever

40-5529-40

3ear speed sensor installation bolt

9-147-10Speed sensor bracket installation bolt

9-14

7-10

3otor to front hub

7-115-8

3otor to rear hub

9-147-10

LUBRICANTSNO5CP-

ItemsBrake fluidSpecified lubricant

MOPAR Brake

Fluid/Conforming to

DOT3Brake pedal bushing inner surface

Clevis pin and washer

Parking brake lever sliding parts

Bushing inner surfaceMOPAR Multi-mileage Lubricant

Part No. 2525035 or equivalent

Page 222 of 1216

Care must be taken not to scratch or scar the rotor’stoothed surface, and not to drop it.

If the rotor’s toothed surface is chipped or the rotor is

deformed, it might not be able to accurately sense the

wheel rotation speed and the system as a result might

__ r-14A¬ perform normally.

4. REMOVAL OF FRONT SPEED SENSORRemove the mounting bolts which hold the speed sensor

bracket to the knuckle, and then remove the speed sensor.

Caution

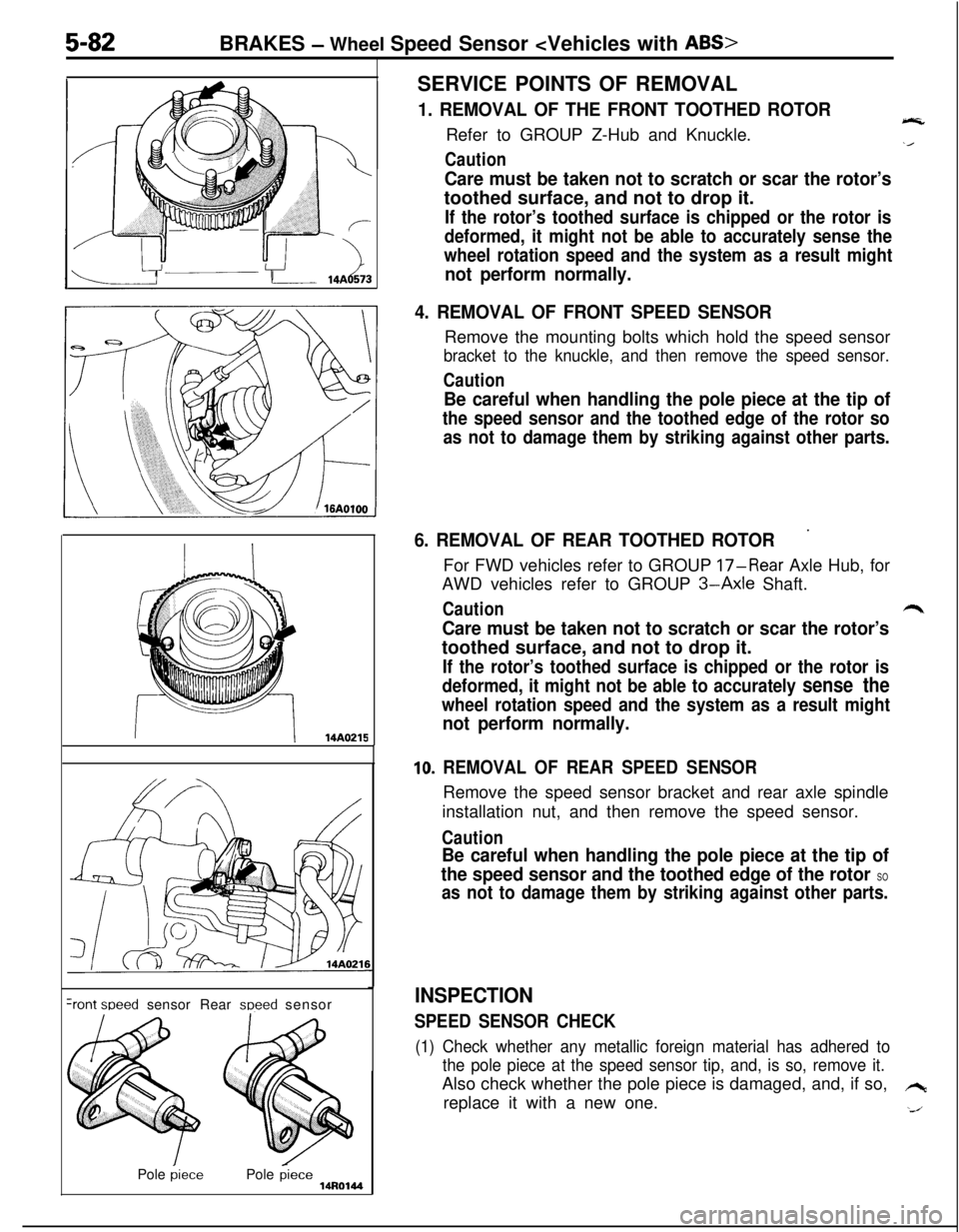

5-82BRAKES - Wheel Speed Sensor

1. REMOVAL OF THE FRONT TOOTHED ROTOReRefer to GROUP Z-Hub and Knuckle.

Caution

Be careful when handling the pole piece at the tip of

the speed sensor and the toothed edge of the rotor so

as not to damage them by striking against other parts.

II14A0215

+ont weed sensor Rear meed sensor

Pole

piecePole piece14R0144

6. REMOVAL OF REAR TOOTHED ROTOR’For FWD vehicles refer to GROUP

17-Rear Axle Hub, for

AWD vehicles refer to GROUP

3-Axle Shaft.

Cautionr*

Care must be taken not to scratch or scar the rotor’stoothed surface, and not to drop it.

If the rotor’s toothed surface is chipped or the rotor is

deformed, it might not be able to accurately

sense the

wheel rotation speed and the system as a result might

not perform normally.

10. REMOVAL OF REAR SPEED SENSORRemove the speed sensor bracket and rear axle spindle

installation nut, and then remove the speed sensor.

Caution

Be careful when handling the pole piece at the tip of

the speed sensor and the toothed edge of the rotor

SO

as not to damage them by striking against other parts.

INSPECTION

SPEED SENSOR CHECK

(1) Check whether any metallic foreign material has adhered to

the pole piece at the speed sensor tip, and, is so, remove it.Also check whether the pole piece is damaged, and, if so,

hreplace it with a new one.

‘J

Page 247 of 1216

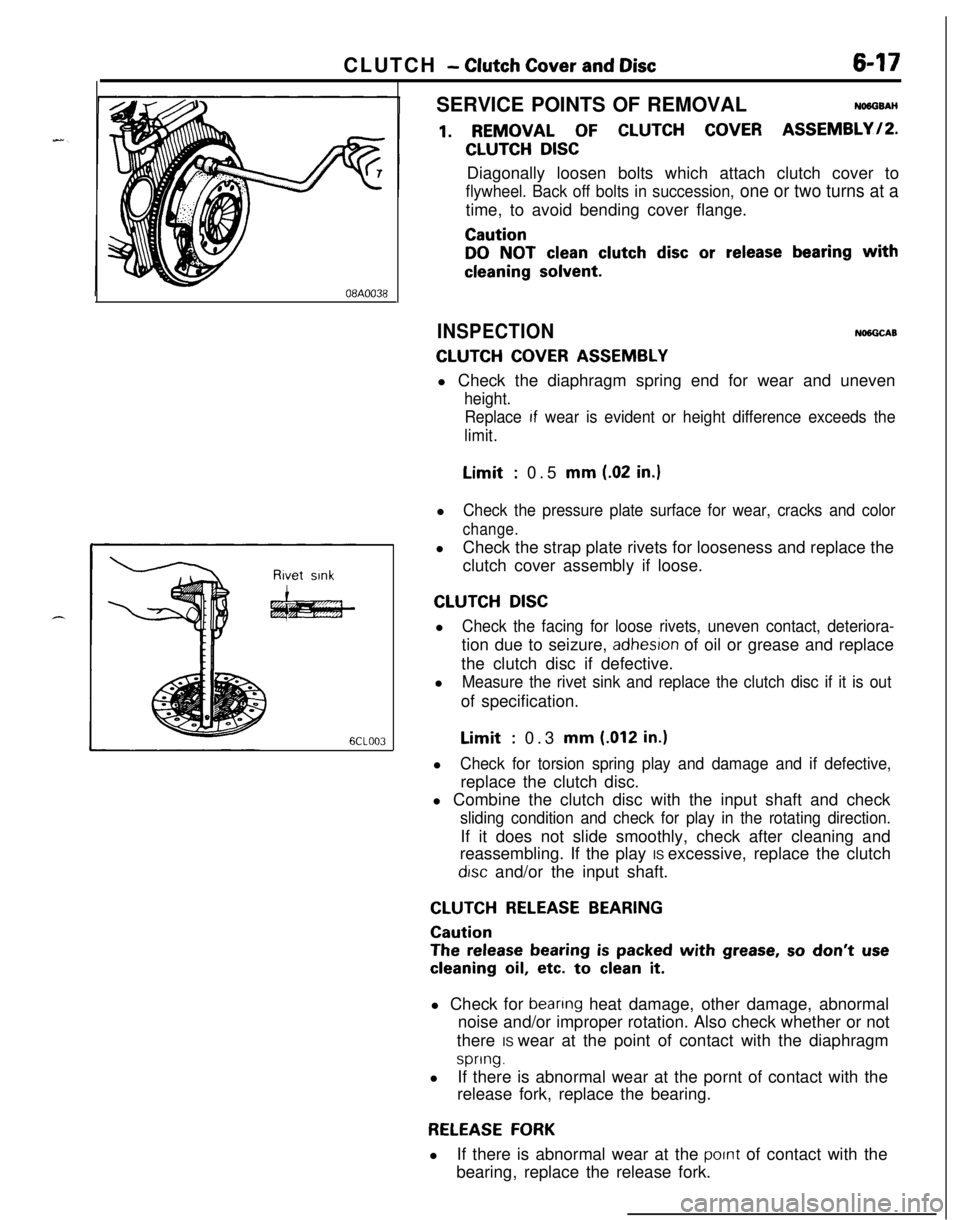

CLUTCH - Clutch Cover and Disc647

08A0038

6CLOO3SERVICE POINTS OF REMOVAL

NO6OSAH

1. REMOVAL OF CLUTCH COVER ASSEMBLY/P.

CLUTCH DISCDiagonally loosen bolts which attach clutch cover to

flywheel. Back off bolts in succession, one or two turns at atime, to avoid bending cover flange.

Caution

DO NOT clean clutch disc or release bearing with

cleaning solvent.

INSPECTIONNlNGCAB

CLUTCH COVER ASSEMBLYl Check the diaphragm spring end for wear and uneven

height.

Replace

If wear is evident or height difference exceeds the

limit.Limit

: 0.5 mm (.02 in.)l

Check the pressure plate surface for wear, cracks and color

change.lCheck the strap plate rivets for looseness and replace the

clutch cover assembly if loose.

CLUTCH DISCl

Check the facing for loose rivets, uneven contact, deteriora-tion due to seizure,

adhesron of oil or grease and replace

the clutch disc if defective.

l

Measure the rivet sink and replace the clutch disc if it is outof specification.Limit

: 0.3 mm (.012 in.)l

Check for torsion spring play and damage and if defective,replace the clutch disc.

l Combine the clutch disc with the input shaft and check

sliding condition and check for play in the rotating direction.If it does not slide smoothly, check after cleaning and

reassembling. If the play IS excessive, replace the clutch

drsc and/or the input shaft.

CLUTCH RELEASE BEARING

Caution

The release bearing is packed with grease, so don’t use

cleaning oil, etc. to clean it.l Check for

beanng heat damage, other damage, abnormal

noise and/or improper rotation. Also check whether or not

there IS wear at the point of contact with the diaphragm

spring.lIf there is abnormal wear at the pornt of contact with the

release fork, replace the bearing.

RELEASE FORKlIf there is abnormal wear at the

pornt of contact with the

bearing, replace the release fork.

Page 248 of 1216

6-18CLUTCH - Clutch Cover and Disc

I6CLO33

Clutch disc

T& assemblyClutch cover

6CLO26

SERVICE POINTS OF INSTALLATIONNWGDAT

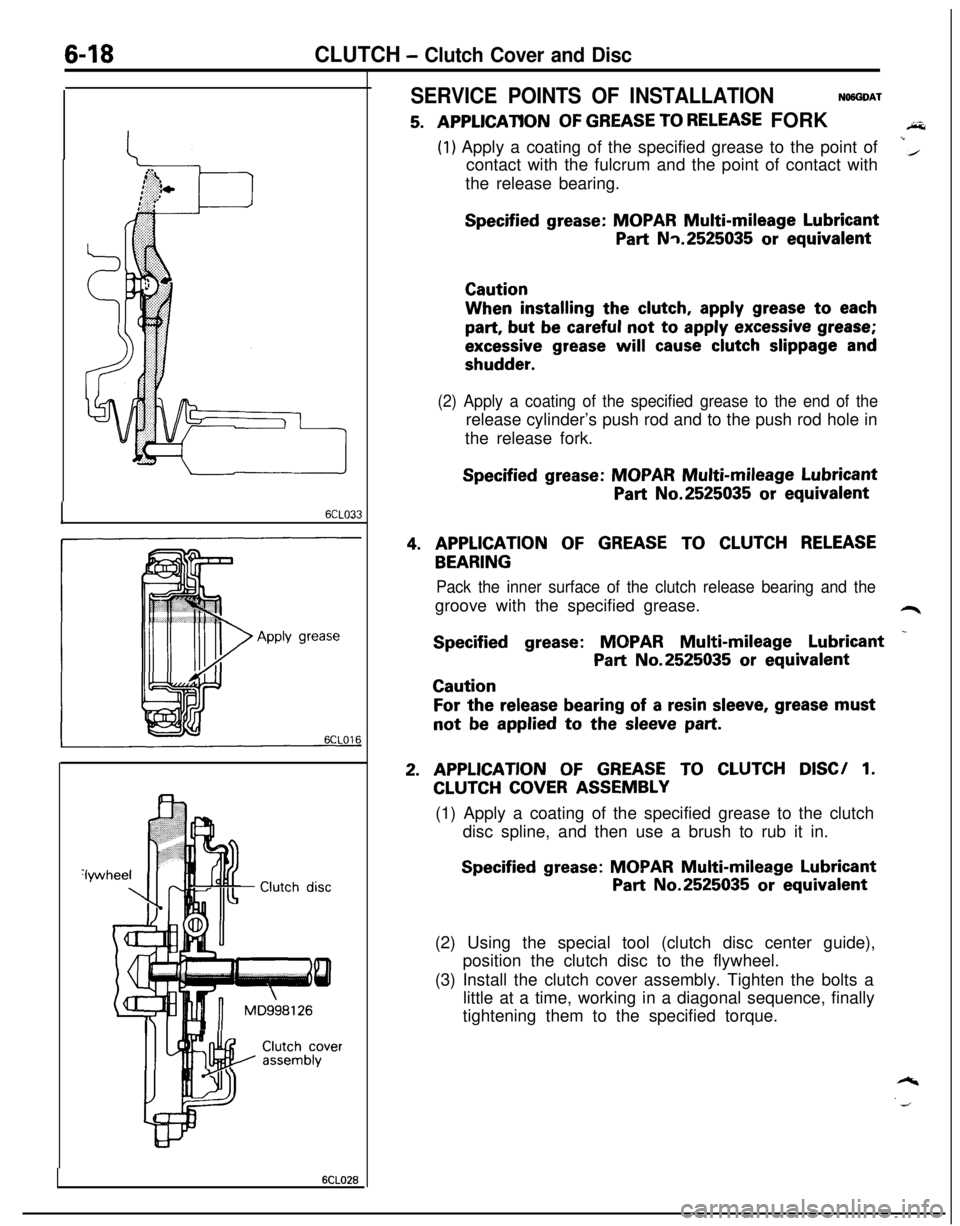

5. A,PPLlCATlONOF GREASE TO RELEASE FORKAi&

(1) Apply a coating of the specified grease to the point of

contact with the fulcrum and the point of contact withi(the release bearing.

Specified grease: MOPAR Multi-mileage Lubricant

Part Nq.2525035 or equivalentCautionWhen installing the

clutch, apply grease to each

part, but be careful not to apply excessive grease;

excessive grease will cause clutch slippage and

shudder.

(2) Apply a coating of the specified grease to the end of therelease cylinder’s push rod and to the push rod hole in

the release fork.

Specified grease: MOPAR Multi-mileage Lubricant

Part No.2525035 or equivalent

4. APPLICATION OF GREASE TO CLUTCH RELEASE

BEARING

Pack the inner surface of the clutch release bearing and thegroove with the specified grease.

L4r

Specified grease: MOPAR Multi-mileage Lubricant _

Part No.2525035 or equivalentCaution

For the release bearing of a resin sleeve, grease mustnot

be applied to the sleeve part.

2. APPLICATION OF GREASE TO CLUTCH DISC/ 1.

CLUTCH COVER ASSEMBLY

(1) Apply a coating of the specified grease to the clutch

disc spline, and then use a brush to rub it in.

Specified grease: MOPAR Multi-mileage Lubricant

Part No.2525035 or equivalent

(2) Using the special tool (clutch disc center guide),

position the clutch disc to the flywheel.

(3) Install the clutch cover assembly. Tighten the bolts a

little at a time, working in a diagonal sequence, finally

tightening them to the specified torque.

Page 302 of 1216

9-18ENGINE - Specifications

TORQUE SPECIFICATIONS

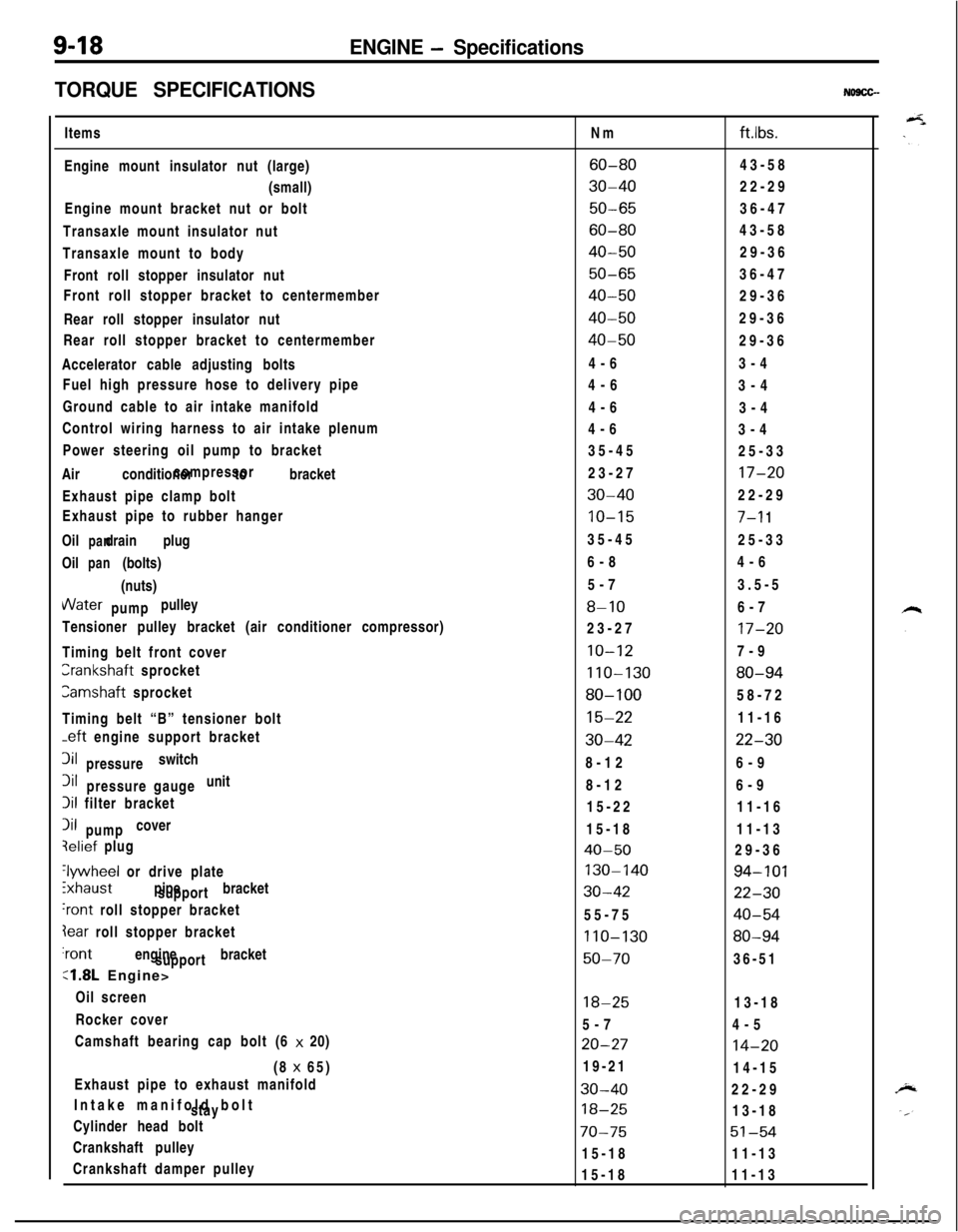

NO9CG-Items

Engine mount insulator nut (large)

(small)

Engine mount bracket nut or bolt

Transaxle mount insulator nut

Transaxle mount to body

Front roll stopper insulator nut

Front roll stopper bracket to centermember

Rear roll stopper insulator nut

Rear roll stopper bracket to centermember

Accelerator cable adjusting bolts

Fuel high pressure hose to delivery pipe

Ground cable to air intake manifold

Control wiring harness to air intake plenum

Power steering oil pump to bracket

Air conditioner to bracketcompressor

Exhaust pipe clamp bolt

Exhaust pipe to rubber hanger

Oil drain plug

panOil (bolts)

pan(nuts)VVater pulley

pump

Tensioner pulley bracket (air conditioner compressor)

Timing belt front coverCrankshaft sprocket

Camshaft sprocket

Timing belt “B” tensioner bolt

-eft engine support bracket3il switch

pressure3il unit

pressure gauge

Iii filter bracket

Iii cover

pumpqelief plug

‘lywheel or drive plate

ixhaust pipe bracket

support

‘rant roll stopper bracket

Iear roll stopper bracket‘rant engine bracket

support

:1.8L Engine>

Oil screen

Rocker cover

Camshaft bearing cap bolt (6 x 20)

(8 x 65)

Exhaust pipe to exhaust manifold

Intake manifold bolt

stay

Cylinder head bolt

Crankshaft pulley

Crankshaft damper pulleyNm

ftlbs.

60-8043-58

30-4022-29

50-6536-47

60-8043-58

40-5029-36

50-6536-47

40-5029-36

40-5029-36

40-5029-36

4-63-4

4-6

3-4

4-6

3-4

4-6

3-4

35-45

25-33

23-27

17-20

30-4022-29

10-157-l 135-45

25-33

6-84-6

5-73.5-5

8-106-7

23-27

17-20

10-127-9

110-13080-94

80-10058-72

15-2211-16

30-4222-308-126-9

8-126-9

15-2211-16

15-1811-13

40-5029-36

130-14094-101

30-4222-3055-75

40-54

110-13080-94

50-7036-51

18-2513-18

5-74-5

20-2714-2019-21

14-15

30-4022-29

18-2513-18

70-7551-5415-1811-13

15-1811-13