wheel bolts MITSUBISHI ECLIPSE 1991 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 355 of 1216

ENGINE - Crankshaft, Flwvheel and Drive Plate9-71

3EN30’lrrow mark toward

cap No,

I

RING GEAR (Engine with a manual transaxle)Check the ring gear for worn, damaged or broken teeth.

Replace the ring gear if teeth are faulty, and also check the

starter motor pinion.

Ring Gear Replacement Procedure(1) Strike outer circumference of ring gear at several points.

Caution

The ring gear cannot be removed if it is heated.(2) Install the ring gear on flywheel after heating the ring gear

to

260-280°C (500-536°F) for shrink fit.

FLYWHEEL (Engine with a manual transaxle)

(1) Visually check the clutch disc friction surface of flywheel forridge wear, streaks and seizure. Replace as necessary.

(2) If the flywheel

runout exceeds the limit, replace it.

Limit: 0.13 mm (0051 in.)

DRIVE PLATE (Engine with an automatic transaxle)Replace if deformed, damaged or cracked.

SERVICE POINTS OF REASSEMBLY

NOSUDAA

15. INSTALLATION OF UPPER BEARINGWhen reusing the main bearings, install them in their

original positions by referring to location marking made at

the time of removal.

Be sure that oil holes in bearings align with those in cylinder

block.

13. INSTALLATION OF LOWER BEARINGMake sure that a bearing without oil groove is used as

lower bearing.

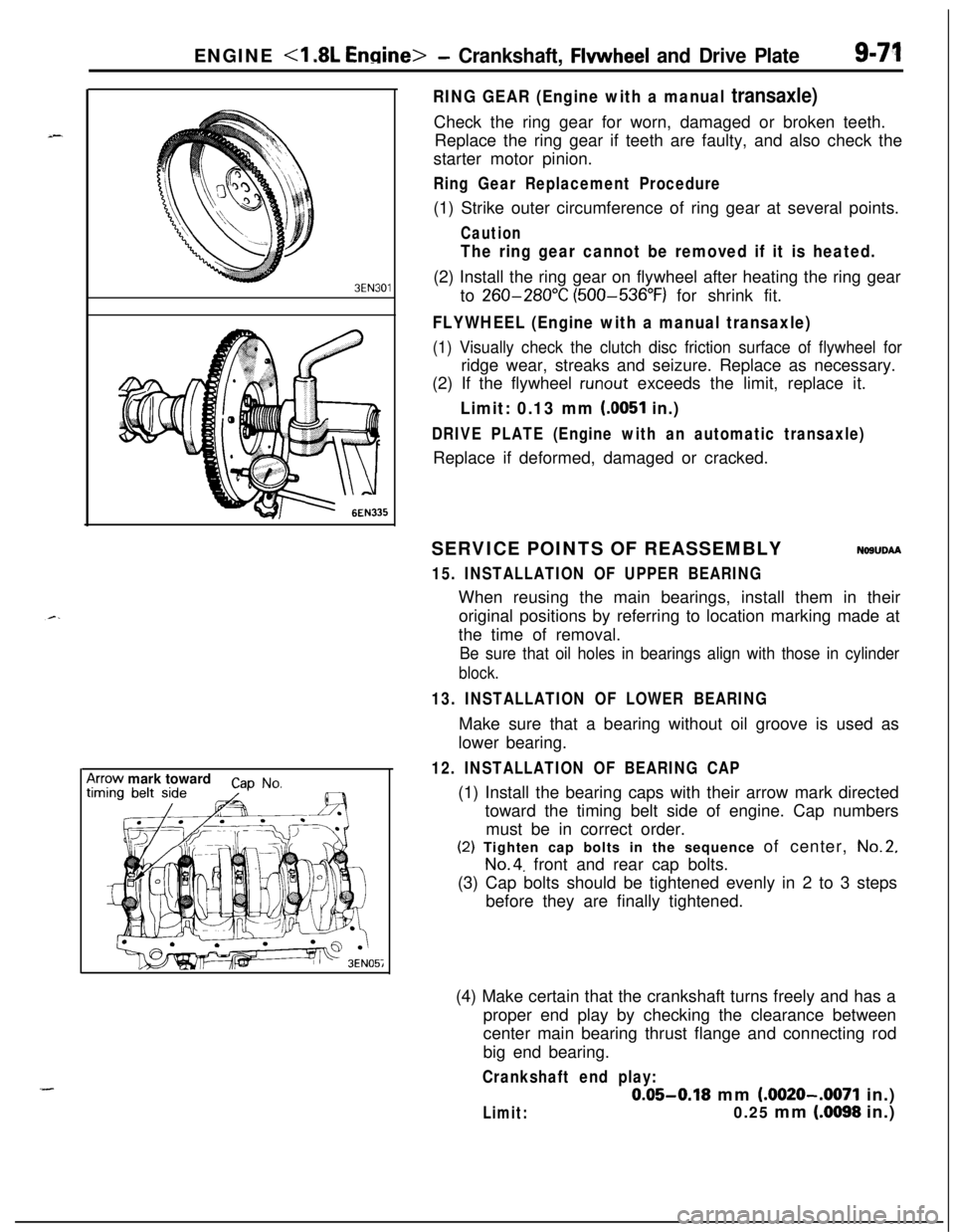

12. INSTALLATION OF BEARING CAP(1) Install the bearing caps with their arrow mark directed

toward the timing belt side of engine. Cap numbers

must be in correct order.(2) Tighten cap bolts in the sequence of center,

No.2,

No.4. front and rear cap bolts.

(3) Cap bolts should be tightened evenly in 2 to 3 steps

before they are finally tightened.

(4) Make certain that the crankshaft turns freely and has a

proper end play by checking the clearance between

center main bearing thrust flange and connecting rod

big end bearing.

Crankshaft end play:

0.05-0.18 mm (.0020-.0071 in.)

Limit:0.25 mm (.0098 in.)

Page 417 of 1216

ENGINE <2.0L DOHC Engine>- Crankshaft, Flywheel and Drive Plate,91133

INSPECTIONNOSUHAD

CRANKSHAFT(1) Check the crankshaft journals and pins for streaks and

seizure. Replace if necessary.

6EN0’228

\3EN056

Plastic

6EN043

. .

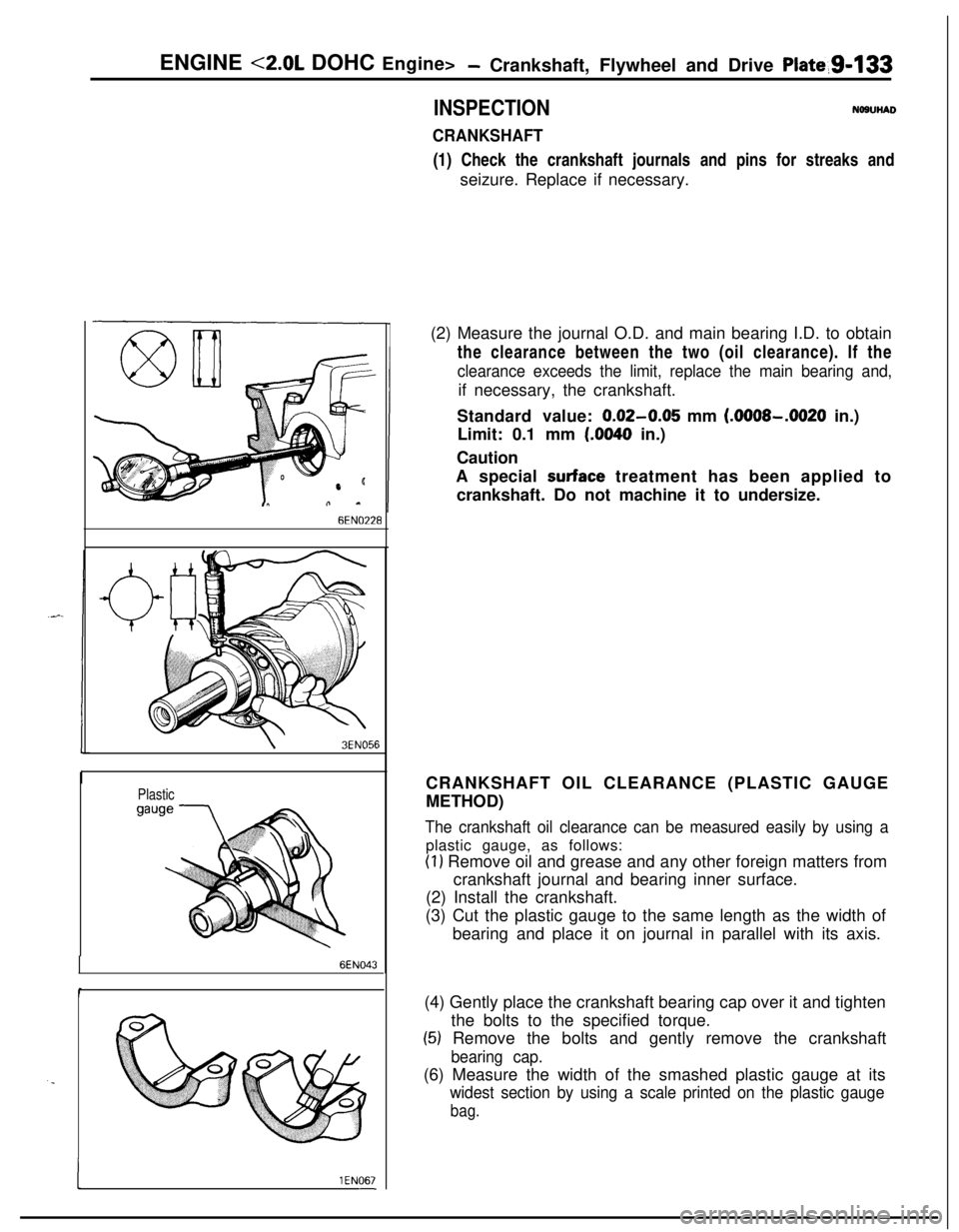

I1 EN067-(2) Measure the journal O.D. and main bearing I.D. to obtain

the clearance between the two (oil clearance). If the

clearance exceeds the limit, replace the main bearing and,if necessary, the crankshaft.

Standard value:

0.02-0.05 mm (.OOOS-.0020 in.)

Limit: 0.1 mm

(.0040 in.)

Caution

A special

surface treatment has been applied to

crankshaft. Do not machine it to undersize.

CRANKSHAFT OIL CLEARANCE (PLASTIC GAUGE

METHOD)

The crankshaft oil clearance can be measured easily by using aplastic gauge, as follows:

(1) Remove oil and grease and any other foreign matters from

crankshaft journal and bearing inner surface.

(2) Install the crankshaft.

(3) Cut the plastic gauge to the same length as the width of

bearing and place it on journal in parallel with its axis.

(4) Gently place the crankshaft bearing cap over it and tighten

the bolts to the specified torque.

(5) Remove the bolts and gently remove the crankshaft

bearing cap.(6) Measure the width of the smashed plastic gauge at its

widest section by using a scale printed on the plastic gauge

bag.

Page 613 of 1216

Special Tools/Troubleshooting/REAR SUSPENSION

SPECIAL TOOLN17DA.A

ToolNumberName1 Use1

L-451 4

Spring compressorRemoval and installation of the coil spring

bodyTROUBLESHOOTINGNI’IEA-A

Symptom

Squeaks or other

abnormal noiseProbable cause

Loose rear suspension installation bolts and nuts

Malfunction of shock absorber

Worn bushings

Remedy

Retighten

Replace

Poor rideExcessive tire inflation pressure

Malfunction of shock absorberWeak or broken springs

Adjust the pressure

Replace

Body tiltingWeak or deteriorated bushings

Weak or broken springs

Replace

SERVICE ADJUSTMENT PROCEDURES

REAR WHEEL ALIGNMENT INSPECTIONN17FAAC

The rear suspension assembly must be free of worn, loosen or

damaged parts prior to measurement of rear wheel alignment.

Standard value:

Toe-in (Left-right difference)

Of3 mm (Of.118 in.)

Camber-45’ + 30’

NOTEThe rear wheel alignment is set at the factory and cannot be

adjusted.If toe-in or camber is not within the standard value, replace

bent or damaged parts.

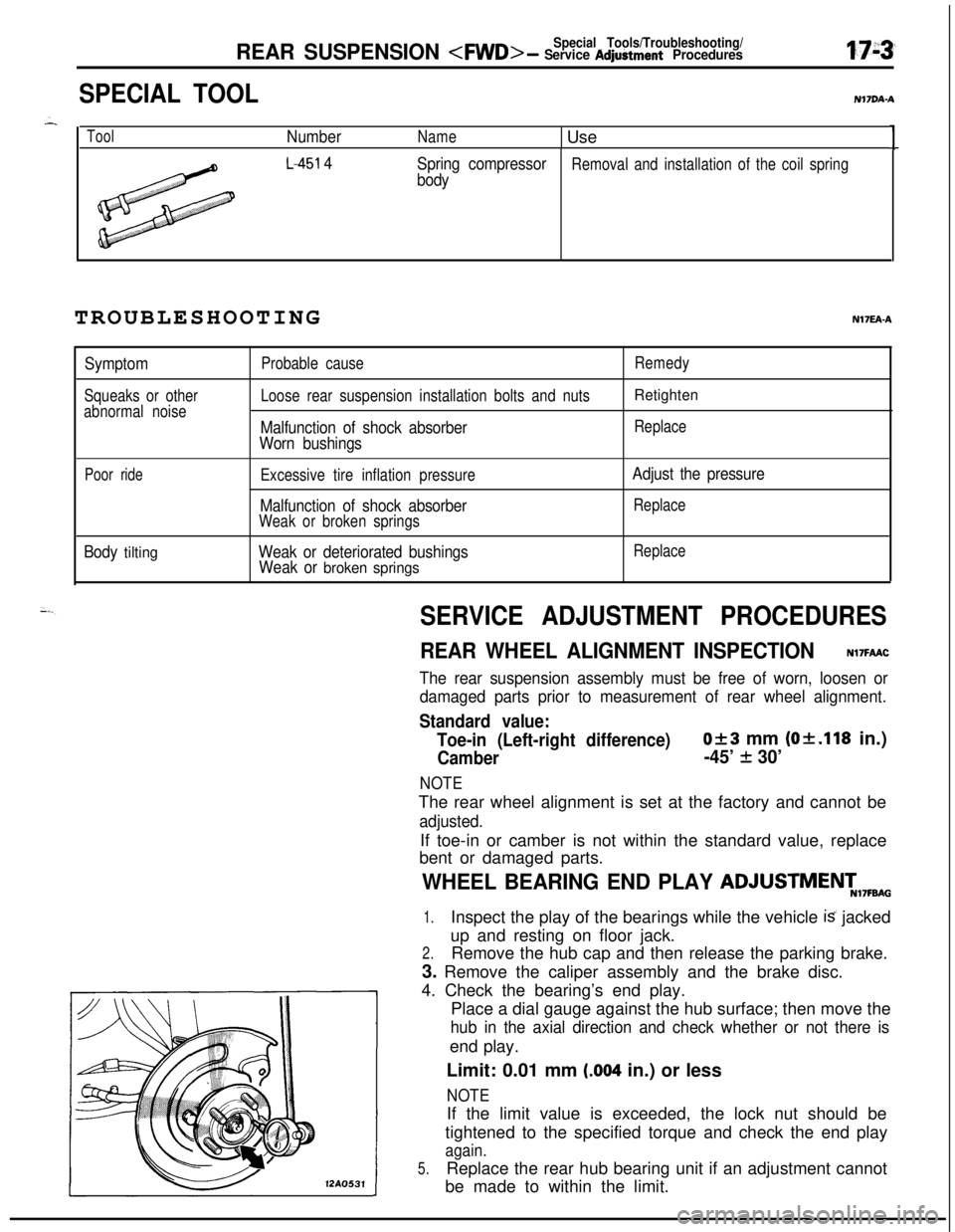

WHEEL BEARING END PLAY ADJUSTMENT,7FBA0

1.Inspect the play of the bearings while the vehicle is jacked

up and resting on floor jack.

2.Remove the hub cap and then release the parking brake.

3. Remove the caliper assembly and the brake disc.

4. Check the bearing’s end play.

Place a dial gauge against the hub surface; then move the

hub in the axial direction and check whether or not there isend play.

Limit: 0.01 mm

(.004 in.) or less

NOTE12AO531If the limit value is exceeded, the lock nut should be

tightened to the specified torque and check the end play

again.

5.Replace the rear hub bearing unit if an adjustment cannot

be made to within the limit.

Page 616 of 1216

17-6REAR SUSPENSION

Drive out

BayArbor

Race

BearingSERVICE POINTS OF REMOVAL

Nl7QBh

1.REMOVAL OF REAR SPEED SENSOR

5-Wheel Speed Sensor.

11. REMOVAL OF LATERAL ROD MOUNTING BOLT

(1) Remove the lateral rod mounting bolt.

(2) Secure and hold the lateral rod to the axle beam with

wire, etc.

13. REMOVAL OF SHOCK ABSORBER UPPER ‘MOUNTINGNUTS/14. TRAILING ARM MOUNTING BOLTS/15

REAR SUSPENSION ASSEMBLY(1) Jack up the torsion axle and arm assembly in order to

raise it slightly.

Caution

1.Always insert a wooden block between the jack

receptacle and the axle beam and place the jackat the center of the axle beam.

2. Make sure that the jack does not contact the

lateral rod.(2) Remove the shock absorber

m,ounting nuts and trailing

arm mounting bolts.

(3) Lower the jack slowly, and then remove the rear

suspension assembly.

#-

INSPECTIONNl7QCAL

lCheck the trailing arm and axle beam for deformation or

damage.l Check the torsion bar for damage.

l Check the lateral rod for damage or deformation.

lCheck the bushings for cracking, deterioration, or unusual

wear.

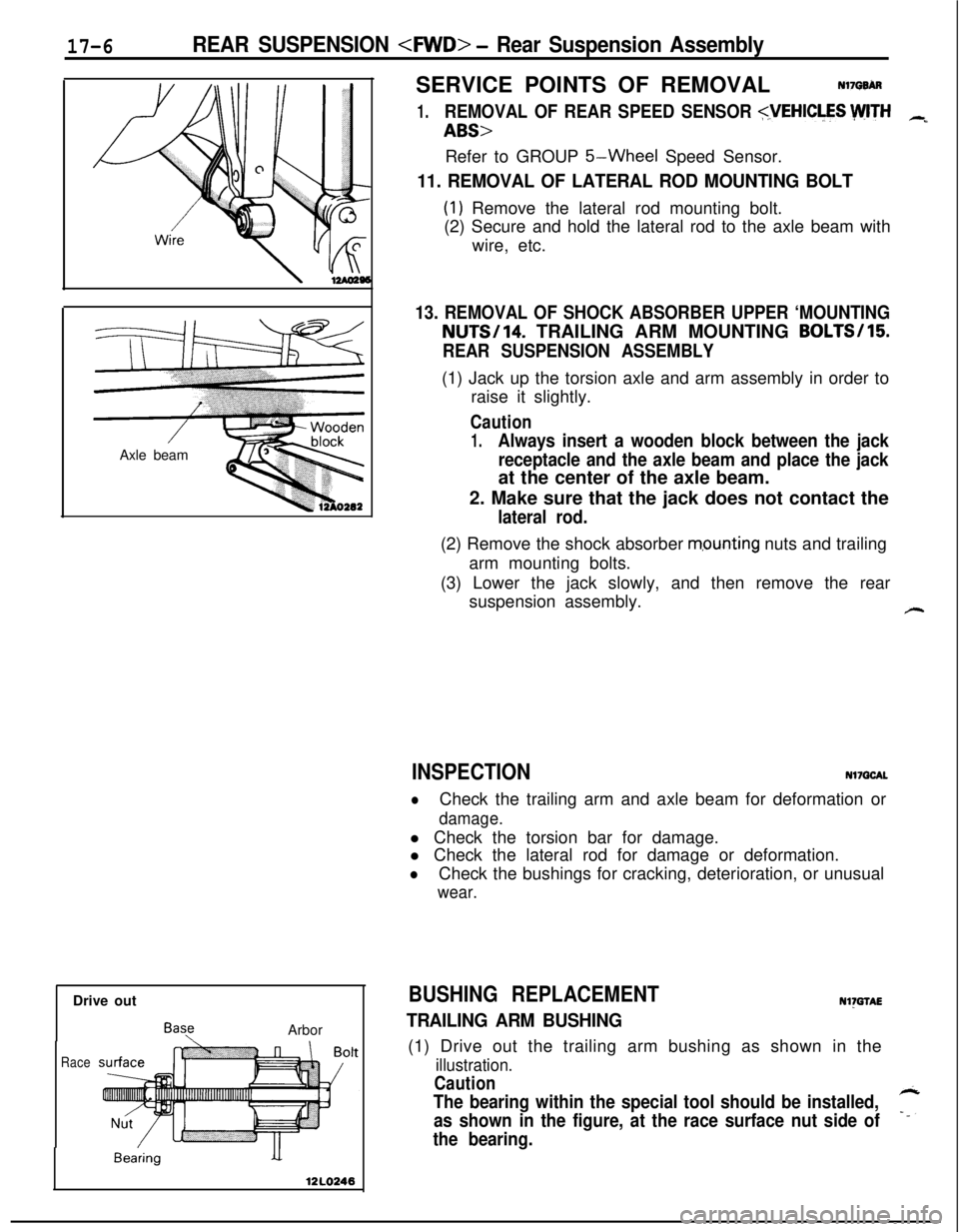

BUSHING REPLACEMENTNl)GTAE

TRAILING ARM BUSHING(1) Drive out the trailing arm bushing as shown in the

illustration.

Caution

The bearing within the special tool should be installed,

as shown in the figure, at the race surface nut side of7

the bearing.

Page 623 of 1216

REAR SUSPENSION

Inut

-

-Spindle

14AO419

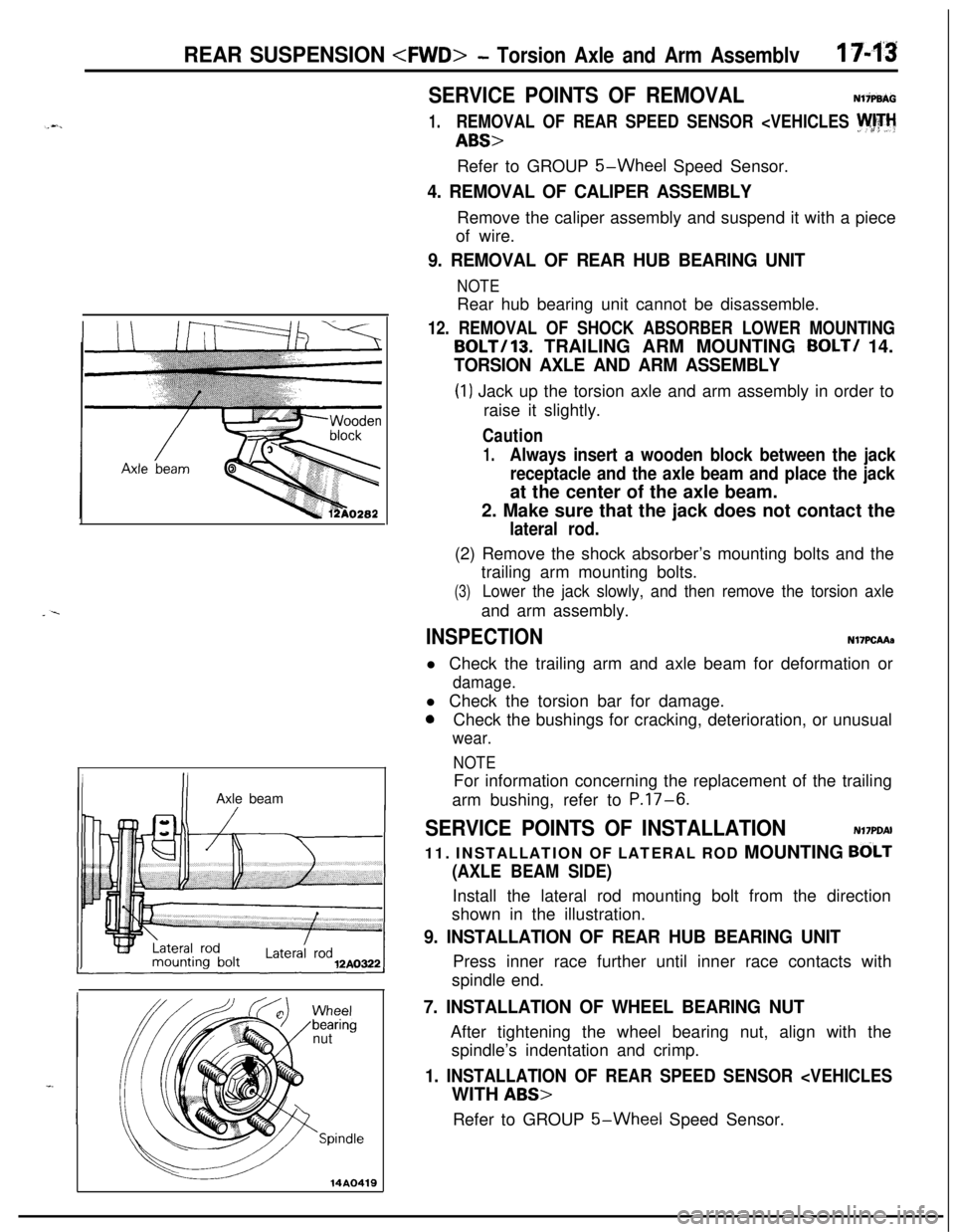

SERVICE POINTS OF REMOVALNliP9AG

1.REMOVAL OF REAR SPEED SENSOR

5-Wheel Speed Sensor.

4. REMOVAL OF CALIPER ASSEMBLYRemove the caliper assembly and suspend it with a piece

of wire.

9. REMOVAL OF REAR HUB BEARING UNIT

NOTERear hub bearing unit cannot be disassemble.

12. REMOVAL OF SHOCK ABSORBER LOWER MOUNTING

BOLT/lB. TRAILING ARM MOUNTING BOLT/ 14.

TORSION AXLE AND ARM ASSEMBLY

(1) Jack up the torsion axle and arm assembly in order to

raise it slightly.

Caution

1.Always insert a wooden block between the jack

receptacle and the axle beam and place the jackat the center of the axle beam.

2. Make sure that the jack does not contact the

lateral rod.(2) Remove the shock absorber’s mounting bolts and the

trailing arm mounting bolts.

(3)Lower the jack slowly, and then remove the torsion axleand arm assembly.

INSPECTIONN17PCAAa

l Check the trailing arm and axle beam for deformation or

damage.l Check the torsion bar for damage.

0Check the bushings for cracking, deterioration, or unusual

wear.

NOTEFor information concerning the replacement of the trailing

arm bushing, refer to

P.17-6.

SERVICE POINTS OF INSTALLATIONN17PDAI

11. INSTALLATION OF LATERAL ROD MOUNTING

BdLT

(AXLE BEAM SIDE)Install the lateral rod mounting bolt from the direction

shown in the illustration.

9. INSTALLATION OF REAR HUB BEARING UNITPress inner race further until inner race contacts with

spindle end.

7. INSTALLATION OF WHEEL BEARING NUTAfter tightening the wheel bearing nut, align with the

spindle’s indentation and crimp.

1. INSTALLATION OF REAR SPEED SENSOR

5-Wheel Speed Sensor.

Page 630 of 1216

17-20REAR SUSPENSION

12R0556-- Upper arm

(L.H.)

12A0081

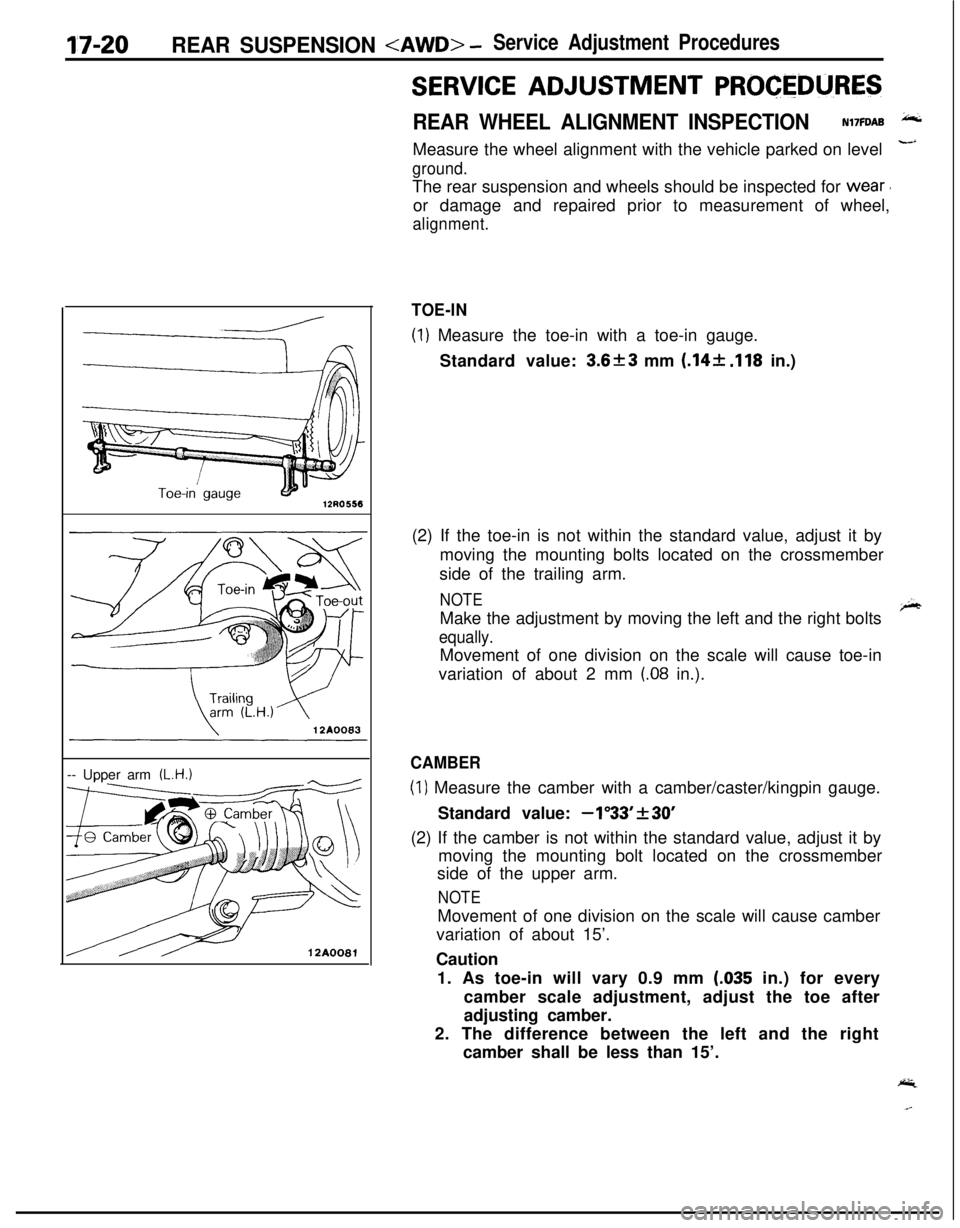

SERVICE ADJUSTMENT PROCEDURES

REAR WHEEL ALIGNMENT INSPECTIONN17FDAB is.Measure the wheel alignment with the vehicle parked on level

--’

ground.The rear suspension and wheels should be inspected for

wear’or damage and repaired prior to measurement of wheel,

alignment.

TOE-IN

(1) Measure the toe-in with a toe-in gauge.

Standard value:

3.6f3 mm (.14+ .I18 in.)

(2) If the toe-in is not within the standard value, adjust it by

moving the mounting bolts located on the crossmember

side of the trailing arm.

NOTEMake the adjustment by moving the left and the right bolts

r;hr

equally.Movement of one division on the scale will cause toe-in

variation of about 2 mm

(.08 in.).

CAMBER

(1) Measure the camber with a camber/caster/kingpin gauge.

Standard value:

-1”33’f30’(2) If the camber is not within the standard value, adjust it by

moving the mounting bolt located on the crossmember

side of the upper arm.

NOTEMovement of one division on the scale will cause camber

variation of about 15’.

Caution

1. As toe-in will vary 0.9 mm

(.035 in.) for every

camber scale adjustment, adjust the toe after

adjusting camber.

2. The difference between the left and the right

camber shall be less than 15’.

Page 660 of 1216

19-12STEERING - Service Adjustment Procedures

Pressure ofWater pump

pulleyOlA0059Fluid fluctuation

While engine

runningWhile enginestopped13uo139

Return hoseVinyl hose

x ,3Ao,42-

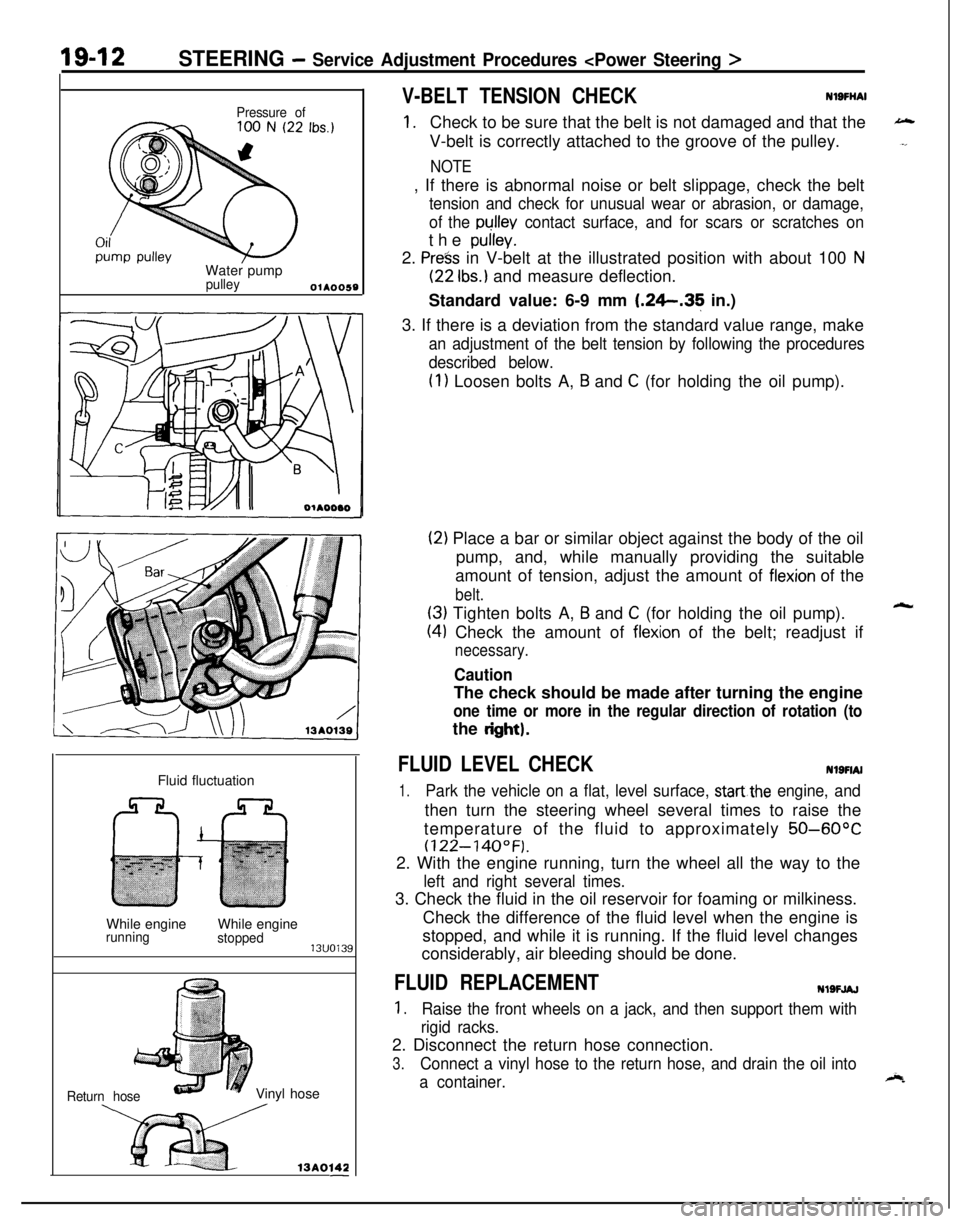

V-BELT TENSION CHECKNlSFliAl

1.Check to be sure that the belt is not damaged and that the

V-belt is correctly attached to the groove of the pulley.

NOTE, If there is abnormal noise or belt slippage, check the belt

tension and check for unusual wear or abrasion, or damage,

of the

pullev contact surface, and for scars or scratches onthe

pulley.2.

Press in V-belt at the illustrated position with about 100 N

(22 Ibs.) and measure deflection.

Standard value: 6-9 mm

1.26.35 in.)

3. If there is a deviation from the standard value range, make

an adjustment of the belt tension by following the procedures

described below.

(1) Loosen bolts A, B and C (for holding the oil pump).

(2) Place a bar or similar object against the body of the oil

pump, and, while manually providing the suitable

amount of tension, adjust the amount of

flexion of the

belt.

(3) Tighten bolts A, B and C (for holding the oil pump).

(4) Check the amount of flexion of the belt; readjust if

necessary.

CautionThe check should be made after turning the engine

one time or more in the regular direction of rotation (tothe

dght).

FLUID LEVEL CHECKNlSFIAI

1.Park the vehicle on a flat, level surface, startthe engine, andthen turn the steering wheel several times to raise the

temperature of the fluid to approximately

50-60°C

(122-140°F).2. With the engine running, turn the wheel all the way to the

left and right several times.3. Check the fluid in the oil reservoir for foaming or milkiness.

Check the difference of the fluid level when the engine is

stopped, and while it is running. If the fluid level changes

considerably, air bleeding should be done.

FLUID REPLACEMENTNlSFJAJ

1.Raise the front wheels on a jack, and then support them with

rigid racks.2. Disconnect the return hose connection.

3.Connect a vinyl hose to the return hose, and drain the oil into

a container.

Page 664 of 1216

19-16STEERING - Steering Wheel and Shaft

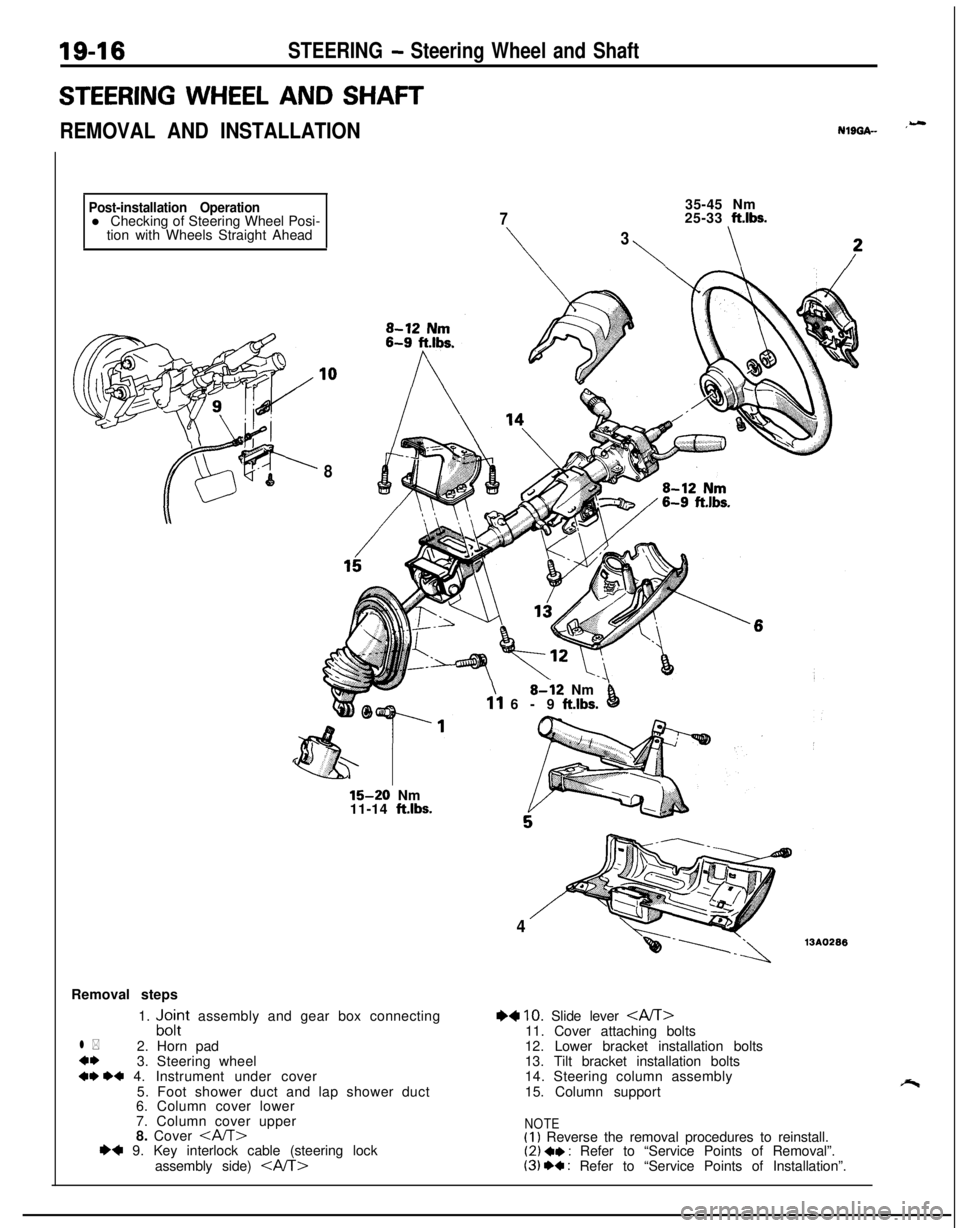

STEERING WHEEL AND SHAFT

REMOVAL AND INSTALLATIONNlL)GA- ‘-

Post-installation Operationl Checking of Steering Wheel Posi-

tion with Wheels Straight Ahead

835-45 Nm

725-33 ft.lbs.

\

3

\\

15-20 Nm

11-14 ft.lbs.Removal steps

1.

“,c$t assembly and gear box connecting

l *2. Horn pad

4*3. Steering wheel

+* ++ 4. Instrument under cover

5. Foot shower duct and lap shower duct

6. Column cover lower

7. Column cover upper

8. Cover

assembly side)

\8-i2 Nm’11 6-9 ft.lbs.0

413AO296

+4 10. Slide lever 11. Cover attaching bolts

12. Lower bracket installation bolts

13. Tilt bracket installation bolts

14. Steering column assembly

15. Column support

NOTE(I) Reverse the removal procedures to reinstall.(2) a* : Refer to “Service Points of Removal”.(3) +a : Refer to “Service Points of Installation”.

Page 667 of 1216

STEERING - Steering Wheel and Shaft

Socket13AO106

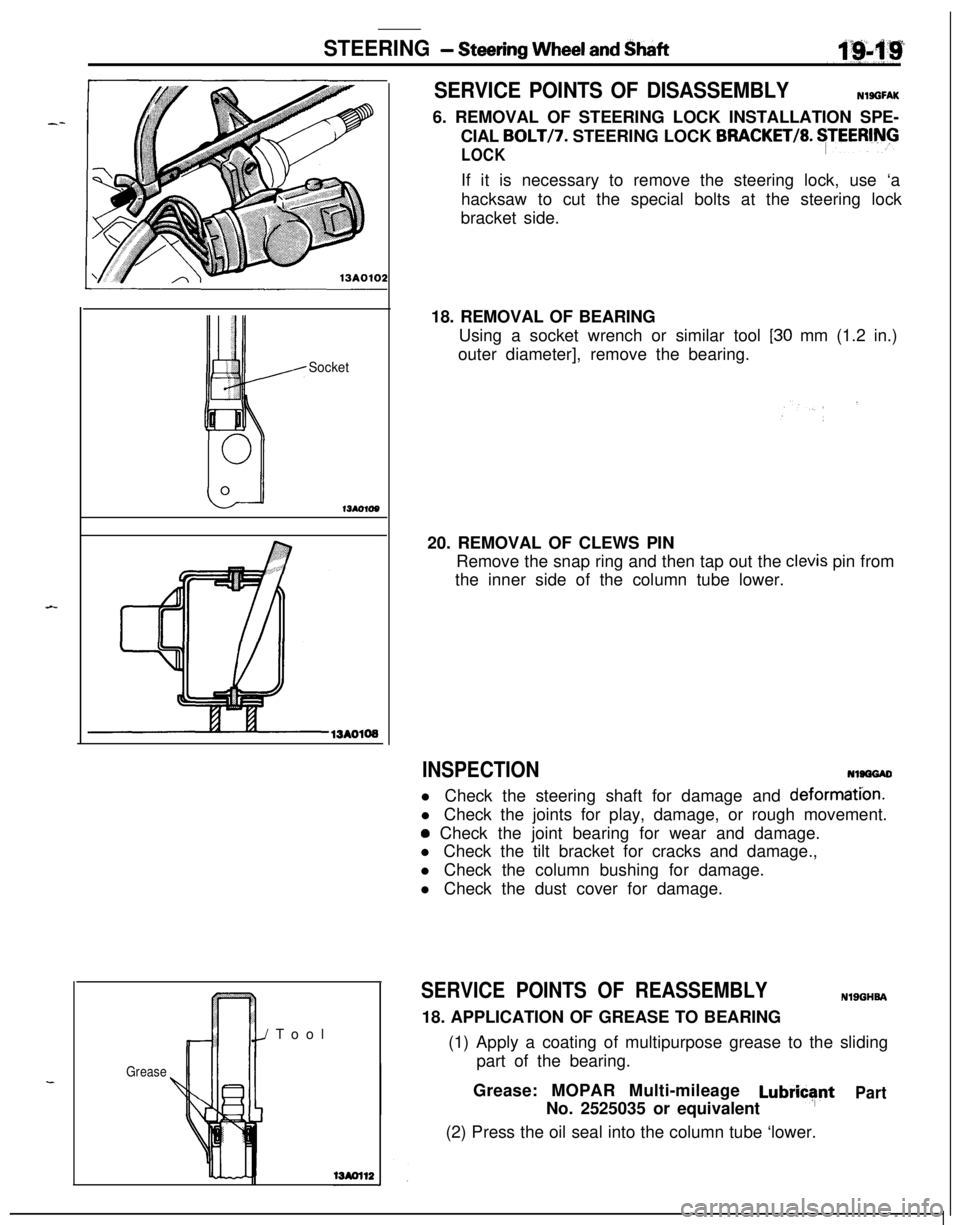

SERVICE POINTS OF DISASSEMBLYNlSGFAK6. REMOVAL OF STEERING LOCK INSTALLATION SPE-

CIAL

BOLTI7. STEERING LOCK BRACKET/8. $EERlNG

LOCKIf it is necessary to remove the steering lock, use ‘a

hacksaw to cut the special bolts at the steering lock

bracket side.

18. REMOVAL OF BEARING

Using a socket wrench or similar tool

[30 mm (1.2 in.)

outer diameter], remove the bearing.

20. REMOVAL OF CLEWS PIN

Remove the snap ring and then tap out the

clevis pin from

the inner side of the column tube lower.

INSPECTIONNlSGGADl Check the steering shaft for damage and

deformati’on.l Check the joints for play, damage, or rough movement.

a Check the joint bearing for wear and damage.

l Check the tilt bracket for cracks and damage.,

l Check the column bushing for damage.

l Check the dust cover for damage.

Grease/Tool

SERVICE POINTS OF REASSEMBLYNlSGHSA18. APPLICATION OF GREASE TO BEARING

(1) Apply a coating of multipurpose grease to the sliding

part of the bearing.

Grease: MOPAR Multi-mileage

LubricsfntPartNo. 2525035 or equivalent

(2) Press the oil seal into the column tube ‘lower.

Page 668 of 1216

19-20STEERING - Steering Wheel and Shaft

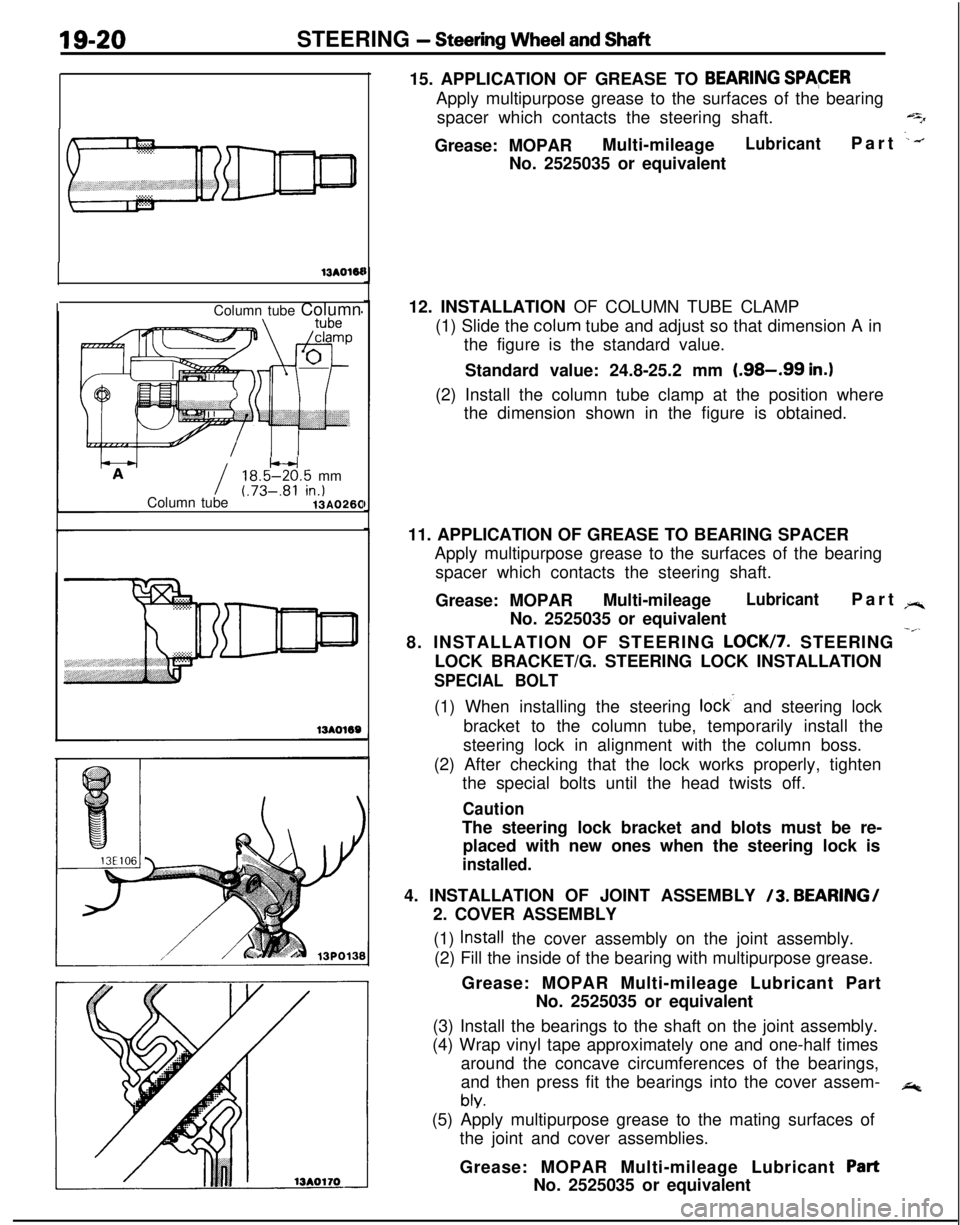

13AOWColumn tube Column

I18.5W.5 mm

Column tube(.73-.81 in.)13AO26015. APPLICATION OF GREASE TO

BEARING SPACERApply multipurpose grease to the surfaces of the bearing

spacer which contacts the steering shaft.

qGrease: MOPARMulti-mileage

LubricantPart .--.No. 2525035 or equivalent

12. INSTALLATION OF COLUMN TUBE CLAMP

(1) Slide the colum tube and adjust so that dimension A in

the figure is the standard value.

Standard value: 24.8-25.2 mm

(.98-.99 in.)(2) Install the column tube clamp at the position where

the dimension shown in the figure is obtained.

11. APPLICATION OF GREASE TO BEARING SPACER

Apply multipurpose grease to the surfaces of the bearing

spacer which contacts the steering shaft.

Grease: MOPARMulti-mileage

LubricantPart rr.No. 2525035 or equivalent

8. INSTALLATION OF STEERING

LOCK/7. STEERING -”LOCK BRACKET/G. STEERING LOCK INSTALLATION

SPECIAL BOLT(1) When installing the steering

lock- and steering lock

bracket to the column tube, temporarily install the

steering lock in alignment with the column boss.

(2) After checking that the lock works properly, tighten

the special bolts until the head twists off.

CautionThe steering lock bracket and blots must be re-

placed with new ones when the steering lock is

installed.4. INSTALLATION OF JOINT ASSEMBLY

/3. BEARING/

2. COVER ASSEMBLY

(1)

Install the cover assembly on the joint assembly.

(2) Fill the inside of the bearing with multipurpose grease.

Grease: MOPAR Multi-mileage Lubricant Part

No. 2525035 or equivalent

(3) Install the bearings to the shaft on the joint assembly.

(4) Wrap vinyl tape approximately one and one-half times

around the concave circumferences of the bearings,

and then press fit the bearings into the cover assem-

*

bly.(5) Apply multipurpose grease to the mating surfaces of

the joint and cover assemblies.

Grease: MOPAR Multi-mileage Lubricant

PartNo. 2525035 or equivalent