ECU MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 692 of 1216

19-44STEERING - Power Steering Oil Pump

13AO350

13PO159

Punch mark

13c214 I

13W03ECutouts for

dowel pin

13PO16110. INSTALLATION OF

O-RING/S. O-RING

Apply specified fluid on O-ring to install.

-,Specified fluid: MOPAR ATF PLUS (Automatic

Trans- ”mission Fluid Type 7176)/Automatic

transmission fluid

“DEXRONY or “DE-XRON II”

1 No. 1I.D. x Widthmm (in.)Identification color

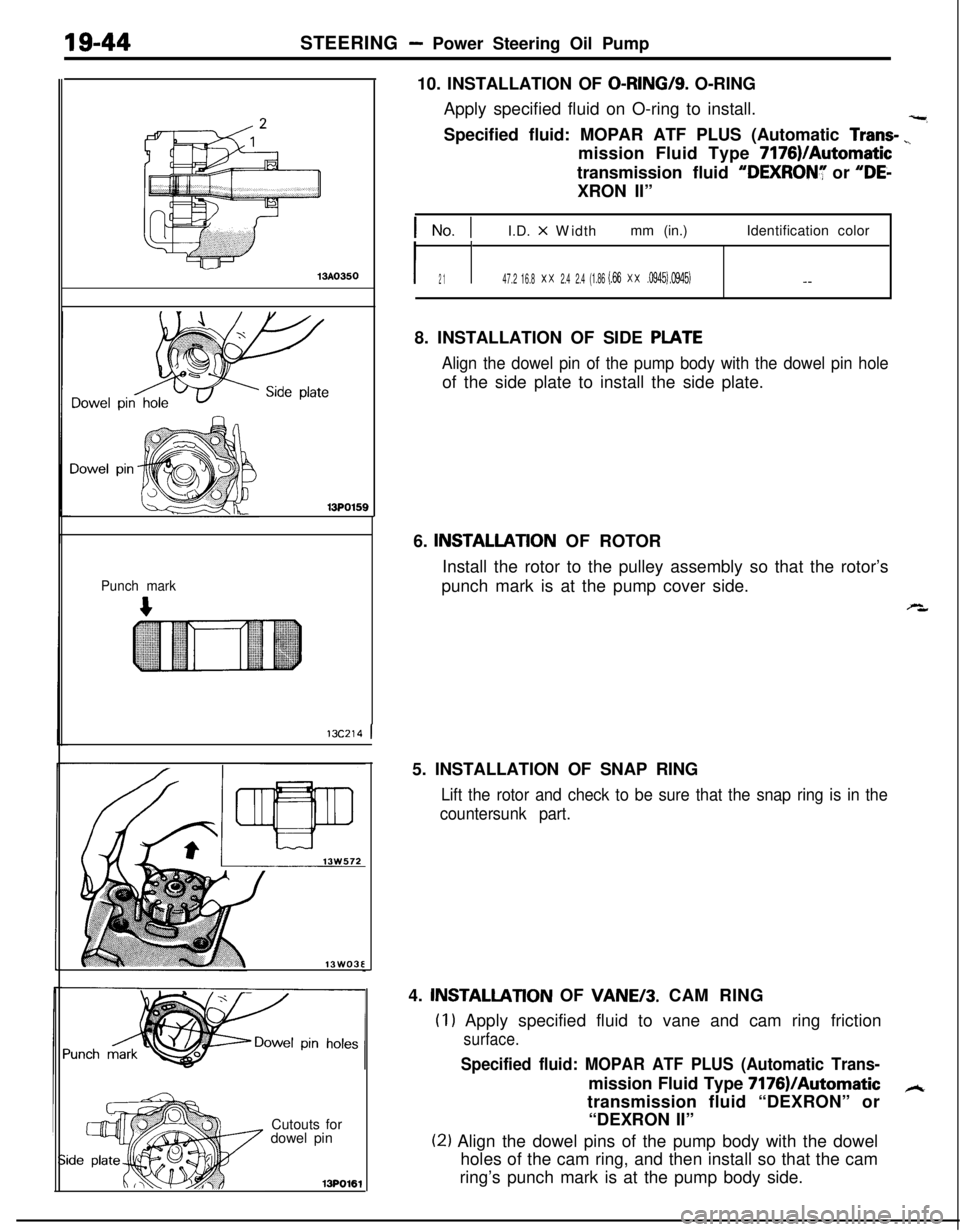

I2 1I47.2 16.8x x2.4 2.4(1.86 (.66x x.0945) .0945)- -8. INSTALLATION OF SIDE

PLATE

Align the dowel pin of the pump body with the dowel pin holeof the side plate to install the side plate.

6.

INSTALLATlON OF ROTOR

Install the rotor to the pulley assembly so that the rotor’s

punch mark is at the pump cover side.

s,5. INSTALLATION OF SNAP RING

Lift the rotor and check to be sure that the snap ring is in the

countersunk part.4.

INSTALLATlON OF VANE/3. CAM RING

(I1 Apply specified fluid to vane and cam ring friction

surface.

Specified fluid: MOPAR ATF PLUS (Automatic Trans-mission Fluid Type 7176)IAutomatic

Atransmission fluid “DEXRON” or

“DEXRON II”

(21 Align the dowel pins of the pump body with the dowel

holes of the cam ring, and then install so that the cam

ring’s punch mark is at the pump body side.

Page 708 of 1216

21-14 MANUAL TRANSAXLE

I-Adapter%A0905SPEEDOMETER CABLE REPLACEMENT

NZlFEAKl

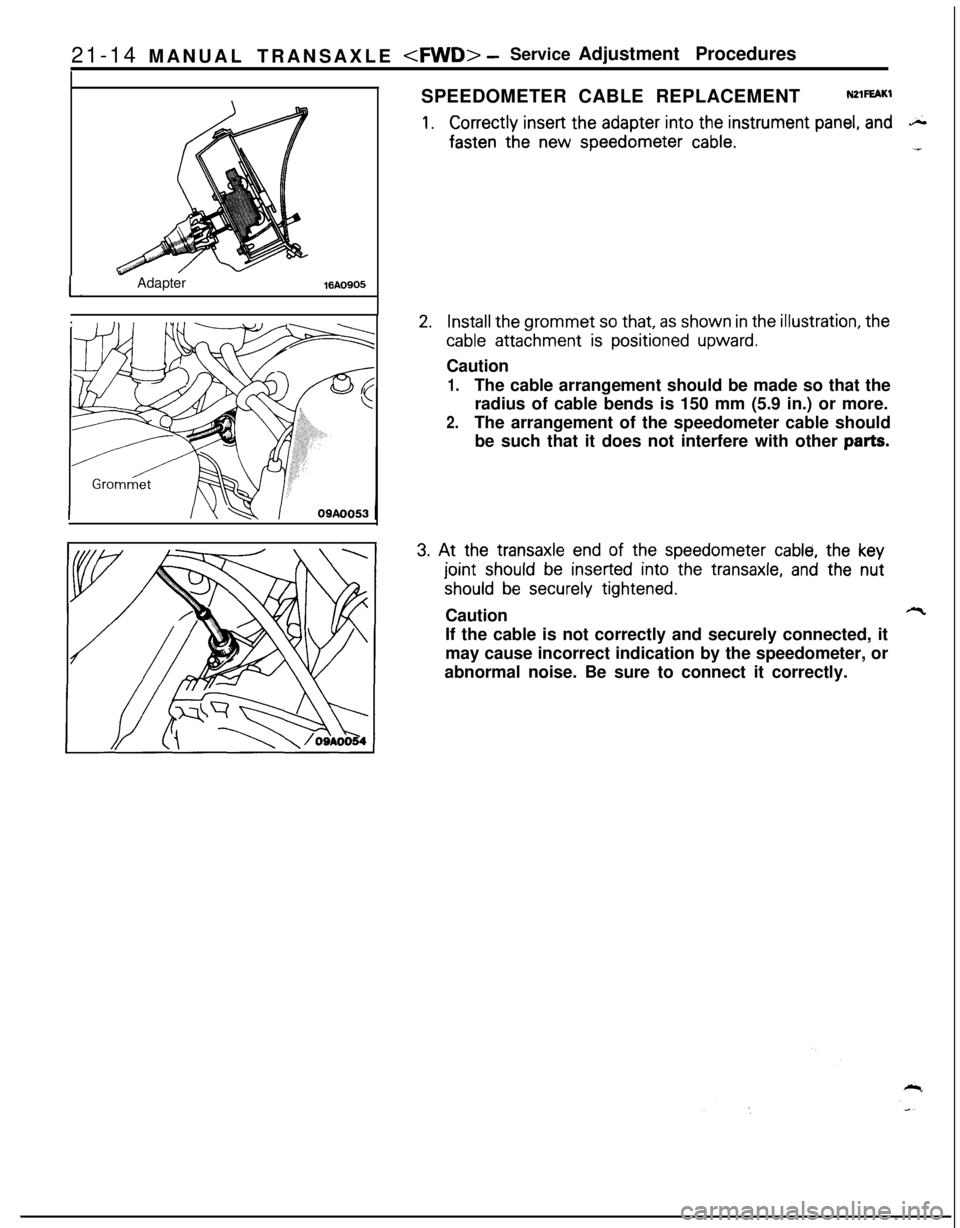

1.Correctly insert the adapter into the instrument panel, andS.

fasten the new speedometer cable.1-

2.Install the grommet so that, as shown in the illustration, the

cable attachment is positioned upward.Caution

1.The cable arrangement should be made so that the

radius of cable bends is 150 mm (5.9 in.) or more.

2.The arrangement of the speedometer cable should

be such that it does not interfere with other

parts.

3. At the transaxle end of the speedometer cable, the key

joint should be inserted into the transaxle, and the nut

should be securely tightened.Caution

lllcIf the cable is not correctly and securely connected, it

may cause incorrect indication by the speedometer, or

abnormal noise. Be sure to connect it correctly.

Page 715 of 1216

MANUAL TRANSAXLE

---

-..

2) ’TransaxlellK611

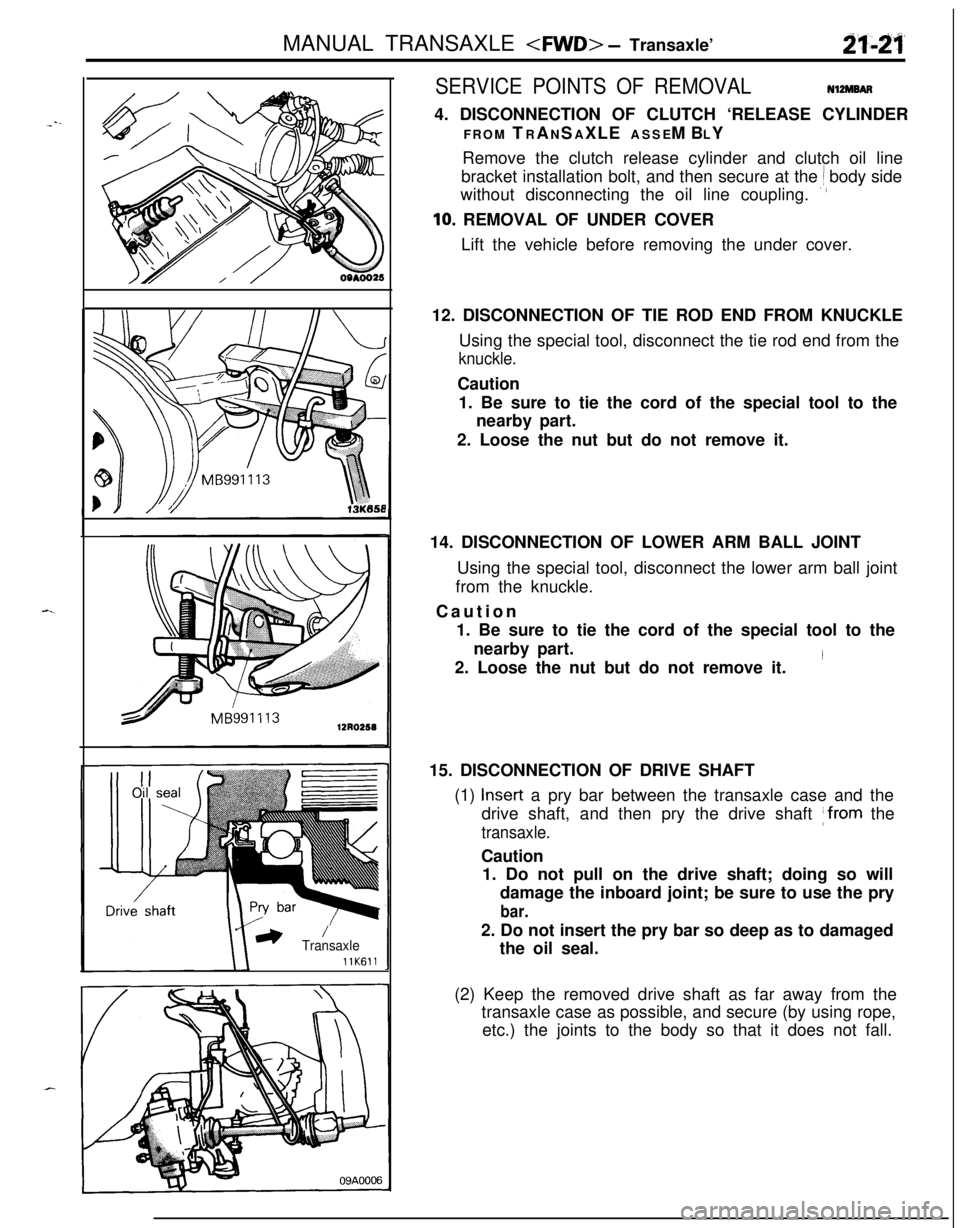

SERVICE POINTS OF REMOVALNlZMBAR4. DISCONNECTION OF CLUTCH ‘RELEASE CYLINDER

FROM TRANSAXLE ASSEMBLY

Remove the clutch release cylinder and clutch oil line

bracket installation bolt, and then secure at the

! body side

without disconnecting the oil line coupling.

”

10. REMOVAL OF UNDER COVER

Lift the vehicle before removing the under cover.

12. DISCONNECTION OF TIE ROD END FROM KNUCKLE

Using the special tool, disconnect the tie rod end from the

knuckle.Caution

1. Be sure to tie the cord of the special tool to the

nearby part.

2. Loose the nut but do not remove it.

14. DISCONNECTION OF LOWER ARM BALL JOINT

Using the special tool, disconnect the lower arm ball joint

from the knuckle.

Caution

1. Be sure to tie the cord of the special tool to the

nearby part.

2. Loose the nut but do not remove it.

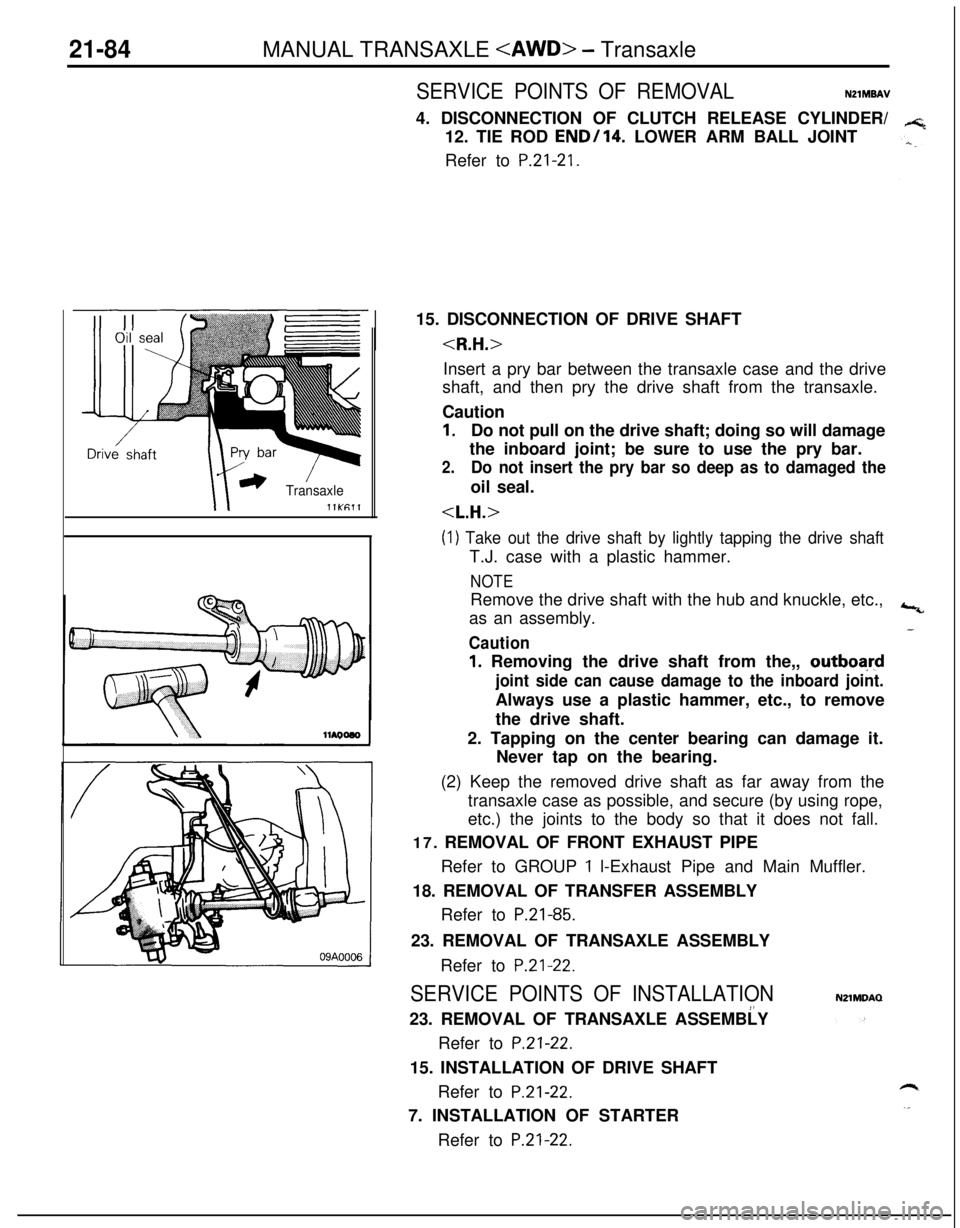

I15. DISCONNECTION OF DRIVE SHAFT

(1)

Insert a pry bar between the transaxle case and the

drive shaft, and then pry the drive shaft

~from the

transaxle.Caution

1. Do not pull on the drive shaft; doing so will

damage the inboard joint; be sure to use the pry

bar.2. Do not insert the pry bar so deep as to damaged

the oil seal.

(2) Keep the removed drive shaft as far away from the

transaxle case as possible, and secure (by using rope,

etc.) the joints to the body so that it does not fall.

Page 716 of 1216

21-22MANUAL TRANSAXLE

1 Transaxleside1 Radiator lower hose

1 Transaxle side1 Radiator lower hosepart ofdrive shaft

I

-Transaxle

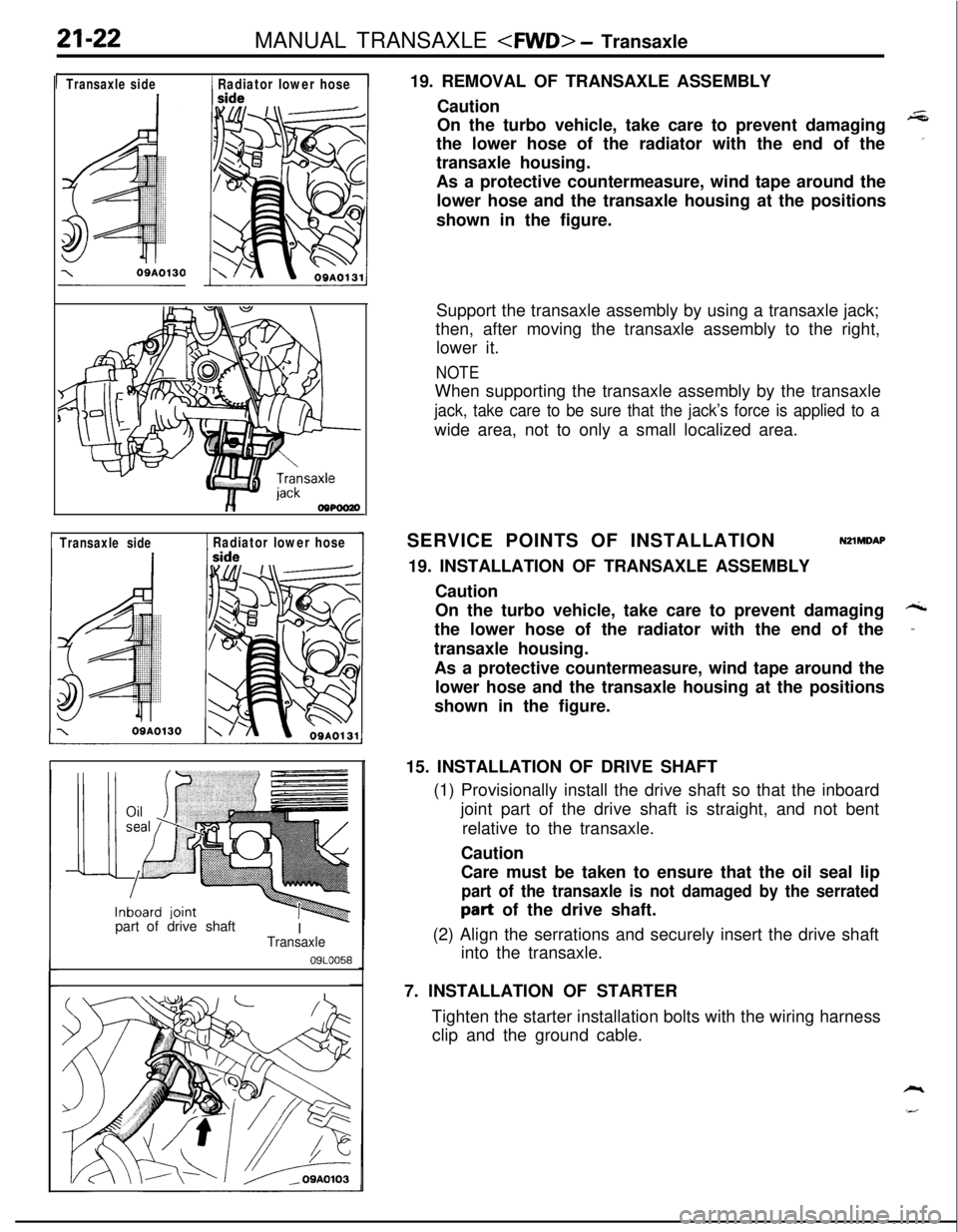

09LOO5819. REMOVAL OF TRANSAXLE ASSEMBLY

Caution

On the turbo vehicle, take care to prevent damaging

+Gthe lower hose of the radiator with the end of the

’transaxle housing.

As a protective countermeasure, wind tape around the

lower hose and the transaxle housing at the positions

shown in the figure.

Support the transaxle assembly by using a transaxle jack;

then, after moving the transaxle assembly to the right,

lower it.

NOTEWhen supporting the transaxle assembly by the transaxle

jack, take care to be sure that the jack’s force is applied to awide area, not to only a small localized area.

SERVICE POINTS OF INSTALLATION

NZlMDAP19. INSTALLATION OF TRANSAXLE ASSEMBLY

Caution

On the turbo vehicle, take care to prevent damaging

Athe lower hose of the radiator with the end of the

-transaxle housing.

As a protective countermeasure, wind tape around the

lower hose and the transaxle housing at the positions

shown in the figure.

15. INSTALLATION OF DRIVE SHAFT

(1) Provisionally install the drive shaft so that the inboard

joint part of the drive shaft is straight, and not bent

relative to the transaxle.

Caution

Care must be taken to ensure that the oil seal lip

part of the transaxle is not damaged by the serratedpart of the drive shaft.

(2) Align the serrations and securely insert the drive shaft

into the transaxle.

7. INSTALLATION OF STARTER

Tighten the starter installation bolts with the wiring harness

clip and the ground cable.

Page 778 of 1216

21-84MANUAL TRANSAXLE

r) ’TransaxlellKfil1

SERVICE POINTS OF REMOVALN21MBAV4. DISCONNECTION OF CLUTCH RELEASE CYLINDER/

12. TIE ROD

END/l4. LOWER ARM BALL JOINT

Refer to

P.21-21.15. DISCONNECTION OF DRIVE SHAFT

shaft, and then pry the drive shaft from the transaxle.

Caution

1.Do not pull on the drive shaft; doing so will damage

the inboard joint; be sure to use the pry bar.

2.Do not insert the pry bar so deep as to damaged theoil seal.

(1) Take out the drive shaft by lightly tapping the drive shaftT.J. case with a plastic hammer.

NOTERemove the drive shaft with the hub and knuckle, etc.,

as an assembly.

Caution

1. Removing the drive shaft from the,, outboa,rd

joint side can cause damage to the inboard joint.Always use a plastic hammer, etc., to remove

the drive shaft.

2. Tapping on the center bearing can damage it.

Never tap on the bearing.

(2) Keep the removed drive shaft as far away from the

transaxle case as possible, and secure (by using rope,

etc.) the joints to the body so that it does not fall.

17. REMOVAL OF FRONT EXHAUST PIPE

Refer to GROUP

1 l-Exhaust Pipe and Main Muffler.

18. REMOVAL OF TRANSFER ASSEMBLY

Refer to

P.21-85.23. REMOVAL OF TRANSAXLE ASSEMBLY

Refer to

P.21-22.

SERVICE POINTS OF INSTALLATION!’23. REMOVAL OF TRANSAXLE ASSEMBLY

Refer to

P.21-22.15. INSTALLATION OF DRIVE SHAFT

Refer to

P.21-22.7. INSTALLATION OF STARTER

Refer to

P.21-22.

NZlMDAQ

Page 791 of 1216

MANUAL TRANSAXLE

I-2mmml

,

Snap r

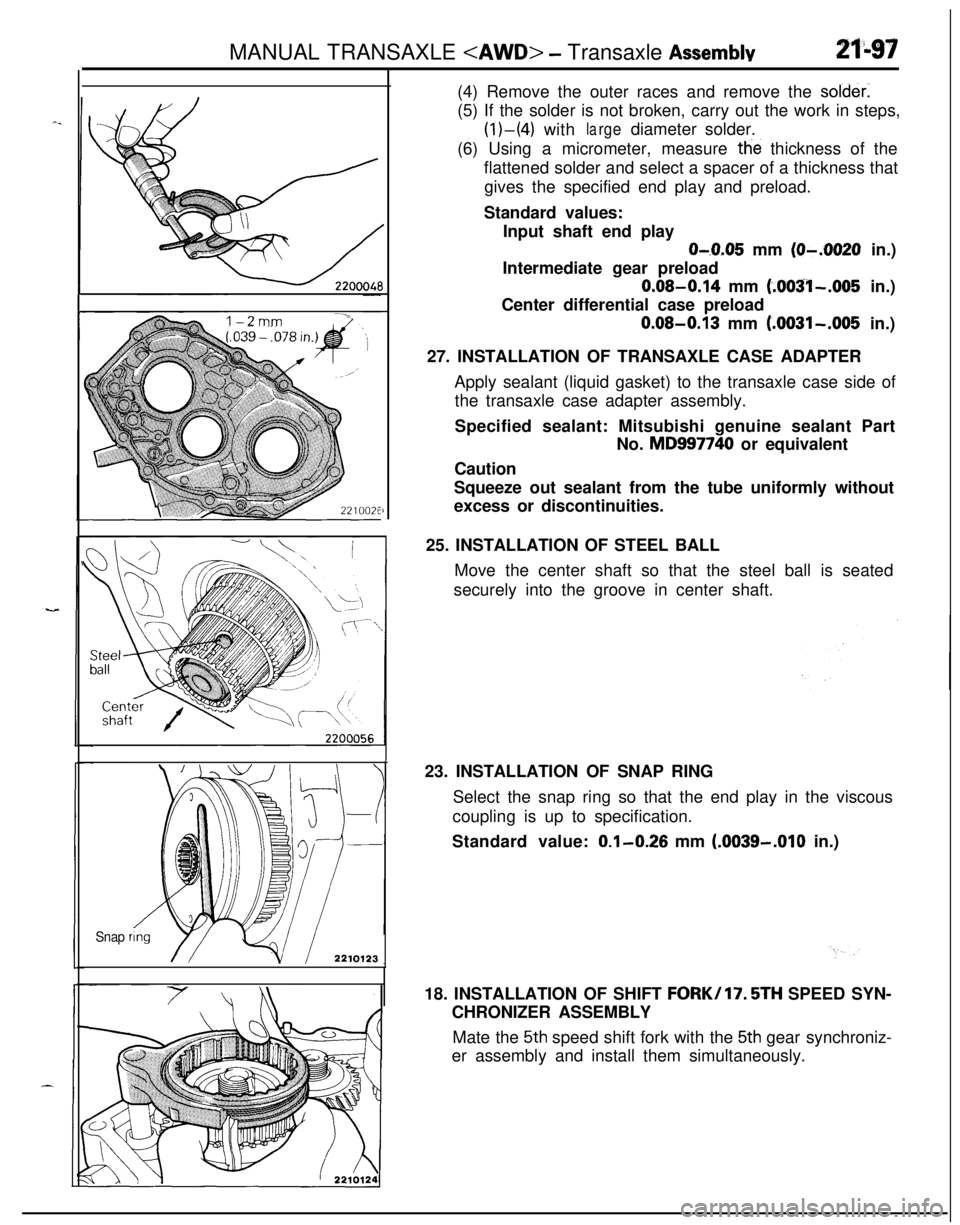

/ /221012:3(4) Remove the outer races and remove the

solder:(5) If the solder is not broken, carry out the work in steps,

(l)-(4) withlargediameter solder.

(6) Using a micrometer, measure ttie thickness of the

flattened solder and select a spacer of a thickness that

gives the specified end play and preload.

Standard values:

Input shaft end play

O-.0.05 mm (O-.0020 in.)

Intermediate gear preload

0.08-0.14 mm (.0031-.005 in.)

Center differential case preload

0.08-0.13 mm (.0031-,005 in.)

27. INSTALLATION OF TRANSAXLE CASE ADAPTER

Apply sealant (liquid gasket) to the transaxle case side of

the transaxle case adapter assembly.

Specified sealant: Mitsubishi genuine sealant Part

No. MD997740 or equivalent

Caution

Squeeze out sealant from the tube uniformly without

excess or discontinuities.

25. INSTALLATION OF STEEL BALL

Move the center shaft so that the steel ball is seated

securely into the groove in center shaft.

23. INSTALLATION OF SNAP RING

Select the snap ring so that the end play in the viscous

coupling is up to specification.

Standard value:

0.1-0.26 mm (.0039-.OlO in.)

18. INSTALLATION OF SHIFT FORK/17.

5TH SPEED SYN-

CHRONIZER ASSEMBLY

Mate the

5th speed shift fork with the 5th gear synchroniz-

er assembly and install them simultaneously.

Page 872 of 1216

21-178AUTOMATIC TRANSAXLE - Troubleshooting

09P0010Fluid level must be

within this range.09PoOll

0”

Two302

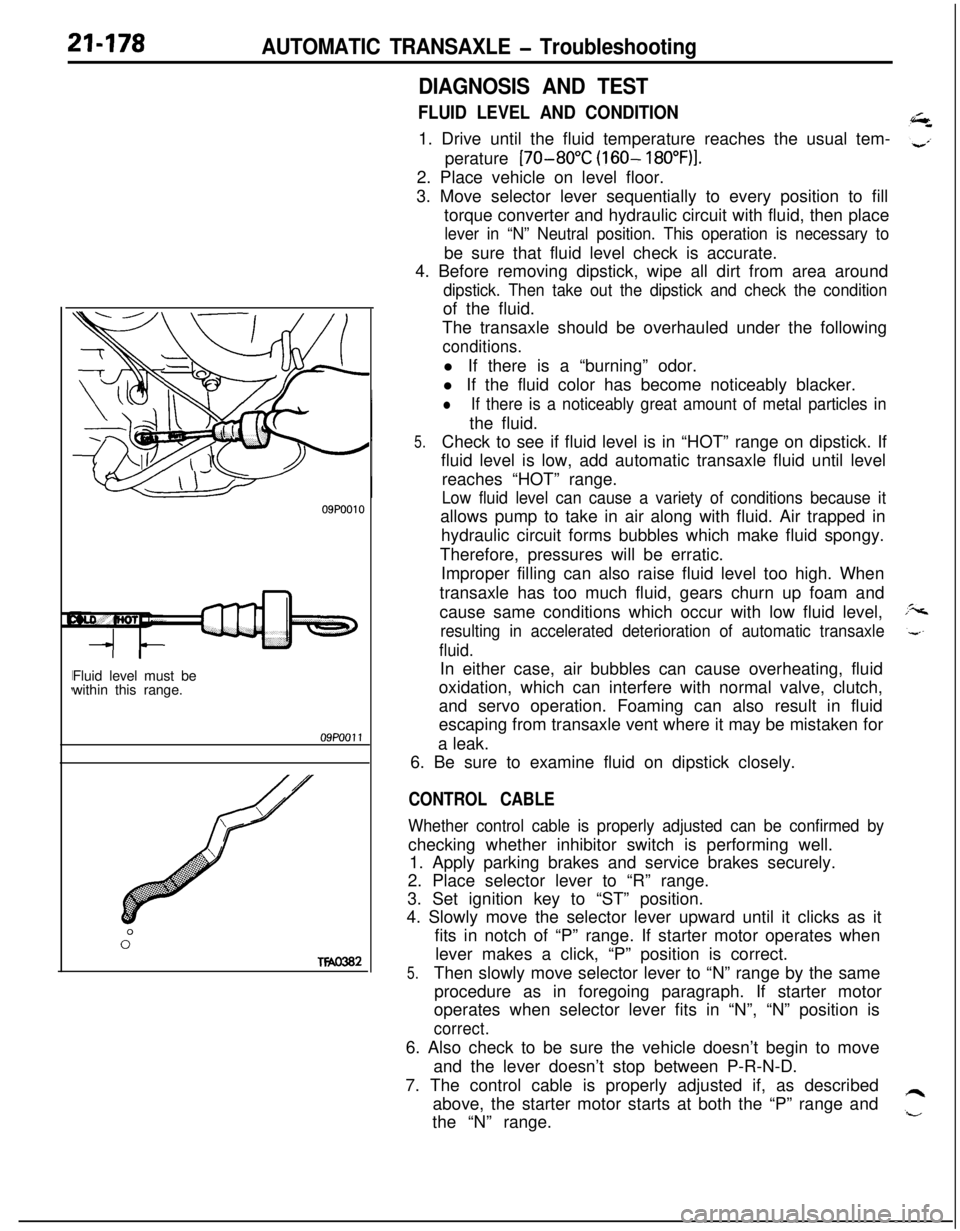

DIAGNOSIS AND TEST

FLUID LEVEL AND CONDITION1. Drive until the fluid temperature reaches the usual tem-

perature

[70-80°C (160- 18O”F)I.2. Place vehicle on level floor.

3. Move selector lever sequentially to every position to fill

torque converter and hydraulic circuit with fluid, then place

lever in “N” Neutral position. This operation is necessary tobe sure that fluid level check is accurate.

4. Before removing dipstick, wipe all dirt from area around

dipstick. Then take out the dipstick and check the conditionof the fluid.

The transaxle should be overhauled under the following

conditions.l If there is a “burning” odor.

l If the fluid color has become noticeably blacker.

lIf there is a noticeably great amount of metal particles inthe fluid.

5.Check to see if fluid level is in “HOT” range on dipstick. If

fluid level is low, add automatic transaxle fluid until level

reaches “HOT” range.

Low fluid level can cause a variety of conditions because itallows pump to take in air along with fluid. Air trapped in

hydraulic circuit forms bubbles which make fluid spongy.

Therefore, pressures will be erratic.

Improper filling can also raise fluid level too high. When

transaxle has too much fluid, gears churn up foam and

cause same conditions which occur with low fluid level,

resulting in accelerated deterioration of automatic transaxle

fluid.In either case, air bubbles can cause overheating, fluid

oxidation, which can interfere with normal valve, clutch,

and servo operation. Foaming can also result in fluid

escaping from transaxle vent where it may be mistaken for

a leak.

6. Be sure to examine fluid on dipstick closely.

CONTROL CABLE

Whether control cable is properly adjusted can be confirmed bychecking whether inhibitor switch is performing well.

1. Apply parking brakes and service brakes securely.

2. Place selector lever to “R” range.

3. Set ignition key to “ST” position.

4. Slowly move the selector lever upward until it clicks as it

fits in notch of “P” range. If starter motor operates when

lever makes a click, “P” position is correct.

5.Then slowly move selector lever to “N” range by the same

procedure as in foregoing paragraph. If starter motor

operates when selector lever fits in “N”, “N” position is

correct.6. Also check to be sure the vehicle doesn’t begin to move

and the lever doesn’t stop between P-R-N-D.

7. The control cable is properly adjusted if, as described

above, the starter motor starts at both the “P” range and

the “N” range.

Page 905 of 1216

AUTOMATIC TRANSAXLE - Service Adjustment Procedures21-21109A0146

OQMOO45

control lever

control lever

5 mm

Section A-A

(2 in.)Manual

controllever

Switch body

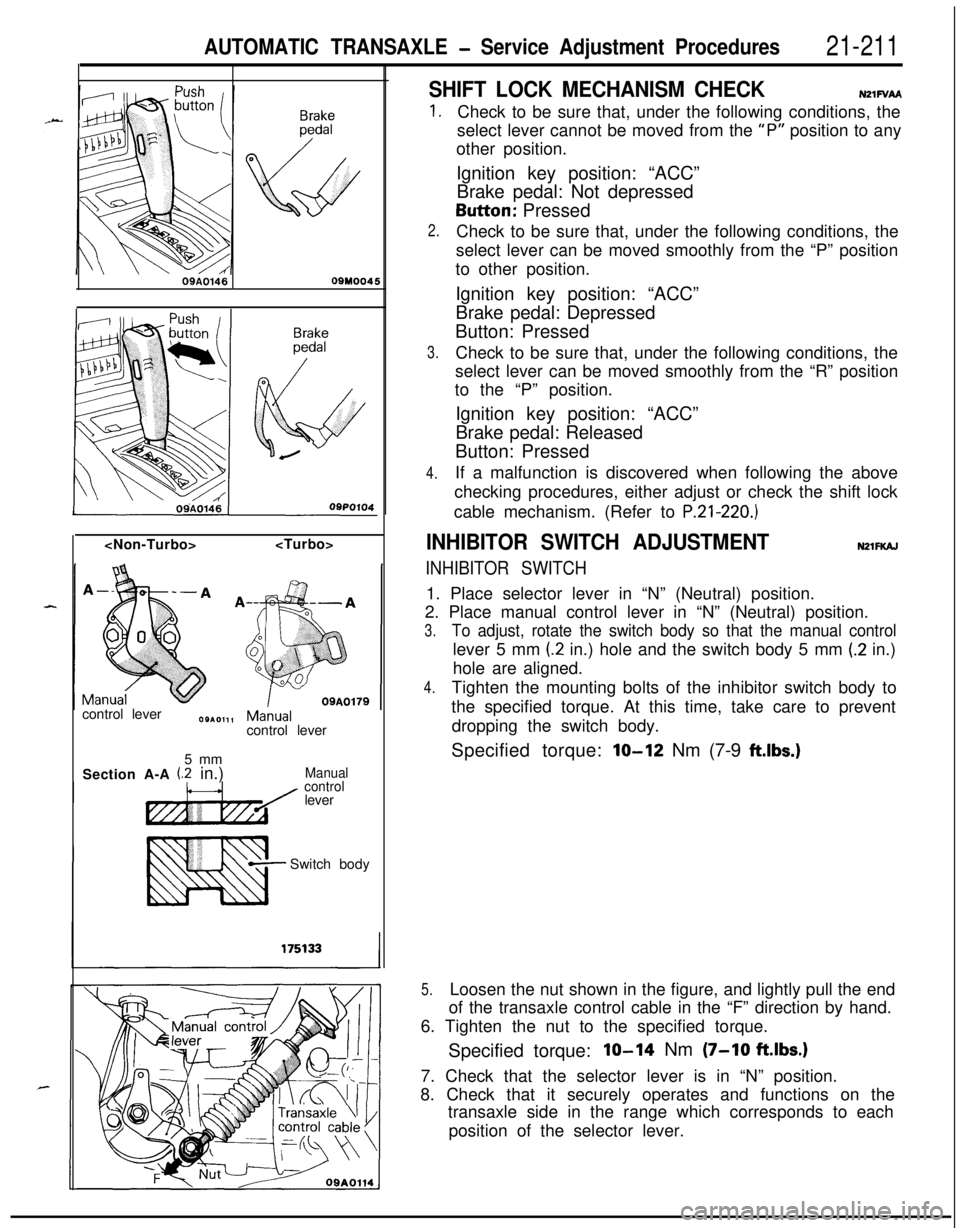

SHIFT LOCK MECHANISM CHECKN21FVAA

1.

2.

3.

4.Check to be sure that, under the following conditions, the

select lever cannot be moved from the

“P” position to any

other position.

Ignition key position: “ACC”

Brake pedal: Not depressedButton: Pressed

Check to be sure that, under the following conditions, the

select lever can be moved smoothly from the “P” position

to other position.

Ignition key position: “ACC”

Brake pedal: Depressed

Button: Pressed

Check to be sure that, under the following conditions, the

select lever can be moved smoothly from the “R” position

to the “P” position.

Ignition key position: “ACC”

Brake pedal: Released

Button: Pressed

If a malfunction is discovered when following the above

checking procedures, either adjust or check the shift lock

cable mechanism. (Refer to

P.21-220.)

INHIBITOR SWITCH ADJUSTMENTNZlFKAJ

INHIBITOR SWITCH1. Place selector lever in “N” (Neutral) position.

2. Place manual control lever in “N” (Neutral) position.

3.To adjust, rotate the switch body so that the manual controllever 5 mm

(2 in.) hole and the switch body 5 mm (.2 in.)

hole are aligned.

4.Tighten the mounting bolts of the inhibitor switch body to

the specified torque. At this time, take care to prevent

dropping the switch body.

Specified torque:

lo-12 Nm (7-9 ftlbs.)

5.Loosen the nut shown in the figure, and lightly pull the end

of the transaxle control cable in the “F” direction by hand.

6. Tighten the nut to the specified torque.

Specified torque:

IO-14 Nm (7-10 ftlbs.)7. Check that the selector lever is in “N” position.

8. Check that it securely operates and functions on the

transaxle side in the range which corresponds to each

position of the selector lever.

Page 910 of 1216

21-216AUTOMATIC TRANSAXLE - Service Adjustment Procedures

I16A0905

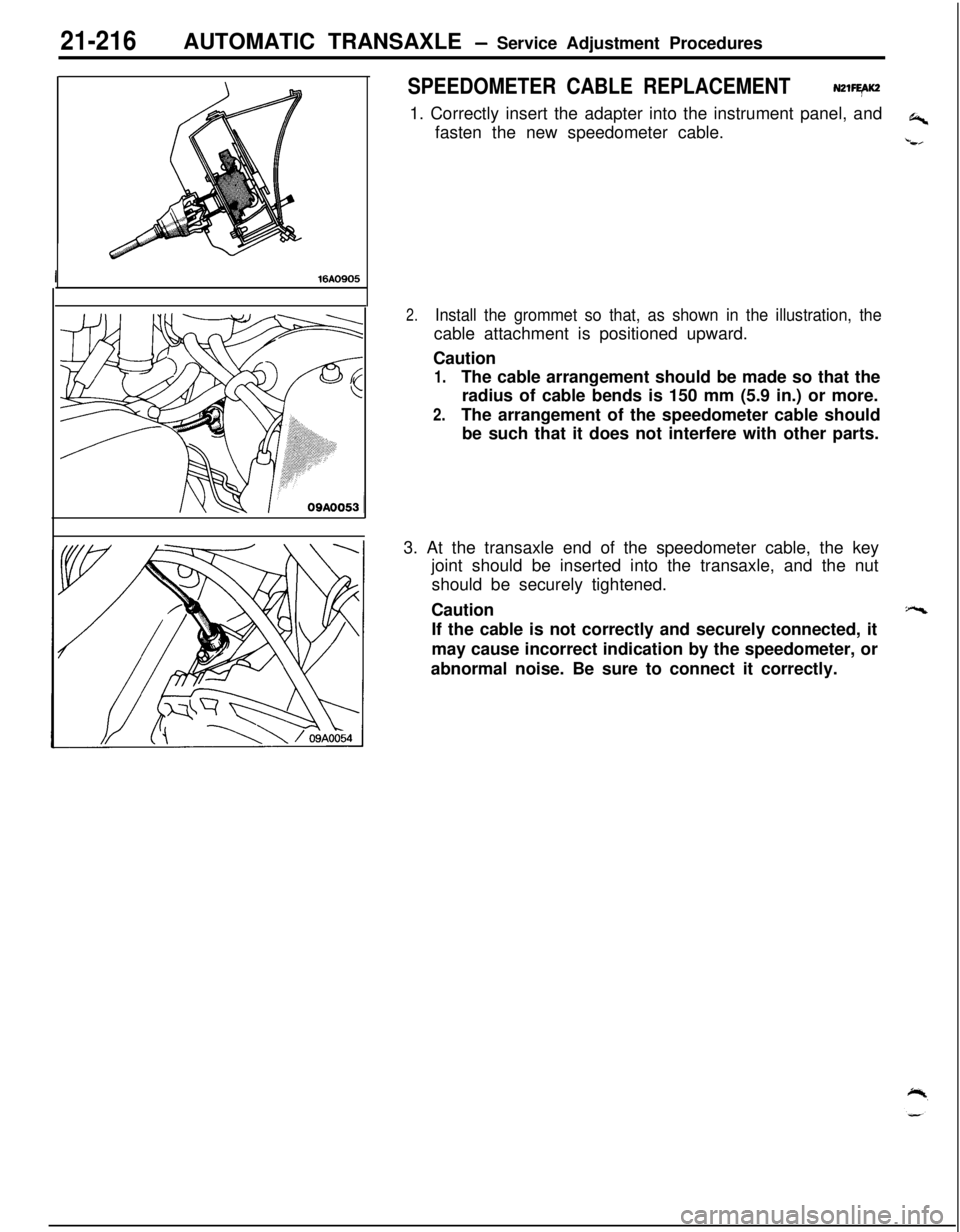

SPEEDOMETER CABLE REPLACEMENTN21FEAK2,1. Correctly insert the adapter into the instrument panel, and

+fasten the new speedometer cable.

t,

2.Install the grommet so that, as shown in the illustration, thecable attachment is positioned upward.

Caution

1.The cable arrangement should be made so that the

radius of cable bends is 150 mm (5.9 in.) or more.

2.The arrangement of the speedometer cable should

be such that it does not interfere with other parts.

3. At the transaxle end of the speedometer cable, the key

joint should be inserted into the transaxle, and the nut

should be securely tightened.

Caution

“ccIf the cable is not correctly and securely connected, it

may cause incorrect indication by the speedometer, or

abnormal noise. Be sure to connect it correctly.

Page 914 of 1216

AUTOMATIC TRANSAXLE - Transaxle Control

:lemotJnt

\\ \09R0058

09AO143

/’

\

’ CoverCoverKey interlock cableOSA0125

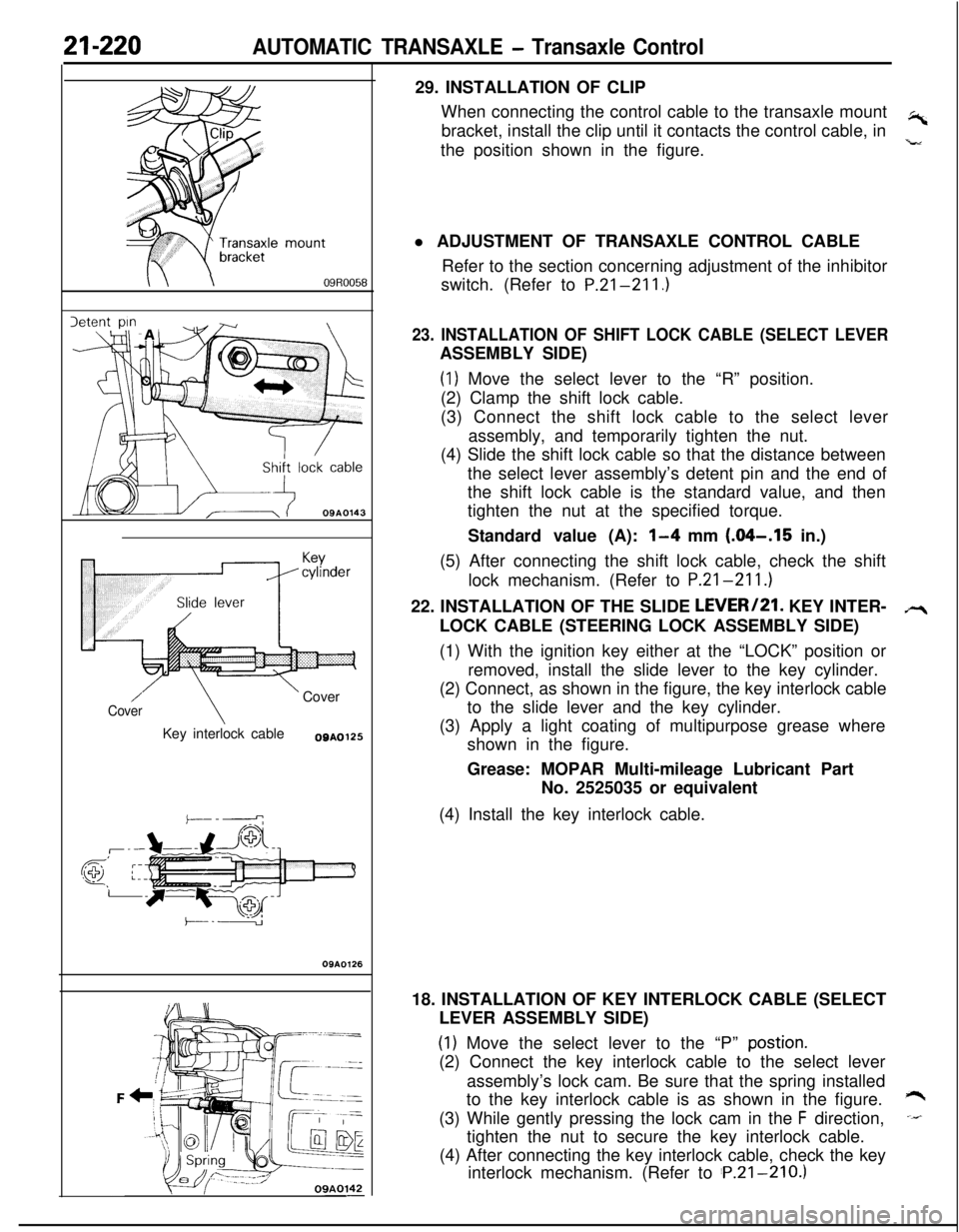

OSAO12629. INSTALLATION OF CLIP

When connecting the control cable to the transaxle mount

,-bracket, install the clip until it contacts the control cable, in

the position shown in the figure.

,”l ADJUSTMENT OF TRANSAXLE CONTROL CABLE

Refer to the section concerning adjustment of the inhibitor

switch. (Refer to P.21-211.)

23. INSTALLATION OF SHIFT LOCK CABLE (SELECT LEVERASSEMBLY SIDE)

(1) Move the select lever to the “R” position.

(2) Clamp the shift lock cable.

(3) Connect the shift lock cable to the select lever

assembly, and temporarily tighten the nut.

(4) Slide the shift lock cable so that the distance between

the select lever assembly’s detent pin and the end of

the shift lock cable is the standard value, and then

tighten the nut at the specified torque.

Standard value (A):

l-4 mm (.04-.I5 in.)

(5) After connecting the shift lock cable, check the shift

lock mechanism. (Refer to P.21-211.)

22. INSTALLATION OF THE SLIDE LEVERI21. KEY INTER-

LOCK CABLE (STEERING LOCK ASSEMBLY SIDE)

(1) With the ignition key either at the “LOCK” position or

removed, install the slide lever to the key cylinder.

(2) Connect, as shown in the figure, the key interlock cable

to the slide lever and the key cylinder.

(3) Apply a light coating of multipurpose grease where

shown in the figure.

Grease: MOPAR Multi-mileage Lubricant Part

No. 2525035 or equivalent

(4) Install the key interlock cable.

18. INSTALLATION OF KEY INTERLOCK CABLE (SELECT

LEVER ASSEMBLY SIDE)

(1) Move the select lever to the “P” postion.(2) Connect the key interlock cable to the select lever

assembly’s lock cam. Be sure that the spring installed

to the key interlock cable is as shown in the figure.

*(3) While gently pressing the lock cam in the

F direction,-tighten the nut to secure the key interlock cable.

(4) After connecting the key interlock cable, check the key

interlock mechanism. (Refer to ‘P.21-210.)