ECU MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 921 of 1216

AUTOMATIC TRANSAXLE - Transaxle Assemblv

-MB991 11312K513Pry bar

*Transaxle

llK611

SERVICE POINTS OF REMOVALN2llEAK

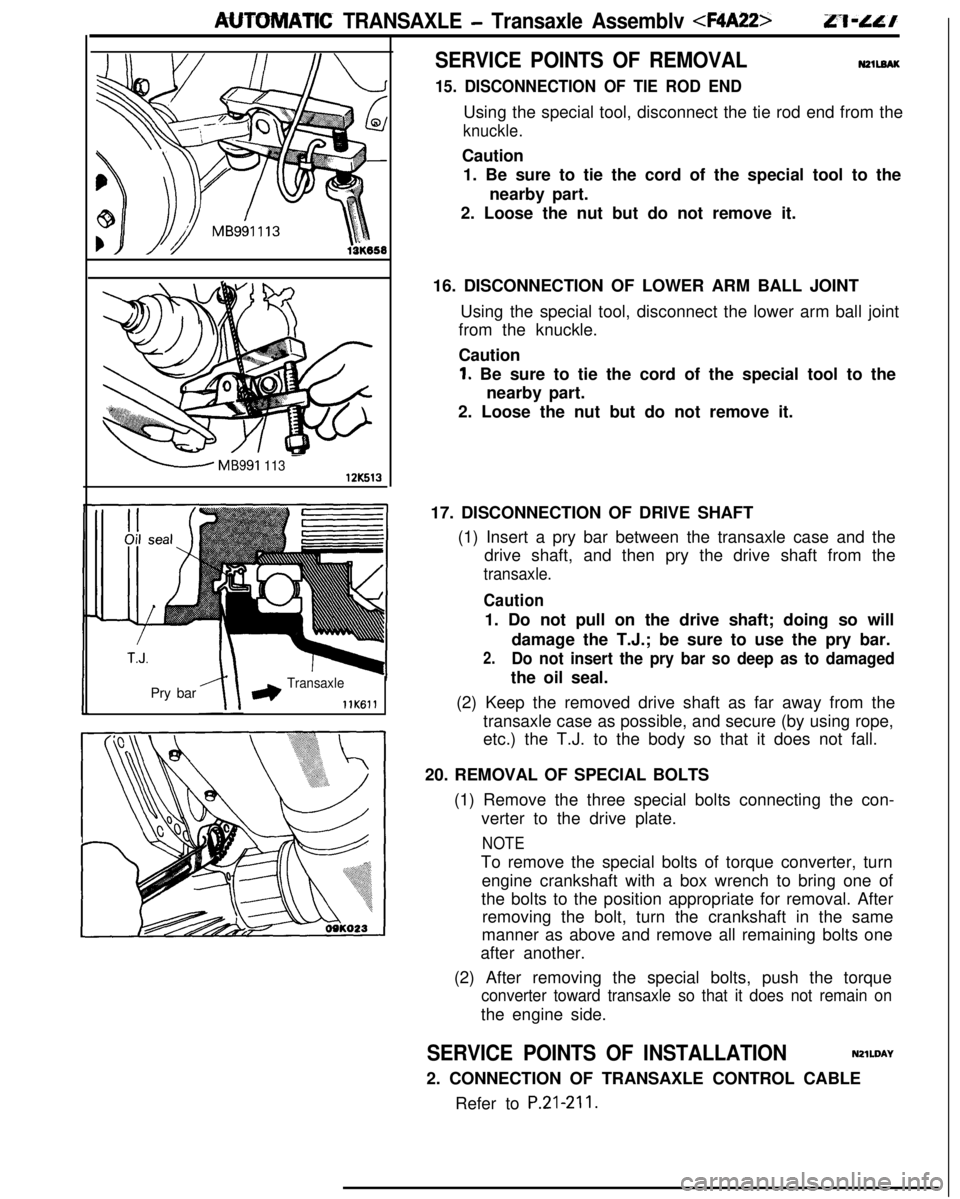

15. DISCONNECTION OF TIE ROD ENDUsing the special tool, disconnect the tie rod end from the

knuckle.Caution

1. Be sure to tie the cord of the special tool to the

nearby part.

2. Loose the nut but do not remove it.

16. DISCONNECTION OF LOWER ARM BALL JOINT

Using the special tool, disconnect the lower arm ball joint

from the knuckle.

Caution

1. Be sure to tie the cord of the special tool to the

nearby part.

2. Loose the nut but do not remove it.

17. DISCONNECTION OF DRIVE SHAFT

(1) Insert a pry bar between the transaxle case and the

drive shaft, and then pry the drive shaft from the

transaxle.

Caution1. Do not pull on the drive shaft; doing so will

damage the T.J.; be sure to use the pry bar.

2.Do not insert the pry bar so deep as to damagedthe oil seal.

(2) Keep the removed drive shaft as far away from the

transaxle case as possible, and secure (by using rope,

etc.) the T.J. to the body so that it does not fall.

20. REMOVAL OF SPECIAL BOLTS

(1) Remove the three special bolts connecting the con-

verter to the drive plate.

NOTETo remove the special bolts of torque converter, turn

engine crankshaft with a box wrench to bring one of

the bolts to the position appropriate for removal. After

removing the bolt, turn the crankshaft in the same

manner as above and remove all remaining bolts one

after another.

(2) After removing the special bolts, push the torque

converter toward transaxle so that it does not remain onthe engine side.

SERVICE POINTS OF INSTALLATIONN2lWAY

2. CONNECTION OF TRANSAXLE CONTROL CABLE

Refer to

P.21-211.

Page 952 of 1216

AUTOMATIC TRANSAXLE - Transaxle Assembly

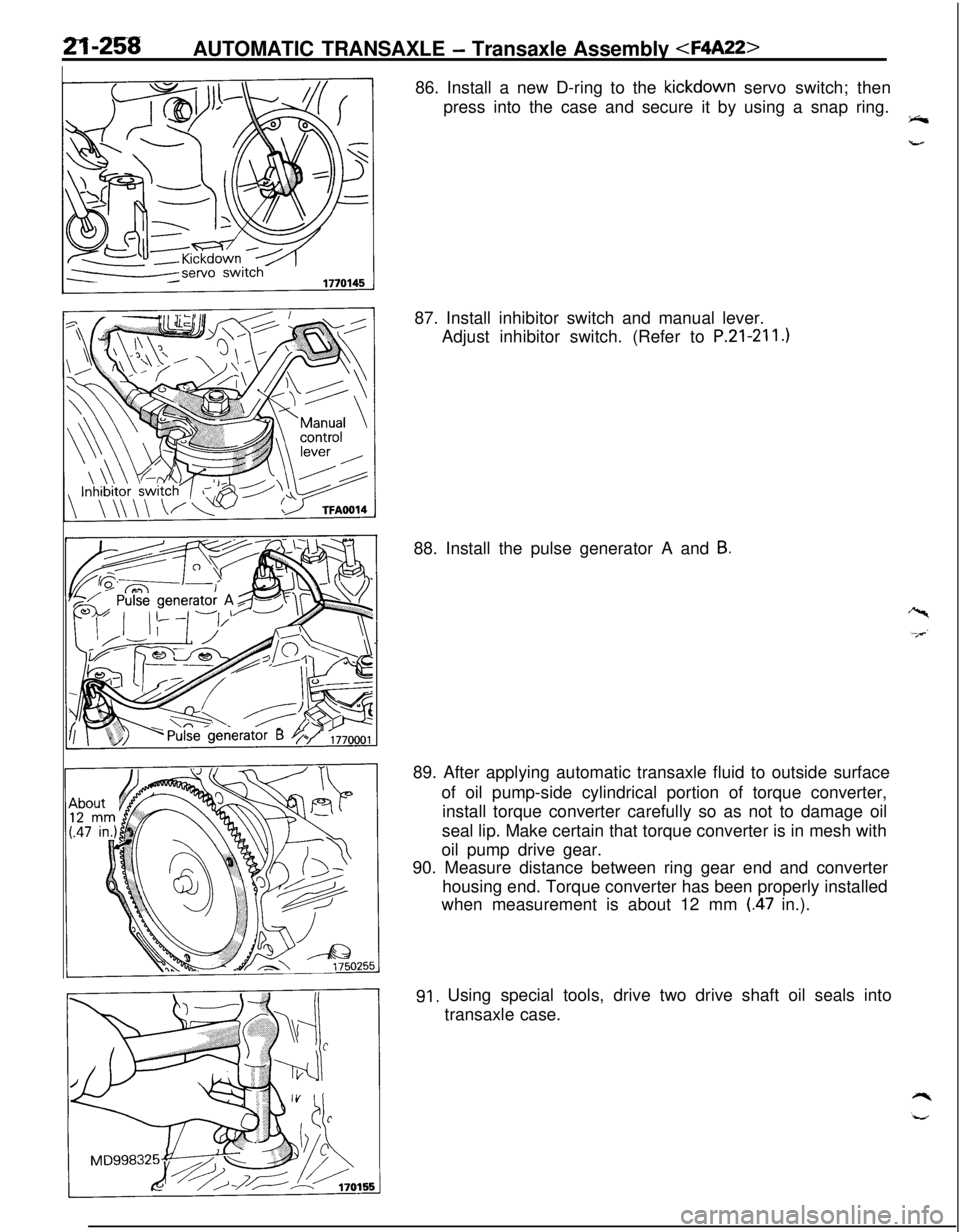

press into the case and secure it by using a snap ring.

87. Install inhibitor switch and manual lever.

Adjust inhibitor switch. (Refer to

P.21-211.)88. Install the pulse generator A and

B.89. After applying automatic transaxle fluid to outside surface

of oil pump-side cylindrical portion of torque converter,

install torque converter carefully so as not to damage oil

seal lip. Make certain that torque converter is in mesh with

oil pump drive gear.

90. Measure distance between ring gear end and converter

housing end. Torque converter has been properly installed

when measurement is about 12 mm

(.47 in.).

91. Using special tools, drive two drive shaft oil seals into

transaxle case.

Page 957 of 1216

AUTOMATR: TRANSAXLE - Transaxle Assemblv

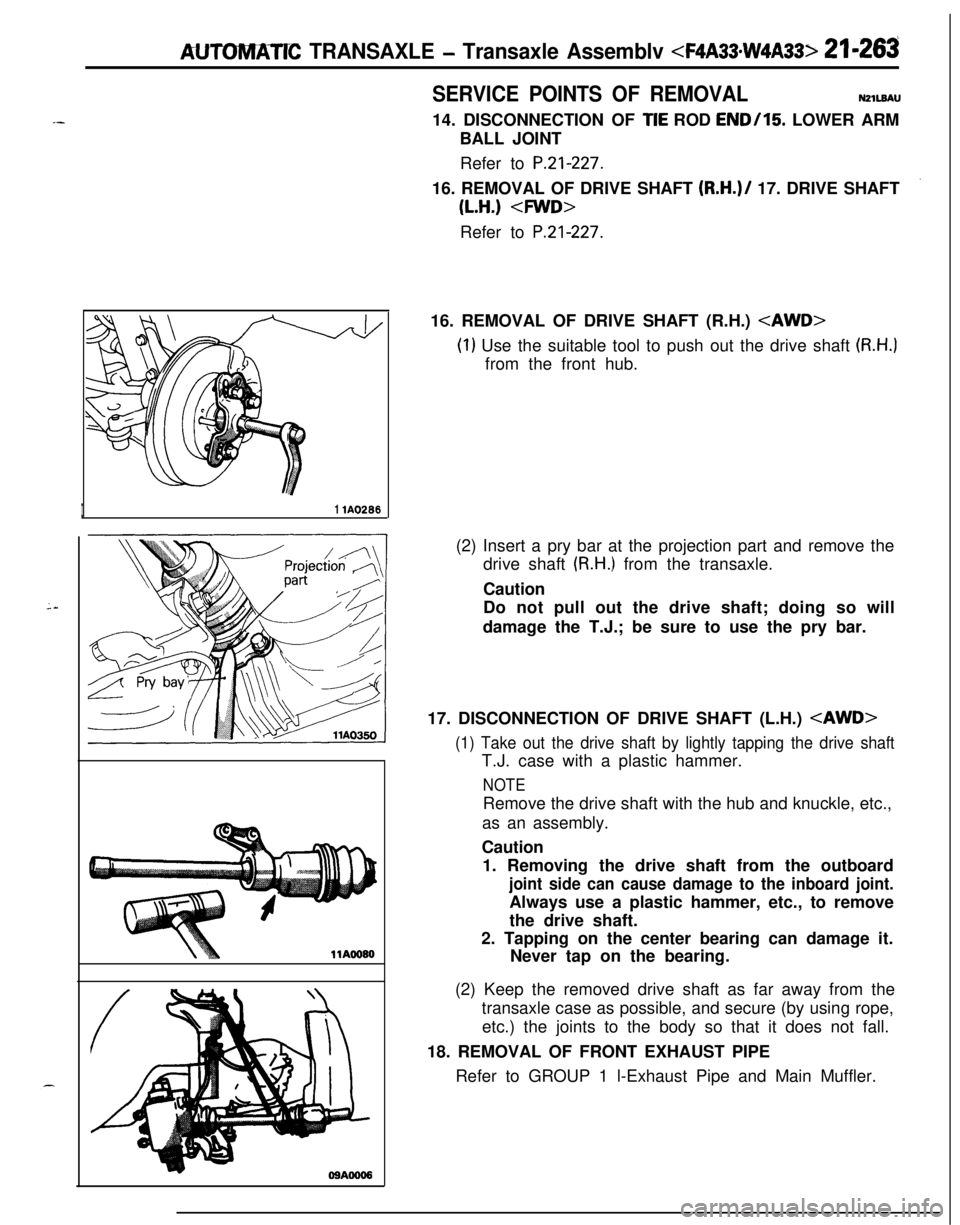

SERVICE POINTS OF REMOVALNZlL8AU14. DISCONNECTION OF

TIE ROD END/15 LOWER ARM

BALL JOINT

Refer to

P.21-227.16. REMOVAL OF DRIVE SHAFT

(R.H.)/ 17. DRIVE SHAFT

(L.H.)

P.21-227.16. REMOVAL OF DRIVE SHAFT (R.H.)

(1) Use the suitable tool to push out the drive shaft (R.H.]from the front hub.

I1 lA0288(2) Insert a pry bar at the projection part and remove the

drive shaft

(R.H.) from the transaxle.

Caution

Do not pull out the drive shaft; doing so will

damage the T.J.; be sure to use the pry bar.

17. DISCONNECTION OF DRIVE SHAFT (L.H.)

(1) Take out the drive shaft by lightly tapping the drive shaftT.J. case with a plastic hammer.

NOTERemove the drive shaft with the hub and knuckle, etc.,

as an assembly.

Caution

1. Removing the drive shaft from the outboard

joint side can cause damage to the inboard joint.Always use a plastic hammer, etc., to remove

the drive shaft.

2. Tapping on the center bearing can damage it.

Never tap on the bearing.

(2) Keep the removed drive shaft as far away from the

transaxle case as possible, and secure (by using rope,

etc.) the joints to the body so that it does not fall.

18. REMOVAL OF FRONT EXHAUST PIPE

Refer to GROUP 1 l-Exhaust Pipe and Main Muffler.

Page 990 of 1216

21-296 AUTOMATIC TRANSAXLE - Transaxle Assembly

77. Install an O-ring in the O-ring groove on top of the valve

body assembly.

78. Replace the solenoid valve harness grommet O-ring with anew O-ring.

79. Pass the solenoid valve connector through from the inside

of the transaxle case hole.

80. Insert the solenoid valve harness grommet in the case hole.,**%4

81. Temporarily install the valve body while inserting the detentplate pin in the manual valve groove. Then install the oil

temperature sensor and holder and tighten the bolts with

the specified torque.

A bolt

= 18 mm (.71 in.)

B bolt = 25 mm (.98 in.)

C bolt = 40 mm (1.57 in.)

Valve body assembly mounting bolts:

lo-12 Nm (7.5-8.5 fklbs.)

Caution

Fix the solenoid valve and oil temperature sensor

harness securely in the position shown.

82. Install the oil filter.

Oil filter mounting bolts: 5-7 Nm (4-5

ft.lbs.1

Page 992 of 1216

21-298 AUTOMATIC TRANSAXLE - Transaxle Assembly

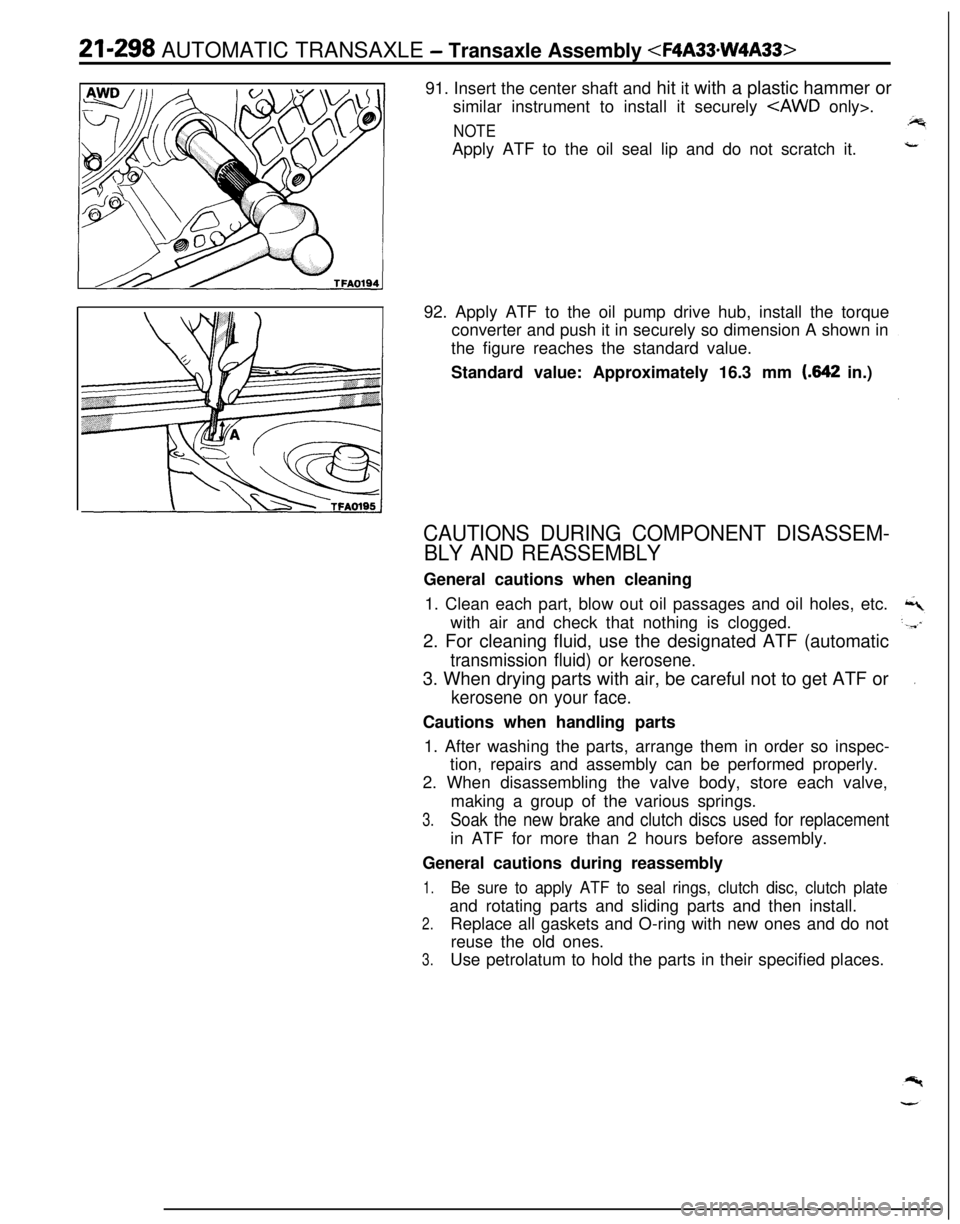

similar instrument to install it securely

NOTEApply ATF to the oil seal lip and do not scratch it.

92. Apply ATF to the oil pump drive hub, install the torque

converter and push it in securely so dimension A shown in

the figure reaches the standard value.

Standard value: Approximately 16.3 mm

(.642 in.)

CAUTIONS DURING COMPONENT DISASSEM-

BLY AND REASSEMBLYGeneral cautions when cleaning

1. Clean each part, blow out oil passages and oil holes, etc.

with air and check that nothing is clogged.

2. For cleaning fluid, use the designated ATF (automatic

transmission fluid) or kerosene.3. When drying parts with air, be careful not to get ATF or

kerosene on your face.Cautions when handling parts

1. After washing the parts, arrange them in order so inspec-

tion, repairs and assembly can be performed properly.

2. When disassembling the valve body, store each valve,

making a group of the various springs.

3.Soak the new brake and clutch discs used for replacementin ATF for more than 2 hours before assembly.

General cautions during reassembly

1.Be sure to apply ATF to seal rings, clutch disc, clutch plateand rotating parts and sliding parts and then install.

2.Replace all gaskets and O-ring with new ones and do not

reuse the old ones.

3.Use petrolatum to hold the parts in their specified places.

Page 1011 of 1216

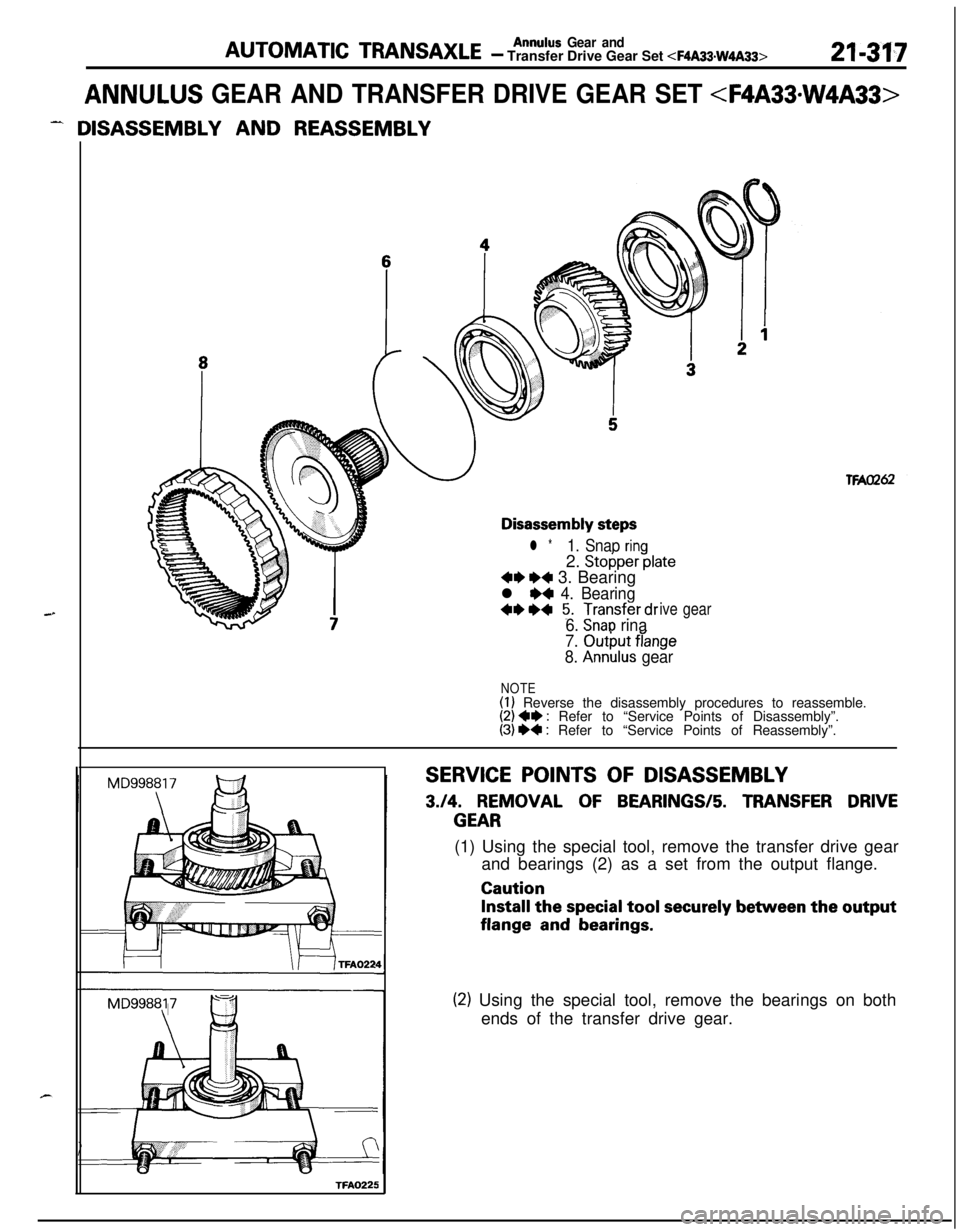

AUTOMATIC TRANSAXLEAnnulus Gear and- Transfer Drive Gear Set 44A33.W4A33>21-317

ANNULUS GEAR AND TRANSFER DRIVE GEAR SET

- DISASSEMBLY AND REASSEMBLY

Disassembly steps

l *1. Snap ring2.

Stopperplate

4eI)+ 3. Bearing

l W 4. Bearing

We+ 5. Transferdrive gear

6. Snar, rina

7.

Outbut frange

8. Annulus gear

NOTE(I) Reverse the disassembly procedures to reassemble.(2) +e : Refer to “Service Points of Disassembly”.(3) ++ : Refer to “Service Points of Reassembly”.

TFA0225

SERVICE POINTS OF DISASSEMBLY

3.14. REMOVAL OF BEARINGW5. TRANSFER DRIVE

GEAR(1) Using the special tool, remove the transfer drive gear

and bearings (2) as a set from the output flange.Caution

Install the special tool securely between the outputflange

and bearings.

) Using the special tool, remove the bearings on both

ends of the transfer drive gear.

Page 1021 of 1216

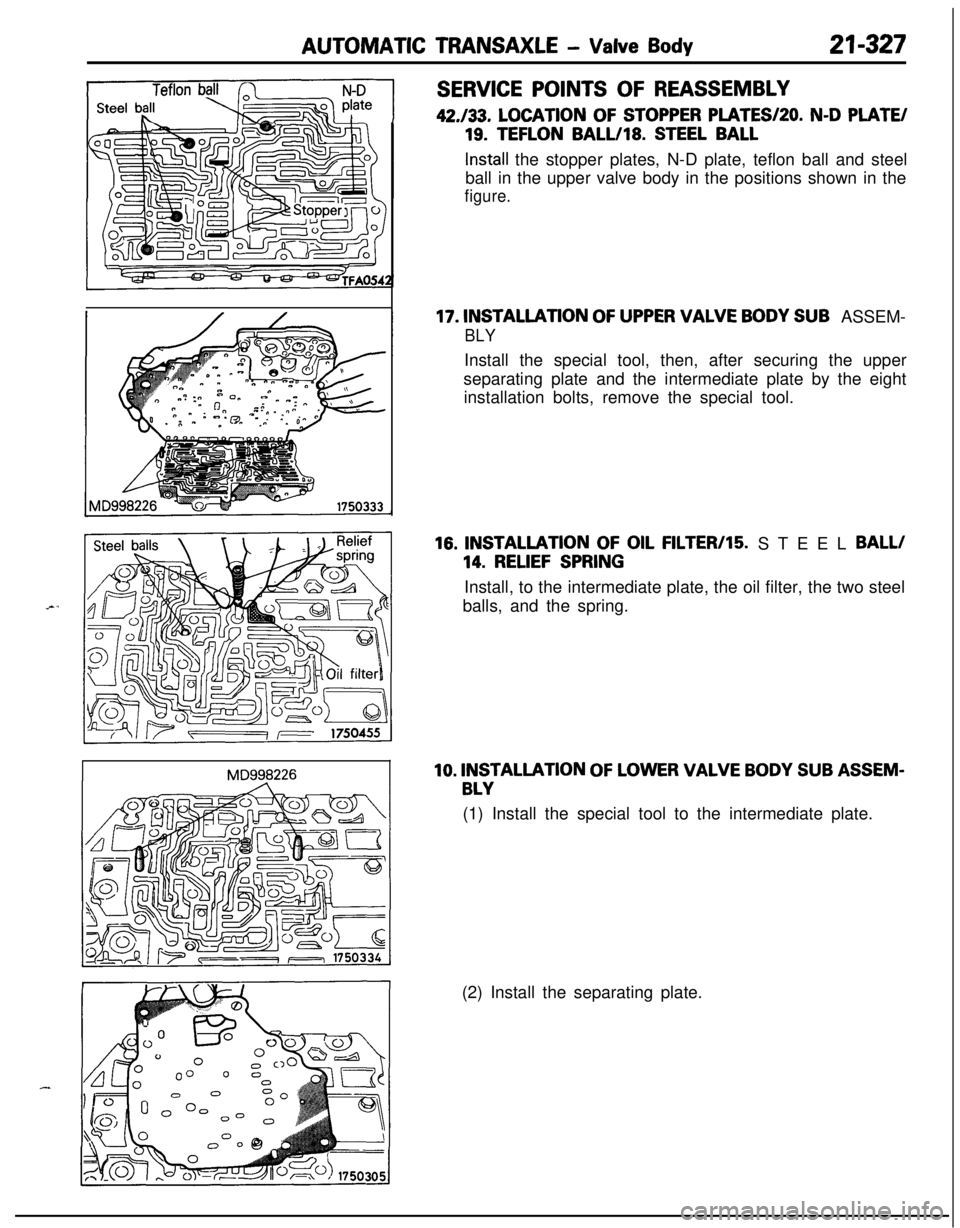

AUTOMATIC TRANSAXLE - Valve Body21-327

SERVICE POINTS OF REASSEMBLY42./33.

LOCATION OF STOPPER PLATES/SO. N-D PLATE/

19. TEFLON BALL/18. STEEL BALL

Install the stopper plates, N-D plate, teflon ball and steel

ball in the upper valve body in the positions shown in the

figure.

17. INSTALLATION OF UPPER VALVE BODY SUB ASSEM-

BLYInstall the special tool, then, after securing the upper

separating plate and the intermediate plate by the eight

installation bolts, remove the special tool.

MD998226

18. INSTALLATION OF OIL FILTER/IS. STEEL BALL/

14. RELIEF SPRINGInstall, to the intermediate plate, the oil filter, the two steel

balls, and the spring.

10. INSTALLATION OF LOWER VALVE BODY SUB ASSEM-

BLY(1) Install the special tool to the intermediate plate.

(2) Install the separating plate.

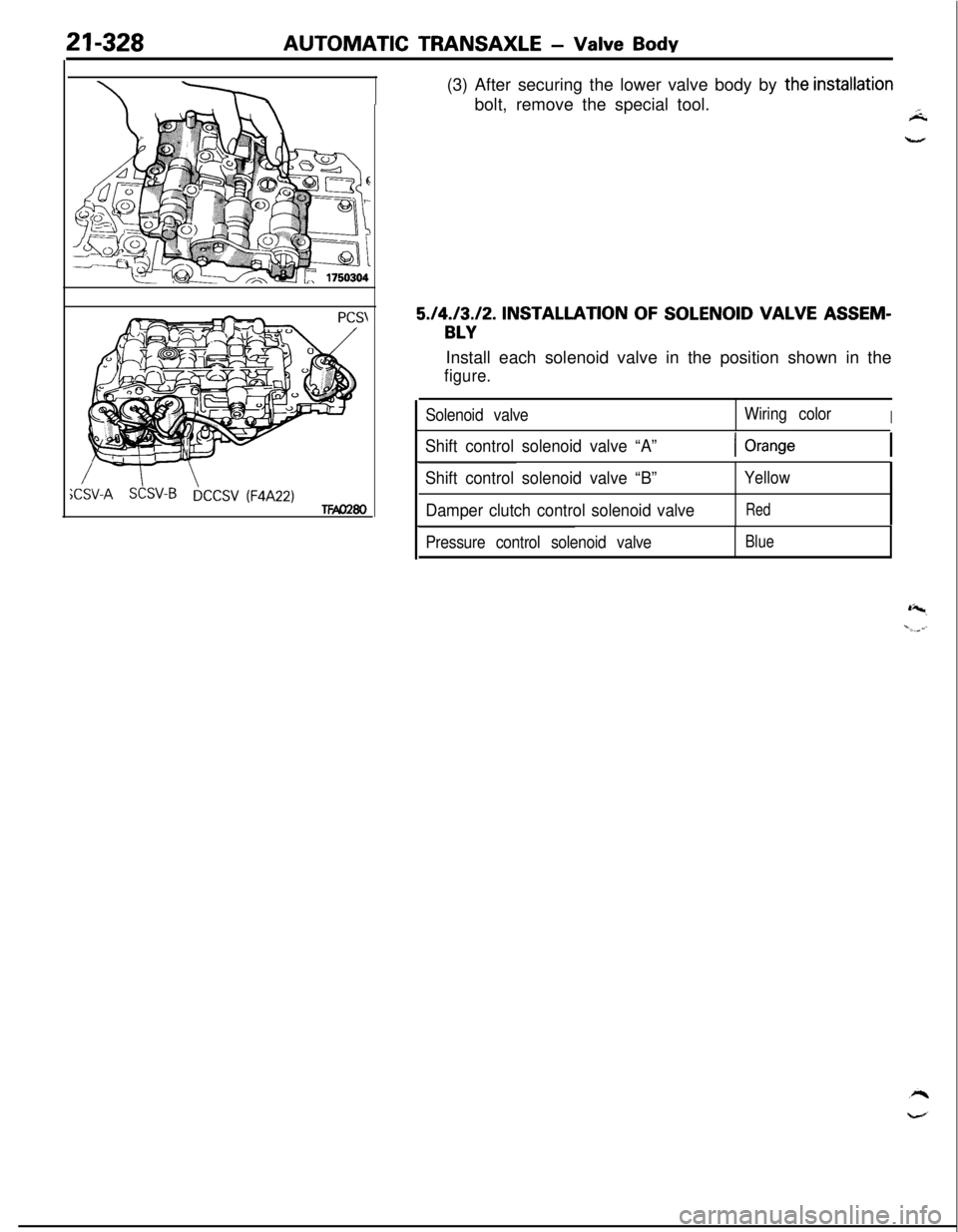

Page 1022 of 1216

21-328AUTOMATIC TRANSAXLE - Valve Bodv

XSV-ASkV-Brj,,SV (FJA22)TFAM80(3) After securing the lower valve body by

the installationbolt, remove the special tool.

Sk

5./4./3./2. INSTALLATION OF SOLENOID VALVE ASSEM-

BLYInstall each solenoid valve in the position shown in the

figure.

Solenoid valveWiring colorI

Shift control solenoid valve “A”

Shift control solenoid valve “B”

Damper clutch control solenoid valve

Yellow

Red

Pressure control solenoid valveBlue

Page 1102 of 1216

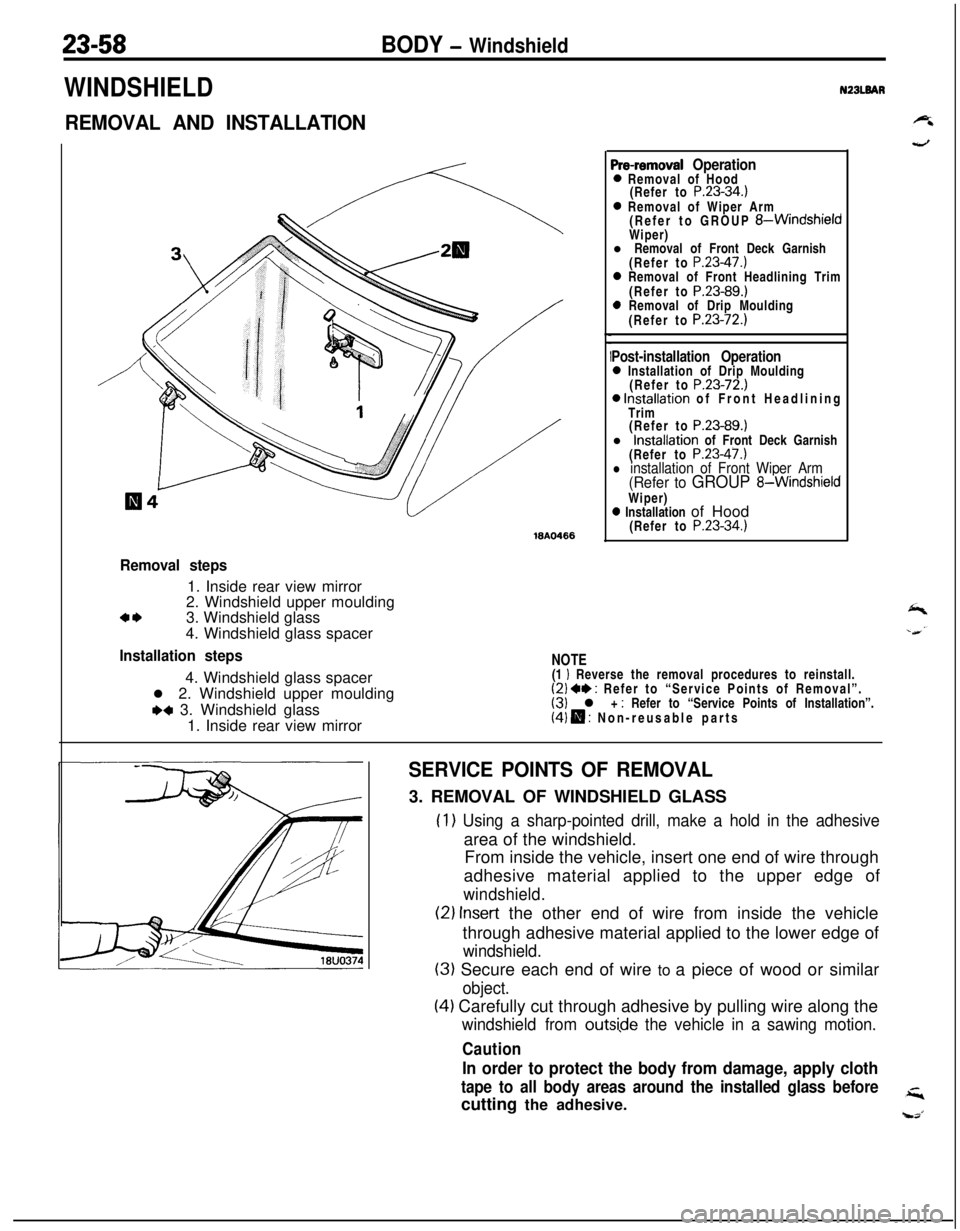

23-58BODY - Windshield

WINDSHIELD

REMOVAL AND INSTALLATION

ISA0466

Pre-removal Operation0 Removal of Hood

(Refer to P.23-34.)0 Removal of Wiper Arm

(Refer to GROUP &WindshieldWiper)

l Removal of Front Deck Garnish

(Refer to

P.23-47.)0 Removal of Front Headlining Trim

(Refer to P.23-89.)0 Removal of Drip Moulding

(Refer to P.23-72.)

Post-installation Operation0 Installation of Drip Moulding

(Refer to P.23-72.)0 Installation of Front Headlining

Trim

(Refer to

P.23-89.)l Installation of Front Deck Garnish

(Refer to

P.23-47.)l installation of Front Wiper Arm(Refer to GROUP 8-WindshieldWiper)

0 Installation of Hood

(Refer to P.23-34.)

NZBLBAR

,

Removal steps1. Inside rear view mirror

2. Windshield upper moulding

a*3. Windshield glass

4. Windshield glass spacer

Installation steps4. Windshield glass spacer

l 2. Windshield upper moulding

+a 3. Windshield glass

1. Inside rear view mirror

NOTE(1 I Reverse the removal procedures to reinstall.(2) +* : Refer to “Service Points of Removal”.(3) l + : Refer to “Service Points of Installation”.(4) H : Non-reusable parts

SERVICE POINTS OF REMOVAL3. REMOVAL OF WINDSHIELD GLASS

(1) Using a sharp-pointed drill, make a hold in the adhesivearea of the windshield.

From inside the vehicle, insert one end of wire through

adhesive material applied to the upper edge of

windshield.

(2) Insert the other end of wire from inside the vehicle

through adhesive material applied to the lower edge of

windshield.

(3) Secure each end of wire to a piece of wood or similar

object.

(4) Carefully cut through adhesive by pulling wire along the

windshield from outsi,de the vehicle in a sawing motion.

Caution

In order to protect the body from damage, apply cloth

tape to all body areas around the installed glass beforecutting the adhesive.

Page 1104 of 1216

23-60BODY - Windshield

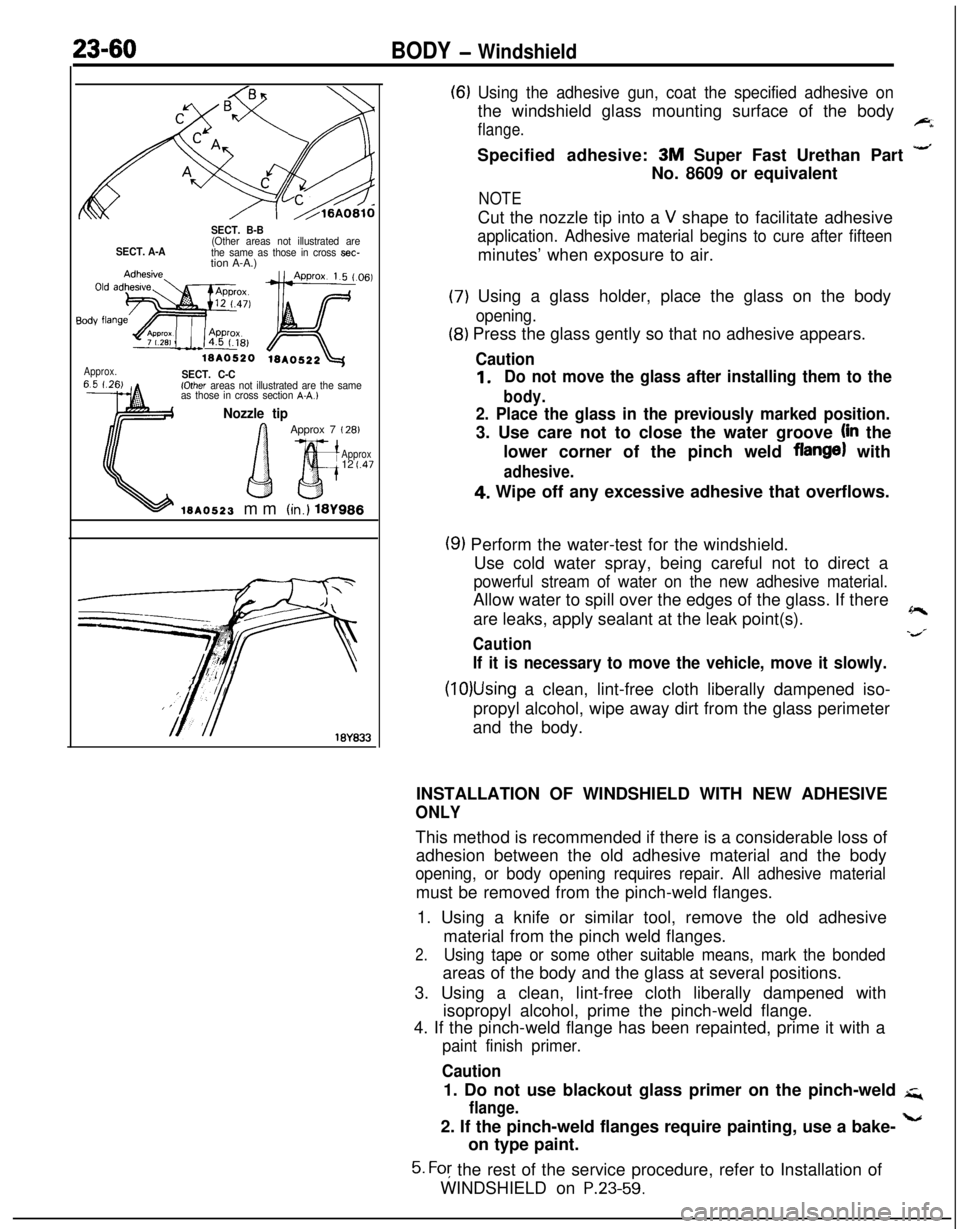

SECT. B-B

SECT. A-A(Other areas not illustrated are

the same as those in cross aec-tion A-A.)

Approx.ISA0520 iSAo522&jSECT. C-C(Other areas not illustrated are the same

as those in cross section A-A.1

Nozzle tip

G QApprox 7

I 28)

Approx12

t.47

1.3~0523 mm (in.) 181988

(6) Using the adhesive gun, coat the specified adhesive onthe windshield glass mounting surface of the body

flange.FiSpecified adhesive:

3M Super Fast Urethan Part -No. 8609 or equivalent

NOTECut the nozzle tip into a

V shape to facilitate adhesive

application. Adhesive material begins to cure after fifteenminutes’ when exposure to air.

(7) Using a glass holder, place the glass on the body

opening.

(8) Press the glass gently so that no adhesive appears.

Caution

1.Do not move the glass after installing them to the

body.

2. Place the glass in the previously marked position.3. Use care not to close the water groove

(in the

lower corner of the pinch weld

flange) with

adhesive.4. Wipe off any excessive adhesive that overflows.

(9) Perform the water-test for the windshield.

Use cold water spray, being careful not to direct a

powerful stream of water on the new adhesive material.Allow water to spill over the edges of the glass. If there

are leaks, apply sealant at the leak point(s).

~

Cautions/

If it is necessary to move the vehicle, move it slowly.

(10)Using a clean, lint-free cloth liberally dampened iso-

propyl alcohol, wipe away dirt from the glass perimeter

and the body.

INSTALLATION OF WINDSHIELD WITH NEW ADHESIVE

ONLYThis method is recommended if there is a considerable loss of

adhesion between the old adhesive material and the body

opening, or body opening requires repair. All adhesive materialmust be removed from the pinch-weld flanges.

1. Using a knife or similar tool, remove the old adhesive

material from the pinch weld flanges.

2.Using tape or some other suitable means, mark the bondedareas of the body and the glass at several positions.

3. Using a clean, lint-free cloth liberally dampened with

isopropyl alcohol, prime the pinch-weld flange.

4. If the pinch-weld flange has been repainted, prime it with a

paint finish primer.

Caution1. Do not use blackout glass primer on the pinch-weld

q

flange.2. If the pinch-weld flanges require painting, use a bake-

Lon type paint.

5. For the rest of the service procedure, refer to Installation of

WINDSHIELD on

P.23-59.