MITSUBISHI ECLIPSE 1991 Service Manual

Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 1211 of 1216

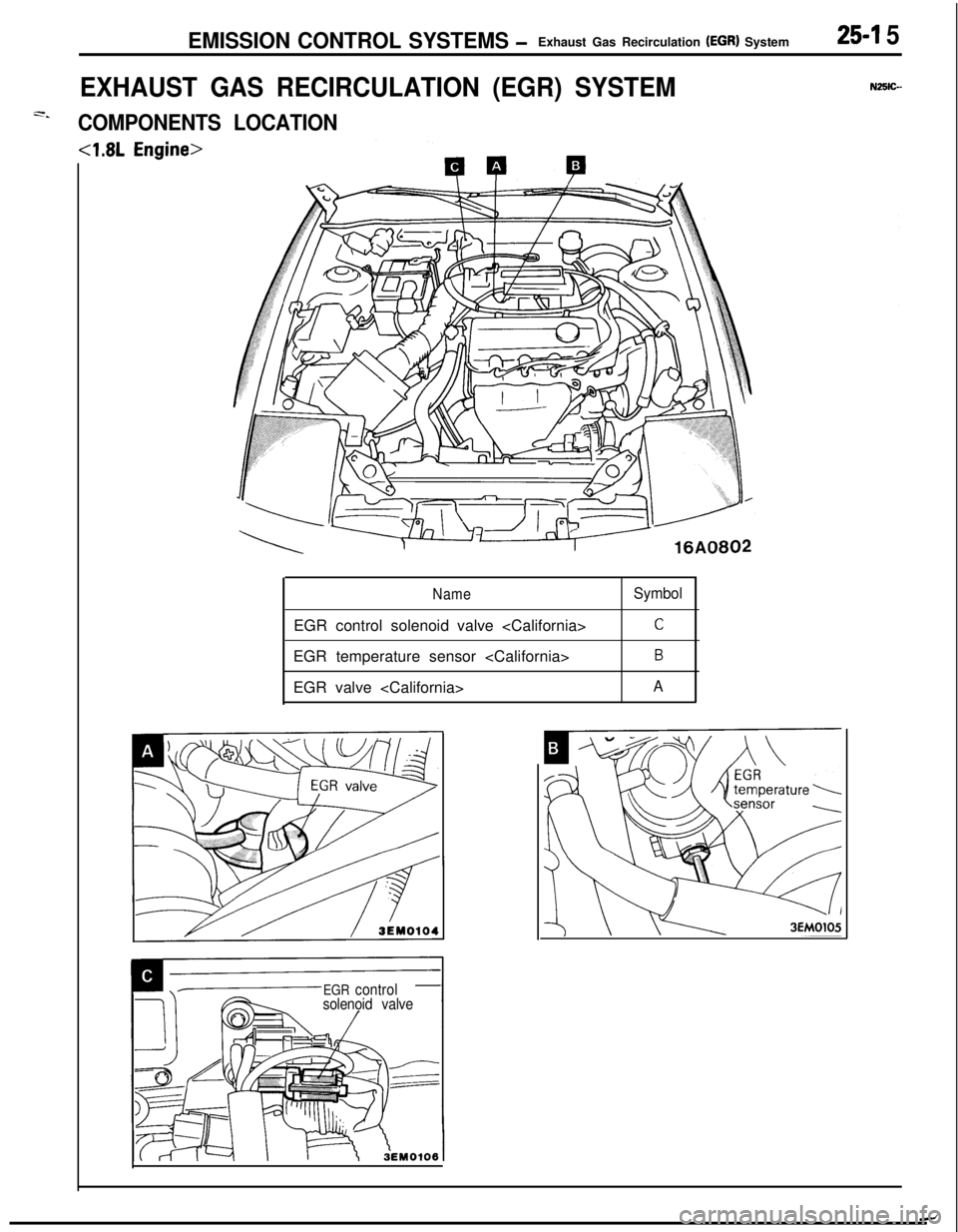

EMISSION CONTROL SYSTEMS -Exhaust Gas Recirculation (EGR) System25-l 5

EXHAUST GAS RECIRCULATION (EGR) SYSTEMN2!5lC-

2,COMPONENTS LOCATION

NameSymbolEGR control solenoid valve

CEGR temperature sensor

BEGR valve

A

EGR control

solenoid valve

Page 1212 of 1216

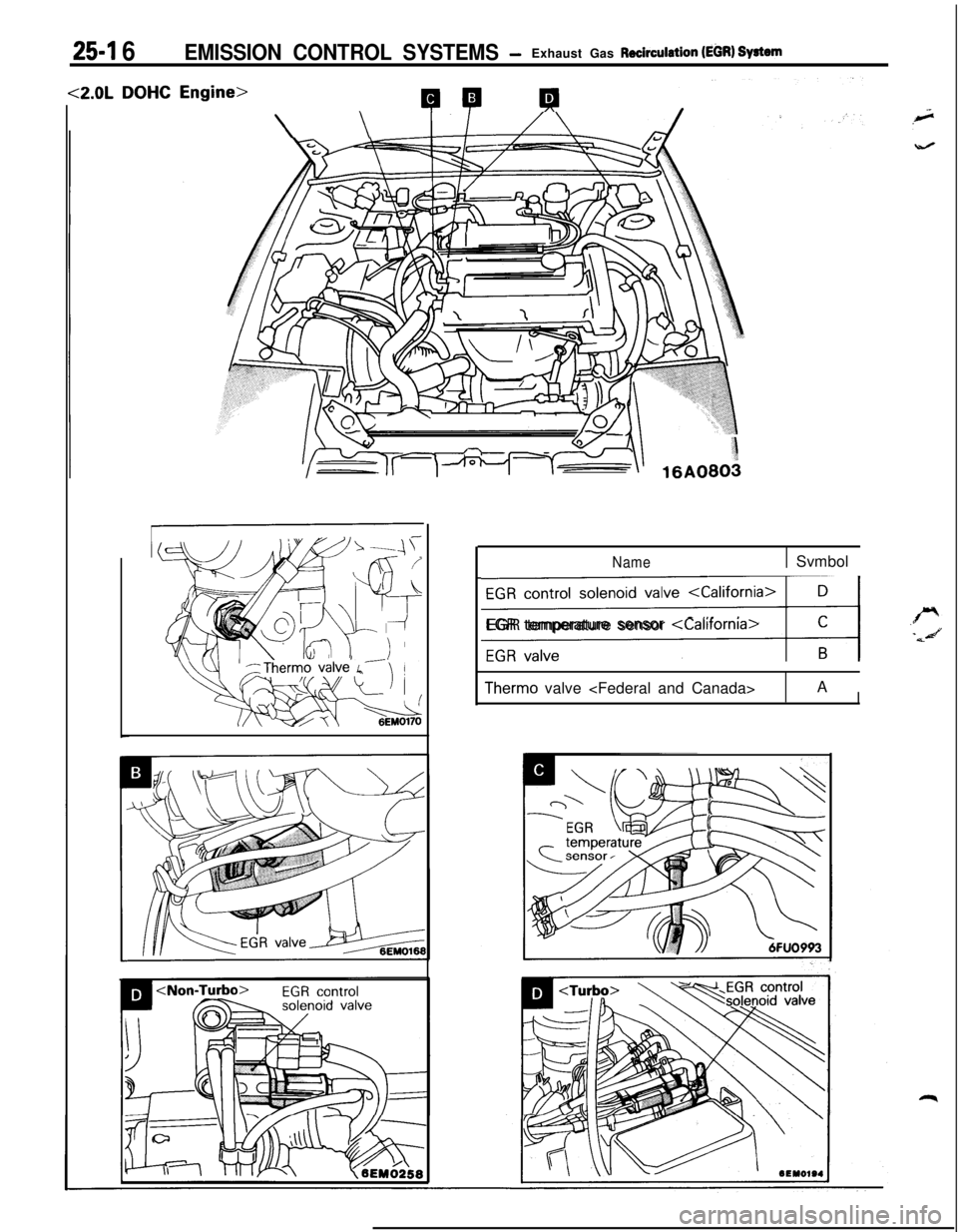

25-l 6EMISSION CONTROL SYSTEMS -Exhaust Gas Recirculation (EOR) SWem

4B

\\

‘\

16A0803

Name1 Svmbol

EGR control solenoid valve

D

IEGR temperature sensor

Therm0 valve

Page 1213 of 1216

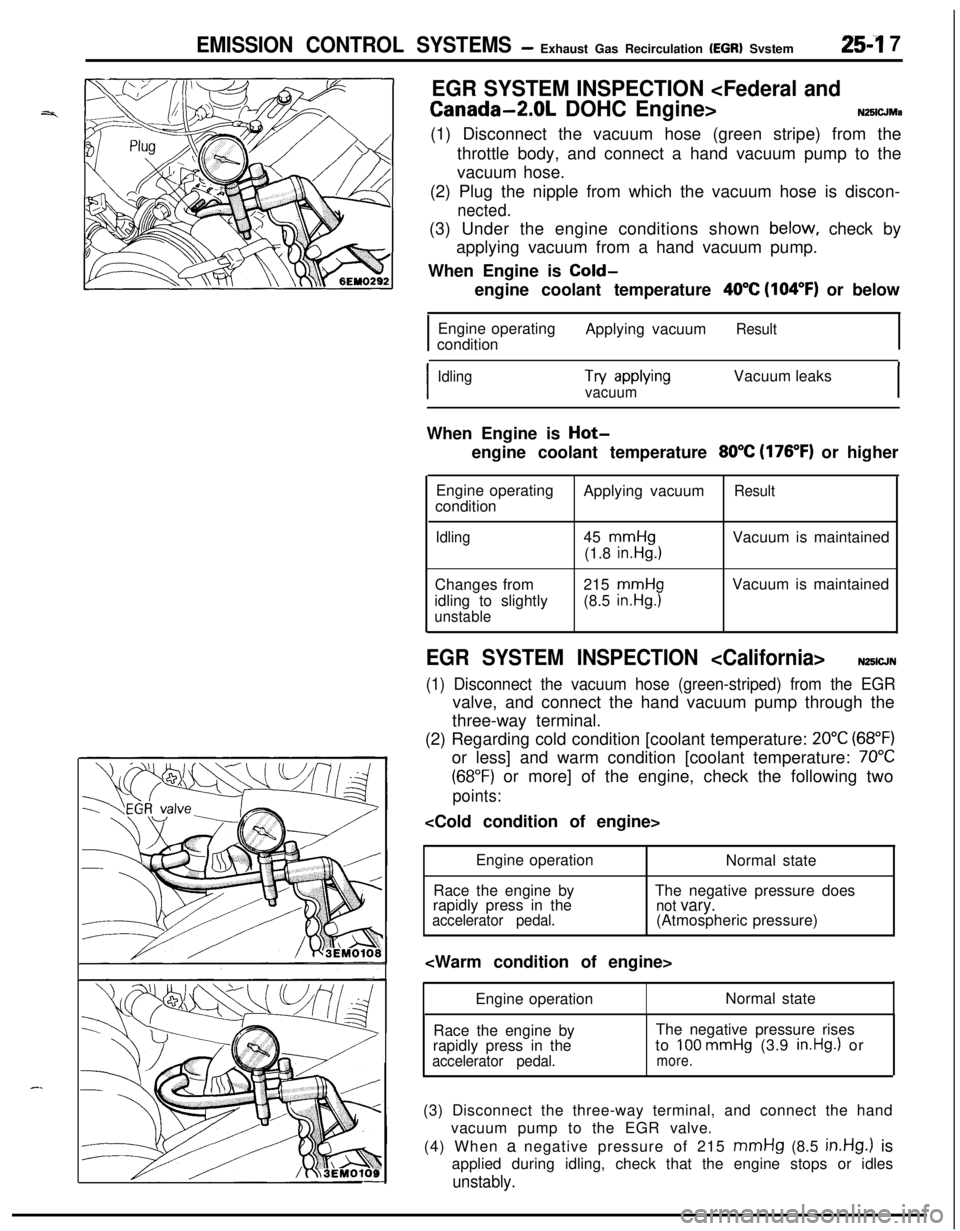

EMISSION CONTROL SYSTEMS- Exhaust Gas Recirculation (EGR) Svstem254 7

EGR SYSTEM INSPECTION

throttle body, and connect a hand vacuum pump to the

vacuum hose.

(2) Plug the nipple from which the vacuum hose is discon-

nected.(3) Under the engine conditions shown

below, check by

applying vacuum from a hand vacuum pump.

When Engine is

Cold-engine coolant temperature

40°C (104°F) or below

Engine operating

conditionApplying vacuum

Result

I

IdlingTry awMngVacuum leaksvacuumIWhen Engine is

Hot-engine coolant temperature

80°C (176°F) or higher

Engine operating

conditionApplying vacuum

Result

Idling45

mmHg(1.8

in.Hg.1Vacuum is maintained

Changes from

idling to slightly

unstable215

mmHg(8.5

in.Hg.1Vacuum is maintained

EGR SYSTEM INSPECTION

(1) Disconnect the vacuum hose (green-striped) from the EGRvalve, and connect the hand vacuum pump through the

three-way terminal.

(2) Regarding cold condition [coolant temperature:

20°C (68°F)or less] and warm condition [coolant temperature:

70°C

(68°F) or more] of the engine, check the following two

points:

Engine operation

Normal state

Race the engine byThe negative pressure does

rapidly press in the

not vary.accelerator pedal.(Atmospheric pressure)

Engine operationNormal state

Race the engine by

rapidly press in the

accelerator pedal.The negative pressure rises

to

100 mmHg (3.9 in.Hg.1 ormore.(3) Disconnect the three-way terminal, and connect the hand

vacuum pump to the EGR valve.

(4) When a negative pressure of 215

mmHg (8.5 in.Hg.) is

applied during idling, check that the engine stops or idles

unstably.

Page 1214 of 1216

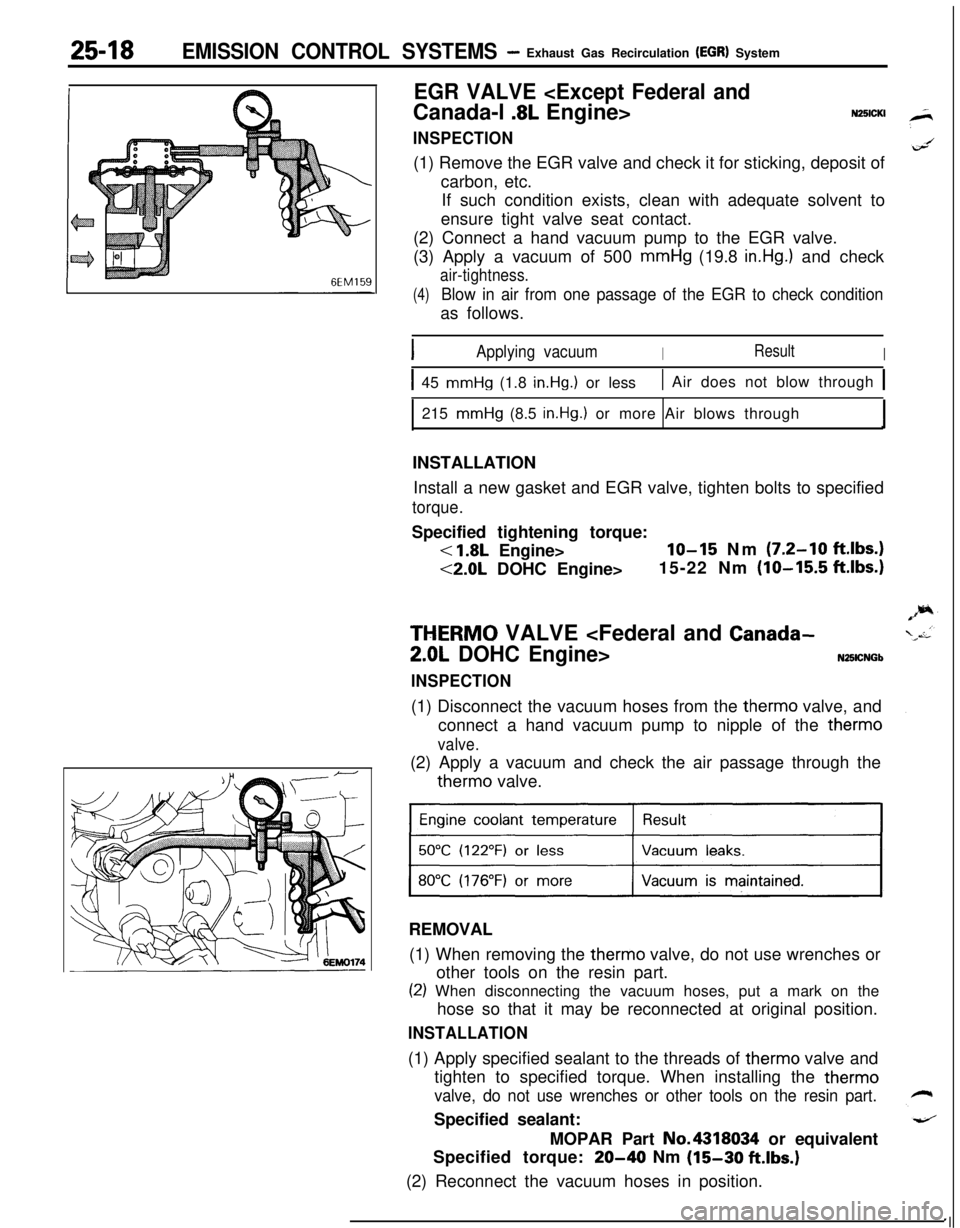

25-18EMISSION CONTROL SYSTEMS- Exhaust Gas Recirculation (EGRI System

EGR VALVE

INSPECTION(1) Remove the EGR valve and check it for sticking, deposit of

carbon, etc.

If such condition exists, clean with adequate solvent to

ensure tight valve seat contact.

(2) Connect a hand vacuum pump to the EGR valve.

(3) Apply a vacuum of 500 mmHg (19.8

in.Hg.) and check

air-tightness.

(4)Blow in air from one passage of the EGR to check conditionas follows.

IApplying vacuumIResultI

I45 mmHg (1.8 in.Hg.1 or less1 Air does not blow through 1215

mmHg (8.5 in.Hg.1 or more Air blows through

INSTALLATION

Install a new gasket and EGR valve, tighten bolts to specified

torque.Specified tightening torque:

< 1.8L Engine>lo-15 Nm (7.2-10 ft.lbs.)

<2.0L DOHC Engine>15-22 Nm (lo-155 ft.lbs.)

THERM0 VALVE

INSPECTION(1) Disconnect the vacuum hoses from the therm0 valve, and

connect a hand vacuum pump to nipple of the therm0

valve.(2) Apply a vacuum and check the air passage through thetherm0 valve.

REMOVAL

(1) When removing the therm0 valve, do not use wrenches or

other tools on the resin part.

(2) When disconnecting the vacuum hoses, put a mark on the

hose so that it may be reconnected at original position.

INSTALLATION(1) Apply specified sealant to the threads of therm0 valve and

tighten to specified torque. When installing the therm0

valve, do not use wrenches or other tools on the resin part.Specified sealant:

MOPAR Part No.4318034 or equivalent

Specified torque:

20-40 Nm (15-30 ftlbs.)(2) Reconnect the vacuum hoses in position.

‘I

Page 1215 of 1216

EMISSION CONTROL SYSTEMS- Exhaust Gas Recirculation (EGR) Svstem25-19

\\

7EM0043

. .

6EM0187

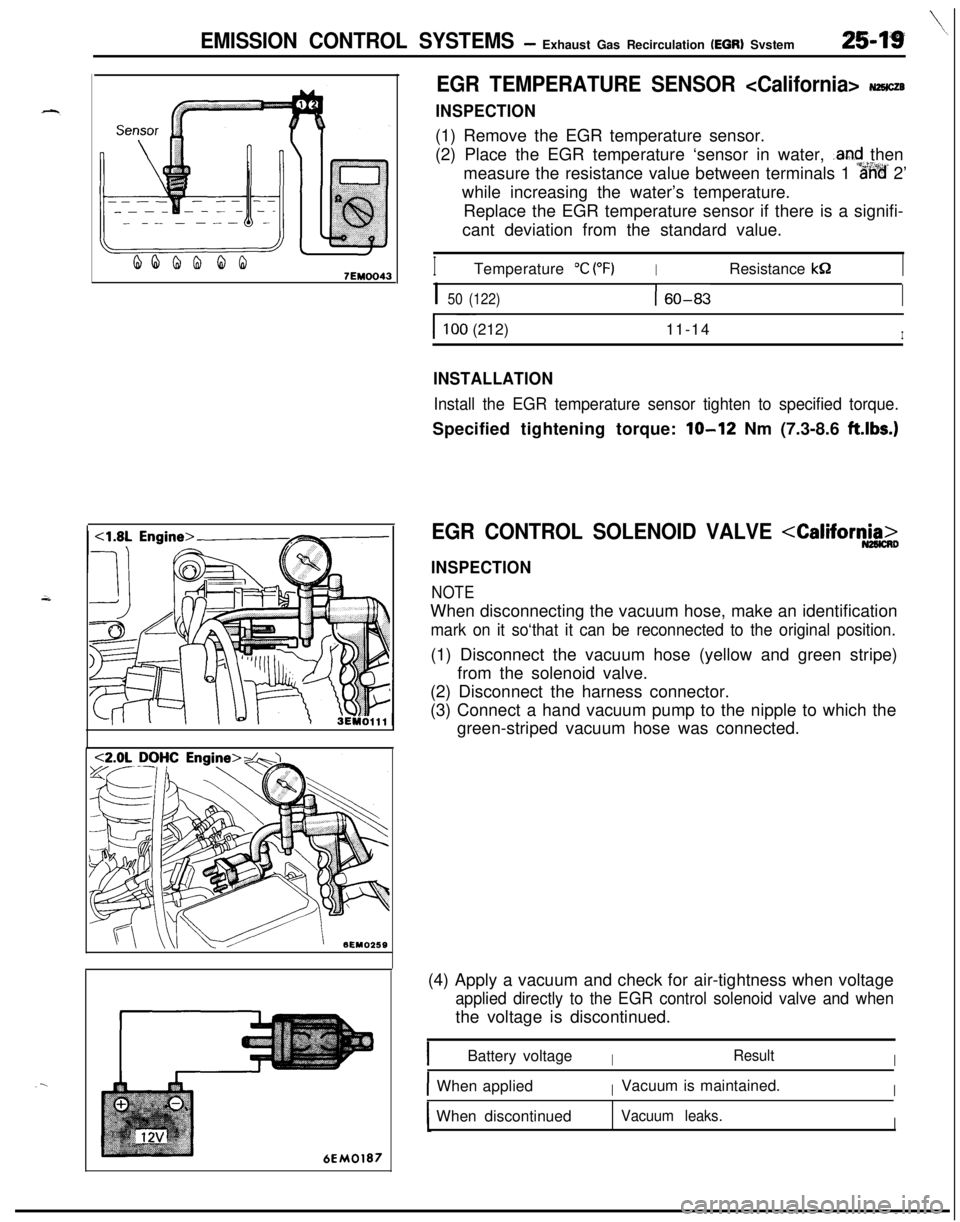

EGR TEMPERATURE SENSOR

INSPECTION(1) Remove the EGR temperature sensor.

(2) Place the EGR temperature ‘sensor in water,

.and then

measure the resistance value between terminals 1

%%’ 2’

while increasing the water’s temperature.

Replace the EGR temperature sensor if there is a signifi-

cant deviation from the standard value.

ITemperature “C (“F)IResistance kS2I

I 50 (122)160-83I

I ~~100 (212)11-14I

INSTALLATION

Install the EGR temperature sensor tighten to specified torque.Specified tightening torque:

lo-12 Nm (7.3-8.6 ft.lbs.)

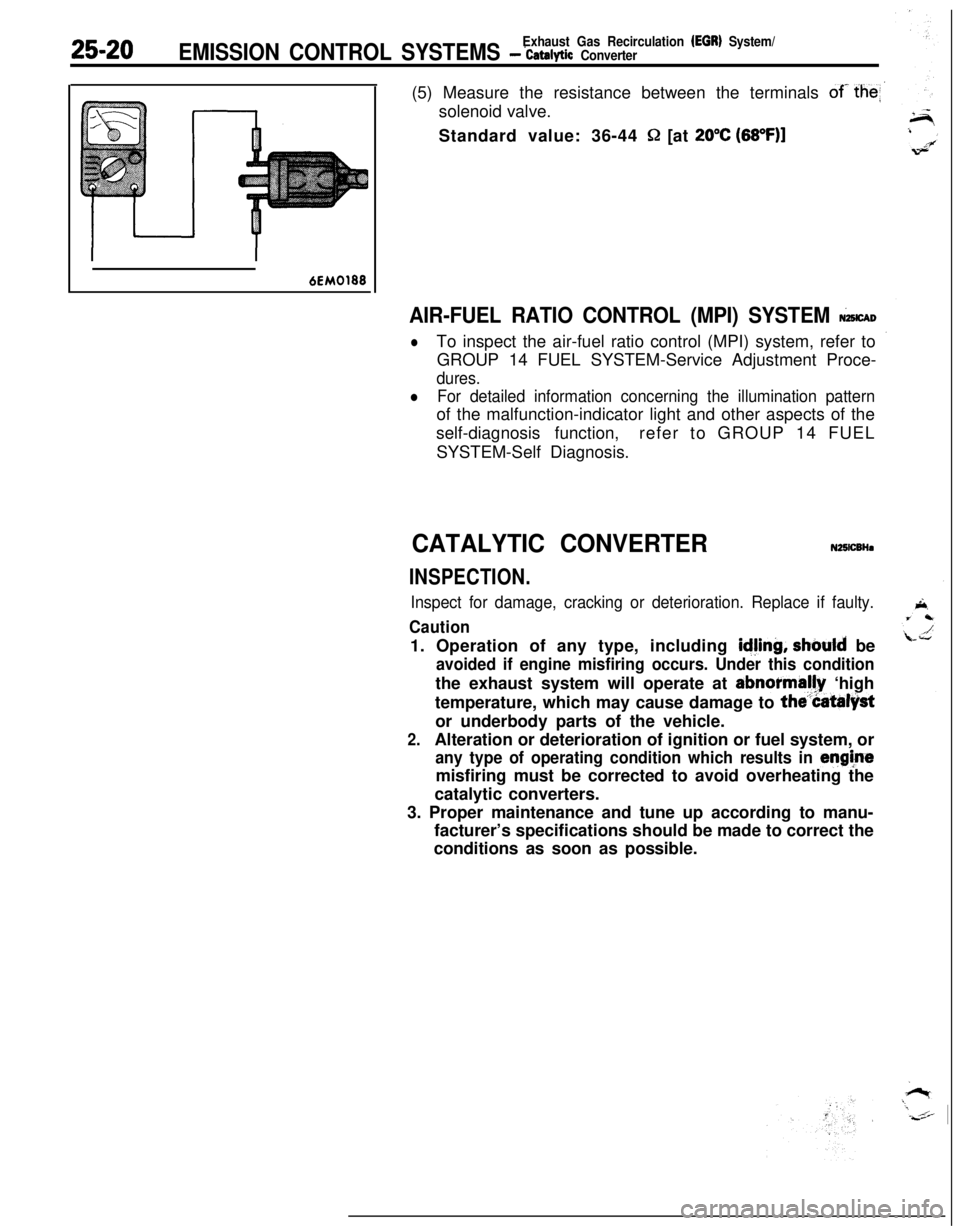

EGR CONTROL SOLENOID VALVE

NOTEWhen disconnecting the vacuum hose, make an identification

mark on it so‘that it can be reconnected to the original position.(1) Disconnect the vacuum hose (yellow and green stripe)

from the solenoid valve.

(2) Disconnect the harness connector.

(3) Connect a hand vacuum pump to the nipple to which the

green-striped vacuum hose was connected.

(4) Apply a vacuum and check for air-tightness when voltage

applied directly to the EGR control solenoid valve and whenthe voltage is discontinued.

IBattery voltageIResultI

IWhen appliedIVacuum is maintained.IWhen discontinued

Vacuum leaks.I

Page 1216 of 1216

25-20Exhaust Gas Recirculation (EGR) System/EMISSION CONTROL SYSTEMS - ‘catalytic Converter(5) Measure the resistance between the terminals

of- the

Q [at 20°C (68OF)l

6EM0188

AIR-FUEL RATIO CONTROL (MPI) SYSTEM &CAD

lTo inspect the air-fuel ratio control (MPI) system, refer to

GROUP 14 FUEL SYSTEM-Service Adjustment Proce-

dures.

lFor detailed information concerning the illumination patternof the malfunction-indicator light and other aspects of the

self-diagnosis function,refer to GROUP 14 FUEL

SYSTEM-Self Diagnosis.

CATALYTIC CONVERTERN25lCBHa

INSPECTION.

Inspect for damage, cracking or deterioration. Replace if faulty.

Caution1. Operation of any type, including

idjing, should be

avoided if engine misfiring occurs. Under this conditionthe exhaust system will operate at abnormally ‘high

temperature, which may cause damage to

the”Catalystor underbody parts of the vehicle.

2.Alteration or deterioration of ignition or fuel system, or

any type of operating condition which results in enghtemisfiring must be corrected to avoid overheating the

catalytic converters.

3. Proper maintenance and tune up according to manu-

facturer’s specifications should be made to correct the

conditions as soon as possible.