MITSUBISHI ECLIPSE 1991 Service Manual

Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 1201 of 1216

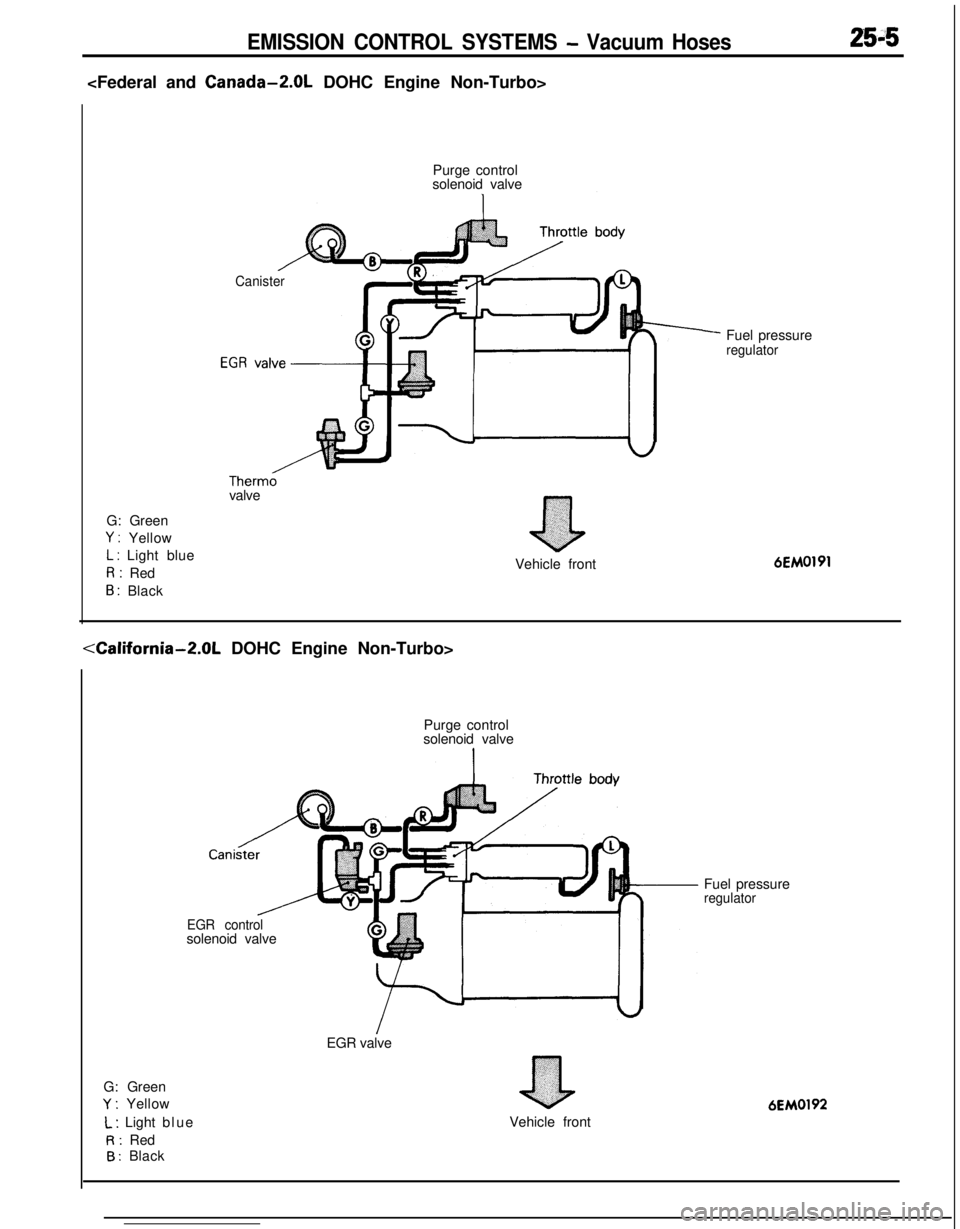

EMISSION CONTROL SYSTEMS - Vacuum Hoses2515

Purge control

solenoid valve

Canister

Therm0valve

G: Green

Y : Yellow

L : Light blueR: Red

B : Black

nVehicle frontFuel pressure

regulator6EM0191

G: Green

Y : YellowPurge control

solenoid valve

Cani

EGR controlsolenoid valve

EGR valve

L : Light blue

R: Red

B : BlackVehicle frontFuel pressure

regulator

6EM0192

Page 1202 of 1216

25-6EMISSION CONTROL SYSTEMS - Vacuum Hoses

G: Green

Y : Yellow

L : Light blueR: Red

B : Black

W: White

Purge control valvg

Purge controlFuel pressure control,solenoid valve/solenoid valve

Therm0 valve’

el pressure regulator

Turbocharger

vvasre gate actuator Waste gate control

solenoid valveVehicle front

6EM0222

G: Green

Y : Yellow

L : Lrght blueR: Red

B : Black

W: White

1sPurge control valve

&+

Air cleanerFuel pressure control

solenoid valve.

Purge control

solenoid valve\Fuel pressure regulator

Waste gate control

solenord valve

Waste gate actuatorv.,~~‘~y:‘;7Vehicle front

6EM0223

Page 1203 of 1216

EMISSION CONTROL SYSTEMS - vacuumHoses/Crankcase Emission Control System25-7

INSPECTION(1) Referring to the VACUUM HOSES ROUTING,

confirm2the vacuum hoses are properly connected.

(2) Check the hoses for irregularities (disconnection, loose-

ness, etc.) and confirm that there is no breakage or

damage.INSTALLATION

’N2SJDAD(1) When connecting a hose, firmly press it onto the nipple.

(2) Referring to the VACUUM HOSES ROUTING, connect the

hoses correctly.

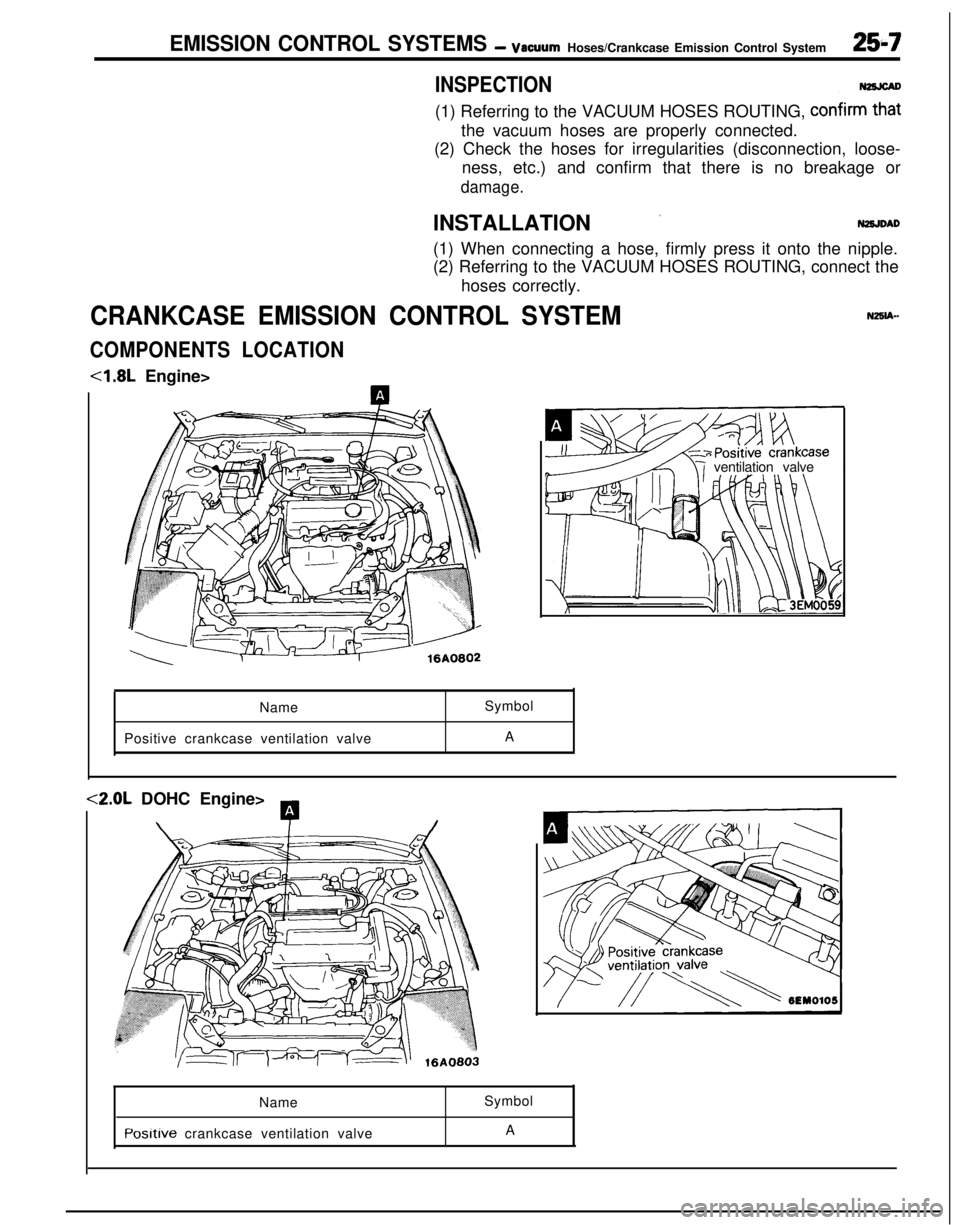

CRANKCASE EMISSION CONTROL SYSTEM

COMPONENTS LOCATION<1.8L Engine>

ventilation valve

NameSymbol

Positive crankcase ventilation valveA<2.0L DOHC Engine>

A

\T/Name

Posltive crankcase ventilation valveSymbol

A

Page 1204 of 1216

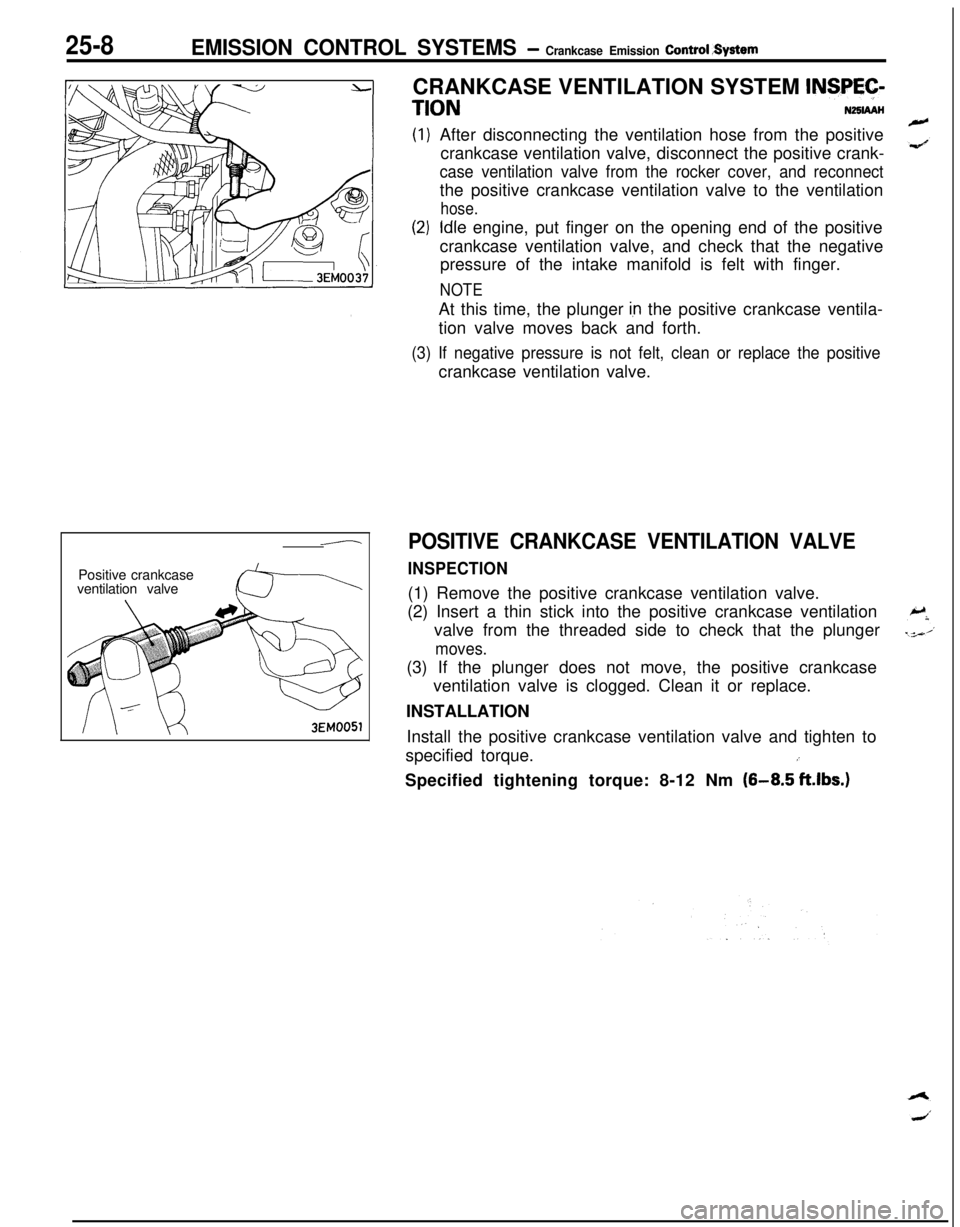

25-8EMISSION CONTROL SYSTEMS - Crankcase Emission Control System

-Positive crankcase

ventilation valve3EM0051CRANKCASE VENTILATION SYSTEM

INSPEC-

TIONNZSIAAHAfter disconnecting the ventilation hose from the positive

crankcase ventilation valve, disconnect the positive crank-

case ventilation valve from the rocker cover, and reconnectthe positive crankcase ventilation valve to the ventilation

hose.

Idle engine, put finger on the opening end of the positive

crankcase ventilation valve, and check that the negative

pressure of the intake manifold is felt with finger.

NOTEAt this time, the plunger

Ian the positive crankcase ventila-

tion valve moves back and forth.

(3) If negative pressure is not felt, clean or replace the positivecrankcase ventilation valve.

POSITIVE CRANKCASE VENTILATION VALVE

INSPECTION(1) Remove the positive crankcase ventilation valve.

(2) Insert a thin stick into the positive crankcase ventilation

valve from the threaded side to check that the plunger

moves.(3) If the plunger does not move, the positive crankcase

ventilation valve is clogged. Clean it or replace.

INSTALLATION

Install the positive crankcase ventilation valve and tighten to

specified torque.

iSpecified tightening torque: 8-12 Nm

(8-8.5 ft.lbs.)

Page 1205 of 1216

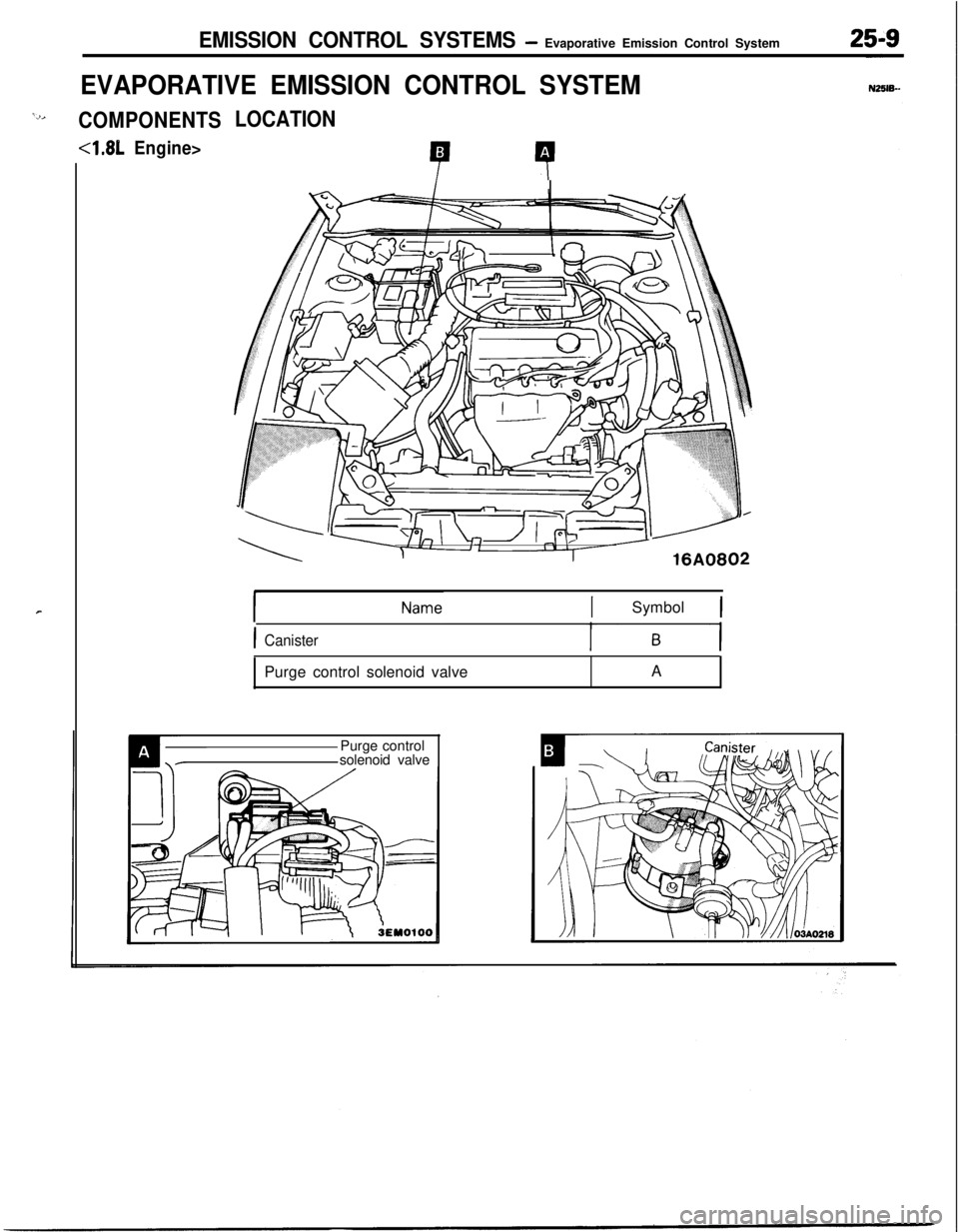

EMISSION CONTROL SYSTEMS- Evaporative Emission Control System

EVAPORATIVE EMISSION CONTROL SYSTEM

‘2,COMPONENTS

4.81,Engine>

r

LOCATION

P 4

xl-#i

ISymbol 1

ICanisterPurge control solenoid valveA

Purge control

solenoid valve

Page 1206 of 1216

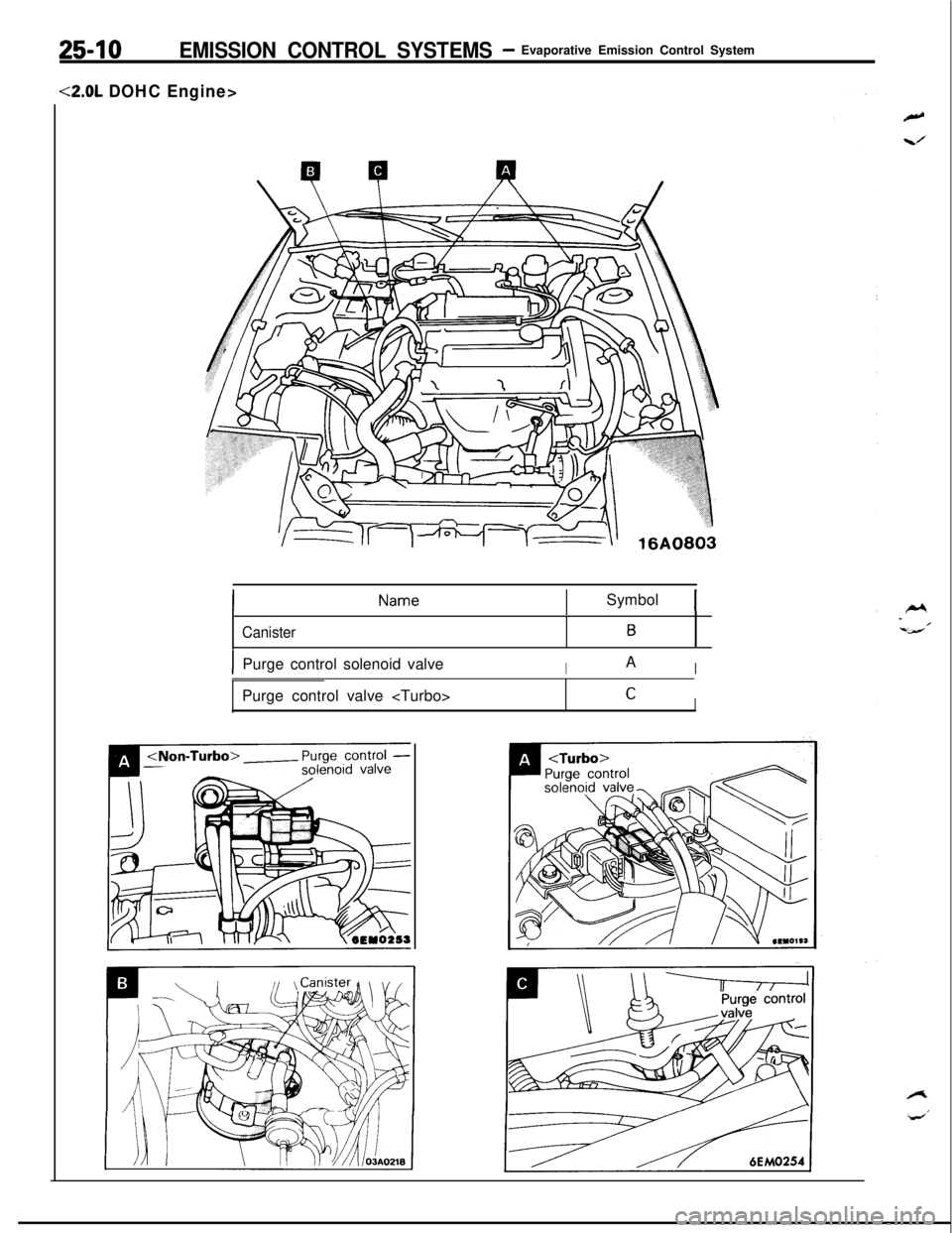

25-10EMISSION CONTROL SYSTEMS- Evaporative Emission Control System

<2.0L DOHC Engine>

ISymbol 1

Canister

1

B

IPurge control solenoid valveIAIPurge control valve

CI

Page 1207 of 1216

EMISSION CONTROL SYSTEMS- Evaporative Emission Control SYStem25-m

PURGE CONTROL SYSTEM INSPECTION

sensor

P+

Engine control unit

IlEM0086(1) Disconnect the vacuum hose (red stripes) from the throttle

body and connect it to a hand vacuum pump.

(2) Plug the nipple from which the vacuum hose is discon-

nected.(3) Under the engine conditions shown below, check by

applying vacuum from a hand vacuum pump.

When engine is cold-engine coolant temperature:

60% (140°F) or less

Engine operating Applying vacuum

>When engine is hot-engine coolant temperature:

70°C (158°F) or higher

Engine operating

condition

Idling3,000 rpm within

three minutes afterstarting engine

3,000 rpm after

three minutes

have elapsedafter starting

engineApplying vacuum

375

mmHg(14.8 in.Hg.1

Try wpMwvacuum375

mmHg(14.8 in.Hg.1

ResultVacuum is maintained

Vacuum leaks

Vacuum will be main-

tained momentarily,

after which it will

leaks.

NOTEThe vacuum will leak

continuously if the

altitude is 2,200

m(7,200 ft.) or higher,or the intake air

temperature is

50°C(122°F) or higher.

Page 1208 of 1216

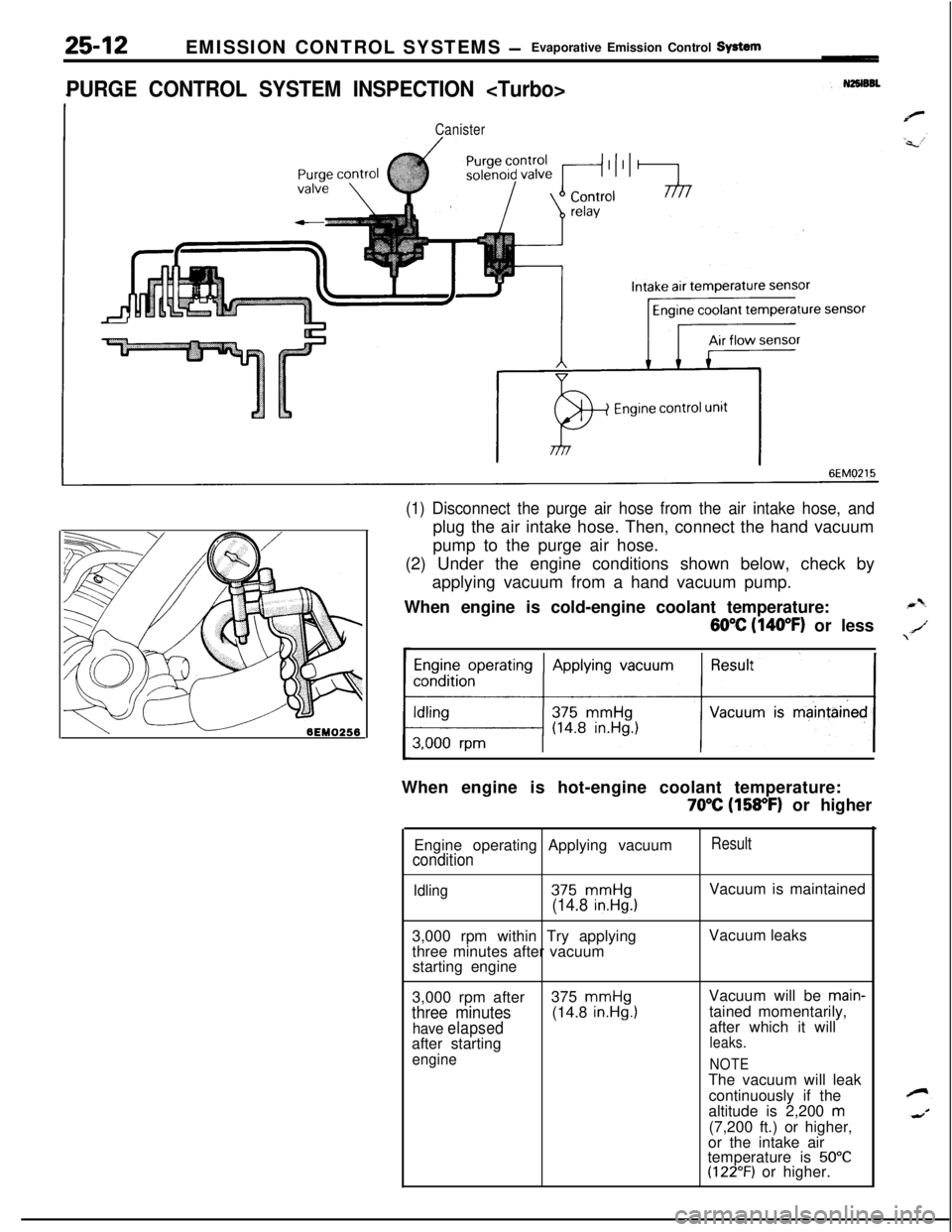

25-12EMISSION CONTROL SYSTEMS -Evaporative Emission Control System

PURGE CONTROL SYSTEM INSPECTION

Canister

6EM0215

(1) Disconnect the purge air hose from the air intake hose, andplug the air intake hose. Then, connect the hand vacuum

pump to the purge air hose.

(2) Under the engine conditions shown below, check by

applying vacuum from a hand vacuum pump.

When engine is cold-engine coolant temperature:

60°C (140°F) or less

Engine operating Applying vacuum

11When engine is hot-engine coolant temperature:

70°C (158°F) or higher

Engine operating Applying vacuum

condition

Result

Idling375 mmHg(14.8 in.Hg.)Vacuum is maintained

3,000 rpm within Try applying

three minutes after vacuum

starting engineVacuum leaks

3,000 rpm after375

mmHgVacuum will be main-

three minutes(14.8 in.Hg.1tained momentarily,

have elapsedafter which it will

after startingleaks.

engineNOTEThe vacuum will leak

continuously if the

altitude is 2,200

m(7,200 ft.) or higher,

or the intake air

temperature is

50°C(122°F) or higher.

Page 1209 of 1216

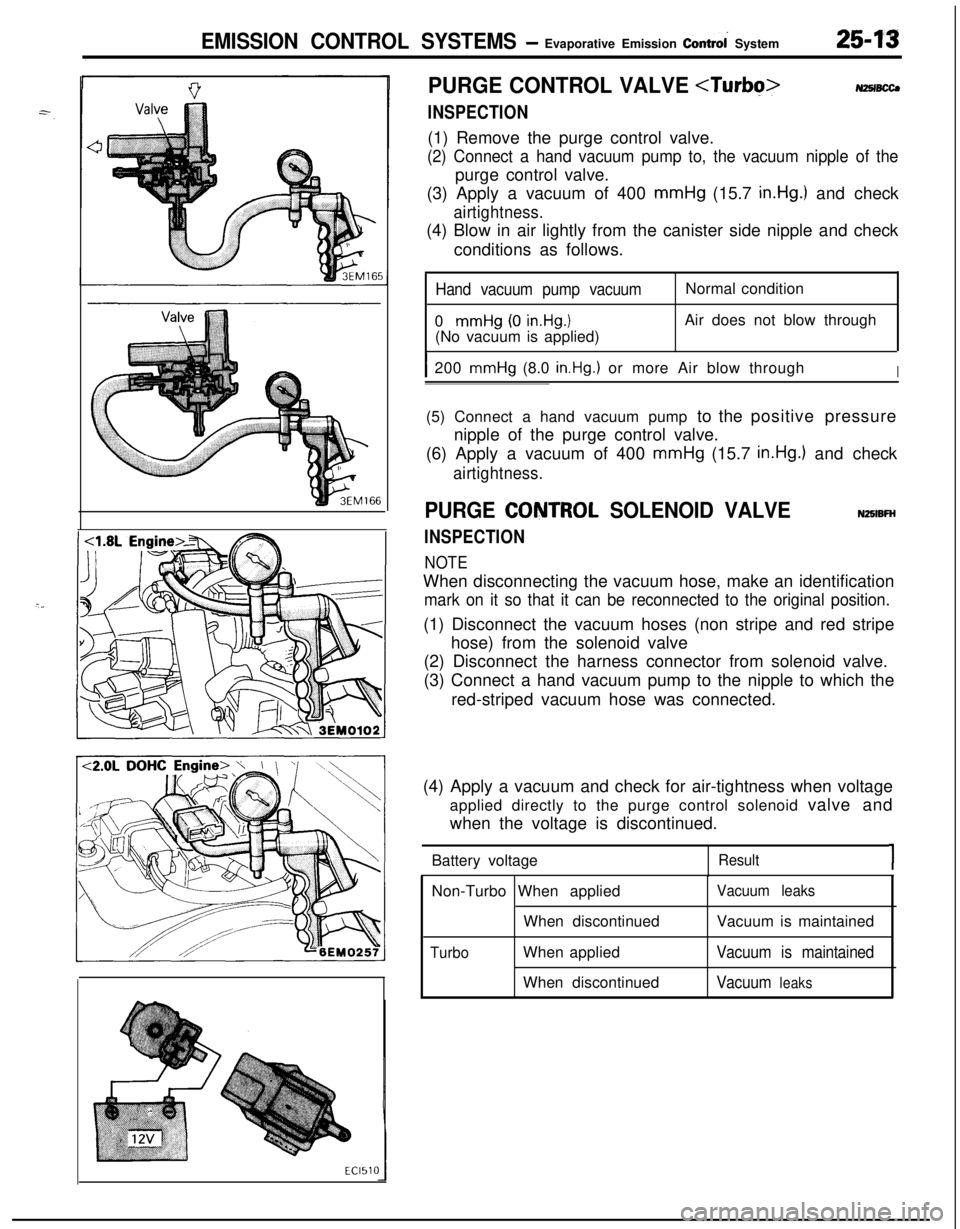

EMISSION CONTROL SYSTEMS- Evaporative Emission Control System25-WECl51C

PURGE CONTROL VALVE

INSPECTION

NZSIBCCJ(1) Remove the purge control valve.

(2) Connect a hand vacuum pump to, the vacuum nipple of thepurge control valve.

(3) Apply a vacuum of 400 mmHg (15.7

in.Hg.) and check

airtightness.(4) Blow in air lightly from the canister side nipple and check

conditions as follows.

Hand vacuum pump vacuum0

mmHg (0 in.Hg.1(No vacuum is applied)Normal condition

Air does not blow through

I200 mmHg (8.0 in.Hg.) or more Air blow throughI(5) Connect a hand vacuum pump to the positive pressure

nipple of the purge control valve.

(6) Apply a vacuum of 400 mmHg (15.7

in.Hg.) and check

airtightness.

PURGE CQNTROL SOLENOID VALVE

INSPECTION

NOTE

NZBIBFHWhen disconnecting the vacuum hose, make an identification

mark on it so that it can be reconnected to the original position.(1) Disconnect the vacuum hoses (non stripe and red stripe

hose) from the solenoid valve

(2) Disconnect the harness connector from solenoid valve.

(3) Connect a hand vacuum pump to the nipple to which the

red-striped vacuum hose was connected.

(4) Apply a vacuum and check for air-tightness when voltage

applied directly to the purge control solenoid valve and

when the voltage is discontinued.

Battery voltage

Result1Non-Turbo When applied

When discontinued

TurboWhen applied

When discontinued

Vacuum leaksVacuum is maintained

Vacuum is maintained

Vacuum

leaks

Page 1210 of 1216

![MITSUBISHI ECLIPSE 1991 Service Manual 25-14EMISSION CONTROL SYSTEMS- Evaporative Emission Control System

(5) Measure the resistance between the terminals of the

solenoid valve.

Standard value: 36-44

Q [at 20°C (68OF)]_

6EM137

AIR FLOW S MITSUBISHI ECLIPSE 1991 Service Manual 25-14EMISSION CONTROL SYSTEMS- Evaporative Emission Control System

(5) Measure the resistance between the terminals of the

solenoid valve.

Standard value: 36-44

Q [at 20°C (68OF)]_

6EM137

AIR FLOW S](/img/19/57104/w960_57104-1209.png)

25-14EMISSION CONTROL SYSTEMS- Evaporative Emission Control System

(5) Measure the resistance between the terminals of the

solenoid valve.

Standard value: 36-44

Q [at 20°C (68OF)]_

6EM137

AIR FLOW SENSOR, ENGINE COOLANT TEMPER-

ATURE SENSOR AND INTAKE AIR TEMPERA-

TURE SENSORTo inspect these parts, refer to GROUP

14-MPI System

Components.‘.

AIR CONDITIONER SWITCHTo inspect the air conditioner switch, refer to GROUP

24’--AirConditioner Switch.

OVERFILL LIMITER (TWO-WAY VALVE)N2BlBE&To inspect the overfill limiter (two-way valve), refer to GROUP

14-Fuel Tank.

CANISTERNzslBmTo inspect the canister, refer to GROUP

14-Fuel Line and

Vapor Line.

FUEL FILLER CAP INSPECTIONNZSIBJACheck the gasket of the fuel filler cap, and, the filler cap itself,

for damage or deformation; replace the cap if necessary.