check oil MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 889 of 1216

AUTOMATIC TRANSAXLE - Troubleshooting21'495

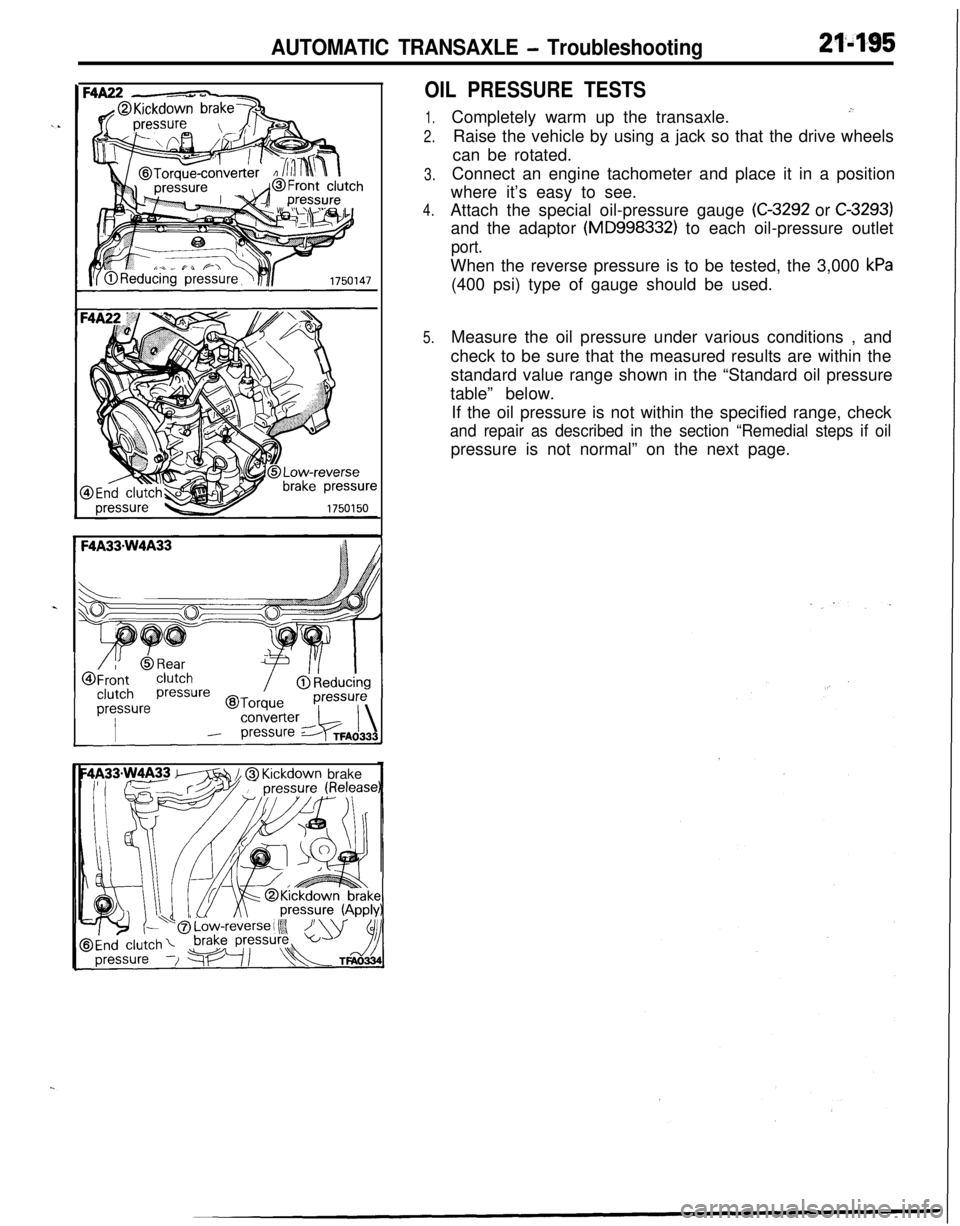

OIL PRESSURE TESTS

1.

2.

3.

4.

5.Completely warm up the transaxle.

.”Raise the vehicle by using a jack so that the drive wheels

can be rotated.

Connect an engine tachometer and place it in a position

where it’s easy to see.

Attach the special oil-pressure gauge

(C-3292 or C-3293)and the adaptor

(MD998332) to each oil-pressure outlet

port.When the reverse pressure is to be tested, the 3,000

kPa(400 psi) type of gauge should be used.

Measure the oil pressure under various conditions , and

check to be sure that the measured results are within the

standard value range shown in the “Standard oil pressure

table” below.

If the oil pressure is not within the specified range, check

and repair as described in the section “Remedial steps if oilpressure is not normal” on the next page.

m // @ Kickdown brake

Page 891 of 1216

AUTOMATIC TRANSAXLE - TroubleshootingRemedial Steps If Oil Pressure Is Not Normal

F4A22.,,‘

frouble symptomProbable causeRemedy1;

I. *Line pressures

a.Clogging of oil filtera.Visually inspect the oil filter; replace the oil filte

are all low (or high).

if it is clogged.

NOTEb.Improper adjustment of oil press-b.Measure line pressure @ (kickdown brake*“Line pressures”ure (line pressure) of regulator

pressure); if the pressure is not the standard

refers to oil

ress-ures@,@, 4 and

8

valvevalue, readjust the line pressure, or, if neces-sary, replace the valve body assembly.

@in the “Standardc.Sticking of regulator valvec.Check the operation of the regulator valve;oil pressure table”repair if necessary, or replace the valve body

on the previousassembly.

page.d.Looseness of valve body tighten-d.Tighten the valve body tightening bolt and

ing partinstallation bolt.‘- ,

e.Improper oil pump dischangee.Check the side clearance of the oil pump gehr;

pressurereplace the oil pump assembly if necessary.

I. Improper reducinga.Improper line pressurea.Check the @ kickdown brake pressure (line

pressurepressure); if the line pressure is not the

standard value, check as described in item 1

above.

b.Clogging of the filter (L-shapedb.Disassemble the valve body assembly and

type) of the reducing-pressure cir-check the filter; replace the filter if it is clogged.cuit

c.Improper adjustment of the re-c.Measure the @I reducing pressure; if it is not

ducing pressurethe standard value, readjust, or replace the

valve body assembly.

d.Sticking of the reducing valved.Check the operation of the reducing valve; if

necessary, repair it, or replace the valve body

assembly.

e.Looseness of valve body tighten-e.Tighten the valve body tightening bolt and

ing partinstallation bolt.

#. Improper kick-a.Malfunction of the D-ring or seala. Disassemble the kickdown servo and check

down brake press-ring of the sleeve or kickdownwhether the seal ring or D-ring is damaged.

ureservo piston.If it is cut or has scratches, replace the seal ring

or D-ring.

b.Looseness of valve body tighten-b.Tighten the valve body tightening bolt and

ing partinstallation bolt.

c.Functional malfunction of thec.Replace the valve body assembly.

valve body assembly

. Improper front

clutch pressure

a.Malfunction of the D-ring or seala. Disassemble the kickdown servo and check

ring of the sleeve or kickdownwhether the seal ring or-D-ring is damaged.servo piston.

If it is cut or has scratches, replace the seal ring

or D-ring.

b.Looseness of valve body tighten-b.Tighten the valve body tightening bolt and

ing partinstallation bolt.c.Functional malfunction of thec.Replace the valve body assembly.

valve body assembly

d.Wear of the front clutch piston ord.Disassemble the transaxle itself and check

retainer, or malfunction of the

@whether or not there is wear of the front clutch

D-ring, @ seal, ring.piston and retainer inner circumference, or

ra;;; to the figure on the nextdamage of the D-ring. If there is any wear or

damage, replace the piston, retainer, D-ring

and/or seal ring.

1. Improper endclutch pressure

a.Malfunction of a D-ring @or seala.Disassemble the end clutch and check the sealring 0, @of the end clutch or

O-ring @I of the pipe (Refer to thering, D-ring of the piston, seal ring of thefollowing figure.)retainer, etc.; replace if there are cuts, scars,

scratches or damage.

b.Looseness of valve body tighten-b.Tighten the valve body tightening bolt and

ing partinstallation bolt.c.Functional malfunction of thec.Replace the valve body assembly.

valve body assembly

Page 892 of 1216

21-198AUTOMATIC TRANSAXLE - Troubleshooting

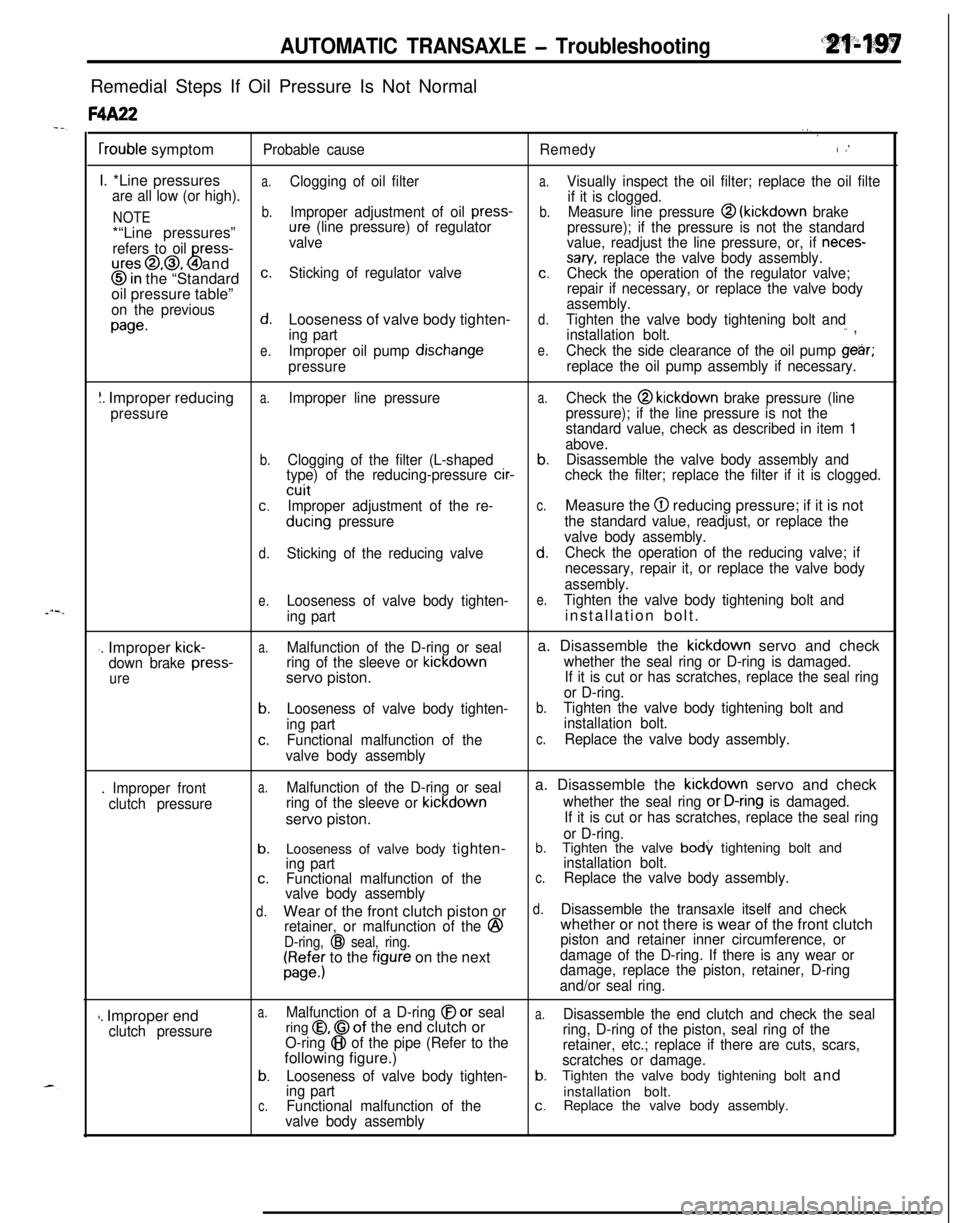

Trouble symptom6. improper

low-

reverse brake

pressure

7. Improper torque

converter pressureProbable causea.O-ring between valve body and

transaxle damaged or missing

b.Looseness of valve body tighten-

ing part

c.Functional malfunction of the

valve body assembly

d.Malfunction of the O-ring 0 of thelow-reverse brake piston or the

O-ring

0 of the retainer (Refer tothe figure below.)

a.Sticking of the damper clutch

control solenoid valve (DCCSV) or

the damper clutch control valve.

b.Clogging or leaking of the oil

cooler and/or piping

2.Damaged seal ring @of the input

shaft (Refer to the figure below.)

3.Malfunction of the torque conver-

ter

Remedy

a.Remove the valve body assembly and check to

be sure that the O-ring at the upper surface of

the upper valve body is not

missinor dam-

aged; install or replace the O-ring i7necessary.

b.Tighten the valve body tightening bolt andinstallation bolt.

c.Replace the valve body assembly.

d.Disassemble the transaxle itself and check the

O-ring for damage; replace if there are cuts,

scars, scratches or damage.

a.Check the operation of the damper clutch

system and the DCCSV.

b.Repair or replace, as necessary, the cooler

and/or piping.

c.Disassemble the transaxle itself and check for

damage of the seal ring; replace the seal ring if

there is damage.

d.Replace the torque converter.

@D-ring@Seal ring

-OD-ring@Seal ring

(@Seal ring

@O-ring

1750437

Page 893 of 1216

AUTOMATIC TRANSAXLE - Troubleshooting

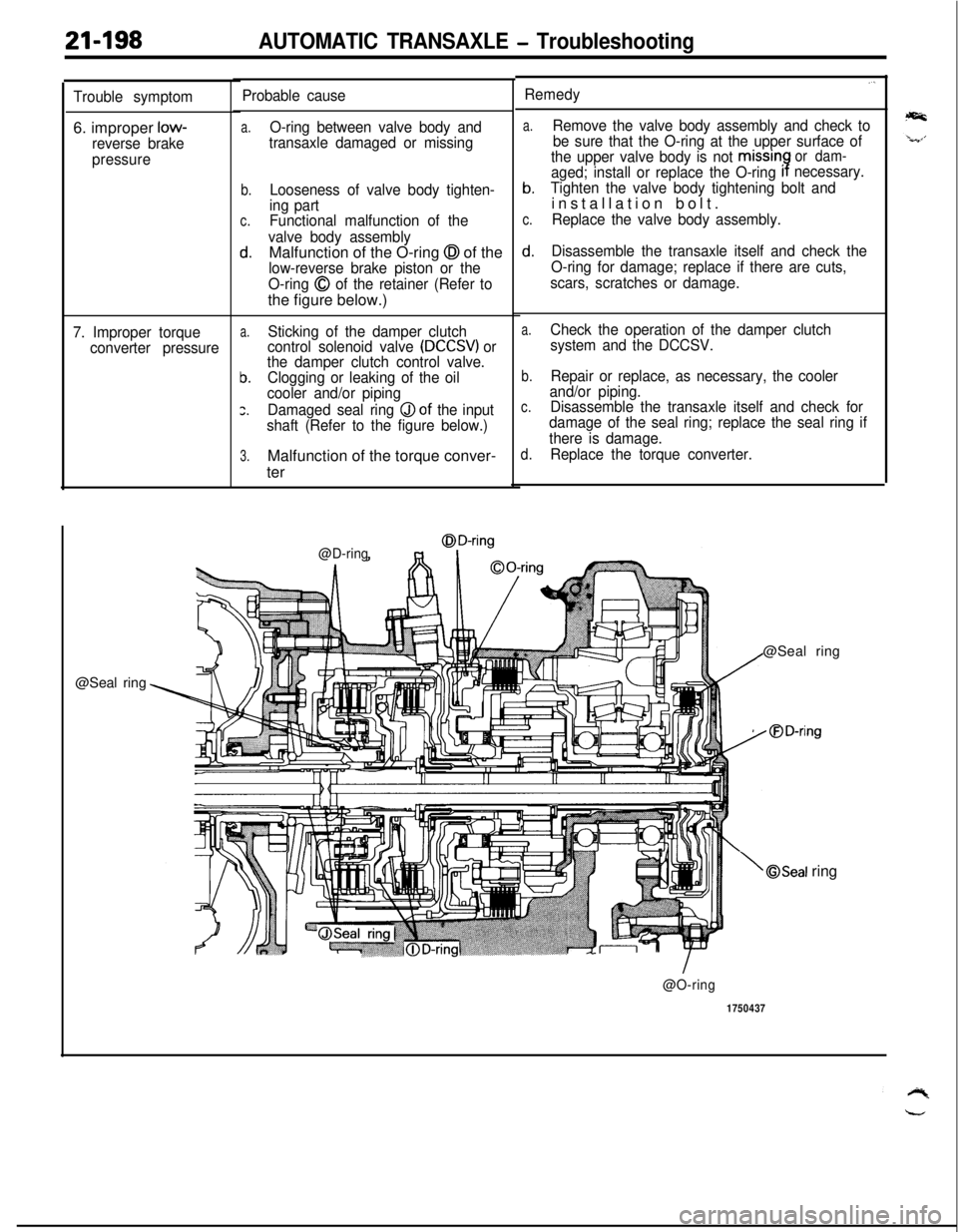

F4A33-W4A33Trouble symptom

1. Line pressures areall low (or high).

NOTE* “Line pressures”

refers to oil

pressure @,@I, 0,0, @I and 0, inthe “Standard oil

pressure table” on

the previous page.

2. Improper reducing

pressure3. Improper

kickdown brake

pressure (Apply)

4. Improper

kickdown brake

pressure (Release)

5. Improper front

clutch pressureProbable cause

a.Clogging of oil filter

b.Improper adjustment of oil

pressure (line pressure of

regulator valve

c.Functional malfunction of valve

body assembly

d.Looseness of valve bodytightening part

e.Improper oil pump dischange

pressure

a.Clogging of the filter (L-shaped

type) of the reducing-pressurecircuit

b.Improper adjustment of oil

pressure

c.Functional malfunction of thevalve body assembly

a.Malfunction of the seal ring @,

D-ring @I or seal ring 0 of thesleeve of the kickdown servo

piston.

b.Functional malfunction of the

valve body assembly

a.Malfunction of the seal ring @,

D-ring @ or seal ring a> of thesleeve of the kickdown servo

piston.

b.Functional malfunctio? of the

valve body assembly

a.Malfunction of the seal ring @,

D-ring @or seal ring Q3 of thesleeve of the kickdown servo

piston.

b.Functional malfunction of the

valve body assembly

c.Wear of the front clutch piston or

retainer, or malfunction of theD-ring 0 or seal ring @.

Remedy

a.Visually inspect the oil filter; replace the oil filter

if it is clogged.

b.Measure line pressure @ (kickdown brake

pressure); if the pressure is not the standard

value, readjust the line pressure, or, if

necessary, replace the valve body assembly.

c.Replace the valve body assembly.

d.Tighten the valve body tightening bolt and

installation bolt.

e.Check the side clearance of the oil pump gear;

replace the oil pump assembly if necessary.

a.Disassemble the valve body assembly and

check the filter; replace the filter if it is clogged.

b.Measure the @ reducing pressure; if it is notthe standard value, readjust, or replace the

valve body assembly.

2.Replace the valve body assembly.

a.Disassemble the kickdown servo and check

whether the seal ring or D-ring is damaged.

If it is cut or has scratches, replace the seal ring

or D-ring.

3.Replace the valve body assembly.

3.Disassemble the kickdown servo and check

whether the seal ring or D-ring is damaged.

If it is cut or has scratches, replace the seal ring

or D-ring.

3.Replace the valve body assembly.

3.Disassemble the kickdown servo and checkwhether the seal ring or D-ring is damaged.

If it is cut or has scratches, replace the seal ring

or D-ring.

I.

Replace the valve body assembly.

:.Disassemble the transaxle itself and checkwhether or not there is wear of the front clutch

piston and retainer inner circumference, or

damage of the D-ring and/or seal ring. If there is

any wear or damage, replace the piston,

retainer, D-ring and/or seal ring.

Page 894 of 1216

21-200AUTOMATIC TRANSAXLE - Troubleshooting

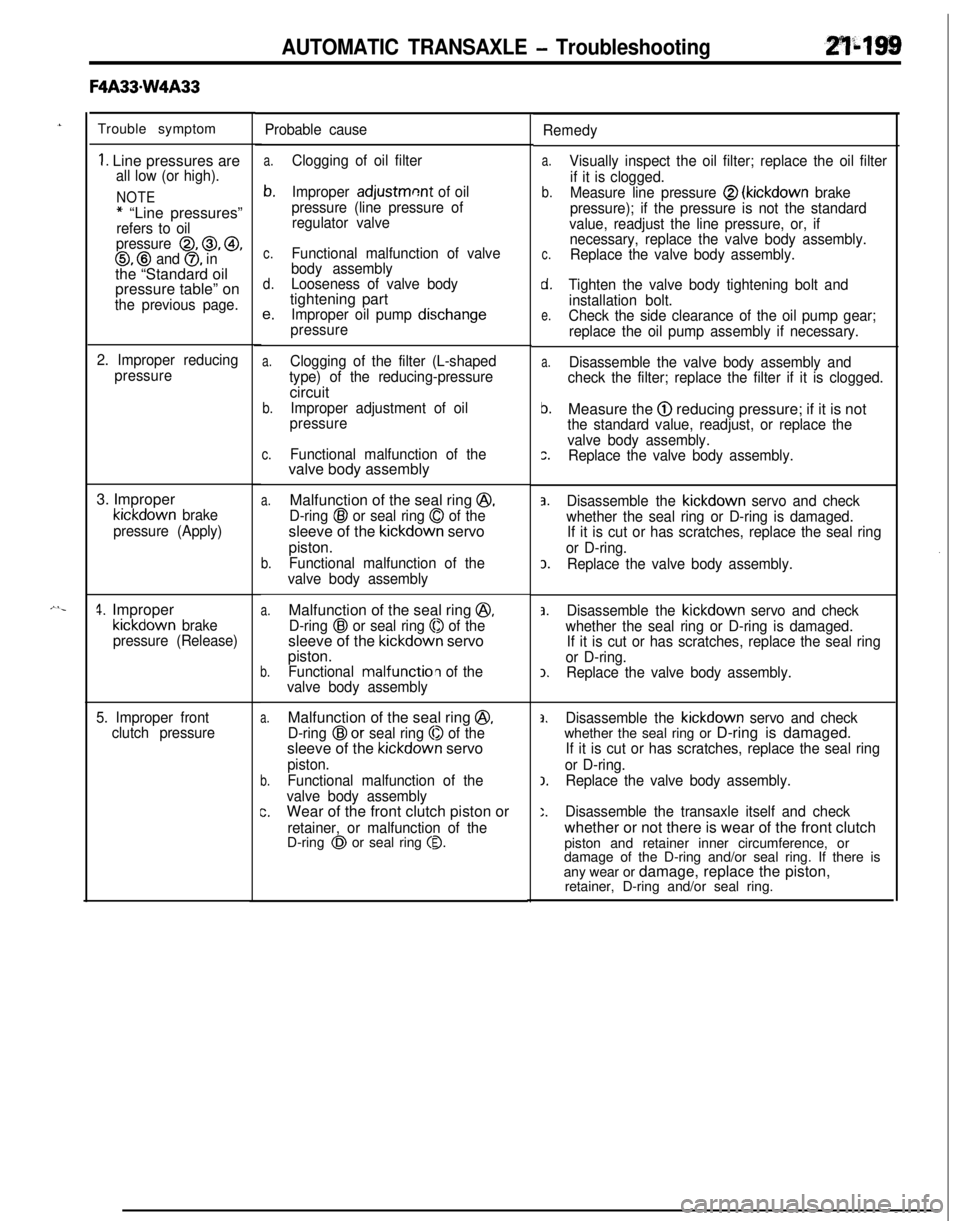

Trouble symptom

6. Improper rear

clutch pressure*,Probable causeRemedy

a.Malfunction of D-ring @of reara.Disassemble the rear clutch, check input shaft

clutch piston, retainer seal ring

@$I

and seal rings @and 0 of inputseal ring, retainer seal ring, piston

D ring, etc.

and replace broken or damaged parts.

shaft.

b.Functional malfunction of theb.Replace the valve body assembly.

valve body assembly7. Improper end

clutch pressure

a.Malfunction of seal ring @or thea.Disassemble the end clutch and check the oil

D-ring

@I and/or oil seal 0 of endseal or D-ring of the piston, seal ring of the

clutch.retainer, etc.; replace if there are cuts, scars,

scratches or damage.

b.Functional malfunction of theb.Replace the valve body assembly.

valve body assembly8. Improper

low-a.O-ring between valve body anda.Remove the valve body assembly and check to

reverse braketransaxle damaged or missingbe sure that the O-ring at the upper surface of

pressurethe upper valve body is not

missin7or dam-

aged; install or replace the O-ring inecessary.

b.Functional malfunction of theb.Replace the valve body assembly.

valve body assembly

c.Malfunction of the D-ring @of thec.Disassemble the transaxle itself and check the

low-reverse brake piston or theD-ring and O-ring for damage; replace if there

O-ring

@I of the retainerare cuts, scars, scratches or damage.9. Improper torque

a.Clogging or leaking of the oila.Repair or replace, as necessary, the coolerconverter pressure

cooler and/or pipingand/or piping.b.Malfunction of the torque conver-b.Replace the torque converter.ter

Page 903 of 1216

AUTOMATIC TRANSAXLE - service Adjustment Procedures21-209

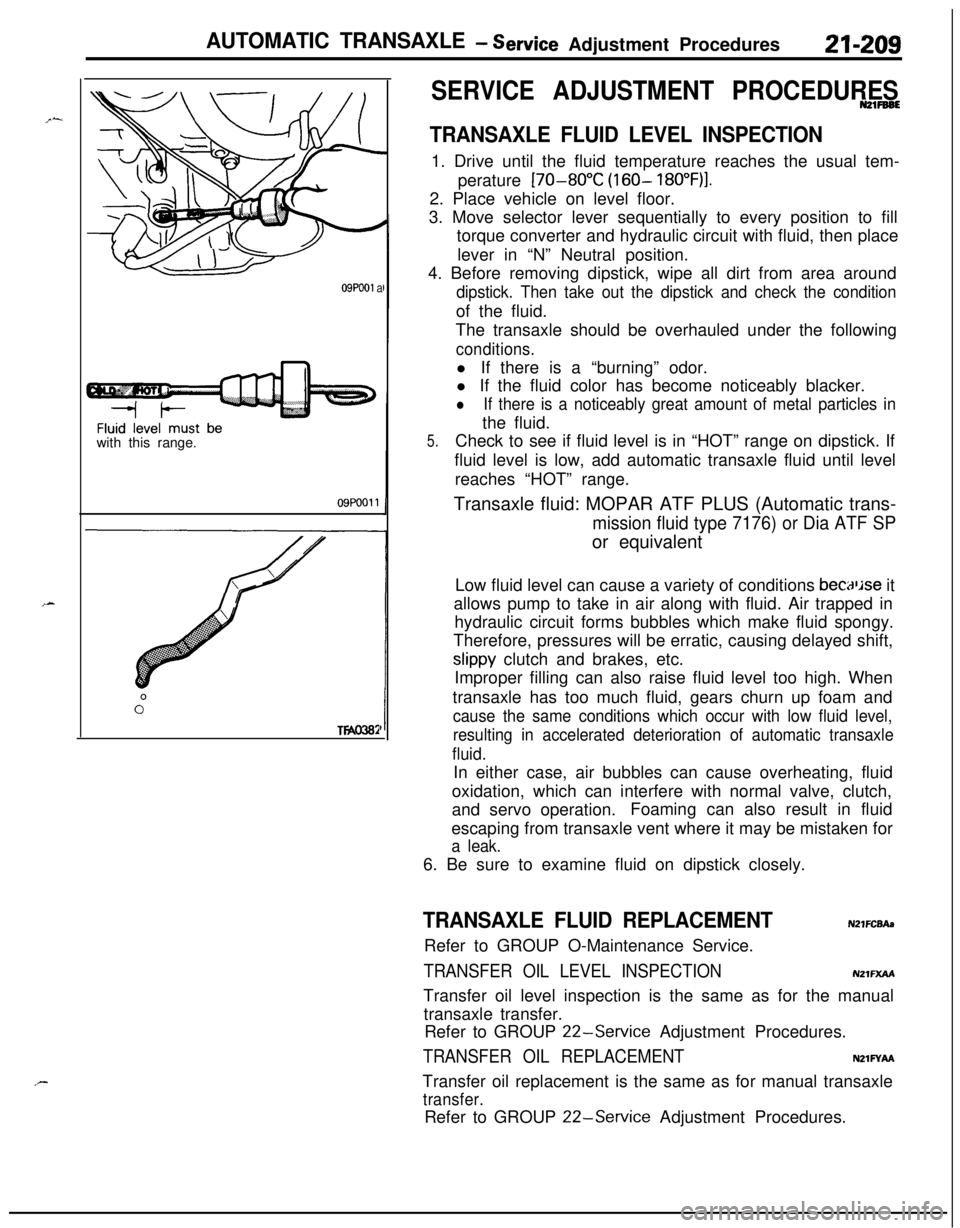

09Pooi awith this range.

09POOll

TWO382

SERVICE ADJUSTMENT PROCEDURESN21FB6E

TRANSAXLE FLUID LEVEL INSPECTION1. Drive until the fluid temperature reaches the usual tem-

perature

[70-80°C (160- 18O”F)I.2. Place vehicle on level floor.

3. Move selector lever sequentially to every position to fill

torque converter and hydraulic circuit with fluid, then place

lever in “N” Neutral position.

4. Before removing dipstick, wipe all dirt from area around

dipstick. Then take out the dipstick and check the conditionof the fluid.

The transaxle should be overhauled under the following

conditions.l If there is a “burning” odor.

l If the fluid color has become noticeably blacker.

lIf there is a noticeably great amount of metal particles inthe fluid.

5.Check to see if fluid level is in “HOT” range on dipstick. If

fluid level is low, add automatic transaxle fluid until level

reaches “HOT” range.

Transaxle fluid: MOPAR ATF PLUS (Automatic trans-

mission fluid type 7176) or Dia ATF SPor equivalent

Low fluid level can cause a variety of conditions

becaljse it

allows pump to take in air along with fluid. Air trapped in

hydraulic circuit forms bubbles which make fluid spongy.

Therefore, pressures will be erratic, causing delayed shift,

slippy clutch and brakes, etc.

Improper filling can also raise fluid level too high. When

transaxle has too much fluid, gears churn up foam and

cause the same conditions which occur with low fluid level,

resulting in accelerated deterioration of automatic transaxle

fluid.In either case, air bubbles can cause overheating, fluid

oxidation, which can interfere with normal valve, clutch,

and servo operation.Foaming can also result in fluid

escaping from transaxle vent where it may be mistaken for

a leak.6. Be sure to examine fluid on dipstick closely.

TRANSAXLE FLUID REPLACEMENTN21FCBAaRefer to GROUP O-Maintenance Service.

TRANSFER OIL LEVEL INSPECTIONNZlFXAATransfer oil level inspection is the same as for the manual

transaxle transfer.

Refer to GROUP

22-Service Adjustment Procedures.

TRANSFER OIL REPLACEMENTNZlFYAFaTransfer oil replacement is the same as for manual transaxle

transfer.Refer to GROUP

22-Service Adjustment Procedures.

Page 908 of 1216

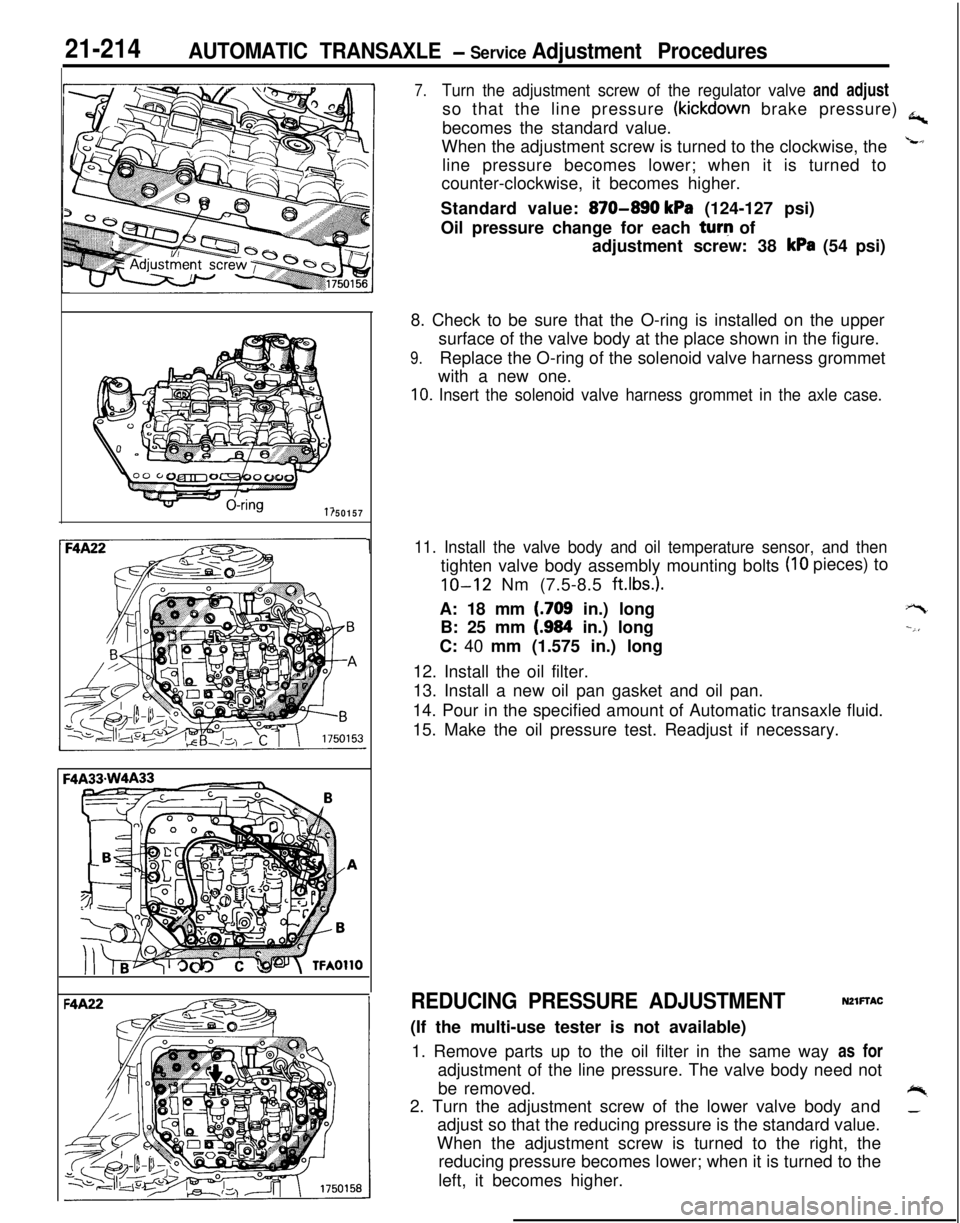

21-214AUTOMATIC TRANSAXLE - Service Adjustment Procedures

'50157

F4

1

7.Turn the adjustment screw of the regulator valve and adjustso that the line pressure

(kickdown brake pressure) a,becomes the standard value.

When the adjustment screw is turned to the clockwise, the

Lline pressure becomes lower; when it is turned to

counter-clockwise, it becomes higher.

Standard value:

870-890 kPa (124-127 psi)

Oil pressure change for each turq of

adjustment screw: 38

kPa (54 psi)

8. Check to be sure that the O-ring is installed on the upper

surface of the valve body at the place shown in the figure.

9.Replace the O-ring of the solenoid valve harness grommet

with a new one.

10. Insert the solenoid valve harness grommet in the axle case.

11. Install the valve body and oil temperature sensor, and then

(IO pieces) to

tighten valve body assembly mounting bolts

IO-12 Nm (7.5-8.5 ft.lbs.).A: 18 mm

(.709 in.) long

B: 25 mm

(.984 in.) long

C: 40 mm (1.575 in.) long

12. Install the oil filter.

13. Install a new oil pan gasket and oil pan.

14. Pour in the specified amount of Automatic transaxle fluid.

15. Make the oil pressure test. Readjust if necessary.

+-t

--,,

REDUCING PRESSURE ADJUSTMENTNZlFTAC(If the multi-use tester is not available)

1. Remove parts up to the oil filter in the same way as for

adjustment of the line pressure. The valve body need not

be removed.

+%2. Turn the adjustment screw of the lower valve body and_adjust so that the reducing pressure is the standard value.

When the adjustment screw is turned to the right, the

reducing pressure becomes lower; when it is turned to the

left, it becomes higher.

Page 917 of 1216

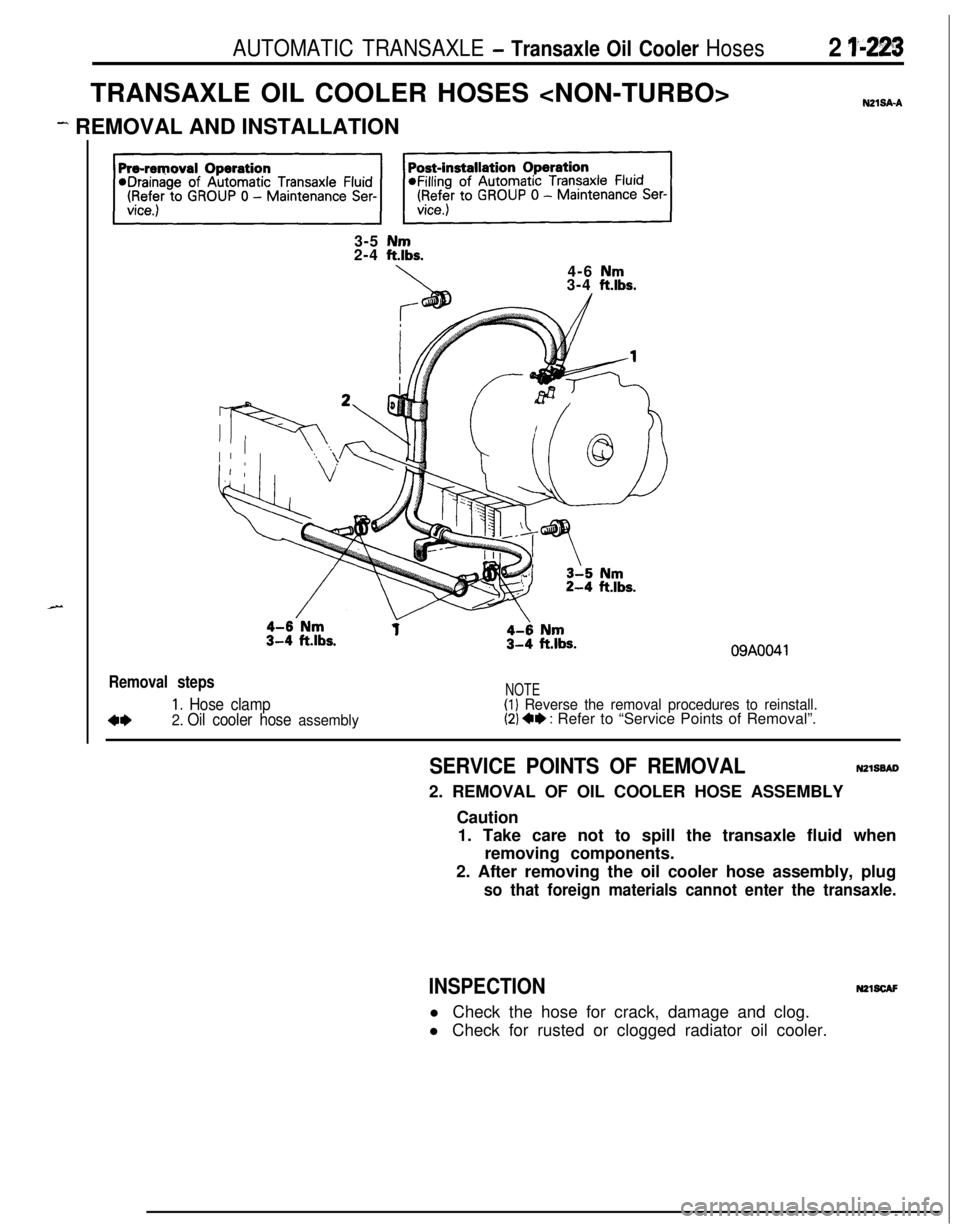

AUTOMATIC TRANSAXLE - Transaxle Oil Cooler Hoses2 I*-223TRANSAXLE OIL COOLER HOSES

NZlSA-A

- REMOVAL AND INSTALLATION

3-5

Nm2-4 ftlbs.

4-6

Nm3-4 ftlbs.

09AOO41

Removal steps

1. Hose clamp

4*2. Oil cooler hose assembly

NOTE(1) Reverse the removal procedures to reinstall.(2) 4e : Refer to “Service Points of Removal”.

SERVICE POINTS OF REMOVALNZISSAD2. REMOVAL OF OIL COOLER HOSE ASSEMBLY

Caution

1. Take care not to spill the transaxle fluid when

removing components.

2. After removing the oil cooler hose assembly, plug

so that foreign materials cannot enter the transaxle.

INSPECTIONm1scAFl Check the hose for crack, damage and clog.

l Check for rusted or clogged radiator oil cooler.

Page 918 of 1216

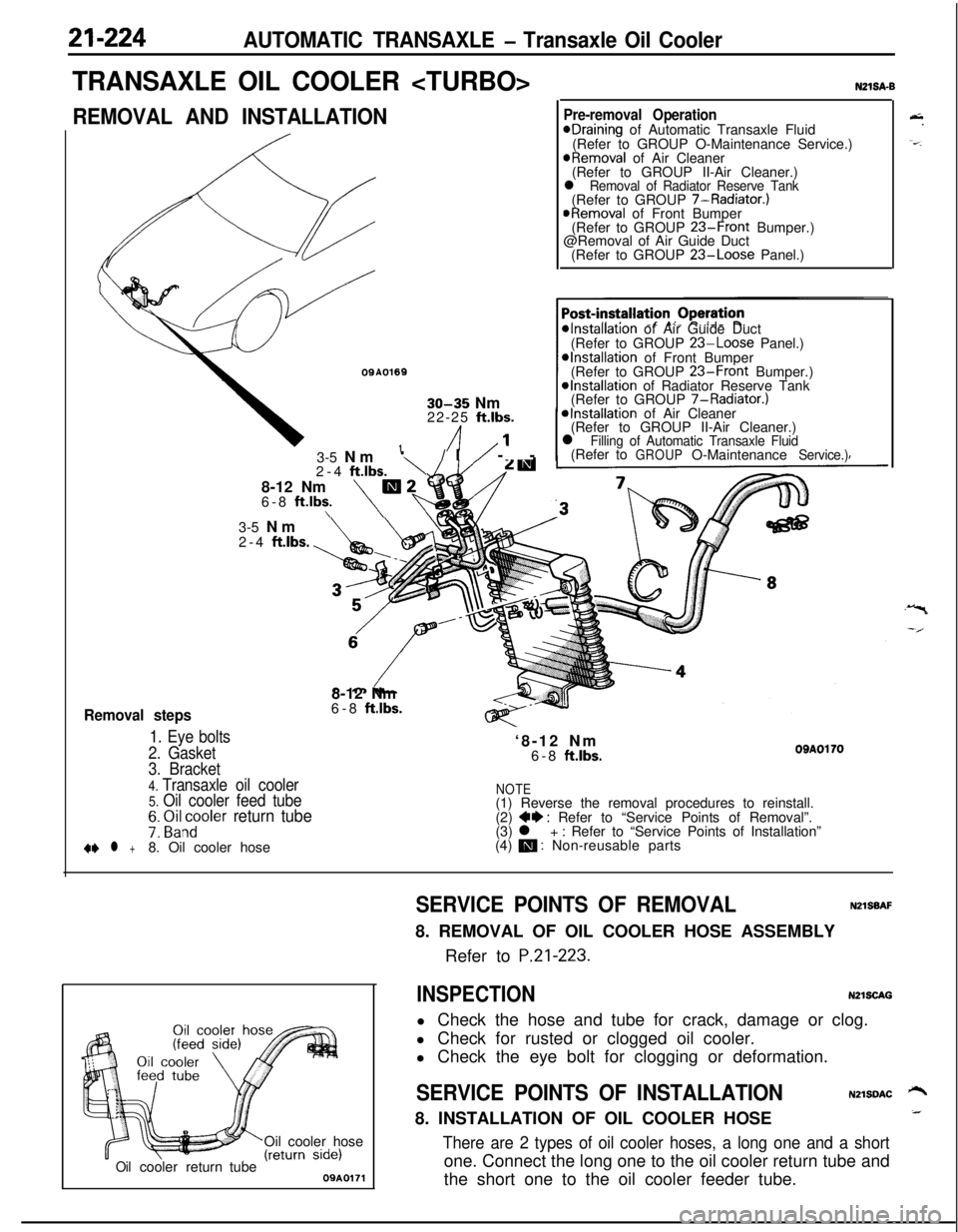

21-224AUTOMATIC TRANSAXLE - Transaxle Oil Cooler

TRANSAXLE OIL COOLER

REMOVAL AND INSTALLATION

OQA01691

30-35 Nm

22-25 ft.lbs.

/I1’

Removal steps

1. Eye bolts

2. Gasket3-5 Nm

‘\/I/ --

2-4

ftlbs.8-12 Nm

m26-8 ft.lbs.\\

N21SA-B

Pre-removal OperationeDraining of Automatic Transaxle Fluid

(Refer to GROUP O-Maintenance Service.)

@Removal of Air Cleaner

(Refer to GROUP II-Air Cleaner.)

l Removal of Radiator Reserve Tank(Refer to GROUP 7-Radiator.)

@Removal of Front Bumper

(Refer to GROUP 23-Front Bumper.)

@Removal of Air Guide Duct

(Refer to GROUP

23-Loose Panel.)

*Installation of Air Guide Duct

(Refer to GROUP 23-Loose Panel.)*Installation of Front Bumper

(Refer to GROUP 23-Front Bumper.)@Installation of Radiator Reserve Tank

(Refer to GROUP 7-Radiator.)

*Installation of Air Cleaner

(Refer to GROUP II-Air Cleaner.)

l Filling of Automatic Transaxle Fluid(Refer toGROUPO-MaintenanceService.)3-5 Nm

2-4

ftlbs.8-12 Nm

6-8

ft.lbs.‘8-12 Nm

6-8

ftlbs.OBAOl703. Bracket

4. Transaxle oil cooler5. Oil cooler feed tubeNOTE(1) Reverse the removal procedures to reinstall.

7: ~i&~oler return tube(2) ++ : Refer to “Service Points of Removal”.

(3) l + : Refer to “Service Points of Installation”

+e l +8. Oil cooler hose(4) m : Non-reusable parts

Oil cooler hose

Oilcoolerreturn tube09A0171

&.

-=-.

SERVICE POINTS OF REMOVALNZlSBAF8. REMOVAL OF OIL COOLER HOSE ASSEMBLY

Refer to

P.21-223.

INSPECTIONN2lSCAGl Check the hose and tube for crack, damage or clog.

l Check for rusted or clogged oil cooler.

l Check the eye bolt for clogging or deformation.

SERVICE POINTS OF INSTALLATIONN2lSDAC ‘-+8. INSTALLATION OF OIL COOLER HOSE_

There are 2 types of oil cooler hoses, a long one and a shortone. Connect the long one to the oil cooler return tube and

the short one to the oil cooler feeder tube.

Page 924 of 1216

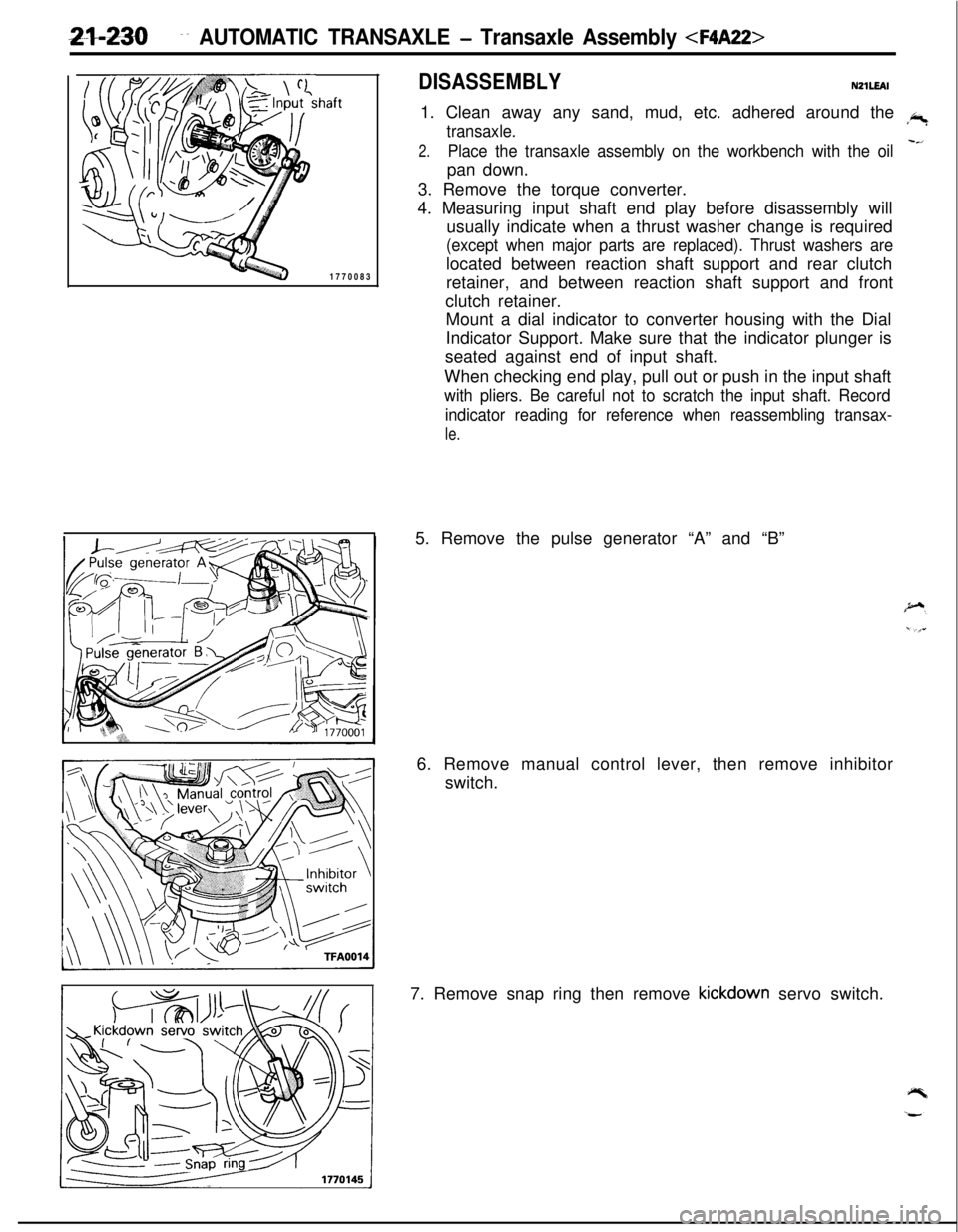

-2.rt-2-30~~ AUTOMATIC TRANSAXLE - Transaxle Assembly

;haft1770083

DISASSEMBLYNZlLEAl1. Clean away any sand, mud, etc. adhered around the

.+

transaxle..

2.

Place the transaxle assembly on the workbench with the oil--’

pan down.

3. Remove the torque converter.

4. Measuring input shaft end play before disassembly will

usually indicate when a thrust washer change is required

(except when major parts are replaced). Thrust washers arelocated between reaction shaft support and rear clutch

retainer, and between reaction shaft support and front

clutch retainer.

Mount a dial indicator to converter housing with the Dial

Indicator Support. Make sure that the indicator plunger is

seated against end of input shaft.

When checking end play, pull out or push in the input shaft

with pliers. Be careful not to scratch the input shaft. Record

indicator reading for reference when reassembling transax-

le.5. Remove the pulse generator “A” and “B”

6. Remove manual control lever, then remove inhibitor

switch.

7. Remove snap ring then remove

kickdown servo switch.