service MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 256 of 1216

7-8COOLING - Service Adjustment Procedures

04DooE

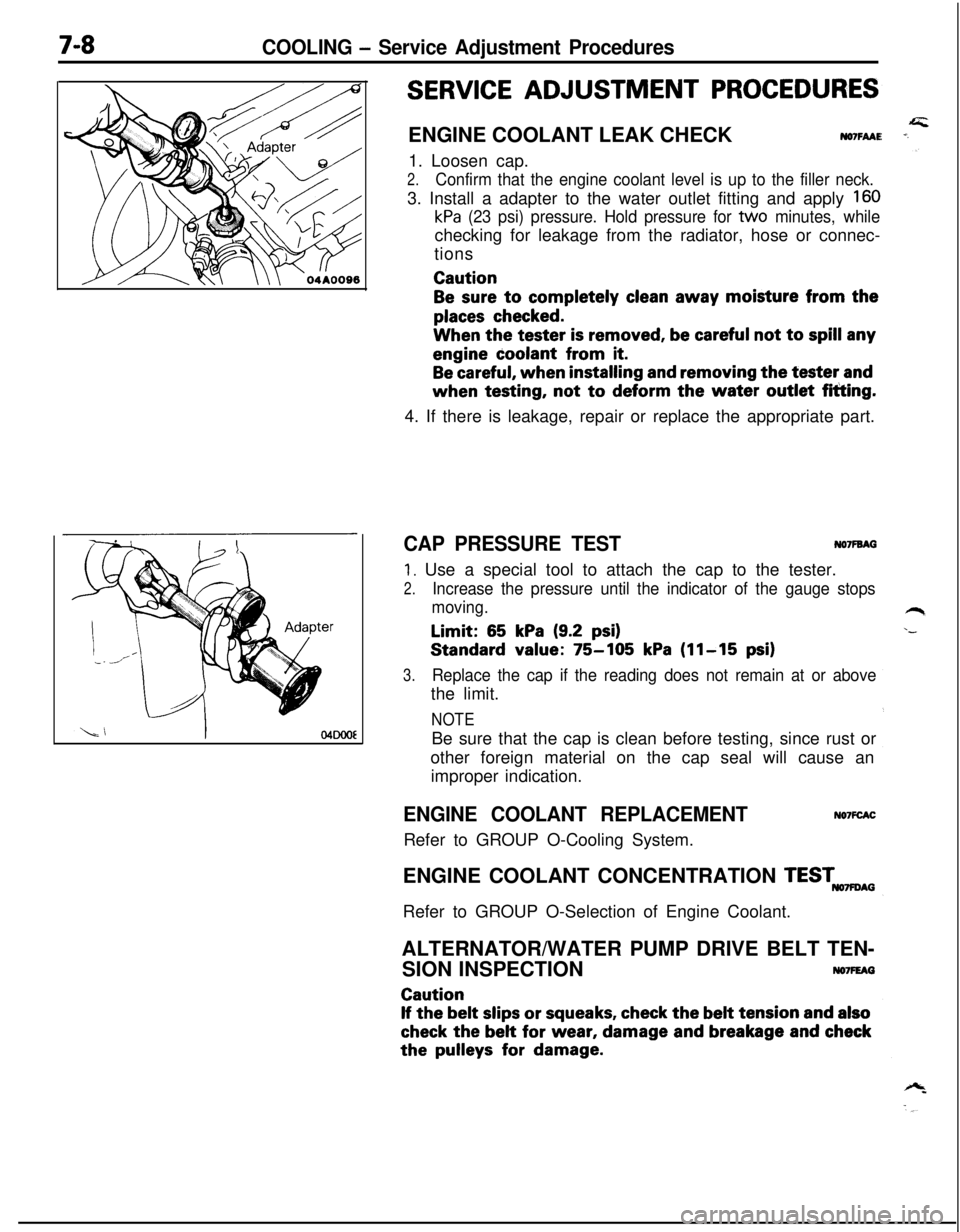

SERVICE ADJUSTMENT PROCEDURESENGINE COOLANT LEAK CHECK

NO7FAAE1. Loosen cap.

2.Confirm that the engine coolant level is up to the filler neck.3. Install a adapter to the water outlet fitting and apply

160

kPa (23 psi) pressure. Hold pressure for tvvo minutes, whilechecking for leakage from the radiator, hose or connec-

tionsCaution

Be sure to completely clean away moisture from the

places checked.When the tester

is removed, be careful not to spill anyengine coolant from

it.

Be careful, when installing and removing the tester andwhen testing, not

to deform the water outlet fitting.

4. If there is leakage, repair or replace the appropriate part.

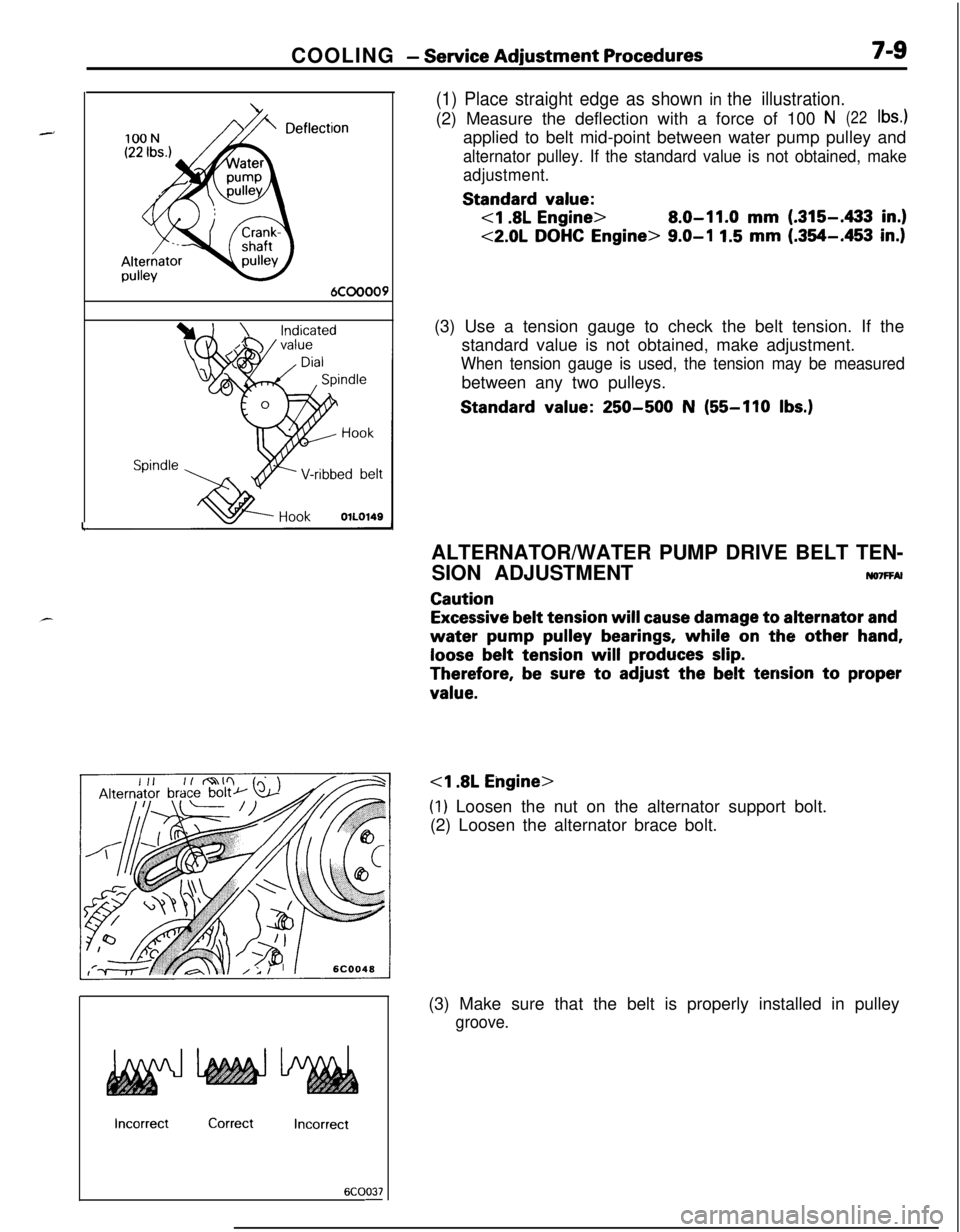

CAP PRESSURE TESTNO’IFBAG

1. Use a special tool to attach the cap to the tester.

2.Increase the pressure until the indicator of the gauge stops

moving.Limit:

65 kPa (9.2 psi)Standard value:

75-105 kPa (11-15 psi)

3.Replace the cap if the reading does not remain at or abovethe limit.

NOTEBe sure that the cap is clean before testing, since rust or

other foreign material on the cap seal will cause an

improper indication.

ENGINE COOLANT REPLACEMENTRefer to GROUP O-Cooling System.NO’IFCACENGINE COOLANT CONCENTRATION

TESTmAGRefer to GROUP O-Selection of Engine Coolant.

ALTERNATOR/WATER PUMP DRIVE BELT TEN-

SION INSPECTION

NO7FEAGCaution

If the belt slips or squeaks, check the belt tension and also

check the belt for wear, damage and breakage and checkthe

pulleys for damage.

Page 257 of 1216

COOLING - Service Adjustment Procedures7-9Alterhatorpulley

6COOOO9

Spindle

l-

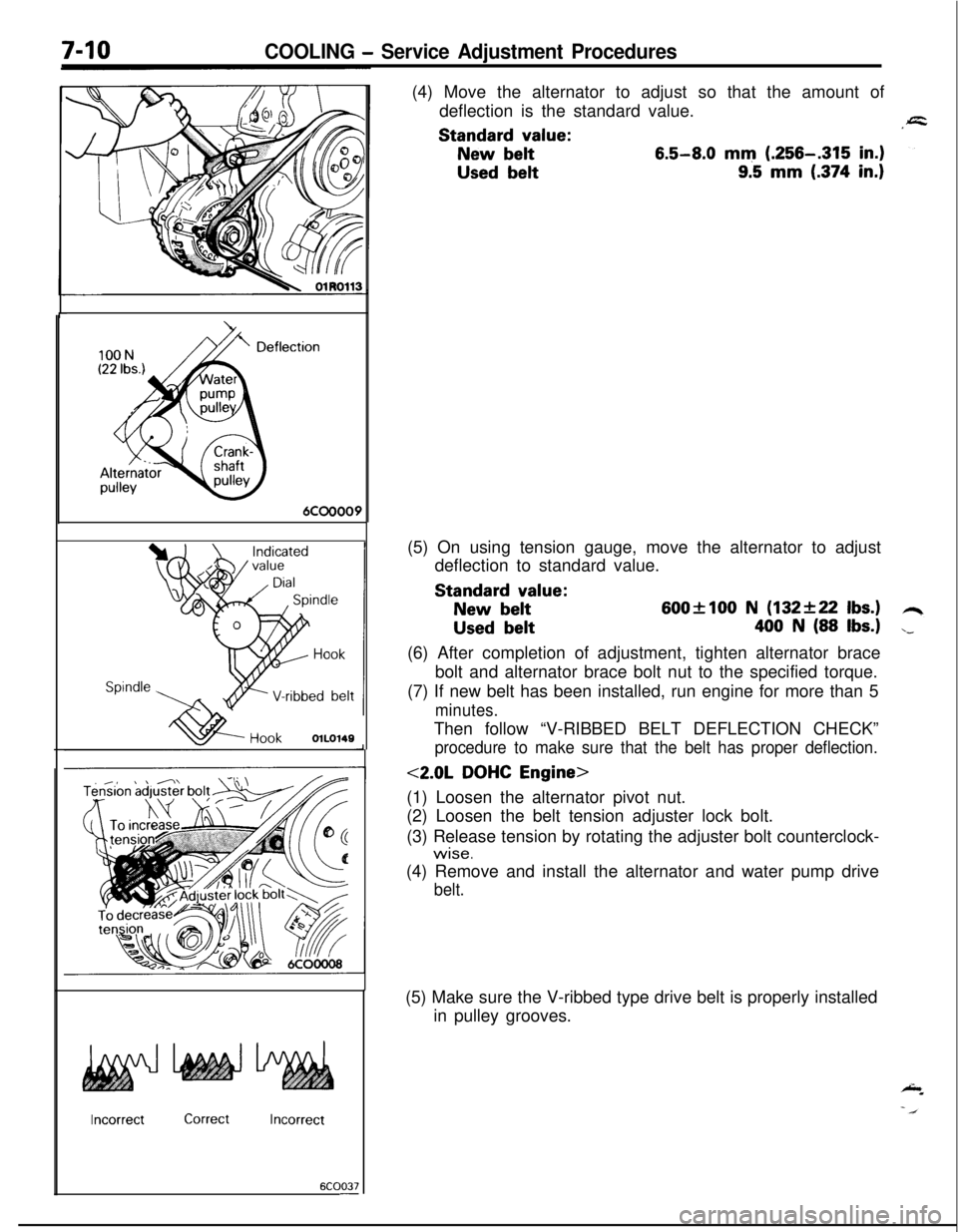

(1) Place straight edge as shown in the illustration.(2) Measure the deflection with a force of 100

N(22lb4applied to belt mid-point between water pump pulley and

alternator pulley. If the standard value is not obtained, make

adjustment.Standard

value:

8.0-11.0 mm (.315-433 in.)

<2.0L DOHC Engine> 9.0-I 1.5 mm (.354-.453 in.)(3) Use a tension gauge to check the belt tension. If the

standard value is not obtained, make adjustment.

When tension gauge is used, the tension may be measuredbetween any two pulleys.Standard

value: 250-500 N (55-110 Ibs.)

IncorrectCorrectIncorrect

6COO37-ALTERNATOR/WATER PUMP DRIVE BELT TEN-

SION ADJUSTMENT

ruo7FFAl

Caution

Excessive belt tension will cause damage to alternator and

water pump pulley bearings, while on the other hand,

loose belt tension will produces slip.

Therefore, be sure to adjust the belt tension to proper

value.

(1) Loosen the nut on the alternator support bolt.

(2) Loosen the alternator brace bolt.

(3) Make sure that the belt is properly installed in pulley

groove.

Page 258 of 1216

COOLING - Service Adjustment Procedures100N

(22 Ibs.)

DeflecAlternator

ypulley

:tion

6COOOO9

Spindle ,

HookOlLO149

IncorrectCorrectIncorrect

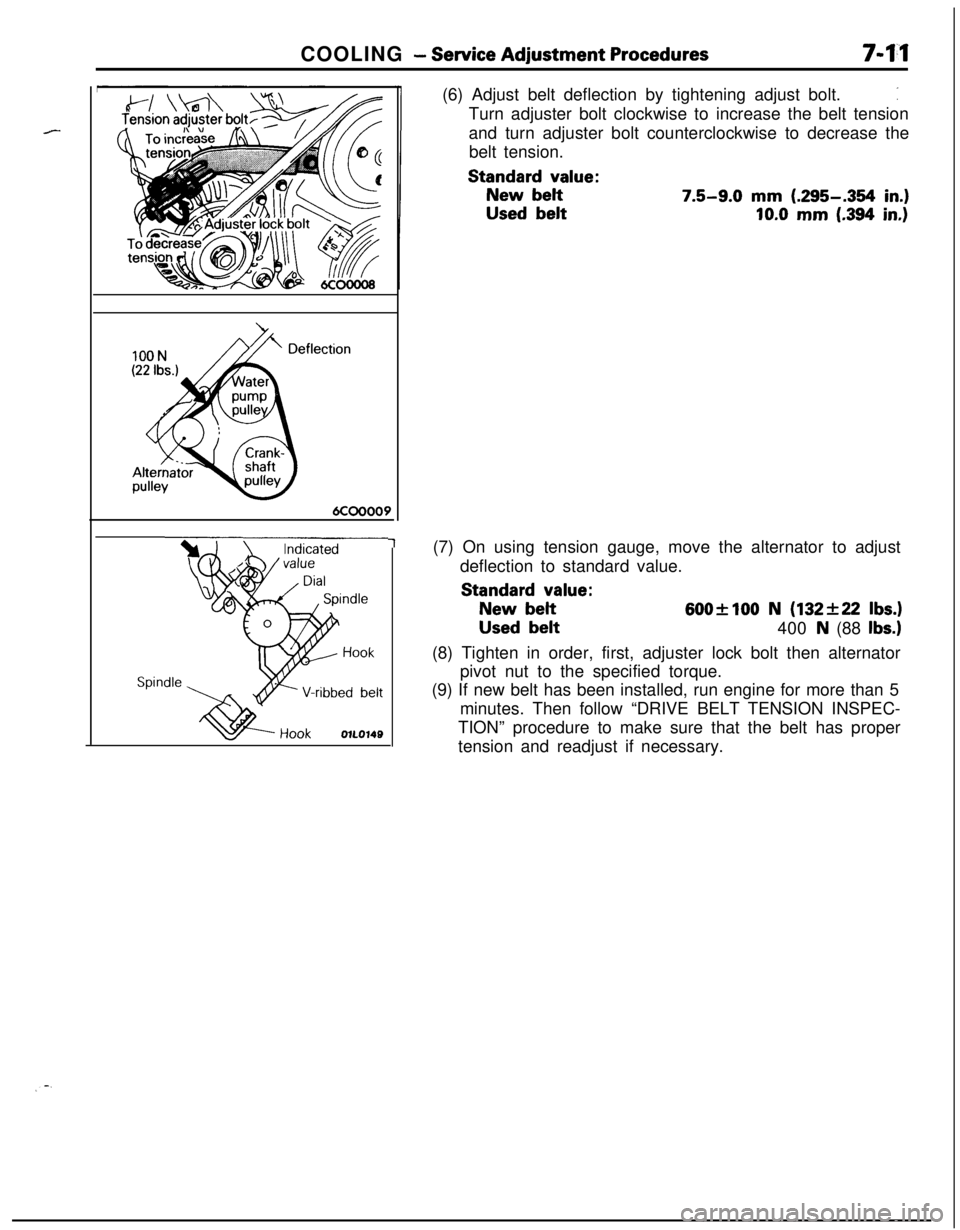

6COO37-(4) Move the alternator to adjust so that the amount of

deflection is the standard value.Standard

value:

New belt6.5-8.0 mm (.256-.315 in.)

Used belt9.5 mm (.374 in.)(5) On using tension gauge, move the alternator to adjust

deflection to standard value.Standard

value:

New belt600flOO N (132+22 Ibs.)

Used belt400 N (88 Ibs.)(6) After completion of adjustment, tighten alternator brace

bolt and alternator brace bolt nut to the specified torque.

(7) If new belt has been installed, run engine for more than 5

minutes.Then follow “V-RIBBED BELT DEFLECTION CHECK”

procedure to make sure that the belt has proper deflection.

<2.0L DOHC Engine>

(1) Loosen the alternator pivot nut.

(2) Loosen the belt tension adjuster lock bolt.

(3) Release tension by rotating the adjuster bolt counterclock-

wise.(4) Remove and install the alternator and water pump drive

belt.(5) Make sure the V-ribbed type drive belt is properly installed

in pulley grooves.

Page 259 of 1216

COOLING - Service Adjustment Procedures7-m

1(6) Adjust belt deflection by tightening adjust bolt.

:Turn adjuster bolt clockwise to increase the belt tension

and turn adjuster bolt counterclockwise to decrease the

belt tension.

Standard value:

New belt7.5-9.0 mm (.295-.354 in.)

Used belt10.0 mm (.394 in.)(7) On using tension gauge, move the alternator to adjust

deflection to standard value.

Standard value:

New belt600+100 N (132f22 Ibs.)

Used belt

400 N (88 Ibs.)(8) Tighten in order, first, adjuster lock bolt then alternator

pivot nut to the specified torque.

(9) If new belt has been installed, run engine for more than 5

minutes. Then follow “DRIVE BELT TENSION INSPEC-

TION” procedure to make sure that the belt has proper

tension and readjust if necessary.

Page 260 of 1216

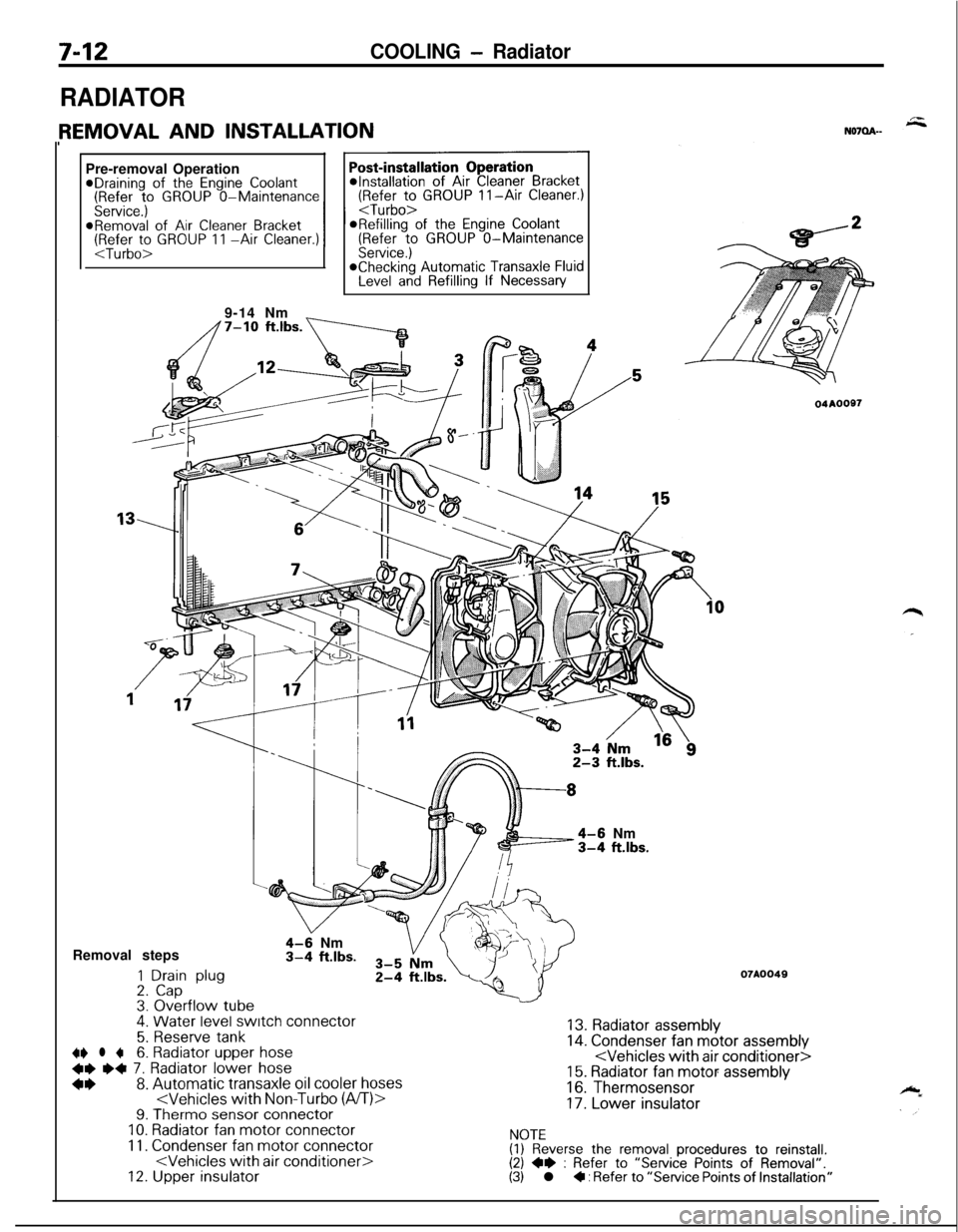

7-12COOLING - Radiator

RADIATORPre-removal Operation

@Draining of the Engine Coolant(Refer to GROUP O-Maintenance(Refer to GROUP II-Air Cleaner.)

Service.)

I I

9-14 Nm

_

4-6 Nm3-4 ft.lbs.Removal steps

1 Drain plug2. Cap3. Overflow tube.

4-9 Nm3-4 ft.lbs.

4. Water level switch connector

5. Reserve tank~~ l +6. Radiator upper hose

+e e+ 7. Radiator lower hose

*I)8. Automatic transaxle oil cooler hoses

11. Condenser fan motor connector

04AOOS7

07A0049

13. Radiator assembly14. Condenser fan motor assembly

16. Thermosensor

17. Lower insulator

NOTE(1) Reverse the removal procedures to reinstall.(2) +e : Refer to “Service Points of Removal”.(3) l + : Refer to “Service Points of Installation”

Page 261 of 1216

COOLING- Radiator7-13Mating

marks

04A0020

SERVICE POINTS OF REMOVALN07QBAH

6. REMOVAL OF RADIATOR UPPER HOSE/7. RADIATOR

LOWER HOSEAfter making mating marks on the radiator hose and the

hose clamp, disconnect the radiator hose.

8. DISCONNECTION OF AUTOMATIC TRANSAXLE OIL

COOLER HOSESUse a plug or otherwise cover the hose and nipple part of

the radiator so that dust, dirt, foreign materials, etc. do not

enter after the hose has been disconnected from the

radiator.

INSPECTIONNo7OcAMl Check for foreign material between radiator fins.

l Check the radiator fins for bent, or damage.

l Check the radiator for corrosion, damage rust or scale.

lCheck the radiator hoses for cracks, damage or deteriora-

tion.l Check the reserve tank for damage.

lCheck the automatic transaxle oil cooler hoses for cracking,damage or deterioration.

RADIATOR FAN MOTOR INSPECTION(1) Check to be sure that the radiator fan rotates when batten/

voltage is applied between terminals (as shown in the

figure).

(2) Check to see that abnormal noises are not produced, whilemotor is turning.

THERM0 SENSOR INSPECTIONCheck for continuity with the therm0 sensor in hot water.

NOTEImmerse therm0 sensor in hot water up to mounting thread to

check for continuity.

Page 262 of 1216

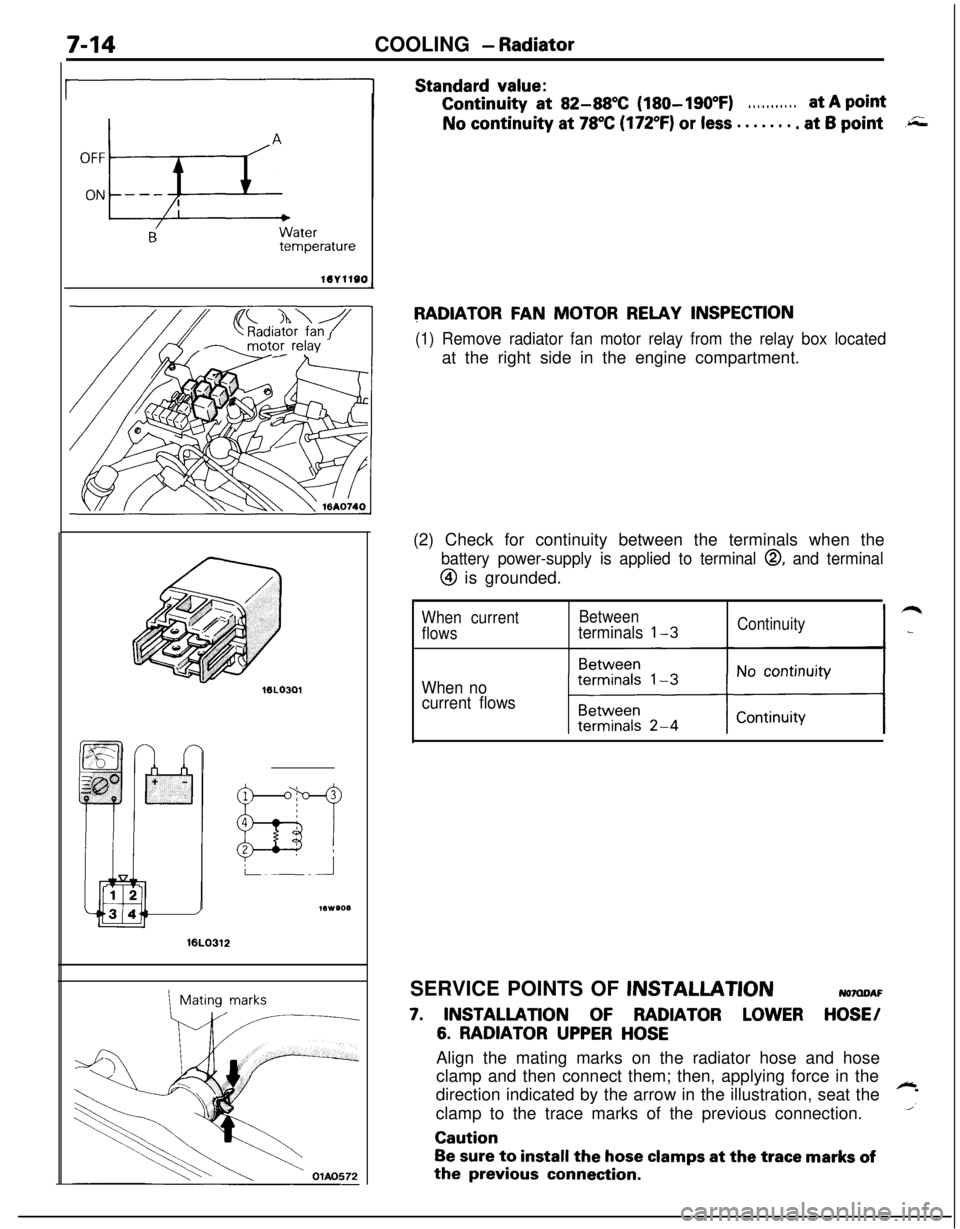

7-14COOLING - Radiator

A

OFF

ON

h

--- ,

BWatertemperature

16v1100

Standard value:Continuity

at 82-88X (180-190°F). . . . . . . . . . .at A pointNo continuity at

78°C (172°F) or less . . . . . . . . at 6 point.r;;;

RADIATOR FAN MOTOR RELAY INSPECTION

(1) Remove radiator fan motor relay from the relay box locatedat the right side in the engine compartment.

16LO312

1Mating marks(2) Check for continuity between the terminals when the

battery power-supply is applied to terminal 0, and terminal

@ is grounded.

When currentBetween

flowsterminals l-3Continuity

When no

current flowsSERVICE POINTS OF

JNSTALLATIONNOMDAF

7. INSTALLATION OF RADIATOR LOWER HOSE/

6. RADIATOR UPPER HOSEAlign the mating marks on the radiator hose and hose

clamp and then connect them; then, applying force in the

direction indicated by the arrow in the illustration, seat the

~

1clamp to the trace marks of the previous connection.Caution

Be sure to install the hose clamps at the trace marks ofthe

previous connection.

Page 263 of 1216

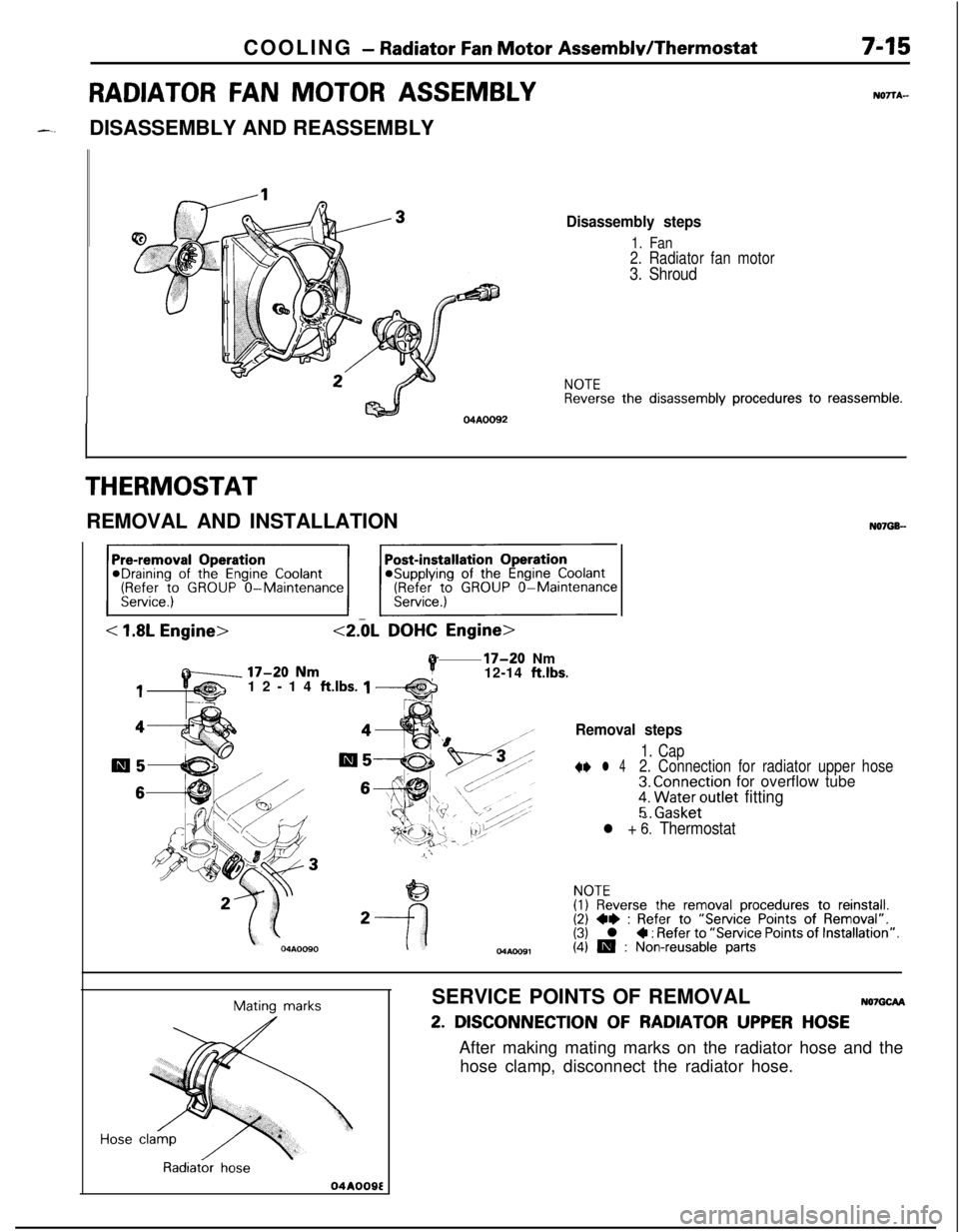

COOLING - Radiator Fan Motor AssemblvIThermostat7-15

RADIATOR FAN MOTOR ASSEMBLYDISASSEMBLY AND REASSEMBLY

04AOO92

NOTTA-

Disassembly steps

1. Fan2. Radiator fan motor

3. Shroud

NOTEReverse the disassembly procedures to reassemble.

THERMOSTATREMOVAL AND INSTALLATION

N07G6-

< 1.8LDOHC

P17-20 Nm

12-14 ft.lbs.

112-14 ftlbs. 1

44Removal steps

m5al51. Cap+e l 42. Connection for radiator upper hose

663. Connection for overflow tube

;. ra;t;er;utlet fitting

l + 6: Thermostat

NOTE

2(I) Reverse the removal procedures to reinstall.(2) ~~ : Refer to “Service Points of Removal”.(3) l 4 : Refer to “Service Points of Installation”.

04Aoo91(4) 19 : Non-reusable parts

Mating marks

Radiator hose

04A009ESERVICE POINTS OF REMOVAL

NO7GCFU

2. DISCONNECTION OF RADIATOR UPPER HOSEAfter making mating marks on the radiator hose and the

hose clamp, disconnect the radiator hose.

Page 264 of 1216

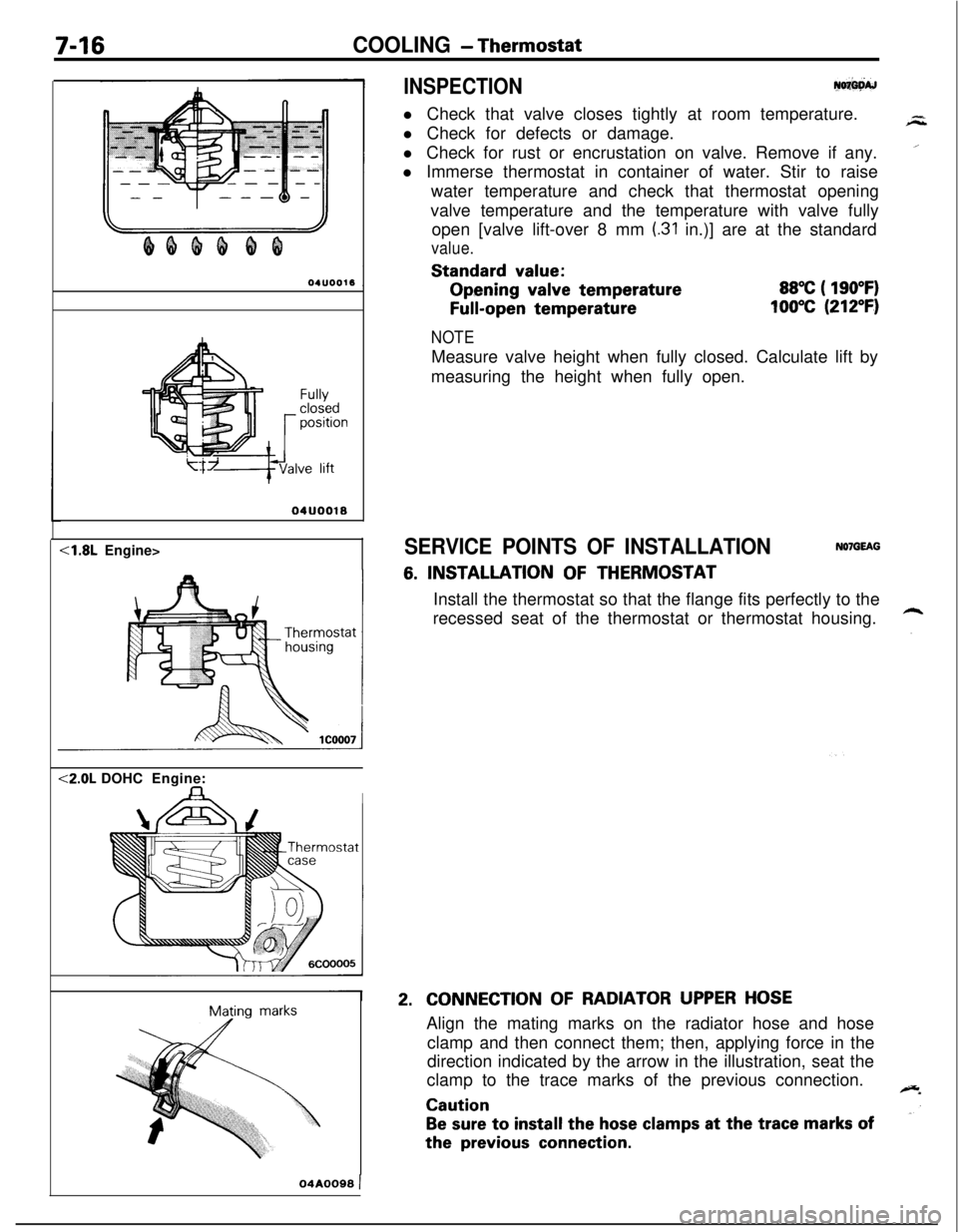

7-16COOLING - Thermostat

INSPECTIONy+w

l Check that valve closes tightly at room temperature.

l Check for defects or damage.

l Check for rust or encrustation on valve. Remove if any.

l Immerse thermostat in container of water. Stir to raise

water temperature and check that thermostat opening

valve temperature and the temperature with valve fully

open [valve lift-over 8 mm

(.31 in.)] are at the standard

value.Standard

value:Opening

valve temperature

Full-open temperature

88°C ( 190°F)

100°C (212°F)

Fullyclosedpositionve lift

04UOO18<1.8L Engine><2.0L DOHCEngine:

IMating

marks

NOTEMeasure valve height when fully closed. Calculate lift by

measuring the height when fully open.

SERVICE POINTS OF INSTALLATIONNOlGEAG

6. INSTALLATION OF THERMOSTAT

Install the thermostat so that the flange fits perfectly to the

recessed seat of the thermostat or thermostat housing.

2.CONNECTION OF RADIATOR UPPER HOSEAlign the mating marks on the radiator hose and hose

clamp and then connect them; then, applying force in the

direction indicated by the arrow in the illustration, seat the

clamp to the trace marks of the previous connection.

Caution

Be sure to install the hose clamps at the trace marks ofthe

previous connection.

04A0099 )

Page 265 of 1216

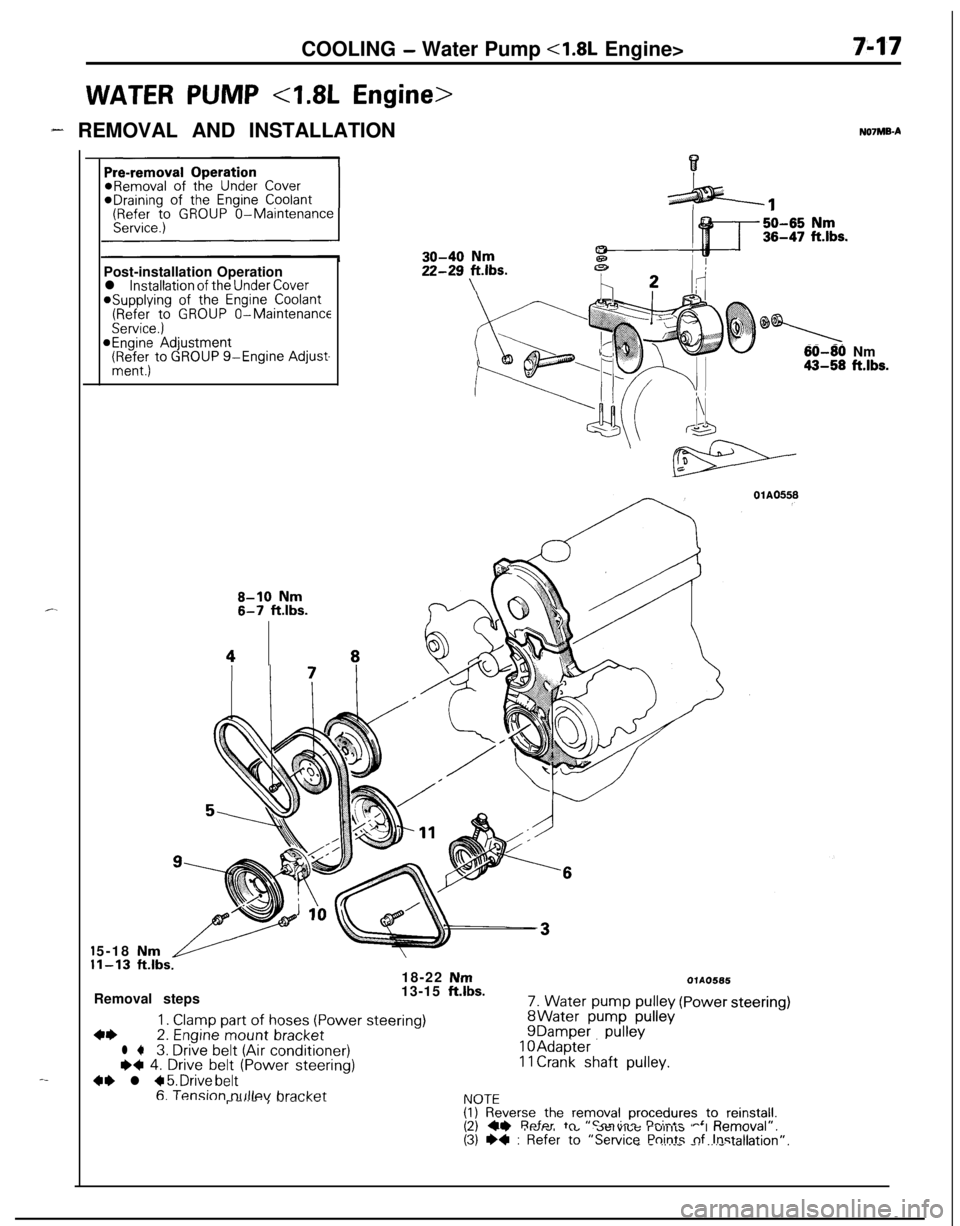

COOLING - Water Pump <1.8L Engine>

WATER PUMP 4.8L Engine>

7-17

- REMOVAL AND INSTALLATION

c.

-_*Draining of

the Engine Coolant(Refer to GROUP O-Maintenance

Post-installation Operation

l installation of the Under Cover@Supplying of the Engine Coolant(Refer to GROUP O-MaintenanceService.)@Engine Adjustment(RR:; to GROUP g-Engine Adjust-

8-10 Nm6-7 ftlbs.

48NOlMB-A

30-40 Nm

22-2g Fbs.

0

60-80 Nm43-58 ft.lbs.5-18

Nm1-13 ft.lbs.18-22 NmRemoval steps13-15 ft.lbs.

1. Clamp part of hoses (Power steering)4+2. Engine mount bracketl +3. Drive belt (Air conditioner)I)+ 4. Drive belt (Power steering)

4+ l + 5. Drive belt

7. Water pump pulleyWater pump pulleyDamper pullevAdapter. ’Crank shaft pulley.

OlAO566

(Powersteering)

6. Tension tx~llev bra&&I\lnTFr--‘--I -‘--‘.--I.VIL(I) Reverse the removal procedures to reinstall.I?\ CI Refer tn “Smvirr rh:-*- -‘ D---./al”,\-, --. I.VIw, .”..-..,u; r”llllb “I “allI”\(3) +4 : Refer to “Service Points nf Instalk_ - .,.__ -. _.._ .-Jion”.