oil MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 414 of 1216

9-130ENGINE <2.0L DOHC Engine> - Piston and Connecting Rod

8. INSTALLATION OF PISTON RING

NO.217. PISTON

RING

NO.1

\ ’7EN250

Non-TurboTurbo

Upper

LCsiae rail

6

3wer’ ‘I

EN041

No.2 ring gap

and spacer gap

der

No.

Notch

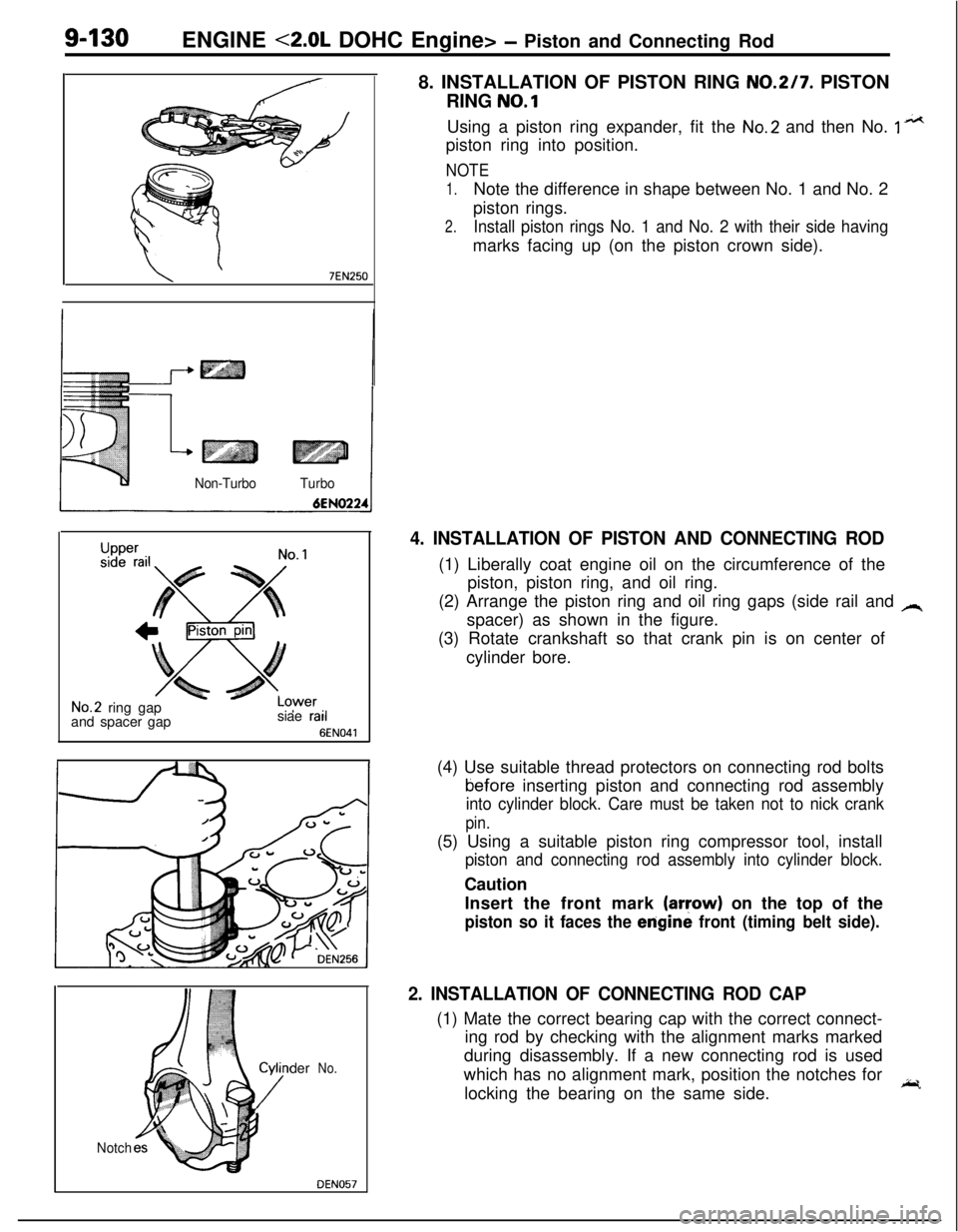

DEN057Using a piston ring expander, fit the

No.2 and then No. 1 n*tpiston ring into position.

NOTE

1.Note the difference in shape between No. 1 and No. 2

piston rings.

2.Install piston rings No. 1 and No. 2 with their side havingmarks facing up (on the piston crown side).

4. INSTALLATION OF PISTON AND CONNECTING ROD(1) Liberally coat engine oil on the circumference of the

piston, piston ring, and oil ring.

(2) Arrange the piston ring and oil ring gaps (side rail and

Aspacer) as shown in the figure.

(3) Rotate crankshaft so that crank pin is on center of

cylinder bore.

(4) Use suitable thread protectors on connecting rod boltstiefore inserting piston and connecting rod assembly

into cylinder block. Care must be taken not to nick crank

pin.(5) Using a suitable piston ring compressor tool, install

piston and connecting rod assembly into cylinder block.Caution

Insert the front mark

(aryow) on the top of the

piston so it faces the erigine front (timing belt side).

2. INSTALLATION OF CONNECTING ROD CAP(1) Mate the correct bearing cap with the correct connect-

ing rod by checking with the alignment marks marked

during disassembly. If a new connecting rod is used

which has no alignment mark, position the notches for

locking the bearing on the same side.

I;r.

Page 416 of 1216

g-132 ENGINE <2.0L DOHC ‘Engine>- Crankshaft, Flywheel and Drive Plate

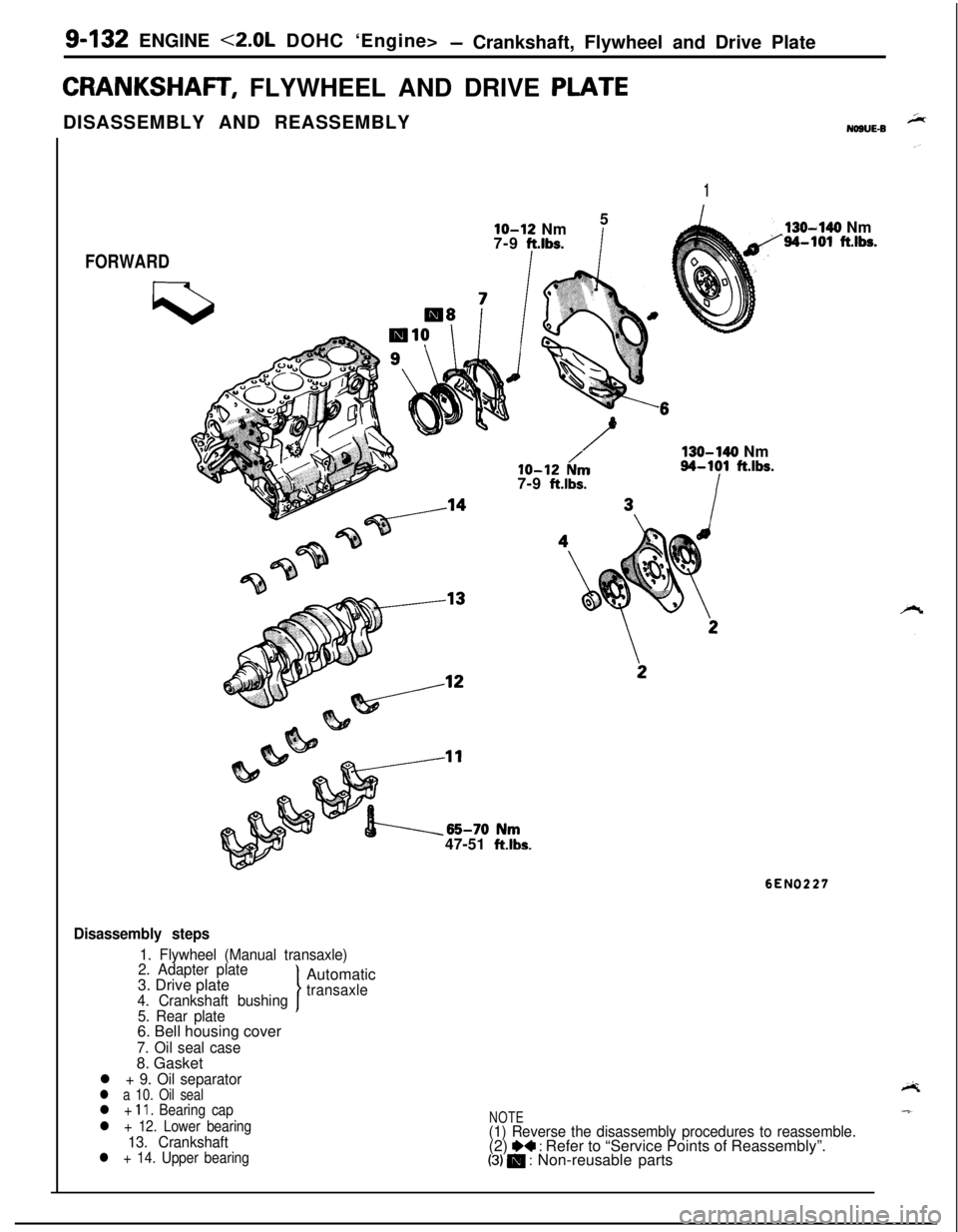

CRANKSHAFT, FLYWHEEL AND DRIVE PLATEDISASSEMBLY AND REASSEMBLY

NOBUE-B

1

lo-12 Nm5

7-9 ft.lbs.I

FORWARDIO-12

N/m7-9 ft.lbs.

130-140 Nm94-101 ft.lbs.

I47-51

ftlbs.

130-140 Nm‘94-101 ft.lbs.

6ENO227

Disassembly steps

1. Flywheel (Manual transaxle)

2. Adapter plate3. Drive plateAutomatic

4. Crankshaft bushingtransaxle

5. Rear plate6. Bell housing cover

7. Oil seal case8. Gasket

l + 9. Oil separatorl a 10. Oil seall + 11. Bearing cap

l + 12. Lower bearing

13. Crankshaftl + 14. Upper bearing

NOTE(1) Reverse the disassembly procedures to reassemble.(2) e+ : Refer to “Service Points of Reassembly”.(3) 0 : Non-reusable parts

Page 417 of 1216

ENGINE <2.0L DOHC Engine>- Crankshaft, Flywheel and Drive Plate,91133

INSPECTIONNOSUHAD

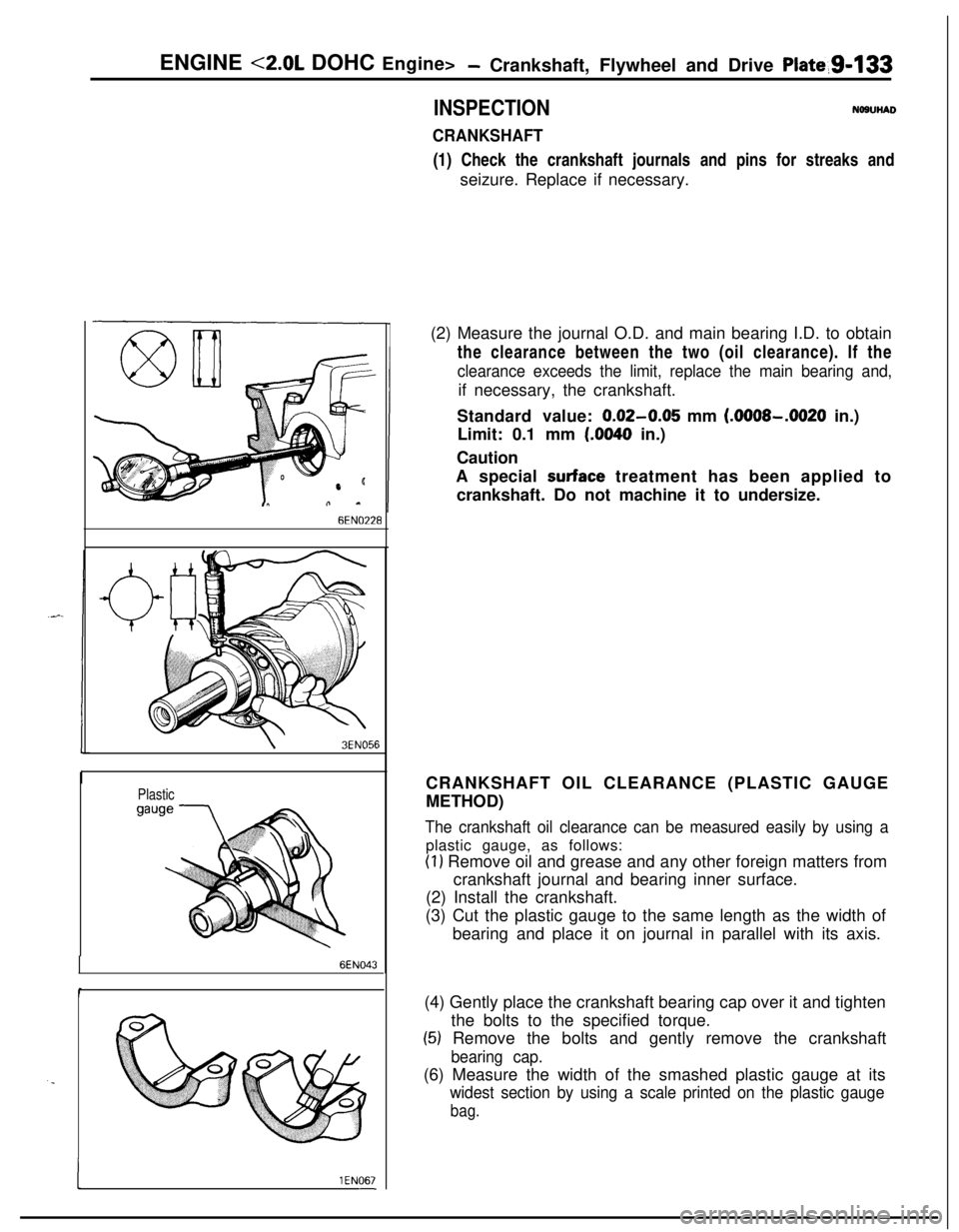

CRANKSHAFT(1) Check the crankshaft journals and pins for streaks and

seizure. Replace if necessary.

6EN0’228

\3EN056

Plastic

6EN043

. .

I1 EN067-(2) Measure the journal O.D. and main bearing I.D. to obtain

the clearance between the two (oil clearance). If the

clearance exceeds the limit, replace the main bearing and,if necessary, the crankshaft.

Standard value:

0.02-0.05 mm (.OOOS-.0020 in.)

Limit: 0.1 mm

(.0040 in.)

Caution

A special

surface treatment has been applied to

crankshaft. Do not machine it to undersize.

CRANKSHAFT OIL CLEARANCE (PLASTIC GAUGE

METHOD)

The crankshaft oil clearance can be measured easily by using aplastic gauge, as follows:

(1) Remove oil and grease and any other foreign matters from

crankshaft journal and bearing inner surface.

(2) Install the crankshaft.

(3) Cut the plastic gauge to the same length as the width of

bearing and place it on journal in parallel with its axis.

(4) Gently place the crankshaft bearing cap over it and tighten

the bolts to the specified torque.

(5) Remove the bolts and gently remove the crankshaft

bearing cap.(6) Measure the width of the smashed plastic gauge at its

widest section by using a scale printed on the plastic gauge

bag.

Page 418 of 1216

g-134 ENGINE <2.0L DOHC Engine>- Crankshaft, Flywheel and Drive Plate

3EN301CRANKSHAFT REAR OIL SEAL

(1) Check oil seal lip for wear and damage.

(2) Check rubber for deterioration or hardening.

(3) Check oil seal case for cracks and damage.

RING GEAR (Engine with a manual transaxle)

Check teeth of ring gear for wear and damage. If necessary,

replace the ring gear.

If the ring gear teeth are worn or damaged, also check the

starter motor pinion.

To remove the ring gear, strike the ring gear at several points

on its outer circumference. The ring gear cannot be removed ifit is heated.

To install the ring gear, heat the ring gear to

300°C (572°F) for

shrink fit.

FLYWHEEL (Engine with a manual transaxle)

(1) Check the clutch disc friction surface for ridge wear,

streaks, and seizure. If necessary, replace flywheel.

(2) If the

runout of flywheel exceeds the limit, replace.++.Limit: 0.13 mm

(.0051 in.)

DRIVE PLATE (Engine with an automatic transaxle)

Replace deformed, damaged, or cracked drive plates.

SERVICE POINTS OF REASSEMBLYNWUGAB

14. INSTALLATION OF CRANKSHAFT BEARING (UPPER)

Install the upper crankshaft bearing to the cylinder block.

There is an oil groove in the upper crankshaft bearing.

There is no difference between upper and lower bearings

for the center (with flange).

12. INSTALLATION OF CRANKSHAFT BEARING (LOWER)

Install the lower crankshaft bearing (with no oil groove;

there is no difference for center) to each bearing cap and

apply engine oil to bearing surfaces.

Page 419 of 1216

ENGINE <2.0L DOHC Engine> -Crankshaft, Flywheel and Drive Plate g-135

‘I. _

Front ofengine

(Timing

belt side)

BEN02

DEN063

6ENO48-

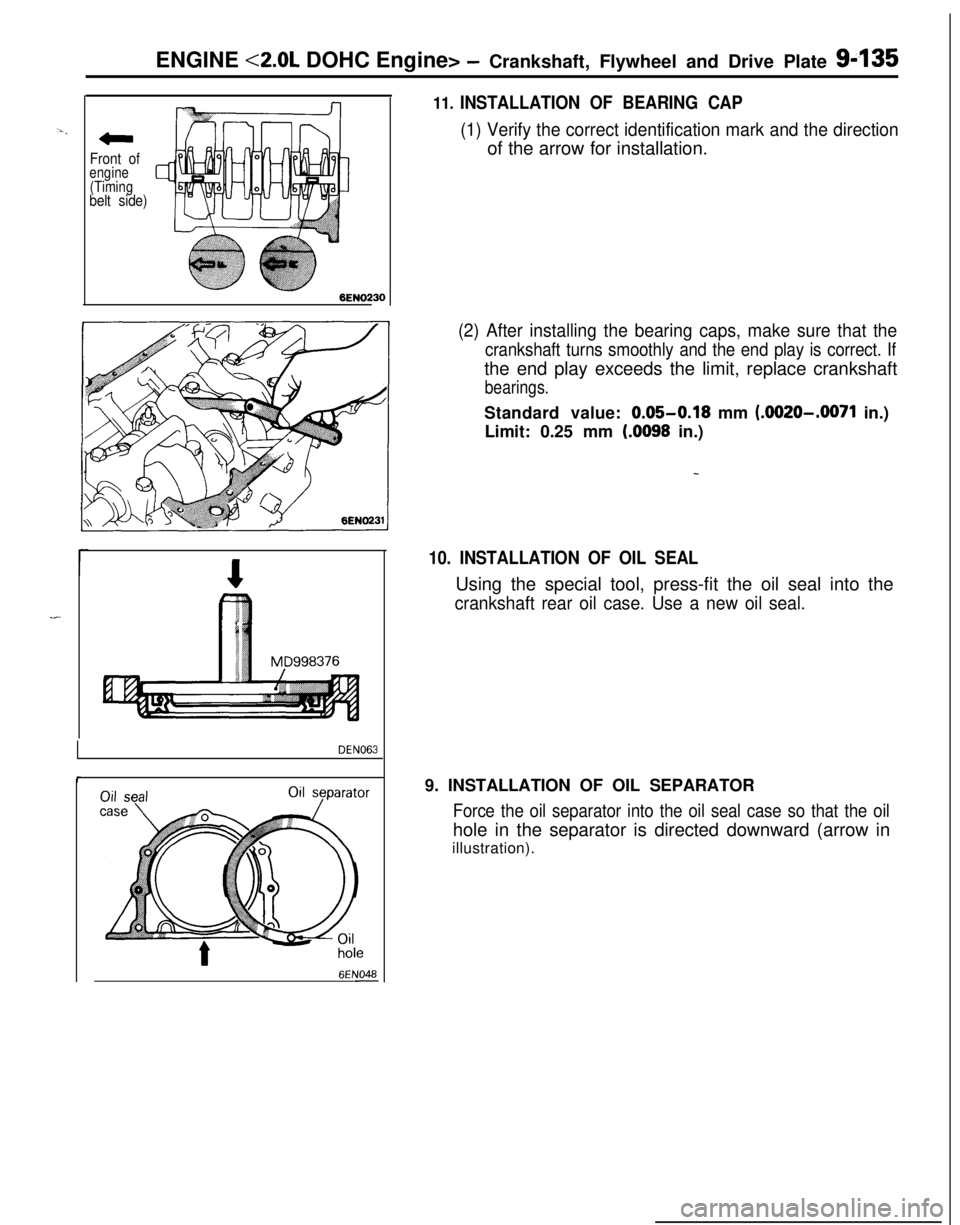

11. INSTALLATION OF BEARING CAP

(1) Verify the correct identification mark and the directionof the arrow for installation.

(2) After installing the bearing caps, make sure that the

crankshaft turns smoothly and the end play is correct. Ifthe end play exceeds the limit, replace crankshaft

bearings.Standard value:

0.05-0.18 mm (.0020-.0071 in.)

Limit: 0.25 mm

(.0098 in.)

10. INSTALLATION OF OIL SEALUsing the special tool, press-fit the oil seal into the

crankshaft rear oil case. Use a new oil seal.9. INSTALLATION OF OIL SEPARATOR

Force the oil separator into the oil seal case so that the oilhole in the separator is directed downward (arrow in

illustration).

Page 420 of 1216

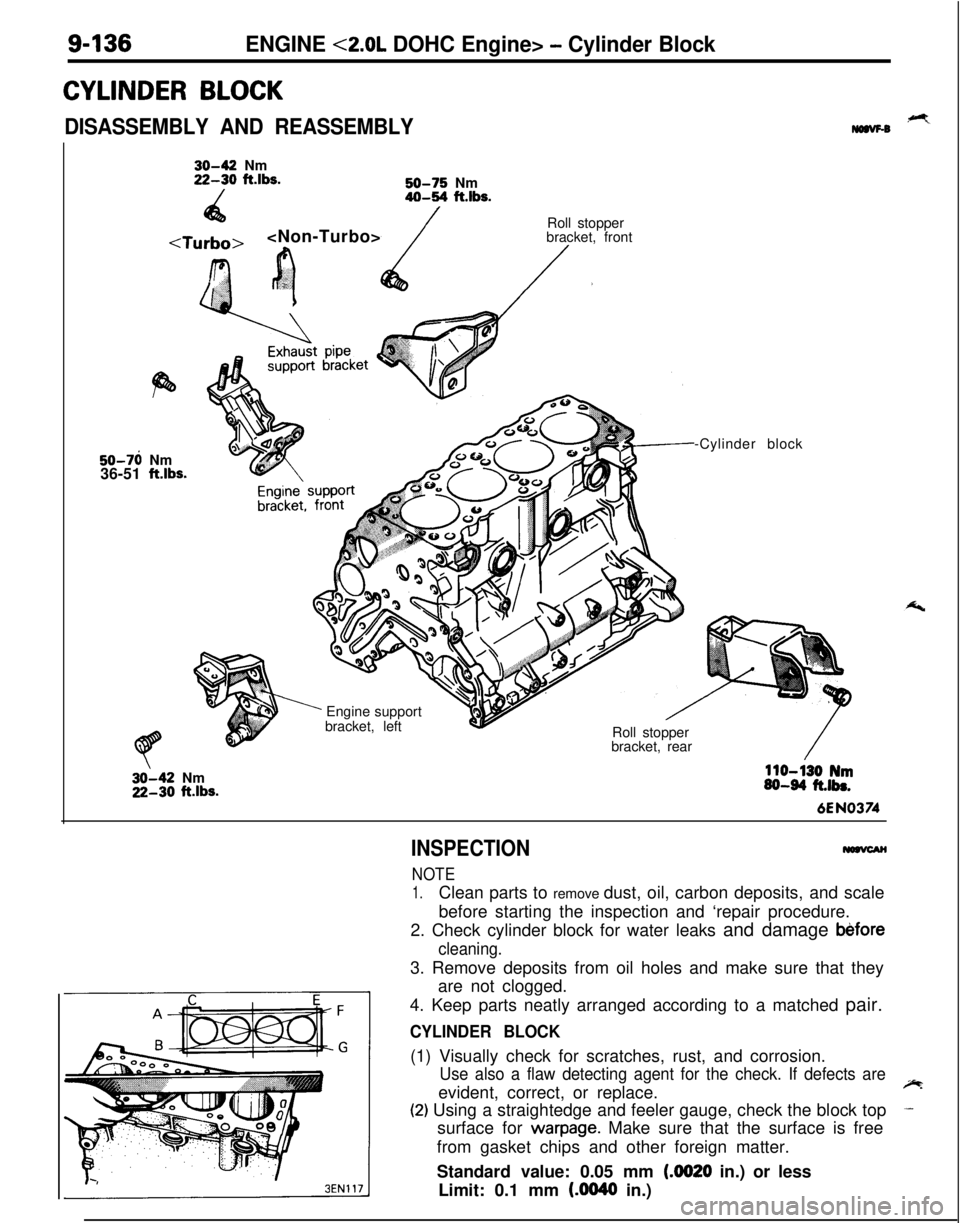

9-136ENGINE <2.0L DOHC Engine> - Cylinder Block

CYLINDER BLOCK

DISASSEMBLY AND REASSEMBLY,+Ymaw-030-42 Nm22-30 ft.lbs.

/50-75 Nm40-54 ft.lbs.

4a

r.‘?’

’ cRoll stopper

bracket, front/.50-76 Nm

36-51

ftlbs.

’ Engine support

bracket, left

Roll stopper

bracket, rear-Cylinder block32-42 Nm22-30

ftlbs.

110-130 Nm60-64 ft.lbs.6EN0374

INSPECTION

NOTE

1.Clean parts to remove dust, oil, carbon deposits, and scale

before starting the inspection and ‘repair procedure.

2. Check cylinder block for water leaks and damage

b&fore

cleaning.3. Remove deposits from oil holes and make sure that they

are not clogged.

4. Keep parts neatly arranged according to a matched pair.

CYLINDER BLOCK(1) Visually check for scratches, rust, and corrosion.

Use also a flaw detecting agent for the check. If defects areevident, correct, or replace.~

(2) Using a straightedge and feeler gauge, check the block top-surface for

warpage. Make sure that the surface is free

from gasket chips and other foreign matter.

Standard value: 0.05 mm

(4020 in.) or less

Limit: 0.1 mm

(AM40 in.)

Page 425 of 1216

--

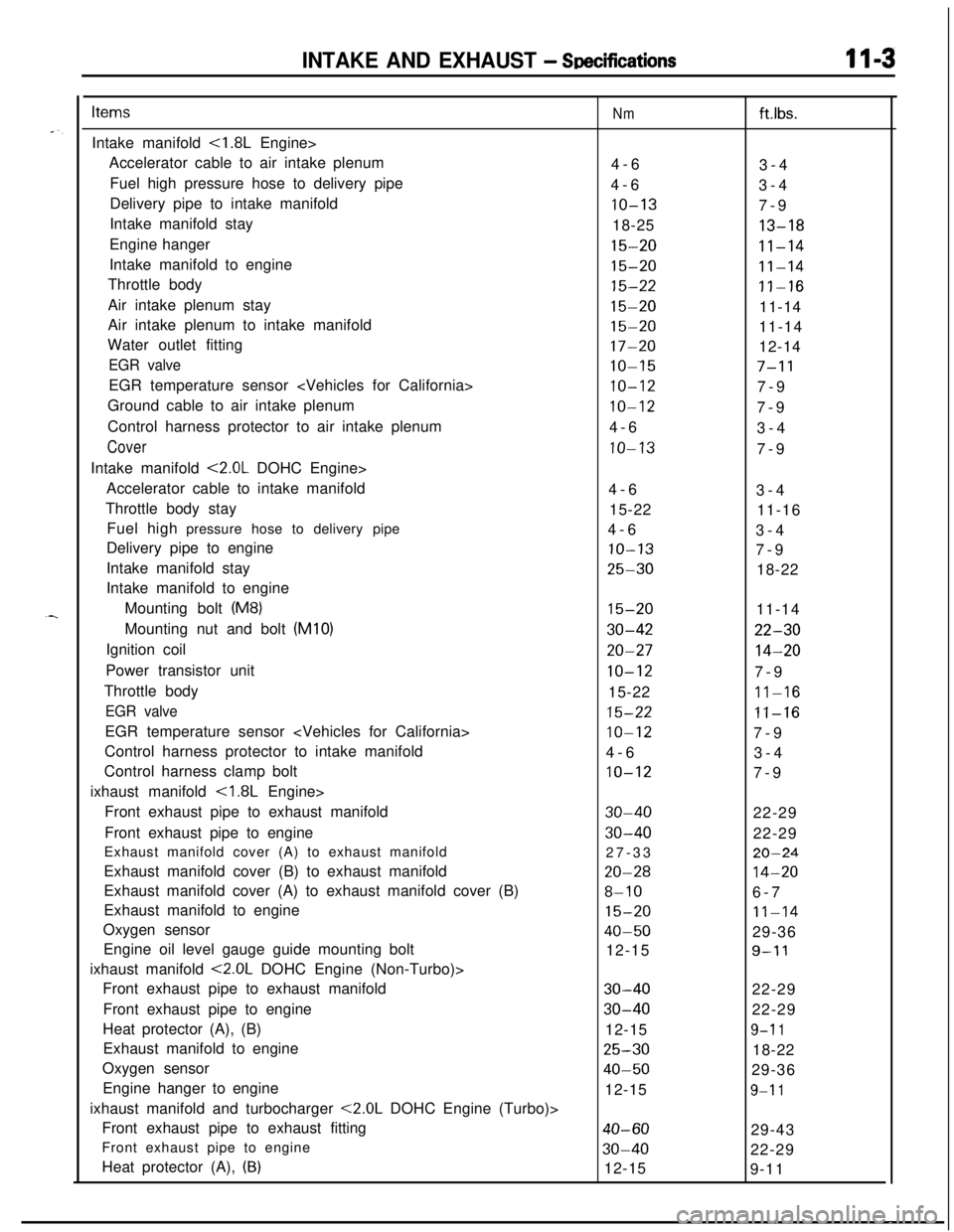

INTAKE AND EXHAUST - SDecificationsII-3

ItemsIntake manifold

<1.8L Engine>

Accelerator cable to air intake plenum

Fuel high pressure hose to delivery pipe

Delivery pipe to intake manifold

Intake manifold stay

Engine hanger

Intake manifold to engine

Throttle body

Air intake plenum stay

Air intake plenum to intake manifold

Water outlet fitting

EGR valveEGR temperature sensor

Ground cable to air intake plenum

Control harness protector to air intake plenum

CoverIntake manifold

<2.0L DOHC Engine>

Accelerator cable to intake manifold

Throttle body stay

Fuel high pressure hose to delivery pipe

Delivery pipe to engine

Intake manifold stay

Intake manifold to engine

Mounting bolt

(M8)Mounting nut and bolt (MIO)

Ignition coil

Power transistor unit

Throttle body

EGR valveEGR temperature sensor

Control harness protector to intake manifold

Control harness clamp bolt

ixhaust manifold

<1.8L Engine>

Front exhaust pipe to exhaust manifold

Front exhaust pipe to engine

Exhaust manifold cover (A) to exhaust manifold

Exhaust manifold cover (B) to exhaust manifold

Exhaust manifold cover (A) to exhaust manifold cover (B)

Exhaust manifold to engine

Oxygen sensor

Engine oil level gauge guide mounting bolt

ixhaust manifold

<2.0L DOHC Engine (Non-Turbo)>

Front exhaust pipe to exhaust manifold

Front exhaust pipe to engine

Heat protector (A), (B)

Exhaust manifold to engine

Oxygen sensor

Engine hanger to engine

ixhaust manifold and turbocharger

<2.0L DOHC Engine (Turbo)>

Front exhaust pipe to exhaust fitting

Front exhaust pipe to engine

Heat protector (A),

(B)

Nmft.lbs.

4-6

3-4

4-6

3-4

IO-137-9

18-25

13-18

15-20II-14

15-2011-14

15-22II-16

15-2011-14

15-2011-14

17-2012-14

IO-157-11

IO-127-9

10-127-9

4-6

3-4

IO-137-9

4-6

3-4

15-22

11-16

4-6

3-4

IO-137-9

25-3018-22

15-2011-14

30-4222-30

20-2714-20

IO-127-9

15-22

11-16

15-22II-16

IO-127-9

4-6

3-4

IO-127-9

30-4022-29

30-4022-29

27-33

20-24

20-2814-20

8-106-7

15-2011-14

40-5029-36

12-15

9-l 1

30-4022-29

30-4022-29

12-15

9-l 1

25-3018-22

40-5029-36

12-15

9-l 1

40-6029-43

30-4022-29

12-15

9-11

Page 426 of 1216

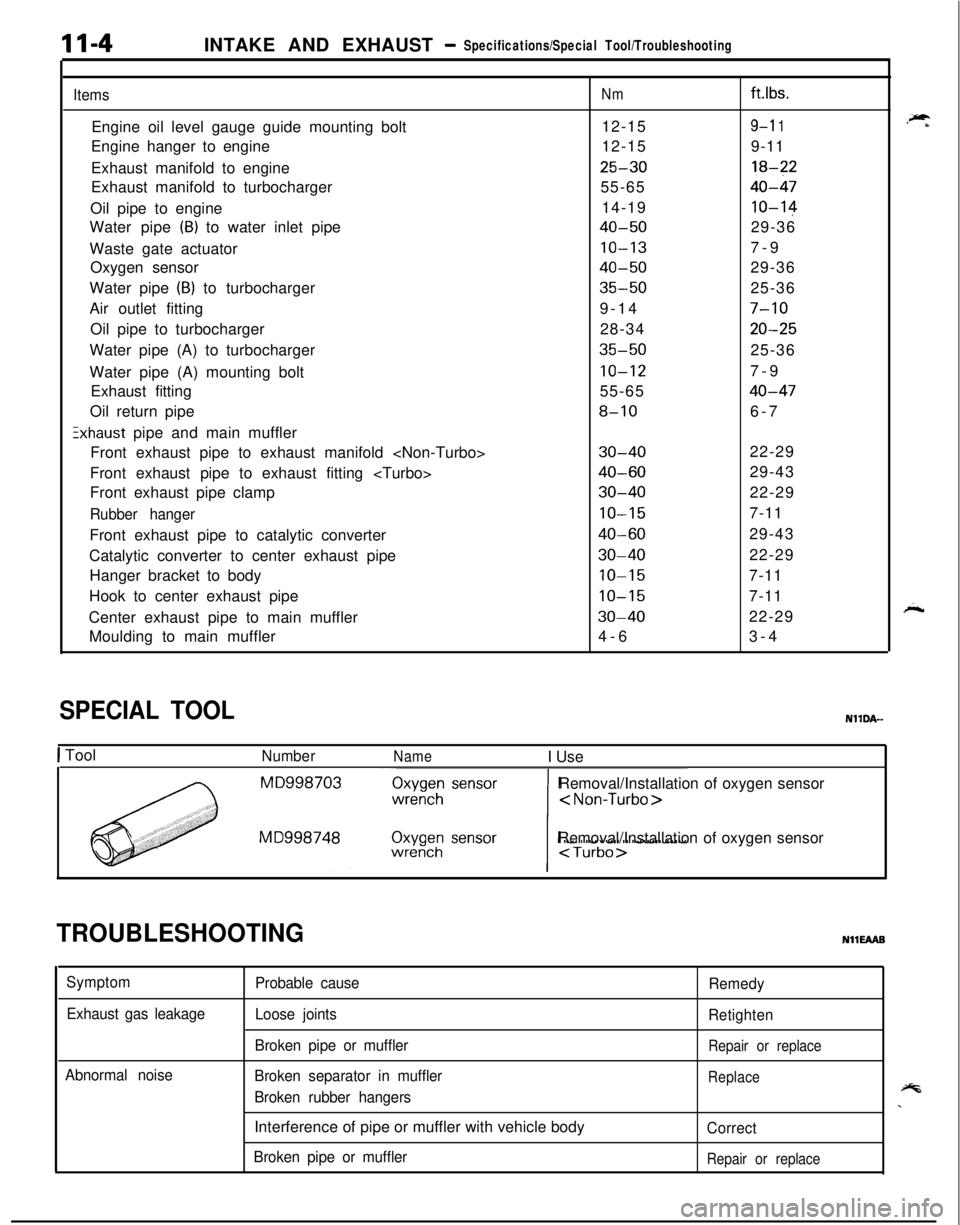

11-4INTAKE AND EXHAUST- Specifications/Special Tool/Troubleshooting

ItemsEngine oil level gauge guide mounting bolt

Engine hanger to engine

Exhaust manifold to engine

Exhaust manifold to turbocharger

Oil pipe to engine

Water pipe

(B) to water inlet pipe

Waste gate actuator

Oxygen sensor

Water pipe

(B) to turbocharger

Air outlet fitting

Oil pipe to turbocharger

Water pipe (A) to turbocharger

Water pipe (A) mounting bolt

Exhaust fitting

Oil return pipe

Exhaust pipe and main muffler

Front exhaust pipe to exhaust manifold

Front exhaust pipe to exhaust fitting

Front exhaust pipe clamp

Rubber hangerFront exhaust pipe to catalytic converter

Catalytic converter to center exhaust pipe

Hanger bracket to body

Hook to center exhaust pipe

Center exhaust pipe to main muffler

Moulding to main muffler

Nmft.lbs.

12-15

9-l 112-159-11

25-3018-?255-65

40-4714-19

IO-l+

40-5029-36

IO-137-9

40-5029-36

35-5025-36

9-14

7-1028-34

20-25

35-5025-36

IO-127-9

55-65

40-47

8-106-7

30-4022-29

40-6029-43

30-4022-29

IO-157-11

40-6029-43

30-4022-29

10-157-11

10-157-11

30-4022-29

4-63-4

TROUBLESHOOTINGNllEAAB

Symptom

Exhaust gas leakage

Abnormal noiseProbable cause

Loose joints

Broken pipe or muffler

Broken separator in muffler

Broken rubber hangersInterference of pipe or muffler with vehicle body

Broken pipe or mufflerRemedy

Retighten

Repair or replace

Replace

Correct

Repair or replace

.-*

SPECIAL TOOLNllDA-

I ToolNumberNameI UseIRemoval/Installation of oxygen sensor

Removal/Installation of oxygen sensor

Fs\

Page 429 of 1216

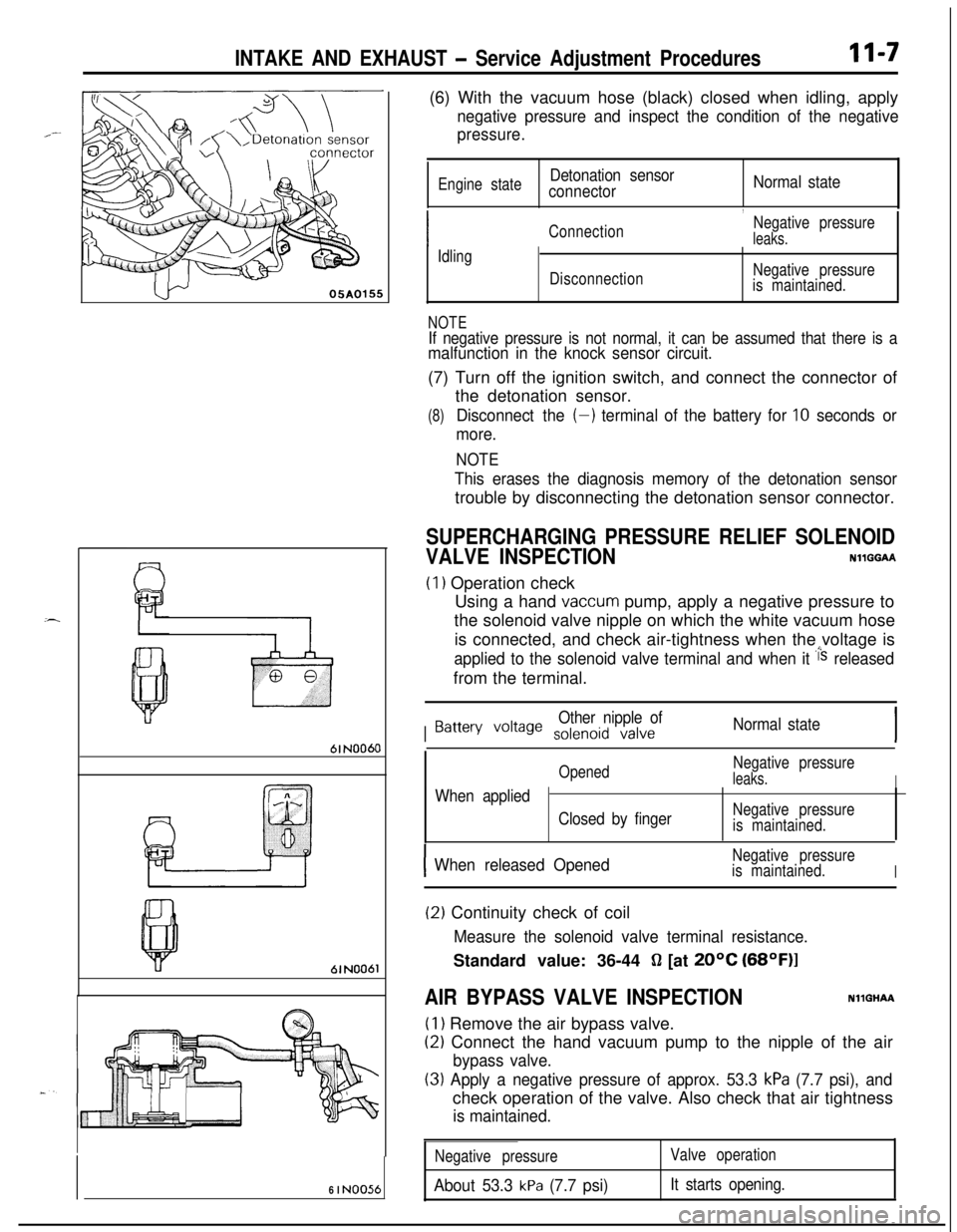

INTAKE AND EXHAUST - Service Adjustment ProceduresII-7

w05A0155

h61

NO06061

NO0616 I

NO056(6) With the vacuum hose (black) closed when idling, apply

negative pressure and inspect the condition of the negative

pressure.

Engine stateDetonation sensor

connectorNormal state

,

ConnectionNegative pressureleaks.

Idling

DisconnectionNegative pressure

is maintained.

NOTEIf negative pressure is not normal, it can be assumed that there is amalfunction in the knock sensor circuit.(7) Turn off the ignition switch, and connect the connector of

the detonation sensor.

(8)Disconnect the (-) terminal of the battery for 10 seconds or

more.

NOTE

This erases the diagnosis memory of the detonation sensortrouble by disconnecting the detonation sensor connector.

SUPERCHARGING PRESSURE RELIEF SOLENOID

VALVE INSPECTIONNllGGAA

(1) Operation check

Using a hand

vaccum pump, apply a negative pressure to

the solenoid valve nipple on which the white vacuum hose

is connected, and check air-tightness when the voltage is

applied to the solenoid valve terminal and when it i‘s releasedfrom the terminal.

I

Other nipple ofBattery voile solenoid valveNormal state

OpenedNegative pressureleaks.IWhen applied

Closed by fingerNegative pressure

is maintained.

IWhen released OpenedNegative pressure

is maintained.

I

(2) Continuity check of coil

Measure the solenoid valve terminal resistance.Standard value: 36-44

fl [at 20°C (68OF)l

AIR BYPASS VALVE INSPECTIONNllGHAA

(1) Remove the air bypass valve.

(2) Connect the hand vacuum pump to the nipple of the air

bypass valve.

(3) Apply a negative pressure of approx. 53.3 kPa (7.7 psi), andcheck operation of the valve. Also check that air tightness

is maintained.

Negative pressure

About 53.3 kPa (7.7 psi)

Valve operation

It starts opening.

Page 440 of 1216

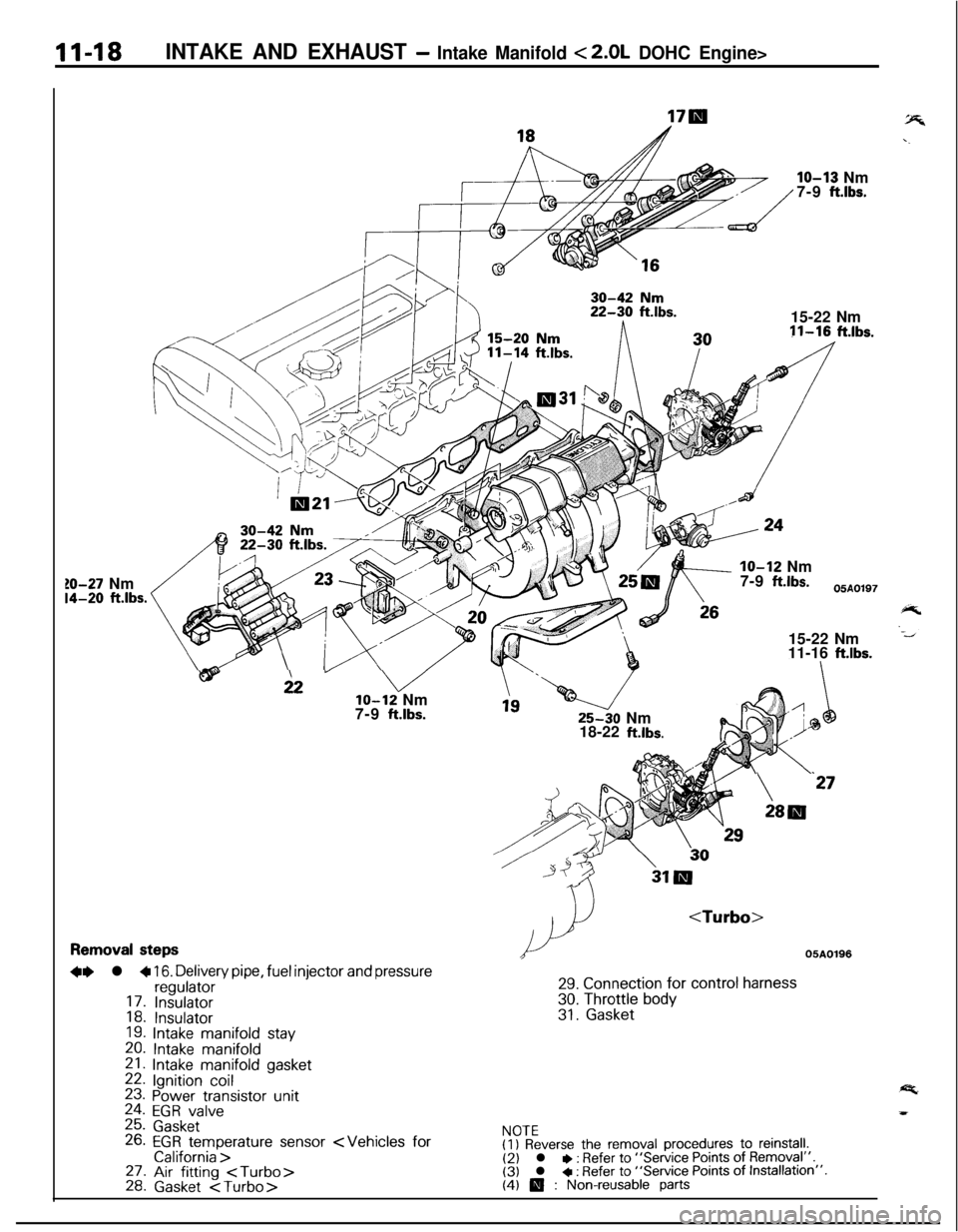

11-18INTAKE AND EXHAUST - Intake Manifold < 2.0L DOHC Engine>

10-27 Nm14-20 ft.lbs.

18hIO-13 Nm

7-9

ft.lbs.15-22 Nm11-16

ft.lbs.IO-12 Nm

7-9

ftlbs.05A0197

15-22 Nm

11-16

ftlbs.

wi2” vlo-12 Nm

7-9 ftlbs.25-30 Nm

18-22

ft.lbs.

24

\‘27

28lll

Removal steps

+e l + 16. Delivery pipe, fuel injector and pressureregulator17. Insulator18. Insulator19. Intake manifold stay

20. Intake manifold21. Intake manifold gasket22. Ignition coil23. Power transistor unit24. EGR valve25. Gasket26. EGR temperature sensor

29. Connection for control harness

30. Throttle body31. Gasket

NOTE(I) Reverse the removal procedures to reinstall.(2) l * : Refer to “Service Points of Removal”.(3) l + : Refer to “Service Points of Installation”.(4) 0 : Non-reusable parts