key MITSUBISHI ECLIPSE 1991 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 665 of 1216

STEERING - Steering Wheel and Shaft

1610778

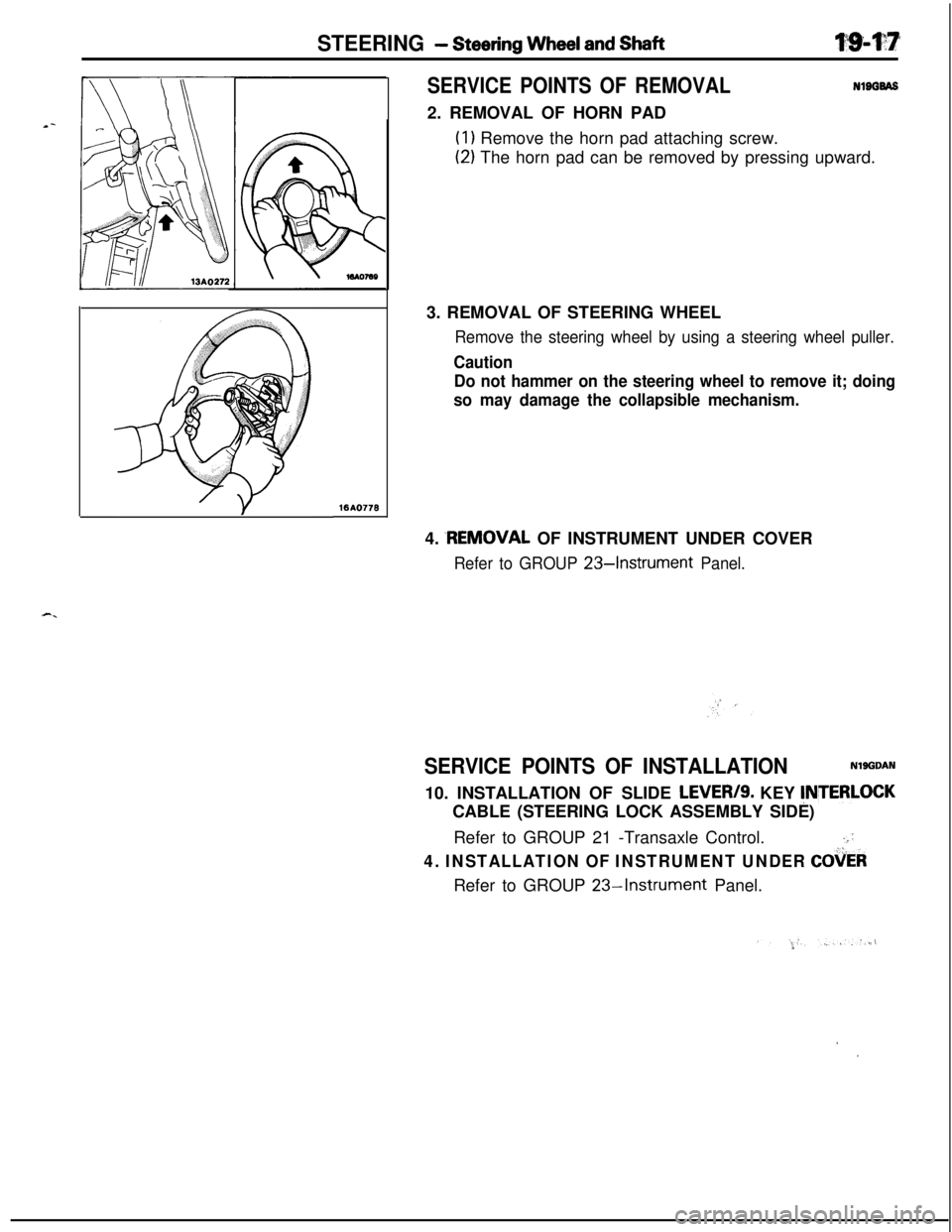

SERVICE POINTS OF REMOVALNlBGBAS2. REMOVAL OF HORN PAD

(1) Remove the horn pad attaching screw.

(2) The horn pad can be removed by pressing upward.

3. REMOVAL OF STEERING WHEEL

Remove the steering wheel by using a steering wheel puller.

Caution

Do not hammer on the steering wheel to remove it; doing

so may damage the collapsible mechanism.4.

.REMOVAL OF INSTRUMENT UNDER COVER

Refer to GROUP 234nstrument Panel.

SERVICE POINTS OF INSTALLATIONNlgGDAN10. INSTALLATION OF SLIDE

LEVER/S. KEY !NTERLOCKCABLE (STEERING LOCK ASSEMBLY SIDE)

Refer to GROUP 21 -Transaxle Control.

.::

4. INSTALLATION OF INSTRUMENT UNDER COiiERRefer to GROUP

23-Instrument Panel.

,I

Page 695 of 1216

TRANSAXLE ’

MANUAL AND AUTOMATICCONTENTS

;-AUTOMATICTRANSAXLE

.....................................................137ANNULUS GEAR AND TRANSFER DRIVE GEAR SET (F4A22)..........315ANNULUS GEAR AND TRANSFER DRIVE GEAR SET(F4A33.W4A33)...........................................................................................317CENTERDIFFERENTIAL(W4A33).............................................................329DIFFERENTIAL............................................................................................319ENDCLUTCHASSEMBLY.........................................................................309EXTENSIONHOUSINGASSEMBLY(W4A33).........................................337FRONTCLUTCHASSEMBLY....................................................................302FRONTOUTPUTSHAFT(W4A33)...........................................................332GENERALINFORMATION.........................................................................137KICKDOWNSERVO....................................................................................322LOW-REVERSEBRAKE..............................................................................323OILPUMP...................................................................................................299PLANETARYGEARSET............................................................................311PLANETARYGEARSET............................................................................313REARCLUTCHASSEMBLY(F4A22)........................................................304REARCLUTCHASSEMBLY(FQA33sW4A33)............................................307SERVICEADJUSTMENTPROCEDURES..................................................Drive

Shaft,OilSealsReplacement....................................................;;;

InhibitorSwtchAdjustment................................................................21 1KeyInterlockMechanismCheck.....................................................KrckdownServoAdjustment..................................zii..............................

LinePressureAdjustment...................................................................213

ReducingPressureAdjustment.........................................................214Selector Lever Operation Check........................................................210ShiftLockMechanismCheck...............................................................21 1SpeedometerCableReplacement.........................................................Throttle-posltipn Sensor Adjustment.................................................z2:

TransaxleFluIdLevelInspectIon......................................................209

TransaxleFluidReplacement.............................................................209

SPECIALTOOLS.........................................................................................SPECIFICATIONS........................................................................................;“5”9

GeneralSpeclficatlons..................................................................1%Lubricants..................................................................................Sealants and Adhesives..............................................................izi

Serwce Speclflcatlons..................................................159...............Spacer andSnapRing.,.,.............................................................Spacer Set..................................................................1::Torque Speclflcatlons...........................................166Valve Body Spring Identification Chart.....................

.................160

SPEEDOMETERGEARASSEMBLY..........................................................TRANSAXLEASSEMBLY(WA22)............................................................zTRANSAXLE

ASSEMBLY(F4A33.W4A33)................................................TRANSAXLECONTROL.............................................................................;;;TRANSAXLE

OILCOOLER........................................................................TRANSFER..................................................................................................fg

TRANSFERASSEMBLY.............................................................................333TRANSFERCASEADAPTERSUBASSEMBLY(W4A33).......................339TRANSFER CASE SUB ASSEMBLY (W4A33)341TRANSFER SHAFT (F4A33)TROUBLESHOOTING..................................................................................................................................................................................................f;;VALVE

BODY.............................................................................................324

MANUAL TRANSAXLE

5TH-SPEEDSYNCHRONIZERASSEMBLY...............................................42GENERALINFORMATION.........................................................................2.-.INPUTfj,-,A,TASSEMBLY

INTERMEDIATE GEAR ASSEMBLY..........................................................56OUTPUT

SHAFT ASSEMBLY....................................................................61SERVICEADJUSTMENTPROCEDURES..................................................DriveShaftOilSealsReplacement......................................................;;Speedometer Cable Replacement.........................................................

Transaxle Oil Level

InspectIon..............................................................‘liTransaxle Oil Replacement....................................................................

I3

SHIFTLEVERASSEMBLY.........................................................................SHIFTRAILSANDFORKS........................................................................g

SPECIALTOOLS.........................................................................................SPECIFICATIONS........................................................................................1:

General Specifications5Lubricants..........................................................................................................................................................................10Sealants and Adhesives

Service Specifications

....................................................................................................................................................1:Snap Ring (for Adjustment) and Spacer...............................................

Torque Specifications.............................................................................

i

SPEEDOMETERGEARASSEMBLY..........................................................TRANS&G.E................................................................................................zTRANSAXLEA!jSEMBLY

TROUBLESHOOTING..................................................................................12

MANUAL TRANSAXLE

CENTERDIFFERENTIAL.............................................................................103CLUTCHHOUSINGASSEMBLY...............................................................DRIVE BEVEL GEAR ASSEMBLY;g

...... .......................................................DRIVENBEVELGEARASSEMBLY...................................a......................EXTENSIONHOUSINGASSEMBLY.........................................................;g

5Tf.jSPEEDSYNCHRONIZERASSEMBLY...............................................101

FRONTDlFFERENTlAL...............................................................................106

FRONTOUTPUTSHAFTASSEMBLY......................................................106

GENERALI~~~~MATN)N...............................................................,.,.......66INPUTSHAFTASSEMBLY........................................................................l~ER,“,EDlATEGEARASSMBLY..........................................................;;i

SERVICEADJUSTMENTPROCEDURES..................................................Drive Shaft Oil Seals Replacement......................................................;;Speedometer Cable Replacement.........................................................

Transaxle

Ojl Level lnspectlon..............................................................;l

Transaxle 011 R~pb33ment....................................................................79Transfer

OilSealReplacement.............................................................80

SHIFTLEVERASSEMBLY.........................................................................SHIFTRAILASSEMBLY............................................................................,z

SPECIALTOOLS.........................................................................................76

SPECIFICATIONS........................................................................................6g

GeneralSpecifications...........................................................................6g

Lubricants...............................................................................................75

SealantsandAdhesives........................................................................76

ServiceSpecifications............................................................................6gSnap Ring (for Adjustment) and Spacer...............................................7 o

TorqueSpecifications.............................................................................74

SPEEDOMETERGEARASSEMBLY..........................................................TRANSAXLE................................................................................................1:TRANSAXLEASSEMBLY...........................................................................86TRANSAXLE

CONTROL

.............................................................................TRANSFER...............................................................................................

g.._TRANSFERA!333lBLY.............................................................................,24

TRANSFERCASEADAPTERSUBASSEMBLY.......................................131TRANSFERCASESUBASSEMBLY.........................................................TR,,UBLES,,OO,,NG..................................................................................1;;

Page 708 of 1216

21-14 MANUAL TRANSAXLE

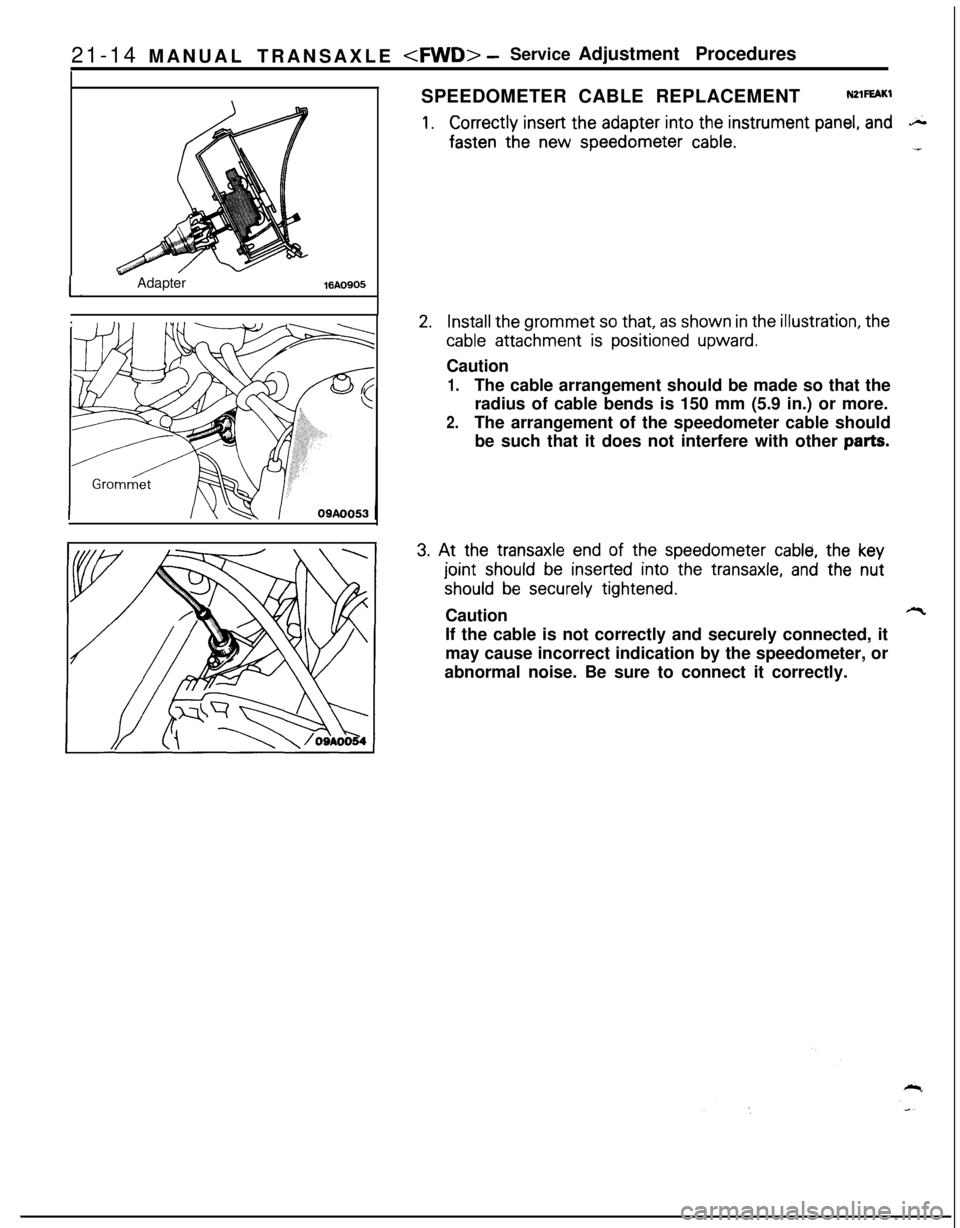

I-Adapter%A0905SPEEDOMETER CABLE REPLACEMENT

NZlFEAKl

1.Correctly insert the adapter into the instrument panel, andS.

fasten the new speedometer cable.1-

2.Install the grommet so that, as shown in the illustration, the

cable attachment is positioned upward.Caution

1.The cable arrangement should be made so that the

radius of cable bends is 150 mm (5.9 in.) or more.

2.The arrangement of the speedometer cable should

be such that it does not interfere with other

parts.

3. At the transaxle end of the speedometer cable, the key

joint should be inserted into the transaxle, and the nut

should be securely tightened.Caution

lllcIf the cable is not correctly and securely connected, it

may cause incorrect indication by the speedometer, or

abnormal noise. Be sure to connect it correctly.

Page 736 of 1216

21-42MANUAL TRANSAXLE

8” in.)TFM0044

4. INSTALLATION OF SCREW BOLTSApply specified adhesive to screw bolts mounting portion.

Specified adhesive: MOPAR Part No.4318031

or MOPAR Part No. 4318032

or ‘equivalent

2. APPLICATION OF SEALANT TO THE REAR COVERApply specified sealant to the

rear cover.

Specified sealant: MITSUBISHI Genuine

Part No.

MD997740

or equivalent

Caution

Squeeze out sealant from the tube uniformly without

excess or discontinuity.

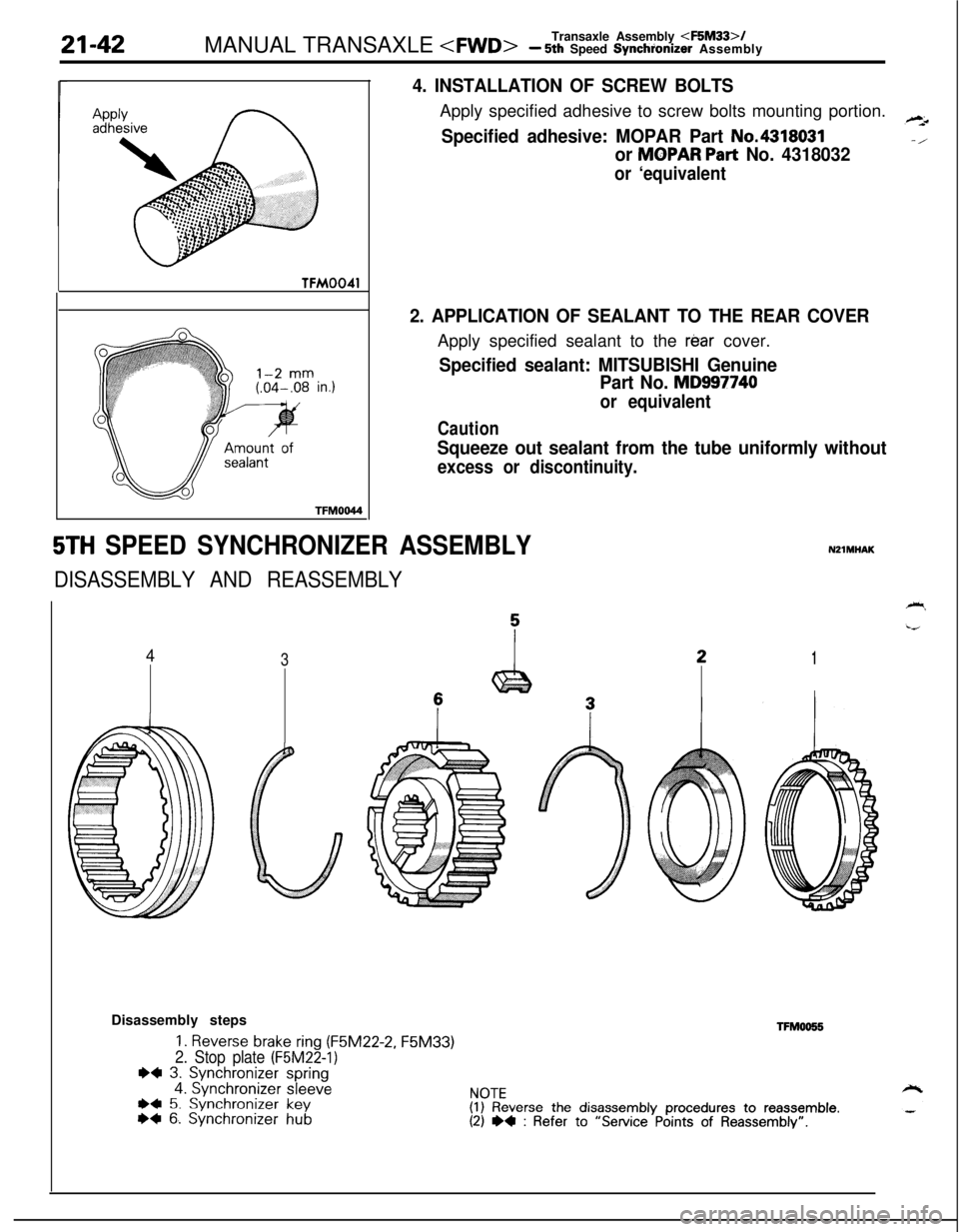

5TH SPEED SYNCHRONIZER ASSEMBLY

DISASSEMBLY AND REASSEMBLY

43

NZlMHAK

1Disassembly steps

1. Reverse brake ring (F5M22-2, F5M33)

2. Stop plate (F5M22-1)I)4 3. Synchronizer spring4. Synchronizer sleeveWI 5. Synchronizer key*+ 6. Synchronizer hubTFM0055

NOTE(1) Reverse the disassembly procedures to reassemble.(2) ~~ : Refer to “Service Points of Reassembly”.

Page 737 of 1216

..-MANUAL TRANSAXLE

-5th Speed Synchr’onizer Assembly tq-43

201044

201045TFM0046

Springprotrusion

Key

2010018

INSPECTION_ -.‘-

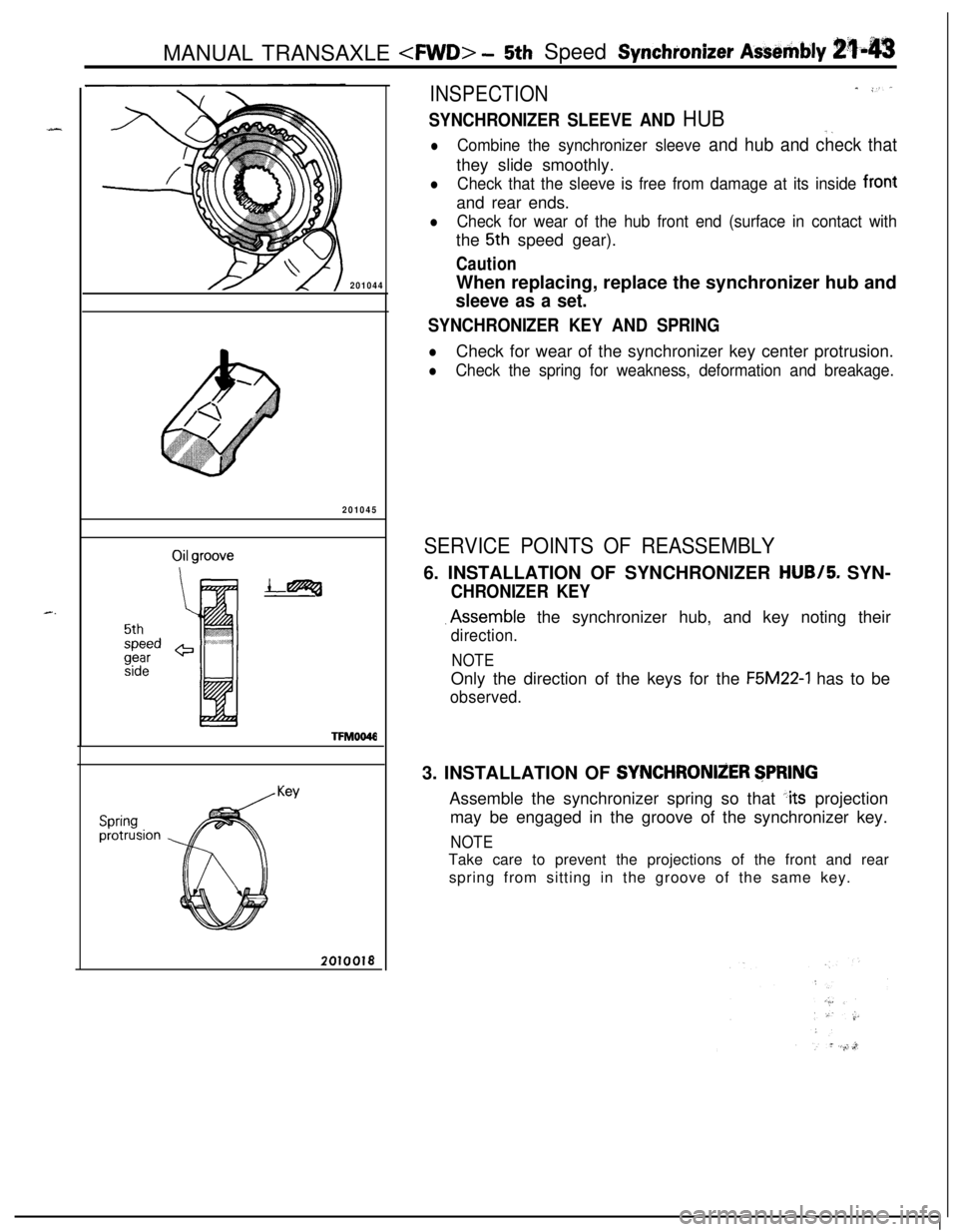

SYNCHRONIZER SLEEVE AND HUB-_

lCombine the synchronizer sleeve and hub and check thatthey slide smoothly.

lCheck that the sleeve is free from damage at its inside frontand rear ends.

lCheck for wear of the hub front end (surface in contact withthe

5th speed gear).

CautionWhen replacing, replace the synchronizer hub and

sleeve as a set.

SYNCHRONIZER KEY AND SPRING

lCheck for wear of the synchronizer key center protrusion.

lCheck the spring for weakness, deformation and breakage.

SERVICE POINTS OF REASSEMBLY6. INSTALLATION OF SYNCHRONIZER HUB/5. SYN-

CHRONIZER KEY.Assemble the synchronizer hub, and key noting their

direction.

NOTEOnly the direction of the keys for the

F5M22-1 has to be

observed.3. INSTALLATION OF

SYNCHRONliER $PRlNGAssemble the synchronizer spring so that

:its projection

may be engaged in the groove of the synchronizer key.

NOTETake care to prevent the projections of the front and rear

spring from sitting in the groove of the same key.

Page 738 of 1216

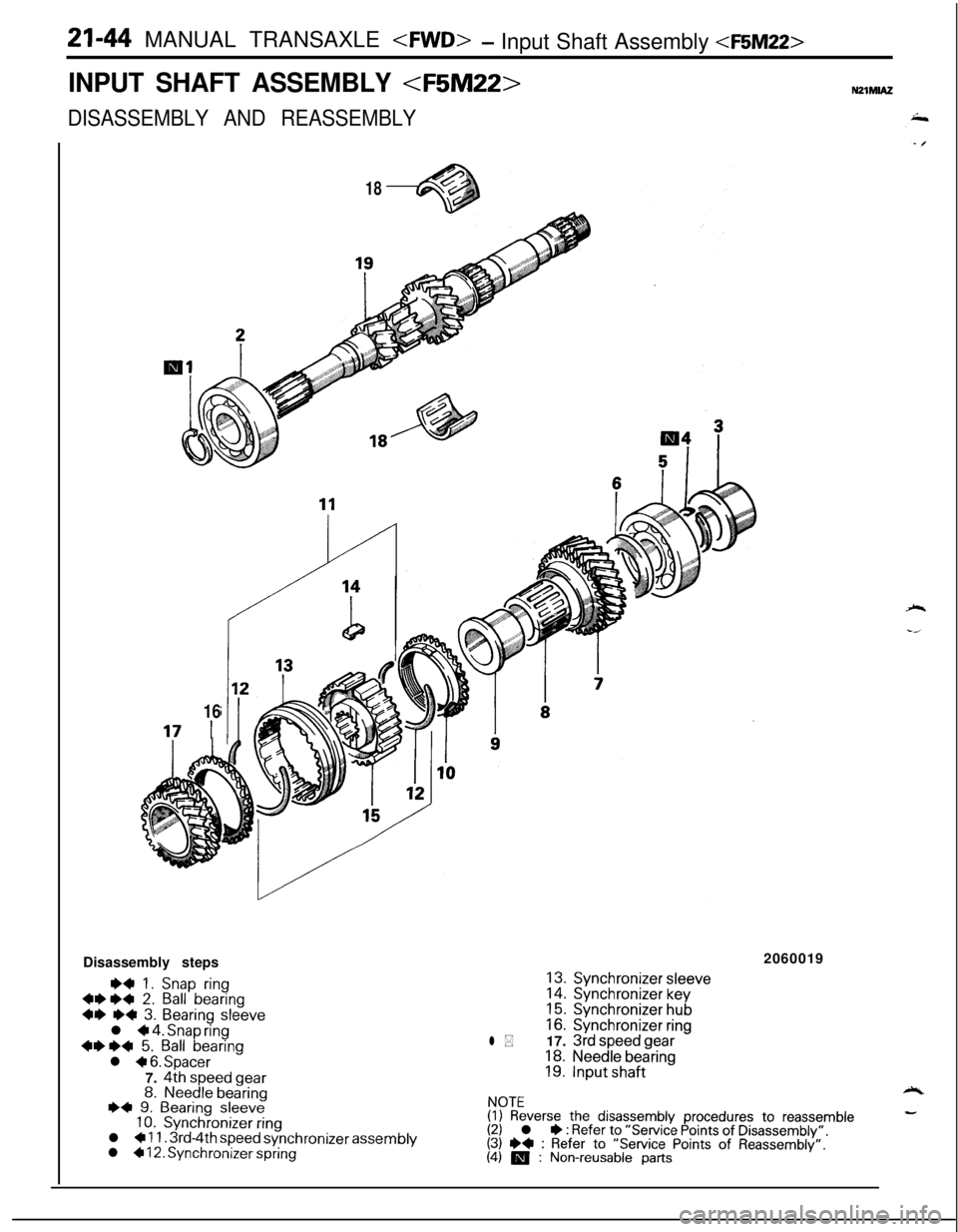

21-44 MANUAL TRANSAXLE

INPUT SHAFT ASSEMBLY

DISASSEMBLY AND REASSEMBLY

18

16

17 IDisassembly steps

*+ 1. Snap ring+1)1)+ 2. Ball bearing

+I) I)+ 3. Bearing sleevel + 4. Snap ring4+*+ 5. Ball bearingl + 6. Spacer

7.

4th speed gear8.Needle bearing~~ 9. Bearing sleeve10.Synchronizer ringl + 11. 3rd-4th speed synchronizer assemblyl + 12. Synchronizer spring2060019

l *

13.Synchronizer sleeve14.Synchronizer key15.Synchronizer hub16.Synchronizer ring

17. 3rd speed gear18.Needle bearing19.Input shaft

NOTE(I) Reverse the disassembly procedures to reassemble(2) l * : Refer to “Service Points of Disassembly”.(3) +* : Refer to “Service Points of Reassembly”.(4) m : Non-reusable parts

Page 740 of 1216

21-46MANUAL TRANSAXLE

201051

TFMO119

Damage, breakage

/

Synchronizer ringGLarTFMOlli

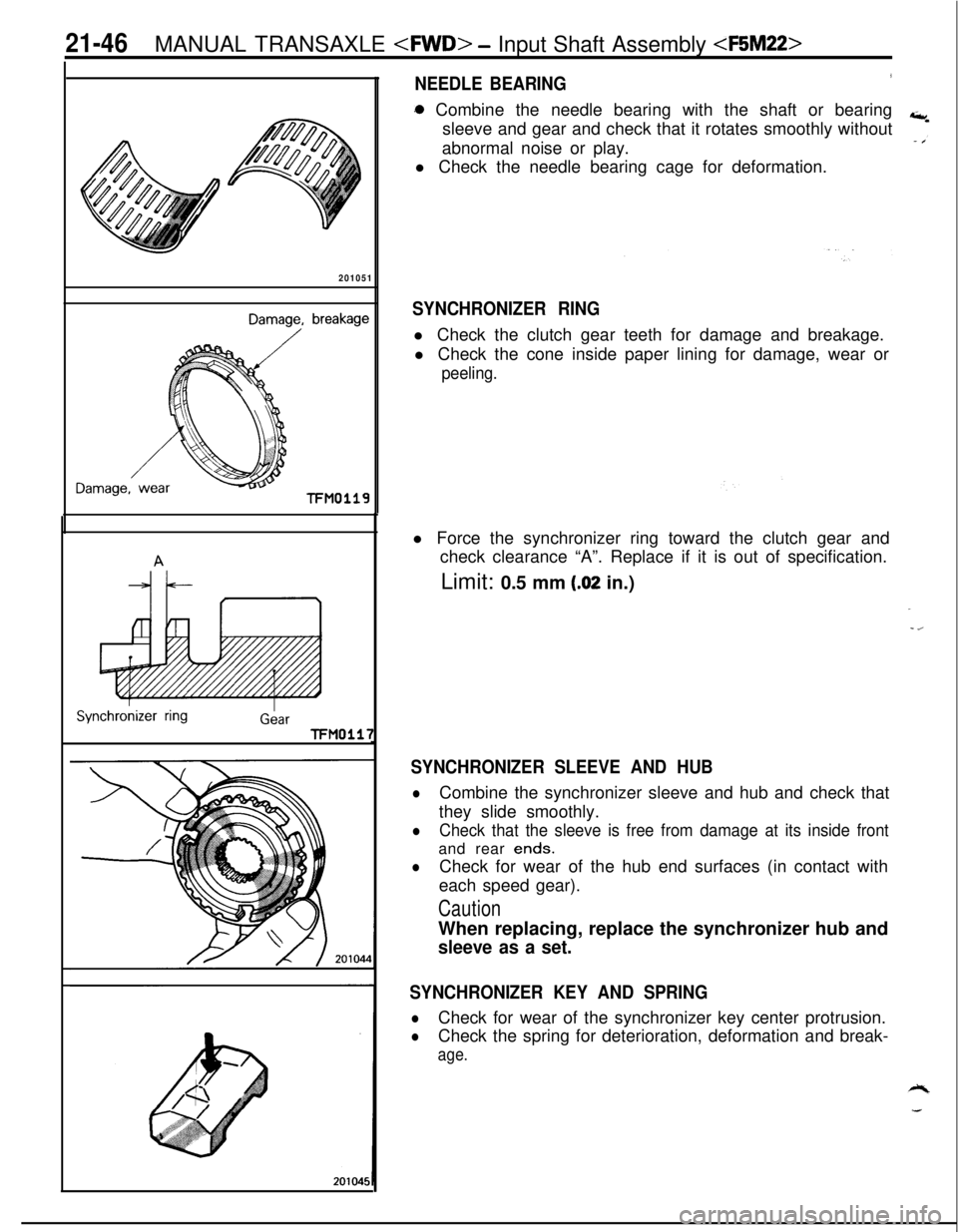

NEEDLE BEARING3a Combine the needle bearing with the shaft or bearing

sleeve and gear and check that it rotates smoothly without

abnormal noise or play.

l Check the needle bearing cage for deformation.

SYNCHRONIZER RINGl Check the clutch gear teeth for damage and breakage.

l Check the cone inside paper lining for damage, wear or

peeling.l Force the synchronizer ring toward the clutch gear and

check clearance “A”. Replace if it is out of specification.

Limit: 0.5 mm

(.02 in.)

SYNCHRONIZER SLEEVE AND HUB

lCombine the synchronizer sleeve and hub and check that

they slide smoothly.

lCheck that the sleeve is free from damage at its inside frontand rear

ends.

lCheck for wear of the hub end surfaces (in contact with

each speed gear).

CautionWhen replacing, replace the synchronizer hub and

sleeve as a set.

SYNCHRONIZER KEY AND SPRING

lCheck for wear of the synchronizer key center protrusion.

lCheck the spring for deterioration, deformation and break-

age.

Page 741 of 1216

MANUAL TRANSAXLE

Springprotrusion2010018TFM0021

MD998320/

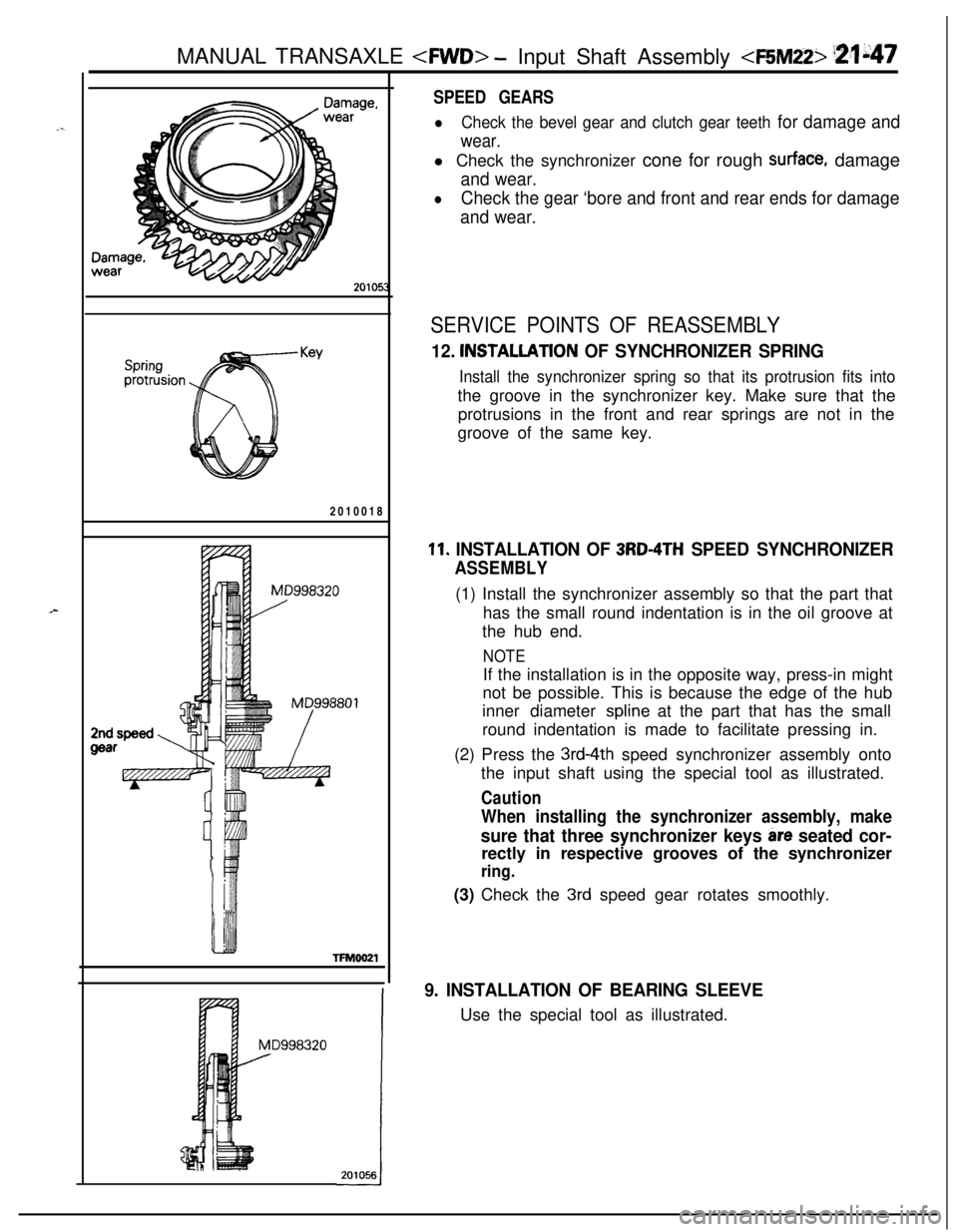

SPEED GEARS

lCheck the bevel gear and clutch gear teeth for damage and

wear.l Check the synchronizer cone for rough

surface, damage

and wear.

lCheck the gear ‘bore and front and rear ends for damage

and wear.

SERVICE POINTS OF REASSEMBLY

12. INSTALLATlON OF SYNCHRONIZER SPRING

Install the synchronizer spring so that its protrusion fits intothe groove in the synchronizer key. Make sure that the

protrusions in the front and rear springs are not in the

groove of the same key.

11. INSTALLATION OF 3RD-4TH SPEED SYNCHRONIZER

ASSEMBLY(1) Install the synchronizer assembly so that the part that

has the small round indentation is in the oil groove at

the hub end.

NOTEIf the installation is in the opposite way, press-in might

not be possible. This is because the edge of the hub

inner diameter

spline at the part that has the small

round indentation is made to facilitate pressing in.

(2) Press the

3rd-4th speed synchronizer assembly onto

the input shaft using the special tool as illustrated.

Caution

When installing the synchronizer assembly, make

sure that three synchronizer keys are seated cor-rectly in respective grooves of the synchronizer

ring.(3) Check the

3rd speed gear rotates smoothly.

9. INSTALLATION OF BEARING SLEEVEUse the special tool as illustrated.

Page 744 of 1216

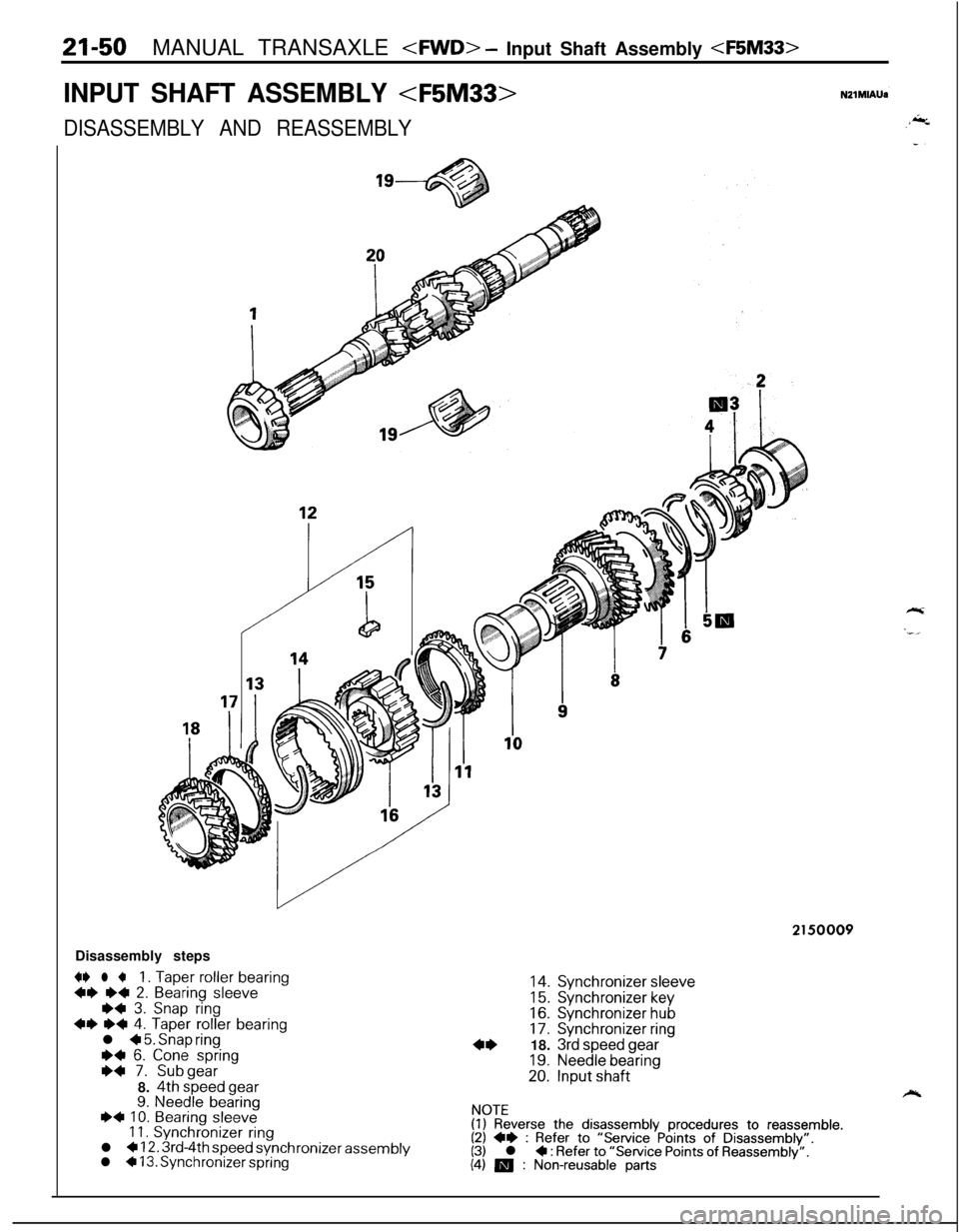

21-50MANUAL TRANSAXLE

INPUT SHAFT ASSEMBLY

DISASSEMBLY AND REASSEMBLYDisassembly steps

+* l +1. Taper roller bearing++ ~~ 2. Bearing sleeve*+ 3. Snap ring++ I)+ 4. Taper roller bearingl + 5. Snap ringI)+ 6. Cone spring

~~ 7. Subgear8. 4th speed gear9. Needle bearing~~ 10. Bearing sleeve11. Synchronizer ringl + 12. 3rd-4th speed synchronizer assemblyl * 13. Synchronizer spring

2150009

14.Synchronizer sleeve

15.Synchronizer key16.Synchronizer hub17.Synchronizer ring

18. 3rd

speed gear

19.Needle bearing20.Input shaft

NOTE(1) Reverse the disassembly procedures to reassemble.(2) ++ : Refer to “Service Points of Disassembly”.(3) l + : Refer to “Service Points of Reassembly”.(4) m : Non-reusable parts

Page 746 of 1216

21-52 MANUAL TRANSAXLE

r

201051

Damage, breakage

Damage,TFMO119

ISynchronver ringGearTFM0117

2010441

NEEDLE BEARINGl Combine the needle bearing with the shaft or bearing

+,sleeve and gear and check that it rotates smoothly without

abnormal noise or play.

l Check the needle bearing cage for deformation.

SYNCHRONIZER RINGl Check the clutch gear teeth for damage and breakage.

l Check the cone inside paper lining for damage, wear or

peeling.l Force the synchronizer ring toward the clutch gear and

check clearance “A”. Replace if it is out of specification.

Limit: 0.5 mm

(.02 in.)

-z

SYNCHRONIZER SLEEVE AND HUB

lCombine the synchronizer sleeve and hub and check that

they slide smoothly.

lCheck that the sleeve is free from damage at its inside frontand rear ends.

lCheck for wear of the hub end surfaces (in contact with

each speed gear).

CautionWhen replacing, replace the synchronizer hub and

sleeve as a set.

SYNCHRONIZER KEY AND SPRING

lCheck for wear of the synchronizer key center protrusion.

lCheck the spring for deterioration, deformation and break-

age.