key MITSUBISHI ECLIPSE 1991 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 168 of 1216

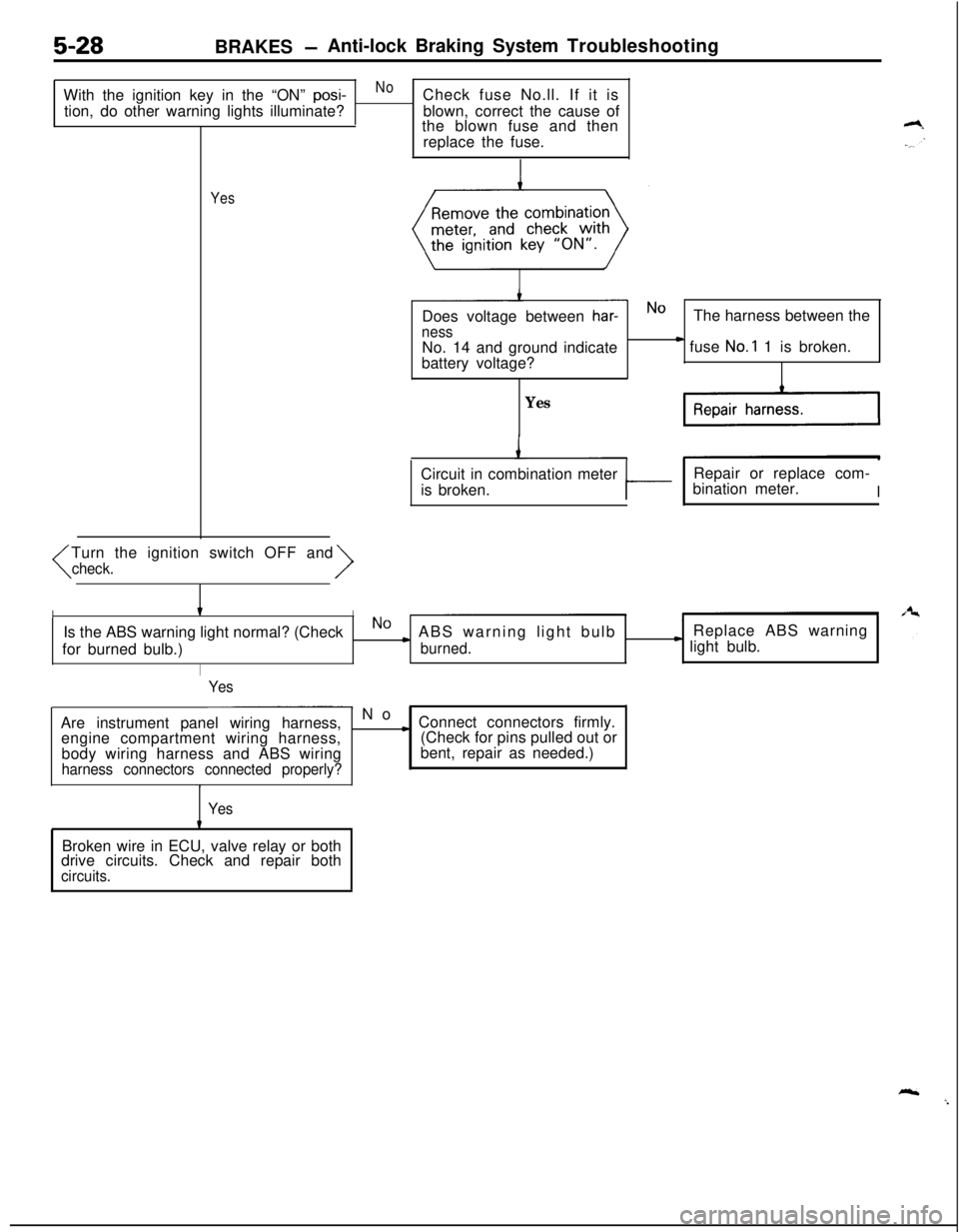

5-28BRAKES -Anti-lock Braking System Troubleshooting

With the ignition key in the “ON”

posi-NoCheck fuse No.ll. If it is

tion, do other warning lights illuminate?blown, correct the cause of

the blown fuse and then

replace the fuse.

YesTurn the ignition switch OFF and

har-NOThe harness between the

nessNo. 14 and ground indicate

battery voltage?) fuse No.1 1 is broken.

YesCircuit in combination meter

is broken.

tRepair or replace com-

bination meter.II

IIIs the ABS warning light normal? (CheckNO) ABS warning light bulbReplace ABS warning

for burned bulb.)

burned.* light bulb.

I

Yes

- No

Are instrument panel wiring harness,

engine compartment wiring harness,

body wiring harness and ABS wiring

harness connectors connected properly?

c Connect connectors firmly.

(Check for pins pulled out or

bent, repair as needed.)

YesBroken wire in ECU, valve relay or both

drive circuits. Check and repair both

circuits.

Page 171 of 1216

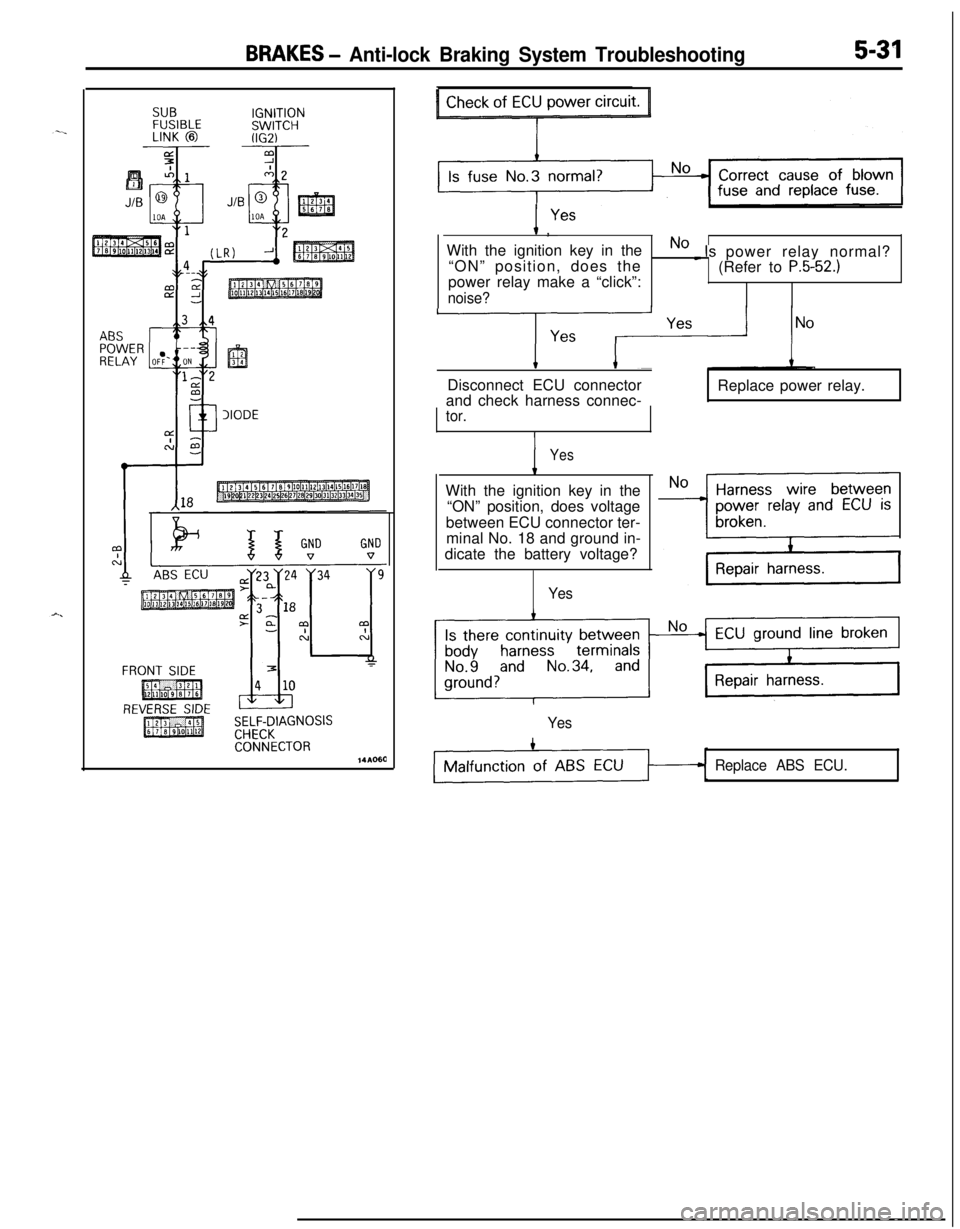

BRAKES - Anti-lock Braking System Troubleshooting5-31

SUBIGNITION

%TB(kEzYCH

IODE

;LLF-FIAGNOSIS

CONNECTOR

I Yes1,

With the ignition key in the

No _ Is power relay normal?

“ON” position, does the

(Refer to P.5-52.)power relay make a “click”:

noise?LDisconnect ECU connector

and check harness connec-Replace power relay.

tor.

YesWith the ignition key in the

“ON” position, does voltage

between ECU connector ter-

minal No. 18 and ground in-

dicate the battery voltage?

Yes

Yes

Replace ABS ECU.

Page 172 of 1216

![MITSUBISHI ECLIPSE 1991 User Guide 5-32BRAKES -Anti-lock Braking System Troubleshooting

CABS warning light does not illuminate when ignition key is in “START” position.

[Explanation]The ABS ECU uses the

IG2 power source which isan MITSUBISHI ECLIPSE 1991 User Guide 5-32BRAKES -Anti-lock Braking System Troubleshooting

CABS warning light does not illuminate when ignition key is in “START” position.

[Explanation]The ABS ECU uses the

IG2 power source which isan](/img/19/57104/w960_57104-171.png)

5-32BRAKES -Anti-lock Braking System Troubleshooting

CABS warning light does not illuminate when ignition key is in “START” position.

[Explanation]The ABS ECU uses the

IG2 power source which isand the ECU turns the valve relay OFF. If the

turned off in the “START” position. The ABSwarning light does not illuminate at this time, there

warning light uses the

IGI power source which isis trouble in the warning light circuit on the valve

not turned off even in the “START” position.relay side.

Consequently, in the “START” position, power is off

MAINIGNITIONFUSIBLESWITCHLINK @I(IGl)J/B

“62

I .1411213141516l7l61911112113114115U6i,79

@COMBINATIONAL METER

“58ABS ECU

1410000

hydraulicunit (HU) connector and

>\/I

1With the ignition key in the

“ON” position, does voltage

between body connector

terminal No.8 and ground

indicate the battery voltage?

Is there continuity between

No~Broken line between HU

body connector terminaland body groundNo.9 and ground?

I

YesIs there continuity between

HU connector terminal No. 8and terminal

No.9?

YesRemove the valve relay. Is

there continuity between

terminal No. 87a and No. 30?

I

Yes1 Replace valve relay.

HU harness malfunction

I

1 Replace HU.

Page 173 of 1216

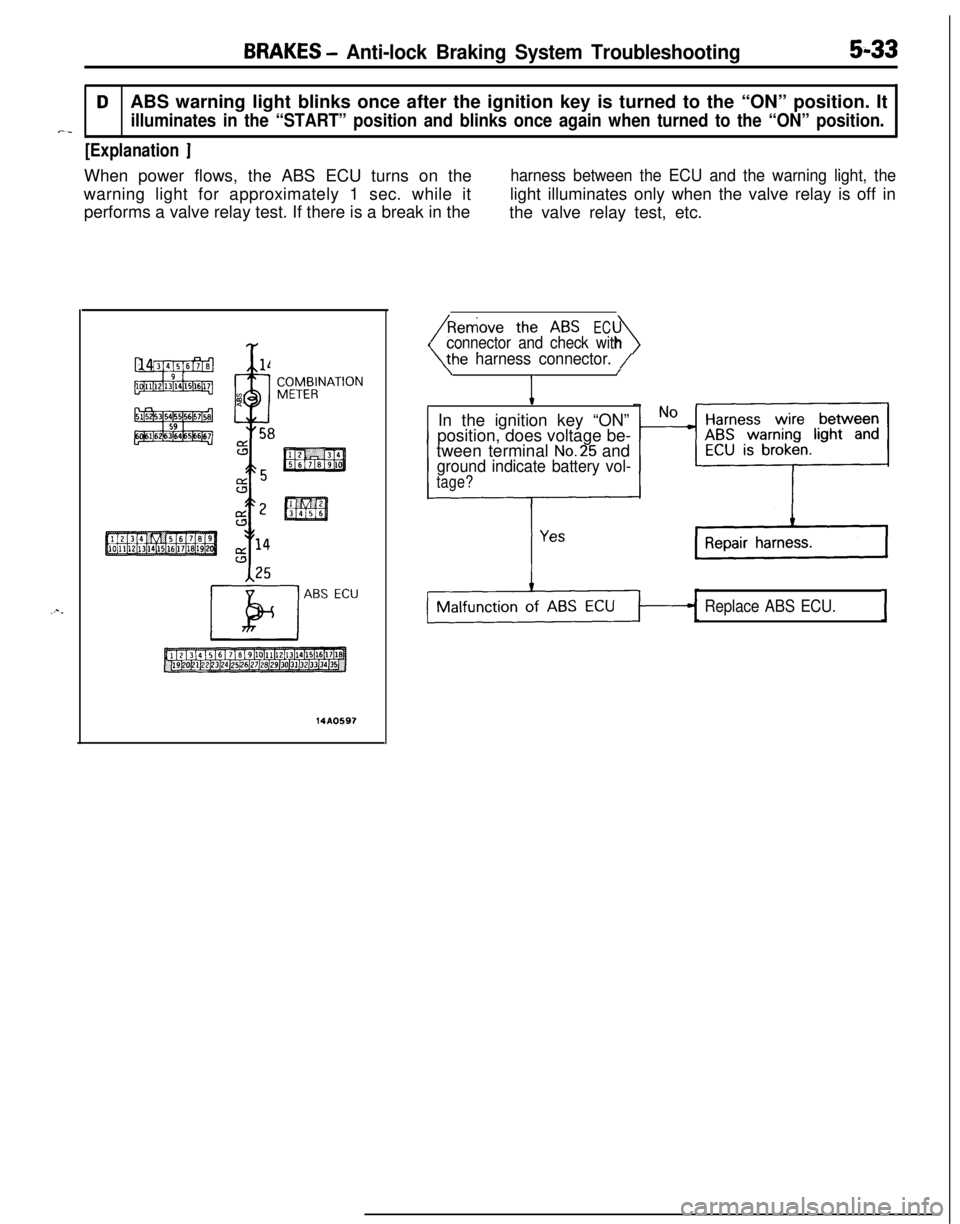

BRAKES - Anti-lock Braking System Troubleshooting5-33

DABS warning light blinks once after the ignition key is turned to the “ON” position. It

illuminates in the “START” position and blinks once again when turned to the “ON” position.*-_

[Explanation ]When power flows, the ABS ECU turns on the

harness between the ECU and the warning light, thewarning light for approximately 1 sec. while itlight illuminates only when the valve relay is off in

performs a valve relay test. If there is a break in the

the valve relay test, etc.

Y

x %l4

9

4

n. 58

ABS ECU

14A0597

EC

4connector and check with

he harness connector. /\/

IIn the ignition key “ON”

position, does voltage be-

tween terminal

No.25 andground indicate battery vol-

tage?

Replace ABS ECU.I

Page 176 of 1216

![MITSUBISHI ECLIPSE 1991 User Guide 5-36BRAKES - Anti-lock Braking System Troubleshooting

E-3Abnormality of G sensor circuit

[Explanation]The ABS ECU turns on the warning light in the

following cases.

lOFF trouble turning G sensor OFF ( MITSUBISHI ECLIPSE 1991 User Guide 5-36BRAKES - Anti-lock Braking System Troubleshooting

E-3Abnormality of G sensor circuit

[Explanation]The ABS ECU turns on the warning light in the

following cases.

lOFF trouble turning G sensor OFF (](/img/19/57104/w960_57104-175.png)

5-36BRAKES - Anti-lock Braking System Troubleshooting

E-3Abnormality of G sensor circuit

[Explanation]The ABS ECU turns on the warning light in the

following cases.

lOFF trouble turning G sensor OFF (It is judged

that the

G sensor continues to be OFF for more

than approximately 13 seconds except when the

lWhen there is a broken wire or short circuit in

the harness for the

G sensor system.

PlUN; F;SIBLEIGNITIONSWITCH (IG2)J/B

G-SENSOR

E-lABSECU

14AO609

Is G sensor normal? (ReferNoto

P.5-86.)Replace G sensor.

I YesWith the ignition key “ON”

_ No m The harness between the

does the voltage betweenG sensor and the ABS

terminal No.6 and groundECU is broken.

indicate battery voltage?

IG sensor circuit is normal.I

Page 325 of 1216

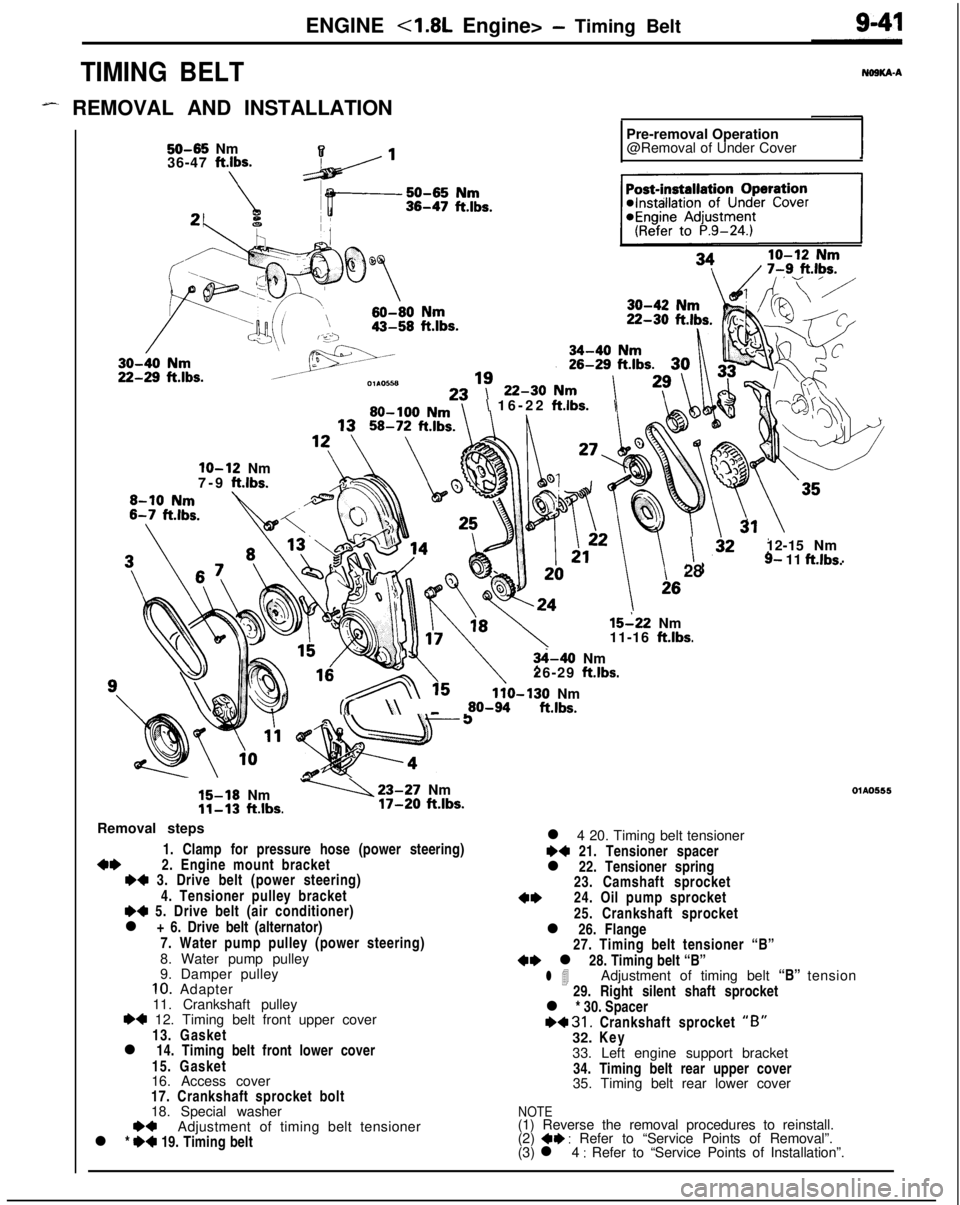

ENGINE <1.8L Engine> - Timing Belt

TIMING BELT

- REMOVAL AND INSTALLATION,

50-65 Nm

36-47 ft.lbs.Pre-removal Operation

@Removal of Under Cover

\ 16-22 ftlbs.\

lo-12 Nm

7-9 ft.lbs.

I28

15-22 Nm

11-16 ft.lbs.

3hO Nm

26-29 ft.lbs.

110-130 Nm(( \\ _ 60-94 ftlbs.

15-16 Nm-23-27 Nm

11-13 ft.lbs.17-20 ft.lbs.12-15 Nm

9- 11 ft.lbs.OlAO555

Removal steps

1. Clamp for pressure hose (power steering)

4*2. Engine mount bracketI)* 3. Drive belt (power steering)

4. Tensioner pulley bracket

H 5. Drive belt (air conditioner)

l + 6. Drive belt (alternator)

7. Water pump pulley (power steering)

8. Water pump pulley

9. Damper pulley

10. Adapter

11. Crankshaft pulley

I)4 12. Timing belt front upper cover

13. Gasket

l 14. Timing belt front lower cover

15. Gasket

16. Access cover

17. Crankshaft sprocket bolt

18. Special washer

Adjustment of timing belt tensioner

l *

:: 19. Timing beltl 4 20. Timing belt tensioner

I)+ 21. Tensioner spacer

l 22. Tensioner spring

23. Camshaft sprocket

4*24. Oil pump sprocket

25. Crankshaft sprocket

l 26. Flange

27. Timing belt tensioner “B”

~~ l 28. Timing belt “B”

l 4Adjustment of timing belt “B” tension

29. Right silent shaft sprocket

l * 30. Spacer

~~ 31. Crankshaft sprocket “B”32. Key

33. Left engine support bracket

34. Timing belt rear upper cover

35. Timing belt rear lower cover

NOTE(1) Reverse the removal procedures to reinstall.

(2)

4* : Refer to “Service Points of Removal”.

(3) l 4 : Refer to “Service Points of Installation”.

Page 513 of 1216

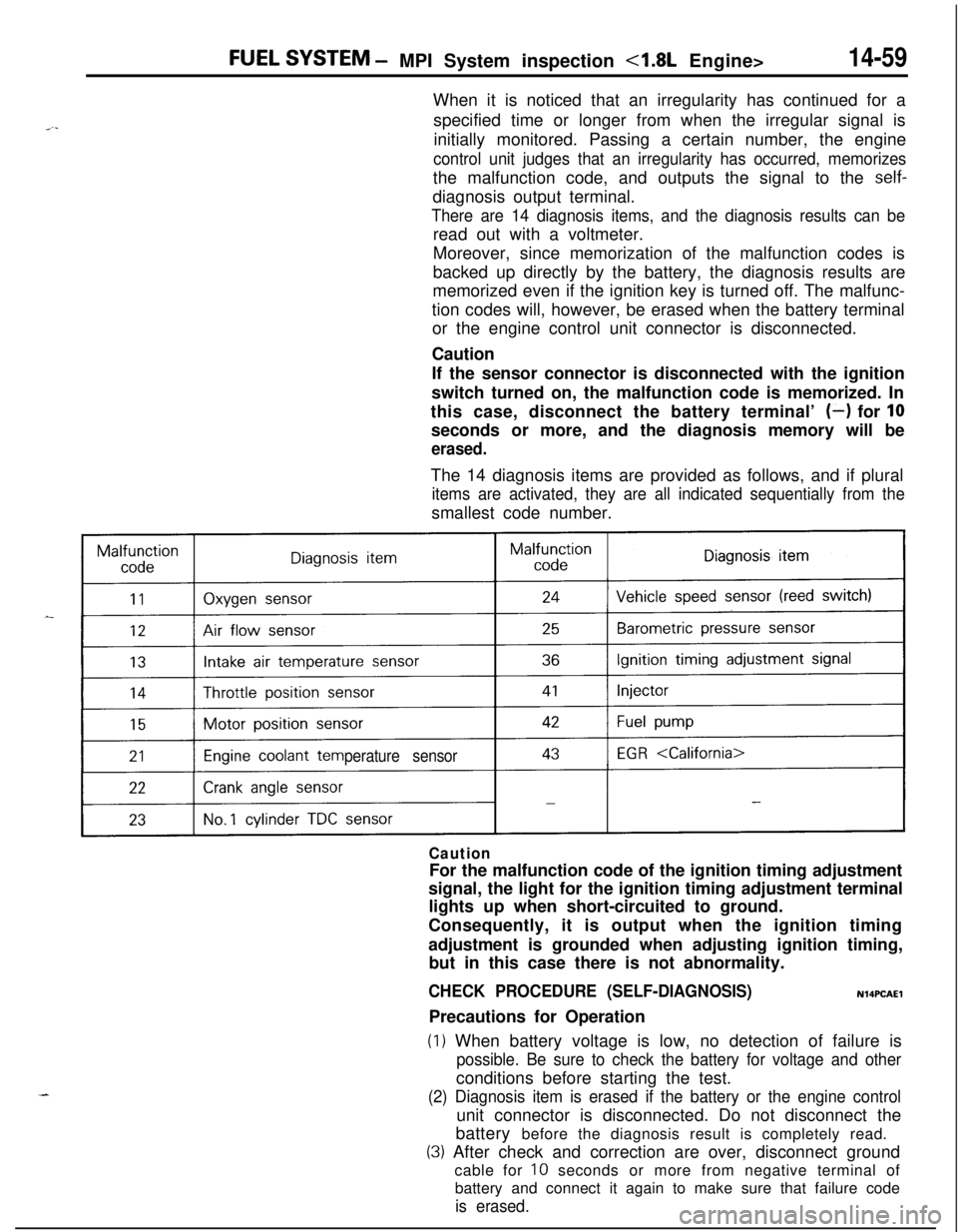

FUEL SYSTEM - MPI System inspection <1.8L Engine>14-59

--..When it is noticed that an irregularity has continued for a

specified time or longer from when the irregular signal is

initially monitored. Passing a certain number, the engine

control unit judges that an irregularity has occurred, memorizesthe malfunction code, and outputs the signal to the

self-diagnosis output terminal.

There are 14 diagnosis items, and the diagnosis results can beread out with a voltmeter.

Moreover, since memorization of the malfunction codes is

backed up directly by the battery, the diagnosis results are

memorized even if the ignition key is turned off. The malfunc-

tion codes will, however, be erased when the battery terminal

or the engine control unit connector is disconnected.

Caution

If the sensor connector is disconnected with the ignition

switch turned on, the malfunction code is memorized. In

this case, disconnect the battery terminal’

(-) for 10seconds or more, and the diagnosis memory will be

erased.The 14 diagnosis items are provided as follows, and if plural

items are activated, they are all indicated sequentially from thesmallest code number.

perature sensor

CautionFor the malfunction code of the ignition timing adjustment

signal, the light for the ignition timing adjustment terminal

lights up when short-circuited to ground.

Consequently, it is output when the ignition timing

adjustment is grounded when adjusting ignition timing,

but in this case there is not abnormality.

CHECK PROCEDURE (SELF-DIAGNOSIS)N14PCAElPrecautions for Operation

(1) When battery voltage is low, no detection of failure is

possible. Be sure to check the battery for voltage and otherconditions before starting the test.

(2) Diagnosis item is erased if the battery or the engine controlunit connector is disconnected. Do not disconnect the

battery before the diagnosis result is completely read.

(3) After check and correction are over, disconnect ground

cable for

10 seconds or more from negative terminal of

battery and connect it again to make sure that failure code

is erased.

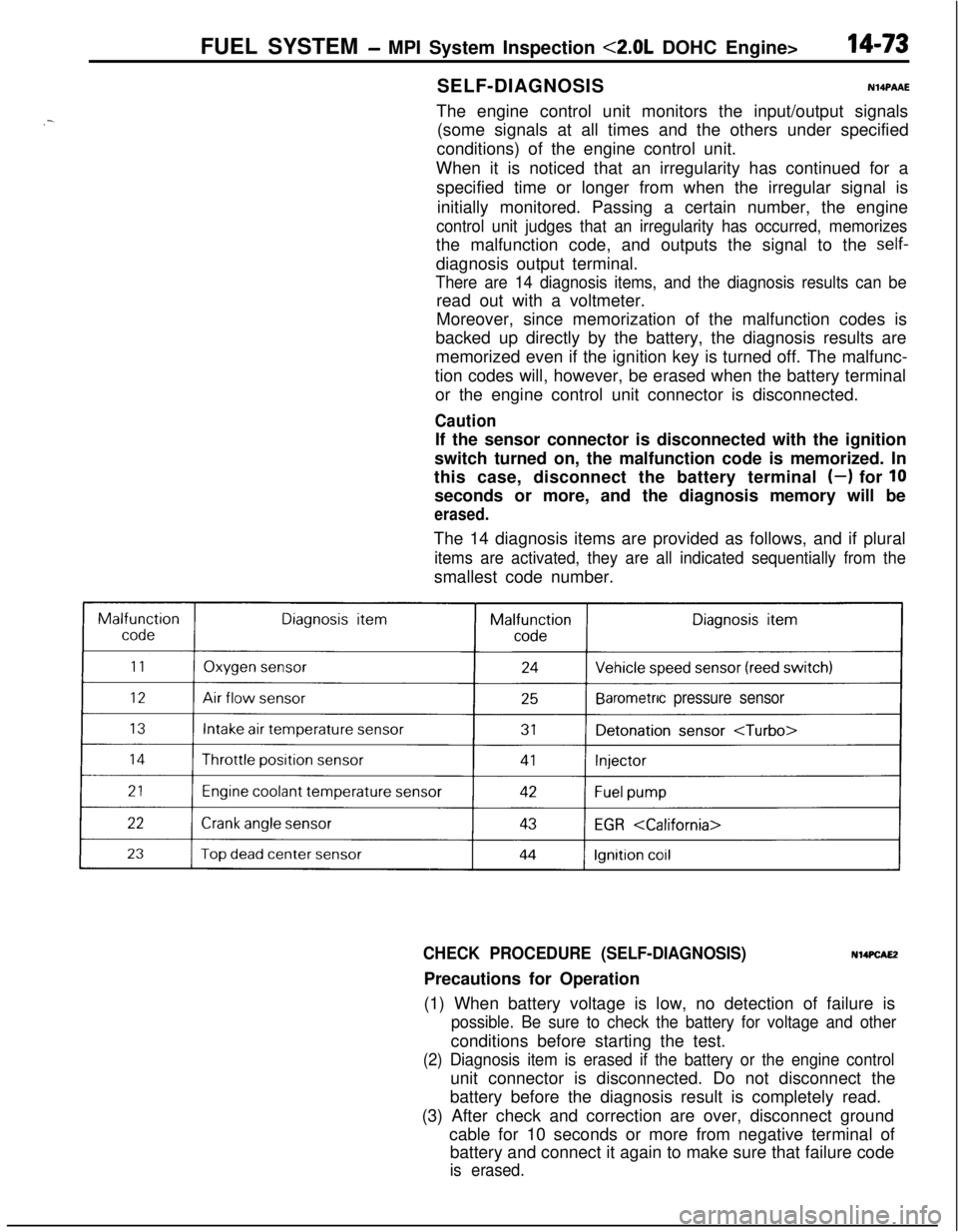

Page 527 of 1216

FUEL SYSTEM - MPI System Inspection <2.0L DOHC Engine>

SELF-DIAGNOSIS14-73

N14PAAEThe engine control unit monitors the input/output signals

(some signals at all times and the others under specified

conditions) of the engine control unit.

When it is noticed that an irregularity has continued for a

specified time or longer from when the irregular signal is

initially monitored. Passing a certain number, the engine

control unit judges that an irregularity has occurred, memorizesthe malfunction code, and outputs the signal to the

self-diagnosis output terminal.

There are 14 diagnosis items, and the diagnosis results can beread out with a voltmeter.

Moreover, since memorization of the malfunction codes is

backed up directly by the battery, the diagnosis results are

memorized even if the ignition key is turned off. The malfunc-

tion codes will, however, be erased when the battery terminal

or the engine control unit connector is disconnected.

CautionIf the sensor connector is disconnected with the ignition

switch turned on, the malfunction code is memorized. In

this case, disconnect the battery terminal

(-) for 10seconds or more, and the diagnosis memory will be

erased.The 14 diagnosis items are provided as follows, and if plural

items are activated, they are all indicated sequentially from thesmallest code number.

arometnc pressure sensor

CHECK PROCEDURE (SELF-DIAGNOSIS)Precautions for OperationN14PCAE2(1) When battery voltage is low, no detection of failure is

possible. Be sure to check the battery for voltage and otherconditions before starting the test.

(2) Diagnosis item is erased if the battery or the engine controlunit connector is disconnected. Do not disconnect the

battery before the diagnosis result is completely read.

(3) After check and correction are over, disconnect ground

cable for 10 seconds or more from negative terminal of

battery and connect it again to make sure that failure code

is erased.

Page 589 of 1216

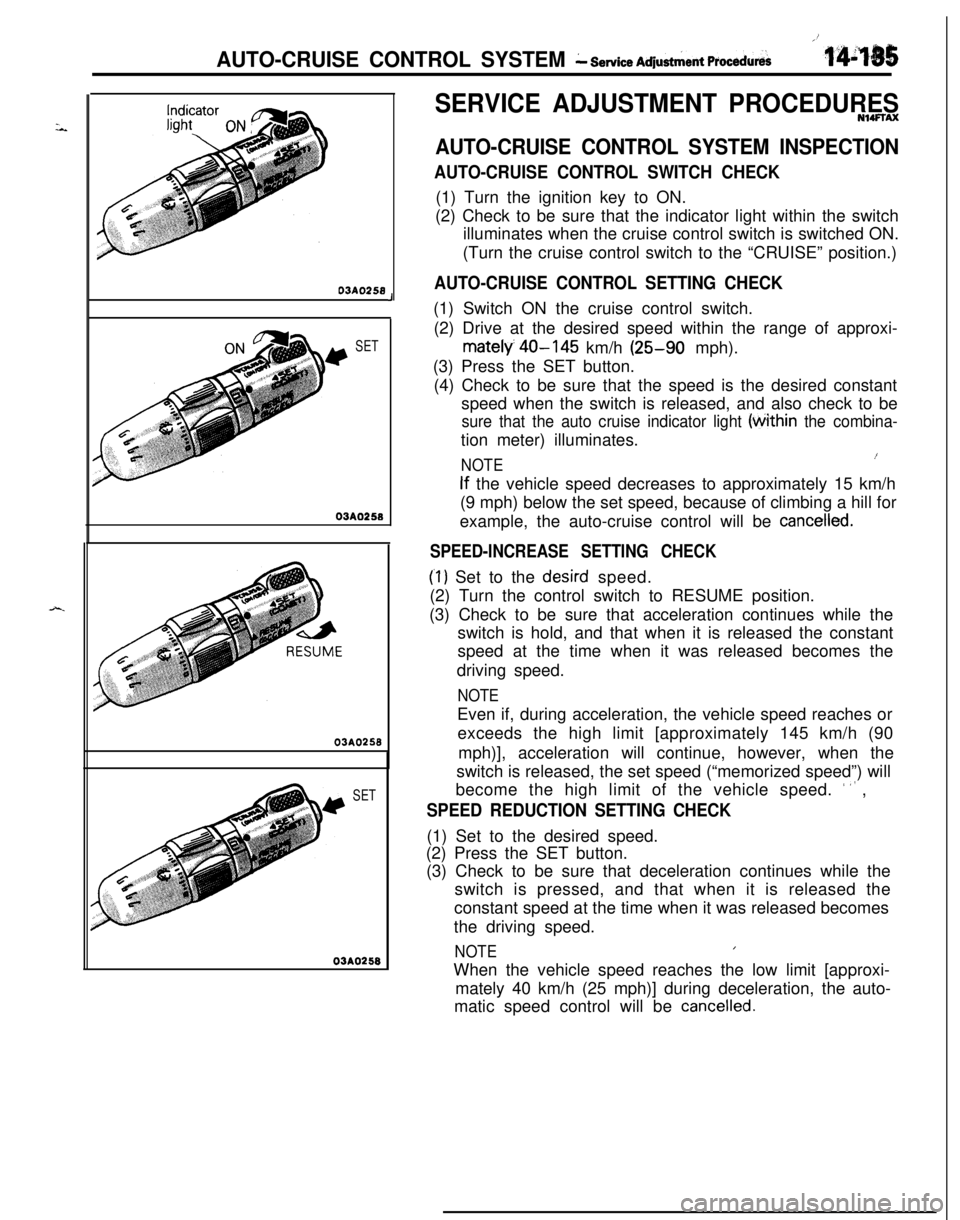

AUTO-CRUISE CONTROL SYSTEM L service Adjustkt Procedw&

03A0258

YSET

03AO258

03AO250

SET

03A025t

JI

SERVICE ADJUSTMENT PROCEDURESNl4FUU

AUTO-CRUISE CONTROL SYSTEM INSPECTION

AUTO-CRUISE CONTROL SWITCH CHECK(1) Turn the ignition key to ON.

(2) Check to be sure that the indicator light within the switch

illuminates when the cruise control switch is switched ON.

(Turn the cruise control switch to the “CRUISE” position.)

AUTO-CRUISE CONTROL SETTING CHECK(1) Switch ON the cruise control switch.

(2) Drive at the desired speed within the range of approxi-

mately 40-145 km/h (25-90 mph).

(3) Press the SET button.

(4) Check to be sure that the speed is the desired constant

speed when the switch is released, and also check to be

sure that the auto cruise indicator light (tithin the combina-tion meter) illuminates.

NOTE1(

If the vehicle speed decreases to approximately 15 km/h

(9 mph) below the set speed, because of climbing a hill for

example, the auto-cruise control will be

cancelled.

SPEED-INCREASE SETTING CHECK

(‘1) Set to the desird speed.

(2) Turn the control switch to RESUME position.

(3) Check to be sure that acceleration continues while the

switch is hold, and that when it is released the constant

speed at the time when it was released becomes the

driving speed.

NOTEEven if, during acceleration, the vehicle speed reaches or

exceeds the high limit [approximately 145 km/h (90

mph)], acceleration will continue, however, when the

switch is released, the set speed (“memorized speed”) will

become the high limit of the vehicle speed.

’ ” ,

SPEED REDUCTION SETTING CHECK(1) Set to the desired speed.

(2) Press the SET button.

(3) Check to be sure that deceleration continues while the

switch is pressed, and that when it is released the

constant speed at the time when it was released becomes

the driving speed.

NOTEIWhen the vehicle speed reaches the low limit [approxi-

mately 40 km/h (25 mph)] during deceleration, the auto-

matic speed control will be

cancelled.

Page 664 of 1216

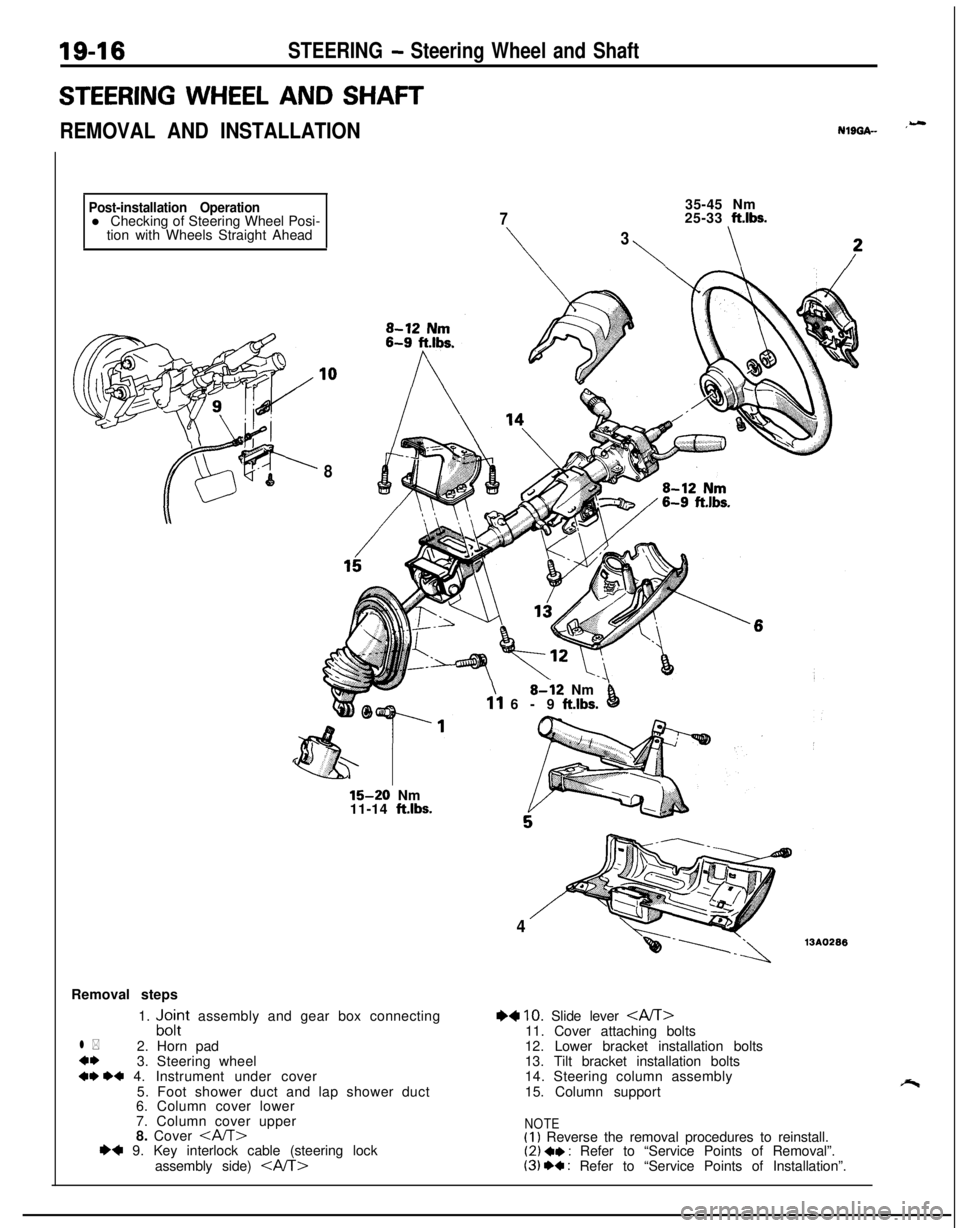

19-16STEERING - Steering Wheel and Shaft

STEERING WHEEL AND SHAFT

REMOVAL AND INSTALLATIONNlL)GA- ‘-

Post-installation Operationl Checking of Steering Wheel Posi-

tion with Wheels Straight Ahead

835-45 Nm

725-33 ft.lbs.

\

3

\\

15-20 Nm

11-14 ft.lbs.Removal steps

1.

“,c$t assembly and gear box connecting

l *2. Horn pad

4*3. Steering wheel

+* ++ 4. Instrument under cover

5. Foot shower duct and lap shower duct

6. Column cover lower

7. Column cover upper

8. Cover

assembly side)

\8-i2 Nm’11 6-9 ft.lbs.0

413AO296

+4 10. Slide lever 11. Cover attaching bolts

12. Lower bracket installation bolts

13. Tilt bracket installation bolts

14. Steering column assembly

15. Column support

NOTE(I) Reverse the removal procedures to reinstall.(2) a* : Refer to “Service Points of Removal”.(3) +a : Refer to “Service Points of Installation”.