key MITSUBISHI ECLIPSE 1991 Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 747 of 1216

MANUAL TRANSAXLE

2010018

2ndgearTFM0024

MD998320

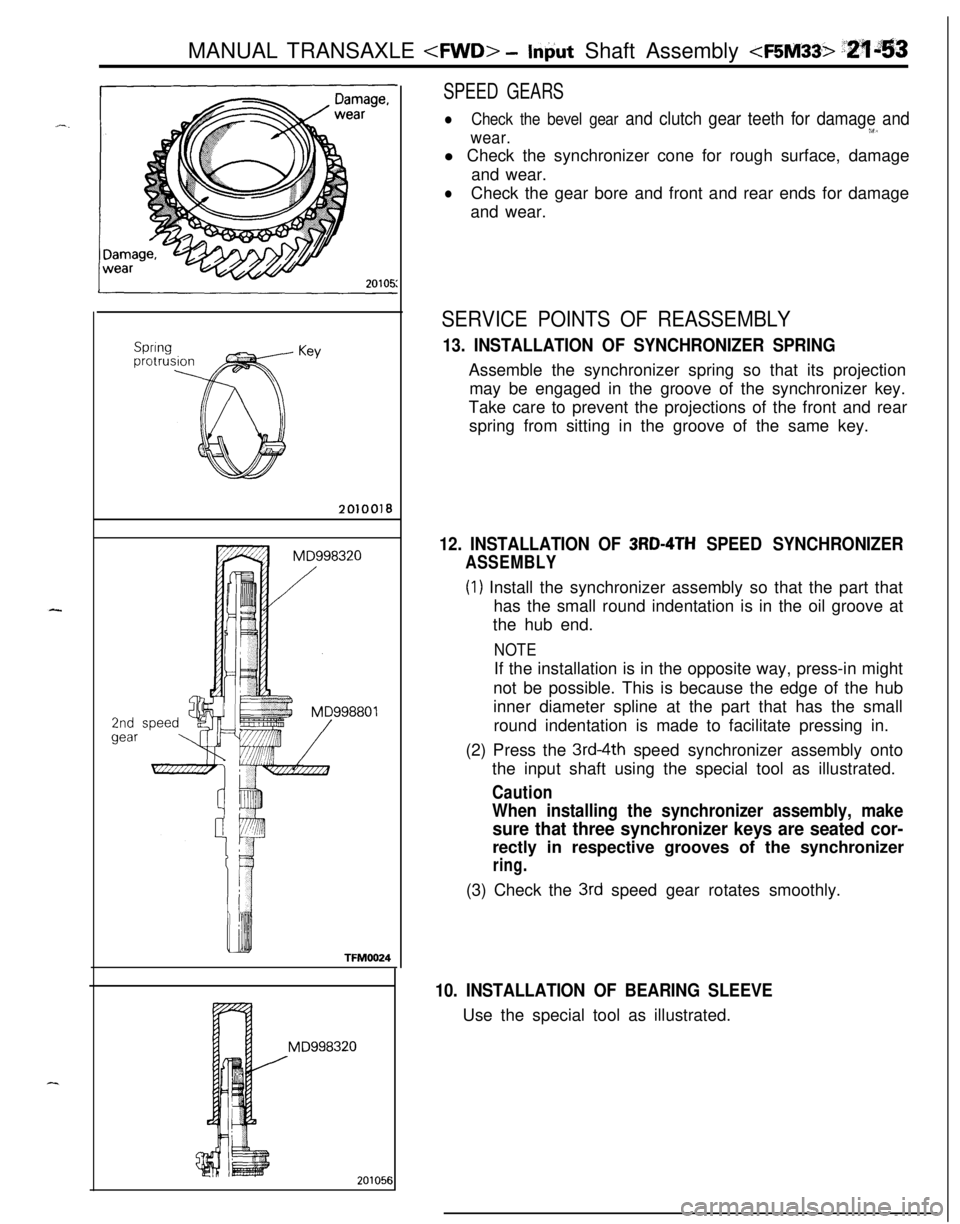

20105f

SPEED GEARS

lCheck the bevel gear and clutch gear teeth for damage andw.wear.l Check the synchronizer cone for rough surface, damage

and wear.

lCheck the gear bore and front and rear ends for damage

and wear.

SERVICE POINTS OF REASSEMBLY

13. INSTALLATION OF SYNCHRONIZER SPRINGAssemble the synchronizer spring so that its projection

may be engaged in the groove of the synchronizer key.

Take care to prevent the projections of the front and rear

spring from sitting in the groove of the same key.

12. INSTALLATION OF 3RD-4TH SPEED SYNCHRONIZER

ASSEMBLY

(1) Install the synchronizer assembly so that the part that

has the small round indentation is in the oil groove at

the hub end.

NOTEIf the installation is in the opposite way, press-in might

not be possible. This is because the edge of the hub

inner diameter spline at the part that has the small

round indentation is made to facilitate pressing in.

(2) Press the

3rd-4th speed synchronizer assembly onto

the input shaft using the special tool as illustrated.

Caution

When installing the synchronizer assembly, make

sure that three synchronizer keys are seated cor-rectly in respective grooves of the synchronizer

ring.(3) Check the

3rd speed gear rotates smoothly.

10. INSTALLATION OF BEARING SLEEVEUse the special tool as illustrated.

j

Page 750 of 1216

21-56MANUAL TRANSAXLE

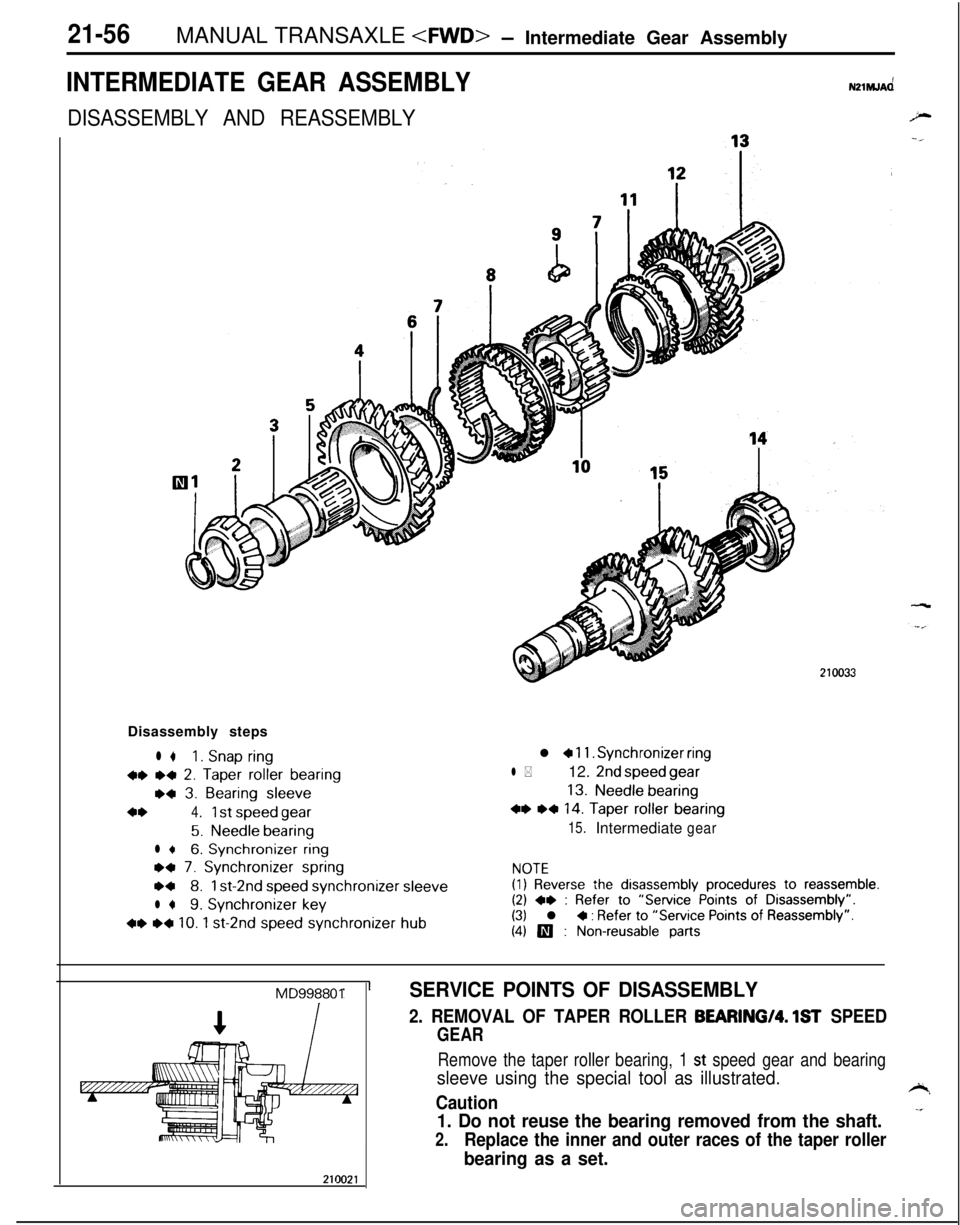

INTERMEDIATE GEAR ASSEMBLYNZlhlJAd

DISASSEMBLY AND REASSEMBLYDisassembly steps

l *1. Snap ring

w *+ 2. Taper roller bearing

w 3. Bearing sleeve

4*4.1 st speed gear

5.Needle bearing

l +6. Synchronizer ring

ea 7. Synchronizer spring

w8.1 st-2nd speed synchronizersleeve

l *9. Synchronizer key

+* ~~ 10. 1 st-2nd speed synchronizer hub

l a 11. Synchronizer ring

l *12. 2nd speed gear

13.Needle bearing

+* ,* 14. Taper roller bearing

15.Intermediategear

NOTE(1) Reverse the disassembly procedures to reassemble.(2) +e : Refer to “Service Points of Disassembly”.(3) l + : Refer to “Service Points of Reassembly”.

(4) III : Non-reusable parts

MD998801SERVICE POINTS OF DISASSEMBLY

2. REMOVAL OF TAPER ROLLER BEARING/Q. 1ST SPEED

GEAR

Remove the taper roller bearing, 1 st speed gear and bearing

sleeve using the special tool as illustrated.

Caution

1. Do not reuse the bearing removed from the shaft.

2.Replace the inner and outer races of the taper roller

bearing as a set.

Page 752 of 1216

21-58MANUAL TRANSAXLE

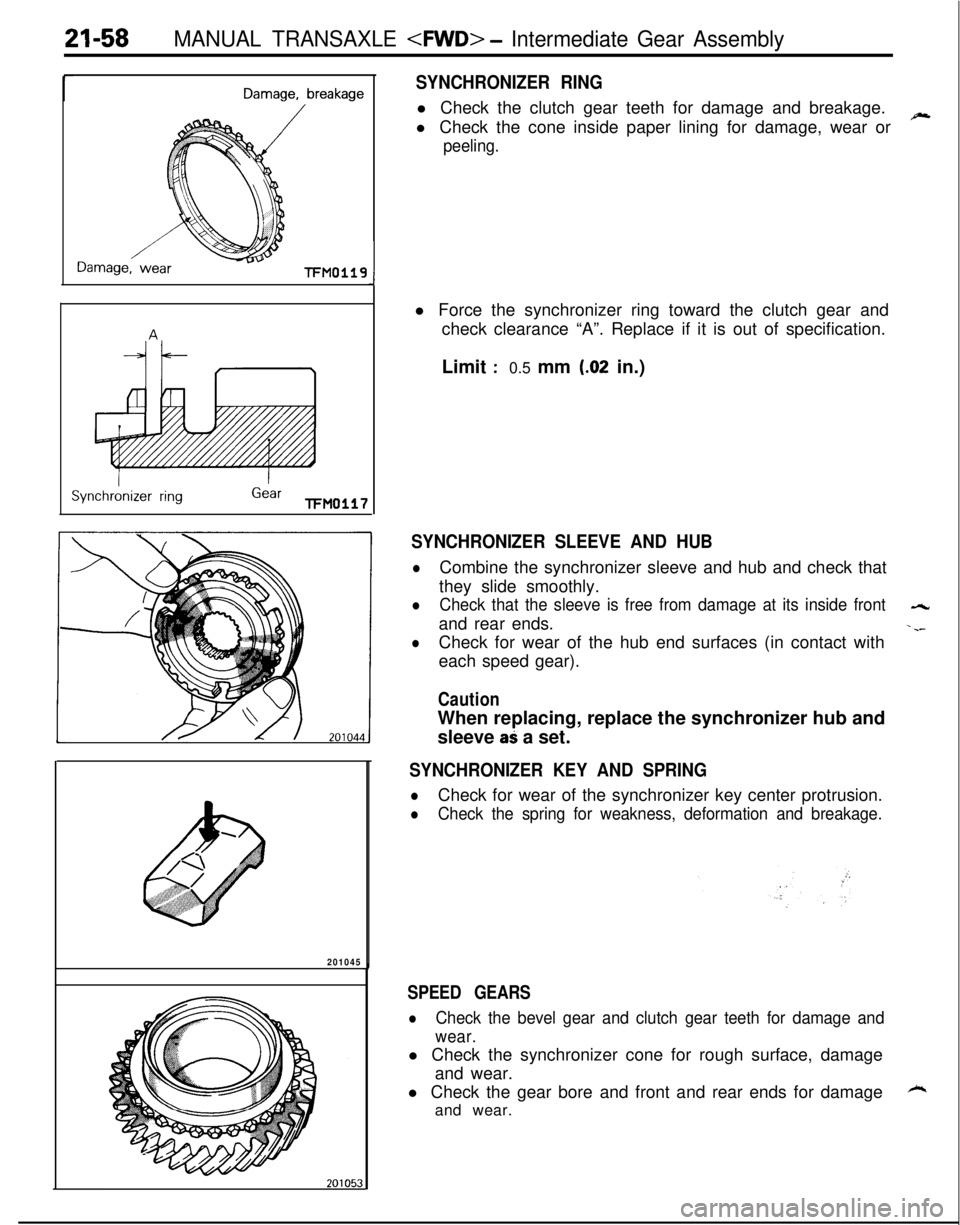

rDamage, breakage

Damage, wearl-FM0119

ISynchronizer ring

IGearTFM0117

SYNCHRONIZER RINGl Check the clutch gear teeth for damage and breakage.

l Check the cone inside paper lining for damage, wear or

~

peeling.

J

201045l Force the synchronizer ring toward the clutch gear and

check clearance “A”. Replace if it is out of specification.

Limit

:0.5 mm (.02 in.)

SYNCHRONIZER SLEEVE AND HUB

lCombine the synchronizer sleeve and hub and check that

they slide smoothly.

lCheck that the sleeve is free from damage at its inside front-4rand rear ends.

-.--

lCheck for wear of the hub end surfaces (in contact with

each speed gear).

CautionWhen replacing, replace the synchronizer hub and

sleeve

aS a set.

SYNCHRONIZER KEY AND SPRING

lCheck for wear of the synchronizer key center protrusion.

lCheck the spring for weakness, deformation and breakage.

SPEED GEARS

lCheck the bevel gear and clutch gear teeth for damage and

wear.l Check the synchronizer cone for rough surface, damage

and wear.

l Check the gear bore and front and rear ends for damage

kand wear.

Page 753 of 1216

MANUAL TRANSAXLE

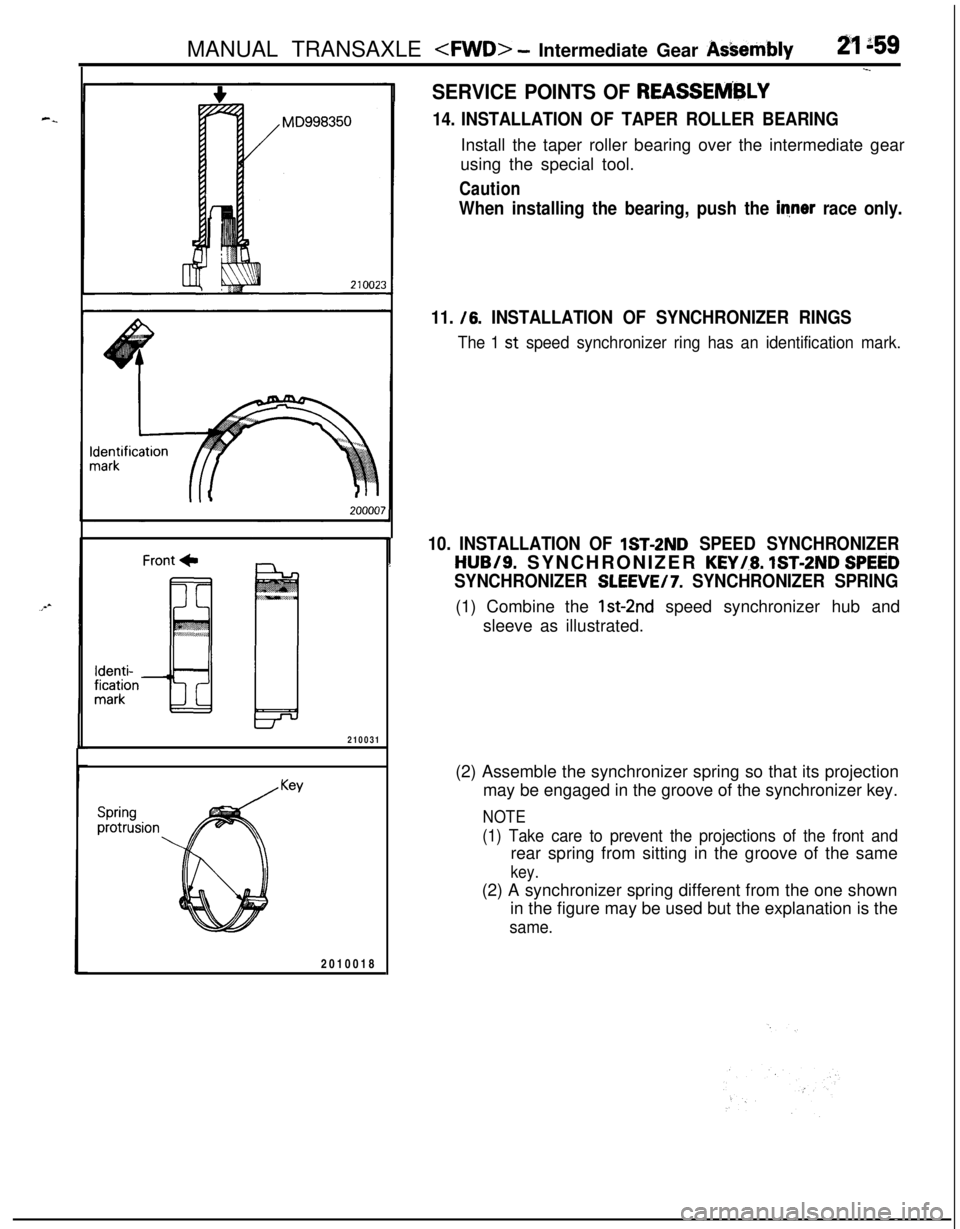

.-_

Front +Identi-fication

mark

210031

Springprotrusion

Key2010018

SERVICE POINTS OF REASSElViBLY

14. INSTALLATION OF TAPER ROLLER BEARINGInstall the taper roller bearing over the intermediate gear

using the special tool.

Caution

When installing the bearing, push the inner race only.

11. /6.

INSTALLATION OF SYNCHRONIZER RINGS

The 1 st speed synchronizer ring has an identification mark.

10. INSTALLATION OF lST-2ND SPEED SYNCHRONIZER

HUB/S. SYNCHRONIZER KEYi.8. IST-2ND SPEED

SYNCHRONIZER SLEEVE/7. SYNCHRONIZER SPRING(1) Combine the

lst-2nd speed synchronizer hub and

sleeve as illustrated.

(2) Assemble the synchronizer spring so that its projection

may be engaged in the groove of the synchronizer key.

NOTE

(1) Take care to prevent the projections of the front andrear spring from sitting in the groove of the same

key.(2) A synchronizer spring different from the one shown

in the figure may be used but the explanation is the

same.

Page 754 of 1216

21-60MANUAL TRANSAXLE

MD998350

/

1 st-2ndspeedsynchronizerassembly

201069

. MD998350

I

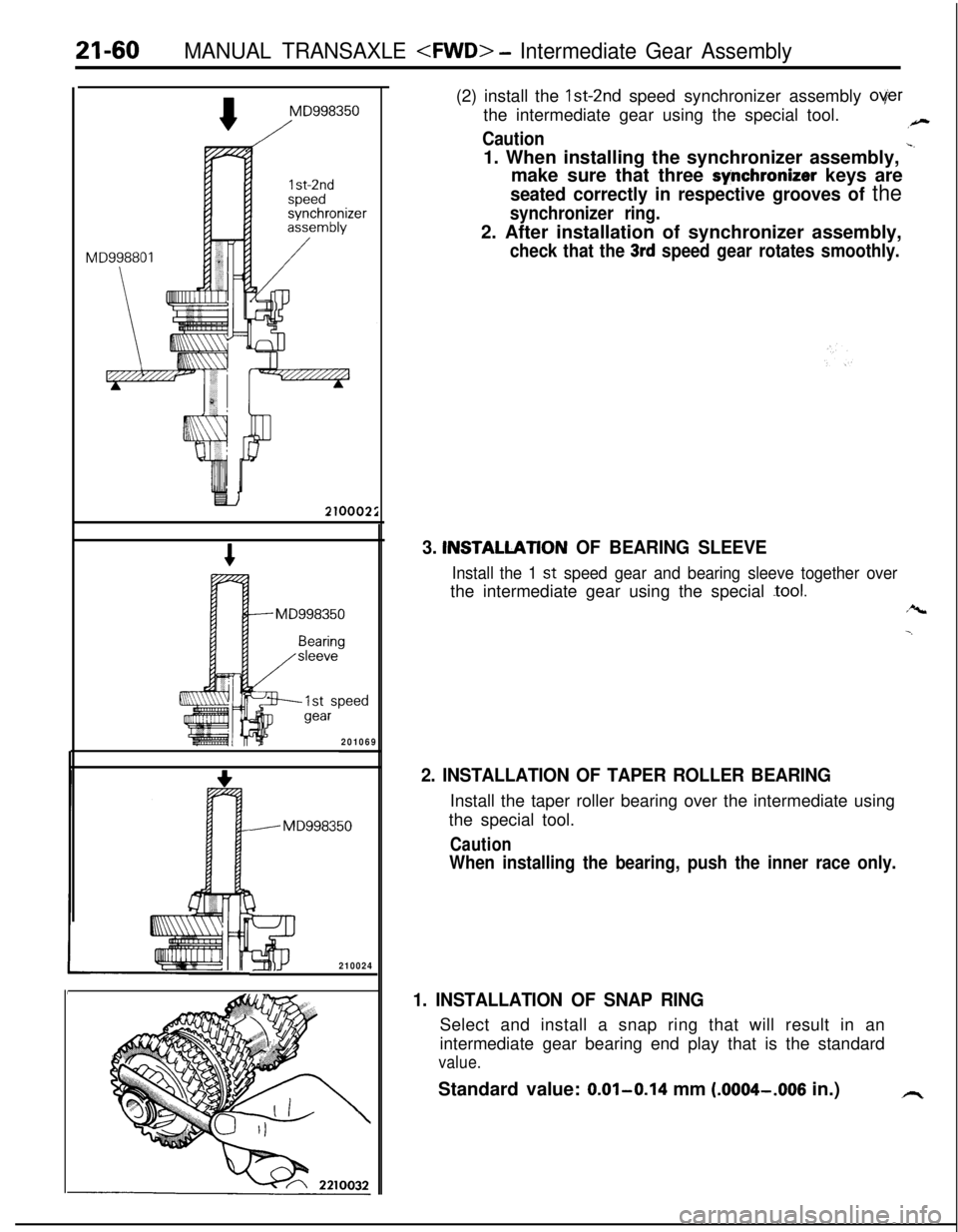

3210024(2) install the Ist-2nd speed synchronizer assembly

overthe intermediate gear using the special tool.

,-

Caution1. When installing the synchronizer assembly,

-‘make sure that three

synchronizer keys are

seated correctly in respective grooves of the

synchronizer ring.2. After installation of synchronizer assembly,

check that the 3rd speed gear rotates smoothly.

3. INSTALLATlON OF BEARING SLEEVE

Install the 1 st speed gear and bearing sleeve together overthe intermediate gear using the special

-tool.

r%

-.

2. INSTALLATION OF TAPER ROLLER BEARINGInstall the taper roller bearing over the intermediate using

the special tool.

Caution

When installing the bearing, push the inner race only.

1. INSTALLATION OF SNAP RINGSelect and install a snap ring that will result in an

intermediate gear bearing end play that is the standard

value.Standard value: 0.01-0.14 mm

(.0004-.OOS in.)h

Page 795 of 1216

MANUAL TRANSAXLE

5TH SPEED SYNCHRONIZER ASSEMBLY

/-- DISASSEMBLY AND REASSEMBLY

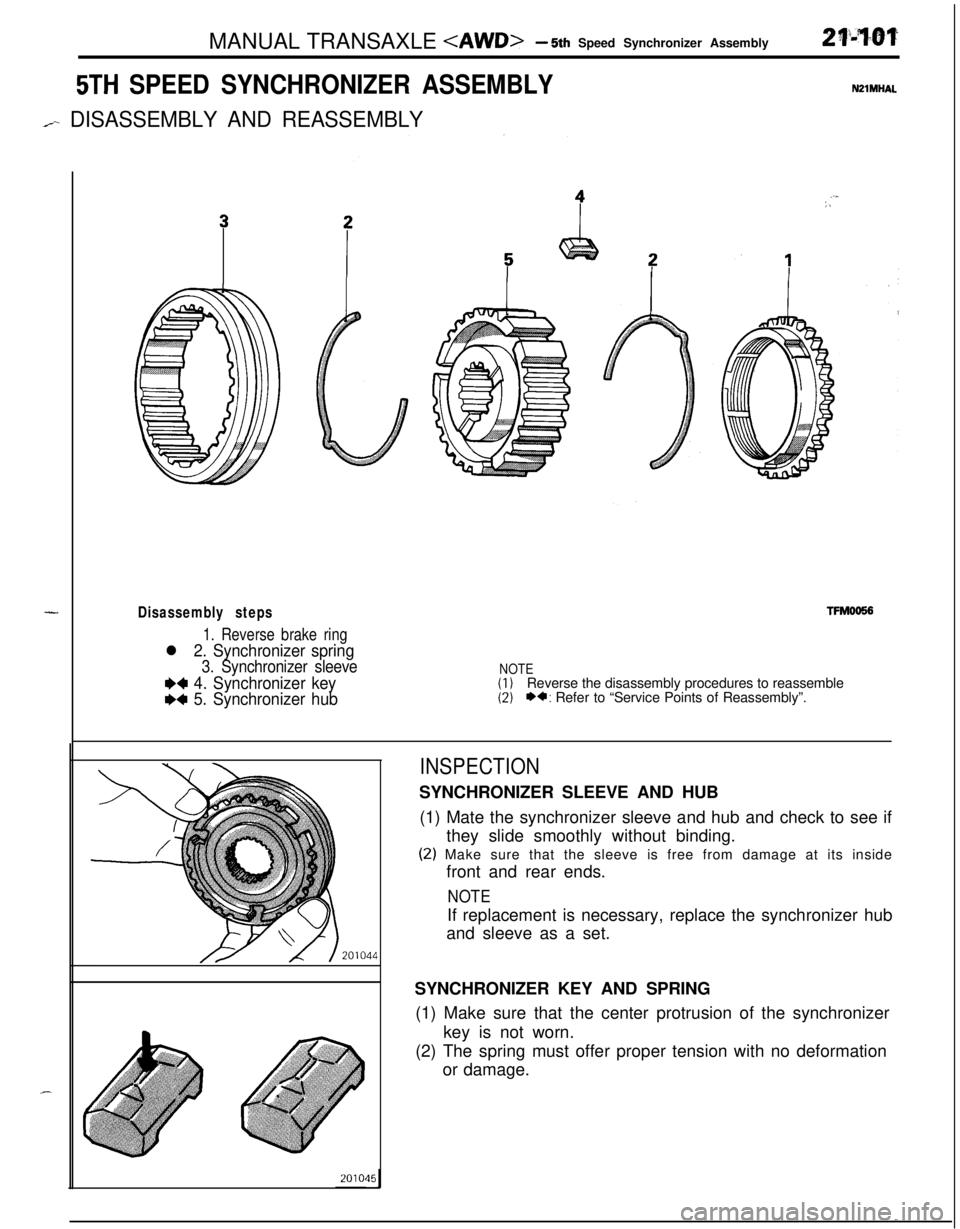

-Disassembly steps

1. Reverse brake ring

l 2. Synchronizer spring

3. Synchronizer sleeve

W 4. Synchronizer key

I)+ 5. Synchronizer hub

WlMHAL

. . I:,

TFMOO!56

NOTE(1)Reverse the disassembly procedures to reassemble(2)*a: Refer to “Service Points of Reassembly”.

INSPECTIONSYNCHRONIZER SLEEVE AND HUB

(1) Mate the synchronizer sleeve and hub and check to see if

they slide smoothly without binding.

(2) Make sure that the sleeve is free from damage at its inside

front and rear ends.

NOTEIf replacement is necessary, replace the synchronizer hub

and sleeve as a set.

SYNCHRONIZER KEY AND SPRING

(1) Make sure that the center protrusion of the synchronizer

key is not worn.

(2) The spring must offer proper tension with no deformation

or damage.

Page 796 of 1216

21-102MANUAL TRANSAXLE

Oil groove

5thspeed +

$2

TFM0046

201001a,

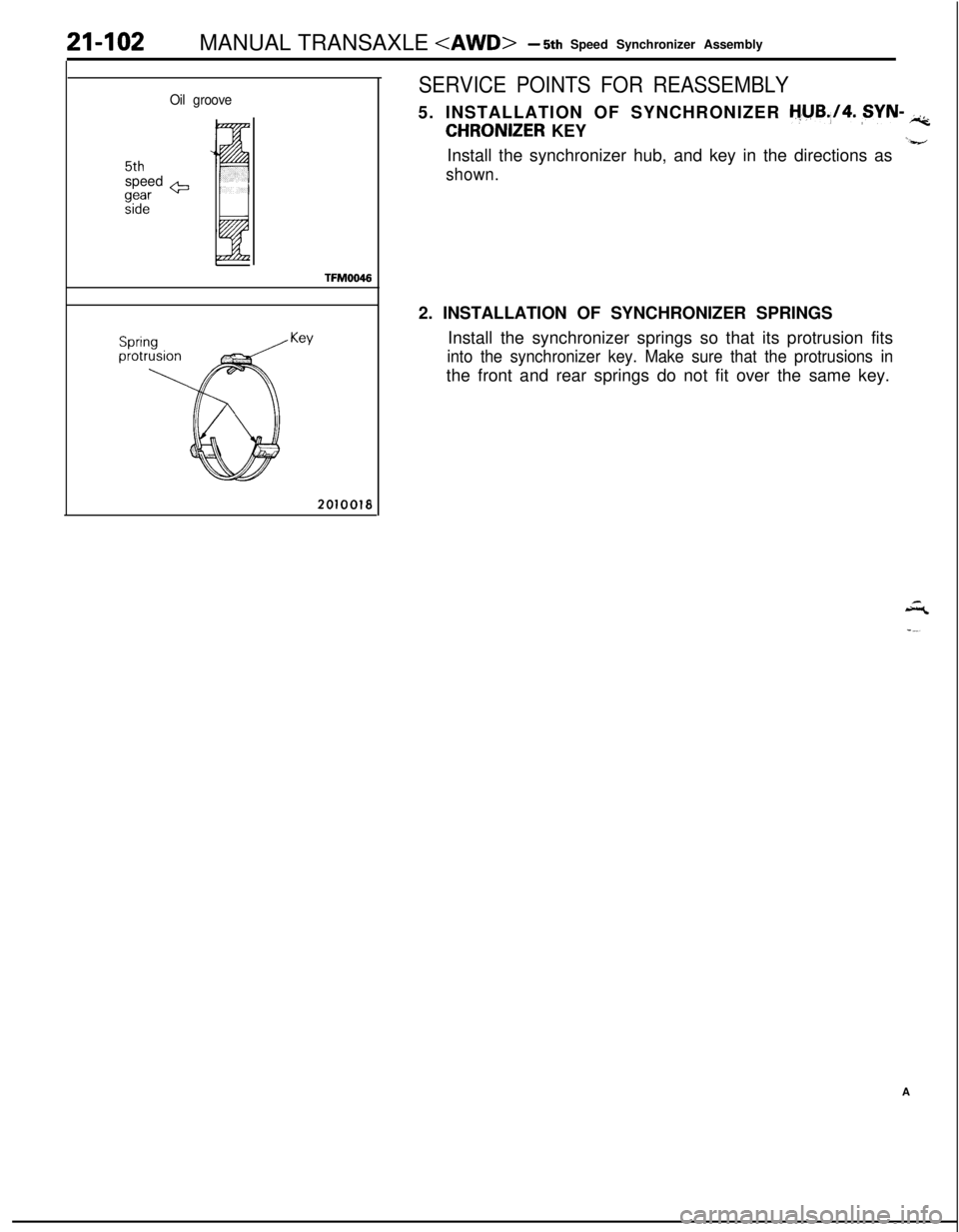

SERVICE POINTS FOR REASSEMBLY5. INSTALLATION OF SYNCHRONIZER

tjyB.,/4. ,SYN- iic;

CHRONIZER KEY‘-a-/Install the synchronizer hub, and key in the directions as

shown.2. INSTALLATION OF SYNCHRONIZER SPRINGS

Install the synchronizer springs so that its protrusion fits

into the synchronizer key. Make sure that the protrusions inthe front and rear springs do not fit over the same key.

A

Page 804 of 1216

21-I 10MANUAL TRANSAXLE

INTERMEDIATE GEAR ASSEMBLYNPlMJAR

DISASSEMBLY AND REASSEMBLY

j”r:

Disassembly steps

** 1. Snap ringl * l +2. Taper roller bearing

l * 3. Bearing sleeve

l *4. 1 st speed gear

5. Needle bearing

l a6. Synchronizer ringl +7. Synchronizer springl a8. 1 st-2nd speed synchronizer sleeve

l *9. Synchronizer keyw l a IO. 1 st-2nd speed synchronizer hub

l * II. Synchronizer ringa*12. 2nd speed gear

13. Needle bearing

l * l * 14. Taper roller bearing

15. Intermediate gearNOTE(I) Reverse the disassembly procedures to reassemble.Ah..(2)+*: Refer to “Service Points of Disassembly”.(3)l C: Refer to “Service Points of Reassembly”.(4)q : Non-reusable parts.

Page 806 of 1216

21-112MANUAL TRANSAXLE

201051

Damage, breakage

I

-FM0119Synchronizer ring

Gear FM0117

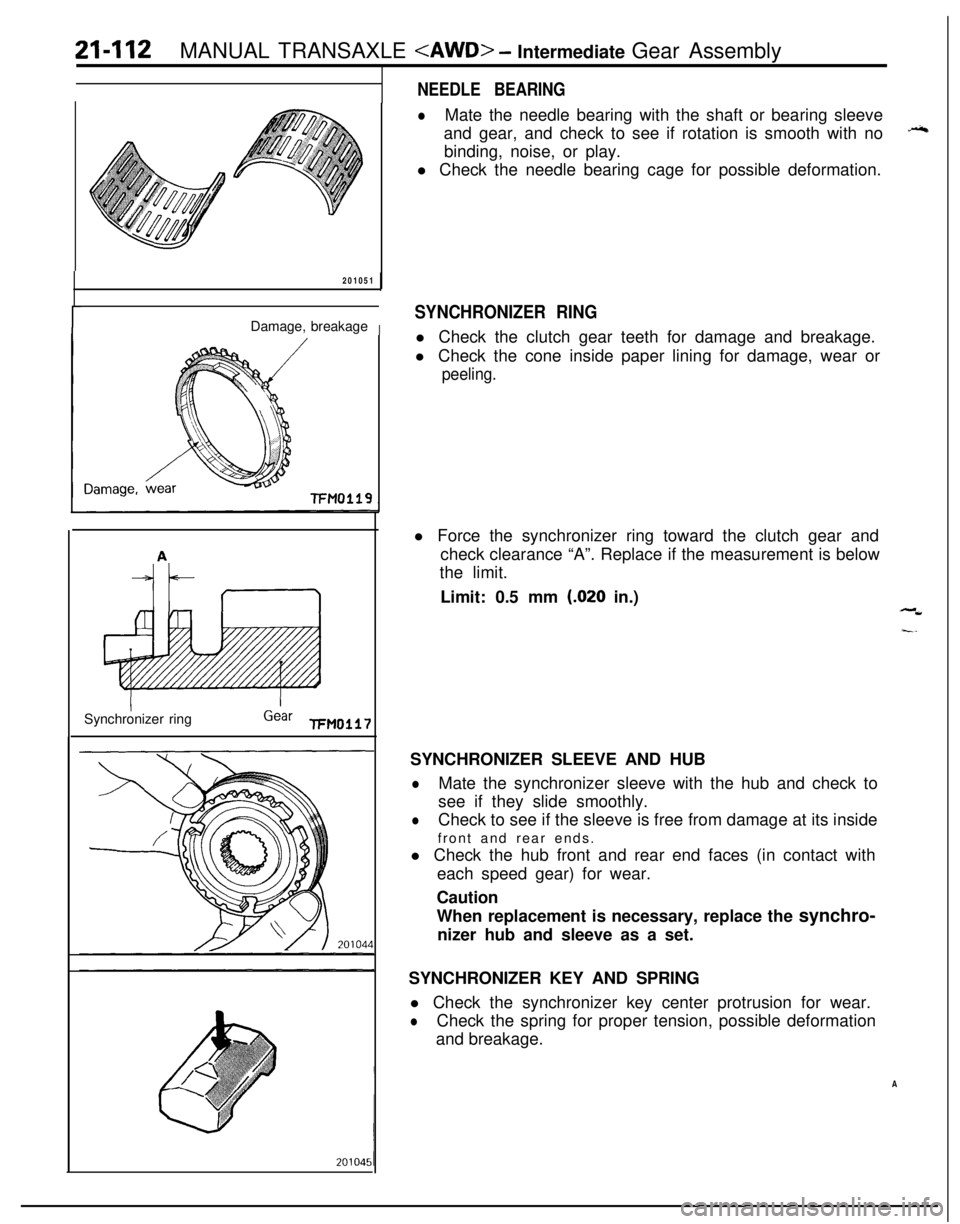

NEEDLE BEARING

lMate the needle bearing with the shaft or bearing sleeve

and gear, and check to see if rotation is smooth with no

++binding, noise, or play.

l Check the needle bearing cage for possible deformation.

SYNCHRONIZER RINGl Check the clutch gear teeth for damage and breakage.

l Check the cone inside paper lining for damage, wear or

peeling.l Force the synchronizer ring toward the clutch gear and

check clearance “A”. Replace if the measurement is below

the limit.

Limit: 0.5 mm

(.020 in.),-W

I-.SYNCHRONIZER SLEEVE AND HUB

lMate the synchronizer sleeve with the hub and check to

see if they slide smoothly.

lCheck to see if the sleeve is free from damage at its inside

front and rear ends.

l Check the hub front and rear end faces (in contact with

each speed gear) for wear.

Caution

When replacement is necessary, replace the synchro-

nizer hub and sleeve as a set.

SYNCHRONIZER KEY AND SPRING

l Check the synchronizer key center protrusion for wear.

lCheck the spring for proper tension, possible deformation

and breakage.

A

Page 807 of 1216

-.

MANUAL TRANSAXLE

D99835021002:

r$J$ch housingc

prorruslon

Sprinprotrusion

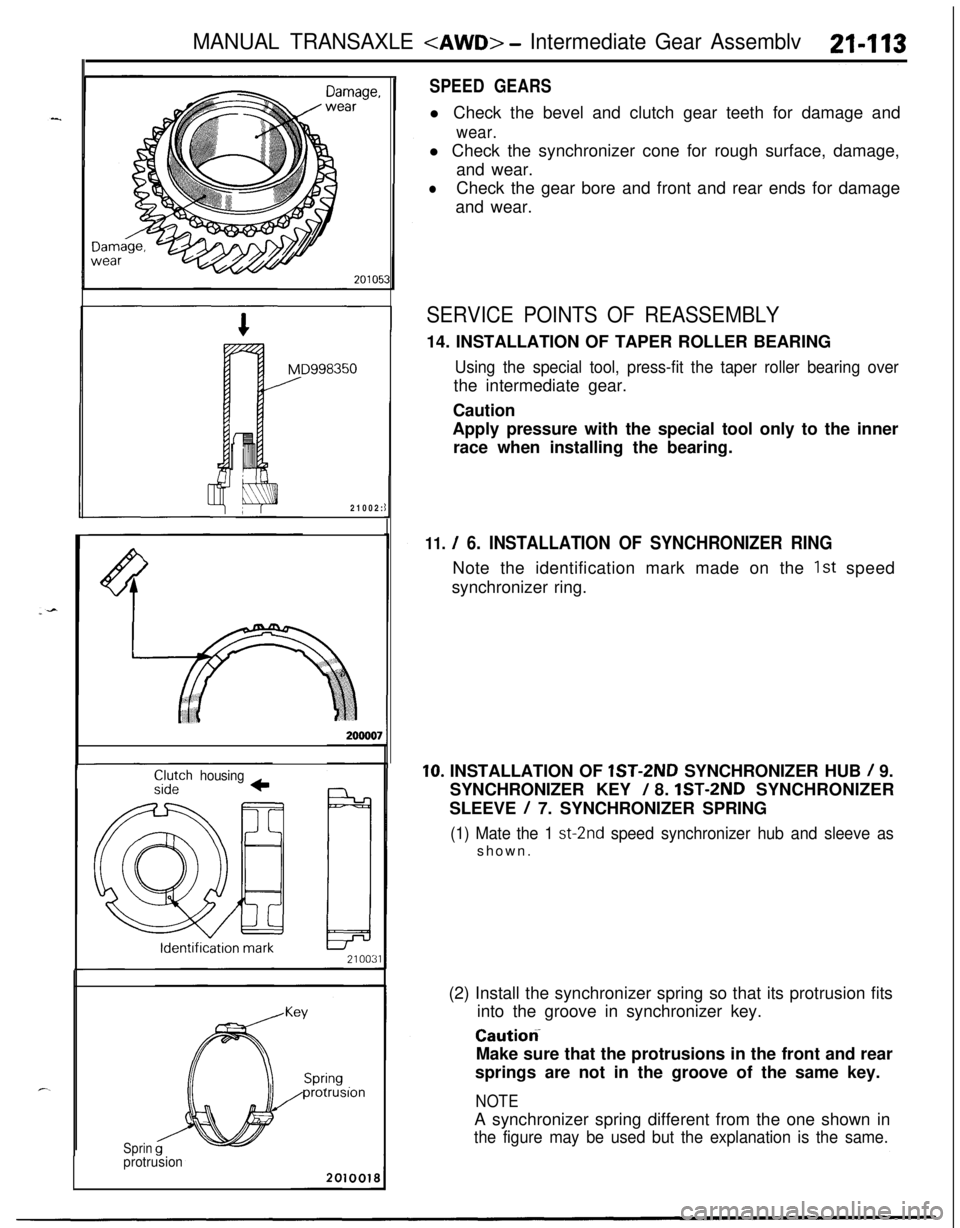

SPEED GEARSl Check the bevel and clutch gear teeth for damage and

wear.l Check the synchronizer cone for rough surface, damage,

and wear.

lCheck the gear bore and front and rear ends for damage

and wear.

SERVICE POINTS OF REASSEMBLY14. INSTALLATION OF TAPER ROLLER BEARING

Using the special tool, press-fit the taper roller bearing overthe intermediate gear.

Caution

Apply pressure with the special tool only to the inner

race when installing the bearing.

11. / 6. INSTALLATION OF SYNCHRONIZER RINGNote the identification mark made on the

1st speed

synchronizer ring.

10. INSTALLATION OF lST-2ND SYNCHRONIZER HUB / 9.

SYNCHRONIZER KEY

/ 8. lST-2ND SYNCHRONIZER

SLEEVE

/ 7. SYNCHRONIZER SPRING

(1) Mate the 1 st-2nd speed synchronizer hub and sleeve asshown.

(2) Install the synchronizer spring so that its protrusion fits

into the groove in synchronizer key.

Caution-Make sure that the protrusions in the front and rear

springs are not in the groove of the same key.

NOTEA synchronizer spring different from the one shown in

the figure may be used but the explanation is the same.