torque specification MITSUBISHI ECLIPSE 1991 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 459 of 1216

FUEL SYSTEM - SDecifications14-5

-.

Items

Injector coil resistance52

Specifications

13-I 6 [at 20°C (68”F)j

2-3 [at 20°C (68”F)I

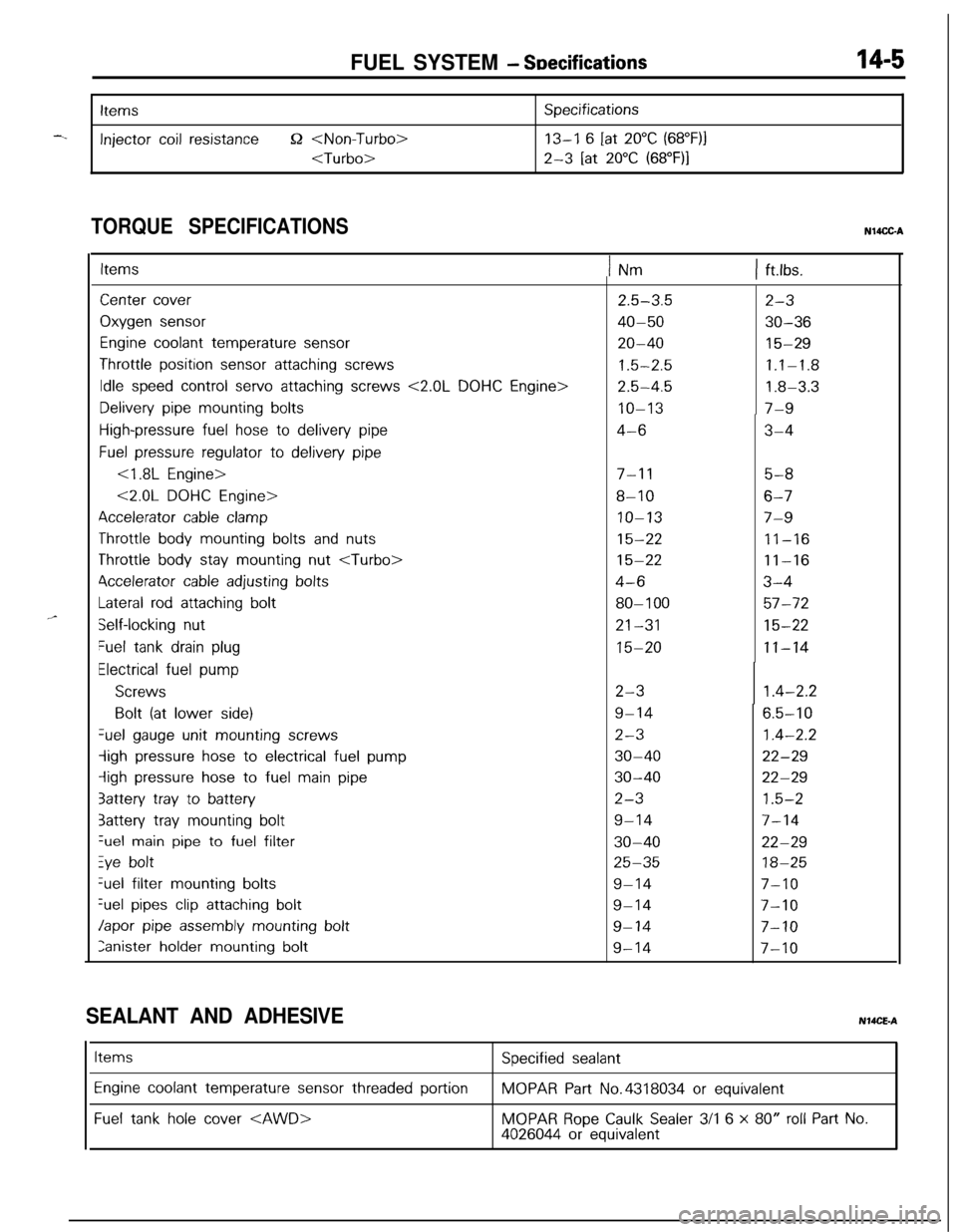

TORQUE SPECIFICATIONSN14CC-A

,,-

ItemsINm1 ft.lbs.

Center cover

Oxygen sensor

Engine coolant temperature sensor

Throttle position sensor attaching screws

Idle speed control servo attaching screws <2.0L DOHC Engine>

Delivery pipe mounting bolts

High-pressure fuel hose to delivery pipe

Fuel pressure regulator to delivery pipe

<1.8L Engine>

<2.0L DOHC Engine>

Accelerator cable clamp

Throttle body mounting bolts and nuts

Throttle body stay mounting nut

4ccelerator cable adjusting bolts

Lateral rod attaching bolt

Self-locking nut

Fuel tank drain plug

Electrical fuel pump

Screws

Bolt (at lower side)Gel

gauge unit mounting screws

-ligh pressure hose to electrical fuel pump

iigh pressure hose to fuel main pipe

3attery tray to battery

3attery tray mounting boltGel

main pipe to fuel filter

Zye boltGel filter

mounting bolts

%el pipes clip attaching bolt

Japor pipe assembly mounting bolt

Ianister holder mounting bolt

2.5-3.5

40-50

20-40

1.5-2.5

2.5-4.5

IO-13

4-6

7-l 15-8

8-106-7

IO-137-9

15-2211-16

15-2211-16

4-63-4

80-l 0057-72

21-3115-22

15-2011-14

2-3

9-14

2-3

30-40

30-40

2-3

9-14

30-40

25-35

9-14

9-14

9-14

9-14

2-3

30-36

15-29

1.1-1.8

1.8-3.3

7-9

3-4

1.4-2.2

6.5-10

1.4-2.2

22-29

22-29

1.5-2

7-14

22-29

18-25

7-10

7-10

7-10

7-10

SEALANT AND ADHESIVENMCE-A

Items

Engine coolant temperature sensor threaded portion

Fuel tank hole cover

Specified sealant

MOPAR Part No.4318034 or equivalent

MOPAR Rope Caulk Sealer 3/l 6 x 80” roll Part No.4026044 or equivalent

Page 517 of 1216

FUEL SYSTEM - MPI Svstem Inspection <1.8L Engine>18-63

Throttle position sensor

Groundoutput

Sensorpower

SUPPlY(5V)

1 FUO507

6FU1244Motor

Dosition sensor connector

(motor ‘side, front view)

T

6FU1247Motor position sensor

connector(motor side, front view)

6FU1252

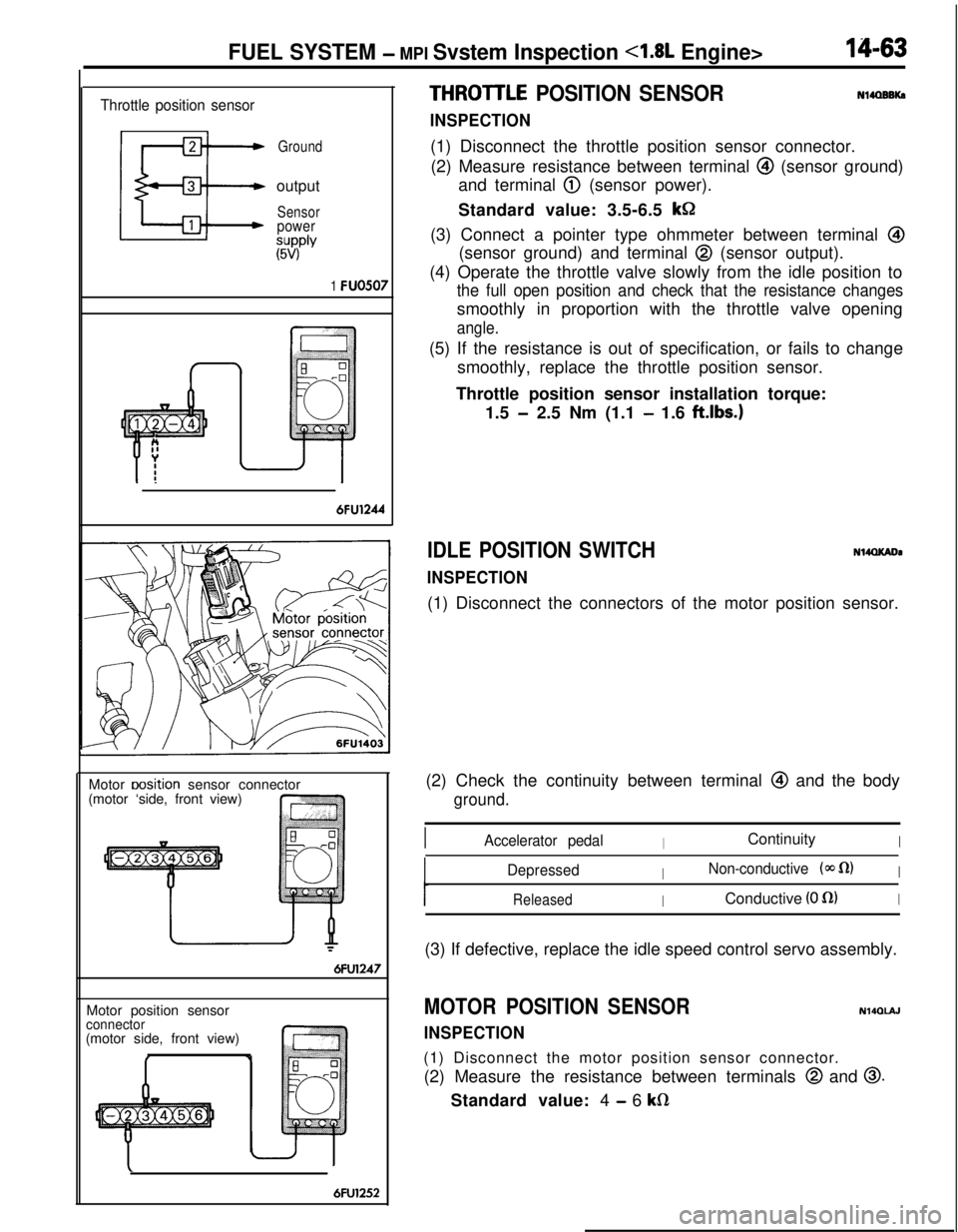

THROITLE POSITION SENSOR

INSPECTION

Nl4OBBKa(1) Disconnect the throttle position sensor connector.

(2) Measure resistance between terminal

@I (sensor ground)

and terminal

@ (sensor power).

Standard value: 3.5-6.5

kGI(3) Connect a pointer type ohmmeter between terminal

@(sensor ground) and terminal

@ (sensor output).

(4) Operate the throttle valve slowly from the idle position to

the full open position and check that the resistance changessmoothly in proportion with the throttle valve opening

angle.(5) If the resistance is out of specification, or fails to change

smoothly, replace the throttle position sensor.

Throttle position sensor installation torque:

1.5

- 2.5 Nm (1.1 - 1.6 ftlbs.)

IDLE POSITION SWITCH

INSPECTION

N14QKADa(1) Disconnect the connectors of the motor position sensor.

(2) Check the continuity between terminal

@ and the body

ground.

IAccelerator pedalIContinuityI

DepressedINon-conductive (@J fl)I

ReleasedIConductive (0 fl)I(3) If defective, replace the idle speed control servo assembly.

MOTOR POSITION SENSOR

INSPECTION

N140lAJ(1) Disconnect the motor position sensor connector.

(2) Measure the resistance between terminals

@ and 0.Standard value: 4

- 6 kfi

Page 531 of 1216

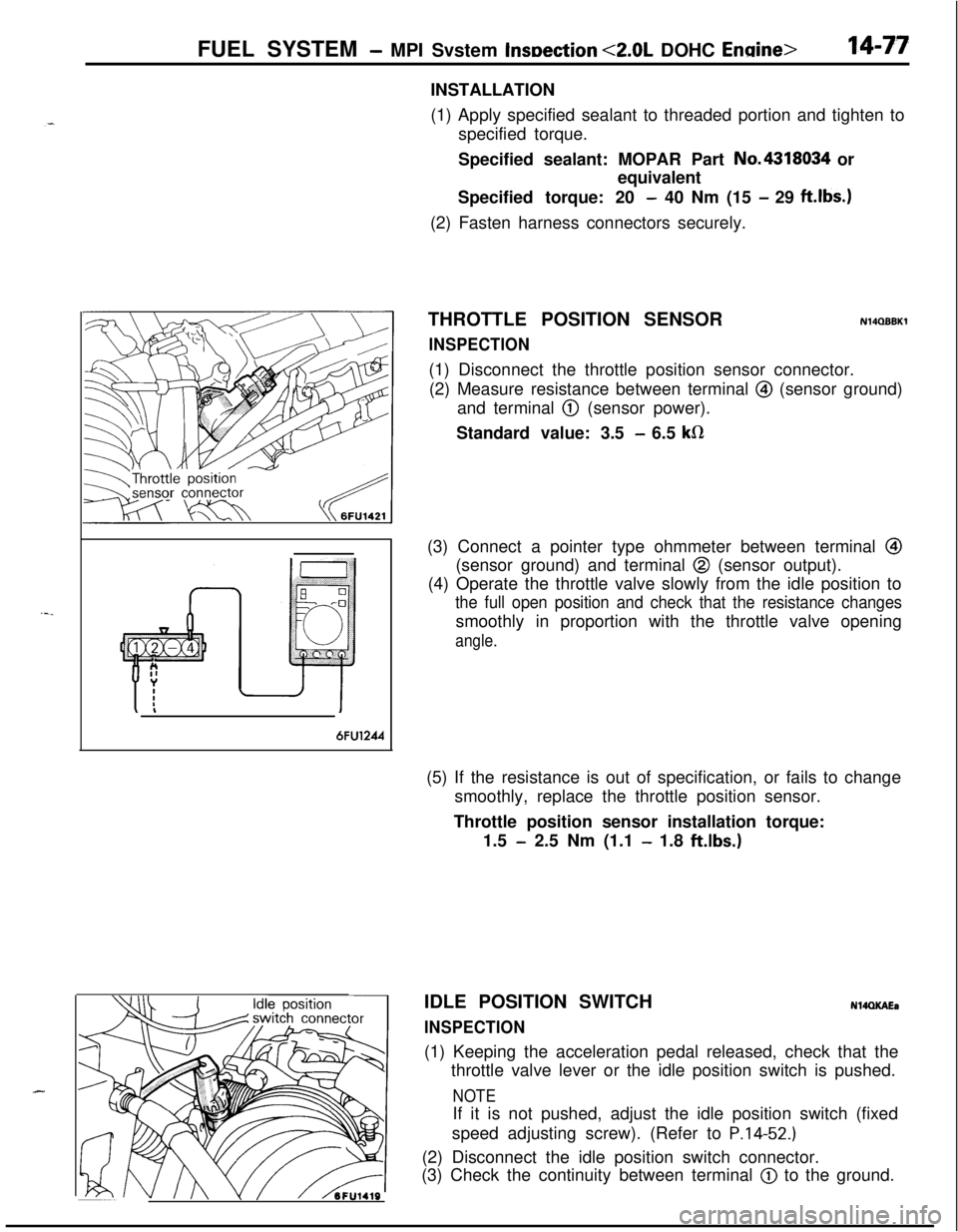

FUEL SYSTEM - MPI Svstem InsDection <2.0L DOHC Engine>14-77INSTALLATION

(1) Apply specified sealant to threaded portion and tighten to

specified torque.

Specified sealant: MOPAR Part No.4318034 or

equivalent

Specified torque: 20

- 40 Nm (15 - 29 ft.lbs.1(2) Fasten harness connectors securely.

THROTTLE POSITION SENSOR

INSPECTION

N14QBBKl(1) Disconnect the throttle position sensor connector.

(2) Measure resistance between terminal

@I (sensor ground)

and terminal

@ (sensor power).

Standard value: 3.5

- 6.5 kR(3) Connect a pointer type ohmmeter between terminal

@I(sensor ground) and terminal

@ (sensor output).

(4) Operate the throttle valve slowly from the idle position to

the full open position and check that the resistance changessmoothly in proportion with the throttle valve opening

angle.

6FU1244(5) If the resistance is out of specification, or fails to change

smoothly, replace the throttle position sensor.

Throttle position sensor installation torque:

1.5

- 2.5 Nm (1.1 - 1.8 ft.lbs.)

J II\/ hFU1419IDLE POSITION SWITCH

INSPECTION

N14QKAEa(1) Keeping the acceleration pedal released, check that the

throttle valve lever or the idle position switch is pushed.

NOTEIf it is not pushed, adjust the idle position switch (fixed

speed adjusting screw). (Refer to

P.14-52.)(2) Disconnect the idle position switch connector.

(3) Check the continuity between terminal

@) to the ground.

Page 559 of 1216

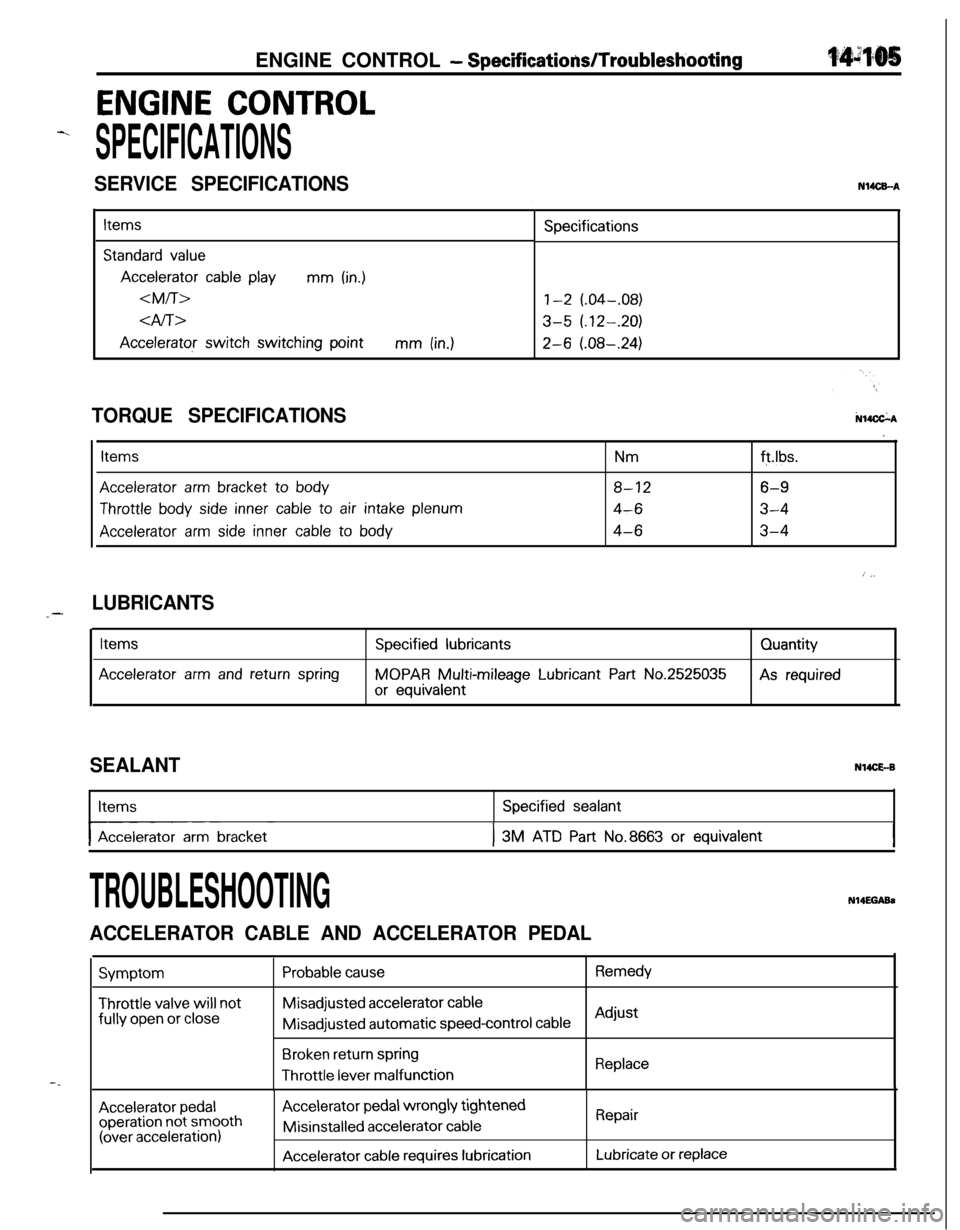

ENGINE CONTROL - SpecificatiodTroubleshooting

ENGINE CONTROL

-.

SPECIFICATIONS

SERVICE SPECIFICATIONSN14CEA

Items

Standard value

Accelerator cable playmm (in.)

dfi>

Accelerator switch switching pointmm (in.)Specifications

1-2 (.04-.08)

3-5 (.12-.20)

2-6 (.08-.24)

N14CkATORQUE SPECIFICATIONS

Items

Accelerator arm bracket to body

Throttle body side inner cable to air intake plenum

Accelerator arm side inner cable to body

Nmft.lbs.

8-126-9

4-63-4

4-63-4

I

: j,

LUBRICANTS_-

Items

Accelerator arm and return spring

Specified lubricants

MOPAR Multi-mileage Lubricant Part No.2525035

or equivalentQuantityAs required

SEALANTN14CE.-BItems

I-- ~Accelerator arm bracket

Specified sealant

I3M ATD Part No.8663 or equivalentI

-.

TROUBLESHOOTINGN14EGABa

ACCELERATOR CABLE AND ACCELERATOR PEDAL

Symptom

Throttle valve will notfully

open or close

Probable causeRemedyMisadjusted

accelerator cableMisadjusted automatic

speed-control cableAdjust

Broken return springThrottle

lever malfunctionReplace

Accelerator pedaloperation not smooth(over acceleration)

Accelerator pedal wrongly tightenedMisinstalled

accelerator cable

Accelerator cable requires lubrication

Repair

Lubricate or replace

Page 563 of 1216

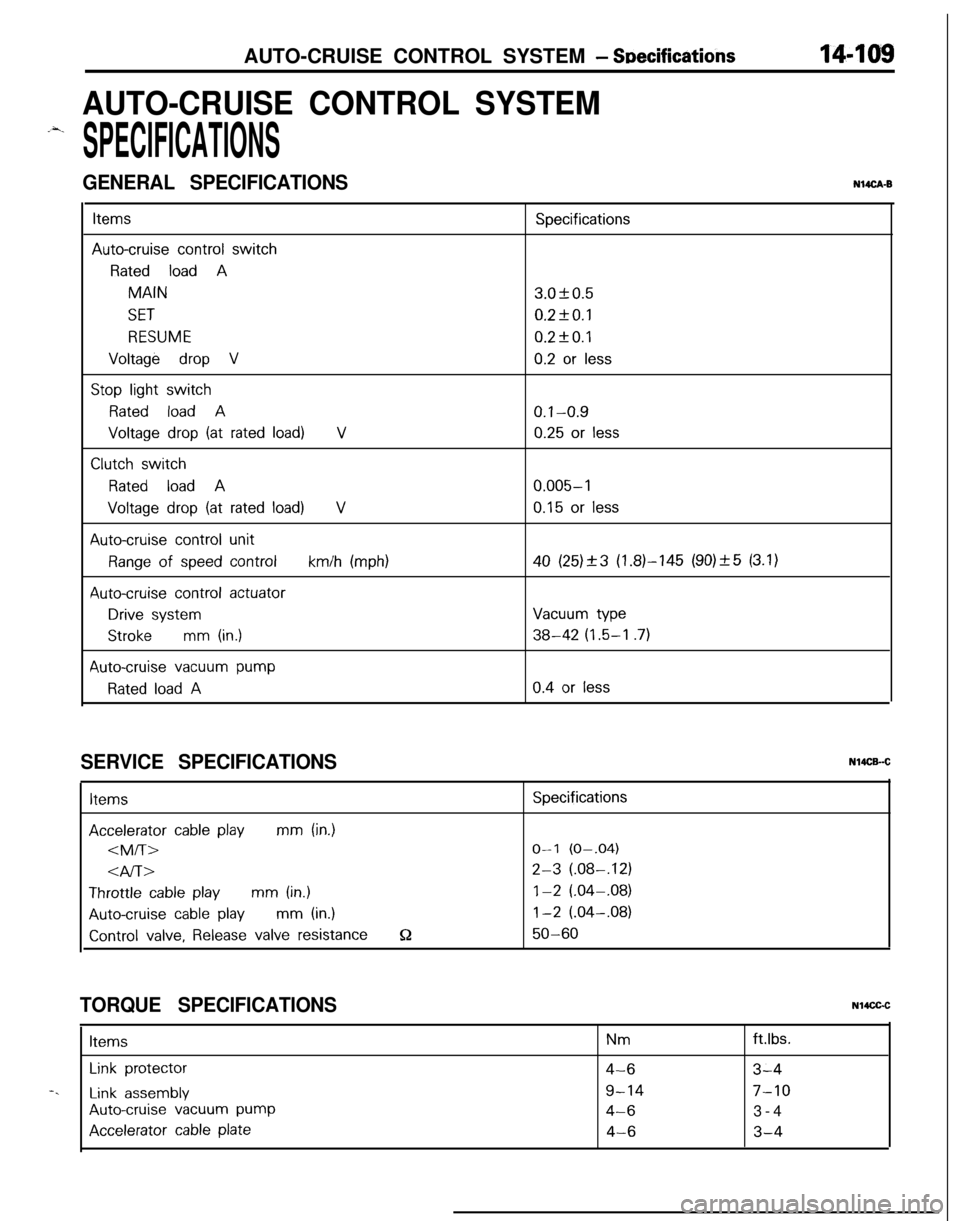

AUTO-CRUISE CONTROL SYSTEM - Snecifications14-109

AUTO-CRUISE CONTROL SYSTEM

.-4.

SPECIFICATIONS

GENERAL SPECIFICATIONSNUCA-B

ItemsSpecifications

Auto-cruise control switch

Rated load AMAIN3.OkO.5

SET0.2fO.l

RESUME0.2kO.l

Voltage drop V0.2 or less

Stop light switch

Rated load A0.1-0.9

Voltage drop (at rated load)V0.25 or less

Clutch switch

Rated load A0.005-l

Voltage drop (at rated load)V0.15 or less

Auto-cruise control unit

Range of speed controlkm/h (mph)40 (25)_+3 (1.81-145 (90)_+5 (3.1)

Auto-cruise control actuator

Drive systemVacuum type

Strokemm (in.)38-42 (1.5-I .7)

Auto-cruise vacuum pump

Rated load A0.4 or less

SERVICE SPECIFICATIONSItems

Accelerator cable playmm (in.)

4l-bThrottle

cable playmm (in.)

Auto-cruise cable playmm (in.)

Control valve, Release valve resistanceQ

Specifications

O-l (O-.04)

2-3 (.08-,121

1-2 (.04-.08)

1-2 (.04-.08)

50-60

TORQUE SPECIFICATIONSN14CGCItems

Nmftlbs.

Link protector4-63-4-.

Link assembly9-147-10

Auto-cruise vacuum pump4-63-4

Accelerator cable plate4-63-4

Page 597 of 1216

, d-a:-;._‘PROPELLER

=. ’SHAFT

CONTENTSNlBAA-

PROPELLER SHAFT........................................4Lubricants......................................................3

2

SPECIAL TOOLS3ServiceSpecifications.................................................................................

TorqueSpecifications...................................2

SPECIFICATIONS.............................................2

TROUBLESHOOTING......................................3

General

Specifications..................................21

Page 598 of 1216

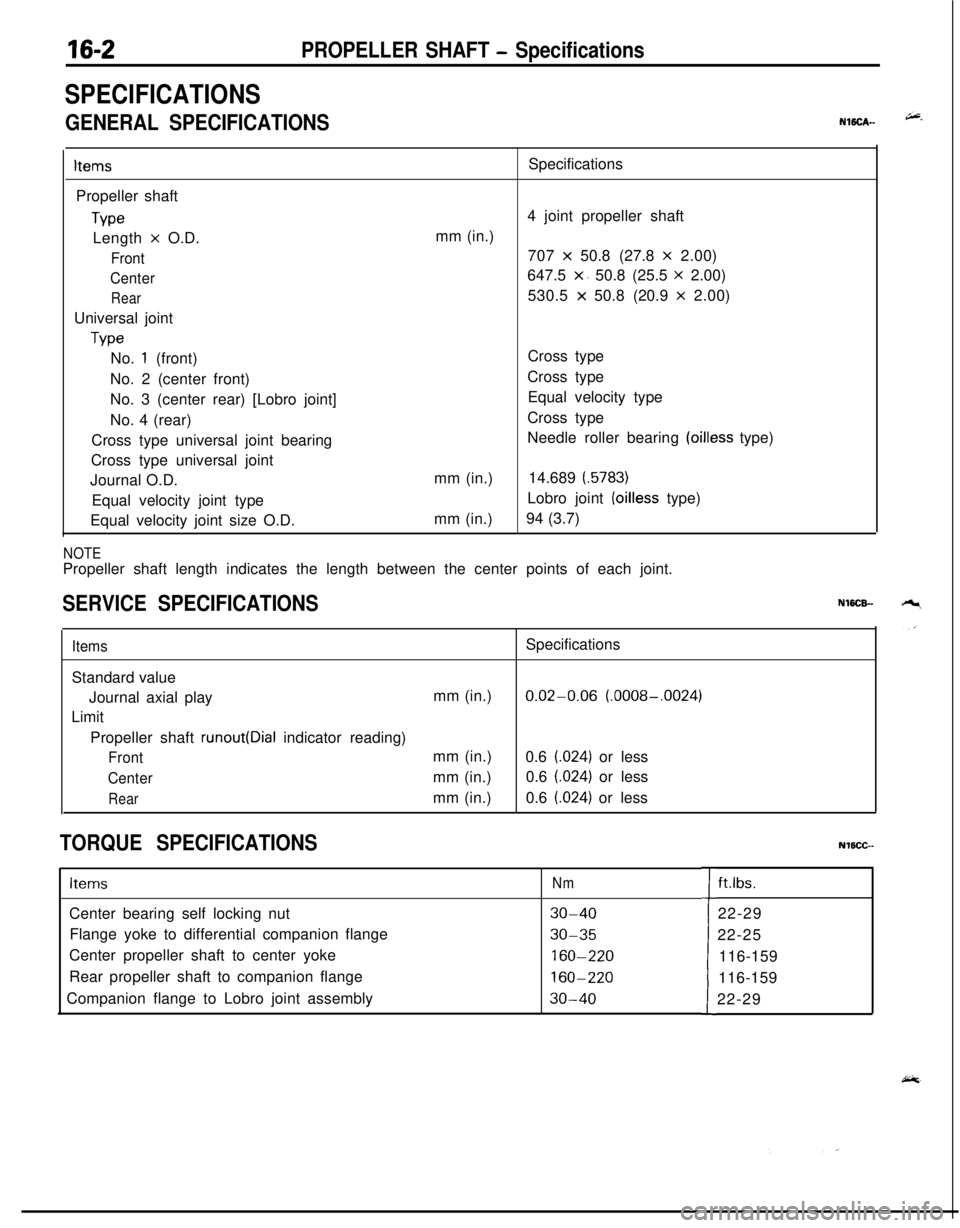

16-2PROPELLER SHAFT - Specifications

SPECIFICATIONS

GENERAL SPECIFICATIONSNWCA--

ItemsPropeller shaft

TypeLength

x O.D.

Front

Center

RearUniversal joint

TypeSpecifications

4 joint propeller shaft

mm (in.)

707

x 50.8 (27.8 x 2.00)

647.5

x. 50.8 (25.5 x 2.00)

530.5

x 50.8 (20.9 x 2.00)

No.

1 (front)

No. 2 (center front)

No. 3 (center rear) [Lobro joint]

No. 4 (rear)

Cross type universal joint bearing

Cross type universal joint

Journal O.D.

Equal velocity joint type

Equal velocity joint size O.D.mm (in.)

mm (in.)Cross type

Cross type

Equal velocity type

Cross type

Needle roller bearing

(oilless type)

14.689

(.5783)Lobro joint

(oilless type)

94 (3.7)

NOTEPropeller shaft length indicates the length between the center points of each joint.

SERVICE SPECIFICATIONSNWCB-

ItemsSpecifications

Standard value

Journal axial playmm (in.)

0.02-0.06 (.0008-.0024)

Limit

Propeller shaft

runout(Dial indicator reading)

Frontmm (in.)

0.6 (.024) or less

Centermm (in.)0.6 (.024) or less

Rearmm (in.)0.6 (.024) or less

TORQUE SPECIFICATIONSNlBCC--

ItemsNmCenter bearing self locking nut

30-40Flange yoke to differential companion flange

30-35Center propeller shaft to center yoke

160-220Rear propeller shaft to companion flange

160-220Companion flange to Lobro joint assembly

30-40tft.lbs.

22-29

22-25

116-159

116-159

22-29

Page 611 of 1216

1 pq

,s I’

:

REAR

SUSPENSION

LATERAL ROD.................................................11

REAR AXLE HUB............................................14

REARSUSPENSIONASSEMBLY..................5

SERVICE ADJUSTMENT PROCEDURES.......3Rear Hub Rotary-Sliding Resistance

(Torque)Adjustment.....................................4Rear Wheel Alignment Inspection

...............3Wheel Bearing End Play Adjustment

..........3

SHOCKABSORBERASSEMBLY...................8

SPECIAL TOOL................................................3

SPECIFICATIONS.............................................2

GeneralSpecifications..................................2

ServiceSpecifications...................................2Torque Specifications

...................................2

TORSION AXLE AND ARM ASSEMBLY......12

TROUBLESHOOTING......................................3

REARSUSPENSIONASSEMBLY . . . . . . . . . . . . . . . . . .21

SHOCK ABSORBER ASSEMBLY...................32

SERVICE ADJUSTMENT PROCEDURES.......20Rear WheelAlignment

Inspection................20

SPECIAL TOOLS.............................................18

SPECIFICATIONS.............................................16

GeneralSpecifications..................................16

ServiceSpecifications...................................16LTorqueSpecifications...................................17

Lubricant.......................................................17

STABILIZER BAR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

TRAILING ARM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

TROUBLESHOOTING......................................19

UPPER AND LOWER ARM............................25

CONTENTSN17AA-

Page 612 of 1216

17-2REAR SUSPENSION

GENERAL SPECIFICATIONS

LN17CAA

ItemsVehicles with 1.8L EngineVehicles with 2.0L DOHC

Engine

jSuspension system

3-link, torsion axle with coil spring type

Coil spring

Wire dia.

x O.D. x free length

mm (in.) 10.1 x 105.1 x 336.510.2 x 105.2 x 316.5

(40 x 4.14 x 13.25)(40 x 4.14 x 12.46)

[Coil spring identification color]

[Light Blue

x 11[Orange x 11Spring constant

N/mm

(Ibs./in.) 20 (112.0)23 (128.8)

Shock absorber

TypeHydraulic, cylindrical, double-acting type

Max. length

mm (in.) 495 (19.5)485 (19.1)

Min. length

mm (in.) 315 (12.4)315 (12.4)

Strokemm (in.) 180 (7.1)170 (6.7)Damping force [at 0.3 m/set. (0.9

ft./set.)]

ExpansionN (Ibs.)800 (176)

ContractionN (Ibs.)300 (66)

Wheel bearing

TypeUnit ball bearing

SERVICE SPECIFICATIONS

Items

Standard valueToe-in (Left-right difference)

Camber

LimitWheel bearing end play

Rear hub rotary-sliding resistance

Rear hub rotary-sliding torque

NOTEToe-in and camber cannot be adjusted.mm (in.)

mm (in.)

N (Ibs.)

Nm

(ftlbs.)

TORQUE SPECIFICATIONS

Specifications

0+3 (Of.1 18)

-45’

f 30’

0.01 (004) or less

31

(7) or less

1.8

(1.30) or lessNI’ICB-A

ItemsNmft.lbs.

Wheel bearing nut

Shock absorber upper mounting nut

Shock absorber lower mounting nut

Lateral rod mounting nut (body side)

Lateral rod mounting bolt (axle beam side)

Trailing arm mounting bolt

Piston rod tightening nut

Brake hose and tube bracket mounting bolt

Caliper assembly mounting nut

Rear speed sensor mounting bolt

200-260

40-50

80- 100

80-100

100-120

100-120

20-2517-26

50-609-14144-188

29-36

58-72

58-72

72-87

72-87

14-18

12-19

36-43

I7-10

Nl7CGA

Page 627 of 1216

REAR SUSPENSION

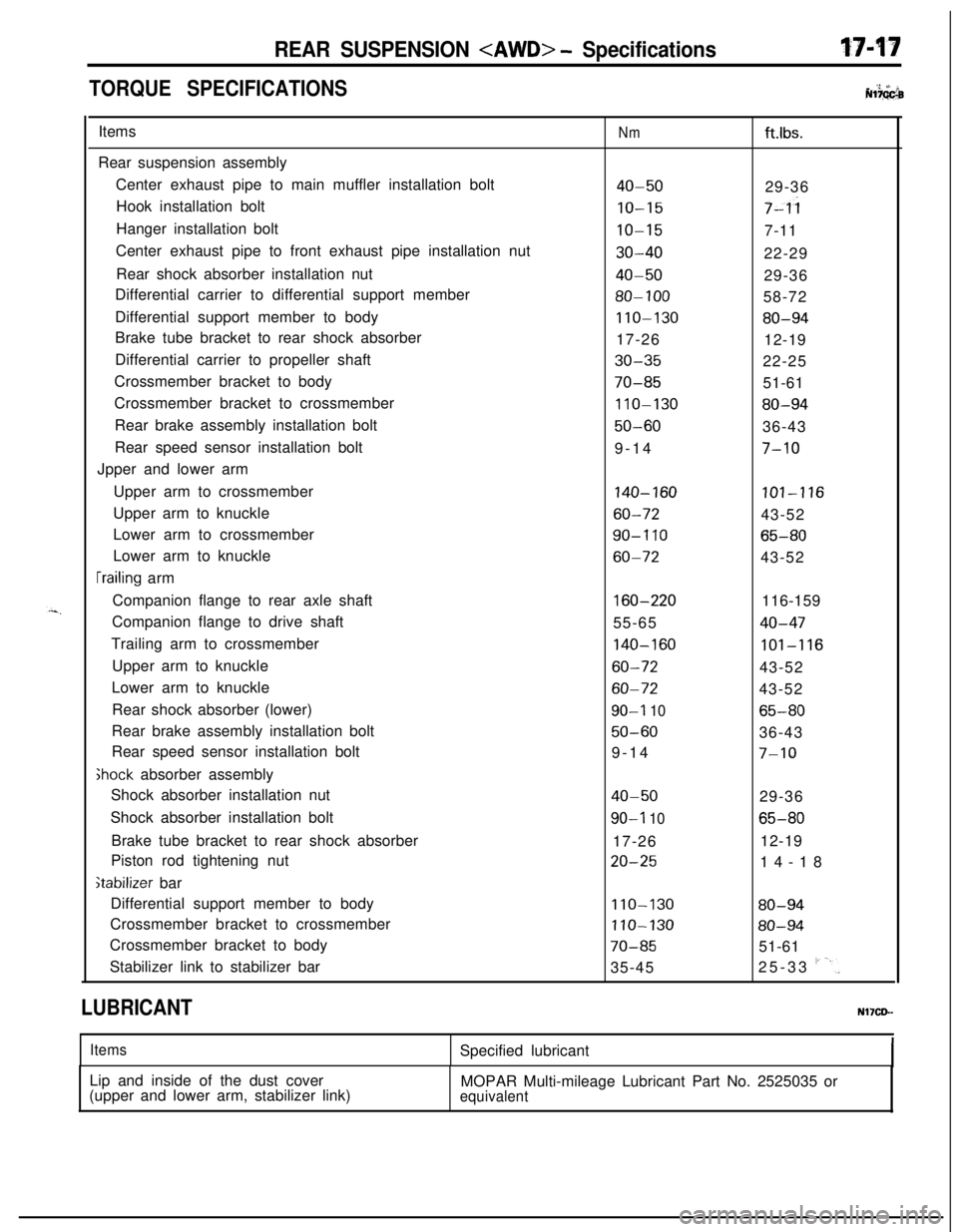

TORQUE SPECIFICATIONS. ‘2 +’ iiNl?GGbItems

Rear suspension assembly

Center exhaust pipe to main muffler installation bolt

Hook installation bolt

Hanger installation bolt

Center exhaust pipe to front exhaust pipe installation nut

Rear shock absorber installation nut

Differential carrier to differential support member

Differential support member to body

Brake tube bracket to rear shock absorber

Differential carrier to propeller shaft

Crossmember bracket to body

Crossmember bracket to crossmember

Rear brake assembly installation bolt

Rear speed sensor installation bolt

Jpper and lower arm

Upper arm to crossmember

Upper arm to knuckle

Lower arm to crossmember

Lower arm to knuckle

[railing arm

Companion flange to rear axle shaft

Companion flange to drive shaft

Trailing arm to crossmember

Upper arm to knuckle

Lower arm to knuckle

Rear shock absorber (lower)

Rear brake assembly installation bolt

Rear speed sensor installation bolt

Ghock absorber assembly

Shock absorber installation nut

Shock absorber installation bolt

Brake tube bracket to rear shock absorber

Piston rod tightening nut

stabilizer bar

Differential support member to body

Crossmember bracket to crossmember

Crossmember bracket to body

Stabilizer link to stabilizer bar

Nmft.lbs.

40-5029-36

IO-157-ii

IO-157-11

30-4022-29

40-5029-36

80-10058-72

110-13080-9417-26

12-19

30-3522-25

70-8551-61

110-13080-94

50-6036-43

9-14

7-10

140-160101-116

60-7243-52

90-I 1065-80

60-7243-52

160-220116-159

55-65

40-47

140-160101-116

60-7243-52

60-7243-52

90-I 1065-80

50-6036-43

9-14

7-10

40-5029-36

90-l 1065-8017-2612-19

20-2514-18

110-13080-94

110-13080-94

70-8551-61

35-4525-33

I'-'.

LUBRICANTNl’ICD-

ItemsSpecified lubricant

Lip and inside of the dust cover

(upper and lower arm, stabilizer link)MOPAR Multi-mileage Lubricant Part No. 2525035 or

equivalent