window MITSUBISHI ECLIPSE 1991 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 1113 of 1216

BODY - Power Window/Door Handle and Latch23-69

I-

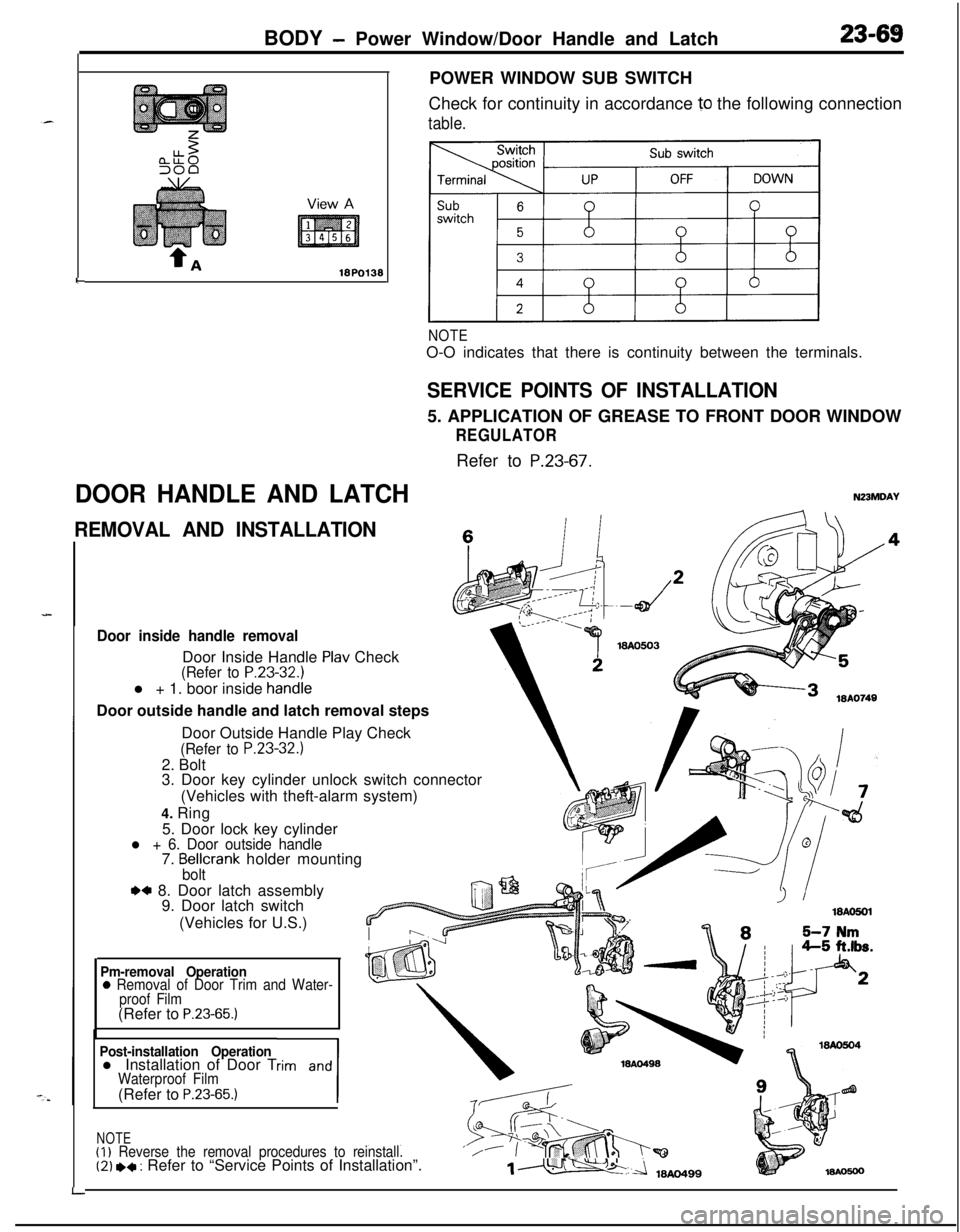

DOOR HANDLE AND LATCHPOWER WINDOW SUB SWITCH

Check for continuity in accordance

10 the following connection

table.

NOTEO-O indicates that there is continuity between the terminals.

SERVICE POINTS OF INSTALLATION5. APPLICATION OF GREASE TO FRONT DOOR WINDOW

REGULATORRefer to

P.23-67.

N23MDAY

REMOVAL AND INSTALLATIONc

Door inside handle removalDoor Inside Handle

Plav Check(Refer to P.23-32.1l + 1. boor inside

handieDoor outside handle and latch removal steps

LDoor Outside Handle Play Check

(Refer to P.23-32.)2. Bolt

3. Door key cylinder unlock switch connector

(Vehicles with theft-alarm system)

4. Ring

5. Door lock key cylinder

l + 6. Door outside handle7. Bellcrank holder mountingbolt

.a 8. Door latch assembly

9. Door latch switch

(Vehicles for U.S.)

Pm-removal Operation0 Removal of Door Trim and Water-

proof Film(Refer to

P.23-65.)

Post-installation Operationl Installation of Door Trim and

1

Waterproof Film(Refer to P.23-65.)

NOTE(I)

Reverse the removal procedures to reinstall.‘/(2) *+ : Refer to “Service Points of Installation”.1m

Page 1115 of 1216

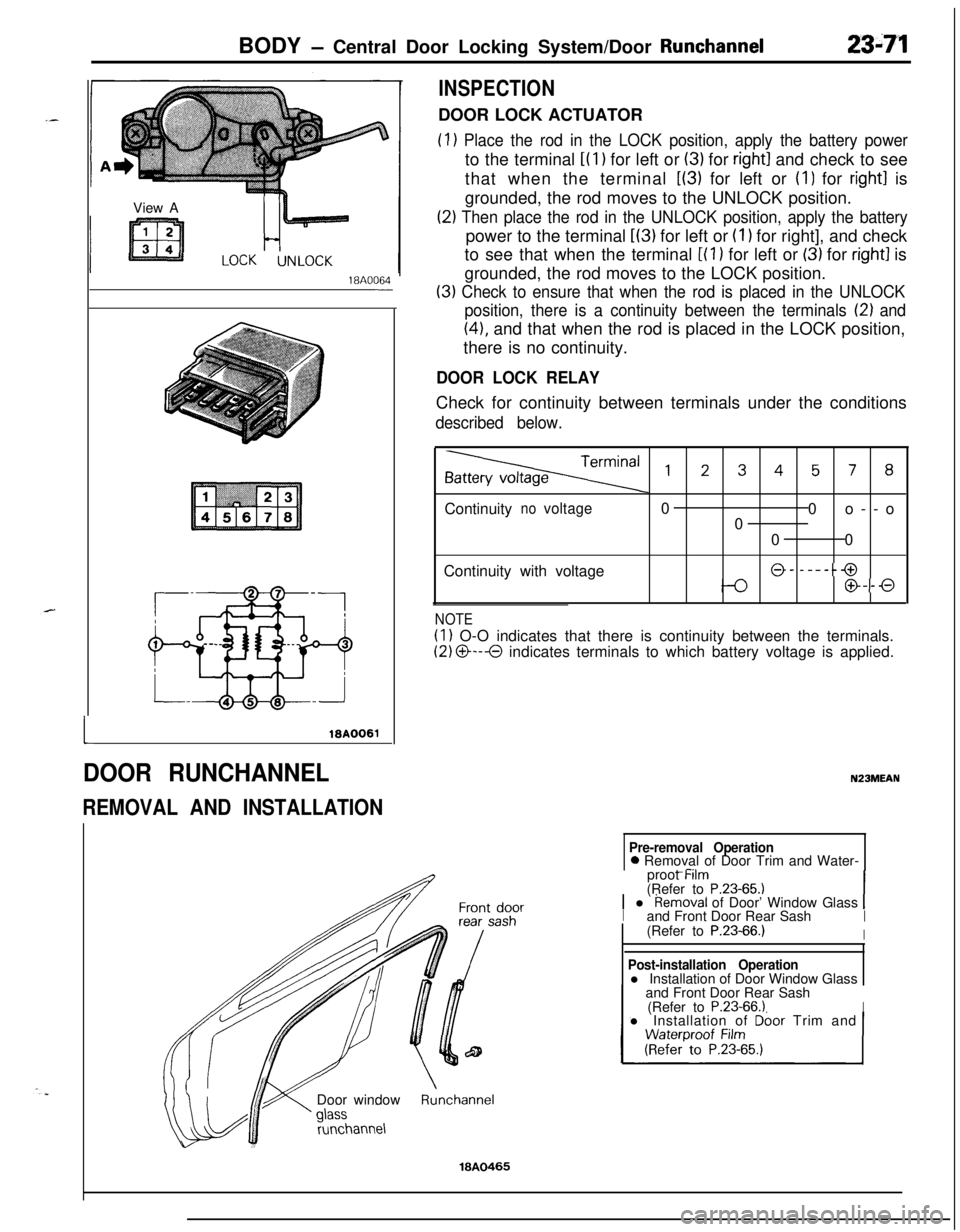

BODY - Central Door Locking System/Door Runchannel23-71View A

18A0064-

L

DOOR RUNCHANNEL

REMOVAL AND INSTALLATION

INSPECTIONDOOR LOCK ACTUATOR

(1) Place the rod in the LOCK position, apply the battery powerto the terminal

i(l) for left or (3) for right1 and check to see

that when the terminal

L(3) for left or (I) for right1 is

grounded, the rod moves to the UNLOCK position.

(2) Then place the rod in the UNLOCK position, apply the batterypower to the terminal

L(3) for left or (I 1 for right], and check

to see that when the terminal

[(l ) for left or (3) for right1 is

grounded, the rod moves to the LOCK position.

(3) Check to ensure that when the rod is placed in the UNLOCK

position, there is a continuity between the terminals

12) and

(41, and that when the rod is placed in the LOCK position,

there is no continuity.

DOOR LOCK RELAYCheck for continuity between terminals under the conditions

described below.

,2345, 8Continuity

novoltage0

0o--o

0

00

Continuity with voltage

@- -----@

@--0

NOTE

(1) O-O indicates that there is continuity between the terminals.

(2) O---O indicates terminals to which battery voltage is applied.

N23MEAN

Pre-removal Operation0 Removal of Door Trim and Water-

_ -..proot Mm

(Refer to

P.23-65.11 l Removal of Door’ Window Glass 1Iand Front Door Rear SashI(Refer to P.23-66.)IDoor window

runchannel

Post-installation Operationl Installation of Door Window Glass

and Front Door Rear Sash

(Refer to

P.23-66.1Il Installation of Dbor Trim and

Runchannel

18A0465

Page 1126 of 1216

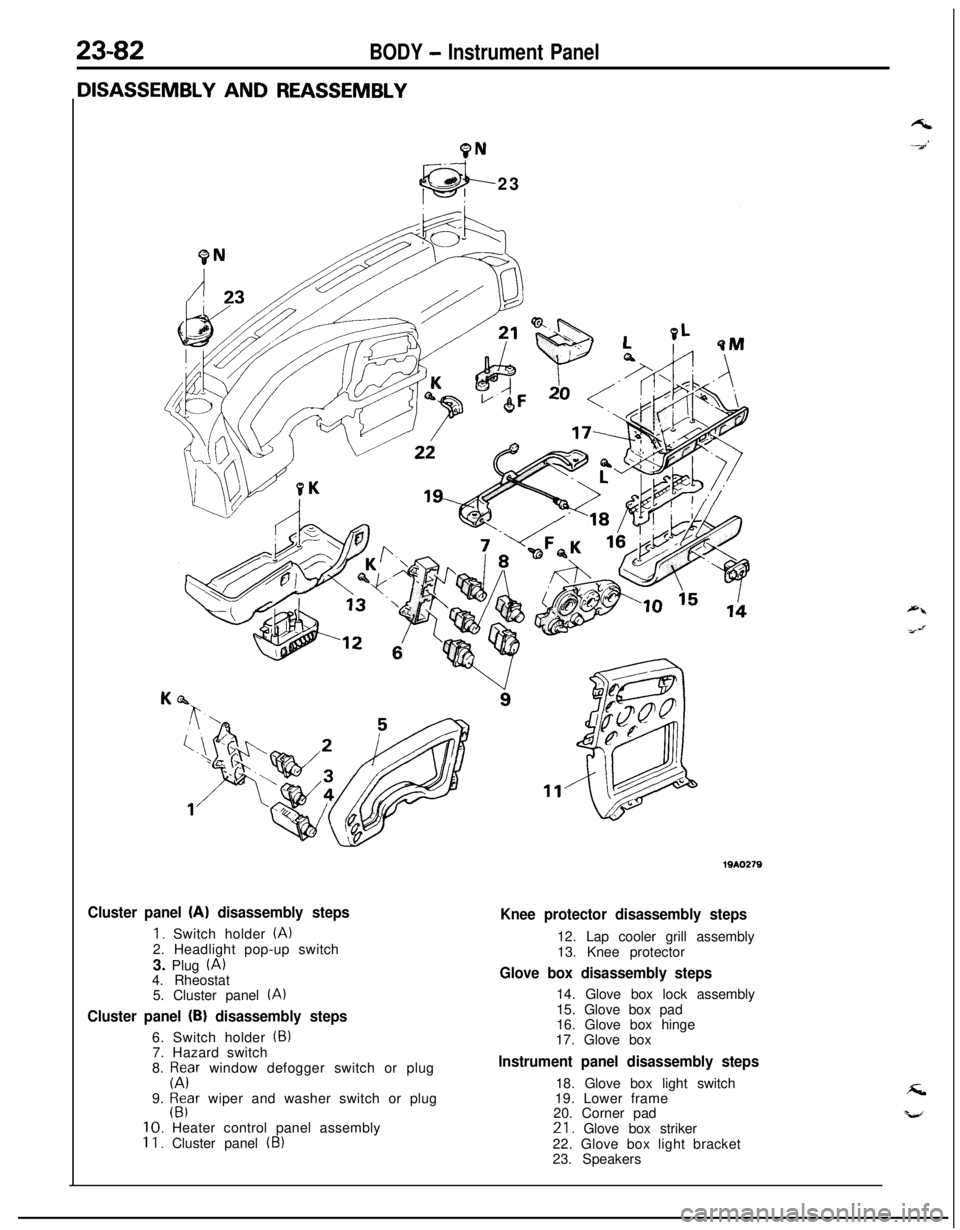

23-82BODY - Instrument Panel

9N23

Cluster panel (A) disassembly steps

1. Switch holder (A)2. Headlight pop-up switch

3. Plug

(A)4. Rheostat

5. Cluster panel

(A)

Cluster panel (B) disassembly steps6. Switch holder

(5)7. Hazard switch

8.

p;Fr window defogger switch or plug

9.

$far wiper and washer switch or plug10. Heater control panel assembly

II. Cluster panel (B)

Knee protector disassembly steps12. Lap cooler grill assembly

13. Knee protector

Glove box disassembly steps14. Glove box lock assembly

15. Glove box pad

16. Glove box hinge

17. Glove box

Instrument panel disassembly steps18. Glove box light switch

19. Lower frame

20. Corner pad21. Glove box striker

22. Glove box light bracket

23. Speakers

Page 1160 of 1216

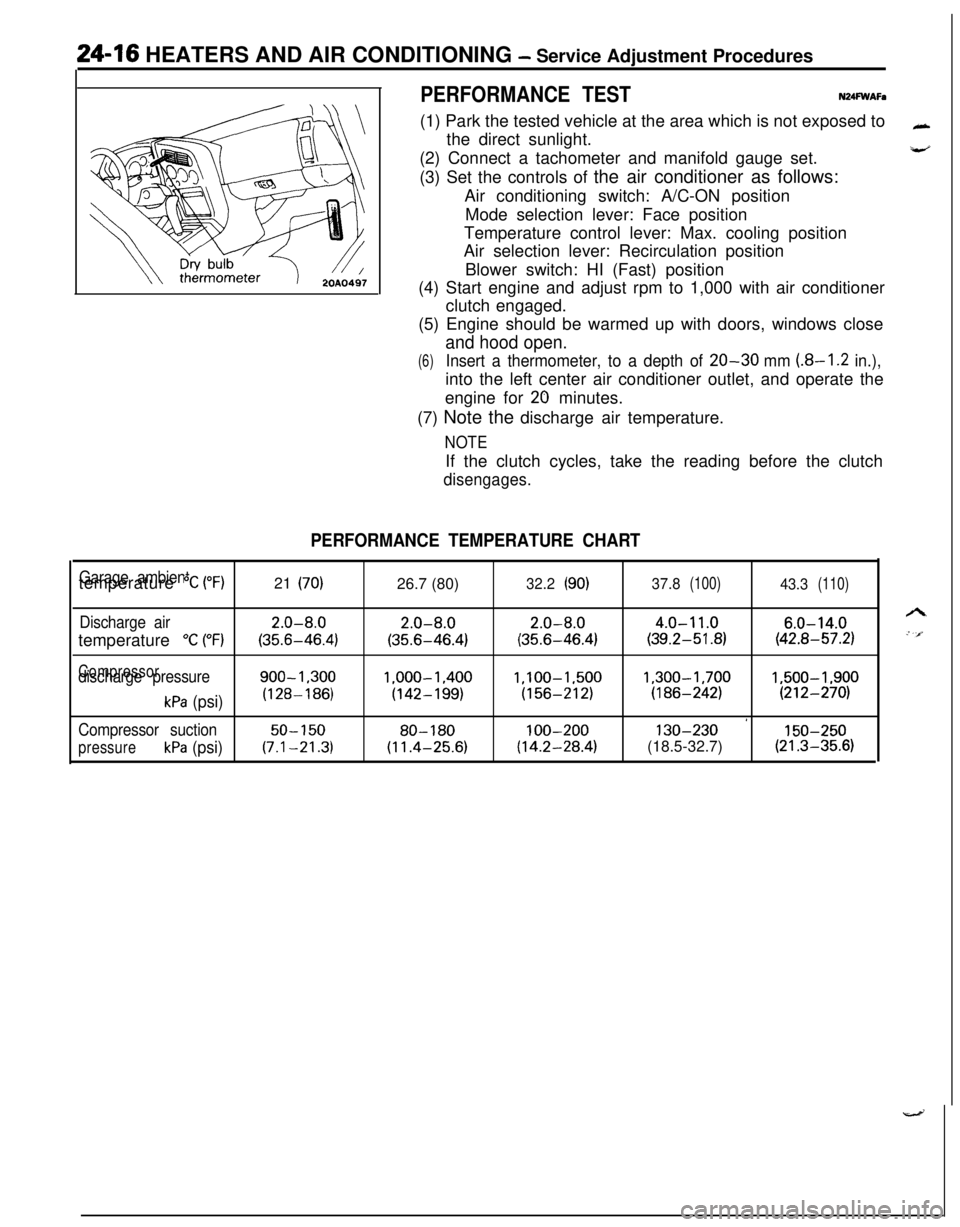

24-16 HEATERS AND AIR CONDITIONING - Service Adjustment Procedures

PERFORMANCE TESTN24FWAFa(1) Park the tested vehicle at the area which is not exposed to

the direct sunlight.

(2) Connect a tachometer and manifold gauge set.

(3) Set the controls of the air conditioner as follows:

Air conditioning switch: A/C-ON position

Mode selection lever: Face position

Temperature control lever: Max. cooling position

Air selection lever: Recirculation position

Blower switch: HI (Fast) position

(4) Start engine and adjust rpm to 1,000 with air conditioner

clutch engaged.

(5) Engine should be warmed up with doors, windows close

and hood open.

(6)Insert a thermometer, to a depth of 20-30 mm (8-I .2 in.),into the left center air conditioner outlet, and operate the

engine for

20 minutes.

(7) Note the discharge air temperature.

NOTEIf the clutch cycles, take the reading before the clutch

disengages.

PERFORMANCE TEMPERATURE CHART

Garage ambienttemperature “C (“F)21 (70)26.7 (80)32.2(90)37.8(100)43.3(110)

Discharge air2.0-8.02.0-8.02.0-8.04.0-11.06.0-14.0temperature

“C (“F)(35.6-46.4)(35.6-46.4)(35.6-46.4)(39.2-51.8)(42.8-57.2)

Compressordischarge pressure900-1.3001.000-1.400l,lOO-1,5001,300-1,7001,500-1,900

kPa (psi)(128-186)(142-199)(156-212)(186-242)(212-270)

’Compressor suction50-15080-180100-200130-230150-250

pressurekPa (psi)(7.1-21.3)(11.4-25.6)(14.2-28.4)(18.5-32.7)(21.3-35.6)

Page 1162 of 1216

24-18 HEATERS AND AIR CONDITIONING - Service Adjustment Procedures

(5) Screw a can of R-12 to the opened manifold valve. Be sure

gasket is in place and in good condition. Tighten refrigerantcan and manifold locking nut to insure a good seal. Do not

overtighten 8 to

11 Nm (6 to 8 ft.lbs.) is sufficient if gasket

is in good condition.

(6) Turn manifold valve (above the refrigerant can) completely

clockwise to puncture the can. This closes the valve and

seals the refrigerant in the can.

Caution

Never heat small cans of refrigerant over

40°C (104°F)as they may explode.

(7) Place the refrigerant in a large pan of water heated to 52°C

(104°F). Place pan of water containing the refrigerant can

on an accurate scale so the amount of refrigerant added

can be weighed. Open the refrigerant manifold valve.

(8) Purge all air from test hoses. Air in the system will be

trapped in the condenser causing abnormally high dis-

charge pressures and interfering with condensing of the

refrigerant.(9) Slightly loosen both test hoses at the gauge set manifold.

Tighten the hoses as soon as the air is purged.

(10)Slightly loosen charging hose connection at gauge set

manifold. This will purge air from the charging hose.

Tighten connection as soon as air is purged.

(I l)With vehicle windows open and hood up, operate engine at1,500 rpm and jump the low pressure switch terminals

located on the receiver drier so the clutch will remain

engaged.

(12)Place air conditioner control on air conditioner and place theblower switch on high.

(13)lf necessary, block the condenser to maintain a discharge

pressure of 1,422 to 1,520

kPa (206 to 220 psi). System

must be charged through the evaporator suction service

ports as follows:

(a) Slowly open the suction service gauge valve.

Meter flow of refrigerant by adjusting, the suciton

service gauge valve so that pressure registered at the

suction service gauge does not exceed 345 kPa (50 psi).Keep refrigerant container upright.

(b) Add refrigerant gas until there is no foam visible at the

sight glass.

Add an additional

170 g (6 oz.)

(c) Close the suction gauge valve.

CautionToo much refrigerant in the system can cause

abnormally high discharge pressures. Care must beused so that the exact recommended amount or

refrigerant is added after foam clears in the sight

glass.(d) Close dispensing manifold valve. Remove test hoses

and adapters from the service ports of compressor,

install protective caps at service ports and reconnect

wiring.(e) Check system performance.

(P.24- 16.)

e

. i”

A

i-4