Oxy MITSUBISHI ECLIPSE 1991 Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 528 of 1216

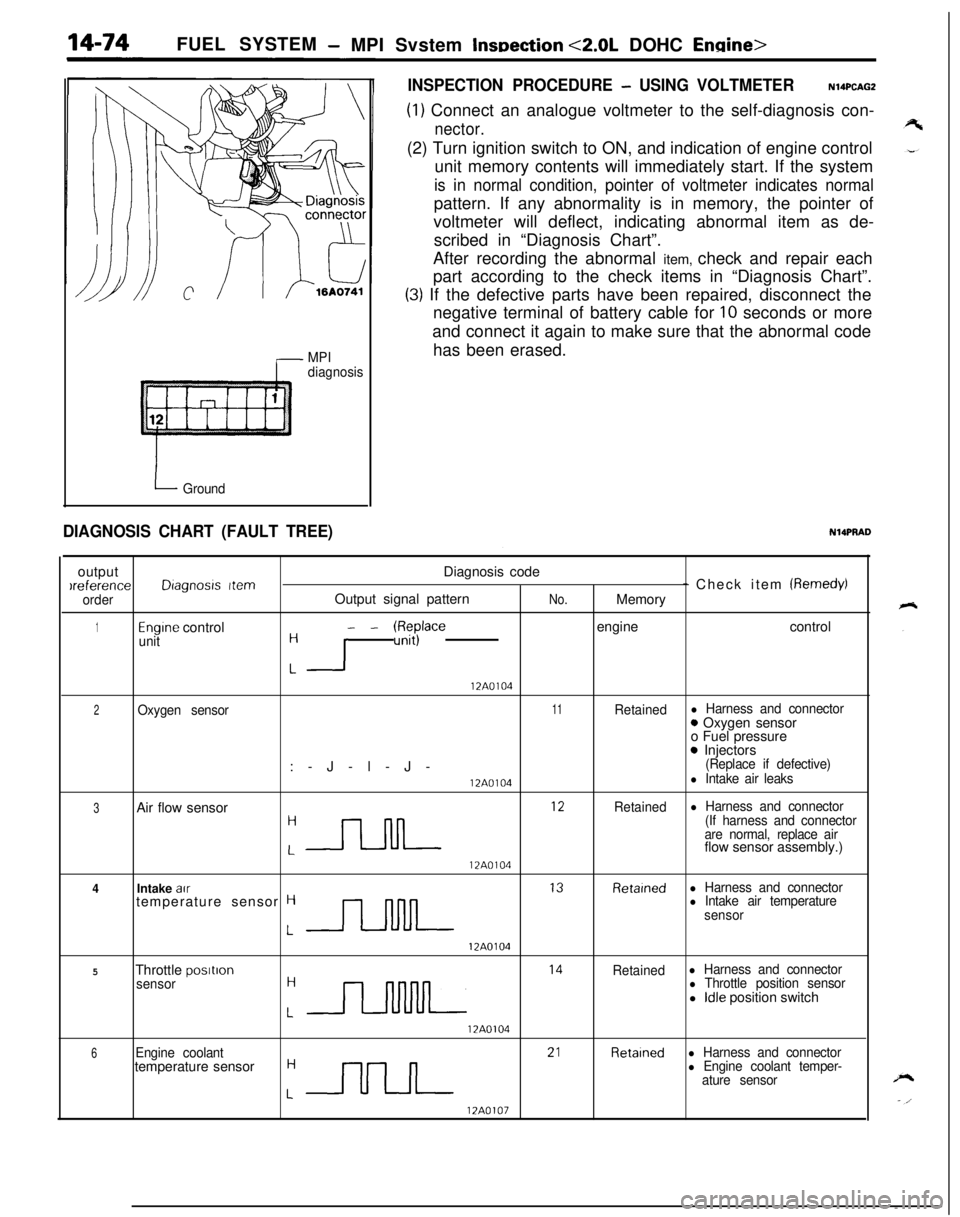

FUEL SYSTEM- MPI Svstem InsDection <2.0L DOHC Engine>

MPI

diagnosis

I Ground

INSPECTION PROCEDURE - USING VOLTMETERN14PCAGZ

(1) Connect an analogue voltmeter to the self-diagnosis con-

nector.(2) Turn ignition switch to ON, and indication of engine control

unit memory contents will immediately start. If the system

is in normal condition, pointer of voltmeter indicates normalpattern. If any abnormality is in memory, the pointer of

voltmeter will deflect, indicating abnormal item as de-

scribed in “Diagnosis Chart”.

After recording the abnormal item, check and repair each

part according to the check items in “Diagnosis Chart”.

(3) If the defective parts have been repaired, disconnect the

negative terminal of battery cable for

10 seconds or more

and connect it again to make sure that the abnormal code

has been erased.

DIAGNOSIS CHART (FAULT TREE)NlQPRADoutputDiagnosis codeIreference

Dragnosrs Item- Check item (Remedy)

orderOutput signal patternNo.Memory

1Engine controlunit- - W$$ace engine control: I

12A0104

2Oxygen sensor11Retainedl Harness and connector:-J-l-J-0 Oxygen sensor

o Fuel pressure

0 Injectors(Replace if defective)

12A0104l Intake air leaks

3Air flow sensor

:-rLJL ‘*

Retainedl Harness and connector

(If harness and connector

are normal, replace airflow sensor assembly.)

12A0104

4Intake au

J--lNlL l3

Retarnedl Harness and connectortemperature sensor Hl Intake air temperature

sensor

12A0104

5Throttle postron

:n l4

Retainedl Harness and connector

sensorl Throttle position sensorl Idle position switch

17A0104

6Engine coolant

:nn 2’

Retainedl Harness and connectortemperature sensorl Engine coolant temper-

ature sensor

12A0107

Page 532 of 1216

FUEL SYSTEM - MPI System Inspection <2.0L DOHC Engine>

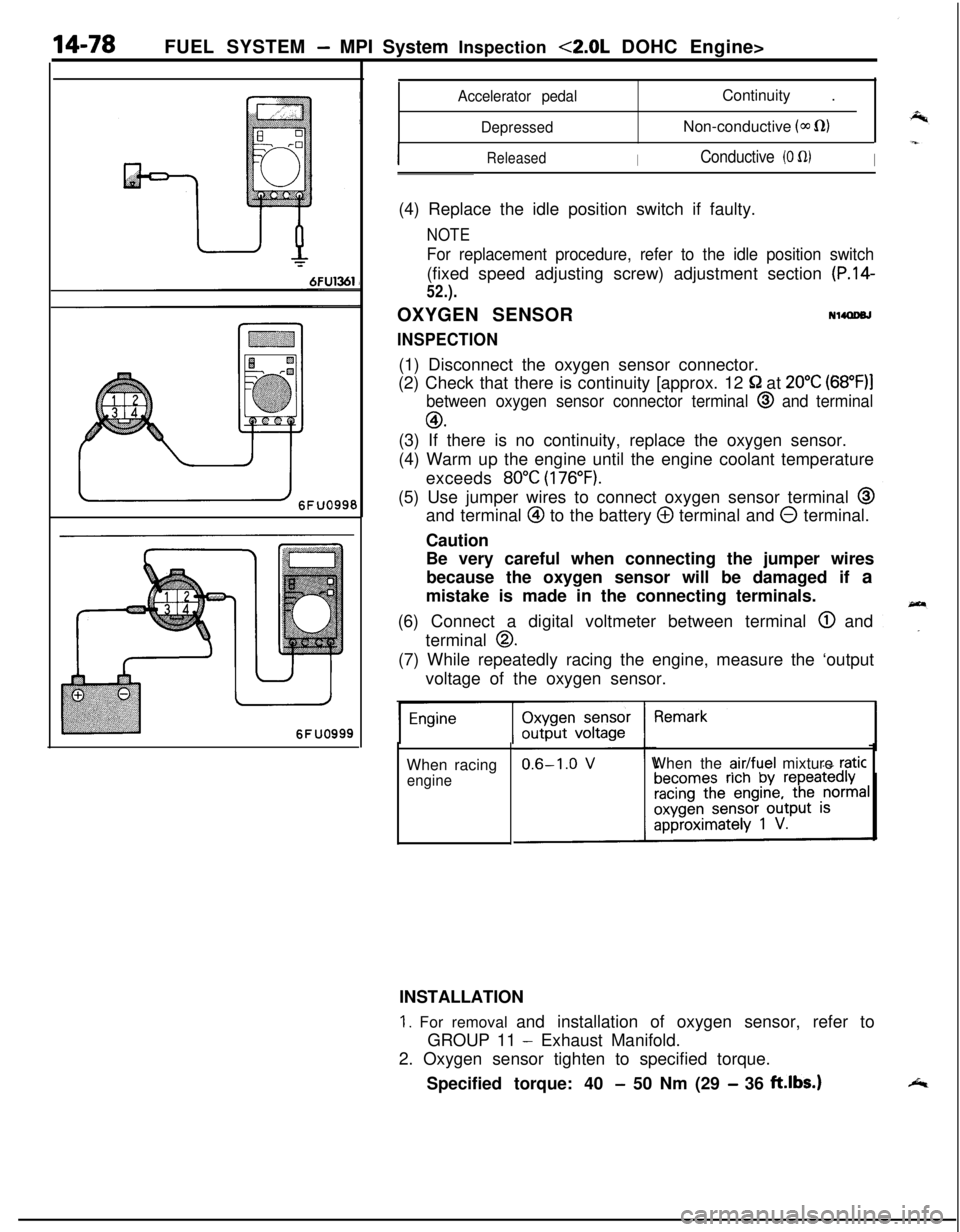

6FUO999

Accelerator pedal

DepressedContinuity .

Non-conductive

(03 fl)

ReleasedIConductive (0 fl)I(4) Replace the idle position switch if faulty.

NOTE

For replacement procedure, refer to the idle position switch(fixed speed adjusting screw) adjustment section

(P.14-

52.).OXYGEN SENSOR

NllQDeJ

INSPECTION(1) Disconnect the oxygen sensor connector.

(2) Check that there is continuity [approx. 12

52 at 20°C (68”F)l

between oxygen sensor connector terminal @ and terminal

GO.(3) If there is no continuity, replace the oxygen sensor.

(4) Warm up the engine until the engine coolant temperature

exceeds

80°C (176°F).(5) Use jumper wires to connect oxygen sensor terminal

@and terminal

@ to the battery @ terminal and 0 terminal.

Caution

Be very careful when connecting the jumper wires

because the oxygen sensor will be damaged if a

mistake is made in the connecting terminals.

(6) Connect a digital voltmeter between terminal

@ and

terminal

0.(7) While repeatedly racing the engine, measure the ‘output

voltage of the oxygen sensor.

When racing

engineWhen the

air/fuel mixture raticINSTALLATION

1. For removal and installation of oxygen sensor, refer to

GROUP 11

- Exhaust Manifold.

2. Oxygen sensor tighten to specified torque.

Specified torque: 40

- 50 Nm (29 - 36 ft.lbs.)