fuel MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 1 of 1216

BACKUPGROUP INDEX &ma

;r Service Manual

LASER

TALON

1991

Volume-l

Engine, Chassis

& Body

FOREWORDThis Service Manual has been prepared with the

latest service information available at the time of

‘* publication.It is subdivided into various group

categories and each section contains diagnosis,

disassembly, repair, and installation procedures

along with complete specifications and tightening

references. Use of this manual will aid in properly

performing any servicing necessary to maintain or

restore the high levels of performance and reliabilitydesigned into these outstanding vehicles.

This BACKUP DSM manual IS to be used ONLY as a BACKUP. Please DO NOT REDISTRIBUTEWHOLE SECTIONS. This BACKUP was sold to you under the fact that you do indeed OWNa GENUINE DSM MANUAL. It CANNOT BE considered a REPLACEMENT (Unless your originalmanual was lost or destroyed.)Please See

README.N or README.HTML for additional information

Thank you. G~mm~emymanual@hotma~l.com

1,

wA

CHRYSLER

CORPORATION

Chrysler Corporation reserves the right to make changes in design 0’: tomake additions to or improvements in its products without lmqoslngd ., . any obligations upon itself to install them on its products previouslymanufactured.

0 1990 Mitsubishi Motors CorporationPrinted in U.S.A.Introduction and

Master

Troubleshooting. . . . . .,. . . . . . . . . r...m,

Lubrication and Maintenance . . . . . . . . ‘-0‘8

; “. i,

.Front Suspension. . . . . . . . . . . . . . ..*............d...Rear Axle

. . . . . . . . . . . . . . . . . . . . . . . . . . . . ..‘.....................

/

ServiceBrakes-Parking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clutch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..~......................‘t.

Cooling. . . . . . . . . . . . . . . . . ..i....................................

,., .‘,-,

Engine..i....~....r...............~....~.*,.~.~.~,‘~~...;..~~..Intake and Exhaust

. . . . . . ..L....................Fuel System

. . . . . . . . . . . ..ti.......r................~...Propeller Shaft

.......................................IRear

Suspensiori.............................y.f...

ManualSteering- Power.....................................Manual

I

transaxle-Automatic .............:;i...,;.....;Wheels

and Tires.................................

Body.............................................................Heater & Air Conditioning

..............Emission

Contr6l Systems..............

INOTE: For Electrical, refer toVolume-2 “Electrical”.

Page 20 of 1216

20INTRODUCTION AND MASTER TROUBLESHOOTING - Towing and Hoisting

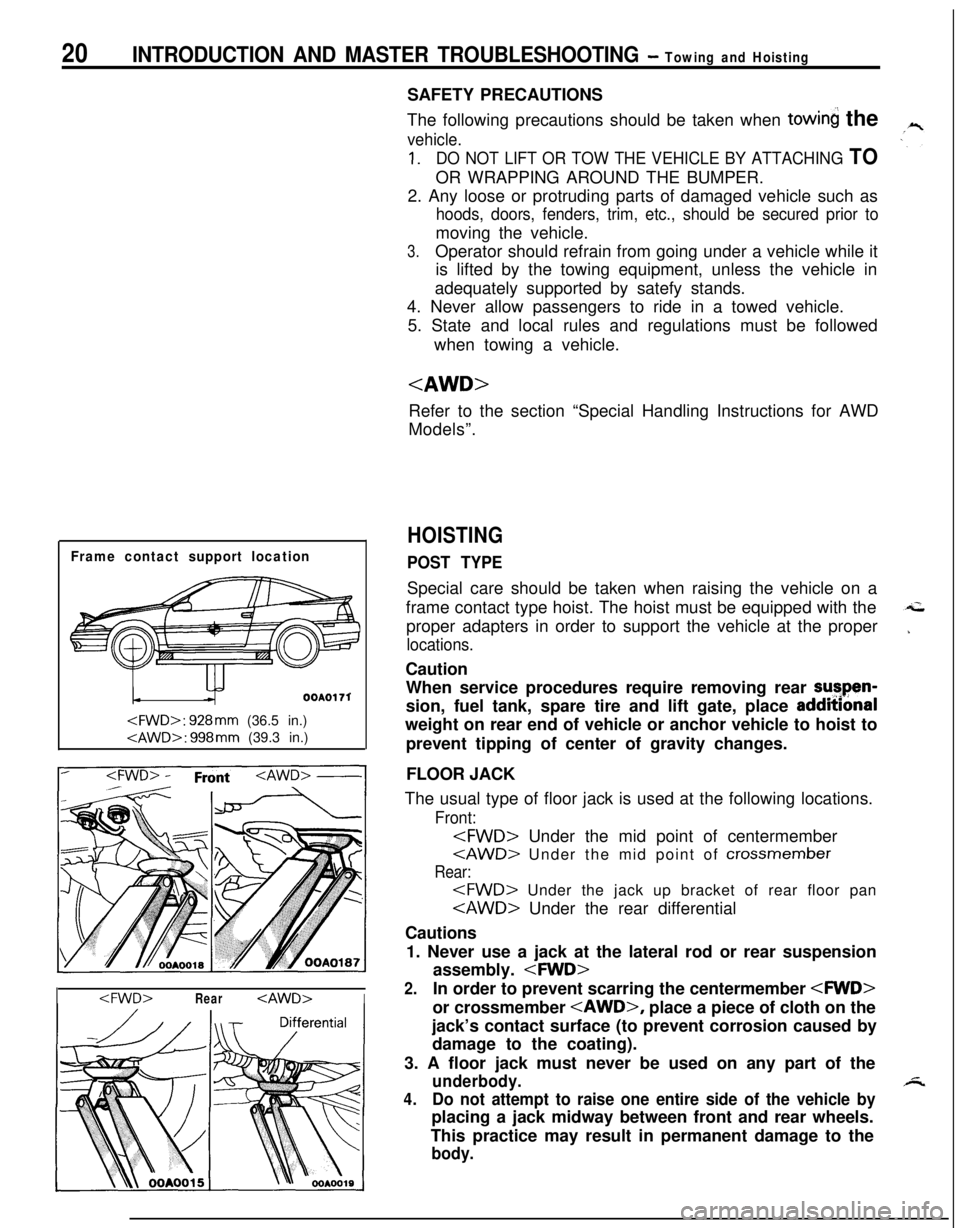

Frame contact support location

OOAOI 71

I

The following precautions should be taken when

towin the

vehicle.

1.DO NOT LIFT OR TOW THE VEHICLE BY ATTACHING TOOR WRAPPING AROUND THE BUMPER.

2. Any loose or protruding parts of damaged vehicle such as

hoods, doors, fenders, trim, etc., should be secured prior tomoving the vehicle.

3.Operator should refrain from going under a vehicle while it

is lifted by the towing equipment, unless the vehicle in

adequately supported by satefy stands.

4. Never allow passengers to ride in a towed vehicle.

5. State and local rules and regulations must be followed

when towing a vehicle.

Refer to the section “Special Handling Instructions for AWD

Models”.

HOISTING

POST TYPESpecial care should be taken when raising the vehicle on a

frame contact type hoist. The hoist must be equipped with the

proper adapters in order to support the vehicle at the proper

locations.Caution

When service procedures require removing rear sutpen-

sion, fuel tank, spare tire and lift gate, place addmonal

weight on rear end of vehicle or anchor vehicle to hoist to

prevent tipping of center of gravity changes.

FLOOR JACK

The usual type of floor jack is used at the following locations.

Front:

Rear:

Cautions

1. Never use a jack at the lateral rod or rear suspension

assembly.

2.In order to prevent scarring the centermember

jack’s contact surface (to prevent corrosion caused by

damage to the coating).

3. A floor jack must never be used on any part of the

underbody.

4.Do not attempt to raise one entire side of the vehicle byplacing a jack midway between front and rear wheels.

This practice may result in permanent damage to the

body.

Page 26 of 1216

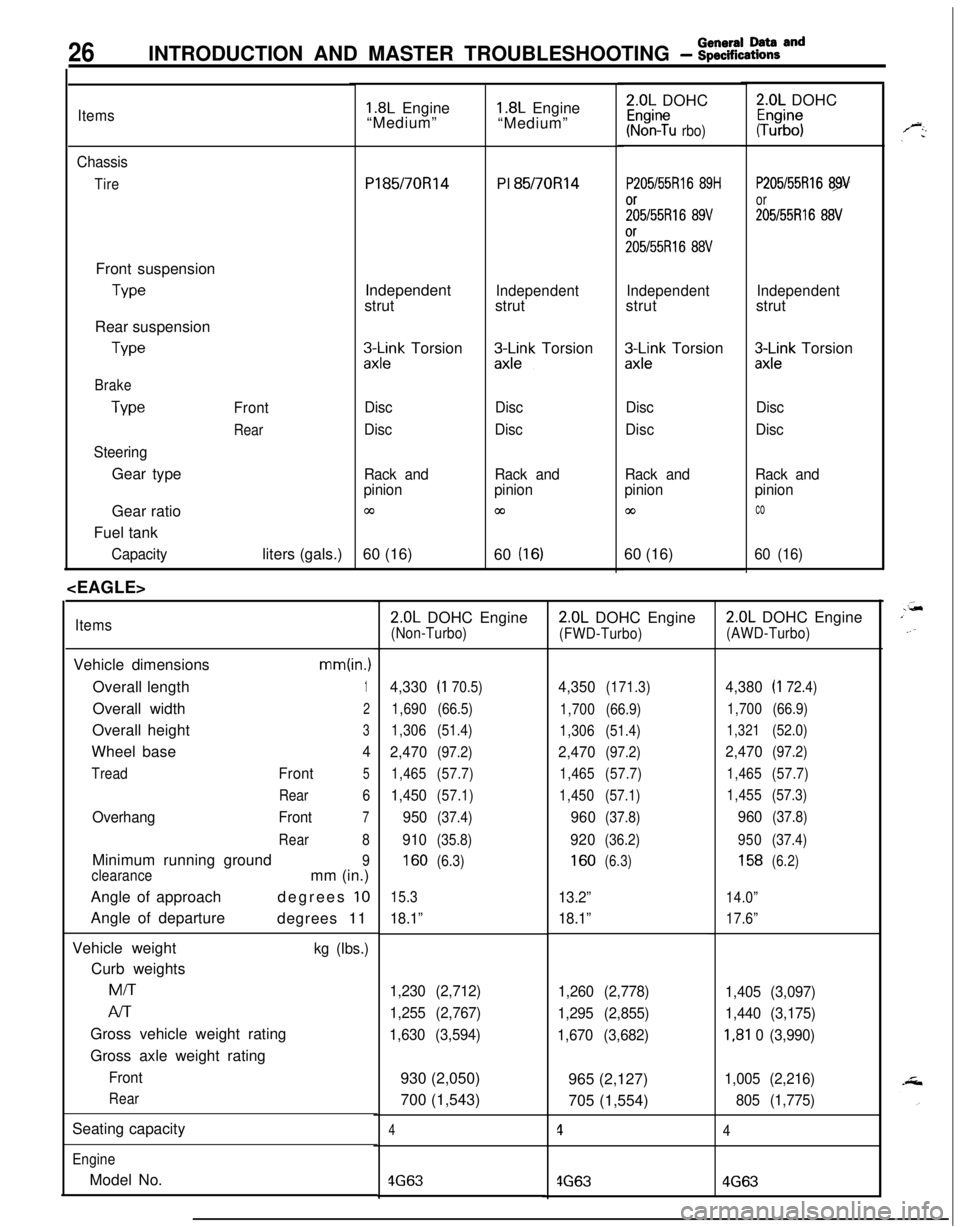

26INTRODUCTION AND MASTER TROUBLESHOOTING - :;:%:a=and

Items

Chassis

TireFront suspension

TypeRear suspension

We

Brake

Type

SteeringGear typeFront

RearGear ratio

Fuel tank

Capacityliters (gals.)

1.8L Engine

“Medium”Pl85/70R14

PI 85/70Rl4

Independent

strut

Independentstrut

3l\Fk Torsion&k-k Torsion

Disc

DiscDisc

Disc

Rack and

pinion

03

Rack and

pinion

cn60 (16)

60

(16)

ItemsVehicle dimensions

mm(in.)Overall length

1Overall width

2Overall height

3Wheel base

4

TreadFront5

Rear6

OverhangFront7

Rear8Minimum running ground

9

clearancemm (in.)

Angle of approachdegrees

10Angle of departure

degrees 11

Vehicle weight

kg (Ibs.)Curb weightsMiT

Al-rGross vehicle weight rating

Gross axle weight rating

Front

RearSeating capacity

EngineModel No.

1.8L Engine

“Medium”2.0L DOHC

Kr%n?u rbo)

P205/55Rl6 89H

;;5/55R16 89V%55R16

88V

Independentstrut

zx;;k Torsion

Disc

Disc

Rack and

pinion

co60 (16)

2.0L DOHC

#b”;

P205/55Rl6 89

or

205155R16 88V

Independentstrut

3Lnk Torsion

Disc

Disc

Rack and

pinion

co

60 (16)

2.0L DOHC Engine(Non-Turbo)

4,330(I 70.5)

1,690(66.5)

1,306(51.4)

2,470(97.2)

1,465(57.7)

1,450(57.1)

950(37.4)

910(35.8)

160(6.3)

15.3

18.1”

1,230 (2,712)

1,255 (2,767)

1,630 (3,594)930 (2,050)

700 (1,543)

4

4G63

2.0L DOHC Engine

(FWD-Turbo)

4,350(171.3)

1,700(66.9)

1,306(51.4)

2,470(97.2)

1,465(57.7)

1,450(57.1)

960(37.8)

920(36.2)

160(6.3)

13.2”

18.1”

1,260 (2,778)

1,295 (2,855)

1,670 (3,682)965 (2,127)

705 (1,554)

1

4G63

2.0L DOHC Engine

(AWD-Turbo)

4,380(I 72.4)

1,700(66.9)

1,321(52.0)

2,470(97.2)

1,465(57.7)

1,455(57.3)

960(37.8)

950(37.4)

158(6.2)

14.0”

17.6”

1,405 (3,097)

1,440 (3,175)

I,81 0 (3,990)

1,005 (2,216)

805 (1,775)

4

4G63

Page 27 of 1216

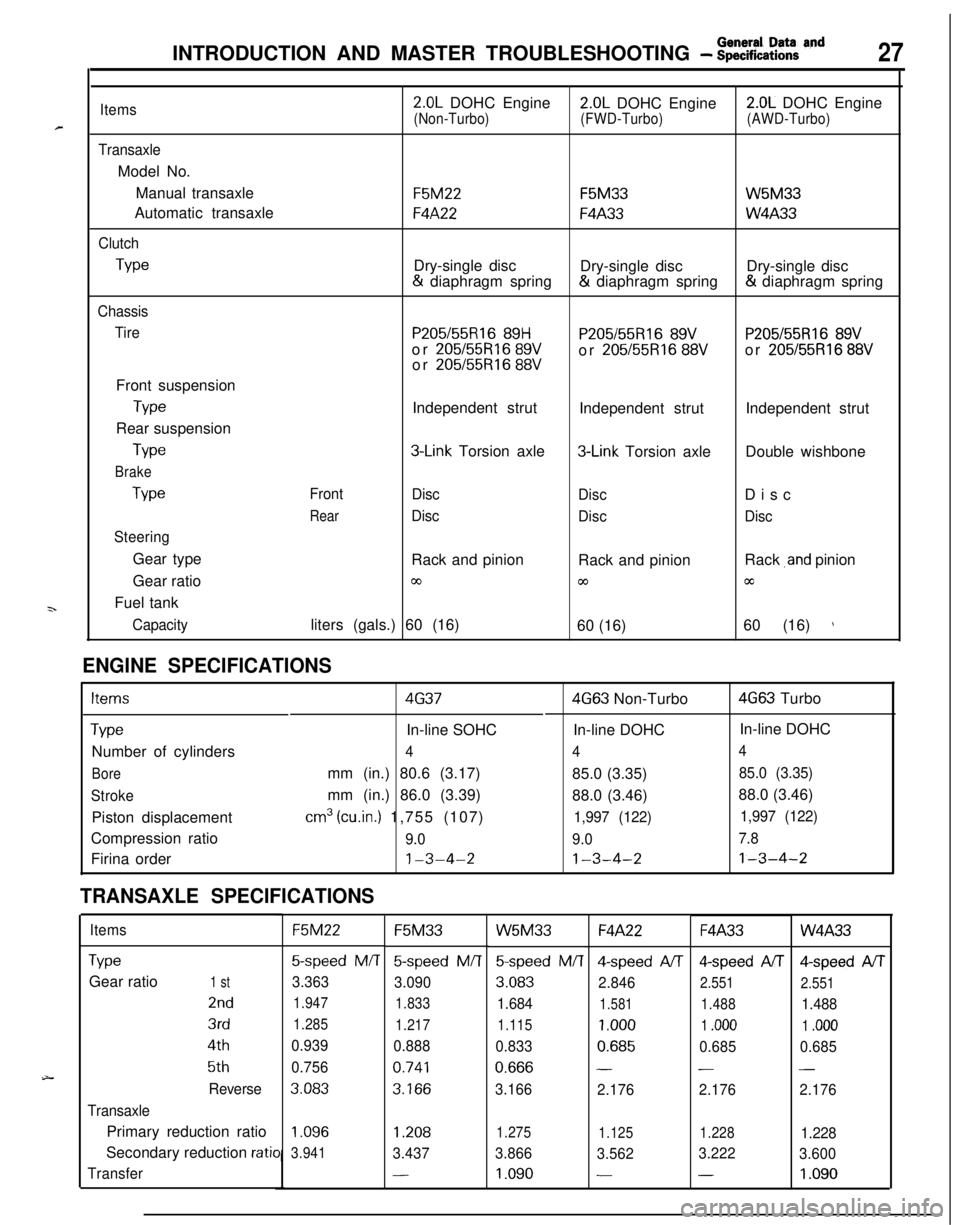

INTRODUCTION AND MASTER TROUBLESHOOTING - f~EEaZ% acld27

=r

9..

Items

TransaxleModel No.

Manual transaxle

Automatic transaxle

Clutch

Type

Chassis

TireFront suspension

TypeRear suspension

Type

Brake

Type

SteeringGear type

Gear ratio

Fuel tank

Capacity

2.0L DOHC Engine2.0L DOHC Engine2.0L DOHC Engine

(Non-Turbo)(FWD-Turbo)(AWD-Turbo)

F5M22F5M33W5M33

F4A22F4A33W4A33Dry-single disc

Dry-single discDry-single disc& diaphragm spring& diaphragm spring& diaphragm spring

P205/55R16 89HP205155R16 89VP205/55R16 89Vor 205/55R16 89Vor 205/55R16 88Vor 205/55R16 88Vor 205/55R16 88VIndependent strut

Independent strutIndependent strut

3-Link Torsion axle3-Link Torsion axleDouble wishbone

Front

Disc

DiscDisc

RearDisc

DiscDiscRack and pinion

Rack and pinionRack

,and pinion

03coccliters (gals.) 60 (16)

60 (16)60 (16)

)

ENGINE SPECIFICATIONS

Items4G374G63 Non-Turbo4G63 Turbo

TypeIn-line SOHCIn-line DOHCIn-line DOHC

Number of cylinders

444

Boremm (in.) 80.6 (3.17)

85.0 (3.35)85.0 (3.35)

Strokemm (in.) 86.0 (3.39)

88.0 (3.46)88.0 (3.46)

Piston displacement

cm3 (cu.in.) 1,755 (107)1,997 (122)1,997 (122)Compression ratio

9.09.07.8Firina order

1-3-4-21-3-4-21-3-4-2

TRANSAXLE SPECIFICATIONS

ItemsF5M22F5M33W5M33F4A22F4A33W4A33

TypeGear ratio

1 st

2nd

3rd

4th

5th

Reverse

TransaxlePrimary reduction ratio

Secondary reduction

ratio

Transfer

5-speed M/T5-speed M/T

3.363

3.090

1.947

1.833

1.285

1.217

0.939

0.888

0.756

0.741

3.0833.166

5speed M/T4-speed A/T4-speed AIT

3.083

2.8462.551

1.6841.5811.488

1.115

1.0001 .ooo

0.8330.6850.685

0.666--

3.166

2.1762.176

Qspeed AIT

2.551

1.488

1 .ooo

0.685

-

2.176

1.096

3.9411.2081.275

1.1251.2281.228

3.4373.866

3.5623.222

3.600

-1.090--1.090

Page 29 of 1216

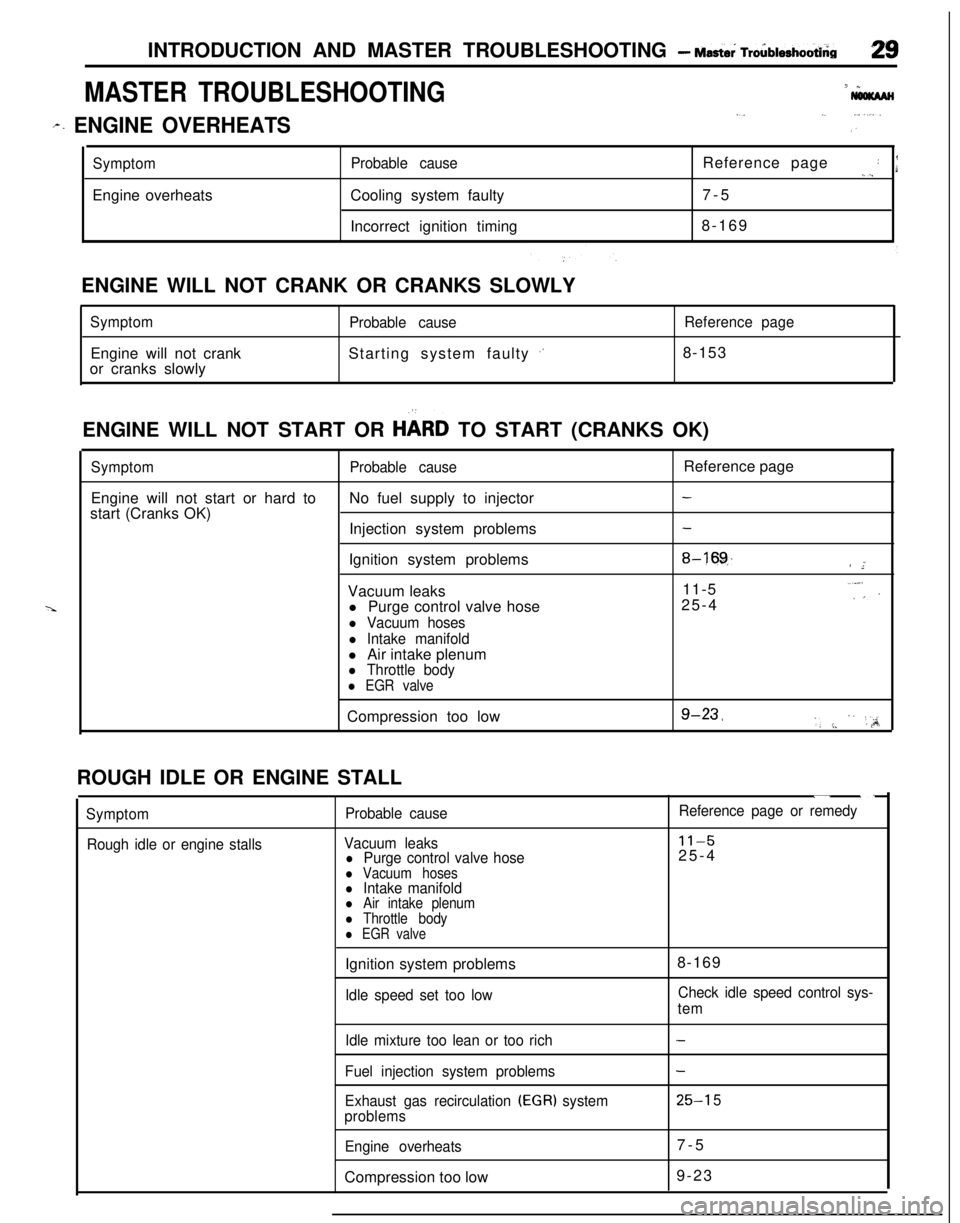

INTRODUCTION AND MASTER TROUBLESHOOTING - Mast& Tro6blerhootbia

MASTER TROUBLESHOOTING7 *

I,._ ,...

r. ENGINE OVERHEATSi ”

SymptomEngine overheatsProbable causeCooling system faulty

Incorrect ignition timingReference page: I._),7-5

8-169

ENGINE WILL NOT CRANK OR CRANKS SLOWLY

SymptomEngine will not crank

or cranks slowlyProbable causeStarting system faulty

,’

Reference page8-153

ENGINE WILL NOT START OR

HbRD TO START (CRANKS OK)

SymptomProbable causeReference page

Engine will not start or hard toNo fuel supply to injector

-start (Cranks OK)

Injection system problems

-Ignition system problems

8-16!$/ ”;Vacuum leaks11-5..“,:’l Purge control valve hose25-4

l Vacuum hoses

l Intake manifoldl Air intake plenum

l Throttle body

l EGR valveCompression too low

g-23,‘, :. ” ‘,;A;ROUGH IDLE OR ENGINE STALL

Symptom

Rough idle or engine stallsProbable cause

Vacuum leaks

l Purge control valve hosel Vacuum hosesl Intake manifoldl Air intake plenuml Throttle bodyl EGR valve

“. ._

Reference page or remedy

11-525-4

Ignition system problems

Idle speed set too low8-169Check idle speed control sys-

tem

Idle mixture too lean or too rich

Fuel injection system problems

Exhaust gas recirculation

(EGR) system

problems

Engine overheatsCompression too low

-

-

25-l 57-5

9-23

Page 30 of 1216

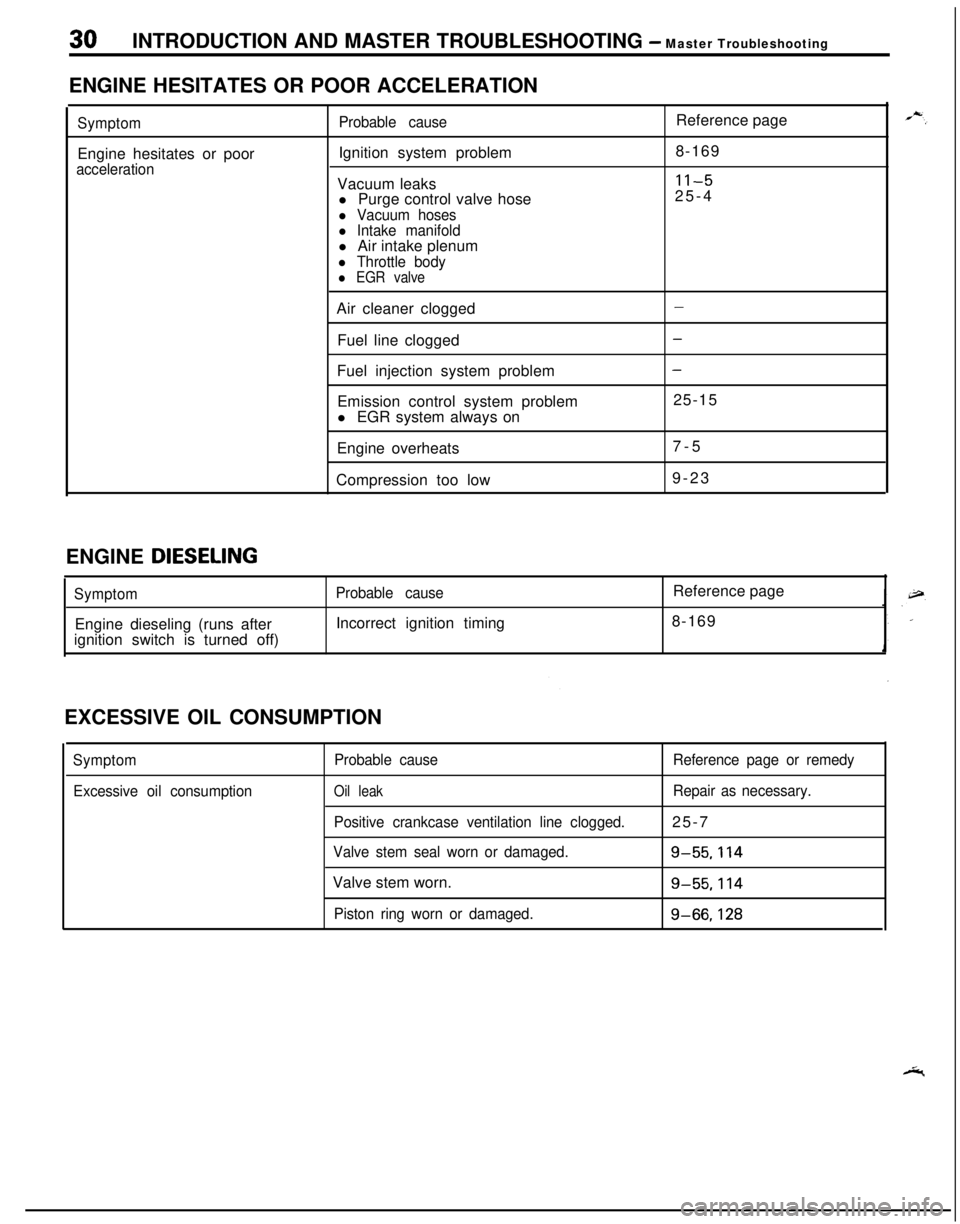

30INTRODUCTION AND MASTER TROUBLESHOOTING - Master Troubleshooting

ENGINE HESITATES OR POOR ACCELERATION

SymptomEngine hesitates or poor

accelerationProbable causeIgnition system problem

Vacuum leaks

l Purge control valve hose

l Vacuum hosesl Intake manifoldl Air intake plenum

l Throttle bodyl EGR valveReference page

8-169

11-525-4

Air cleaner clogged

Fuel line clogged

Fuel injection system problem

Emission control system problem

l EGR system always on

Engine overheats

Compression too low

-

-

-25-15

7-5

9-23

ENGINE

DIESELING

SymptomEngine dieseling (runs after

ignition switch is turned off)Probable causeIncorrect ignition timingReference page

8-169

EXCESSIVE OIL CONSUMPTION

Symptom

Excessive oil consumptionProbable cause

Oil leak

Positive crankcase ventilation line clogged.

Valve stem seal worn or damaged.Valve stem worn.

Piston ring worn or damaged.Reference page or remedy

Repair as necessary.25-7

g-55.114

g-55.114

g-66,128

Page 31 of 1216

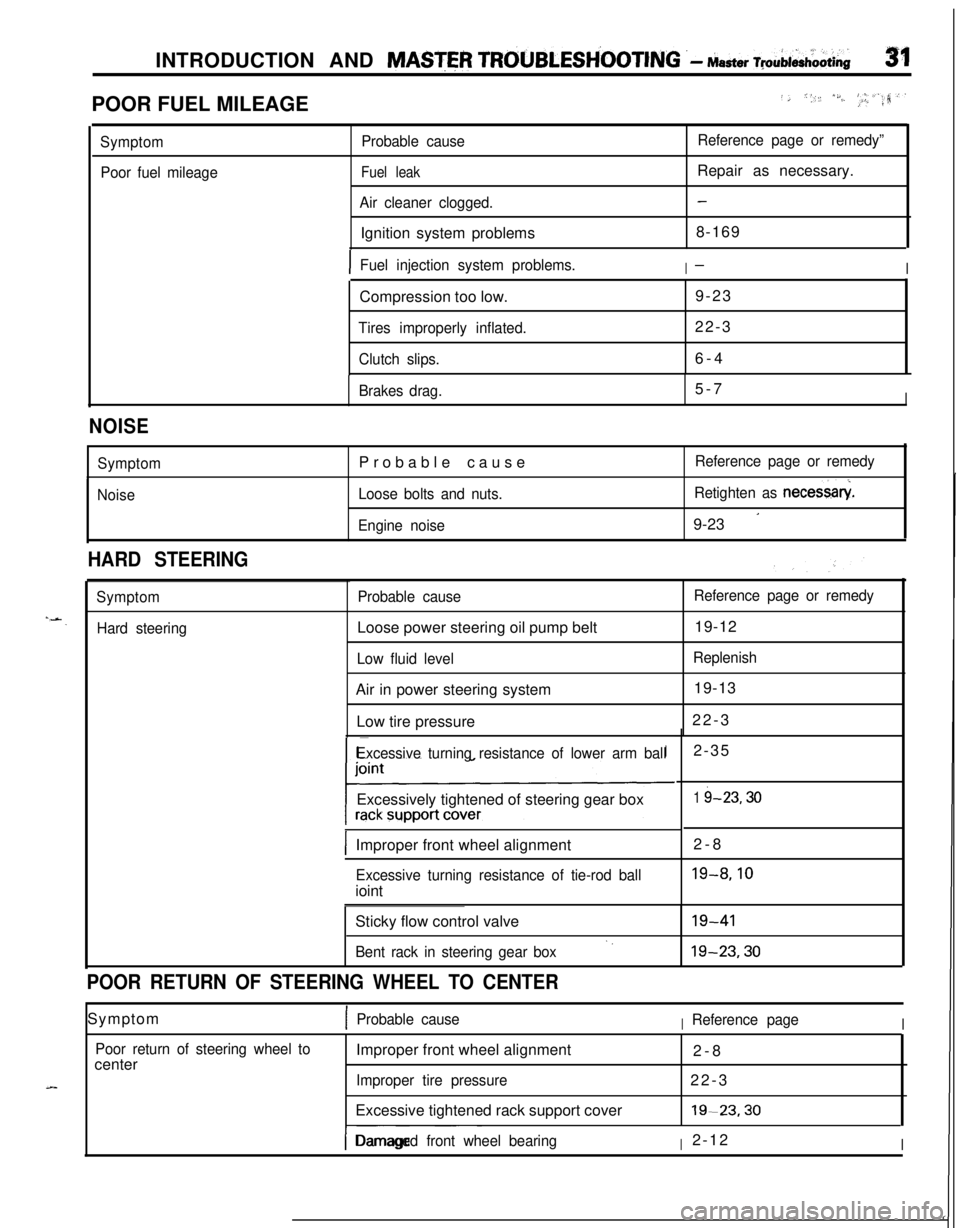

INTRODUCTION AND MASTER TROUBLESH’OOTING .- Master ~pAi&oOti~31POOR FUEL MILEAGE

../, *,, /S./..‘, _I, #_.a,‘.rr?

Symptom

Poor fuel mileageProbable cause

Fuel leak

Air cleaner clogged.Ignition system problems

Reference page or remedy”Repair as necessary.

-8-169

IFuel injection system problems.I-ICompression too low.9-23

Tires improperly inflated.22-3

Clutch slips.6-4

Brakes drag.5-7I

NOISE

Symptom

NoiseProbable cause

Loose bolts and nuts.

Engine noiseReference page or remedy

Retighten as necessary

9-23

’

HARD STEERING

Symptom

Hard steeringProbable causeLoose power steering oil pump belt

Low fluid levelAir in power steering system

Low tire pressure

Reference page or remedy19-12

Replenish19-13

22-3

Excessive turning resistance of lower arm ballExcessively tightened of steering gear box

IImproper front wheel alignment2-8

Excessive turning resistance of tie-rod ballioint2-35

1 i-23.30

19-8.10Sticky flow control valve

Bent rack in steering gear box‘.19-4119-23.30

POOR RETURN OF STEERING WHEEL TO CENTERSymptom

1Probable causeIReference pageI

Poor return of steering wheel tocenterImproper front wheel alignment

2-8

Improper tire pressure22-3

Excessive tightened rack support cover19-23.30

I-- ~~~Damaged front wheel bearingI2-12I

Page 35 of 1216

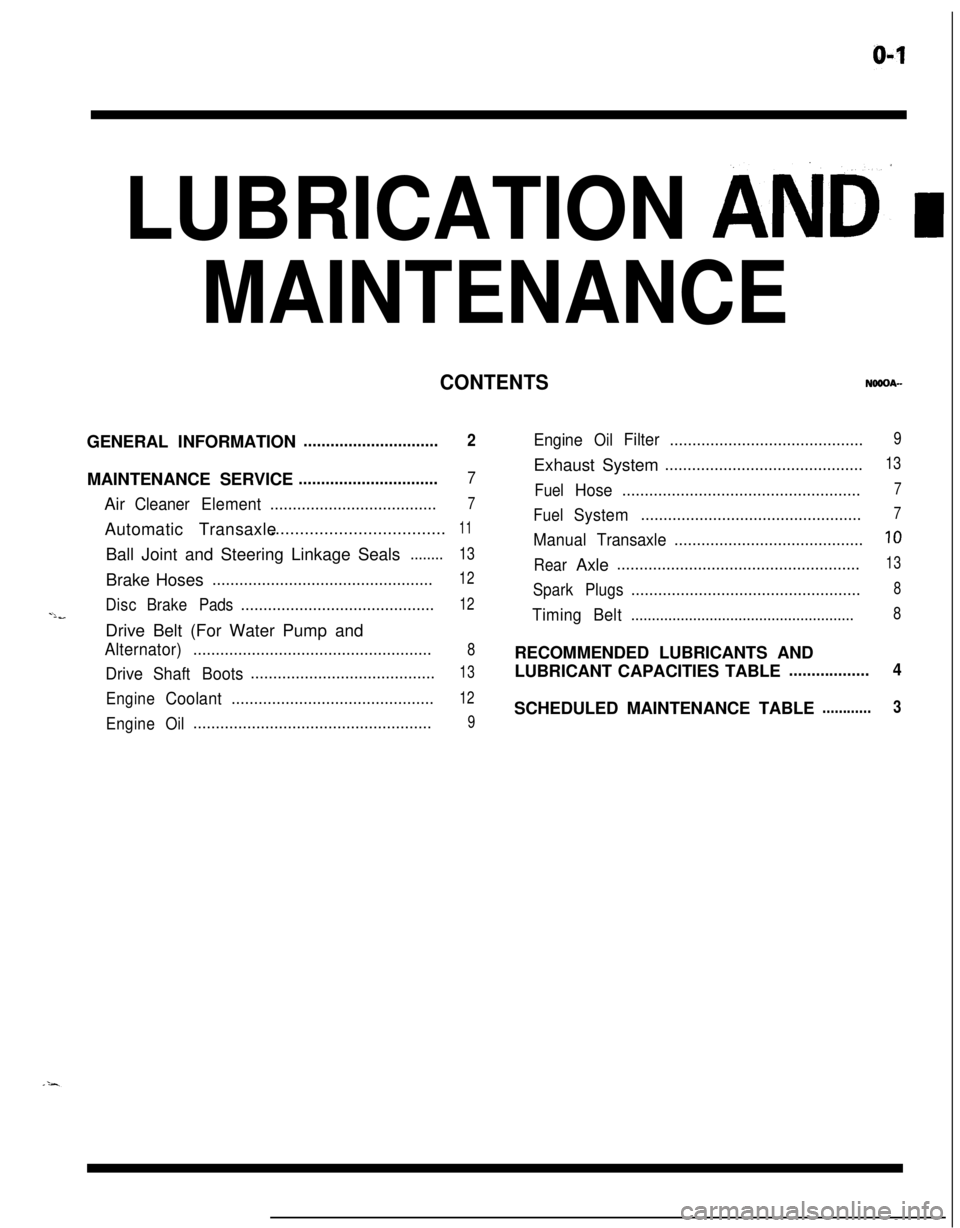

LUBRICATION AND’ I

MAINTENANCE

CONTENTSGENERAL INFORMATION

..............................2MAINTENANCE SERVICE

...............................7Air

CleanerElement.....................................7Automatic Transaxle....................................

11Ball Joint and Steering Linkage Seals

........13Brake Hoses

.................................................12

DiscBrakePads...........................................12-lbDrive Belt (For Water Pump and

Alternator).....................................................8

DriveShaftBoots.........................................13

EngineCoolant.............................................12

EngineOil.....................................................9

EngineOilFilter...........................................9Exhaust System

............................................13

FuelHose.....................................................7

FuelSystem.................................................7

ManualTransaxle..........................................10

RearAxle......................................................13

SparkPlugs...................................................8

TimingBelt......................................................8RECOMMENDED LUBRICANTS AND

LUBRICANT CAPACITIES TABLE

..................4SCHEDULED MAINTENANCE TABLE

............3

Page 36 of 1216

o-2LUBRICATION AND MAINTENANCE - General Information

GENERAL INFORMATIONNGQPA--Maintenance and lubrication service recommenda-

tions have been compiled to provide maximum

protection for the vehicle owner’s investment

against all reasonable types of driving conditions.

Since these conditions vary with the individual

vehicle owner’s driving habits, the area in which the

vehicle is operated and the type of driving to which

the vehicle is subjected, it is necessary to prescribe

lubrication and maintenance service on a time

frequency as well as mileage interval basis.

Oils, lubricants and greases are classified and

graded according to standards recommended by theSociety of Automotive Engineers (SAE), the Amer-

ican Petroleum Institute (API) and the National

Lubricating Grease Institute

(NLGI).MAINTENANCE SCHEDULES

Information for service maintenance is provided

under “SCHEDULED MAINTENANCE TABLE”.

Three schedules are provided; one for “Required

Maintenance”, one for “General Maintenance” and

one for “Severe Usage Service”.

Item numbers in the “SCHEDULED MAINTE-

NANCE TABLE” correspond to the item numbers in

the “MAINTENANCE SERVICE” section.

SEVERE SERVICEVehicles operating under severe service conditions

will require more frequent service.

Component service information is included in

appropriate units for vehicles operating under one ormore of the following conditions:

1.Trailer towing or police, taxi, or commercial type

operation2. Operation of Vehicle

(1) Short-trip operation at freezing temperature

(engine not thoroughly warmed up)

(2) More than 50% operation in heavy city

traffic during hot weather above

32°C (90°F)(3) Extensive idling

(4) Driving in sandy areas

(5) Driving in salty areas

(6) Driving in dusty conditions

ENGINE OIL

The SAE grade number indicates the viscosity of

engine oils, for example, SAE 30, which is a single

grade oil. Engine oils are also identified by a dual

number, for example, SAE

lOW-30, which indicates

a multigrade oil.

The API classification system defines oil perform-

ance in terms of engine usage. Only engine oil

designed “For Service SG” or “For Service

SGKD”,when available, should be used. These oils contain

sufficient chemical additives to provide maximum

engine protection. Both the SAE grade and the API

designation can be found on the container.Caution

Test results submitted to EPA have shown thatlaboratory animals develop skin cancer after

prolonged contact with used engine oil. Accor-

dingly, the potential exists for humans

to de-

velop a number of skin disorders, including

cancer, from such exposure to used engine oil.

Care should be’ taken, therefore, when changingengine oil, to minimize the amount and length of

exposure time to used engine

pi! on your skin.

Protective clothing and gloves, that cannot be

penetrated by oil, should be worn. The skin

should be thoroughly washed with soap and

water, or use waterless hand cleaner, to removeany used engine oil. Do not use gasoline,

thinners, or solvents.

GEAR LUBRICANTSThe SAE grade number also indicates the viscosity

of Multi-Purpose Gear Lubricants.

The API classfication system defines gear lubricants

in terms of usage. Typically gear lubricants conform-ing to API

GL-4 or GL-5 with a viscosity of SAE

75W-85W are recommended for manual transaxle.

LUBRICANTS

- GREASES

Semi-solid lubricants, bear the NLGI designation andare further classified as grades 0, 1, 2, 3 etc.

Whenever “Chassis Lubricant” is specified, Multi-

Purpose Grease,

NLGI grade 2 should be used.

MOPAR Multi-Mileage Lubricant, P&t Number

2525035 or equivalent, meets these requirement

and is recommended.

FUEL USAGE STATEMENT

Use gasolines having a minimum anti-knock index

(Octane Value) of 87,

(R + M)/2. This designation is

comparable to a Research Octane Number of 91.

Unleaded gasolines only must be used in vehicles

equipped with catalyst emission control systems.

All vehicles, so equipped, have labels located on the

instrument panel and on the back of fuel filler lid that

state, “UNLEADED GASOLINE ONLY”. These vehi-

cles also have fuel filler tubes especially designed toaccept the smaller diameter unleaded gasoline

dispensing nozzles only.

MATERIALS ADDED

TO FUELIndiscriminate use of fuel system cleanng agents

should be avoided. Many of these materials in-

tended for gum and varnish removal may contain

highly active solvents or similar ingredients that can

be harmful to gasket and diaphragm materials usedin fuel system component parts.

Page 37 of 1216

LUBRICATION AND MAINTENANCE - Scheduled MaintenanCe Table. &3

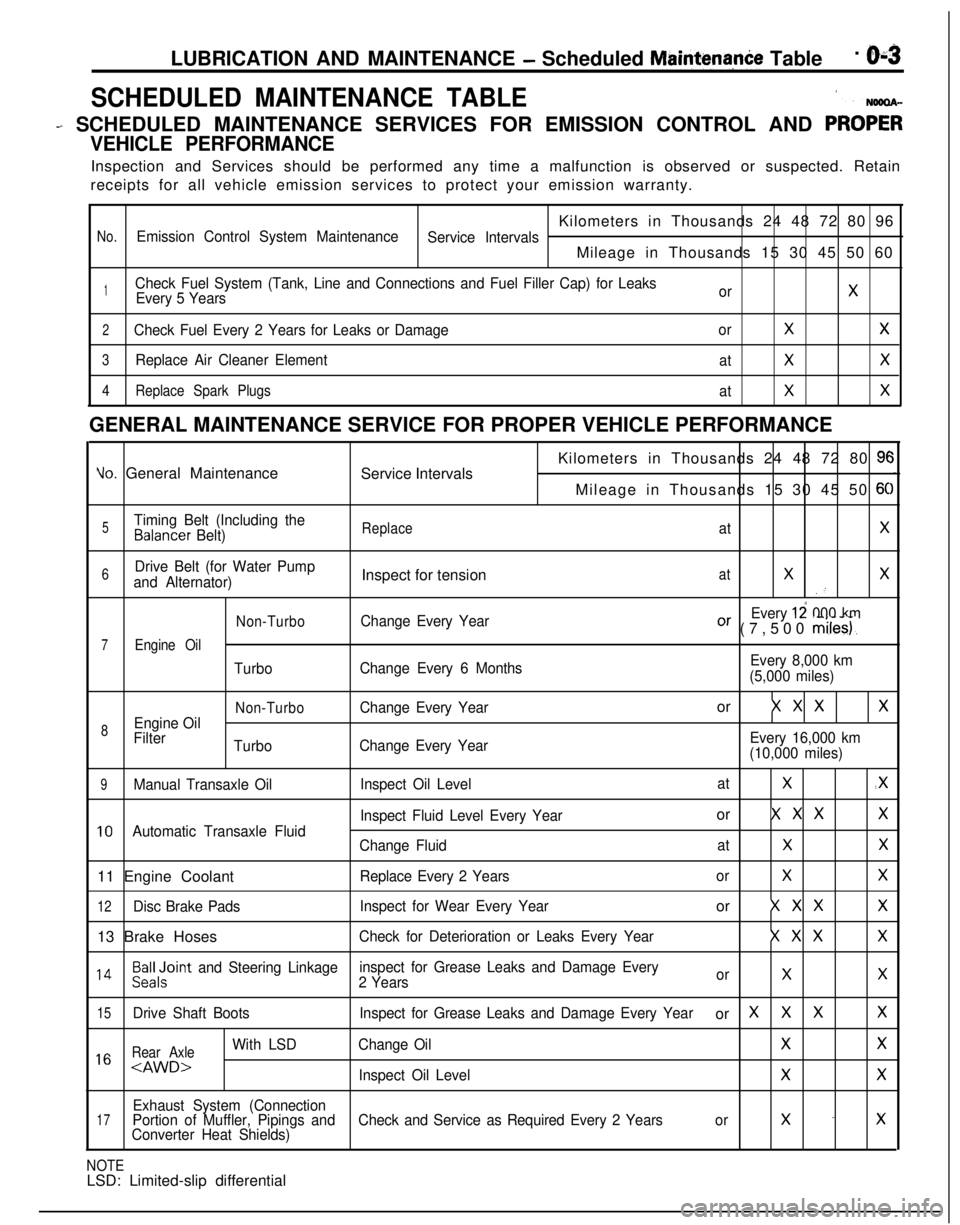

SCHEDULED MAINTENANCE TABLE1

- SCHEDULED MAINTENANCE SERVICES FOR EMISSION CONTROL AND PRO;;

VEHICLE PERFORMANCEInspection and Services should be performed any time a malfunction is observed or suspected. Retain

receipts for all vehicle emission services to protect your emission warranty.

Kilometers in Thousands 24 48 72 80 96

No.Emission Control System Maintenance

Service IntervalsMileage in Thousands 15 30 45 50 60

1Check Fuel System (Tank, Line and Connections and Fuel Filler Cap) for Leaks

Every 5 YearsorX

2Check Fuel Every 2 Years for Leaks or DamageorXX

3Replace Air Cleaner Element

atXX

4Replace Spark Plugs

atXXGENERAL MAINTENANCE SERVICE FOR PROPER VEHICLE PERFORMANCE

Yo. General Maintenance

Service IntervalsKilometers in Thousands 24 48 72 80 9cMileage in Thousands 15 30 45 50

6C

5Timing Belt (Including theBalancer Belt)ReplaceatX

6Drive Belt (for Water Pump

and Alternator)Inspect for tensionatXX.’

Non-TurboChange Every YearEvery 12 000 kmOr (7,500 miles).

7Engine Oil

TurboChange Every 6 MonthsEvery 8,000 km

(5,000 miles)

Non-TurboChange Every Yearor X X XX

8Engine Oil

Filter

TurboChange Every YearEvery 16,000 km

(10,000 miles)

9Manual Transaxle OilInspect Oil LevelatX.X

Inspect Fluid Level Every Yearor X X XX

10Automatic Transaxle Fluid

Change FluidatXX11 Engine Coolant

Replace Every 2 YearsorXX

12Disc Brake PadsInspect for Wear Every Yearor X X XX13 Brake Hoses

Check for Deterioration or Leaks Every YearX X XX

l 4Beiloint and Steering Linkageinspect for Grease Leaks and Damage Every

2 YearsorXX

15Drive Shaft BootsInspect for Grease Leaks and Damage Every Yearor XXXX

Rear Axle

With LSDChange OilXX1 6

Exhaust System (Connection17Portion of Muffler, Pipings andCheck and Service as Required Every 2 Yearsorx -xConverter Heat Shields)

NOTELSD: Limited-slip differential