length MITSUBISHI ECLIPSE 1991 Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 612 of 1216

17-2REAR SUSPENSION

GENERAL SPECIFICATIONS

LN17CAA

ItemsVehicles with 1.8L EngineVehicles with 2.0L DOHC

Engine

jSuspension system

3-link, torsion axle with coil spring type

Coil spring

Wire dia.

x O.D. x free length

mm (in.) 10.1 x 105.1 x 336.510.2 x 105.2 x 316.5

(40 x 4.14 x 13.25)(40 x 4.14 x 12.46)

[Coil spring identification color]

[Light Blue

x 11[Orange x 11Spring constant

N/mm

(Ibs./in.) 20 (112.0)23 (128.8)

Shock absorber

TypeHydraulic, cylindrical, double-acting type

Max. length

mm (in.) 495 (19.5)485 (19.1)

Min. length

mm (in.) 315 (12.4)315 (12.4)

Strokemm (in.) 180 (7.1)170 (6.7)Damping force [at 0.3 m/set. (0.9

ft./set.)]

ExpansionN (Ibs.)800 (176)

ContractionN (Ibs.)300 (66)

Wheel bearing

TypeUnit ball bearing

SERVICE SPECIFICATIONS

Items

Standard valueToe-in (Left-right difference)

Camber

LimitWheel bearing end play

Rear hub rotary-sliding resistance

Rear hub rotary-sliding torque

NOTEToe-in and camber cannot be adjusted.mm (in.)

mm (in.)

N (Ibs.)

Nm

(ftlbs.)

TORQUE SPECIFICATIONS

Specifications

0+3 (Of.1 18)

-45’

f 30’

0.01 (004) or less

31

(7) or less

1.8

(1.30) or lessNI’ICB-A

ItemsNmft.lbs.

Wheel bearing nut

Shock absorber upper mounting nut

Shock absorber lower mounting nut

Lateral rod mounting nut (body side)

Lateral rod mounting bolt (axle beam side)

Trailing arm mounting bolt

Piston rod tightening nut

Brake hose and tube bracket mounting bolt

Caliper assembly mounting nut

Rear speed sensor mounting bolt

200-260

40-50

80- 100

80-100

100-120

100-120

20-2517-26

50-609-14144-188

29-36

58-72

58-72

72-87

72-87

14-18

12-19

36-43

I7-10

Nl7CGA

Page 626 of 1216

17-16REAR SUSPENSION

SPECIFICATIONS

GENERAL SPECIFICATIONSNl’ICA-B jG

ItemsSpecifications

Suspension systemDouble wishbone suspension type

Coil spring

Wire dia. x O.D.

x free lengthmm (in.)11.0 x 106.0 x 332.5 (.43 x 4.17 x 13.1)Coil spring identification colorPurple

x 1Spring constantN/mm

(Ibs./in.) 25.0 (140)

Shock absorber

TypeHydraulic, cylindrical, double-acting type

Max. lengthmm (in.) 568

(22.4)Min. lengthmm (in.) 380

(15.0)

Strokemm (in.) 188 (7.4)

Damping force [at 0.3 m/set. (0.9

ft./set.)]

ExpansionN (Ibs.) 900 (198)

ContractionN (Ibs.) 300 (66)

SERVICE SPECIFICATIONS

Items

Standard value

Toe-in

CamberSpecificationsmm (in.) 3.6+3 (.14f.l18)

-1"33'f30'

Nl7CEB

:&

Page 675 of 1216

--STEERING - Manual Steering Gear Boxm-2.7

13AO175

Grease

136007(1184-186 mm

(7.24-7.32

in.)

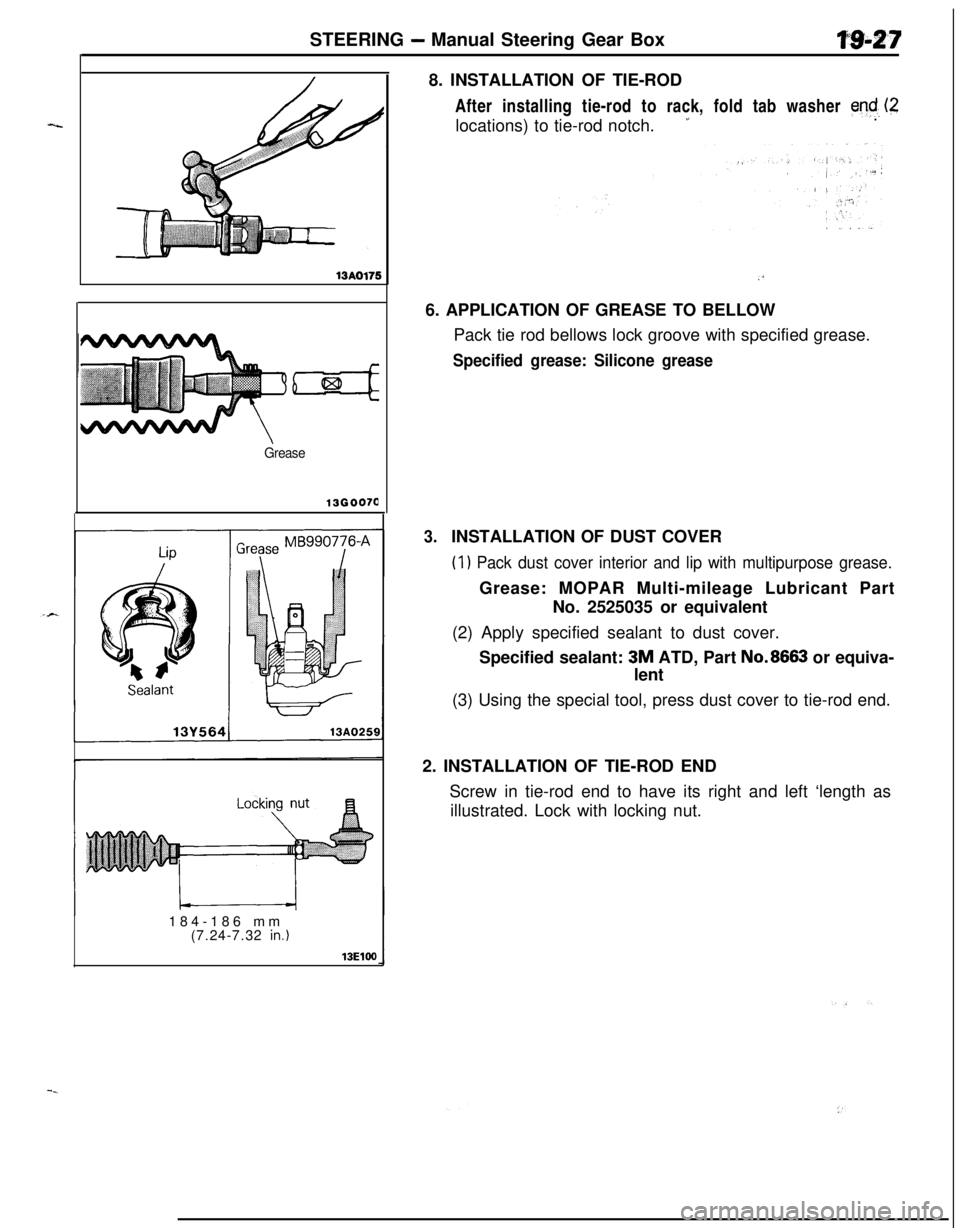

13ElW8. INSTALLATION OF TIE-ROD

After installing tie-rod to rack, fold tab washer

end, (2locations) to tie-rod notch.

’.

.‘6. APPLICATION OF GREASE TO BELLOW

Pack tie rod bellows lock groove with specified grease.

Specified grease: Silicone grease

3.INSTALLATION OF DUST COVER

(1) Pack dust cover interior and lip with multipurpose grease.Grease: MOPAR Multi-mileage Lubricant Part

No. 2525035 or equivalent

(2) Apply specified sealant to dust cover.

Specified sealant:

3M ATD, Part No.8663 or equiva-

lent

(3) Using the special tool, press dust cover to tie-rod end.

2. INSTALLATION OF TIE-ROD END

Screw in tie-rod end to have its right and left ‘length as

illustrated. Lock with locking nut.

Page 686 of 1216

STEERING - Power Steering Gear Box

I-

-l

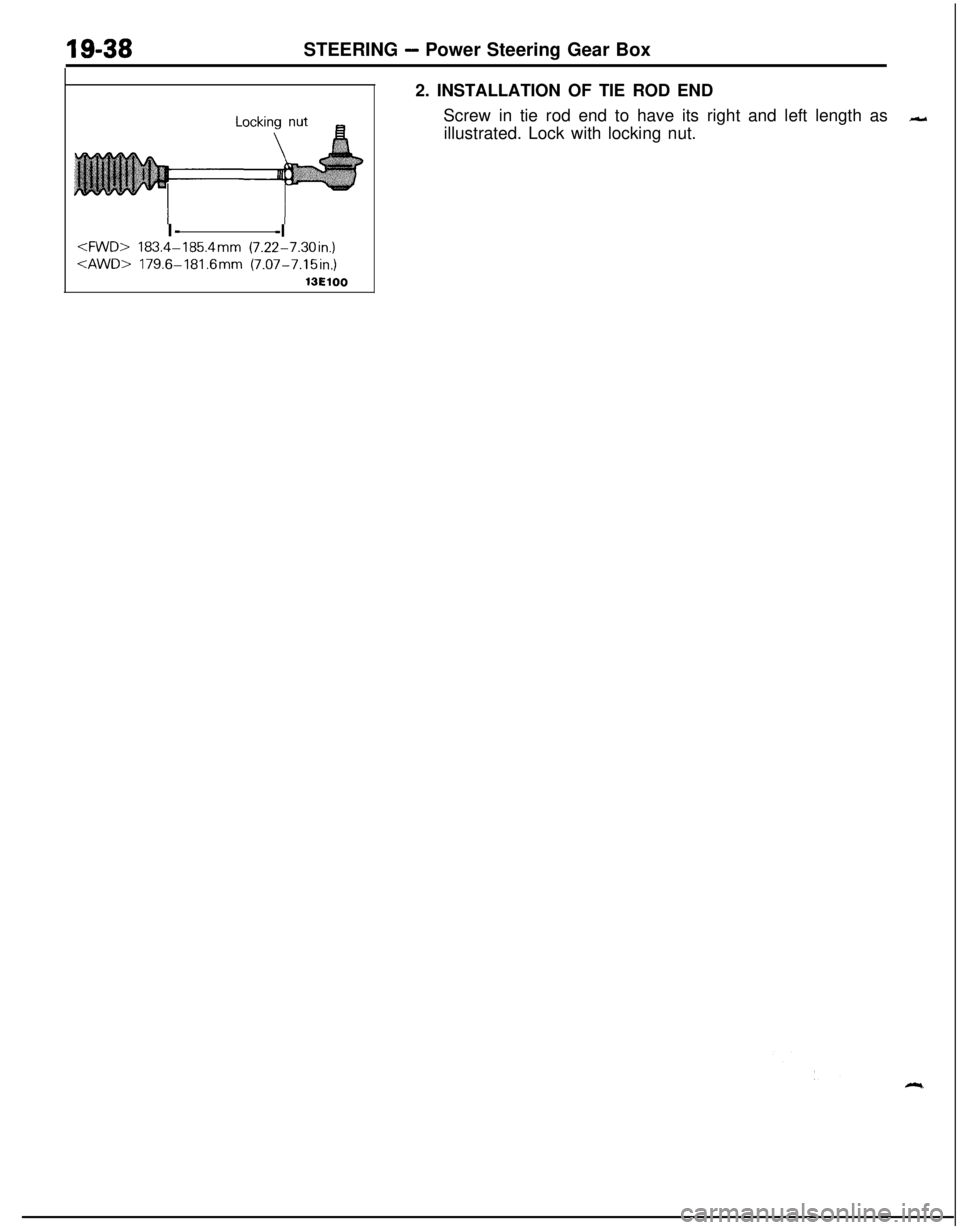

13ElOO2. INSTALLATION OF TIE ROD END

Screw in tie rod end to have its right and left length as

-illustrated. Lock with locking nut.

Page 711 of 1216

MANUAL TRANSAXLE

erShift

lever

09A0159

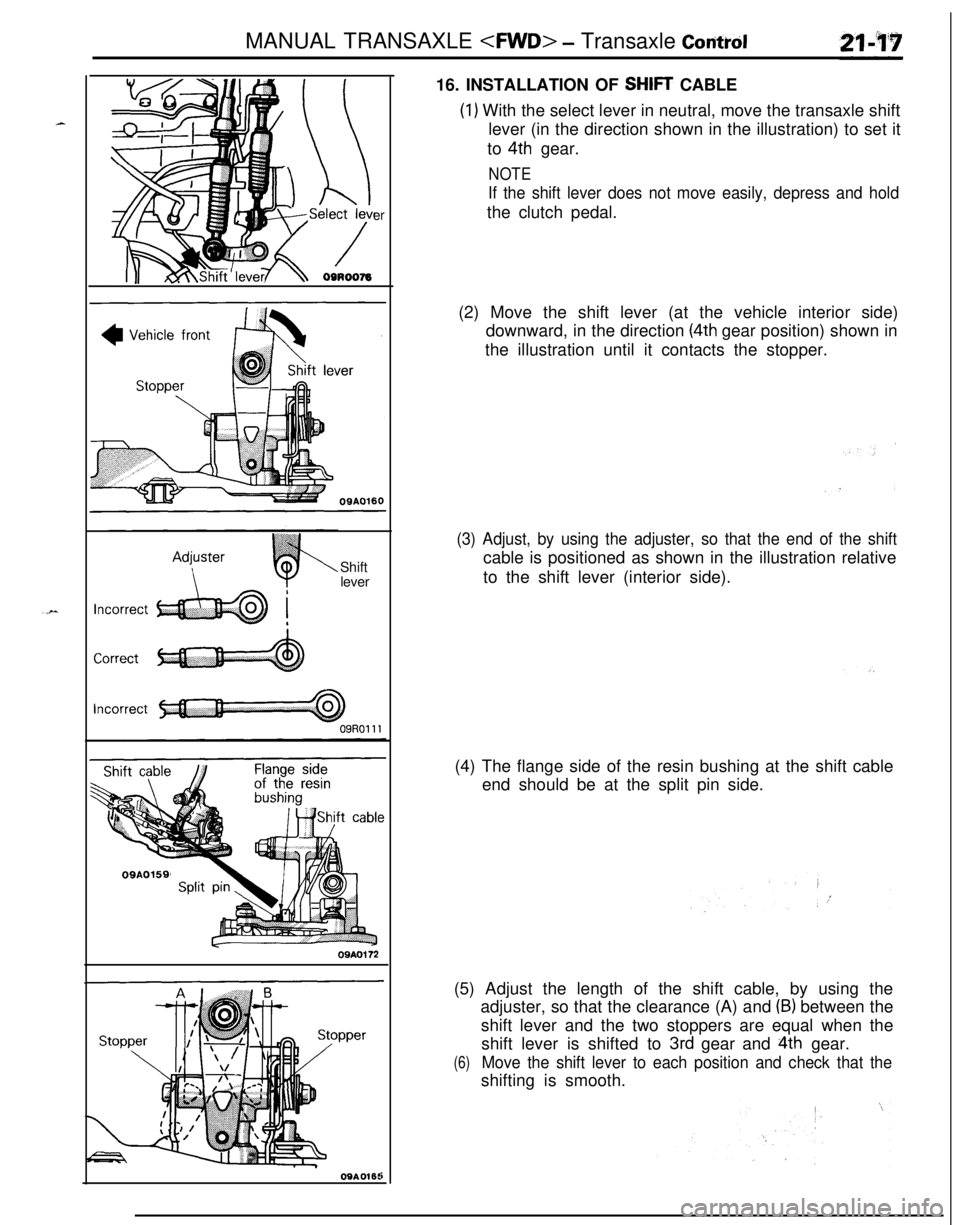

09A016t16. INSTALLATION OF

SHIFT CABLE

(1) With the select lever in neutral, move the transaxle shift

lever (in the direction shown in the illustration) to set it

to

4th gear.

NOTE

If the shift lever does not move easily, depress and holdthe clutch pedal.

(2) Move the shift lever (at the vehicle interior side)

downward, in the direction

(4th gear position) shown in

the illustration until it contacts the stopper.

(3) Adjust, by using the adjuster, so that the end of the shiftcable is positioned as shown in the illustration relative

to the shift lever (interior side).

(4) The flange side of the resin bushing at the shift cable

end should be at the split pin side.

(5) Adjust the length of the shift cable, by using the

adjuster, so that the clearance (A) and

(B) between the

shift lever and the two stoppers are equal when the

shift lever is shifted to

3rd gear and 4th gear.

(6)Move the shift lever to each position and check that theshifting is smooth.

Page 723 of 1216

MANUAL TRANSAXLE

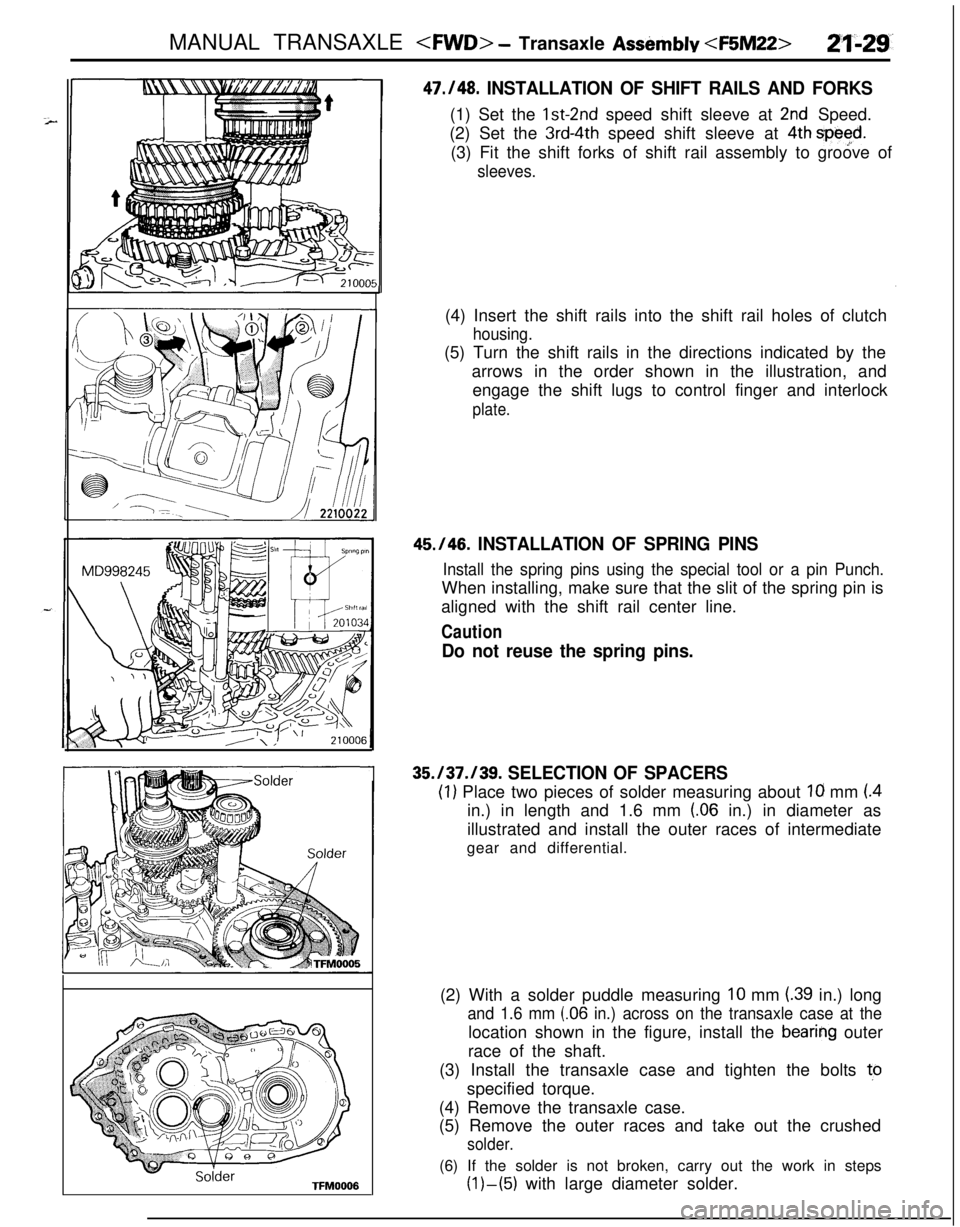

47./48. INSTALLATION OF SHIFT RAILS AND FORKS(1) Set the

lst-2nd speed shift sleeve at 2nd Speed.

(2) Set the

3rd-4th speed shift sleeve at 4th spe$d.(3) Fit the shift forks of shift rail assembly to groove of

sleeves.(4) Insert the shift rails into the shift rail holes of clutch

housing.(5) Turn the shift rails in the directions indicated by the

arrows in the order shown in the illustration, and

engage the shift lugs to control finger and interlock

plate.

45.146. INSTALLATION OF SPRING PINS

Install the spring pins using the special tool or a pin Punch.When installing, make sure that the slit of the spring pin is

aligned with the shift rail center line.

Caution

Do not reuse the spring pins.

35.137.139. SELECTION OF SPACERS

(1) Place two pieces of solder measuring about Ia mm (.4in.) in length and 1.6 mm

(.06 in.) in diameter as

illustrated and install the outer races of intermediate

gear and differential.

(2) With a solder puddle measuring

10 mm (.39 in.) long

and 1.6 mm (.06 in.) across on the transaxle case at thelocation shown in the figure, install the

bearing outer

race of the shaft.

(3) Install the transaxle case and tighten the bolts to

specified torque.

(4) Remove the transaxle case.

(5) Remove the outer races and take out the crushed

solder.(6) If the solder is not broken, carry out the work in steps

(l)-(5) with large diameter solder.

Page 733 of 1216

MANUAL TRANSAXLE

/Shift rail

11-t201034er

2150008

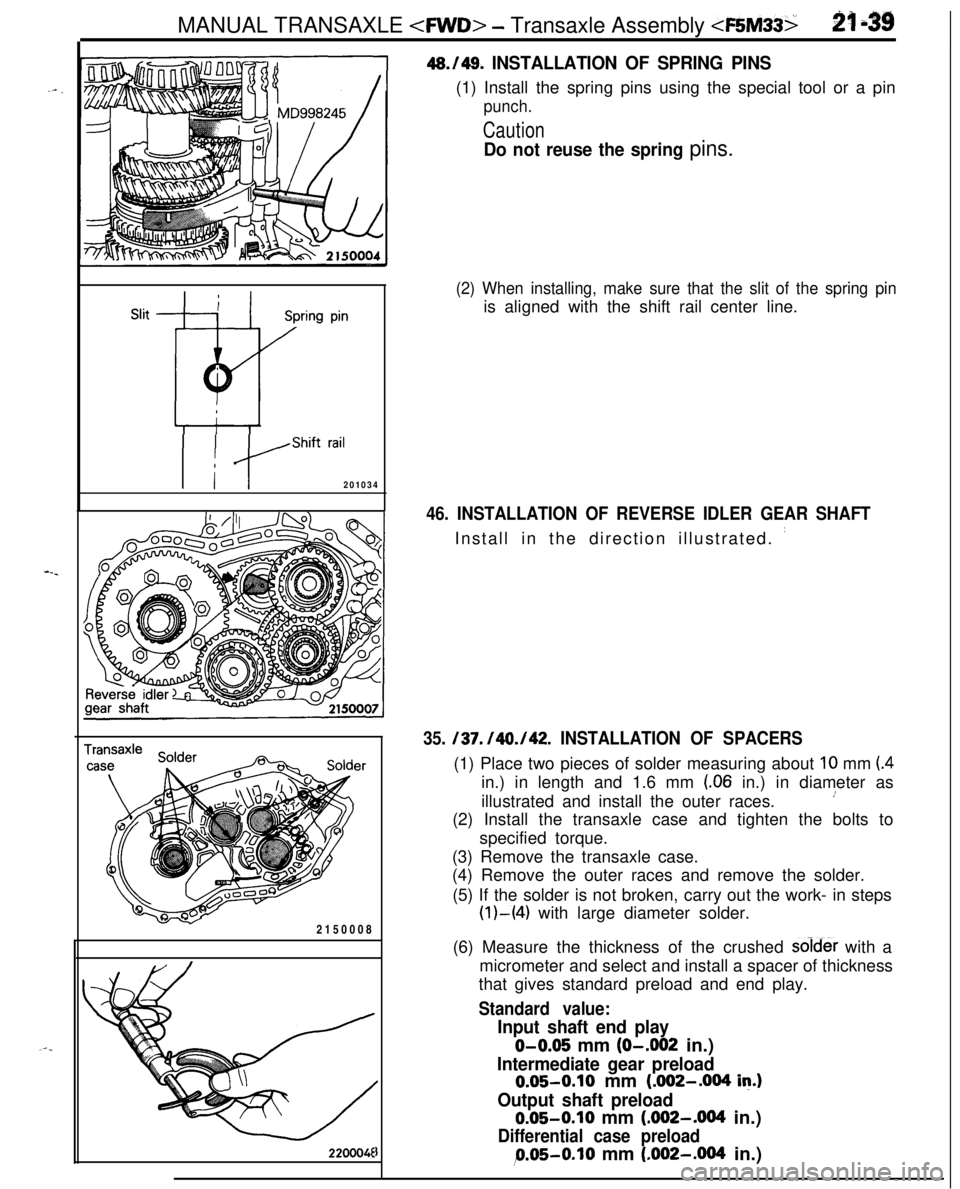

220004E46./49.

INSTALLATION OF SPRING PINS(1) Install the spring pins using the special tool or a pin

punch.

Caution

Do not reuse the spring pins.

(2) When installing, make sure that the slit of the spring pinis aligned with the shift rail center line.

46. INSTALLATION OF REVERSE IDLER GEAR SHAFTInstall in the direction illustrated.

’

35. /37. /40./42. INSTALLATION OF SPACERS(1) Place two pieces of solder measuring about

10 mm (4in.) in length and 1.6 mm

(.06 in.) in diameter as

illustrated and install the outer races.

’(2) Install the transaxle case and tighten the bolts to

specified torque.

(3) Remove the transaxle case.

(4) Remove the outer races and remove the solder.

(5) If the solder is not broken, carry out the work- in steps

(l)-(4) with large diameter solder.

(6) Measure the thickness of the crushed soid& with a

micrometer and select and install a spacer of thickness

that gives standard preload and end play.

Standard value:

Input shaft end play

O-0.05 mm (O-.002 in.)

Intermediate gear preload0.05-0.10 mm (.002-.004

in.)

Output shaft preload0.05-0.10 mm (.092-.004 in.)

Differential case preload

9.05-0.10 mm (.002-.004 in.)

Page 854 of 1216

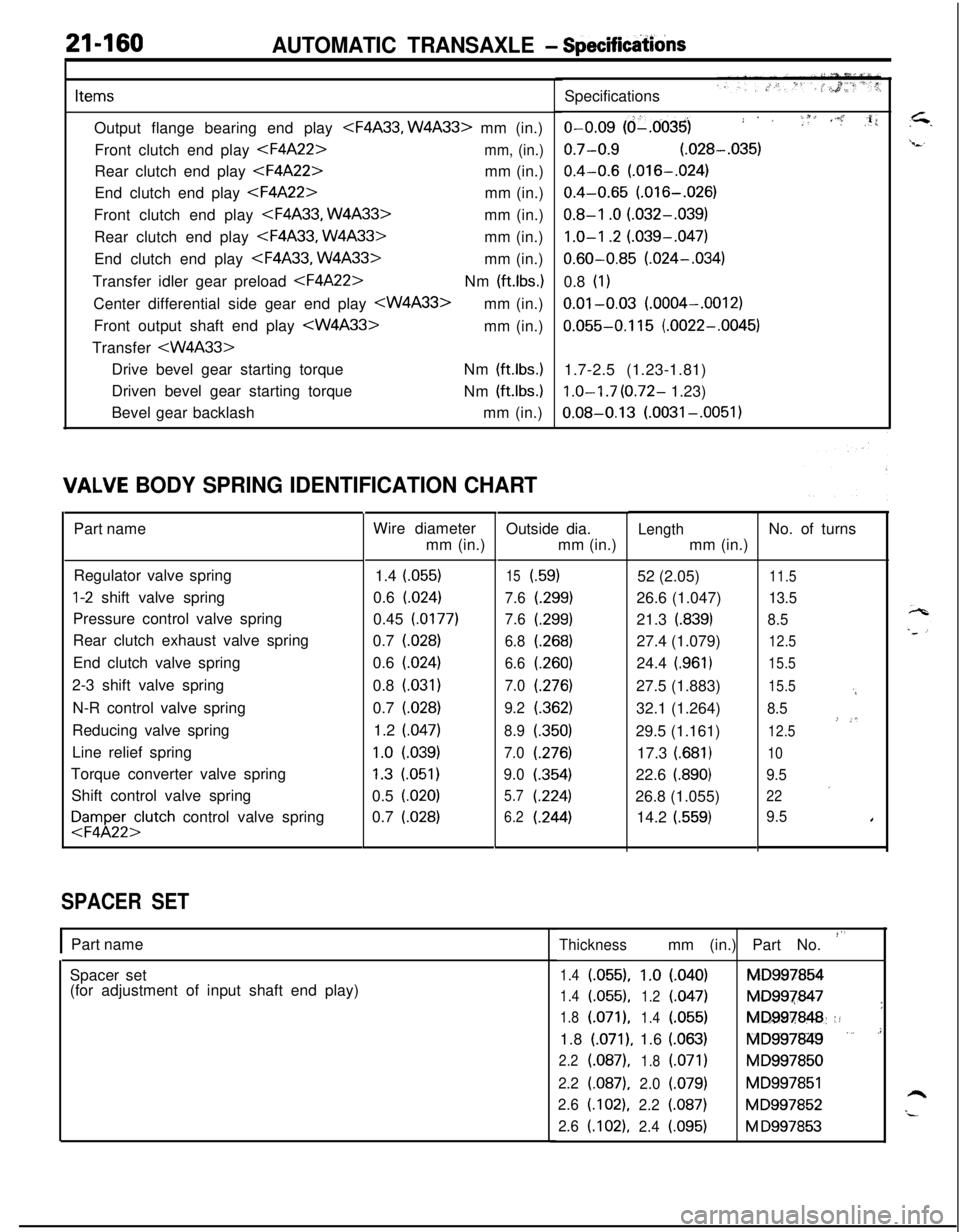

21-160AUTOMATIC TRANSAXLE - Specifidons

ItemsOutput flange bearing end play

Front clutch end play

End clutch end play

Front clutch end play

Rear clutch end play

End clutch end play

Transfer idler gear preload

Front output shaft end play

Transfer

Driven bevel gear starting torque

Bevel gear backlashNm

(ft.lbs.)Nm

(ft.lbs.)mm (in.)

IALVE BODY SPRING IDENTIFICATION CHARTPart name

Regulator valve spring

l-2 shift valve spring

Pressure control valve spring

Rear clutch exhaust valve spring

End clutch valve spring

2-3 shift valve spring

N-R control valve spring

Reducing valve spring

Line relief spring

Torque converter valve spring

Shift control valve spring

FFyl;;;lutch control valve spring

SPACER SETWire diameter

mm (in.)

1.4 (055)

0.6 (024)

0.45 (0177)

0.7 (028)

0.6

(.024)0.8

(.031)0.7 (028)

1.2 (047)

1.0 l.039)

1.3 (051)

0.5 (020)

0.7

(.028)Outside dia.

mm (in.)

15i.59)

7.6

t.299)

7.6(.299)

6.8(.268)

6.6(260)

7.0(276)

9.2(.362)

8.9(350)

7.0(276)

9.0(.354)

5.7(224)

6.2(.244)

IPart name

Spacer set

(for adjustment of input shaft end play)Specifications

o-0.09 (d-.0035); . ,i f 1, ,i’.” :,li

0.7-0.9 (.028-.035)

0.4-0.6 (.016-.024)

0.4-0.65 (.016-.026)

0.8-I .O (.032-.039)

1.0-I .2 (.039-.047)

0.60-0.85 (.024-.034)

0.8

(1)

0.01-0.03 (.0004-.0012)

0.055-0.115 (.0022-.0045)

1.7-2.5 (1.23-1.81)

1.0-I .7 (0.72- 1.23)

0.08-0.13 (.0031-.0051)

Lengthmm (in.)

52 (2.05)

26.6 (1.047)

21.3

(.839)27.4 (1.079)

24.4

(.961)27.5 (1.883)

32.1 (1.264)

29.5 (1.161)

17.3

(.681)22.6

i.890)26.8 (1.055)

14.2

(.559)No. of turns

11.5

13.5

8.5

12.5

15.5

15.5

‘4

8.5

’-*12.5

10

9.5

’22

9.5I

Thicknessmm (in.) Part No. “’

1.4(055).1.0l.040)MD997854

1.4(.055),

1.2(047)MD997847

’1.8(.071),

1.4l.055)MD997848::!1.8

(.071), 1.6 (.063)fQlD997849 ” .’

2.2(.087),

1.8(.071)MD997850

2.2(.087),2.0(.079)MD997851h2.6(.102),2.2(.087)MD997852“-2.6(.102),2.4i.095)M D997853

Page 948 of 1216

AUTOMATIC TRANSAXLE - Transaxle Assemblv

Solder

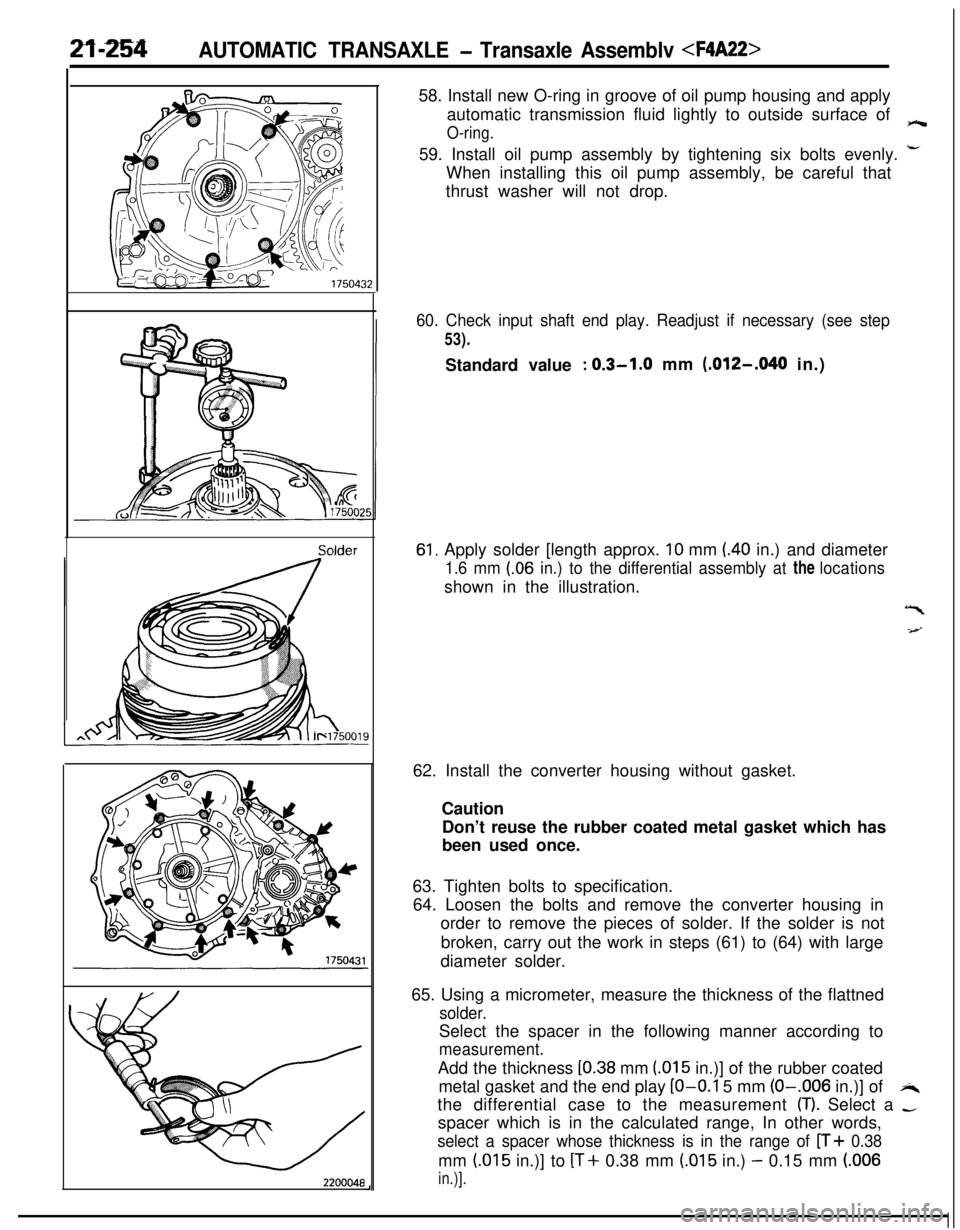

220004858. Install new O-ring in groove of oil pump housing and apply

automatic transmission fluid lightly to outside surface of

O-ring.e59. Install oil pump assembly by tightening six bolts evenly.

i-When installing this oil pump assembly, be careful that

thrust washer will not drop.

60. Check input shaft end play. Readjust if necessary (see step

53).Standard value

: 0.3-1.0 mm (.012-,040 in.)

61, Apply solder [length approx. 10 mm (40 in.) and diameter

1.6 mm (.06 in.) to the differential assembly at the locationsshown in the illustration.

“I

-4--J62. Install the converter housing without gasket.

Caution

Don’t reuse the rubber coated metal gasket which has

been used once.

63. Tighten bolts to specification.

64. Loosen the bolts and remove the converter housing in

order to remove the pieces of solder. If the solder is not

broken, carry out the work in steps (61) to (64) with large

diameter solder.

65. Using a micrometer, measure the thickness of the flattned

solder.Select the spacer in the following manner according to

measurement.Add the thickness

[0.38 mm (015 in.)] of the rubber coated

metal gasket and the end play

LO-O.1 5 mm (O-.006 in.)] ofi4the differential case to the measurement

(T). Select a -spacer which is in the calculated range, In other words,

select a spacer whose thickness is in the range of n+ 0.38mm

(.015 in.)] to [T+ 0.38 mm (.015 in.) - 0.15 mm (.006

in.)].

Page 973 of 1216

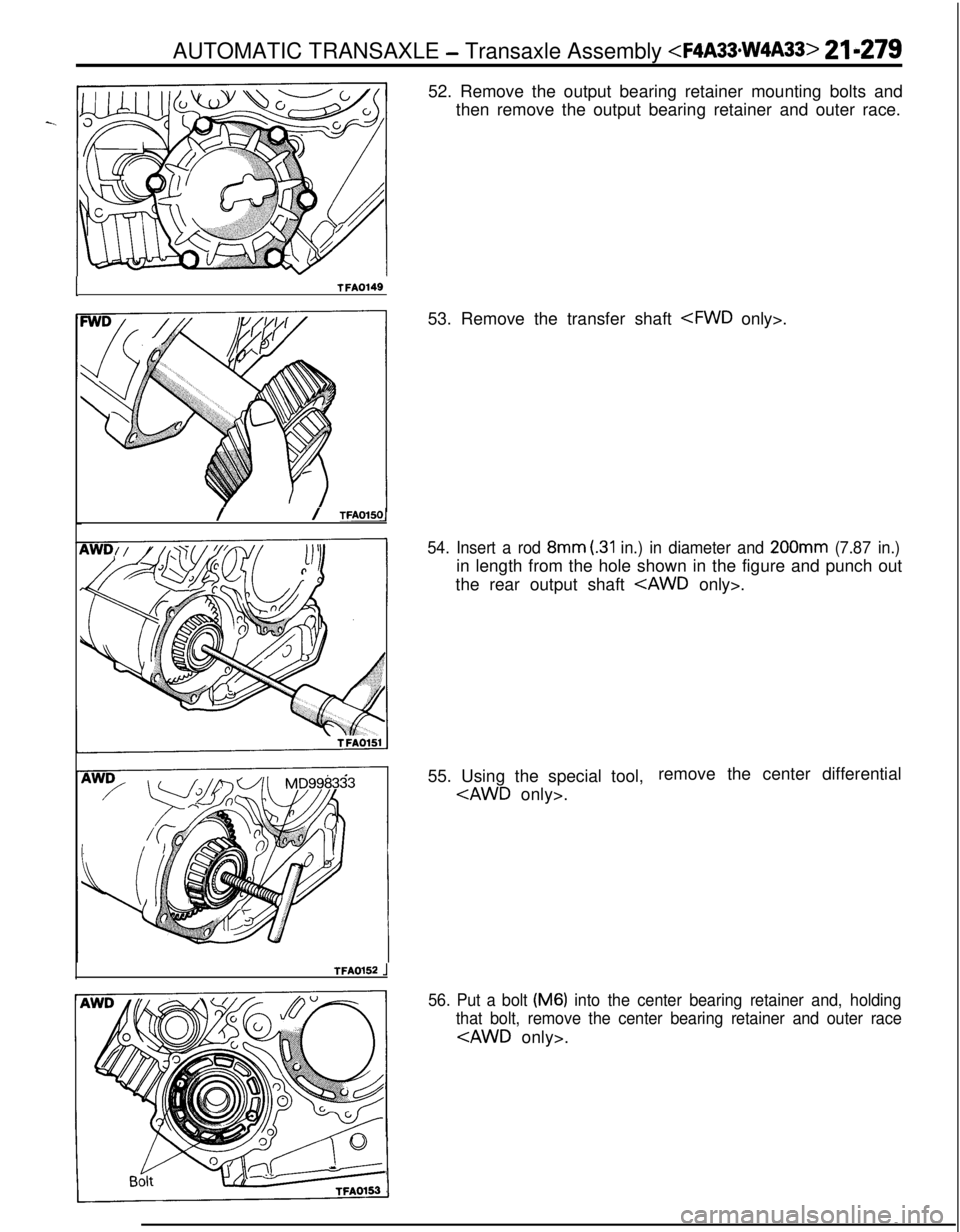

ITFA014952. Remove the output bearing retainer mounting bolts and

then remove the output bearing retainer and outer race.

// TFAOlSOl53. Remove the transfer shaft

54. Insert a rod 8mm (.31 in.) in diameter and 200mm (7.87 in.)in length from the hole shown in the figure and punch out

the rear output shaft

- Transaxle Assembly

TFA0152 .j55. Using the special tool,remove the center differential

56. Put a bolt (M6) into the center bearing retainer and, holding

that bolt, remove the center bearing retainer and outer race