length MITSUBISHI ECLIPSE 1991 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 298 of 1216

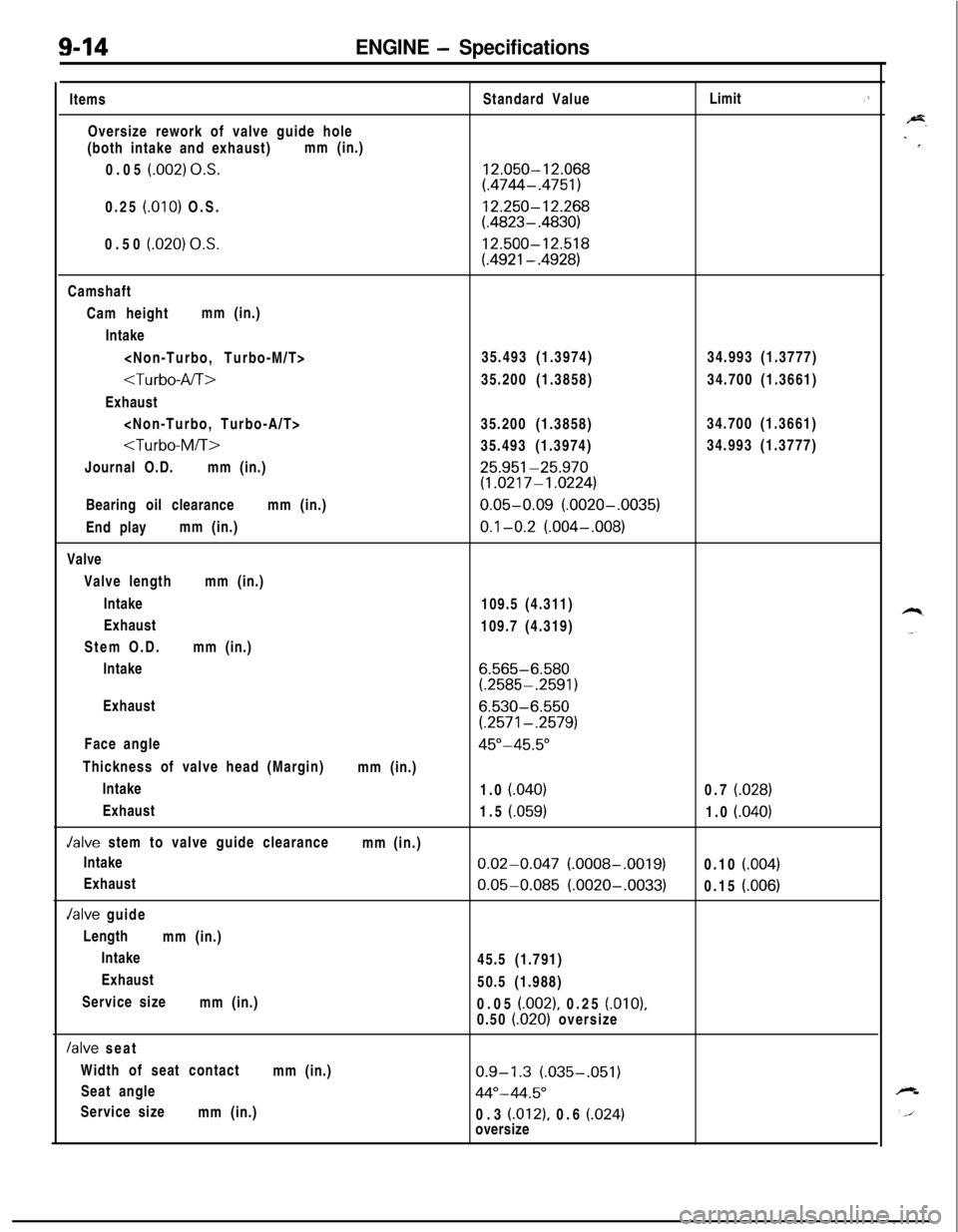

9-14ENGINE - SpecificationsItems

Oversize rework of valve guide hole

(both intake and exhaust)mm (in.)

0.05

(.002) O.S.0.25

(.OlO) O.S.

0.50

(.020) 0,s.Standard Value

12.050-12.068(.4744-.4751)

12.250-12.268(.4823-.4830)

12.500-12.518

(.4921-.4928)Limit

,’Camshaft

Cam heightmm (in.)

Intake

Exhaust

Journal O.D.mm (in.)

25.951-25.970(1.0217-1.0224)Bearing oil clearancemm (in.)

0.05-0.09 (.0020-.0035)End playmm (in.)

0.1-0.2 (.004-,008)Valve

Valve lengthmm (in.)

Intake

109.5 (4.311)

Exhaust

109.7 (4.319)

Stem O.D.mm (in.)

Intake

6.565-6.580(.2585-.2591)Exhaust

6.530-6.550

(.2571-.2579)Face angle

45"-45.5"Thickness of valve head (Margin)

mm (in.)

Intake

1.0

(.040)0.7 (.028)Exhaust

1.5

(.059)1.0 (.040)Jalve stem to valve guide clearance

mm (in.)

Intake

0.02-0.047 (.0008-.0019)0.10 (.004)Exhaust

0.05-0.085 (.0020-.0033)0.15 (.006)Jalve guide

Length

mm (in.)

Intake

45.5 (1.791)

Exhaust

50.5 (1.988)

Service size

mm (in.)

0.05

(.002), 0.25 (.OlO),0.50 (.020) oversize

/alve seat

Width of seat contact

mm (in.)

0.9-1.3 (.035-.051)Seat angle

44"-44.5"Service size

mm (in.)

0.3

(.012), 0.6 (.024)oversize

Page 299 of 1216

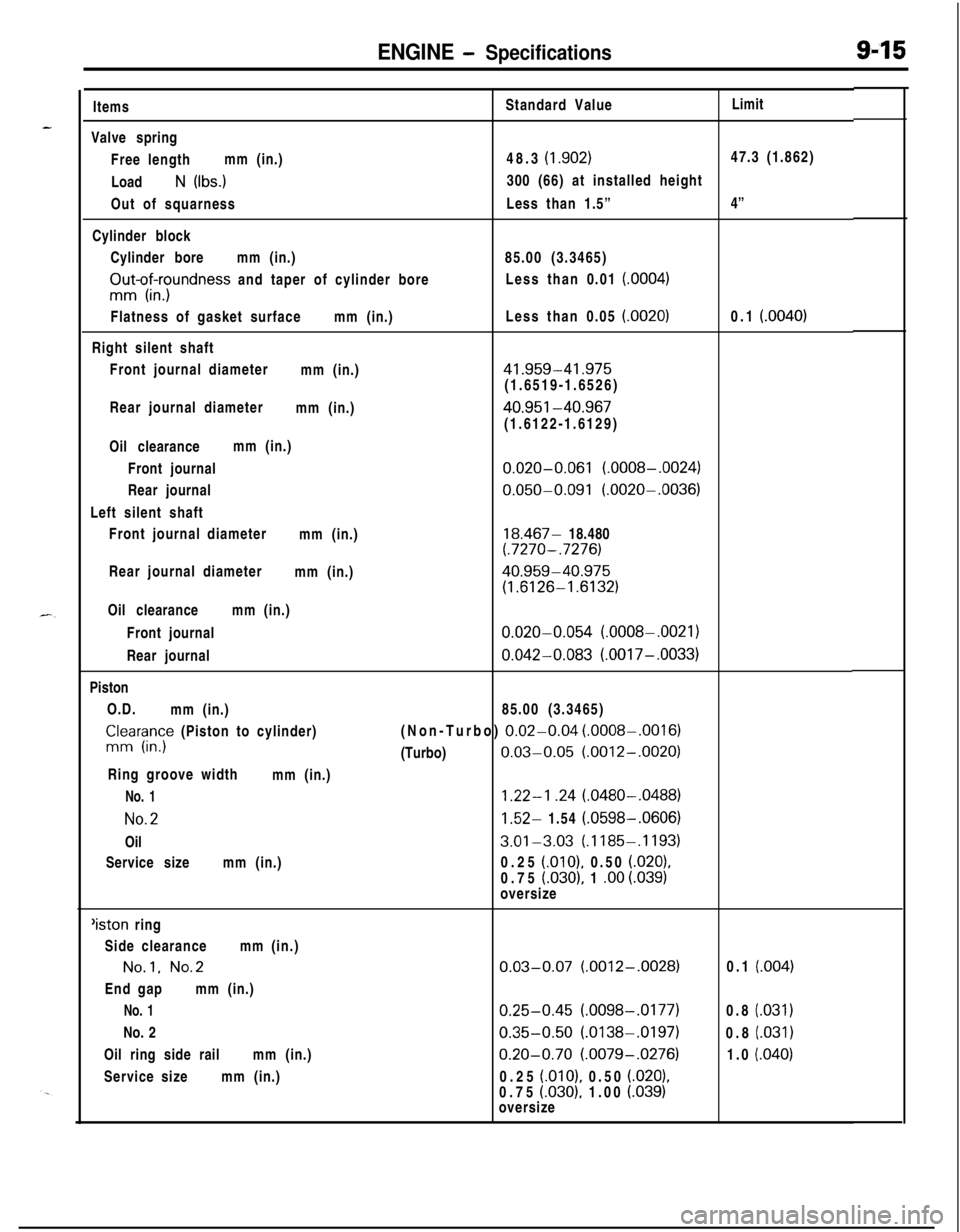

ENGINE - Specifications9-15ItemsStandard ValueLimit

Valve spring

Free lengthmm (in.)48.3

(1.902)47.3 (1.862)

Load

N (Ibs.)300 (66) at installed height

Out of squarnessLess than 1.5”4”

Cylinder block

Cylinder boremm (in.)85.00 (3.3465)

FIu-o$xrndness and taper of cylinder boreLess than 0.01 (0004)Flatness of gasket surfacemm (in.)Less than 0.05

(.0020)0.1 (.0040)Right silent shaft

Front journal diameter

mm (in.)

41.959-41.975(1.6519-1.6526)

Rear journal diameter

mm (in.)

40.951-40.967(1.6122-1.6129)

Oil clearancemm (in.)

Front journal

0.020-0.061 (.0008-.0024)Rear journal

0.050-0.091 (.0020-.0036)Left silent shaft

Front journal diameter

mm (in.)

18.467- 18.480(.7270-.7276)Rear journal diameter

mm (in.)

40.959-40.975

(1.6126-1.6132)Oil clearancemm (in.)

Front journal

0.020-0.054 (.0008-.0021)Rear journal

0.042-0.083 (.0017-.0033)Piston

O.D.

mm (in.)85.00 (3.3465)

CnlIr;;y (Piston to cylinder)(Non-Turbo) 0.02-0.04 (.0008-.0016)(Turbo)

0.03-0.05 (.0012-.0020)Ring groove width

mm (in.)

No. 11.22-l .24 (.0480-.0488)

No.21.52- 1.54 (.0598-.0606)Oil

3.01-3.03 (.1185-.1193)Service sizemm (in.)0.25

(.OlO), 0.50 (.020),0.75

(.030), 1 .oo i.039)oversize‘iston ring

Side clearancemm (in.)

No.1. No.2End gapmm (in.)

No. 1No. 2

Oil ring side railmm (in.)

Service sizemm (in.)

0.03-0.07 (.0012-.0028)

0.25-0.45 (.0098-.0177)

0.35-0.50 (.0138-.0197)

0.20-0.70 (.0079-.0276)0.25

(.OlO), 0.50 (.020),0.75 (030). 1.00 i.039)oversize0.1

(.004)0.8

(.031)0.8

(.031)1.0

(.040)

Page 300 of 1216

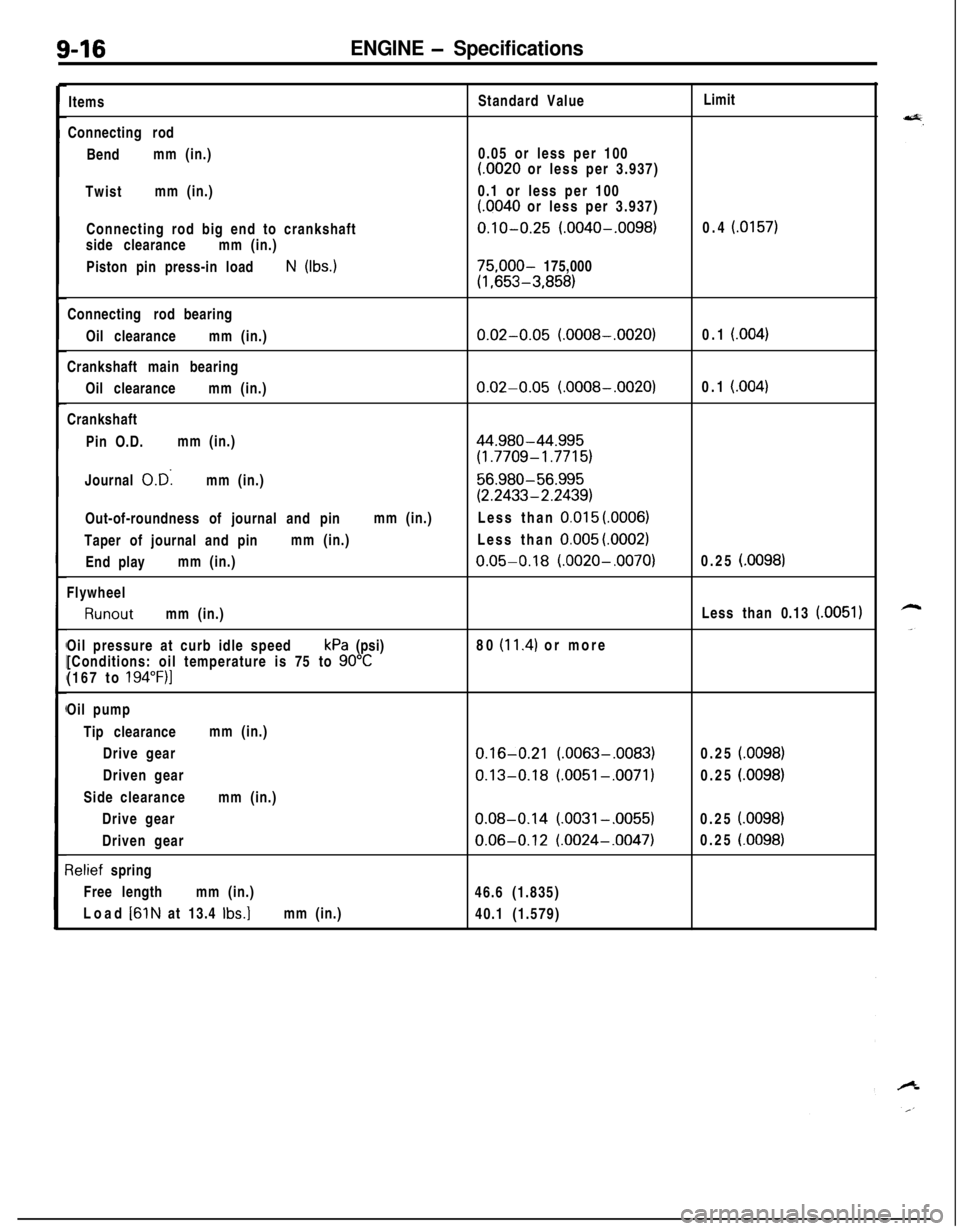

9-16ENGINE - SpecificationsItems

Connecting rod

Bendmm (in.)

Twistmm (in.)

Connecting rod big end to crankshaft

side clearancemm (in.)

Piston pin press-in loadN (Ibs.)Standard Value

0.05 or less per 100

(0020 or less per 3.937)

0.1 or less per 100

(0040 or less per 3.937)

0.10-0.25 (.0040-.0098)

75,000- 175,000

(1,653-3,858)Limit

0.4

(0157)Connectingrod bearing

Oil clearancemm (in.)

Crankshaft main bearing

Oil clearancemm (in.)

Crankshaft

Pin O.D.mm (in.)

Journal

0.D:mm (in.)

Out-of-roundness of journal and pinmm (in.)

Taper of journal and pinmm (in.)

End playmm (in.)

FlywheelRunoutmm (in.)

Oil pressure at curb idle speedkPa (psi)

[Conditions: oil temperature is 75 to

90°C(167 to 194”F)l

0.02-0.05 (.0008-.0020)

0.02-0.05 (.0008-.0020)

44.980-44.995

(1.7709-1.7715)

56.980-56.995

(2.2433-2.2439)Less than

0.015 (.0006)Less than

0.005 (.0002)

0.05-0.18 (.0020-.0070)80

(11.4) or more0.1

(.004)0.1

(004)0.25

LOO981Less than 0.13

(.0051)Oil pump

Tip clearancemm (in.)

Drive gear

0.16-0.21 (.0063-.0083)0.25 f.0098)Driven gear

0.13-0.18 (.0051-.0071)0.25 t.0098)Side clearancemm (in.)

Drive gear

0.08-0.14 (.0031-.0055)0.25 (.0098)Driven gear

0.06-0.12 (.0024-.0047)0.25 i.0098)

qelief spring

Free lengthmm (in.)

46.6 (1.835)

Load

[61N at 13.4 Ibs.]mm (in.)

40.1 (1.579)

Page 331 of 1216

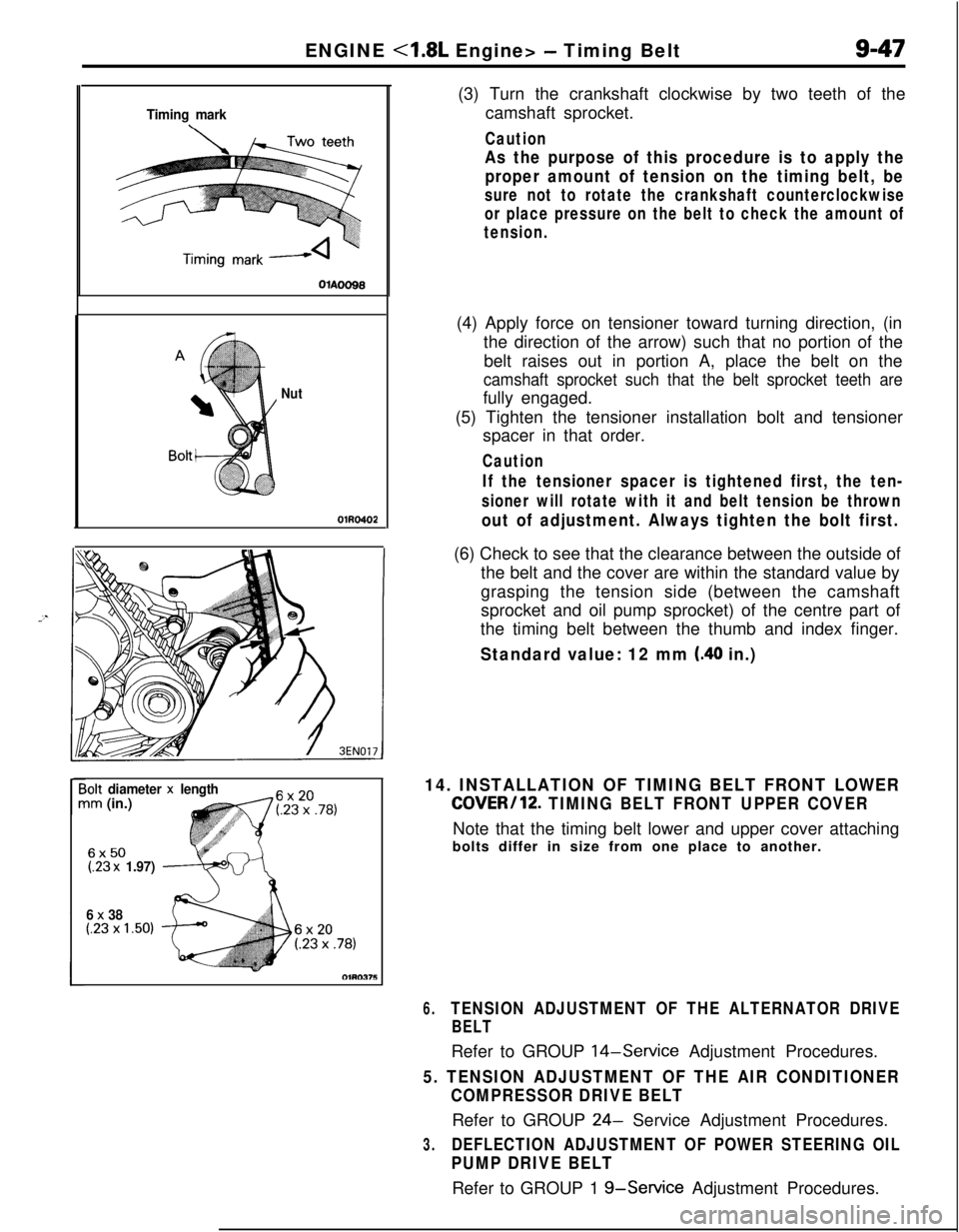

ENGINE <1.8L Engine> - Timing Belt9-47

Timing mark

Nut

;olt diameter x lengthim (in.)

6x50(.23 x 1.97)

6

x 38(.23 x 1.50)(3) Turn the crankshaft clockwise by two teeth of the

camshaft sprocket.

Caution

As the purpose of this procedure is to apply the

proper amount of tension on the timing belt, be

sure not to rotate the crankshaft counterclockwise

or place pressure on the belt to check the amount of

tension.(4) Apply force on tensioner toward turning direction, (in

the direction of the arrow) such that no portion of the

belt raises out in portion A, place the belt on the

camshaft sprocket such that the belt sprocket teeth arefully engaged.

(5) Tighten the tensioner installation bolt and tensioner

spacer in that order.

Caution

If the tensioner spacer is tightened first, the ten-

sioner will rotate with it and belt tension be thrown

out of adjustment. Always tighten the bolt first.(6) Check to see that the clearance between the outside of

the belt and the cover are within the standard value by

grasping the tension side (between the camshaft

sprocket and oil pump sprocket) of the centre part of

the timing belt between the thumb and index finger.

Standard value: 12 mm (.40 in.)

14. INSTALLATION OF TIMING BELT FRONT LOWER

COVER/12. TIMING BELT FRONT UPPER COVERNote that the timing belt lower and upper cover attaching

bolts differ in size from one place to another.

6.TENSION ADJUSTMENT OF THE ALTERNATOR DRIVE

BELTRefer to GROUP

14-Service Adjustment Procedures.

5. TENSION ADJUSTMENT OF THE AIR CONDITIONER

COMPRESSOR DRIVE BELTRefer to GROUP

24- Service Adjustment Procedures.

3.DEFLECTION ADJUSTMENT OF POWER STEERING OIL

PUMP DRIVE BELTRefer to GROUP 1

g-Service Adjustment Procedures.

Page 339 of 1216

ENGINE - Cylinder Head and Valve9-55

3EN026

w -w===j=Margin , EN034

Squareness

IFree length

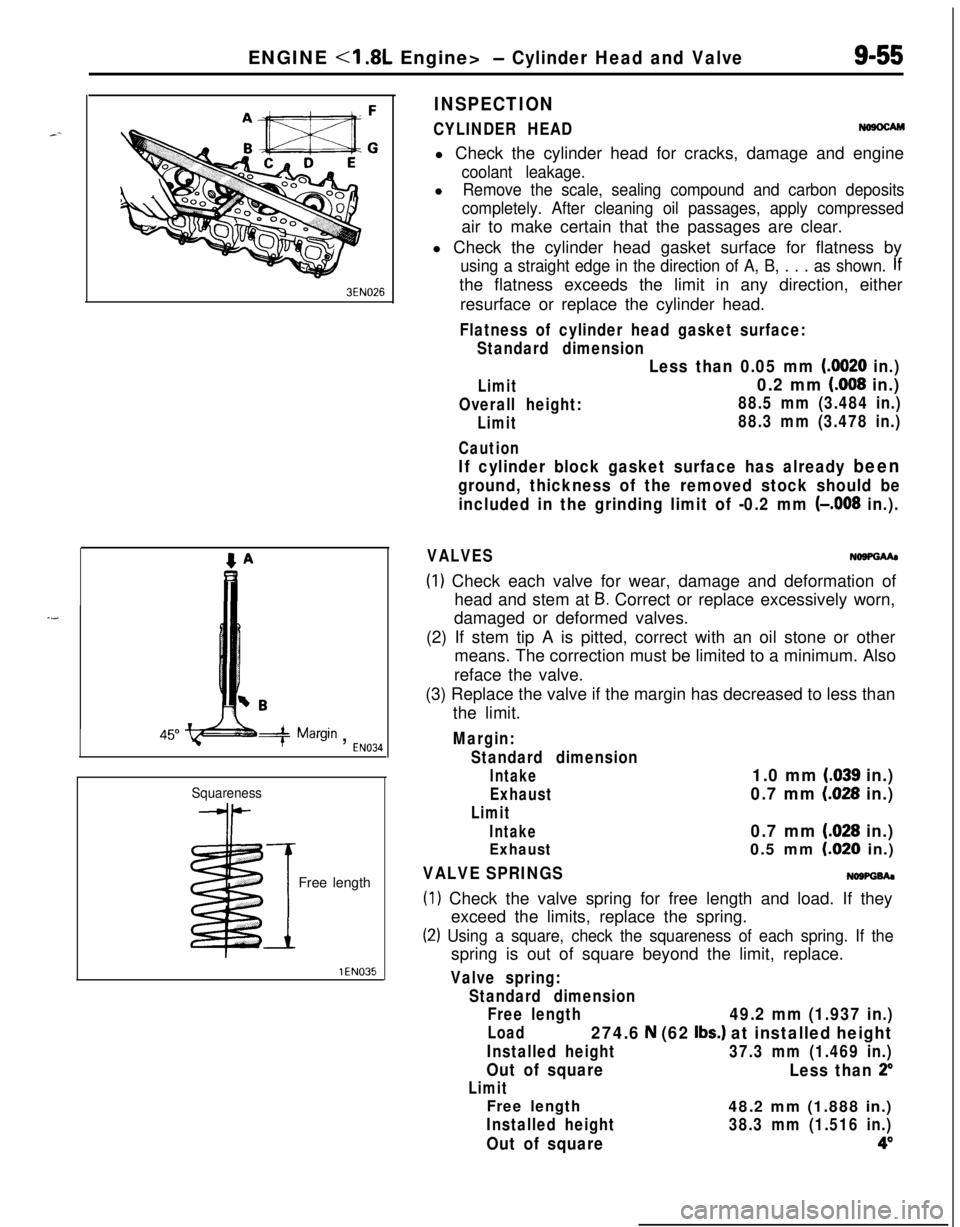

INSPECTION

CYLINDER HEADNosocAMl Check the cylinder head for cracks, damage and engine

coolant leakage.l

Remove the scale, sealing compound and carbon deposits

completely. After cleaning oil passages, apply compressedair to make certain that the passages are clear.

l Check the cylinder head gasket surface for flatness by

using a straight edge in the direction of A, B, . . . as shown. Ifthe flatness exceeds the limit in any direction, either

resurface or replace the cylinder head.

Flatness of cylinder head gasket surface:

Standard dimension

Limit

Overall height:

Limit

Caution

Less than 0.05 mm (0020 in.)

0.2 mm (008 in.)

88.5 mm (3.484 in.)

88.3 mm (3.478 in.)

If cylinder block gasket surface has already been

ground, thickness of the removed stock should be

included in the grinding limit of -0.2 mm

(-,008 in.).

VALVESNo9PGMa

(1) Check each valve for wear, damage and deformation of

head and stem at

B. Correct or replace excessively worn,

damaged or deformed valves.

(2) If stem tip A is pitted, correct with an oil stone or other

means. The correction must be limited to a minimum. Also

reface the valve.

(3) Replace the valve if the margin has decreased to less than

the limit.

Margin:

Standard dimension

Intake1.0 mm (.039 in.)

Exhaust0.7 mm (028 in.)

Limit

Intake0.7 mm (.028 in.)

Exhaust0.5 mm LO20 in.)

VALVE SPRINGSNOWGh

(1) Check the valve spring for free length and load. If they

exceed the limits, replace the spring.

(2) Using a square, check the squareness of each spring. If thespring is out of square beyond the limit, replace.

Valve spring:

Standard dimension

Free length

49.2 mm (1.937 in.)

Load274.6 N (62 Ibs.) at installed height

Installed height37.3 mm (1.469 in.)

Out of square

Less than 2”

Limit

Free length48.2 mm (1.888 in.)

Installed height38.3 mm (1.516 in.)

Out of square4”

Page 347 of 1216

ENGINE <1.8L Engine> -Front Case, Oil Pump and Silent Shaft9-63

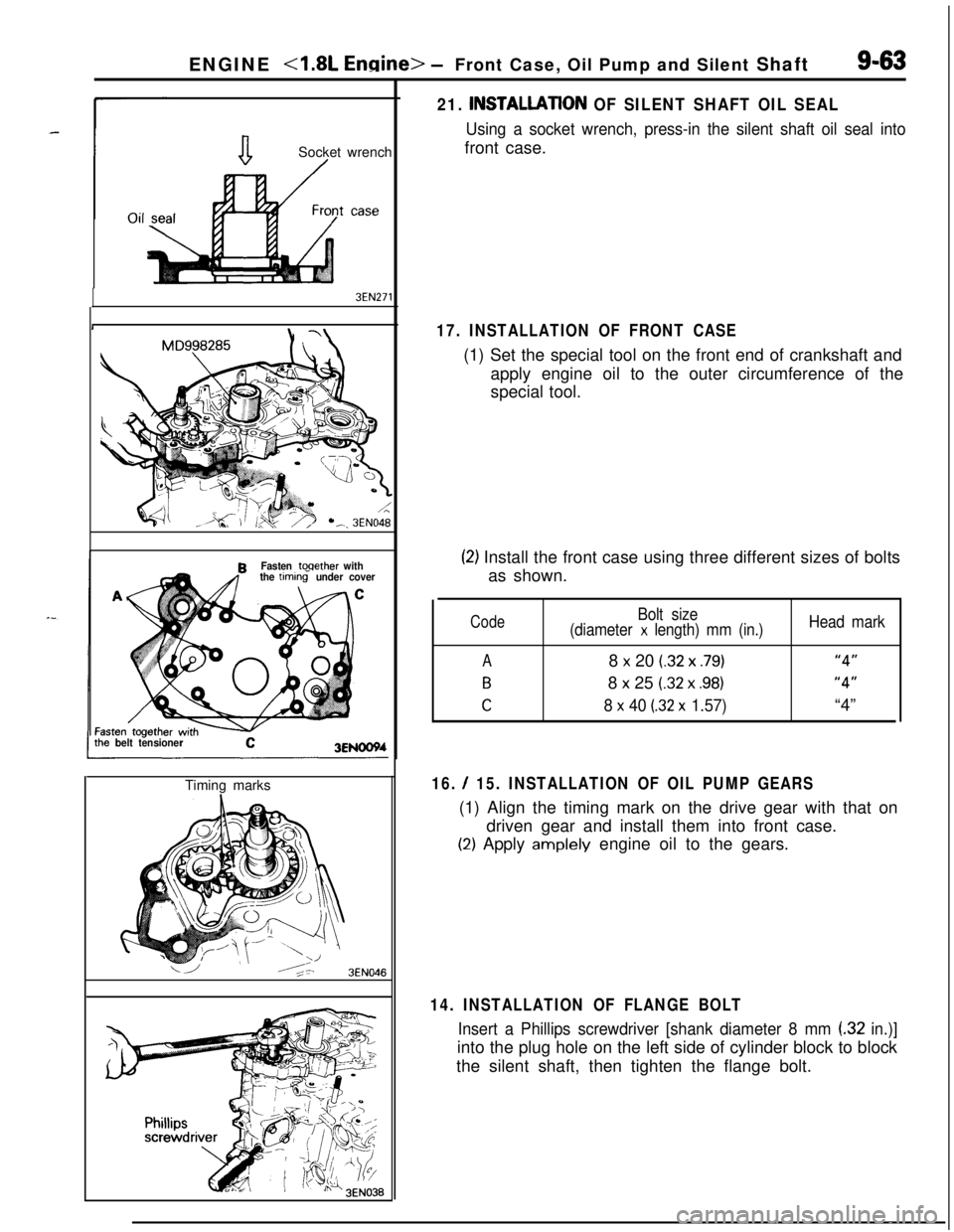

aSocket wrench/

3EN271

MD998285R

Fasten toqether with

the timtins under cover

C

belt tensioner3ENOOWTiming marks

16. / 15. INSTALLATION OF OIL PUMP GEARS(1) Align the timing mark on the drive gear with that on

driven gear and install them into front case.

(2) Apply amplely engine oil to the gears.

3EN046

21. INSTALLATlON OF SILENT SHAFT OIL SEAL

Using a socket wrench, press-in the silent shaft oil seal intofront case.

17. INSTALLATION OF FRONT CASE(1) Set the special tool on the front end of crankshaft and

apply engine oil to the outer circumference of the

special tool.

(2) Install the front case using three different sizes of bolts

as shown.

Code

A

B

C

Bolt size

(diameter x length) mm (in.)8

x 20 (.32 x .79)8

x 25 (.32 x .98)

8 x 40 (32 x 1.57)

Head mark

“4”

“4”“4”

14. INSTALLATION OF FLANGE BOLT

Insert a Phillips screwdriver [shank diameter 8 mm (32 in.)]into the plug hole on the left side of cylinder block to block

the silent shaft, then tighten the flange bolt.

Page 354 of 1216

ENGINE <1.8L Engine> -Crankshaft, Flywheel and Drive Plate

3EN055

6EN043

1 EN067

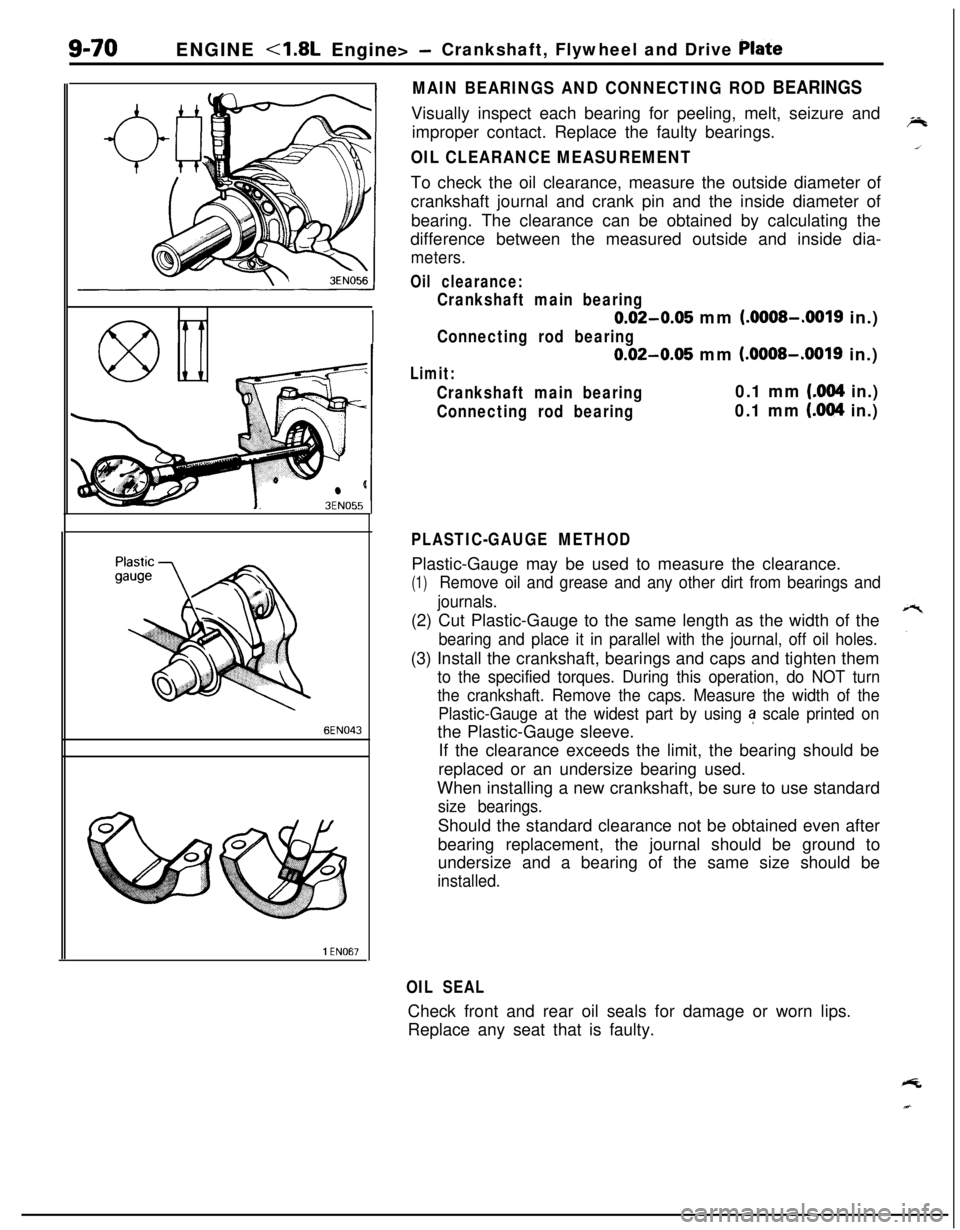

MAIN BEARINGS AND CONNECTING ROD BEARINGSVisually inspect each bearing for peeling, melt, seizure and

improper contact. Replace the faulty bearings.

OIL CLEARANCE MEASUREMENTTo check the oil clearance, measure the outside diameter of

crankshaft journal and crank pin and the inside diameter of

bearing. The clearance can be obtained by calculating the

difference between the measured outside and inside dia-

meters.

Oil clearance:

Crankshaft main bearing

0.02-0.05 mm (.OOOS-.0019 in.)

Connecting rod bearing

0.02-0.05 mm (.OOOS-.0019 in.)

Limit:

Crankshaft main bearing0.1 mm (.004 in.)

Connecting rod bearing0.1 mm (.004 in.)

PLASTIC-GAUGE METHODPlastic-Gauge may be used to measure the clearance.

(1)Remove oil and grease and any other dirt from bearings and

journals.(2) Cut Plastic-Gauge to the same length as the width of the

bearing and place it in parallel with the journal, off oil holes.(3) Install the crankshaft, bearings and caps and tighten them

to the specified torques. During this operation, do NOT turn

the crankshaft. Remove the caps. Measure the width of the

Plastic-Gauge at the widest part by using

a scale printed onthe Plastic-Gauge sleeve.

If the clearance exceeds the limit, the bearing should be

replaced or an undersize bearing used.

When installing a new crankshaft, be sure to use standard

size bearings.Should the standard clearance not be obtained even after

bearing replacement, the journal should be ground to

undersize and a bearing of the same size should be

installed.

OIL SEALCheck front and rear oil seals for damage or worn lips.

Replace any seat that is faulty.

Page 410 of 1216

9-126ENGINE <2.0L DOHC Engine>- Front Case, Oil Pump and Silent Shaft

6EN0213

w Crank pulley side

Oil pan

from lower side

‘- Apply sealant7LUOOO0

6LUOO49 tBracket side

-----Be

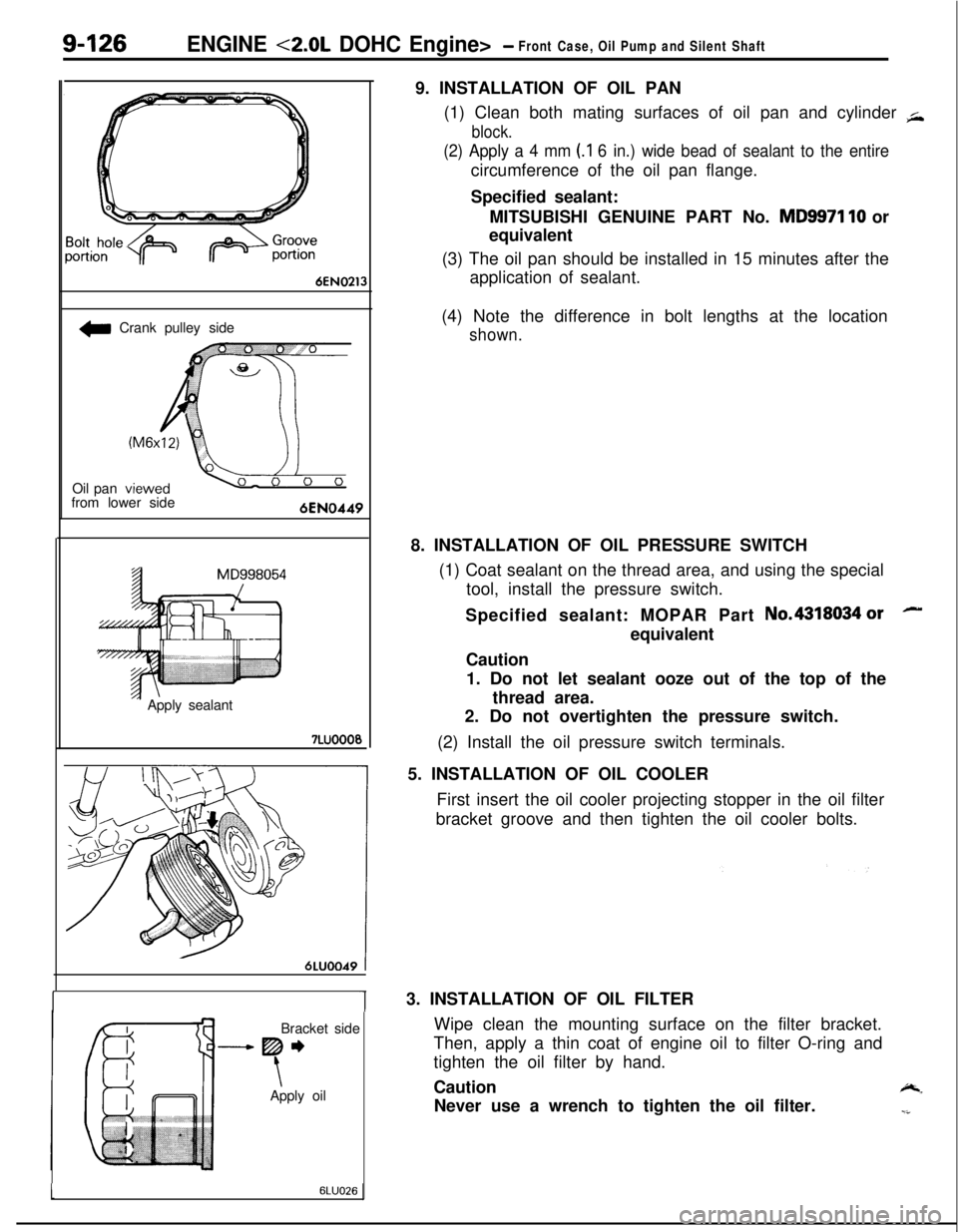

\Apply oil9. INSTALLATION OF OIL PAN

(1) Clean both mating surfaces of oil pan and cylinder

+

block.

(2) Apply a 4 mm (.I 6 in.) wide bead of sealant to the entirecircumference of the oil pan flange.

Specified sealant:

MITSUBISHI GENUINE PART No.

MD9971 10 or

equivalent

(3) The oil pan should be installed in 15 minutes after the

application of sealant.

(4) Note the difference in bolt lengths at the location

shown.8. INSTALLATION OF OIL PRESSURE SWITCH

(1) Coat sealant on the thread area, and using the special

tool, install the pressure switch.

Specified sealant: MOPAR Part No.4318034

orequivalent

Caution

1. Do not let sealant ooze out of the top of the

thread area.

2. Do not overtighten the pressure switch.

(2) Install the oil pressure switch terminals.

5. INSTALLATION OF OIL COOLER

First insert the oil cooler projecting stopper in the oil filter

bracket groove and then tighten the oil cooler bolts.lu3. INSTALLATION OF OIL FILTER

Wipe clean the mounting surface on the filter bracket.

Then, apply a thin coat of engine oil to filter O-ring and

tighten the oil filter by hand.

Caution

-.Never use a wrench to tighten the oil filter.

-i

16LUO26

Page 417 of 1216

ENGINE <2.0L DOHC Engine>- Crankshaft, Flywheel and Drive Plate,91133

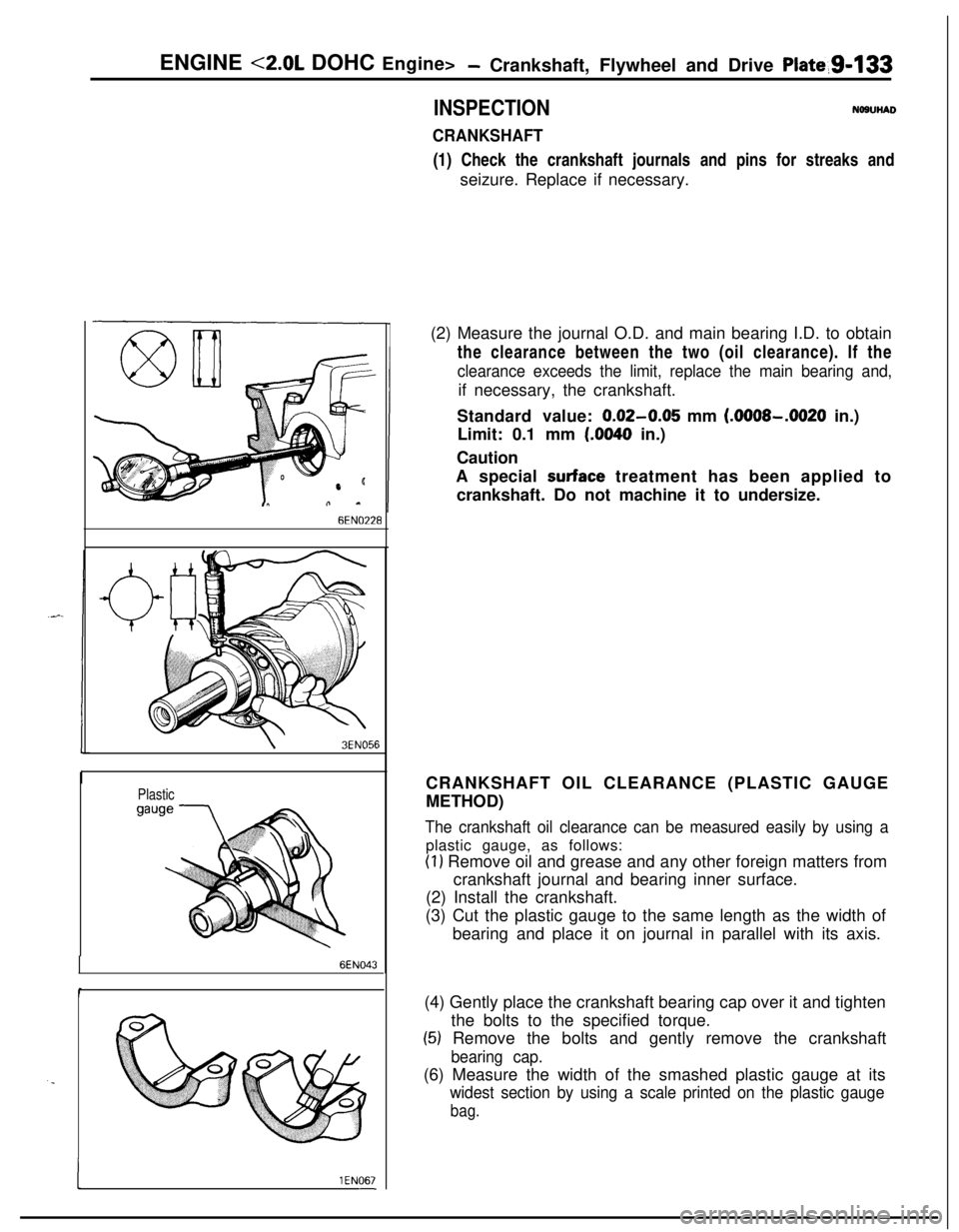

INSPECTIONNOSUHAD

CRANKSHAFT(1) Check the crankshaft journals and pins for streaks and

seizure. Replace if necessary.

6EN0’228

\3EN056

Plastic

6EN043

. .

I1 EN067-(2) Measure the journal O.D. and main bearing I.D. to obtain

the clearance between the two (oil clearance). If the

clearance exceeds the limit, replace the main bearing and,if necessary, the crankshaft.

Standard value:

0.02-0.05 mm (.OOOS-.0020 in.)

Limit: 0.1 mm

(.0040 in.)

Caution

A special

surface treatment has been applied to

crankshaft. Do not machine it to undersize.

CRANKSHAFT OIL CLEARANCE (PLASTIC GAUGE

METHOD)

The crankshaft oil clearance can be measured easily by using aplastic gauge, as follows:

(1) Remove oil and grease and any other foreign matters from

crankshaft journal and bearing inner surface.

(2) Install the crankshaft.

(3) Cut the plastic gauge to the same length as the width of

bearing and place it on journal in parallel with its axis.

(4) Gently place the crankshaft bearing cap over it and tighten

the bolts to the specified torque.

(5) Remove the bolts and gently remove the crankshaft

bearing cap.(6) Measure the width of the smashed plastic gauge at its

widest section by using a scale printed on the plastic gauge

bag.

Page 598 of 1216

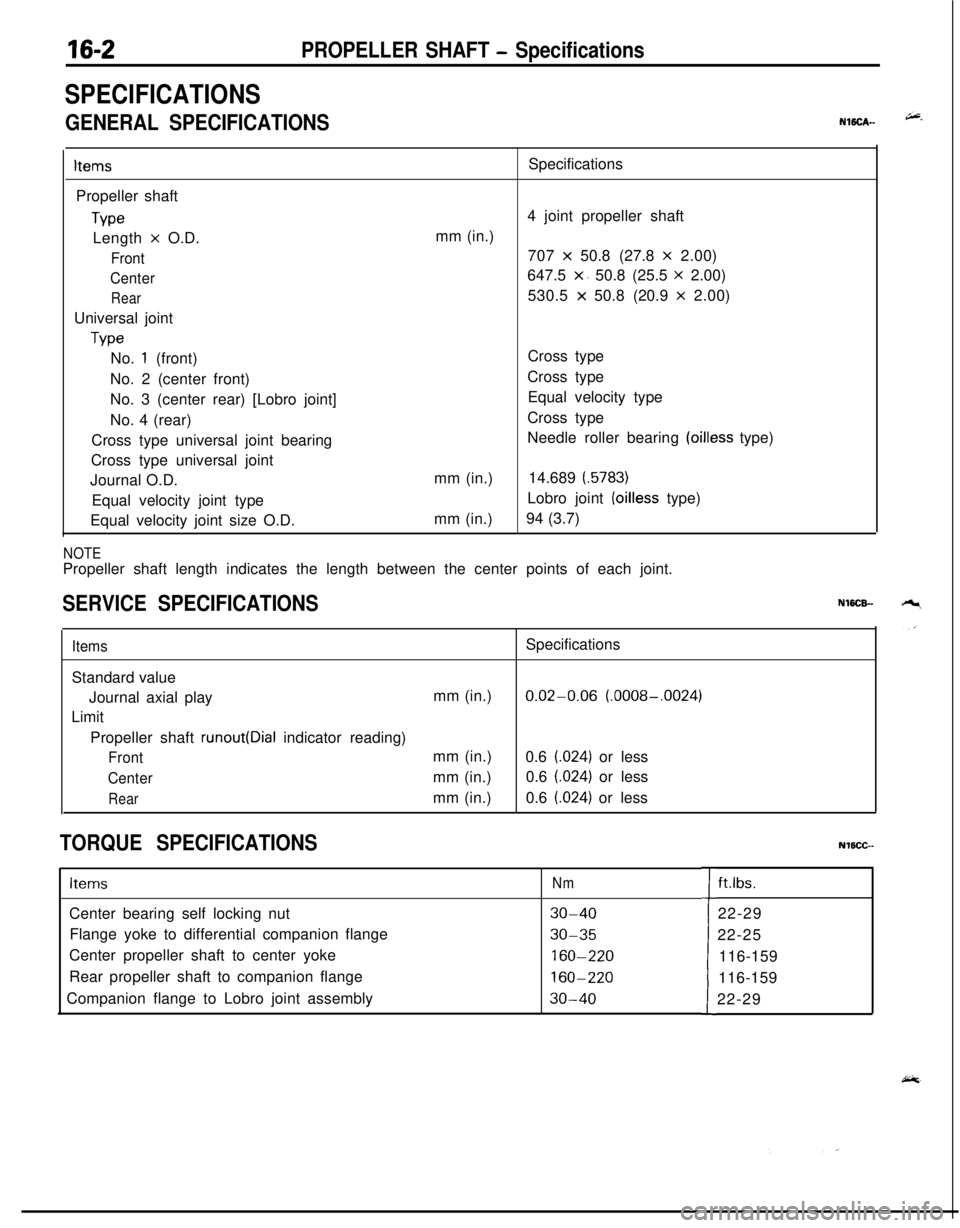

16-2PROPELLER SHAFT - Specifications

SPECIFICATIONS

GENERAL SPECIFICATIONSNWCA--

ItemsPropeller shaft

TypeLength

x O.D.

Front

Center

RearUniversal joint

TypeSpecifications

4 joint propeller shaft

mm (in.)

707

x 50.8 (27.8 x 2.00)

647.5

x. 50.8 (25.5 x 2.00)

530.5

x 50.8 (20.9 x 2.00)

No.

1 (front)

No. 2 (center front)

No. 3 (center rear) [Lobro joint]

No. 4 (rear)

Cross type universal joint bearing

Cross type universal joint

Journal O.D.

Equal velocity joint type

Equal velocity joint size O.D.mm (in.)

mm (in.)Cross type

Cross type

Equal velocity type

Cross type

Needle roller bearing

(oilless type)

14.689

(.5783)Lobro joint

(oilless type)

94 (3.7)

NOTEPropeller shaft length indicates the length between the center points of each joint.

SERVICE SPECIFICATIONSNWCB-

ItemsSpecifications

Standard value

Journal axial playmm (in.)

0.02-0.06 (.0008-.0024)

Limit

Propeller shaft

runout(Dial indicator reading)

Frontmm (in.)

0.6 (.024) or less

Centermm (in.)0.6 (.024) or less

Rearmm (in.)0.6 (.024) or less

TORQUE SPECIFICATIONSNlBCC--

ItemsNmCenter bearing self locking nut

30-40Flange yoke to differential companion flange

30-35Center propeller shaft to center yoke

160-220Rear propeller shaft to companion flange

160-220Companion flange to Lobro joint assembly

30-40tft.lbs.

22-29

22-25

116-159

116-159

22-29