warning light MITSUBISHI ECLIPSE 1991 Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 1063 of 1216

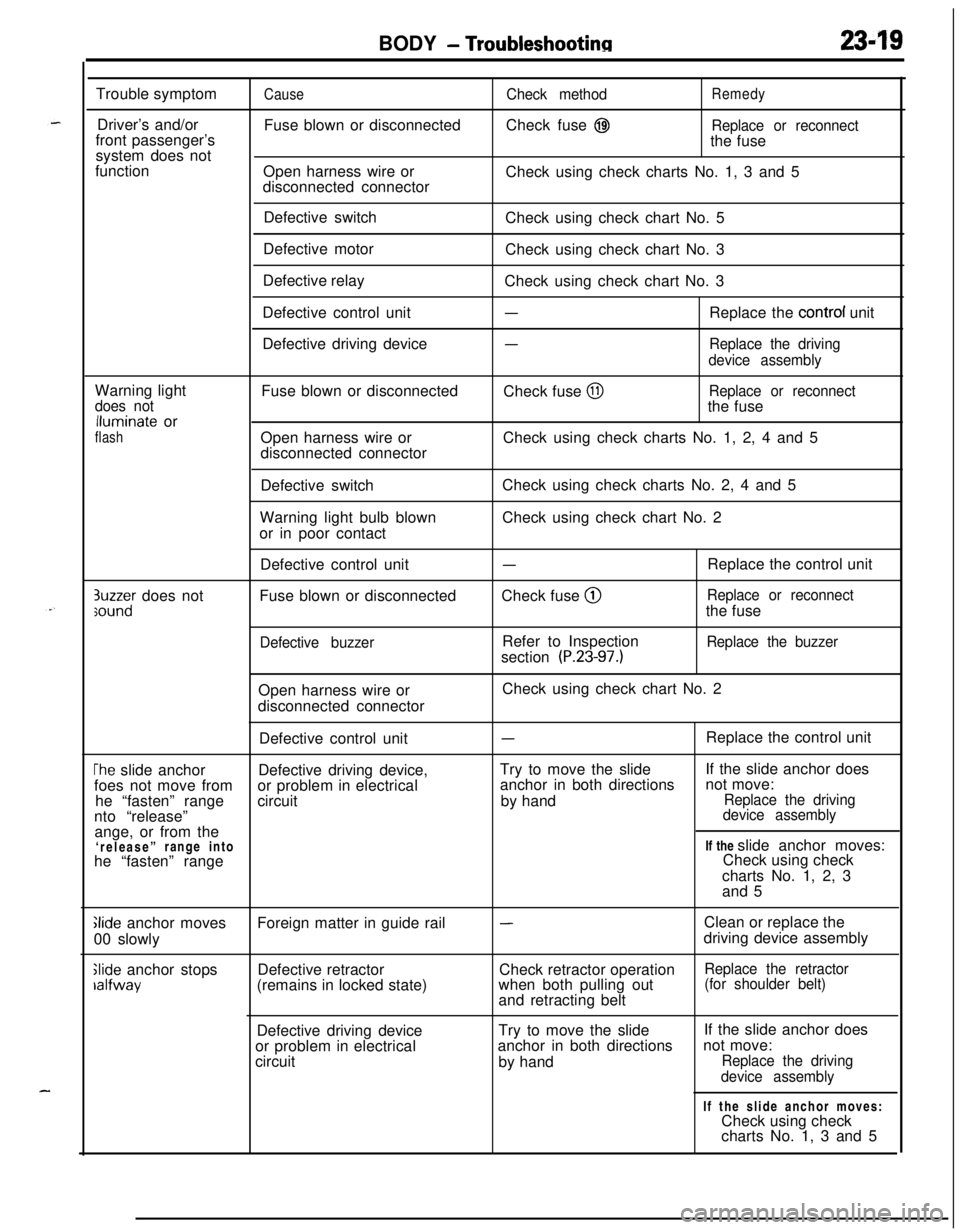

BODY - Troubleshootinn2349Trouble symptom

Driver’s and/or

front passenger’s

system does not

function

CauseFuse blown or disconnected

Open harness wire or

disconnected connectorCheck methodRemedyCheck fuse

@IReplace or reconnectthe fuse

Check using check charts No. 1, 3 and 5

Defective switch

Defective motor

Defective relay

Defective control unit

Defective driving deviceCheck using check chart No. 5

Check using check chart No. 3

Check using check chart No. 3

-Replace the control unit

-Replace the driving

device assemblyWarning light

does notlluminate or

flashFuse blown or disconnected

Open harness wire or

disconnected connectorCheck fuse

@IReplace or reconnectthe fuse

Check using check charts No. 1, 2, 4 and 5

Defective switch

Warning light bulb blown

or in poor contactCheck using check charts No. 2, 4 and 5

Check using check chart No. 2

3uzzer does notsoundDefective control unit

Fuse blown or disconnected

Defective buzzer

-Check fuse @

Refer to Inspection

section

(P.23-97.)Replace the control unit

Replace or reconnectthe fuse

Replace the buzzerOpen harness wire or

disconnected connectorCheck using check chart No. 2

Defective control unit

-Replace the control unit

The slide anchorDefective driving device,Try to move the slideIf the slide anchor does

foes not move fromor problem in electricalanchor in both directionsnot move:

he “fasten” rangecircuitby hand

Replace the drivingnto “release”device assemblyange, or from the

‘release”range intoIf the slide anchor moves:

he “fasten” rangeCheck using check

charts No. 1, 2, 3

and 5

Glide anchor moves

00 slowly

Slide anchor stopsralfwayForeign matter in guide rail

Defective retractor

(remains in locked state)

-Clean or replace the

driving device assembly

Check retractor operation

Replace the retractorwhen both pulling out(for shoulder belt)and retracting belt

Defective driving deviceTry to move the slide

or problem in electricalanchor in both directions

circuit

by handIf the slide anchor does

not move:

Replace the driving

device assemblyIf the slide anchor moves:

Check using check

charts No. 1, 3 and 5

Page 1064 of 1216

23-20BODY - Troubleshooting

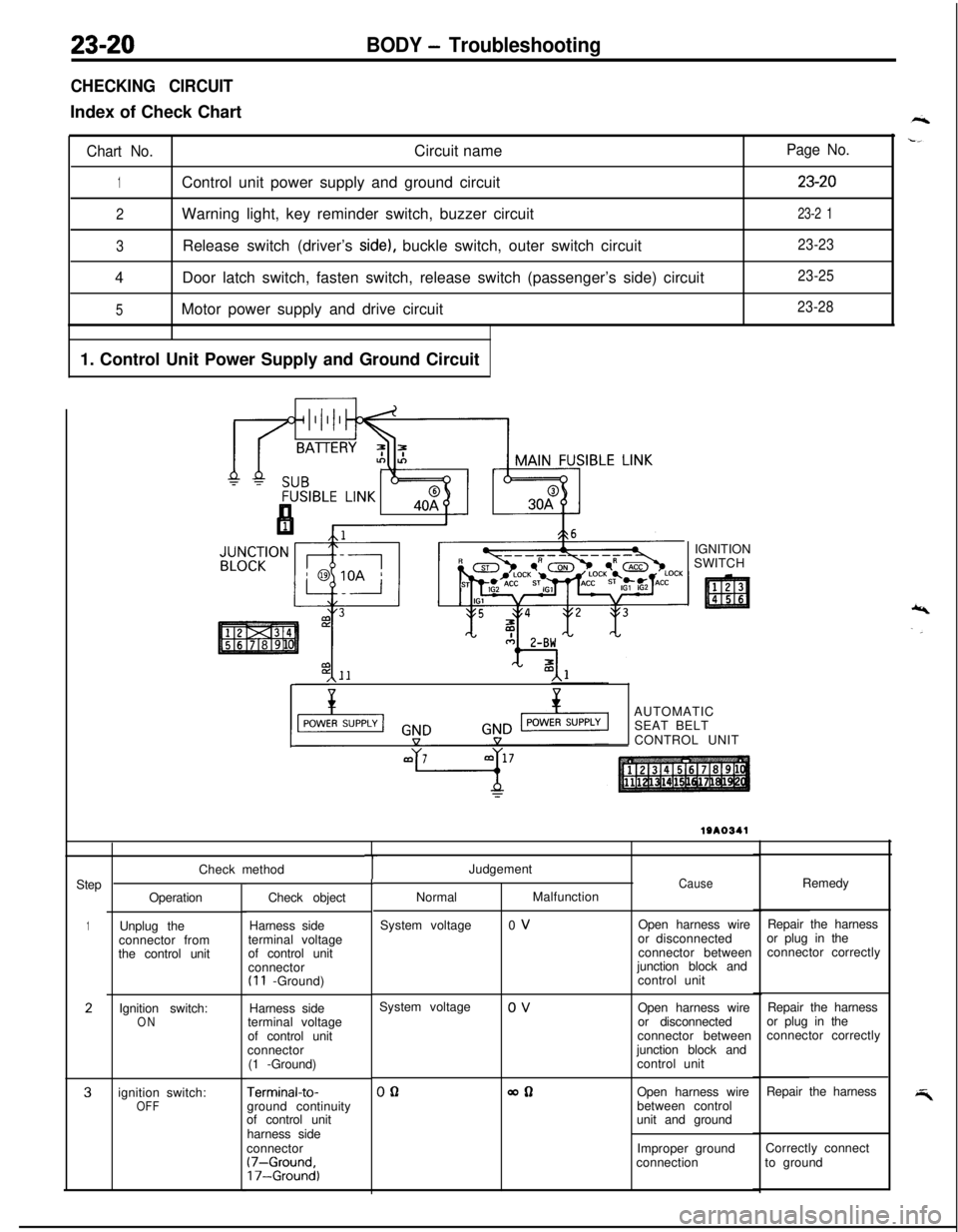

CHECKING CIRCUITIndex of Check Chart

Chart No.Circuit name

1Control unit power supply and ground circuit

2Warning light, key reminder switch, buzzer circuit

3Release switch (driver’s side), buckle switch, outer switch circuit

4Door latch switch, fasten switch, release switch (passenger’s side) circuit

5Motor power supply and drive circuit

1. Control Unit Power Supply and Ground Circuit

Page No.

23-20

23-2 1

23-23

23-25

23-28IGNITION

SWITCH

,\--AUTOMATIC

SEAT BELT

CONTROL UNIT

Step

1

2

3Check method

Operation

Unplug the

connector from

the control unit

Ignition switch:

ONignition switch:

OFFCheck object

Harness side

terminal voltage

of control unit

connector

(I 1 -Ground)

Harness side

terminal voltage

of control unit

connector

(1 -Ground)

Terminal-to-ground continuity

of control unit

harness side

connector

(7-Ground,17-Ground)

TJudgement

NormalMalfunction

System voltage0 VCauseOpen harness wire

or disconnected

connector between

junction block and

control unitRemedy

Repair the harness

or plug in the

connector correctly

System voltage

0 V

Open harness wire

or disconnected

connector between

junction block and

control unitRepair the harness

or plug in the

connector correctly

00allOpen harness wire

between control

unit and groundRepair the harness

Improper groundCorrectly connect

connectionto ground

Page 1065 of 1216

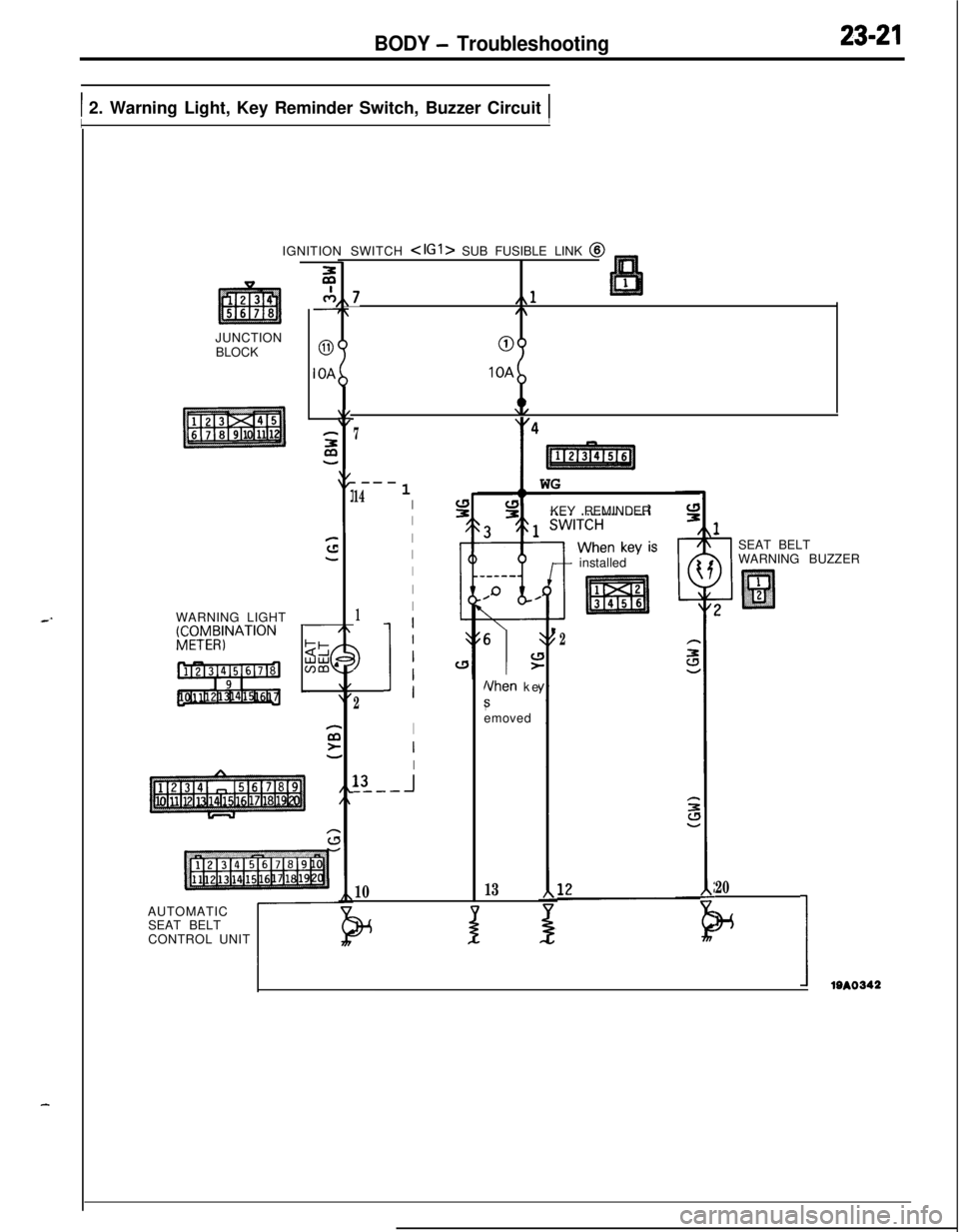

BODY - Troubleshooting23-21

1 2. Warning Light, Key Reminder Switch, Buzzer Circuit 1IIJUNCTION

BLOCK

WARNING LIGHT

gCTy4;NATION

c-7,,7L,,l7,/\

00IOA

IOA

2:y47

.---

141I

I

I

I

I

I

1I

3

2

11

I

I

I13

-I_---

10IGNITION SWITCH

SEAT BELT

CONTROL UNIT

t

11 WG

KEY REMINDER

6

\IL!>

Nhen ke

8emoved

13

+ installed

J

2

1SEAT BELT

WARNING BUZZER

20

w

IIem

Page 1066 of 1216

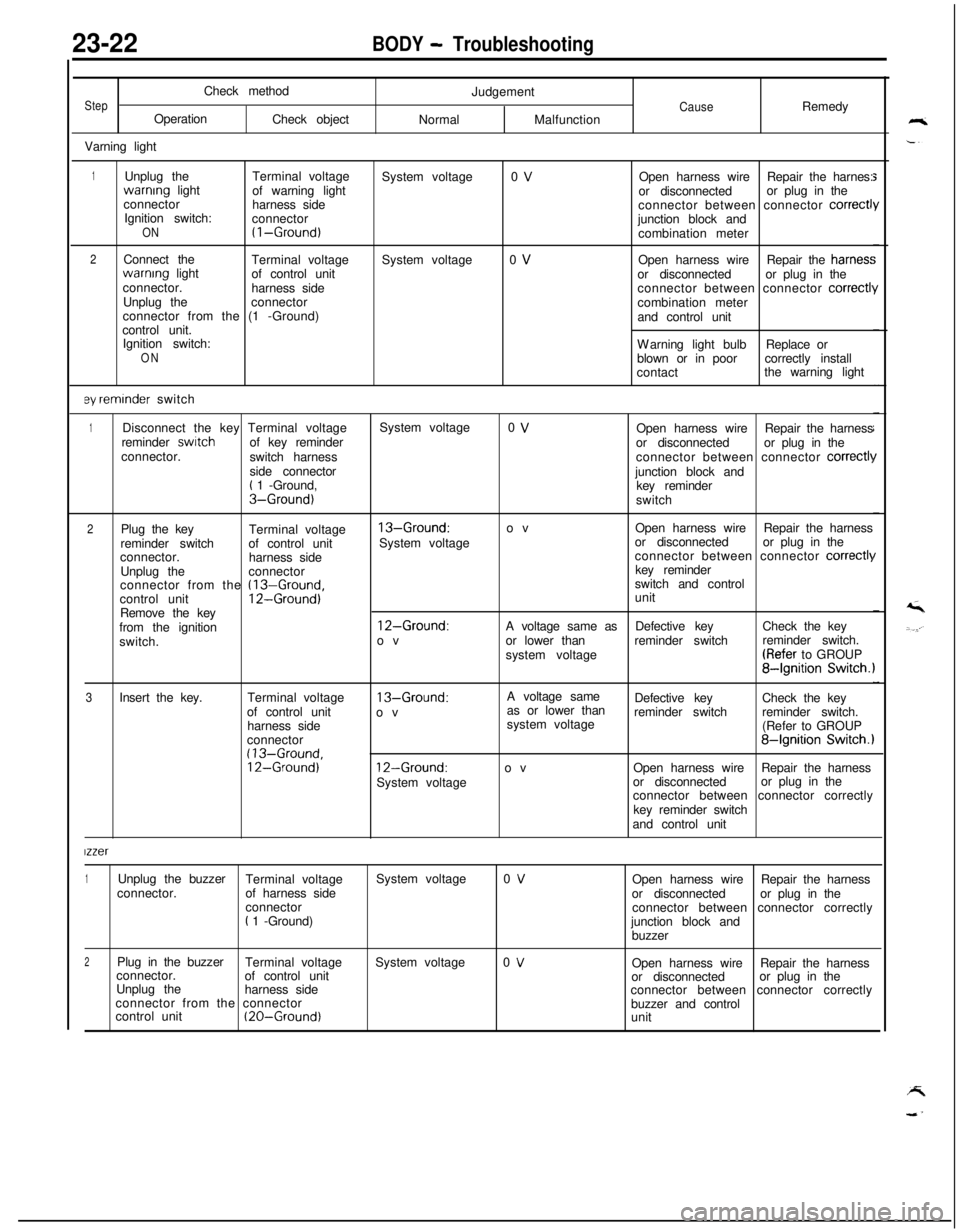

23-22BODY - TroubleshootingCheck method

StepOperation

Check object

Varning lightJudgementCauseRemedy

NormalMalfunction

1Unplug theTerminal voltagewarnrng light

of warning light

connector

harness side

Ignition switch:

connector

ON(I-Ground)

2Connect the

Terminal voltagewarnrng light

of control unit

connector.

harness side

Unplug theconnector

connector from the (1 -Ground)

control unit.

Ignition switch:

ON

ey reminder switchSystem voltage

System voltage0 V

0 VOpen harness wireRepair the harnes:

or disconnectedor plug in the

connector between connector

correct1junction block and

combination meter

Open harness wireRepair the harries:

or disconnectedor plug in the

connector between connector

correctl!combination meter

and control unit

Warning light bulbReplace or

blown or in poorcorrectly install

contactthe warning light

1Disconnect the key Terminal voltageSystem voltage0 VOpen harness wireRepair the harness

reminder switchof key reminder

or disconnectedor plug in the

connector.

switch harnessconnector between connector

correct11side connector

junction block and

t 1 -Ground,

key reminderS-Ground)switch

2Plug the key

Terminal voltage13-Ground:ovOpen harness wireRepair the harness

reminder switchof control unitSystem voltageor disconnectedor plug in the

connector.

harness sideconnector between connector

correct11Unplug theconnectorkey reminder

connector from the

(13-Ground,switch and control

control unit12-Ground)unit

Remove the key

from the ignition

12-Ground:A voltage same asDefective keyCheck the key

switch.ovor lower thanreminder switchreminder switch.

system voltage(Refer to GROUP

84gnition Switch.1

3Insert the key.Terminal voltage

13-Ground:A voltage same

as or lower thanDefective keyCheck the key

of control unit

ovreminder switchreminder switch.

harness sidesystem voltage

(Refer to GROUP

connector

84gnition Switch.1(13-Ground,12-Ground)12-Ground:ovOpen harness wireRepair the harness

System voltageor disconnectedor plug in the

connector between connector correctly

key reminder switch

and control unit

lzzer

1Unplug the buzzer

Terminal voltageSystem voltage0 VOpen harness wireRepair the harness

connector.of harness side

or disconnectedor plug in the

connector

connector between connector correctly

t 1 -Ground)

junction block and

buzzer

2Plug in the buzzer

Terminal voltageSystem voltage0 VOpen harness wireRepair the harness

connector.

of control unit

or disconnectedor plug in the

Unplug the

harness side

connector between connector correctly

connector from the connector

buzzer and control

control unit

(20-Ground)unit

Page 1073 of 1216

.-

BODY - Troubleshooting

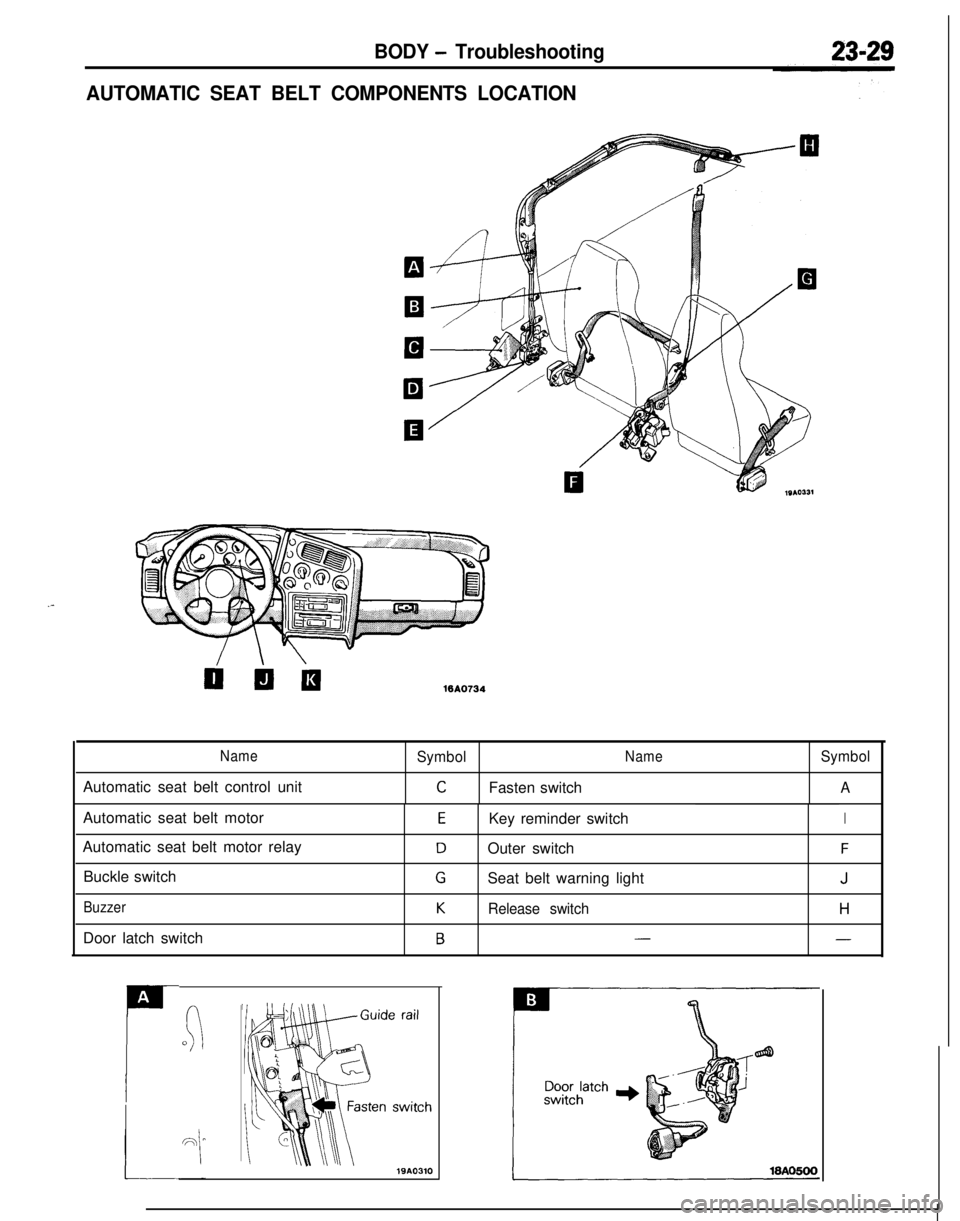

AUTOMATIC SEAT BELT COMPONENTS LOCATION

WA0734

NameSymbolNameSymbolAutomatic seat belt control unit

CFasten switchAAutomatic seat belt motor

Automatic seat belt motor relay

Buckle switch

BuzzerDoor latch switch

EKey reminder switchI

DOuter switchF

GSeat belt warning lightJ

KRelease switchH

B--

A

P

(:0

Page 1159 of 1216

HEATERS AND AIR CONDITIONING - Service Adjustment Procedures 24-15

Liquid

line

\Liquid lineI

ILiquid lineHigh pressure

hose2010439

detector torch

Electric leakAdetector tester

2OUO338

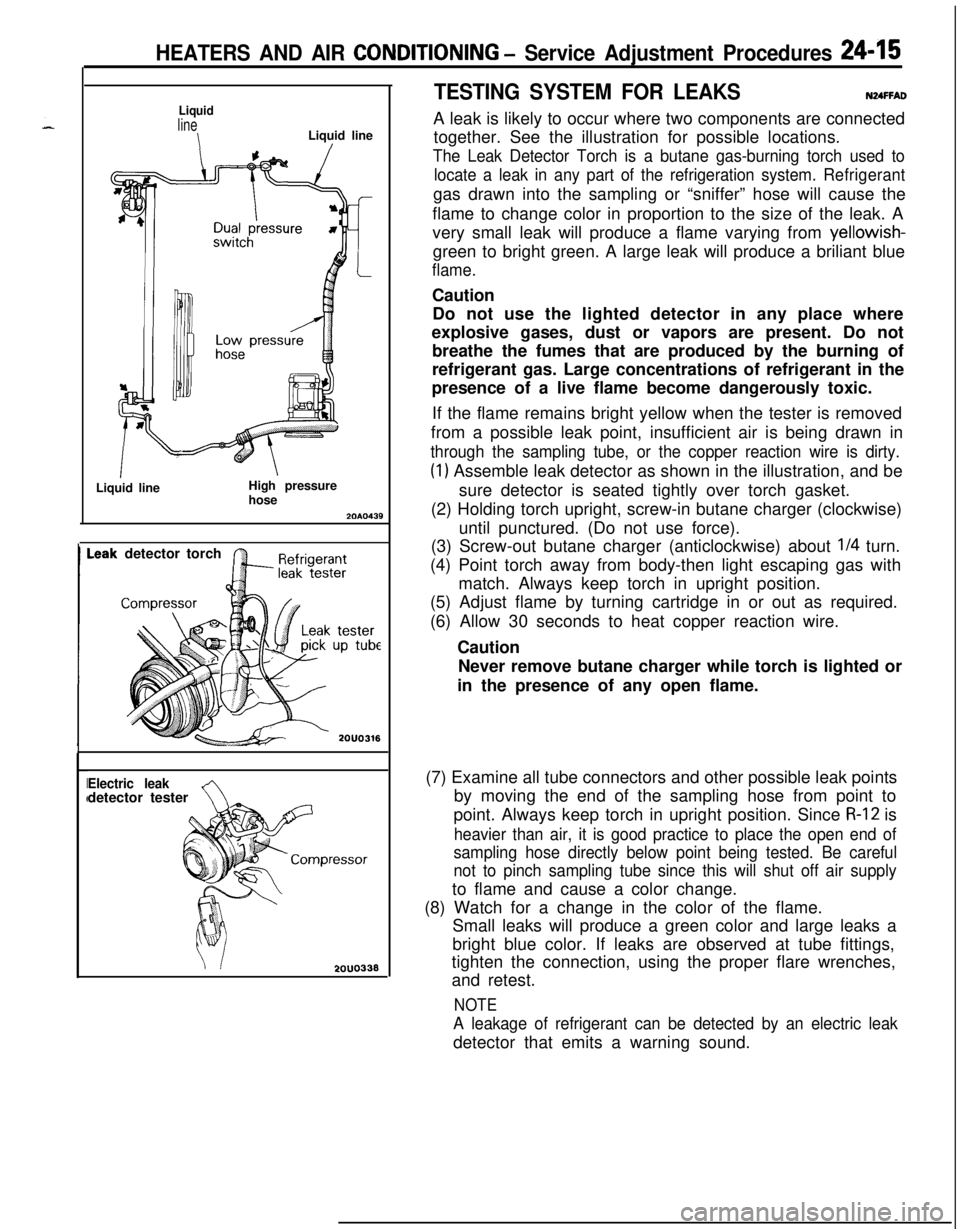

TESTING SYSTEM FOR LEAKSNUFFADA leak is likely to occur where two components are connected

together. See the illustration for possible locations.

The Leak Detector Torch is a butane gas-burning torch used to

locate a leak in any part of the refrigeration system.Refrigerantgas drawn into the sampling or “sniffer” hose will cause the

flame to change color in proportion to the size of the leak. A

very small leak will produce a flame varying from yellowish-

green to bright green. A large leak will produce a briliant blue

flame.Caution

Do not use the lighted detector in any place where

explosive gases, dust or vapors are present. Do not

breathe the fumes that are produced by the burning of

refrigerant gas. Large concentrations of refrigerant in the

presence of a live flame become dangerously toxic.

If the flame remains bright yellow when the tester is removed

from a possible leak point, insufficient air is being drawn in

through the sampling tube, or the copper reaction wire is dirty.

(1) Assemble leak detector as shown in the illustration, and be

sure detector is seated tightly over torch gasket.

(2) Holding torch upright, screw-in butane charger (clockwise)

until punctured. (Do not use force).

(3) Screw-out butane charger (anticlockwise) about

l/4 turn.

(4) Point torch away from body-then light escaping gas with

match. Always keep torch in upright position.

(5) Adjust flame by turning cartridge in or out as required.

(6) Allow 30 seconds to heat copper reaction wire.

Caution

Never remove butane charger while torch is lighted or

in the presence of any open flame.

(7) Examine all tube connectors and other possible leak points

by moving the end of the sampling hose from point to

point. Always keep torch in upright position. Since

R-12 is

heavier than air, it is good practice to place the open end of

sampling hose directly below point being tested. Be careful

not to pinch sampling tube since this will shut off air supplyto flame and cause a color change.

(8) Watch for a change in the color of the flame.

Small leaks will produce a green color and large leaks a

bright blue color. If leaks are observed at tube fittings,

tighten the connection, using the proper flare wrenches,

and retest.

NOTE

A leakage of refrigerant can be detected by an electric leakdetector that emits a warning sound.