cooling MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 1 of 1216

BACKUPGROUP INDEX &ma

;r Service Manual

LASER

TALON

1991

Volume-l

Engine, Chassis

& Body

FOREWORDThis Service Manual has been prepared with the

latest service information available at the time of

‘* publication.It is subdivided into various group

categories and each section contains diagnosis,

disassembly, repair, and installation procedures

along with complete specifications and tightening

references. Use of this manual will aid in properly

performing any servicing necessary to maintain or

restore the high levels of performance and reliabilitydesigned into these outstanding vehicles.

This BACKUP DSM manual IS to be used ONLY as a BACKUP. Please DO NOT REDISTRIBUTEWHOLE SECTIONS. This BACKUP was sold to you under the fact that you do indeed OWNa GENUINE DSM MANUAL. It CANNOT BE considered a REPLACEMENT (Unless your originalmanual was lost or destroyed.)Please See

README.N or README.HTML for additional information

Thank you. G~mm~emymanual@hotma~l.com

1,

wA

CHRYSLER

CORPORATION

Chrysler Corporation reserves the right to make changes in design 0’: tomake additions to or improvements in its products without lmqoslngd ., . any obligations upon itself to install them on its products previouslymanufactured.

0 1990 Mitsubishi Motors CorporationPrinted in U.S.A.Introduction and

Master

Troubleshooting. . . . . .,. . . . . . . . . r...m,

Lubrication and Maintenance . . . . . . . . ‘-0‘8

; “. i,

.Front Suspension. . . . . . . . . . . . . . ..*............d...Rear Axle

. . . . . . . . . . . . . . . . . . . . . . . . . . . . ..‘.....................

/

ServiceBrakes-Parking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clutch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..~......................‘t.

Cooling. . . . . . . . . . . . . . . . . ..i....................................

,., .‘,-,

Engine..i....~....r...............~....~.*,.~.~.~,‘~~...;..~~..Intake and Exhaust

. . . . . . ..L....................Fuel System

. . . . . . . . . . . ..ti.......r................~...Propeller Shaft

.......................................IRear

Suspensiori.............................y.f...

ManualSteering- Power.....................................Manual

I

transaxle-Automatic .............:;i...,;.....;Wheels

and Tires.................................

Body.............................................................Heater & Air Conditioning

..............Emission

Contr6l Systems..............

INOTE: For Electrical, refer toVolume-2 “Electrical”.

Page 29 of 1216

INTRODUCTION AND MASTER TROUBLESHOOTING - Mast& Tro6blerhootbia

MASTER TROUBLESHOOTING7 *

I,._ ,...

r. ENGINE OVERHEATSi ”

SymptomEngine overheatsProbable causeCooling system faulty

Incorrect ignition timingReference page: I._),7-5

8-169

ENGINE WILL NOT CRANK OR CRANKS SLOWLY

SymptomEngine will not crank

or cranks slowlyProbable causeStarting system faulty

,’

Reference page8-153

ENGINE WILL NOT START OR

HbRD TO START (CRANKS OK)

SymptomProbable causeReference page

Engine will not start or hard toNo fuel supply to injector

-start (Cranks OK)

Injection system problems

-Ignition system problems

8-16!$/ ”;Vacuum leaks11-5..“,:’l Purge control valve hose25-4

l Vacuum hoses

l Intake manifoldl Air intake plenum

l Throttle body

l EGR valveCompression too low

g-23,‘, :. ” ‘,;A;ROUGH IDLE OR ENGINE STALL

Symptom

Rough idle or engine stallsProbable cause

Vacuum leaks

l Purge control valve hosel Vacuum hosesl Intake manifoldl Air intake plenuml Throttle bodyl EGR valve

“. ._

Reference page or remedy

11-525-4

Ignition system problems

Idle speed set too low8-169Check idle speed control sys-

tem

Idle mixture too lean or too rich

Fuel injection system problems

Exhaust gas recirculation

(EGR) system

problems

Engine overheatsCompression too low

-

-

25-l 57-5

9-23

Page 39 of 1216

LUBRICATION AND MAINTENANCE - Recommended Lubrie’ntsand Lubrtcant Capacttles Table

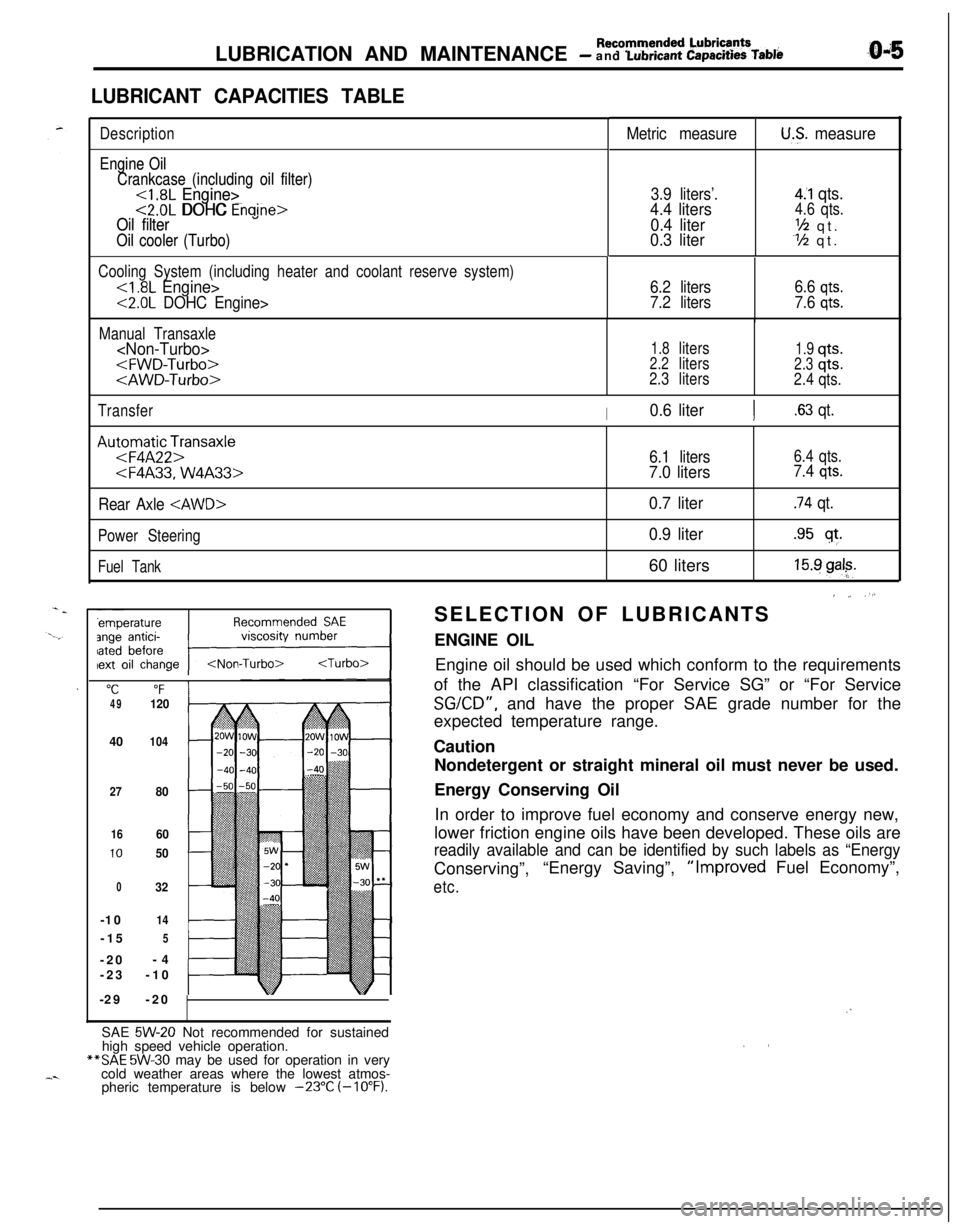

LUBRICANT CAPACITIES TABLE

Description

Engine Oil Engine Oil

Crankcase (including oil filter) Crankcase (including oil filter)

<1.8L Engine><1.8L Engine><2.0L DOHC Engine><2.0L DOHC Enaine>Oil filter Oil filter

Oil cooler (Turbo) Oil cooler (Turbo)

Metric measureU.S. measure

3.9 liters’.4.4 liters

0.4 liter

0.3 liter

4.‘1 qts.4.6 qts.

‘h qt.Y2 qt.

Cooling System (including heater and coolant reserve system)

<2.0L DOHC Engine>6.2 liters

7.2 liters6.6

qts.

7.6 qts.

Manual Transaxle

1.8liters1.9qts.2.2liters2.3qts.

2.3liters

2.4qts.

Transfer

I0.6 literI.63 qt.

Au:oFmqaAtF2pnsaxle

Rear Axle

Power Steering

Fuel Tank

"C“F4912040

104

27

80

1660

1050

032-10

14-15

5-20-4

-23-10

-29-20

6.1 liters6.4 qts.

7.0 liters7.4 qts.

0.7 liter.74 qt.

0.9 liter.95 sf.60 liters

15.9 gal?.

’ ~ “.SELECTION OF LUBRICANTS

ENGINE OIL

Engine oil should be used which conform to the requirements

of the API classification “For Service SG” or “For Service

SGKD”, and have the proper SAE grade number for the

expected temperature range.

Caution

Nondetergent or straight mineral oil must never be used.

Energy Conserving Oil

In order to improve fuel economy and conserve energy new,

lower friction engine oils have been developed. These oils are

readily available and can be identified by such labels as “EnergyConserving”,“Energy Saving”,“Improved Fuel Economy”,

etc.

/”SAE

5W-20 Not recommended for sustained

high speed vehicle operation.**SAE

5W-30 may be used for operation in very

cold weather areas where the lowest atmos-

pheric temperature is below

-23°C (-10°F).

Page 40 of 1216

O-6LUBRICATION AND MAINTENANCE - Capacities TableRecommended Lubricants and Lubricant

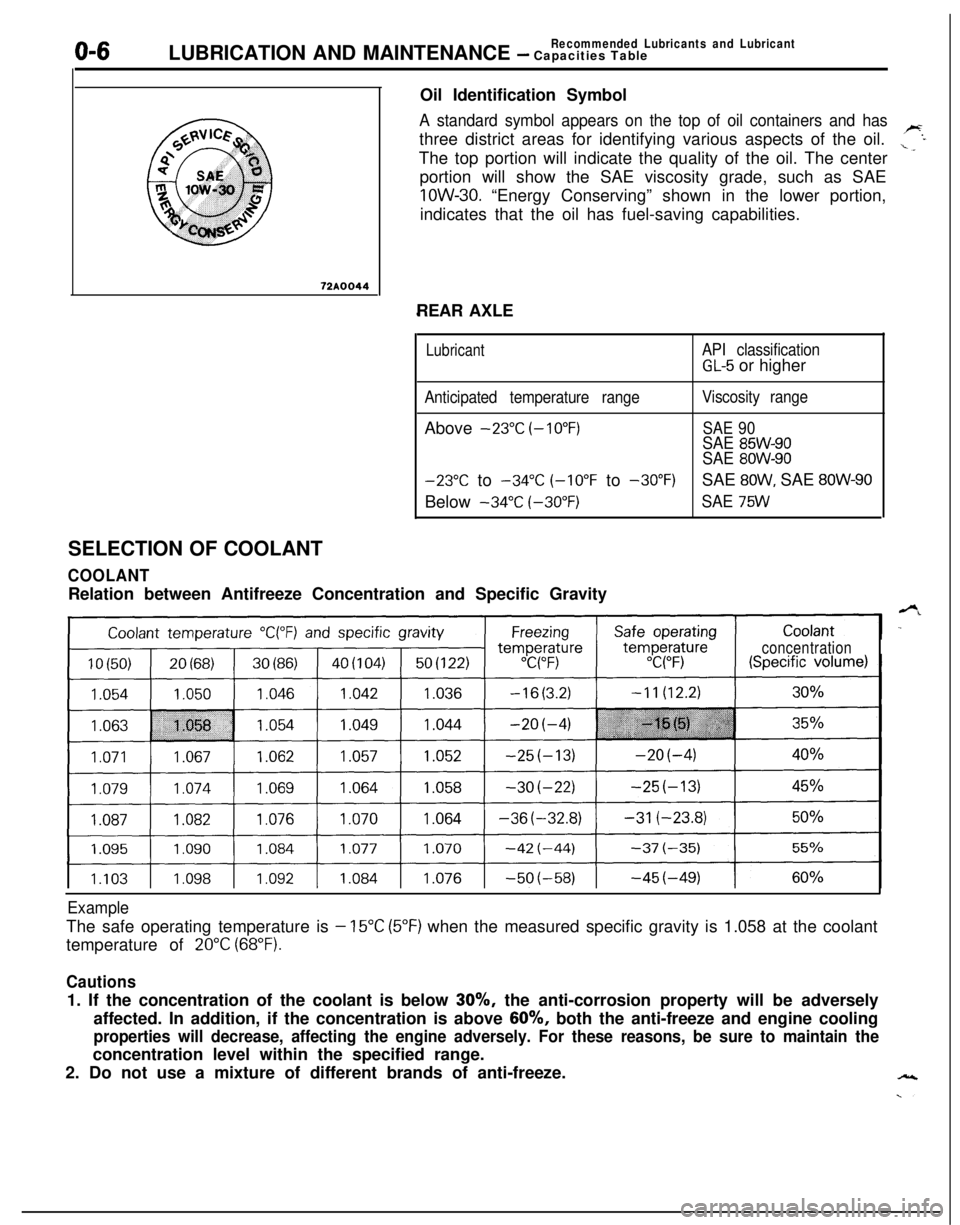

72A0044Oil Identification Symbol

A standard symbol appears on the top of oil containers and hasthree district areas for identifying various aspects of the oil.

The top portion will indicate the quality of the oil. The center

portion will show the SAE viscosity grade, such as SAE

IOW-30. “Energy Conserving” shown in the lower portion,

indicates that the oil has fuel-saving capabilities.

REAR AXLE

LubricantAPI classification

GL-5 or higher

Anticipated temperature rangeViscosity rangeAbove -23°C

(-10°F)SAE 90SAE 85W-90SAE 8OW-90

-23°C to -34°C (-10°F to -30°F)SAE 8OW, SAE 8OW-90Below -34°C

(-30°F)SAE 75WSELECTION OF COOLANT

COOLANTRelation between Antifreeze Concentration and Specific Gravity

concentration

ExampleThe safe operating temperature is

- 15°C (5°F) when the measured specific gravity is 1.058 at the coolant

temperature of

20°C (68°F).

Cautions1. If the concentration of the coolant is below 30%, the anti-corrosion property will be adversely

affected. In addition, if the concentration is above 60%, both the anti-freeze and engine cooling

properties will decrease, affecting the engine adversely. For these reasons, be sure to maintain theconcentration level within the specified range.

2. Do not use a mixture of different brands of anti-freeze.

Page 46 of 1216

LUBRICATION AND MAINTENANCE - Maintenance Service

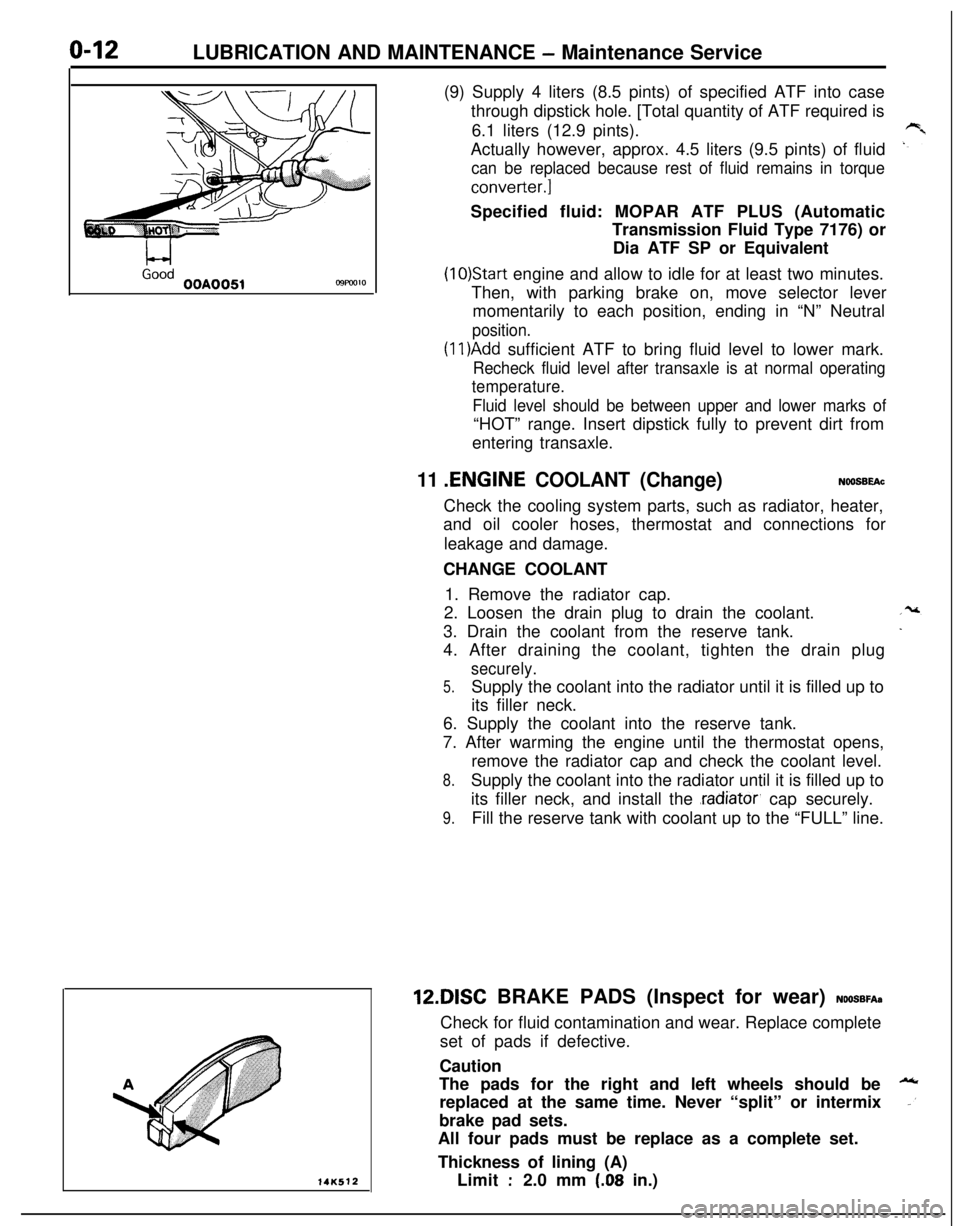

L-4GoodOOA0051C9FW1014K512(9) Supply 4 liters (8.5 pints) of specified ATF into case

through dipstick hole. [Total quantity of ATF required is

6.1 liters (12.9 pints).

Actually however, approx. 4.5 liters (9.5 pints) of fluid

can be replaced because rest of fluid remains in torque

converter.]Specified fluid: MOPAR ATF PLUS (Automatic

Transmission Fluid Type 7176) or

Dia ATF SP or Equivalent

(10)Start engine and allow to idle for at least two minutes.

Then, with parking brake on, move selector lever

momentarily to each position, ending in “N” Neutral

position.

(1 l)Add sufficient ATF to bring fluid level to lower mark.

Recheck fluid level after transaxle is at normal operating

temperature.

Fluid level should be between upper and lower marks of“HOT” range. Insert dipstick fully to prevent dirt from

entering transaxle.

11 .ENGINE COOLANT (Change)NOOSBEAcCheck the cooling system parts, such as radiator, heater,

and oil cooler hoses, thermostat and connections for

leakage and damage.

CHANGE COOLANT

1. Remove the radiator cap.

2. Loosen the drain plug to drain the coolant.

3. Drain the coolant from the reserve tank.

4. After draining the coolant, tighten the drain plug

securely.

5.Supply the coolant into the radiator until it is filled up to

its filler neck.

6. Supply the coolant into the reserve tank.

7. After warming the engine until the thermostat opens,

remove the radiator cap and check the coolant level.

8.Supply the coolant into the radiator until it is filled up to

its filler neck, and install the

.radiator, cap securely.

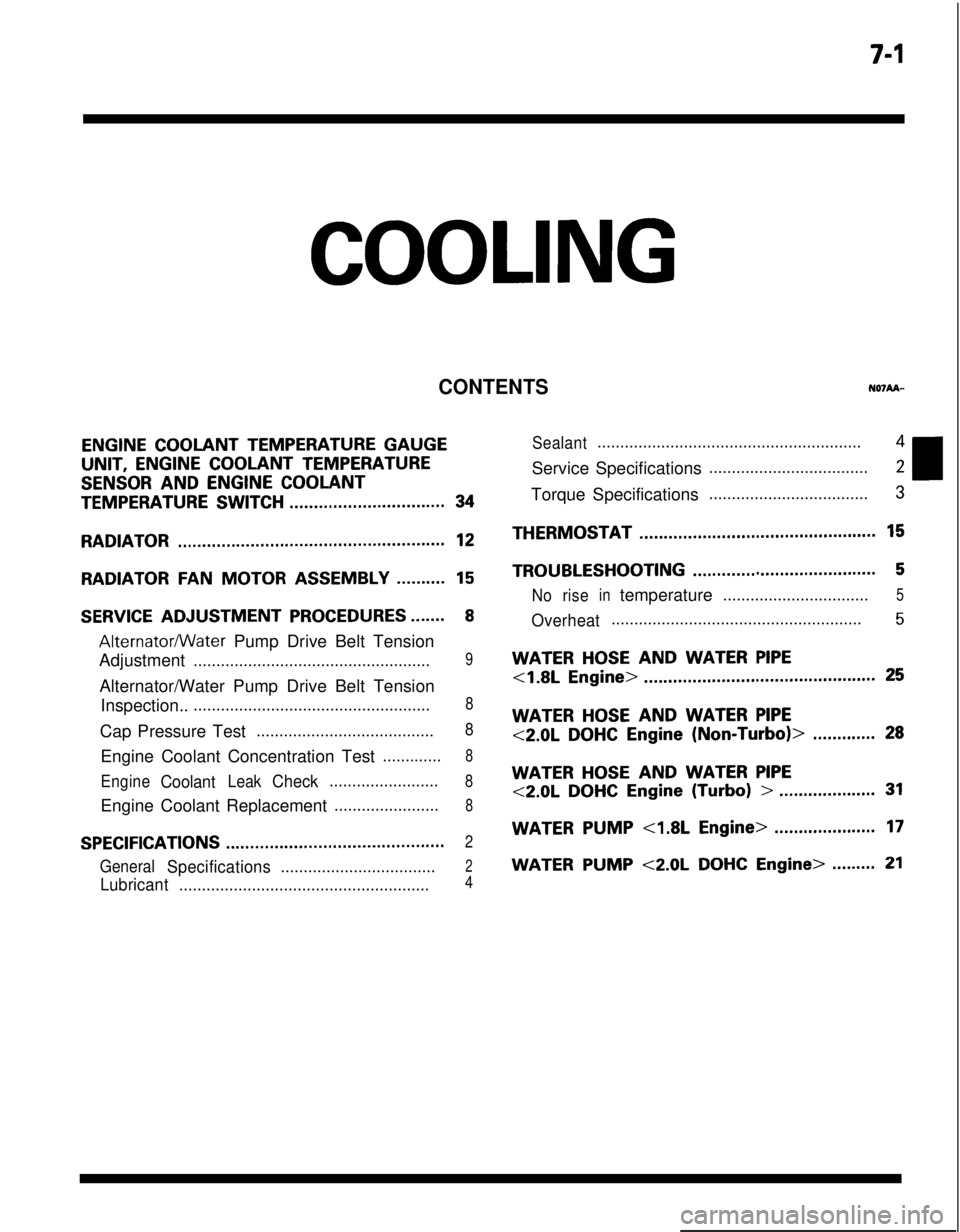

9.Fill the reserve tank with coolant up to the “FULL” line.12DISC BRAKE PADS (Inspect for wear)

NOOSBFA~Check for fluid contamination and wear. Replace complete

set of pads if defective.

Caution

The pads for the right and left wheels should be

replaced at the same time. Never “split” or intermix

brake pad sets.

All four pads must be replace as a complete set.

Thickness of lining (A)

Limit

:2.0 mm (.08 in.)

Page 249 of 1216

7-l

COOLING

CONTENTS

ENGINE COOLANT TEMPERATURE GAUGEUNIT,

ENGINE COOLANT TEMPERATURE

SENSOR AND ENGINE COOLANT

TEMPERATURE SWITCH................................34

RADIATOR.......................................................12

RADIATORFANMOTOR ASSEMBLY..........15

SERVICE ADJUSTMENT PROCEDURES.......8

Alternatormater Pump Drive Belt Tension

Adjustment

....................................................9Alternator/Water Pump Drive Belt Tension

Inspection..

....................................................8Cap Pressure Test

.......................................8Engine Coolant Concentration Test

.............8

EngineCoolantLeakCheck........................8Engine Coolant Replacement

.......................8

SPECIFICATIONS.............................................2

GeneralSpecifications..................................2

Lubricant.......................................................4

Sealant..........................................................4Service Specifications

...................................2Torque Specifications

...................................3THERMOSTAT

.................................................15

TROUBLESHOOTING......................................5

Noriseintemperature................................5

Overheat.......................................................5

WATER HOSE AND WATER PIPE

<1.8L Engine>................................................25

WATER HOSE AND WATER PIPE

<2.0LDOHCEngine(Non-Turbo)>.............28

WATER HOSE AND WATER PIPE

<2.0LDOHCEngine(Turbo)>....................31

WATERPUMP<1.8LEngine>.....................17

WATER PUMP <2.0L DOHC Engine>.........21

Page 250 of 1216

7-2COOLING - Specifications

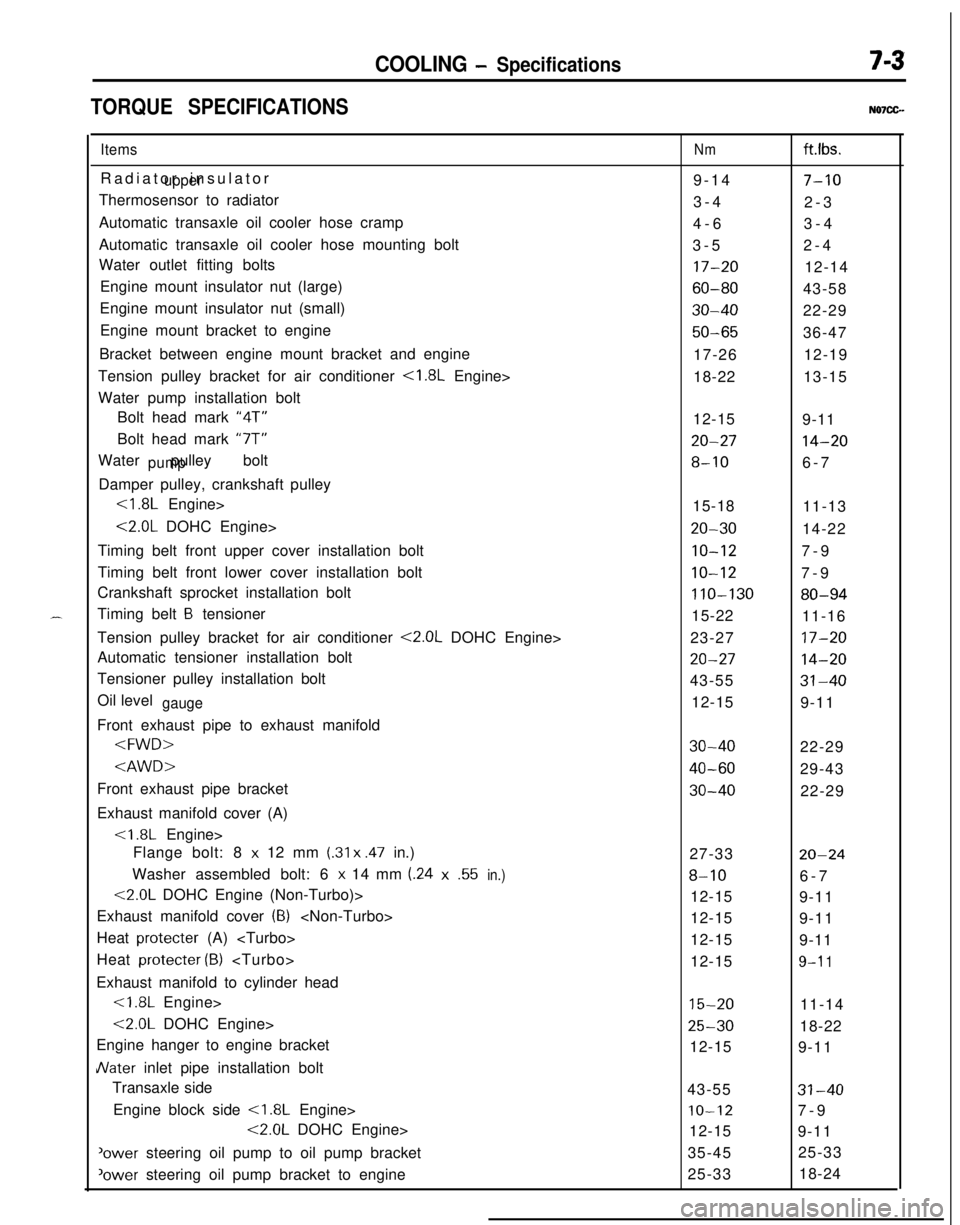

SPECIFICATIONS

GENERAL SPECIFICATIONSIcNQ7cA- I

ItemsCooling method

Radiator

TypeRadiator fan motor

TypeWater pump

Type

Thermostat

TypeIdentification mark

Drive belt

TypeEngine coolant temperature gauge unit

WeEngine coolant temperature sensor (Engine control)

TypeEngine coolant temperature switch (Air conditioner)

WeSpecifications

Water-cooled, pressurized, forced circulation

with electrical fan

Pressurized corrugated fin type

Direct current ferrite type

Impeller of centrifugal type

Wax pellet type with jiggle valve

88 (Stamped on flange)

V-ribbed belt

Thermistor type

Thermistor type

Thermistor type

SERVICE SPECIFICATIONSN07CB.-

Items

Standard valueRange of coolant antifreeze concentration

%

ThermostatValve opening temperature of thermostat

“C (“F)Full-opening temperature of thermostat

“C (“F)Opening pressure of cap high pressure valve

kPa (psi)

Therm0 sensor (on radiator)

Operating temperature

OFF

+ ON“C (“F)ON

--P OFF“C (“F)Engine coolant temperature gauge unit

ResistanceAt

70°C (158°F) QEngine coolant temperature sensor (Engine control)

ResistanceAt

20°C (68°F) kQAt

80°C (176°F) QEngine coolant temperature

switch (Air conditioner)

ON -+ OFF operating temperature

“C (“F)Limit

Opening pressure cap high pressure valve

kPa (psi)

Specifications

30-6088 (190)

100 (212) or more

75-105 (11-15)

82-88 (180-190)

78 (172) or less

104f 13.5

2.45

I!I 0.24

296

+ 32

112-l 18 (234-244)

65 (9.2)

Page 251 of 1216

COOLING - Specifications7-3

TORQUE SPECIFICATIONSN07CG.

ItemsRadiator insulator

upperThermosensor to radiator

Automatic transaxle oil cooler hose cramp

Automatic transaxle oil cooler hose mounting bolt

Water outlet fitting bolts

Engine mount insulator nut (large)

Engine mount insulator nut (small)

Engine mount bracket to engine

Bracket between engine mount bracket and engine

Tension pulley bracket for air conditioner

<1.8L Engine>

Water pump installation bolt

Bolt head mark “4T”

Bolt head mark “7T”

Water pulley bolt

pumpDamper pulley, crankshaft pulley

<1.8L Engine>

<2.0L DOHC Engine>

Timing belt front upper cover installation bolt

Timing belt front lower cover installation bolt

Crankshaft sprocket installation bolt

Timing belt

B tensioner

Tension pulley bracket for air conditioner

<2.0L DOHC Engine>

Automatic tensioner installation bolt

Tensioner pulley installation bolt

Oil level

gaugeFront exhaust pipe to exhaust manifold

Exhaust manifold cover (A)

Flange bolt: 8

x 12 mm (.31 x .47 in.)

Washer assembled bolt: 6

x 14 mm (.24x.55in.)

<2.0L DOHC Engine (Non-Turbo)>

Exhaust manifold cover

(8)

Heat protecter (A)

Heat protecter

(B)

Exhaust manifold to cylinder head<1.8L Engine>

<2.0L DOHC Engine>

Engine hanger to engine bracket

JVater inlet pipe installation bolt

Transaxle side

Engine block side

<1.8L Engine>

<2.0L DOHC Engine>

'ower steering oil pump to oil pump bracket

‘ower steering oil pump bracket to engine

Nmft.lbs.

9-14

7-103-4

2-3

4-63-4

3-52-4

17-2012-14

60-8043-58

30-4022-29

50-6536-47

17-2612-19

18-2213-15

12-15

9-11

20-2714-20

8-106-7

15-18

11-13

20-3014-22

IO-127-9

10-127-9

110-13080-9415-22

11-16

23-27

17-20

20-2714-2043-55

31-4012-15

9-11

30-4022-29

40-6029-43

30-4022-29

27-33

20-24

8-106-7

12-15

9-11

12-15

9-11

12-15

9-11

12-15

9-l 1

15-2011-14

25-3018-22

12-15

9-11

43-55

31-40

IO-127-9

12-15

9-11

35-4525-33

25-3318-24

Page 252 of 1216

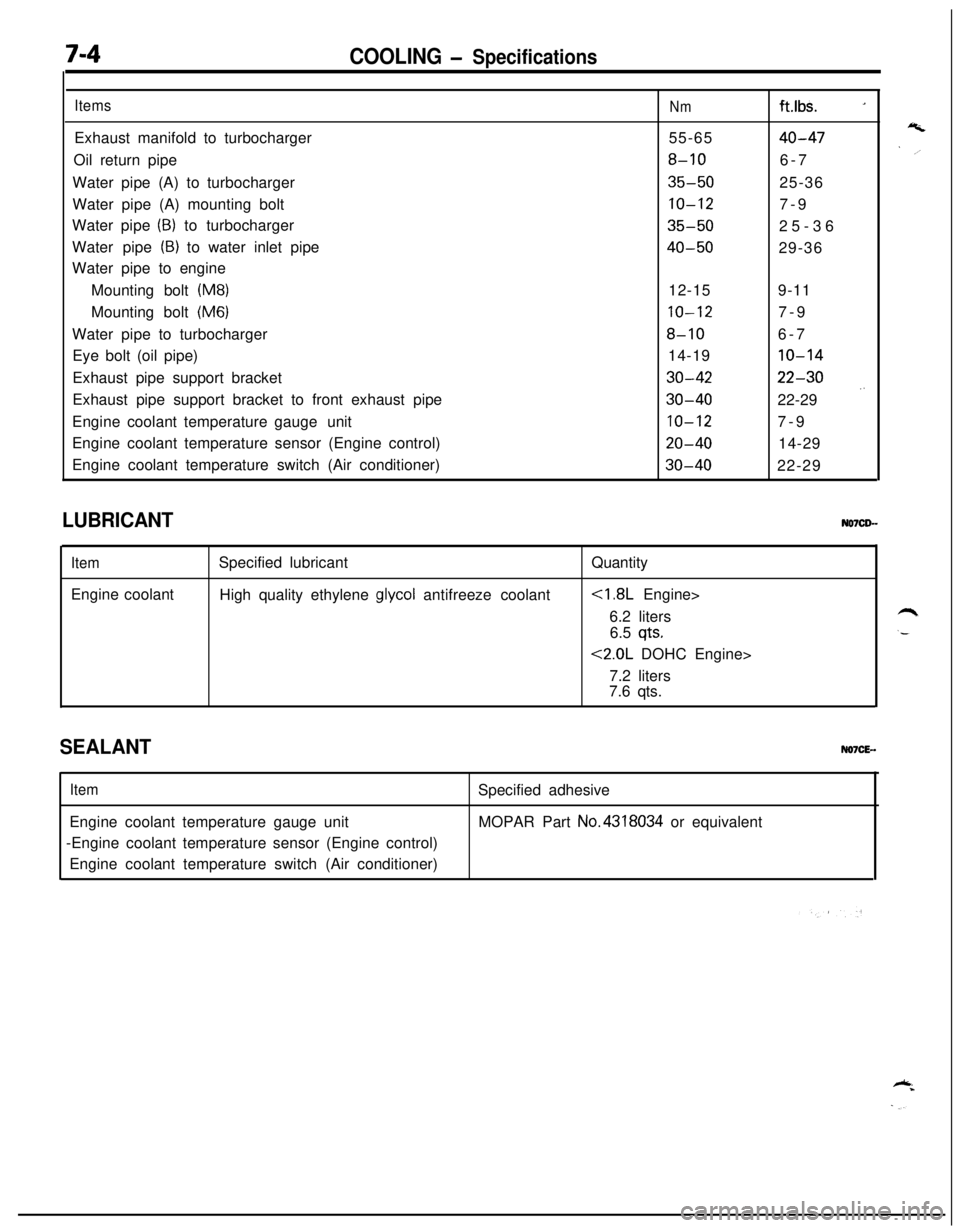

7-4COOLING - Specifications

ItemsExhaust manifold to turbocharger

Oil return pipe

Water pipe (A) to turbocharger

Water pipe (A) mounting bolt

Water pipe

(B) to turbocharger

Water pipe

(B) to water inlet pipe

Water pipe to engine

Mounting bolt

(M8)Mounting bolt

(M6)Water pipe to turbocharger

Eye bolt (oil pipe)

Exhaust pipe support bracket

Exhaust pipe support bracket to front exhaust pipe

Engine coolant temperature gaugeunit

Engine coolant temperature sensor (Engine control)

Engine coolant temperature switch (Air conditioner)

Nmft.lbs. _155-65

40-47

8-106-7

35-5025-36

10-127-9

35-5025-36

40-5029-36

12-159-11

10-127-9

8-106-7

14-19

10-14

30-4222-30

30-4022-29 .’

10-127-9

20-4014-29

30-4022-29

LUBRICANT

ItemEngine coolantSpecified lubricant

High quality ethylene

glycol antifreeze coolantQuantity

6.2 liters

6.5

qts.

<2.0L DOHC Engine>

7.2 liters

7.6 qts.

SEALANTNO7CE-.

ItemEngine coolant temperature gauge unit

-Engine coolant temperature sensor (Engine control)

Engine coolant temperature switch (Air conditioner)Specified adhesive

MOPAR Part No.4318034 or equivalent

Page 253 of 1216

COOLING - Troubleshootina7-5

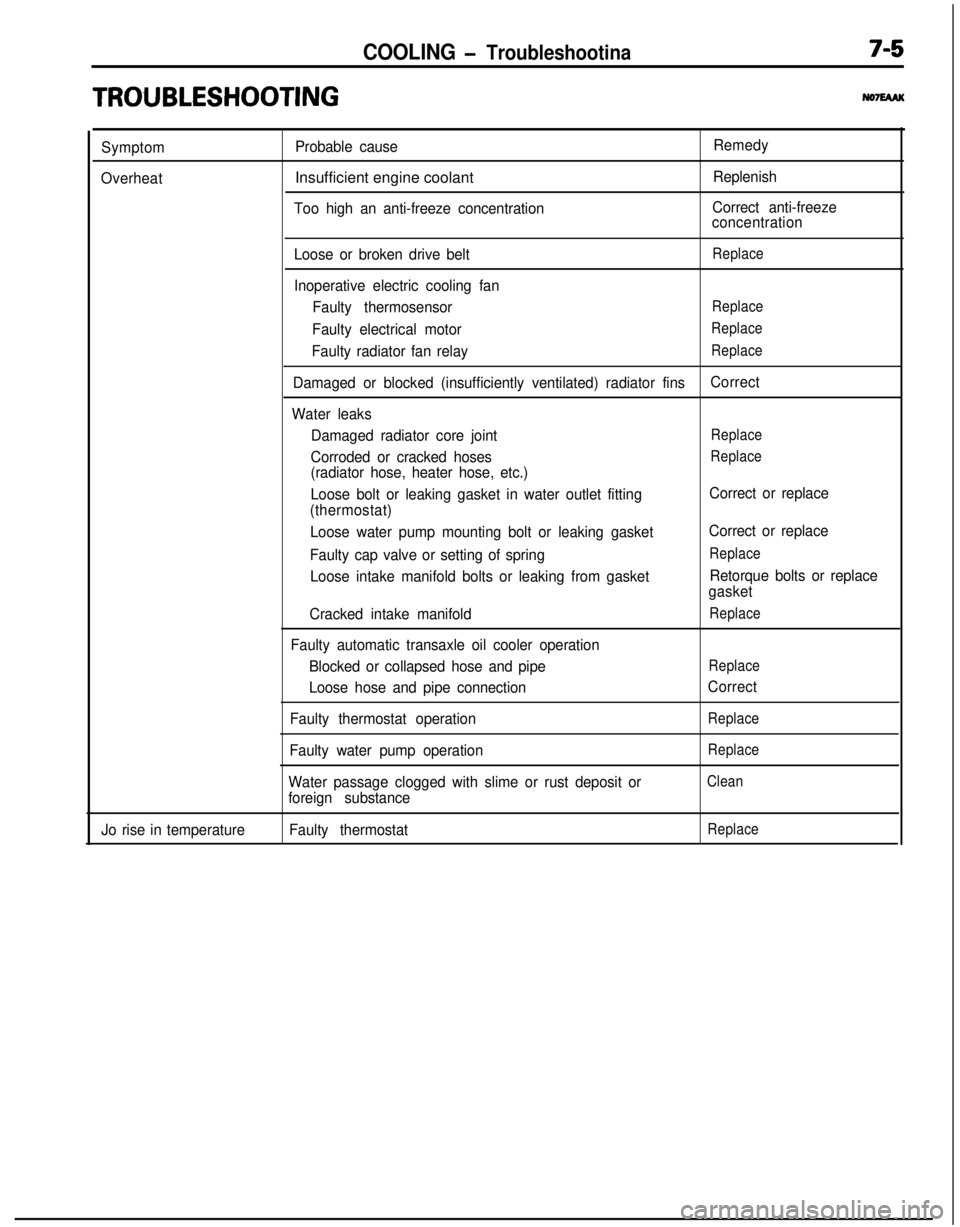

TRO,UBLESHOOTlNG

Symptom

OverheatProbable causeInsufficient engine coolant

Too high an anti-freeze concentrationRemedy

Replenish

Correct anti-freeze

concentration

Loose or broken drive belt

Replace

Inoperative electric cooling fan

Faulty thermosensor

Replace

Faulty electrical motorReplace

Faulty radiator fan relayReplace

Damaged or blocked (insufficiently ventilated) radiator finsCorrect

Water leaks

Damaged radiator core joint

Replace

Corroded or cracked hosesReplace

(radiator hose, heater hose, etc.)

Loose bolt or leaking gasket in water outlet fitting

(thermostat)

Loose water pump mounting bolt or leaking gasket

Faulty cap valve or setting of spring

Loose intake manifold bolts or leaking from gasket

Cracked intake manifold

Faulty automatic transaxle oil cooler operation

Blocked or collapsed hose and pipe

Loose hose and pipe connection

Faulty thermostat operation

Faulty water pump operation

Water passage clogged with slime or rust deposit or

foreign substanceCorrect or replace

Correct or replace

Replace

Retorque bolts or replace

gasket

Replace

Replace

Correct

Replace

Replace

Clean

Jo rise in temperatureFaulty thermostatReplace