clutch MITSUBISHI ECLIPSE 1991 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 580 of 1216

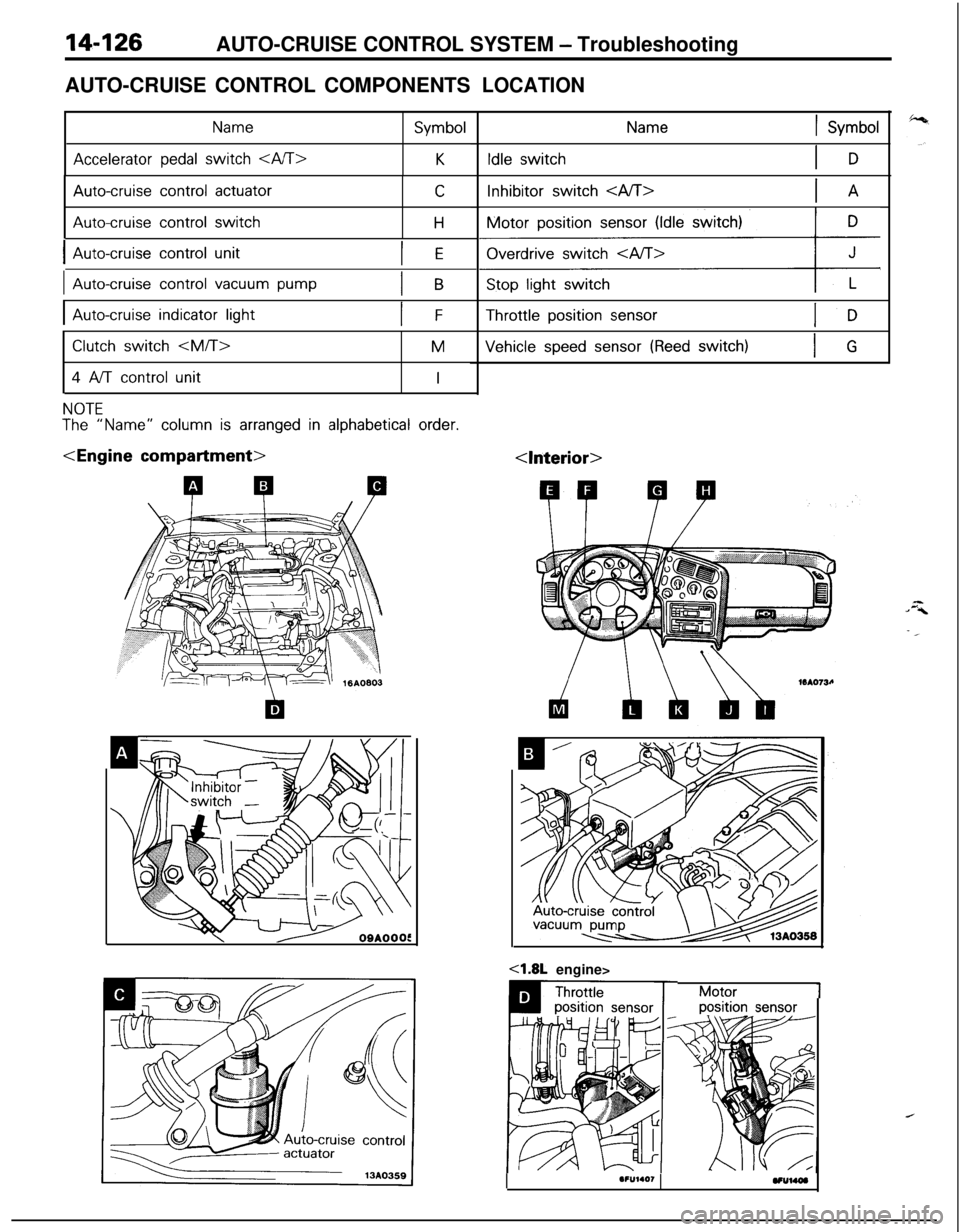

14-126AUTO-CRUISE CONTROL SYSTEM - Troubleshooting

AUTO-CRUISE CONTROL COMPONENTS

Name

Accelerator pedal switch

Symbol

K

Auto-cruise control actuator

Auto-cruise control switch

C

H

IAuto-cruise control unitIE

IAuto-cruise control vacuum pumpIB

IAuto-cruise indicator lightIF

Clutch switch

4 A/T control unit

M

I

NOTE

The “Name” column is arranged in alphabetical order.

LOCATION

1 Symbol

Idle switchIDInhibitor switch

Motor position

sensor (Idle switch)

ziz&Gy+Throttle position

sensor

Vehicle speed sensor (Reed switch)IG

Motor1position sensor

I.F”l.O,VUUW

Page 590 of 1216

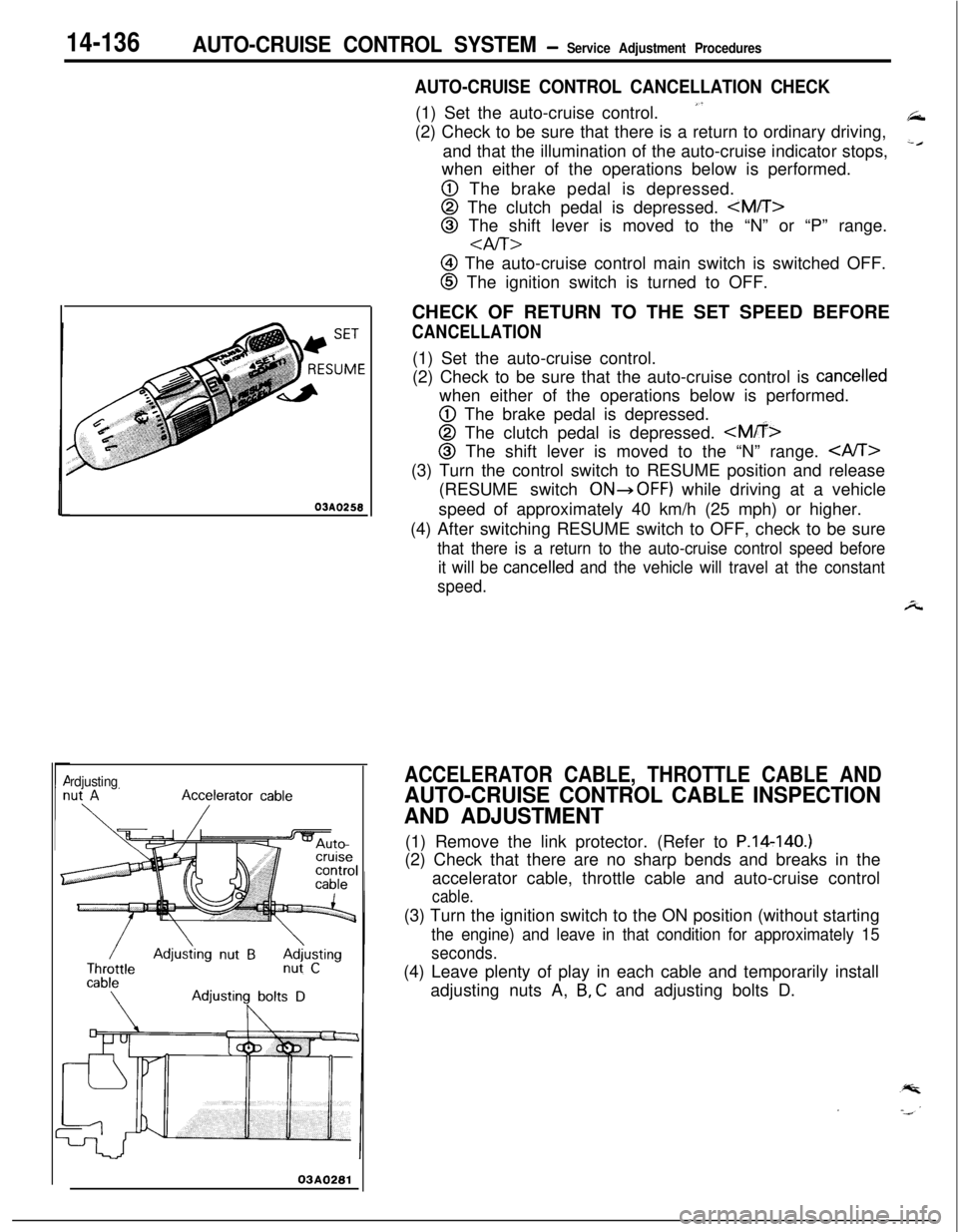

14-136AUTO-CRUISE CONTROL SYSTEM- Service Adjustment Procedures03AQ250

rdjusting

03A0281

AUTO-CRUISE CONTROL CANCELLATION CHECK(1) Set the auto-cruise control.

”(2) Check to be sure that there is a return to ordinary driving,

and that the illumination of the auto-cruise indicator stops,

‘cwhen either of the operations below is performed.

@ The brake pedal is depressed.

@ The clutch pedal is depressed.

@ The shift lever is moved to the “N” or “P” range.

aIT>

@ The auto-cruise control main switch is switched OFF.

@ The ignition switch is turned to OFF.

CHECK OF RETURN TO THE SET SPEED BEFORE

CANCELLATION(1) Set the auto-cruise control.

(2) Check to be sure that the auto-cruise control is

cancelledwhen either of the operations below is performed.

@ The brake pedal is depressed.

@ The clutch pedal is depressed.

@I The shift lever is moved to the “N” range. (3) Turn the control switch to RESUME position and release

(RESUME switch

ONdOFF) while driving at a vehicle

speed of approximately 40 km/h (25 mph) or higher.

(4) After switching RESUME switch to OFF, check to be sure

that there is a return to the auto-cruise control speed before

it will be

cancelled and the vehicle will travel at the constant

speed.

A

ACCELERATOR CABLE, THROTTLE CABLE AND

AUTO-CRUISE CONTROL CABLE INSPECTION

AND ADJUSTMENT(1) Remove the link protector. (Refer to P.14140.)

(2) Check that there are no sharp bends and breaks in the

accelerator cable, throttle cable and auto-cruise control

cable.(3) Turn the ignition switch to the ON position (without starting

the engine) and leave in that condition for approximately 15

seconds.(4) Leave plenty of play in each cable and temporarily install

adjusting nuts A,

B, C and adjusting bolts D.

Page 592 of 1216

14-138AUTO-CRUISE CONTROL SYSTEM - Service Adjustment Procedures

07A0051

07AOO50

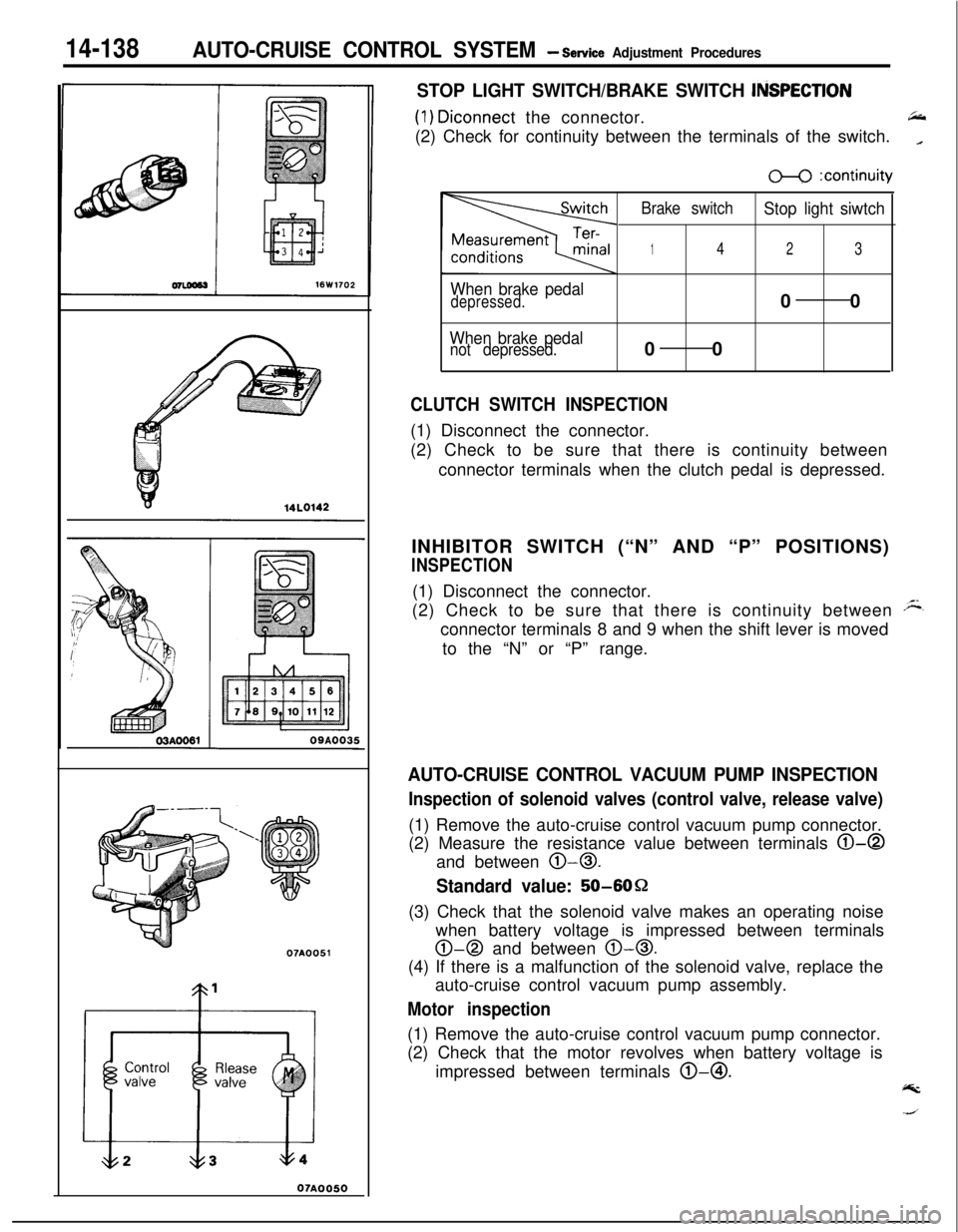

STOP LIGHT SWITCH/BRAKE SWITCH ItiSPECTlON

(1) Diconnect the connector.66(2) Check for continuity between the terminals of the switch.

_

When brake pedaldepressed.

When brake pedalnot depressed.

m :continuity

Brake switch

Stop light siwtch

142300

00

CLUTCH SWITCH INSPECTION(1) Disconnect the connector.

(2) Check to be sure that there is continuity between

connector terminals when the clutch pedal is depressed.

INHIBITOR SWITCH (“N” AND “P” POSITIONS)

INSPECTION(1) Disconnect the connector.

(2) Check to be sure that there is continuity between

Aconnector terminals 8 and 9 when the shift lever is moved

to the “N” or “P” range.

AUTO-CRUISE CONTROL VACUUM PUMP INSPECTION

Inspection of solenoid valves (control valve, release valve)(1) Remove the auto-cruise control vacuum pump connector.

(2) Measure the resistance value between terminals

0-0and between

0-0.

Standard value: 50-6OQ

(3) Check that the solenoid valve makes an operating noise

when battery voltage is impressed between terminals

0-0 and between 0-0.(4) If there is a malfunction of the solenoid valve, replace the

auto-cruise control vacuum pump assembly.

Motor inspection(1) Remove the auto-cruise control vacuum pump connector.

(2) Check that the motor revolves when battery voltage is

impressed between terminals @-@I.

@k

Page 594 of 1216

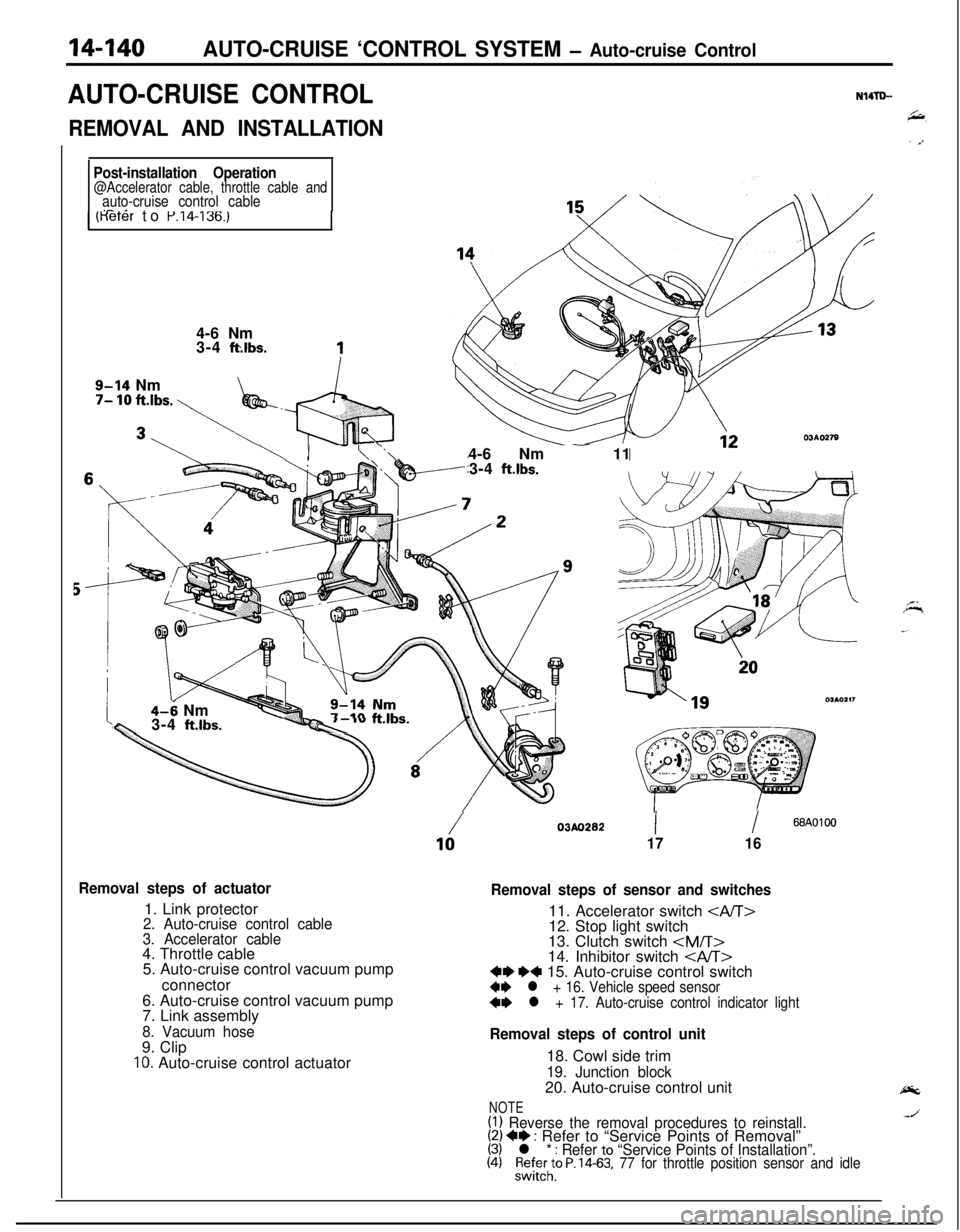

14-140AUTO-CRUISE ‘CONTROL SYSTEM - Auto-cruise Control

AUTO-CRUISE CONTROLN14TLL

REMOVAL AND INSTALLATION

Post-installation Operation@Accelerator cable, throttle cable andauto-cruise control cableI- _1 (Keter to P.14-136.)4-6 Nm

3-4

ft:lbs.

9-14 Nm7- 10 ft.lbs. \

\ I- \ ‘.\-4-6 Nm - 11

3-4 ft.lbs.

4-6 Nmw3-4 ft.lbs.--Qc ‘”

Removal steps of actuator1. Link protector

2. Auto-cruise control cable

3. Accelerator cable4. Throttle cable

5. Auto-cruise control vacuum pump

connector

6. Auto-cruise control vacuum pump

7. Link assembly

8. Vacuum hose9. Clip

IO. Auto-cruise control actuator

/03AO28210II68AOlOO

1716

Removal steps of sensor and switches11. Accelerator switch

12. Stop light switch

13. Clutch switch

Removal steps of control unit18. Cowl side trim

19. Junction block20. Auto-cruise control unit

NOTE(1) Reverse the removal procedures to reinstall.(2) +* : Refer to “Service Points of Removal”(3) l * : Refer to “Service Points of Installation”.(4)%l;;to P. 14-63, 77 for throttle position sensor and idle

Page 695 of 1216

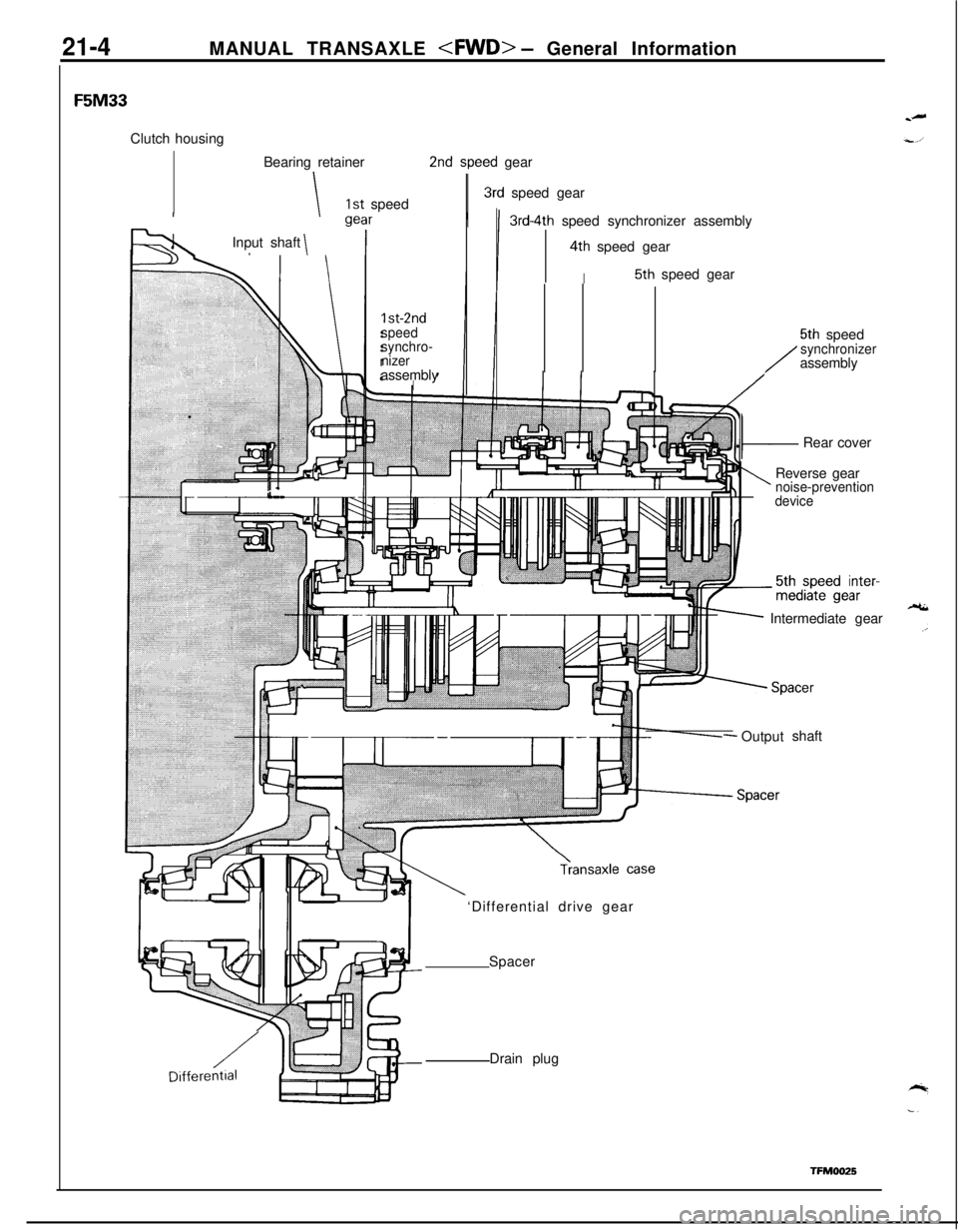

TRANSAXLE ’

MANUAL AND AUTOMATICCONTENTS

;-AUTOMATICTRANSAXLE

.....................................................137ANNULUS GEAR AND TRANSFER DRIVE GEAR SET (F4A22)..........315ANNULUS GEAR AND TRANSFER DRIVE GEAR SET(F4A33.W4A33)...........................................................................................317CENTERDIFFERENTIAL(W4A33).............................................................329DIFFERENTIAL............................................................................................319ENDCLUTCHASSEMBLY.........................................................................309EXTENSIONHOUSINGASSEMBLY(W4A33).........................................337FRONTCLUTCHASSEMBLY....................................................................302FRONTOUTPUTSHAFT(W4A33)...........................................................332GENERALINFORMATION.........................................................................137KICKDOWNSERVO....................................................................................322LOW-REVERSEBRAKE..............................................................................323OILPUMP...................................................................................................299PLANETARYGEARSET............................................................................311PLANETARYGEARSET............................................................................313REARCLUTCHASSEMBLY(F4A22)........................................................304REARCLUTCHASSEMBLY(FQA33sW4A33)............................................307SERVICEADJUSTMENTPROCEDURES..................................................Drive

Shaft,OilSealsReplacement....................................................;;;

InhibitorSwtchAdjustment................................................................21 1KeyInterlockMechanismCheck.....................................................KrckdownServoAdjustment..................................zii..............................

LinePressureAdjustment...................................................................213

ReducingPressureAdjustment.........................................................214Selector Lever Operation Check........................................................210ShiftLockMechanismCheck...............................................................21 1SpeedometerCableReplacement.........................................................Throttle-posltipn Sensor Adjustment.................................................z2:

TransaxleFluIdLevelInspectIon......................................................209

TransaxleFluidReplacement.............................................................209

SPECIALTOOLS.........................................................................................SPECIFICATIONS........................................................................................;“5”9

GeneralSpeclficatlons..................................................................1%Lubricants..................................................................................Sealants and Adhesives..............................................................izi

Serwce Speclflcatlons..................................................159...............Spacer andSnapRing.,.,.............................................................Spacer Set..................................................................1::Torque Speclflcatlons...........................................166Valve Body Spring Identification Chart.....................

.................160

SPEEDOMETERGEARASSEMBLY..........................................................TRANSAXLEASSEMBLY(WA22)............................................................zTRANSAXLE

ASSEMBLY(F4A33.W4A33)................................................TRANSAXLECONTROL.............................................................................;;;TRANSAXLE

OILCOOLER........................................................................TRANSFER..................................................................................................fg

TRANSFERASSEMBLY.............................................................................333TRANSFERCASEADAPTERSUBASSEMBLY(W4A33).......................339TRANSFER CASE SUB ASSEMBLY (W4A33)341TRANSFER SHAFT (F4A33)TROUBLESHOOTING..................................................................................................................................................................................................f;;VALVE

BODY.............................................................................................324

MANUAL TRANSAXLE

5TH-SPEEDSYNCHRONIZERASSEMBLY...............................................42GENERALINFORMATION.........................................................................2.-.INPUTfj,-,A,TASSEMBLY

INTERMEDIATE GEAR ASSEMBLY..........................................................56OUTPUT

SHAFT ASSEMBLY....................................................................61SERVICEADJUSTMENTPROCEDURES..................................................DriveShaftOilSealsReplacement......................................................;;Speedometer Cable Replacement.........................................................

Transaxle Oil Level

InspectIon..............................................................‘liTransaxle Oil Replacement....................................................................

I3

SHIFTLEVERASSEMBLY.........................................................................SHIFTRAILSANDFORKS........................................................................g

SPECIALTOOLS.........................................................................................SPECIFICATIONS........................................................................................1:

General Specifications5Lubricants..........................................................................................................................................................................10Sealants and Adhesives

Service Specifications

....................................................................................................................................................1:Snap Ring (for Adjustment) and Spacer...............................................

Torque Specifications.............................................................................

i

SPEEDOMETERGEARASSEMBLY..........................................................TRANS&G.E................................................................................................zTRANSAXLEA!jSEMBLY

TROUBLESHOOTING..................................................................................12

MANUAL TRANSAXLE

CENTERDIFFERENTIAL.............................................................................103CLUTCHHOUSINGASSEMBLY...............................................................DRIVE BEVEL GEAR ASSEMBLY;g

...... .......................................................DRIVENBEVELGEARASSEMBLY...................................a......................EXTENSIONHOUSINGASSEMBLY.........................................................;g

5Tf.jSPEEDSYNCHRONIZERASSEMBLY...............................................101

FRONTDlFFERENTlAL...............................................................................106

FRONTOUTPUTSHAFTASSEMBLY......................................................106

GENERALI~~~~MATN)N...............................................................,.,.......66INPUTSHAFTASSEMBLY........................................................................l~ER,“,EDlATEGEARASSMBLY..........................................................;;i

SERVICEADJUSTMENTPROCEDURES..................................................Drive Shaft Oil Seals Replacement......................................................;;Speedometer Cable Replacement.........................................................

Transaxle

Ojl Level lnspectlon..............................................................;l

Transaxle 011 R~pb33ment....................................................................79Transfer

OilSealReplacement.............................................................80

SHIFTLEVERASSEMBLY.........................................................................SHIFTRAILASSEMBLY............................................................................,z

SPECIALTOOLS.........................................................................................76

SPECIFICATIONS........................................................................................6g

GeneralSpecifications...........................................................................6g

Lubricants...............................................................................................75

SealantsandAdhesives........................................................................76

ServiceSpecifications............................................................................6gSnap Ring (for Adjustment) and Spacer...............................................7 o

TorqueSpecifications.............................................................................74

SPEEDOMETERGEARASSEMBLY..........................................................TRANSAXLE................................................................................................1:TRANSAXLEASSEMBLY...........................................................................86TRANSAXLE

CONTROL

.............................................................................TRANSFER...............................................................................................

g.._TRANSFERA!333lBLY.............................................................................,24

TRANSFERCASEADAPTERSUBASSEMBLY.......................................131TRANSFERCASESUBASSEMBLY.........................................................TR,,UBLES,,OO,,NG..................................................................................1;;

Page 696 of 1216

21-2MANUAL TRANSAXLE

MANUAL TRANSAXLE

NZlBAAP

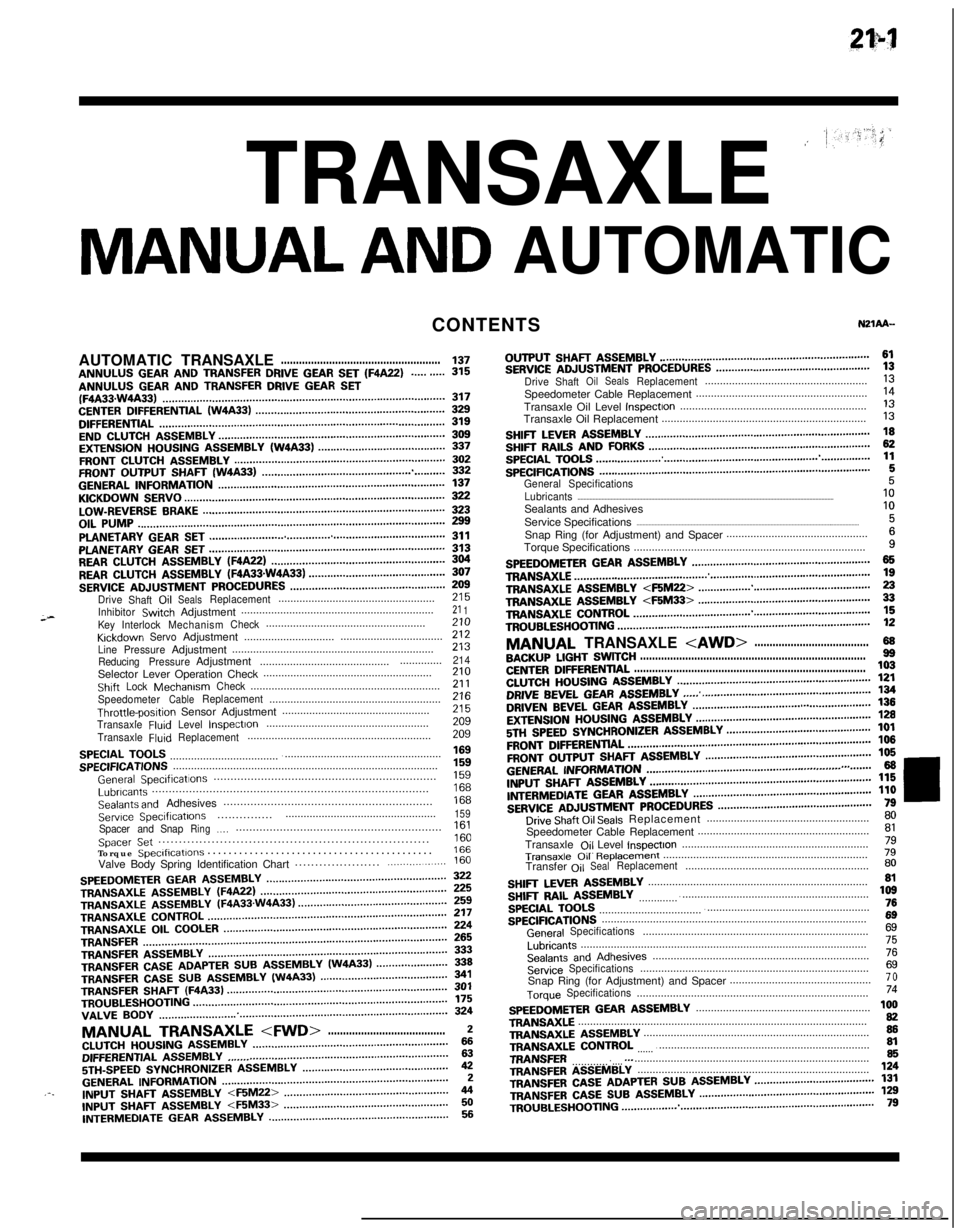

F5M22 (4637 Engine)

Clutch housing

Bearing retainer

2nd speed gear

3rd soeedaear

5th speedsynchronizerassemblv

-----..-.IRear cover

5th speed inter-

mediate gear

Intermediate gear

SpacerOutput shaft

SpacerTransaxle case

\Dif ferential drive gear

Diffelential

Spacer

#&---- Drain plug

2060020

Page 697 of 1216

MANUAL TRANSAXLE

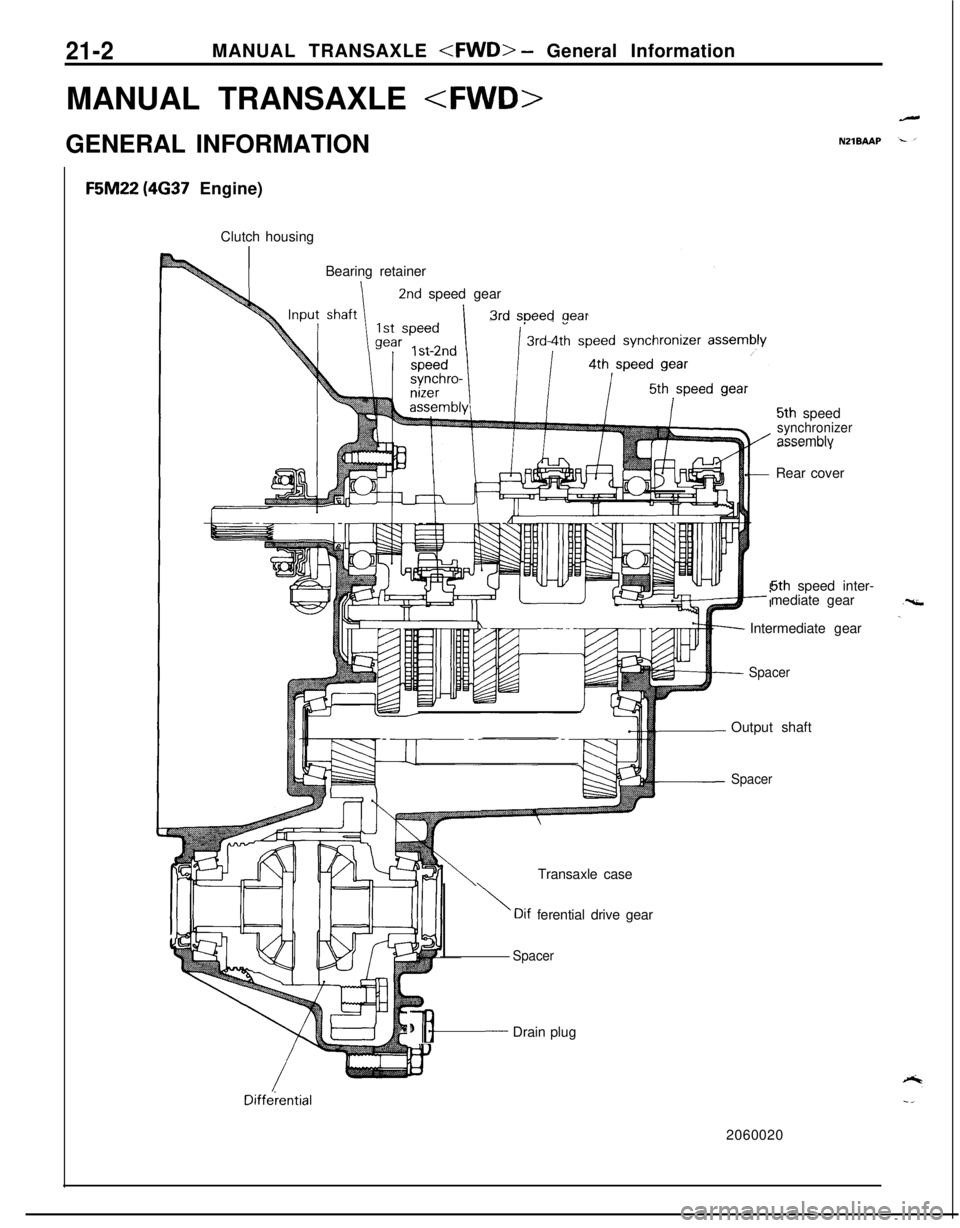

F5M22 (4G63 Engine)

Clutch housing

Bearrin

‘. ;

lg retainer

2nd speed gear

1st speedgear

1 st-2ndspeed

synchro-

I,

nizerassembly

3rd speed gear

3rd-4th speed synchronizer assembly4th speed gear

5th speed gear

5th speed

/

synchronizerassembly

Rear cover

,Reverse gear.norse-preventron

device

SpacerOutput shaft

Spacer‘Differential drive gear

SpacerDrain plug

TFMOOI 1

Page 698 of 1216

21-4MANUAL TRANSAXLE

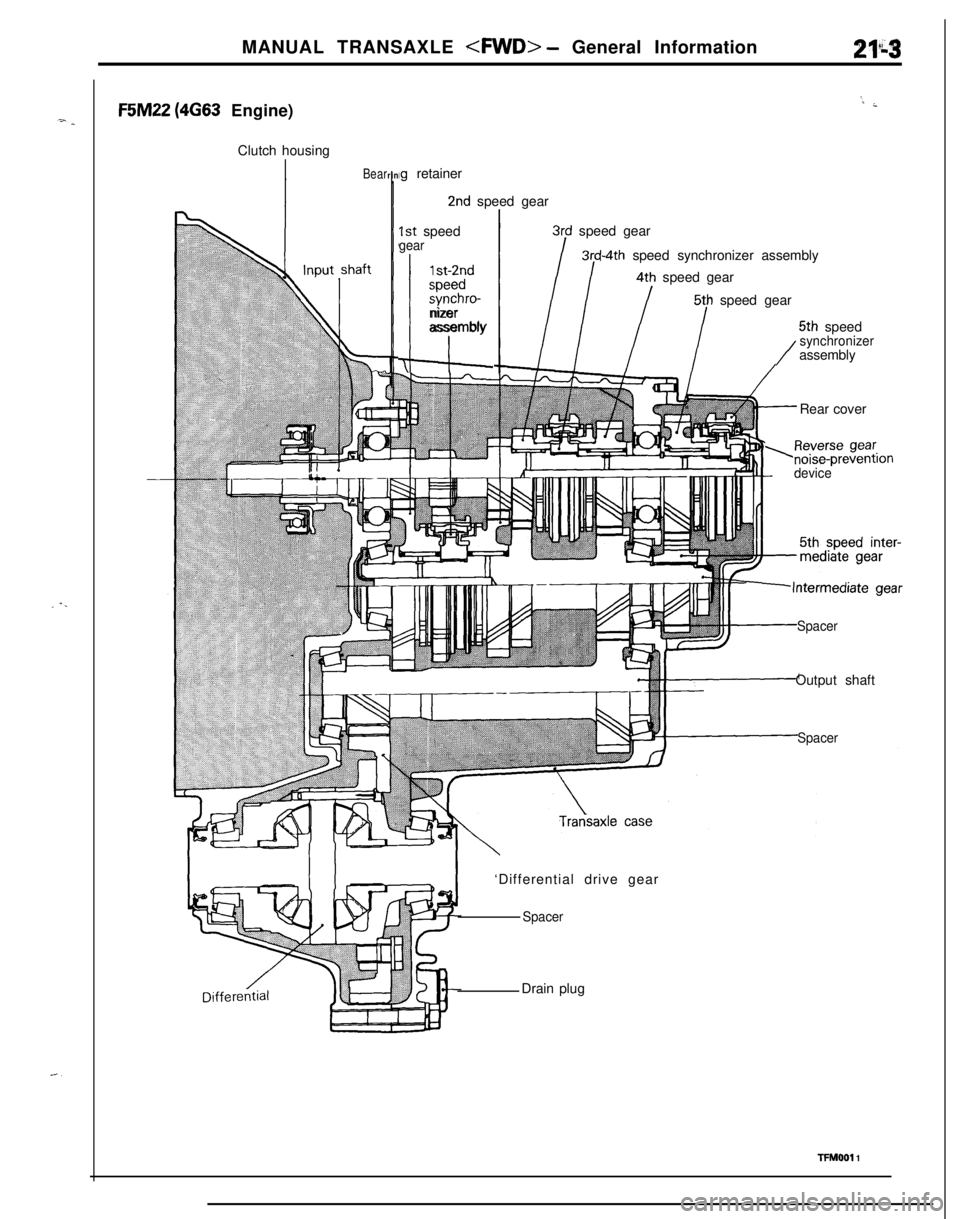

F5M33Clutch housing

Bearing retainer

2nd

1st speed

sPteed gear

3rd speed gear

ge’-

l--z& , I ii’Input shaft

3rd-4th speed synchronizer assembly

4th speed gear

I5th speed gear

1 st-2nd

speed

synchro-

nizerassembly

I

5th speed

/

synchronizerassembly

cRear cover

Reverse gear

noise-prevention

deviceIntermediate gear

- Outputshaft

‘Differential drive gear

Spacer

Drain plug

/Differentral

TFMOO25

Page 699 of 1216

MANUAL TRANSAXLE

SPECIFICATIQNS

3ENERAL SPECIFICATIONS

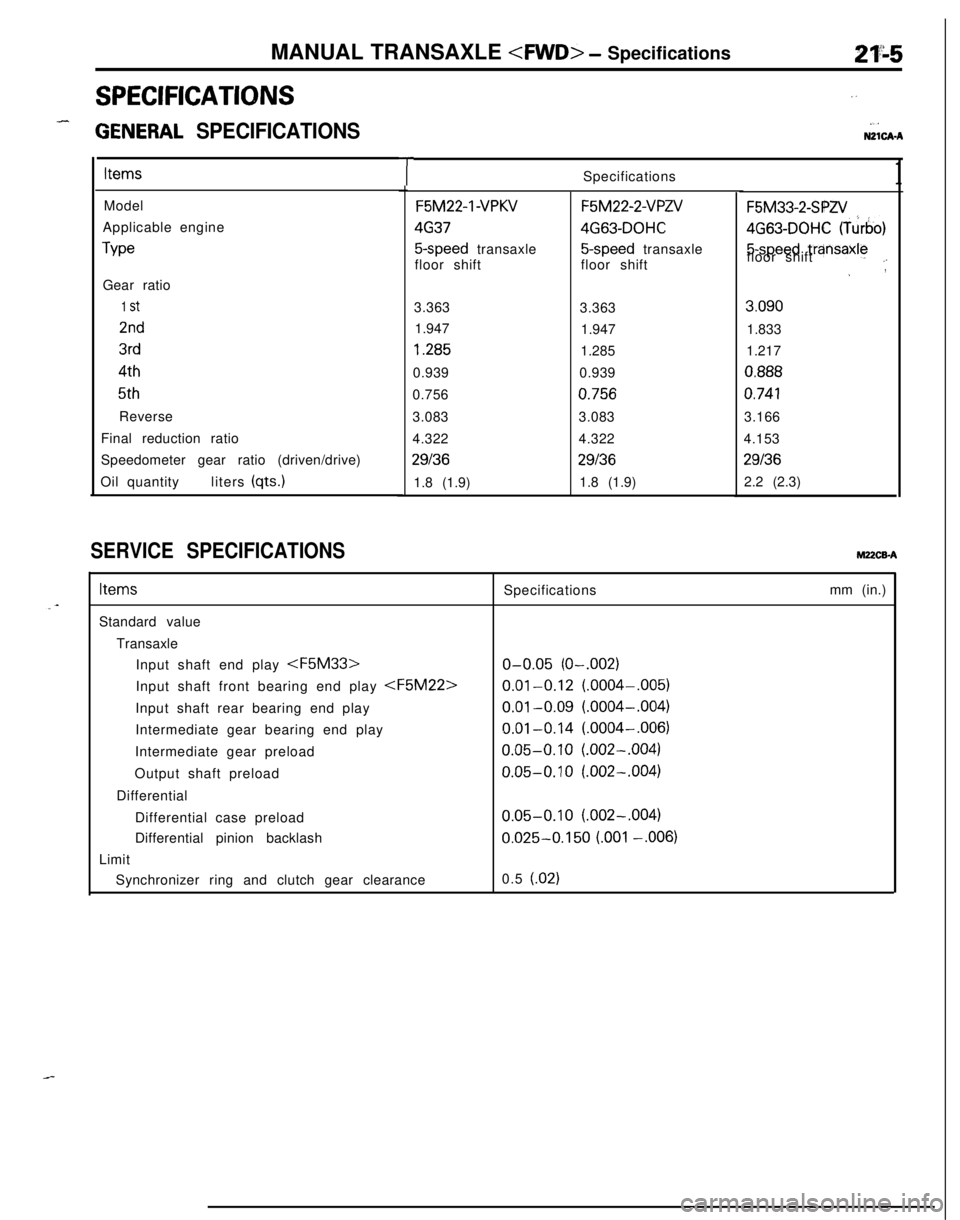

ItemsModel

Applicable engine

TypeGear ratio

1 st2nd3rd

4th5th

Reverse

Final reduction ratio

Speedometer gear ratio (driven/drive)

Oil quantityliters (qts.)

SERVICE SPECIFICATIONShl22CBA

”

.,NZlCA-ASpecifications

1TF5M22-1

-VFWF5M22-2-VPZV

46374G63-DOHC

5-speed transaxle5-speed transaxle

floor shiftfloor shift

3.363

3.363

1.947

1.9471.285

1.285

0.9390.939

0.756

0.7563.0833.083

4.3224.322

29136291361.8 (1.9)1.8 (1.9)

F5M33-2-SPA!4G63-DOHC (Turbo)5-speed

trzinsaxlefloor shift.-~,3.090

1.833

1.217

0.888

0.7413.166

4.153

291362.2 (2.3)

ItemsStandard value

Transaxle

Input shaft end play

Intermediate gear bearing end play

Intermediate gear preload

Output shaft preload

Differential

Differential case preload

Differential pinion backlash

LimitSpecifications

o-0.05 (O-.002)

0.01-0.12 (.0004-.005)

0.01-0.09 (.0004-.004)

0.01-0.14 (.0004-,006)

0.05-0.10 (.002-.004)

0.05-0.10 (.002-.004)

0.05-0.10 (.002-.004)

0.025-0.150 LOO1 -.006)mm (in.)

Synchronizer ring and clutch gear clearance0.5 (.02)

Page 703 of 1216

MANUAL TRANSAXLE

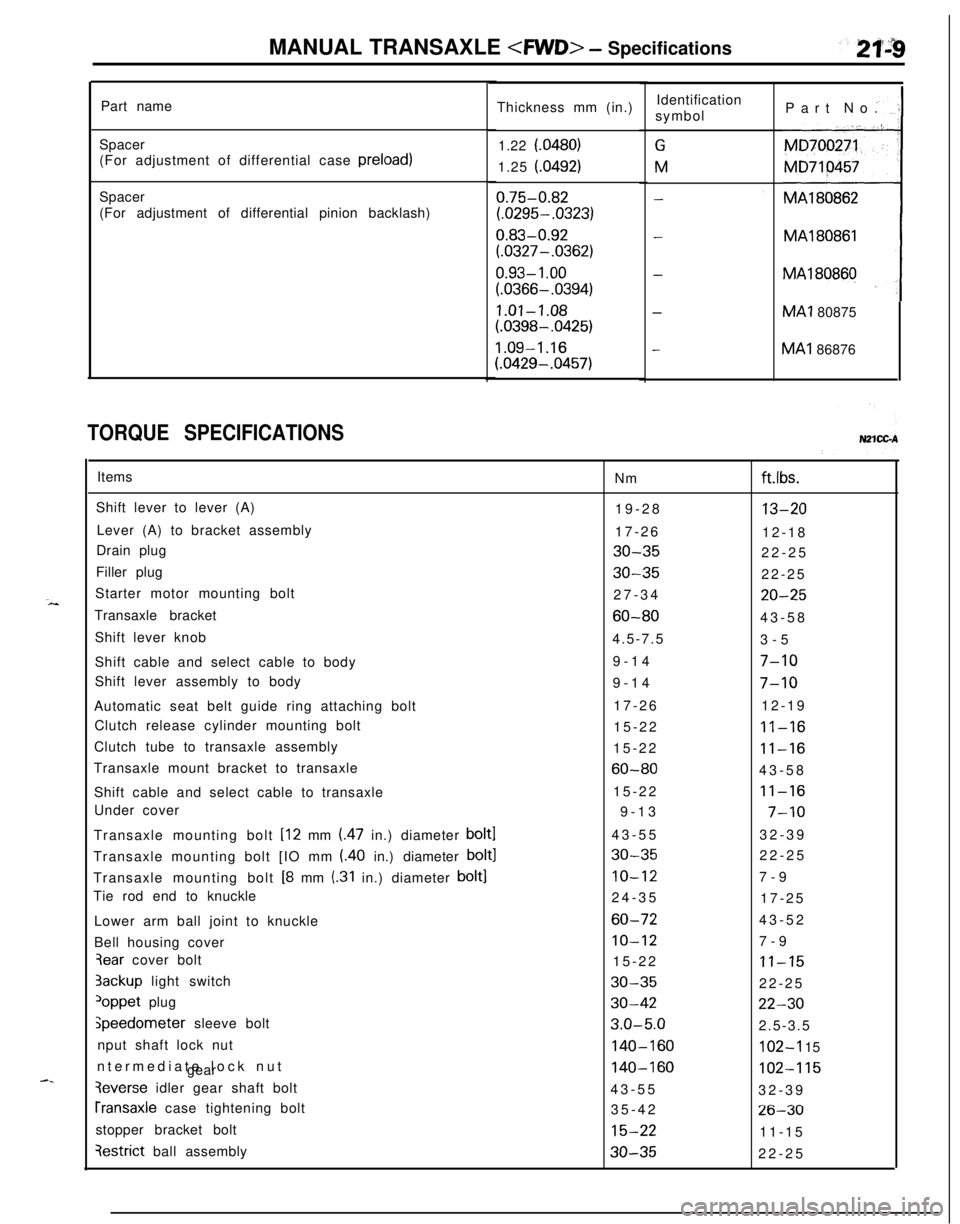

Part name

Spacer

(For adjustment of differential case preload)

Spacer

(For adjustment of differential pinion backlash)

TORQUE SPECIFICATIONSThickness mm (in.)

1.22 f.0480)

1.25 (.0492)

0.75-0.82

(.0295-.0323)

0.83-0.92

(.0327-.0362)

0.93- 1 .oo

(.0366-.0394)

1.01-1.08

(.0398-.0425)

1.09-1.16

(.0429-.0457)Identification

symbol

GM

-

-

-

-Part No.

MA180862MA1

80866MA1 80875MA1 86876

Items

Nm

Shift lever to lever (A)

19-28

Lever (A) to bracket assembly

17-26

Drain plug

30-35Filler plug

30-35Starter motor mounting bolt

27-34

Transaxle bracket

60-80Shift lever knob

4.5-7.5

Shift cable and select cable to body9-14

Shift lever assembly to body

9-14

Automatic seat belt guide ring attaching bolt17-26

Clutch release cylinder mounting bolt

15-22

Clutch tube to transaxle assembly

15-22

Transaxle mount bracket to transaxle

60-80Shift cable and select cable to transaxle15-22

Under cover

9-13

Transaxle mounting bolt [12 mm (.47 in.) diameter

bolt143-55

Transaxle mounting bolt [IO mm (.40 in.) diameter

bolt130-35Transaxle mounting bolt

[8 mm (.31 in.) diameter bolt]IO-12Tie rod end to knuckle

24-35

Lower arm ball joint to knuckle

60-72Bell housing cover

IO-123ear cover bolt

15-223ackup light switch

30-35

loppet plug30-42

jpeedometer sleeve bolt3.0-5.0nput shaft lock nut

140-160ntermediate lock nut

gear

140-160

3everse idler gear shaft bolt

43-55

rransaxle case tightening bolt

35-42

stopper bracket bolt

15-22

qestrict ball assembly30-35

ft.lbs.

13-2012-18

22-25

22-25

20-2543-58

3-5

7-10

7-1012-19

11-16

11-1643-58

11-16

7-1032-39

22-25

7-9

17-25

43-52

7-9

11-1522-25

22-302.5-3.5

102-I 15

102-11532-39

26-3011-15

22-25