clutch MITSUBISHI ECLIPSE 1991 Manual Online

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 786 of 1216

MANUAL TRANSAXLE

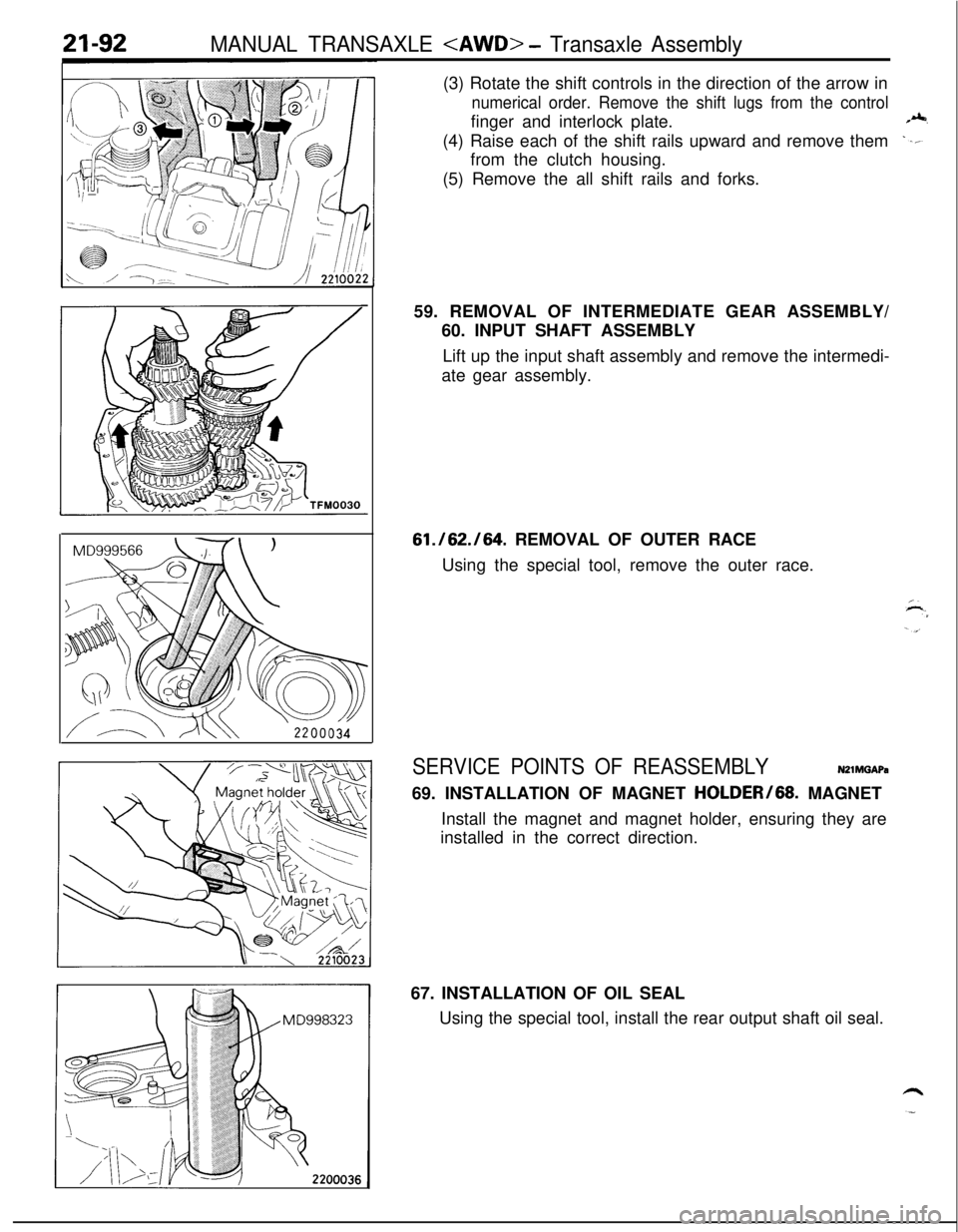

numerical order. Remove the shift lugs from the controlfinger and interlock plate.

(4) Raise each of the shift rails upward and remove them

from the clutch housing.

(5) Remove the all shift rails and forks.

59. REMOVAL OF INTERMEDIATE GEAR ASSEMBLY/

60. INPUT SHAFT ASSEMBLY

Lift up the input shaft assembly and remove the intermedi-

ate gear assembly.

61./62./64. REMOVAL OF OUTER RACE

Using the special tool, remove the outer race.

SERVICE POINTS OF REASSEMBLYN21MGAPa69. INSTALLATION OF MAGNET HOLDER/68. MAGNET

Install the magnet and magnet holder, ensuring they are

installed in the correct direction.

67. INSTALLATION OF OIL SEAL

Using the special tool, install the rear output shaft oil seal.

Page 788 of 1216

21-94MANUAL TRANSAXLE

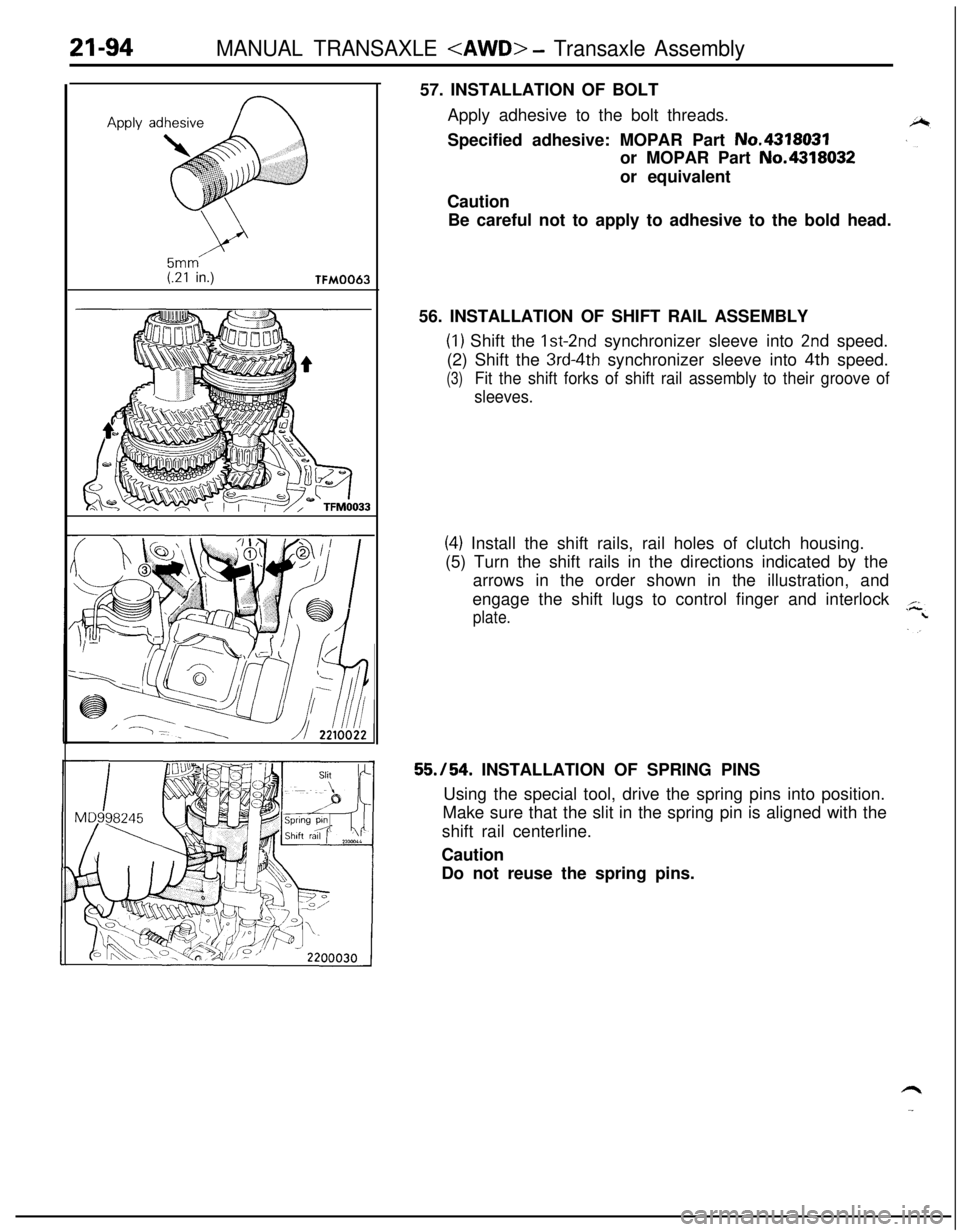

5mm(.21 in.)TFM006357. INSTALLATION OF BOLT

Apply adhesive to the bolt threads.

Specified adhesive: MOPAR Part No.4318031

or MOPAR Part No.4318032

or equivalent

Caution

Be careful not to apply to adhesive to the bold head.

56. INSTALLATION OF SHIFT RAIL ASSEMBLY

(1) Shift the Ist-2nd synchronizer sleeve into 2nd speed.

(2) Shift the

3rd-4th synchronizer sleeve into 4th speed.

(3)Fit the shift forks of shift rail assembly to their groove of

sleeves.

(4) Install the shift rails, rail holes of clutch housing.

(5) Turn the shift rails in the directions indicated by the

arrows in the order shown in the illustration, and

engage the shift lugs to control finger and interlock

plate.

55./54. INSTALLATION OF SPRING PINS

Using the special tool, drive the spring pins into position.

Make sure that the slit in the spring pin is aligned with the

shift rail centerline.

Caution

Do not reuse the spring pins.

Page 790 of 1216

21-96MANUAL TRANSAXLE

/._~~1 - 2 mm l.039 - ,078 in.)2200051

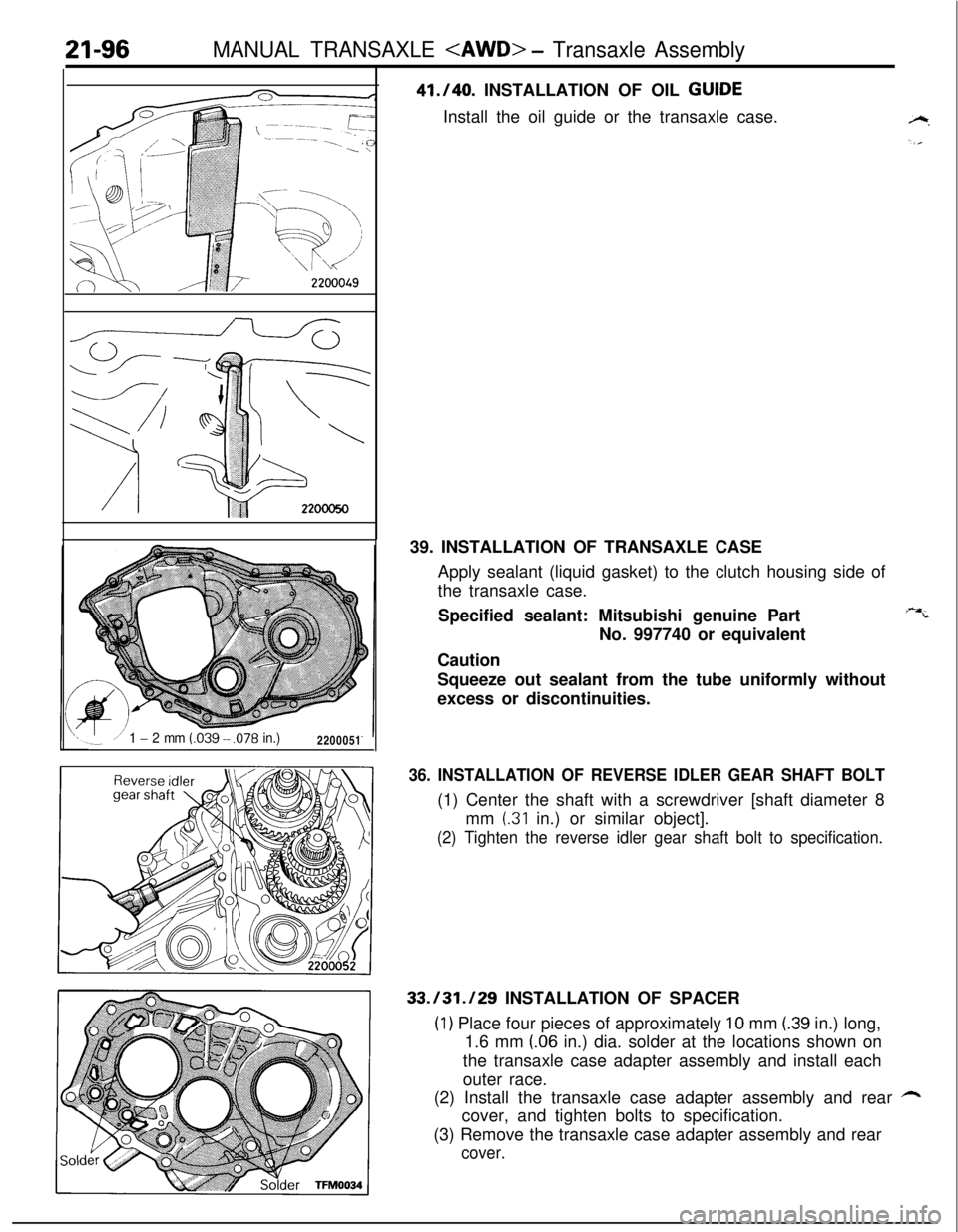

41./40. INSTALLATION OF OIL GUIDE

Install the oil guide or the transaxle case.

39. INSTALLATION OF TRANSAXLE CASE

Apply sealant (liquid gasket) to the clutch housing side of

the transaxle case.

Specified sealant: Mitsubishi genuine Part

No. 997740 or equivalent

Caution

Squeeze out sealant from the tube uniformly without

excess or discontinuities.

36. INSTALLATION OF REVERSE IDLER GEAR SHAFT BOLT(1) Center the shaft with a screwdriver [shaft diameter 8

mm

(.31 in.) or similar object].

(2) Tighten the reverse idler gear shaft bolt to specification.33.131.129 INSTALLATION OF SPACER

(1) Place four pieces of approximately 10 mm (.39 in.) long,

1.6 mm

(06 in.) dia. solder at the locations shown on

the transaxle case adapter assembly and install each

outer race.

(2) Install the transaxle case adapter assembly and rear

Acover, and tighten bolts to specification.

(3) Remove the transaxle case adapter assembly and rear

cover.

Page 793 of 1216

MANUAL TRANSAXLE

sealant

TFM0041

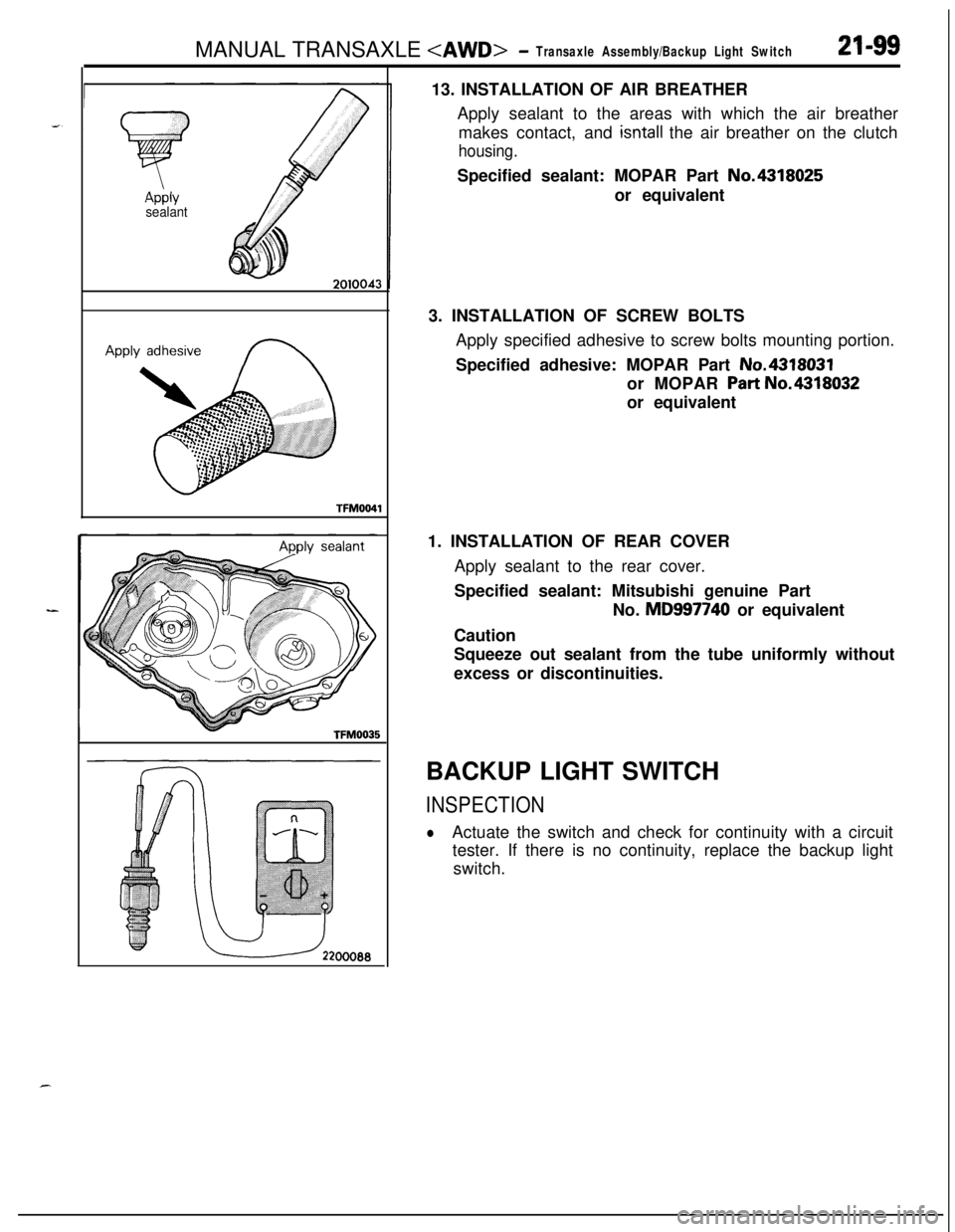

TFM003513. INSTALLATION OF AIR BREATHER

Apply sealant to the areas with which the air breather

makes contact, and

isntall the air breather on the clutch

housing.Specified sealant: MOPAR Part No.4318025

or equivalent

3. INSTALLATION OF SCREW BOLTS

Apply specified adhesive to screw bolts mounting portion.

Specified adhesive: MOPAR Part No.4318031

or MOPAR

Part No.4318032

or equivalent

1. INSTALLATION OF REAR COVER

Apply sealant to the rear cover.

Specified sealant: Mitsubishi genuine Part

No. MD997740 or equivalent

Caution

Squeeze out sealant from the tube uniformly without

excess or discontinuities.

BACKUP LIGHT SWITCH

INSPECTION

lActuate the switch and check for continuity with a circuit

tester. If there is no continuity, replace the backup light

switch.

Page 806 of 1216

21-112MANUAL TRANSAXLE

201051

Damage, breakage

I

-FM0119Synchronizer ring

Gear FM0117

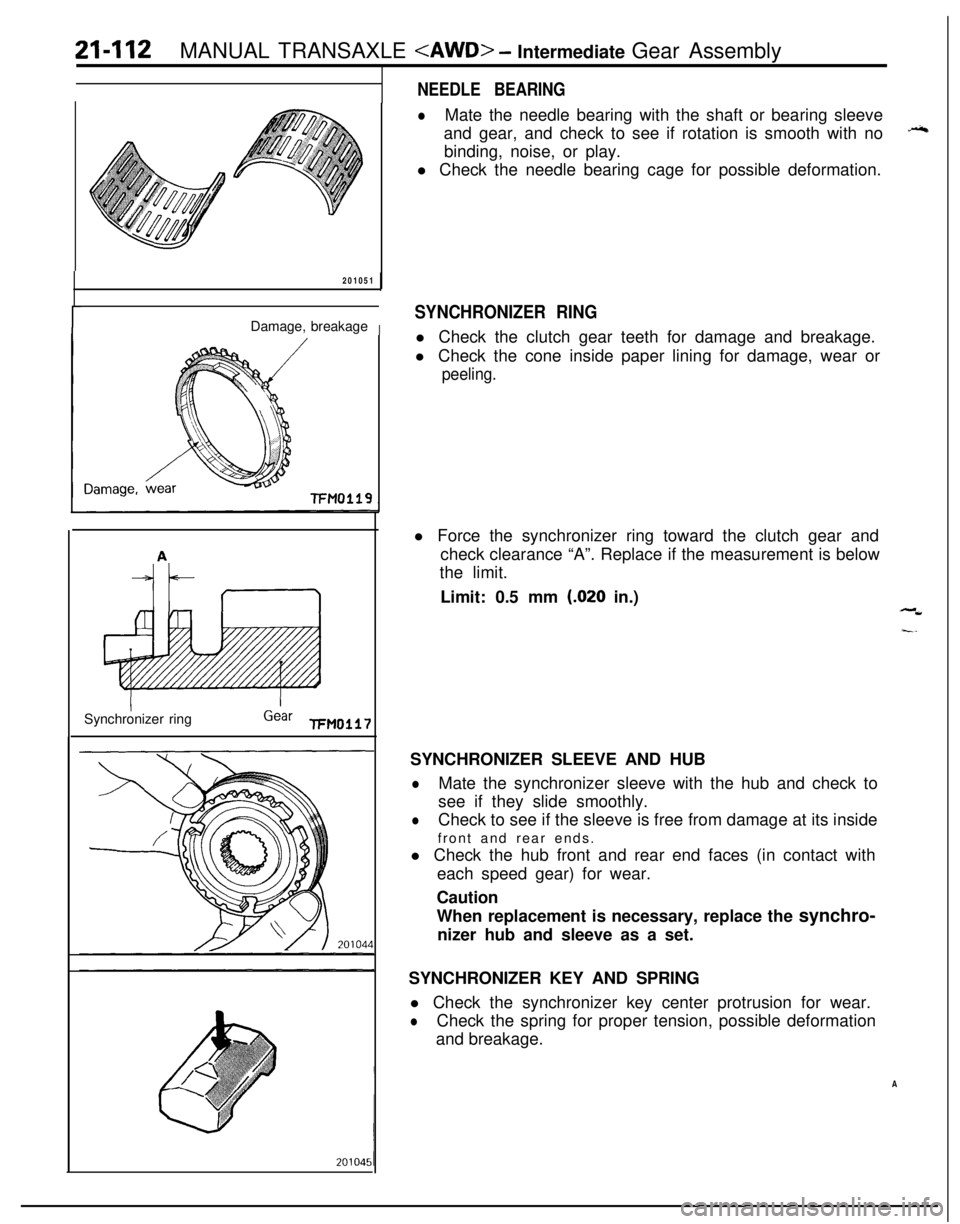

NEEDLE BEARING

lMate the needle bearing with the shaft or bearing sleeve

and gear, and check to see if rotation is smooth with no

++binding, noise, or play.

l Check the needle bearing cage for possible deformation.

SYNCHRONIZER RINGl Check the clutch gear teeth for damage and breakage.

l Check the cone inside paper lining for damage, wear or

peeling.l Force the synchronizer ring toward the clutch gear and

check clearance “A”. Replace if the measurement is below

the limit.

Limit: 0.5 mm

(.020 in.),-W

I-.SYNCHRONIZER SLEEVE AND HUB

lMate the synchronizer sleeve with the hub and check to

see if they slide smoothly.

lCheck to see if the sleeve is free from damage at its inside

front and rear ends.

l Check the hub front and rear end faces (in contact with

each speed gear) for wear.

Caution

When replacement is necessary, replace the synchro-

nizer hub and sleeve as a set.

SYNCHRONIZER KEY AND SPRING

l Check the synchronizer key center protrusion for wear.

lCheck the spring for proper tension, possible deformation

and breakage.

A

Page 807 of 1216

-.

MANUAL TRANSAXLE

D99835021002:

r$J$ch housingc

prorruslon

Sprinprotrusion

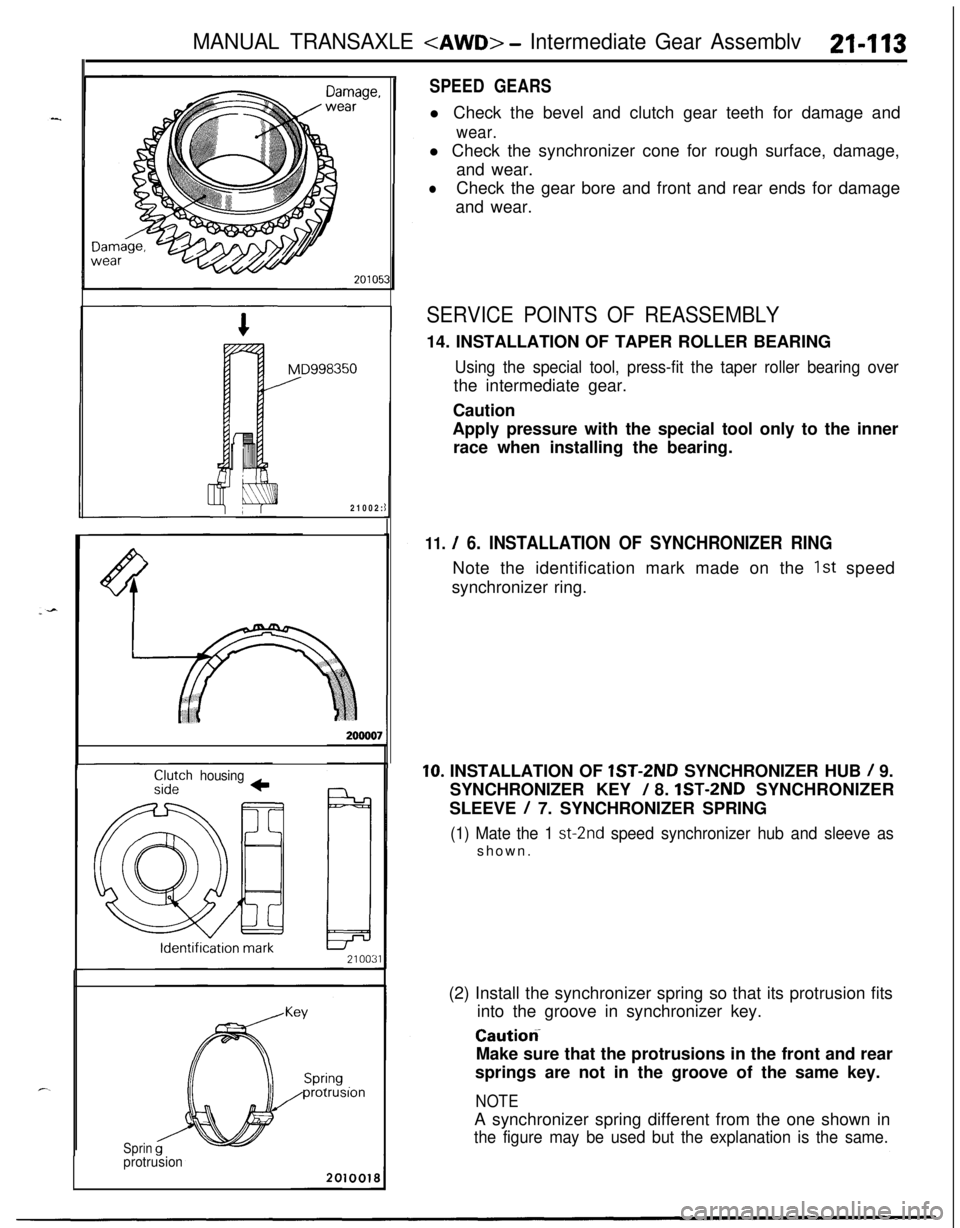

SPEED GEARSl Check the bevel and clutch gear teeth for damage and

wear.l Check the synchronizer cone for rough surface, damage,

and wear.

lCheck the gear bore and front and rear ends for damage

and wear.

SERVICE POINTS OF REASSEMBLY14. INSTALLATION OF TAPER ROLLER BEARING

Using the special tool, press-fit the taper roller bearing overthe intermediate gear.

Caution

Apply pressure with the special tool only to the inner

race when installing the bearing.

11. / 6. INSTALLATION OF SYNCHRONIZER RINGNote the identification mark made on the

1st speed

synchronizer ring.

10. INSTALLATION OF lST-2ND SYNCHRONIZER HUB / 9.

SYNCHRONIZER KEY

/ 8. lST-2ND SYNCHRONIZER

SLEEVE

/ 7. SYNCHRONIZER SPRING

(1) Mate the 1 st-2nd speed synchronizer hub and sleeve asshown.

(2) Install the synchronizer spring so that its protrusion fits

into the groove in synchronizer key.

Caution-Make sure that the protrusions in the front and rear

springs are not in the groove of the same key.

NOTEA synchronizer spring different from the one shown in

the figure may be used but the explanation is the same.

Page 811 of 1216

MANUAL TRANSAXLE

_.Damage, breakage

TFMO119Synchronizer ring

GearTFM0117

20104~

201045

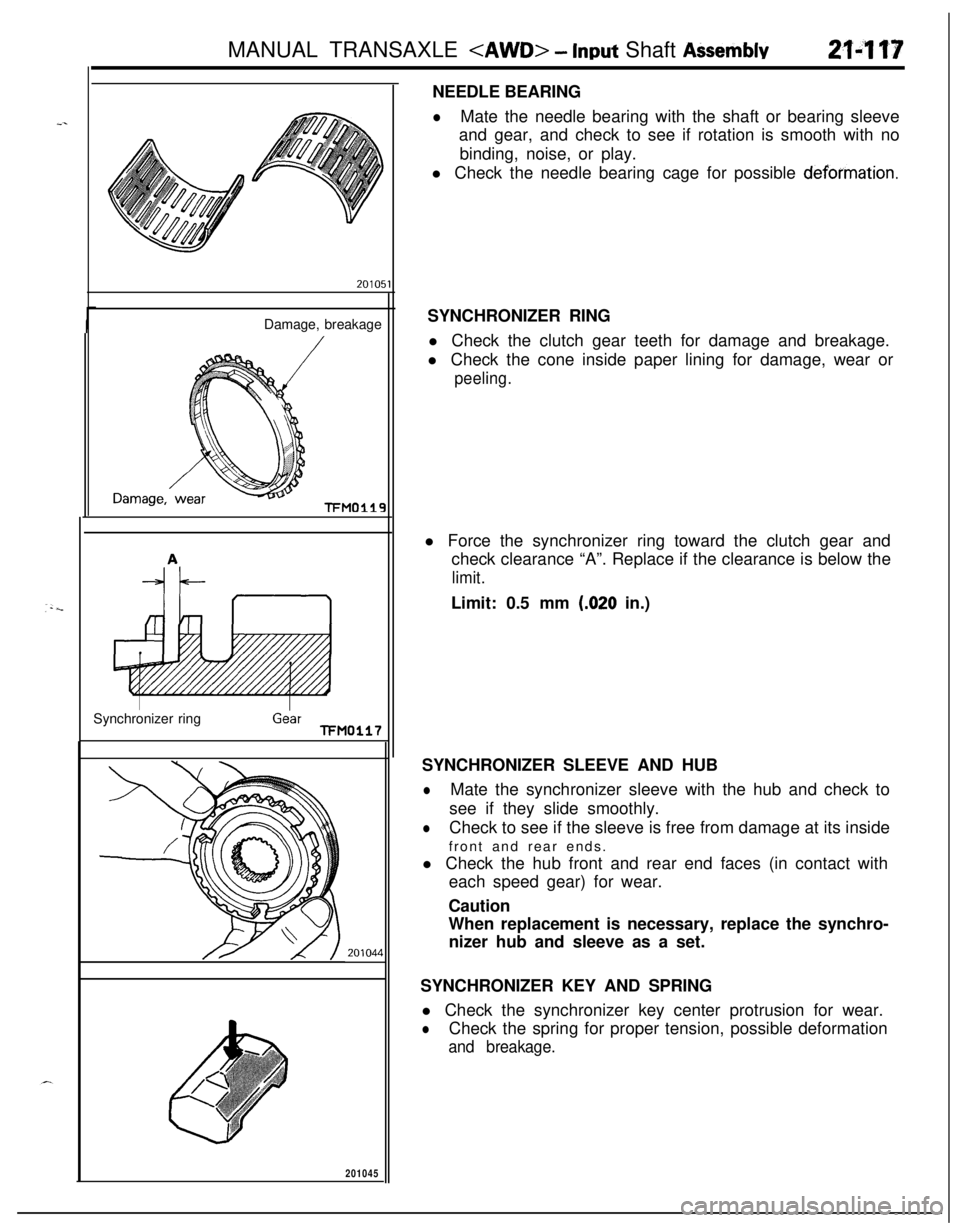

1NEEDLE BEARING

lMate the needle bearing with the shaft or bearing sleeve

and gear, and check to see if rotation is smooth with no

binding, noise, or play.

l Check the needle bearing cage for possible

deformation.SYNCHRONIZER RING

l Check the clutch gear teeth for damage and breakage.

l Check the cone inside paper lining for damage, wear or

peeling.l Force the synchronizer ring toward the clutch gear and

check clearance “A”. Replace if the clearance is below the

limit.Limit: 0.5 mm

(.020 in.)

SYNCHRONIZER SLEEVE AND HUB

lMate the synchronizer sleeve with the hub and check to

see if they slide smoothly.

lCheck to see if the sleeve is free from damage at its inside

front and rear ends.

l Check the hub front and rear end faces (in contact with

each speed gear) for wear.

Caution

When replacement is necessary, replace the synchro-

nizer hub and sleeve as a set.

SYNCHRONIZER KEY AND SPRING

l Check the synchronizer key center protrusion for wear.

lCheck the spring for proper tension, possible deformation

and breakage.

Page 812 of 1216

MANUAL TRANSAXLE

vear210018

Springprotrusion

Key

201001::

TFM0023

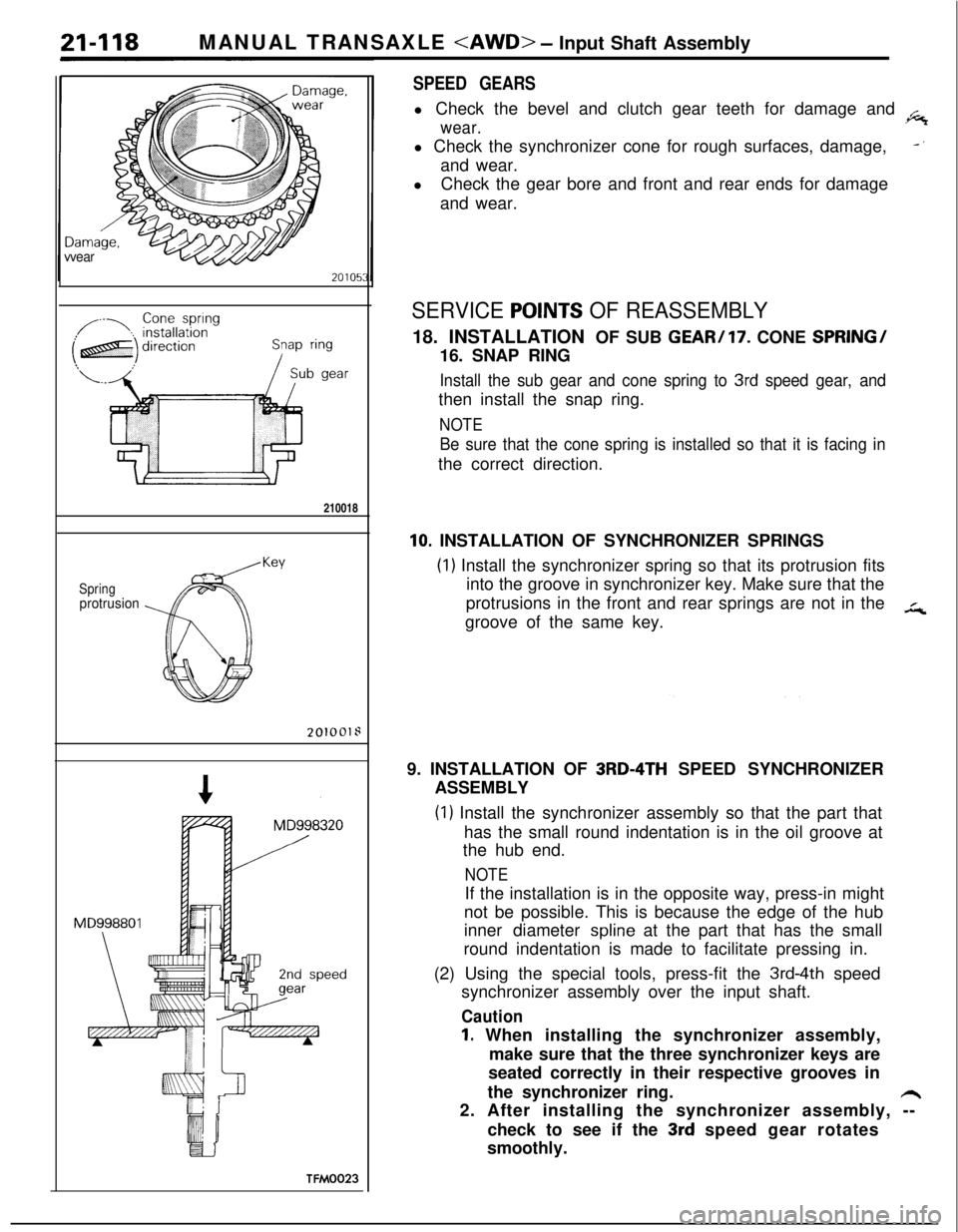

SPEED GEARSl Check the bevel and clutch gear teeth for damage and

.6

wear.l Check the synchronizer cone for rough surfaces, damage,

-‘and wear.

lCheck the gear bore and front and rear ends for damage

and wear.

SERVICE POlNTS OF REASSEMBLY18. INSTALLATION OF SUB

GEAR/17. CONE SPRING/16. SNAP RING

Install the sub gear and cone spring to 3rd speed gear, andthen install the snap ring.

NOTE

Be sure that the cone spring is installed so that it is facing inthe correct direction.

10. INSTALLATION OF SYNCHRONIZER SPRINGS

(1) Install the synchronizer spring so that its protrusion fits

into the groove in synchronizer key. Make sure that the

protrusions in the front and rear springs are not in the

in,groove of the same key.

9. INSTALLATION OF

3RD-4TH SPEED SYNCHRONIZER

ASSEMBLY

(1) Install the synchronizer assembly so that the part that

has the small round indentation is in the oil groove at

the hub end.

NOTEIf the installation is in the opposite way, press-in might

not be possible. This is because the edge of the hub

inner diameter

spline at the part that has the small

round indentation is made to facilitate pressing in.

(2) Using the special tools, press-fit the

3rd-4th speed

synchronizer assembly over the input shaft.

Caution

1. When installing the synchronizer assembly,

make sure that the three synchronizer keys are

seated correctly in their respective grooves in

the synchronizer ring.

h2. After installing the synchronizer assembly, --

check to see if the

3rd speed gear rotates

smoothly.

Page 815 of 1216

MANUAL TRANSAXLE

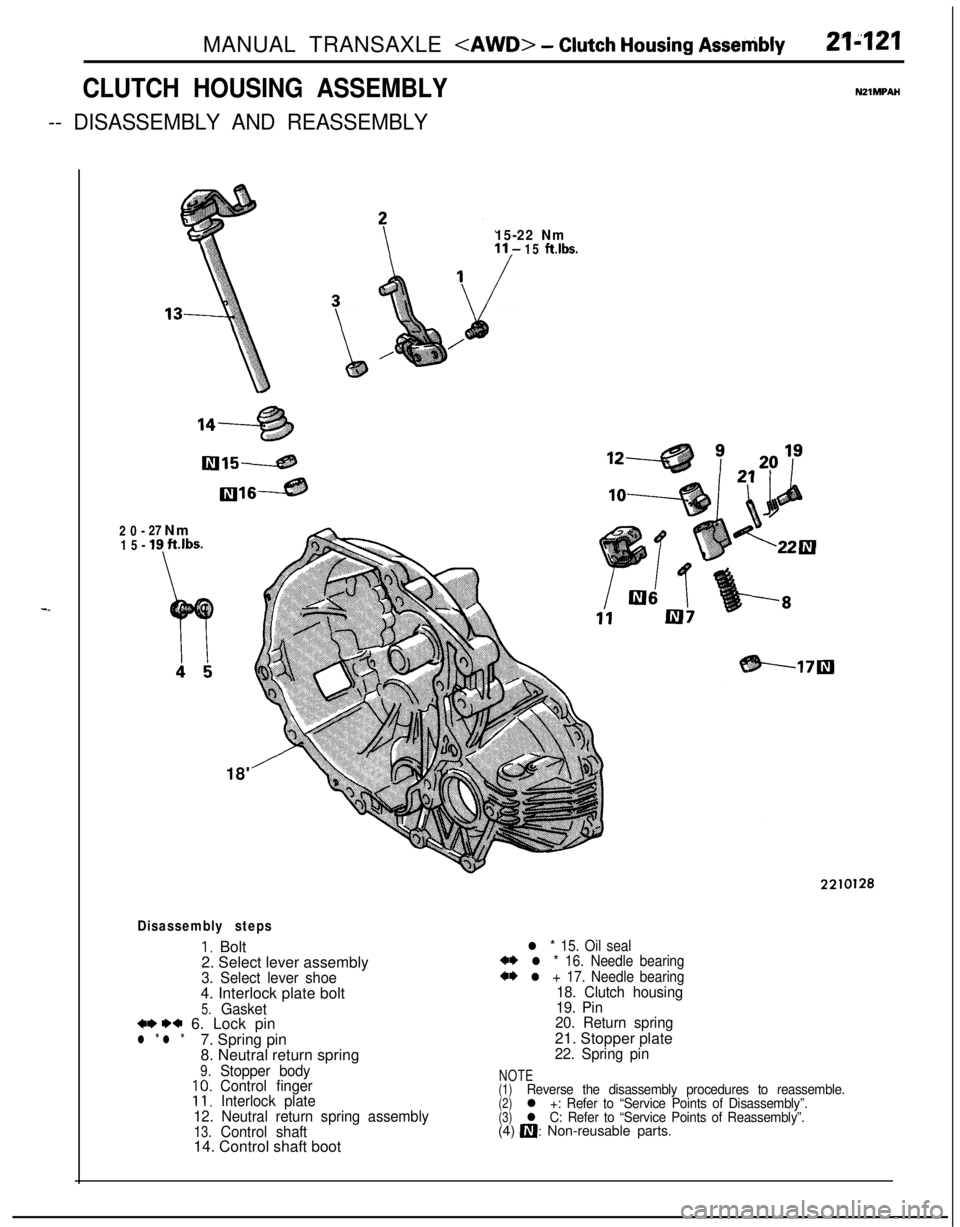

CLUTCH HOUSING ASSEMBLY

-- DISASSEMBLY AND REASSEMBLY

NZlMPAH

-20-27 Nm

15-

19 ft.lbs.

15-22 Nm15 ft.lbs.18'

Disassembly steps

I, Bolt

2. Select lever assembly

3. Select lever shoe4. Interlock plate bolt

5.Gasket+* WC 6. Lock pinl * l *7. Spring pin

8. Neutral return spring

9.Stopper body10.Control finger11,Interlock plate

12. Neutral return spring assembly

13.Control shaft14. Control shaft boot

2210128

l * 15. Oil seal*I) l * 16. Needle bearing

a* l + 17. Needle bearing18. Clutch housing

19. Pin

20. Return spring21. Stopper plate

22. Spring pin

NOTE(1)Reverse the disassembly procedures to reassemble.(2)l +: Refer to “Service Points of Disassembly”.(3)l C: Refer to “Service Points of Reassembly”.(4) a: Non-reusable parts.

Page 816 of 1216

21-122MANUAL TRANSAXLE

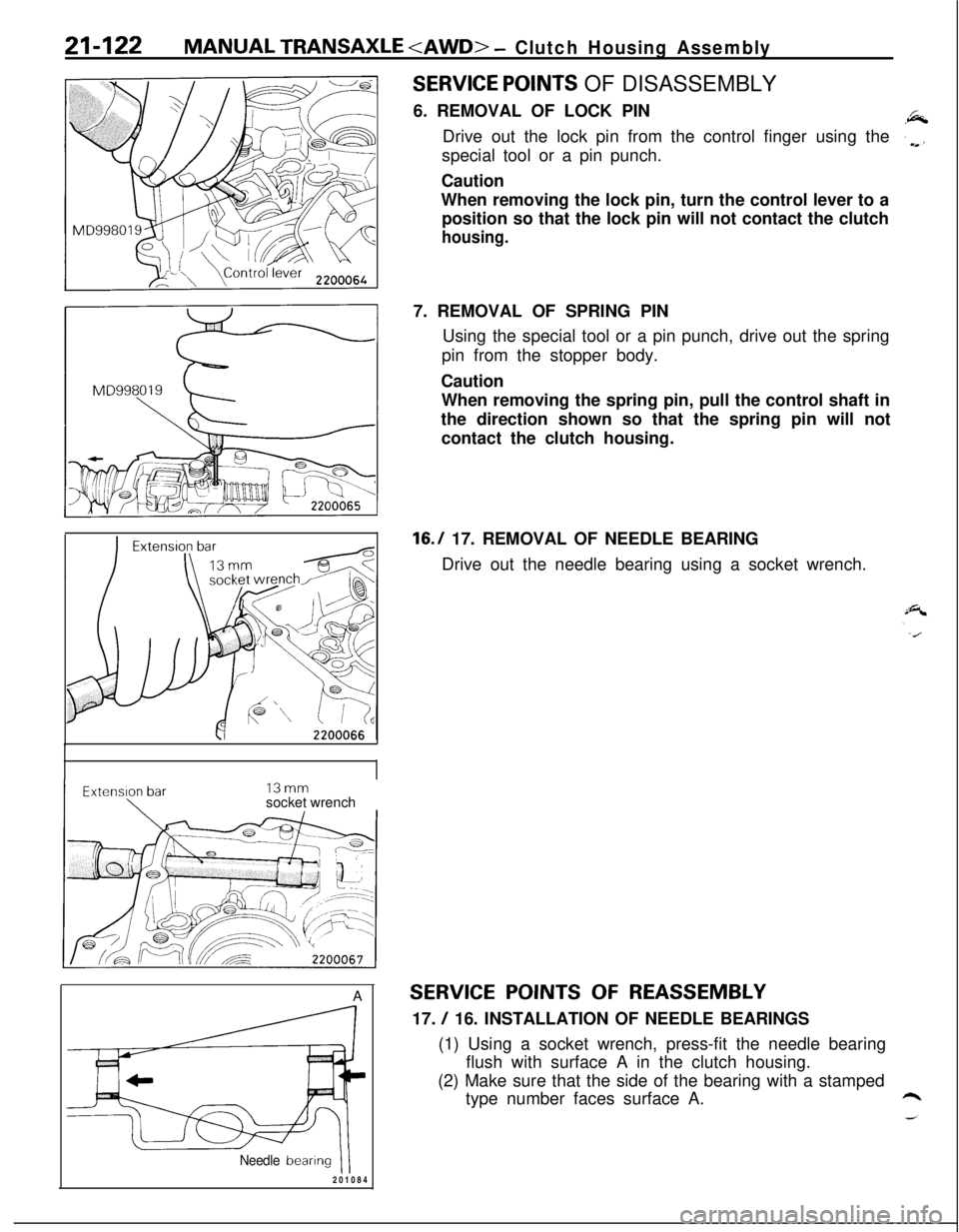

SERVICE POINTS OF DISASSEMBLY

6. REMOVAL OF LOCK PIN

Drive out the lock pin from the control finger using the

special tool or a pin punch.

Caution

When removing the lock pin, turn the control lever to a

position so that the lock pin will not contact the clutch

housing.13mm

socket wrench

A

Needle bearingII2010847. REMOVAL OF SPRING PIN

Using the special tool or a pin punch, drive out the spring

pin from the stopper body.

Caution

When removing the spring pin, pull the control shaft in

the direction shown so that the spring pin will not

contact the clutch housing.

16.7 17. REMOVAL OF NEEDLE BEARING

Drive out the needle bearing using a socket wrench.

SERVICE POINTS OF REASSEMBLY17.

/ 16. INSTALLATION OF NEEDLE BEARINGS

(1) Using a socket wrench, press-fit the needle bearing

flush with surface A in the clutch housing.

(2) Make sure that the side of the bearing with a stamped

type number faces surface A.