clutch MITSUBISHI ECLIPSE 1991 Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 255 of 1216

COOLING - Troubleshooting7A7

OPERATION

1. When the output of the air conditioner*--control unit is “LO” (OV)(when the

compressor magnet clutch isdeenergized)

l When the ignition switch is at “ON” , and if

engine coolant temperature rises to

85°C

(185”F), the thermosensor contacts close,

causing current to flow through the radiator

fan motor relay (coil), thermosensor and

ground, causing the radiator fan motor relay

contacts to close.

l Current flows through the radiator fan motor

relay contacts, radiator fan motor and ground,causing the radiator fan motor to rotate.

2. When the output of the air conditioner

control unit is “HI” (approx. 12V)(when the

compressor magnet clutch is

energized)l If the therm0 sensor is “ON” when the

engine coolant temperature exceeds

85°C

(185°F). the condenser fan motor control relay

is also “ON”, thus the condenser fan as well

as the radiator fan start rotating at a high

speed.

TROUBLESHOOTING HINTS

1. Neither the radiator fan nor condenser fanrotate at

all.l Check sub fusible link

No.3.

2. Only the condenser fan does not operate.l Check dedicated fuse

No.5.

3. The radiator fan and condenser fan do notoperate

in the low speed mode, but operateotherwise.

(1)The A/C compressor magnet clutch does not

enter the “ON” state.

l Check whether the output of the air con-

ditioner control unit is available.

NOTEFor troubleshooting of the air conditioner

control unit, refer to GROUP 24.

(2)The A/C compressor magnet clutch enters

the “ON” state.

l Check the resistor.Conditions

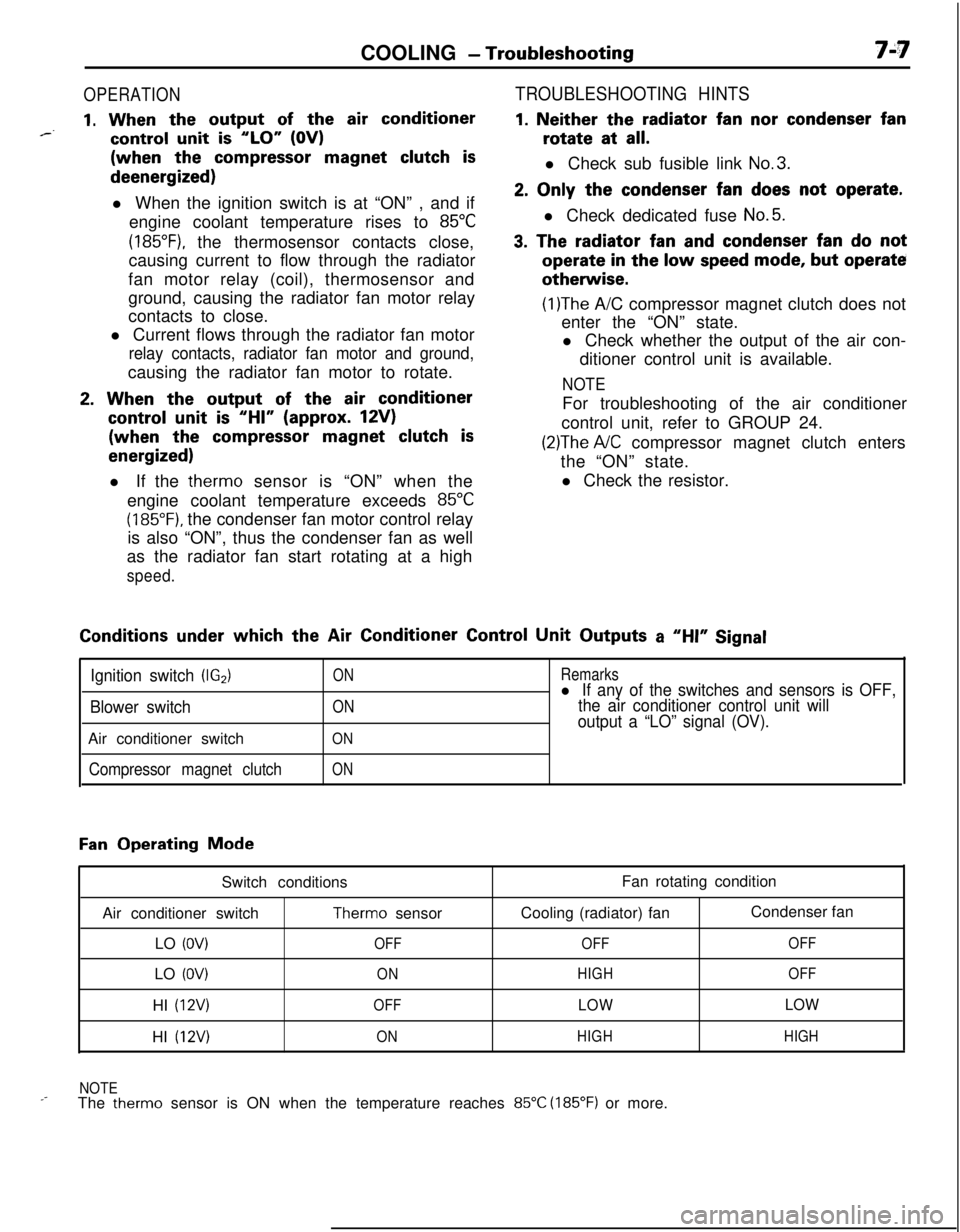

under which the Air Conditioner Control Unit Outputs a “HI” Signal

Ignition switch (IG2)

Blower switchAir conditioner switch

Compressor magnet clutch

ON

ON

ON

ON

Remarksl If any of the switches and sensors is OFF,

the air conditioner control unit will

output a “LO” signal (OV).

Fan Operating Mode

Switch conditions

Air conditioner switch

Therm0 sensor

LO

(OV)OFFLO

(OV)ONHI

(12V)OFFHI

(12V)ONFan rotating condition

Cooling (radiator) fanCondenser fan

OFFOFF

HIGHOFF

LOWLOW

HIGHHIGH

NOTE

_-The therm0 sensor is ON when the temperature reaches 85°C (185°F) or more.

Page 355 of 1216

ENGINE - Crankshaft, Flwvheel and Drive Plate9-71

3EN30’lrrow mark toward

cap No,

I

RING GEAR (Engine with a manual transaxle)Check the ring gear for worn, damaged or broken teeth.

Replace the ring gear if teeth are faulty, and also check the

starter motor pinion.

Ring Gear Replacement Procedure(1) Strike outer circumference of ring gear at several points.

Caution

The ring gear cannot be removed if it is heated.(2) Install the ring gear on flywheel after heating the ring gear

to

260-280°C (500-536°F) for shrink fit.

FLYWHEEL (Engine with a manual transaxle)

(1) Visually check the clutch disc friction surface of flywheel forridge wear, streaks and seizure. Replace as necessary.

(2) If the flywheel

runout exceeds the limit, replace it.

Limit: 0.13 mm (0051 in.)

DRIVE PLATE (Engine with an automatic transaxle)Replace if deformed, damaged or cracked.

SERVICE POINTS OF REASSEMBLY

NOSUDAA

15. INSTALLATION OF UPPER BEARINGWhen reusing the main bearings, install them in their

original positions by referring to location marking made at

the time of removal.

Be sure that oil holes in bearings align with those in cylinder

block.

13. INSTALLATION OF LOWER BEARINGMake sure that a bearing without oil groove is used as

lower bearing.

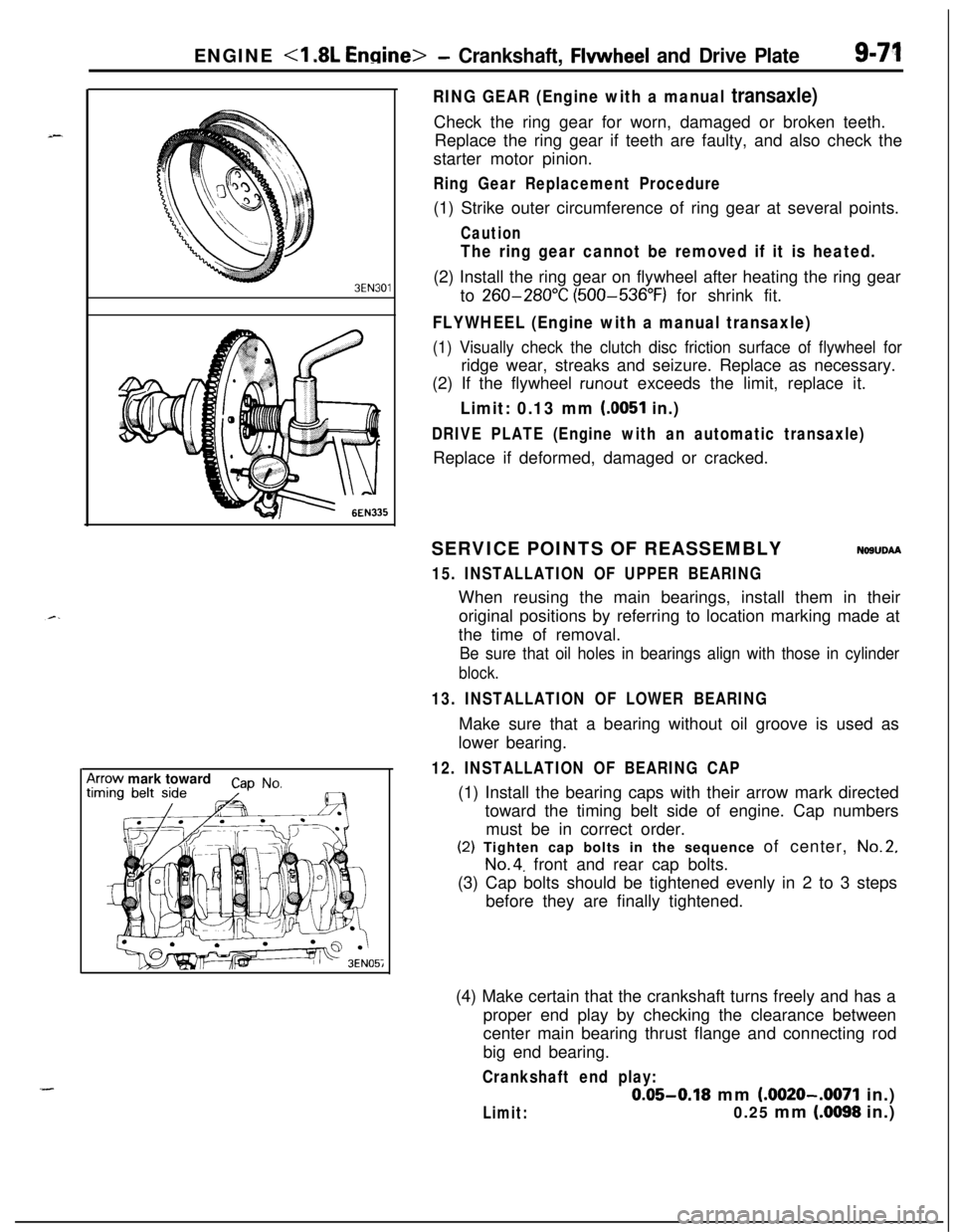

12. INSTALLATION OF BEARING CAP(1) Install the bearing caps with their arrow mark directed

toward the timing belt side of engine. Cap numbers

must be in correct order.(2) Tighten cap bolts in the sequence of center,

No.2,

No.4. front and rear cap bolts.

(3) Cap bolts should be tightened evenly in 2 to 3 steps

before they are finally tightened.

(4) Make certain that the crankshaft turns freely and has a

proper end play by checking the clearance between

center main bearing thrust flange and connecting rod

big end bearing.

Crankshaft end play:

0.05-0.18 mm (.0020-.0071 in.)

Limit:0.25 mm (.0098 in.)

Page 418 of 1216

g-134 ENGINE <2.0L DOHC Engine>- Crankshaft, Flywheel and Drive Plate

3EN301CRANKSHAFT REAR OIL SEAL

(1) Check oil seal lip for wear and damage.

(2) Check rubber for deterioration or hardening.

(3) Check oil seal case for cracks and damage.

RING GEAR (Engine with a manual transaxle)

Check teeth of ring gear for wear and damage. If necessary,

replace the ring gear.

If the ring gear teeth are worn or damaged, also check the

starter motor pinion.

To remove the ring gear, strike the ring gear at several points

on its outer circumference. The ring gear cannot be removed ifit is heated.

To install the ring gear, heat the ring gear to

300°C (572°F) for

shrink fit.

FLYWHEEL (Engine with a manual transaxle)

(1) Check the clutch disc friction surface for ridge wear,

streaks, and seizure. If necessary, replace flywheel.

(2) If the

runout of flywheel exceeds the limit, replace.++.Limit: 0.13 mm

(.0051 in.)

DRIVE PLATE (Engine with an automatic transaxle)

Replace deformed, damaged, or cracked drive plates.

SERVICE POINTS OF REASSEMBLYNWUGAB

14. INSTALLATION OF CRANKSHAFT BEARING (UPPER)

Install the upper crankshaft bearing to the cylinder block.

There is an oil groove in the upper crankshaft bearing.

There is no difference between upper and lower bearings

for the center (with flange).

12. INSTALLATION OF CRANKSHAFT BEARING (LOWER)

Install the lower crankshaft bearing (with no oil groove;

there is no difference for center) to each bearing cap and

apply engine oil to bearing surfaces.

Page 563 of 1216

AUTO-CRUISE CONTROL SYSTEM - Snecifications14-109

AUTO-CRUISE CONTROL SYSTEM

.-4.

SPECIFICATIONS

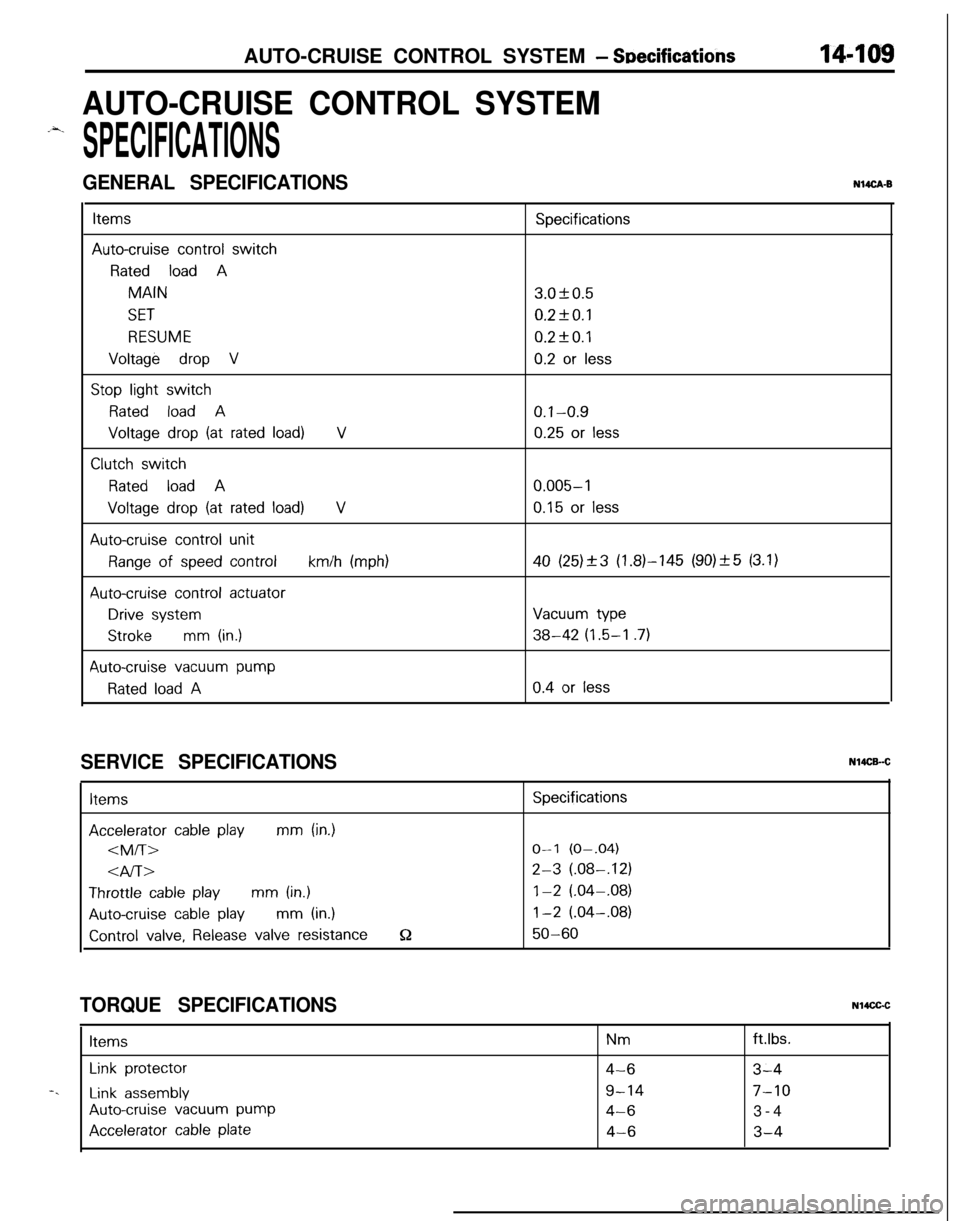

GENERAL SPECIFICATIONSNUCA-B

ItemsSpecifications

Auto-cruise control switch

Rated load AMAIN3.OkO.5

SET0.2fO.l

RESUME0.2kO.l

Voltage drop V0.2 or less

Stop light switch

Rated load A0.1-0.9

Voltage drop (at rated load)V0.25 or less

Clutch switch

Rated load A0.005-l

Voltage drop (at rated load)V0.15 or less

Auto-cruise control unit

Range of speed controlkm/h (mph)40 (25)_+3 (1.81-145 (90)_+5 (3.1)

Auto-cruise control actuator

Drive systemVacuum type

Strokemm (in.)38-42 (1.5-I .7)

Auto-cruise vacuum pump

Rated load A0.4 or less

SERVICE SPECIFICATIONSItems

Accelerator cable playmm (in.)

4l-bThrottle

cable playmm (in.)

Auto-cruise cable playmm (in.)

Control valve, Release valve resistanceQ

Specifications

O-l (O-.04)

2-3 (.08-,121

1-2 (.04-.08)

1-2 (.04-.08)

50-60

TORQUE SPECIFICATIONSN14CGCItems

Nmftlbs.

Link protector4-63-4-.

Link assembly9-147-10

Auto-cruise vacuum pump4-63-4

Accelerator cable plate4-63-4

Page 565 of 1216

AUTO-CRUISE CONTROL SYSTEM - Troubleshooting144w

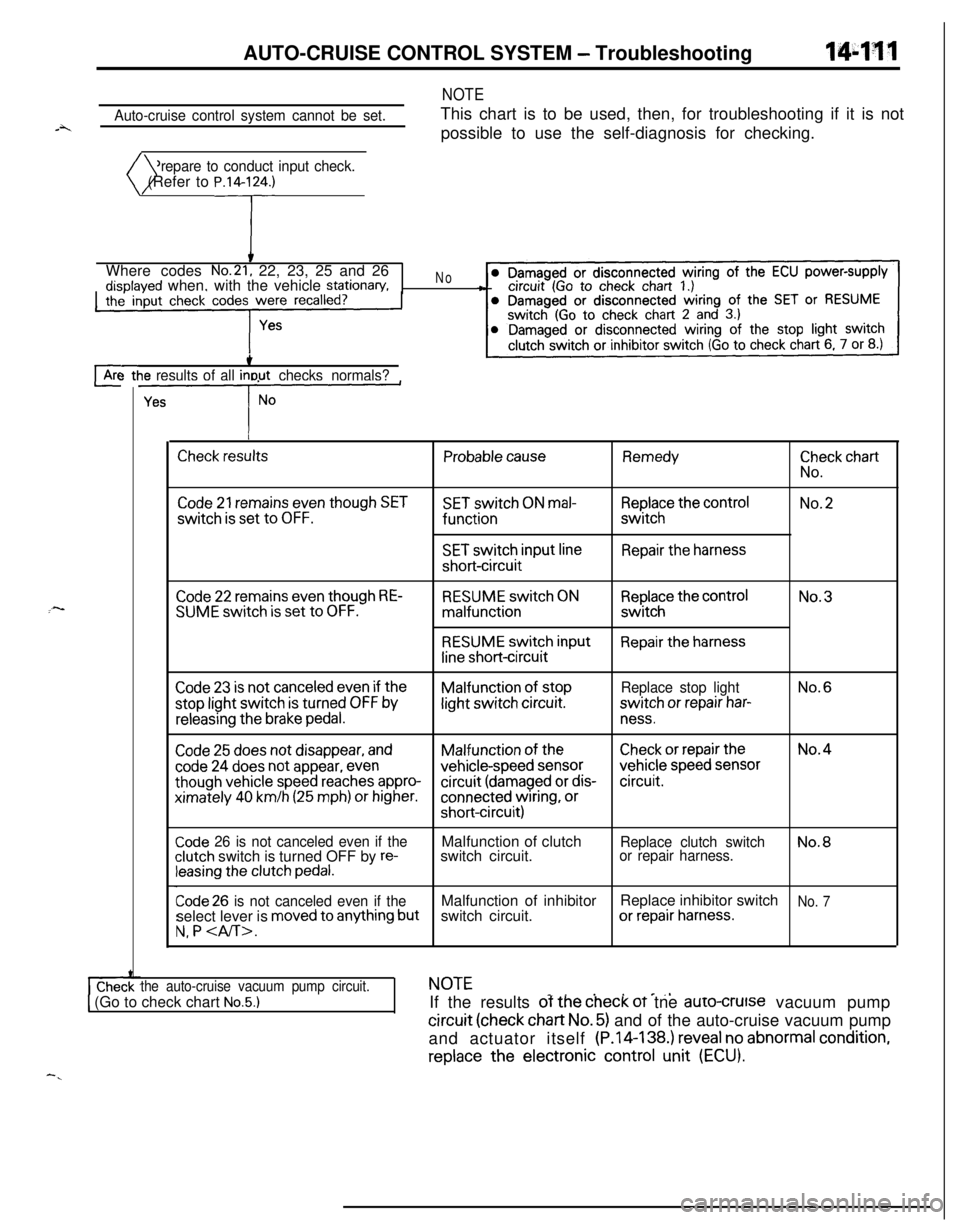

Auto-cruise control system cannot be set.

NOTEThis chart is to be used, then, for troubleshooting if it is not

possible to use the self-diagnosis for checking.

Prepare to conduct input check.

)( (Refer to P.14lrWhere codes

No.21, 22, 23, 25 and 26disolaved when, with the vehicle stationary,the’ input check codes were recalled?

‘#

No-8

cArc-3 ttie results of all inout checks normals?

L--y--

I

Check resultsProbable causeRemedy

ii”,:” chart

Code 21 remains even though SETSET switch ON mal-Replace the controlNo.2switch

is set to OFF.functionswitch

SET switch input lineRepair the harnessshort-circuit

:-Code 22 remains even though RE-SUME switch is set to OFF.RESUME switch ONmalfunction

RESUME switch input

line short-circuit

Replace the controlswitch

Repair the harnessNo.3

Code 23 is not canceled even if theMalfunction of stopReplace stop lightNo.6stop light switch

is turned OFF bylight switch circuit.switch or repair har-

releasing the brake pedal.ness.

Code 25 does not disappear, andMalfunction of theCheck or repair theNo.4

code 24 does not appear, evenvehicle-speed sensorvehicle speed sensor

though vehicle speed reaches appro-circuit (damaged or dis-circuit.ximately

40 km/h (25 mph) or higher.connected wiring, orshort-circuit)

Code 26 is not canceled even if theclutch switch is turned OFF by re-leasing the clutch pedal.Malfunction of clutch

switch circuit.

Replace clutch switchNo.8or repair harness.

Code 26 is not canceled even if theMalfunction of inhibitorReplace inhibitor switchNo. 7select lever is moved to anything butswitch circuit.or repair harness.

N, P

the auto-cruise vacuum pump circuit.NOTE_. . . e_,1 (Go to check chart No.5.)IIf the results of the check oT tne auro-crutse vacuum pump

circuit (check chart No. 5) and of the auto-cruise vacuum pump

and actuator itself (P.14-138.) reveal no abnormal

condition,replace

the electronic control unit (ECU).

-.

Page 566 of 1216

14-112AUTO-CRUISE CONTROL SYSTEM - Troubleshootina

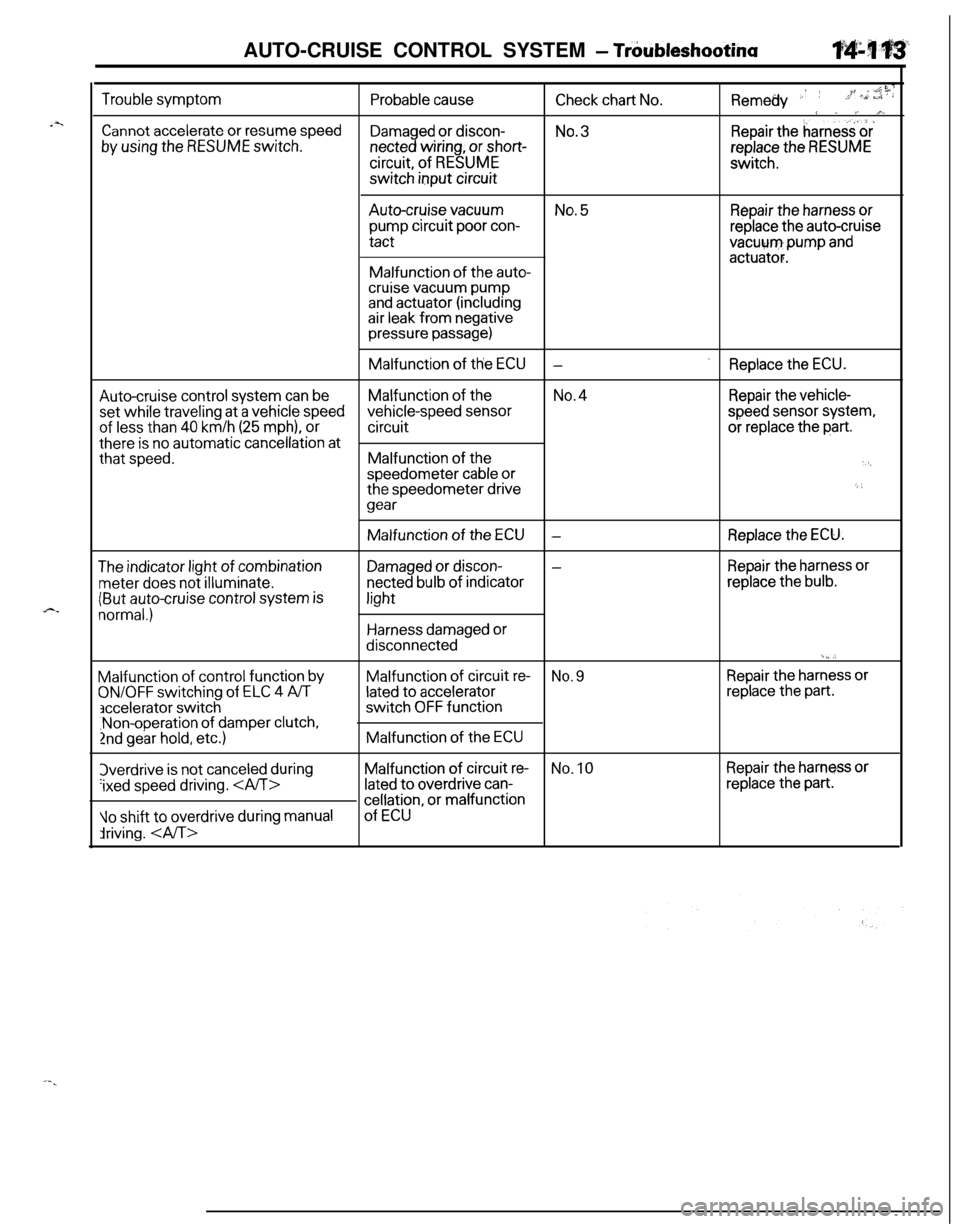

Trouble symptomProbable causeCheck chart No.Remedy

l The set vehicle speed variesMalfunction of the vehi-No.4Repair the vehicle speec

greatly upward or downward.cle speed sensor circuitsensor system, or re-l “Hunching”

(repeated alternatingplace the part.

acceleration and deceleration)Malfunction of the

occurs after setting is made.speedometer cable orspeedometer drive gearAuto-cruise

vacuumNo.5Repair the auto-cruise

pump circuit poor con-vacuum pump, ortactreplace the part.Malfunction of the

auto-

cruise vacuum pumpMalfunction of the

ECU-Replace the ECU.

The auto-cruise control system is notDamaged or discon-If the input check codeRepair the harness or

canceled when the brake pedal isnetted wiring of theNo. 23 indicates a mal-replace the stop light

depressed.stop light switch inputfunction. No. 6switch.circuit; brake switch (forauto-cruise control) mal-function (short-circuit)Auto-cruise

vacuumNo. 5Repair the harness or

pump drive circuit short-replace the auto-cruisecircuitvacuum pump.Malfunction of the

ECU-Replace the ECU.

The auto-cruise control system is notDamaged or discon-If the input check codeRepair the harness, or

canceled when the clutch pedal isnetted wiring of clutchNo. 26 indicates a mal-repair or replace the

depressed. (vehicles with a manualswitch input circuitfunction. No. 8clutch switch.

transaxle)(It is canceled, however, when theClutch switch improper

brake pedal is depressed.)installation (won’tswitch ON)Malfunction of the

ECU-Replace the ECU.

The auto-cruise control system is notDamaged or discon-If the input check codeRepair the harness, orcanceled when the shift lever isnetted wiring of inhibi-No. 26 indicates a mal-repair or replace the in-

moved to the “N” position. (vehiclestor switch input circuitfunction. No.7hibitor switch.llvith an automatic transaxle)

[It is canceled, however, when theImproper adjustment of

Drake pedal is depressed.)inhibitor switchMalfunction of the

ECU-Replace the ECU.

Cannot decelerate by using the SETTemporary damaged orNo. 2Repair the harness orswitchdisconnected wiring ofreplace the SET switch.SET switch input circuitAuto-cruise

vacuumNo.5Repair the harness orpump circuit poor con-replace the auto-cruisetactvacuum pump andactuator.Malfunction of the auto-cruise vacuum pump

and actuator (includingclogging of negativepressure passage)Malfunction of the

ECU-Replace the ECU.

Page 567 of 1216

.z

c-AUTO-CRUISE CONTROL SYSTEM

- Tr6ubleshootina

Trouble symptom

Cannot accelerate or resume speed

by using the RESUME switch.

Probable cause

Damaged or discon-netted wiring, or short-circuit, of

RESUMEswitch input circuit

Remedy .’ ’-c liiCheck chart No.,;+ >,, a”:; : :

9 . /~ A%No.3.Repair theharness‘&

replace the RESUMEswitch.Auto-cruise

vacuumNo. 5Repair the harness orpump circuit poor con-replace the auto-cruisetact

vacuum,pump andactuator.Malfunction of the auto-cruise vacuum pumpand actuator (includingair leak from negativepressure passage)Malfunction of the

ECU.-Replace the ECU.

Auto-cruise control system can beMalfunction of theNo.4Repair the vehicle-set while

traveling at a vehicle speedvehicle-speed sensorspeed sensor system,

of less than 40 km/h (25 mph), orcircuitor replace the part.there

is no automatic cancellation atthat

speed.Malfunction of the‘I,speedometer cable orthe speedometer drive6 i

gear

The indicator light of combination

meter does not illuminate.

(But auto-cruise control system is

normal.)Malfunction

of control function by

ON/OFF switching of ELC 4 A/T

accelerator switch,Non-operation of damper clutch,

2nd gear hold, etc.)3verdrive

is not canceled during

‘ixed speed driving.

10 shift to overdrive during manual

driving. Malfunction of the

ECU-Replace the ECU.

Damaged or discon--Repair the harness or

netted bulb of indicatorreplace the bulb.light

Harness damaged ordisconnected

‘._,.Malfunction of circuit

re-No. 9Repair the harness or

lated to acceleratorreplace the part.switch

OFF functionMalfunction of the

ECUMalfunction of circuit

re-No. 10Repair the harness or

lated to overdrive can-replace the part.

cellation, or malfunction

of ECU

Page 572 of 1216

14-118AUTO-CRUISE CONTROL SYSTEM - Troubleshooting

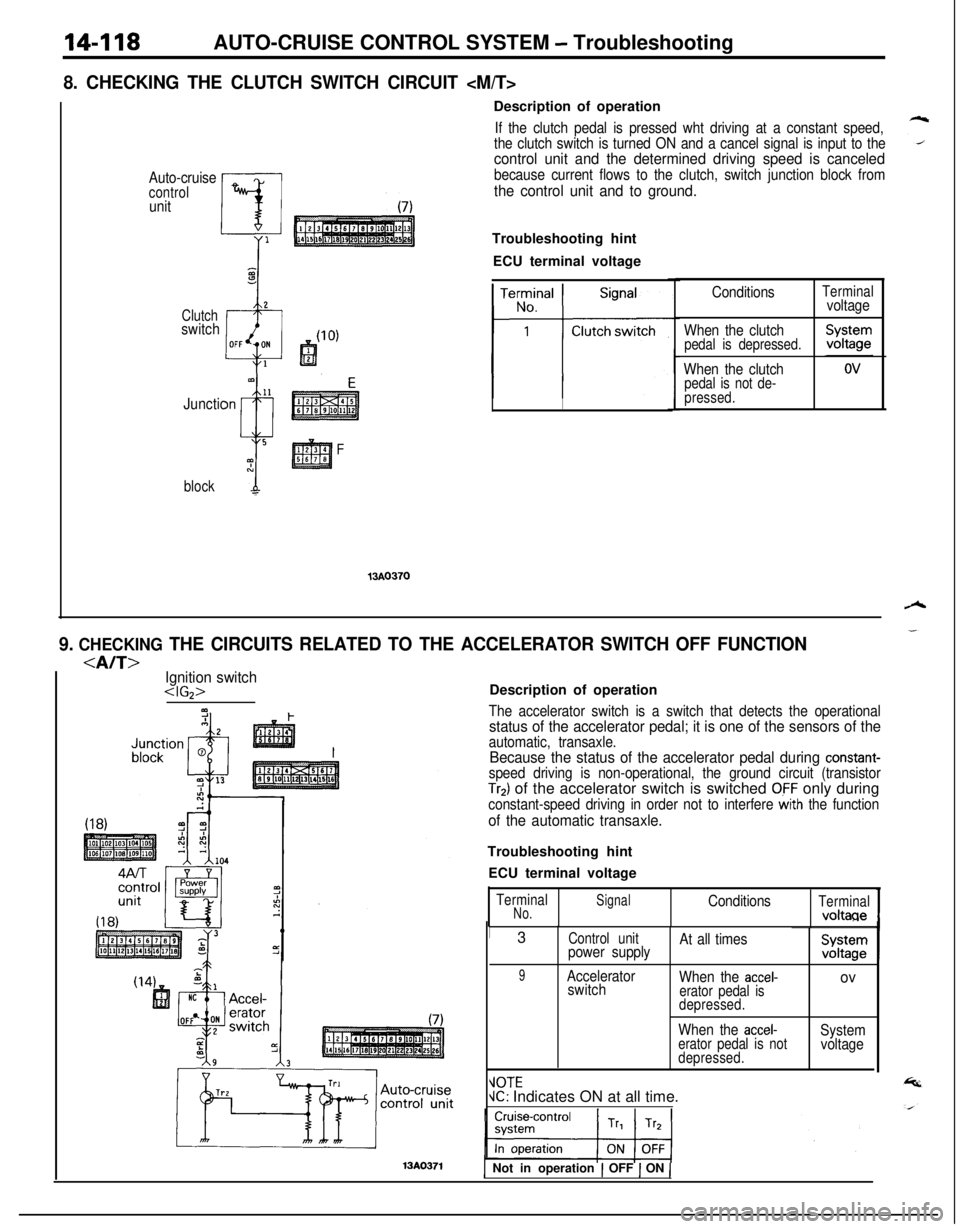

8. CHECKING THE CLUTCH SWITCH CIRCUIT

Auto-cruisecontrolunit9

2ClutchswitchOFF ON

1m11Junction

blockI

13AO370Description of operation

If the clutch pedal is pressed wht driving at a constant speed,

the clutch switch is turned ON and a cancel signal is input to the

control unit and the determined driving speed is canceled

because current flows to the clutch, switch junction block from

the control unit and to ground.Troubleshooting hint

ECU terminal voltage

TerminalSignal

No.

1Clutch switch

t--l--II

ConditionsTerminalvoltage

When the clutch

pedal is depressed.

When the clutchpedal is not de-

pressed.

9. CHECKING THE CIRCUITS RELATED TO THE ACCELERATOR SWITCH OFF FUNCTION

Ignition switch

& Accel-/Description of operation

The accelerator switch is a switch that detects the operationalstatus of the accelerator pedal; it is one of the sensors of theautomatic, transaxle.Because the status of the accelerator pedal during constant-speed driving is non-operational, the ground circuit (transistorTr2) of the accelerator switch is switched OFF only during

constant-speed driving in order not to interfere wtth the function

of the automatic transaxle.Troubleshooting hint

ECU terminal voltage

TerminalNo.SignalConditionsTerminalvoltaoe

’ 3Control unitAt all times

power supply

9Accelerator

When the accel-ovswitcherator pedal is

depressed.

When the accel-Systemerator pedal is not

depressed.voltage

\lOTEJC: Indicates ON at all time.

13AO3711 Not in operation ) OFF 1 ON (

Page 578 of 1216

14-124AUTO-CRUISE CONTROL SYSTEM - Troubleshooting

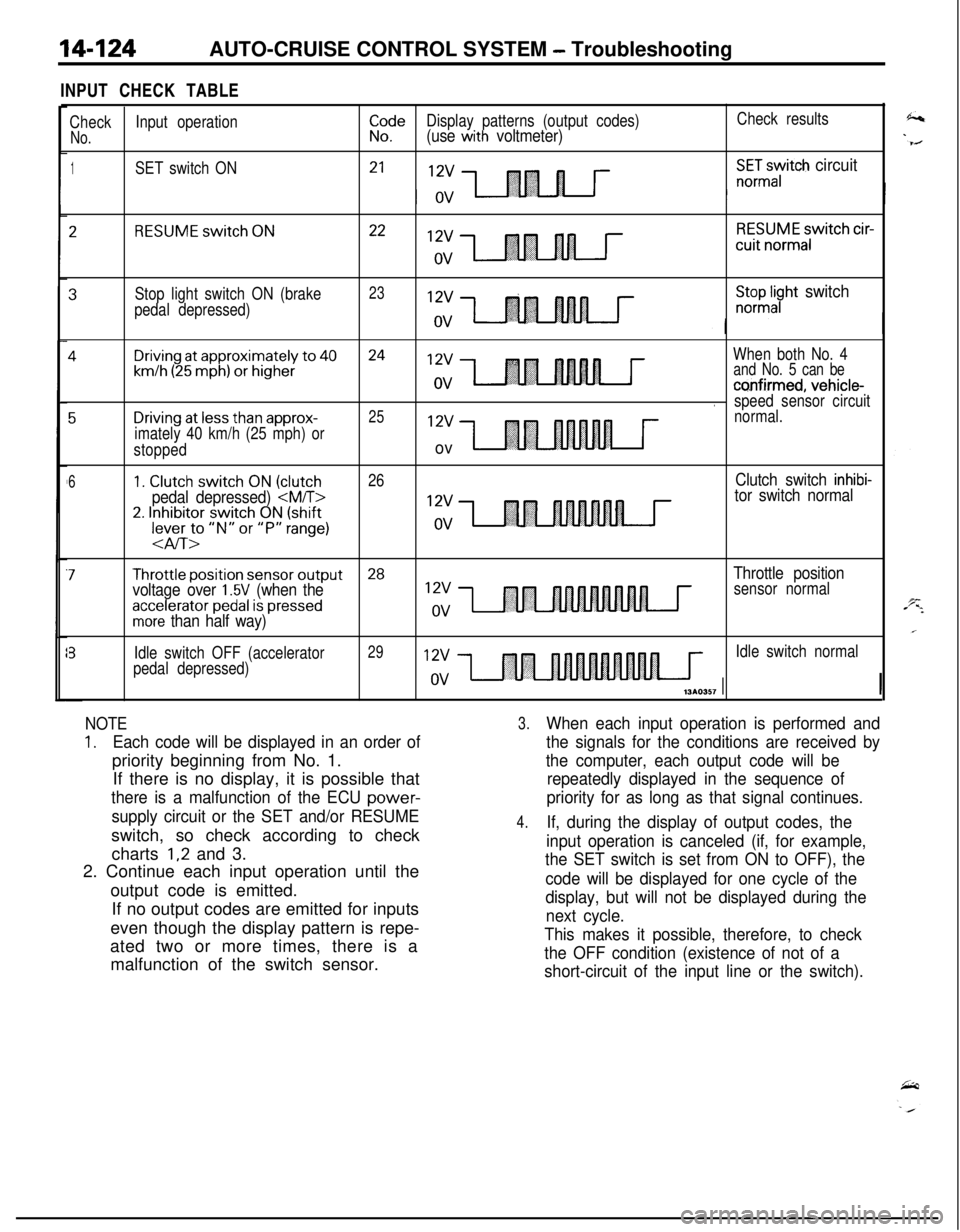

INPUT CHECK TABLE

CheckInput operationiI!eDisplay patterns (output codes)Check results

No.(use with voltmeter)

1SET switch ON21X:Gayitch circuit

2RESUME switch ON2212vRESUME switch cir-cuit

normalov

3Stop light switch ON (brake23

pedal depressed)

;;pl;yht switch

4Driving at approximately to 4024When both No. 4

km/h (25 mph) or higherand No. 5 can be

co,nfirmed, vehicle-.speed sensor circuit

5Driving at less than approx-2512vnormal.

imately 40 km/h (25 mph) or

stopped

ov

61. Clutch switch ON (clutch26Clutch switch inhibi-

pedal depressed)

2. Inhibitor switch ON (shift12vlever to “N” or “P” range)ov

-aIT>

7Throttle position sensor output28

voltage over 1.5V (when theThrottle positionsensor normal

accelerator pedal is pressedmore than half way)

?Idle switch OFF (accelerator29Idle switch normal

pedal depressed)

NOTE

1.Each code will be displayed in an order ofpriority beginning from No. 1.

If there is no display, it is possible that

there is a malfunction of the ECU power-

supply circuit or the SET and/or RESUMEswitch, so check according to check

charts

1,2 and 3.

2. Continue each input operation until the

output code is emitted.

If no output codes are emitted for inputs

even though the display pattern is repe-

ated two or more times, there is a

malfunction of the switch sensor.

3.When each input operation is performed and

the signals for the conditions are received by

the computer, each output code will be

repeatedly displayed in the sequence of

priority for as long as that signal continues.

4.If, during the display of output codes, the

input operation is canceled (if, for example,

the SET switch is set from ON to OFF), the

code will be displayed for one cycle of the

display, but will not be displayed during the

next cycle.

This makes it possible, therefore, to check

the OFF condition (existence of not of a

short-circuit of the input line or the switch).

Page 579 of 1216

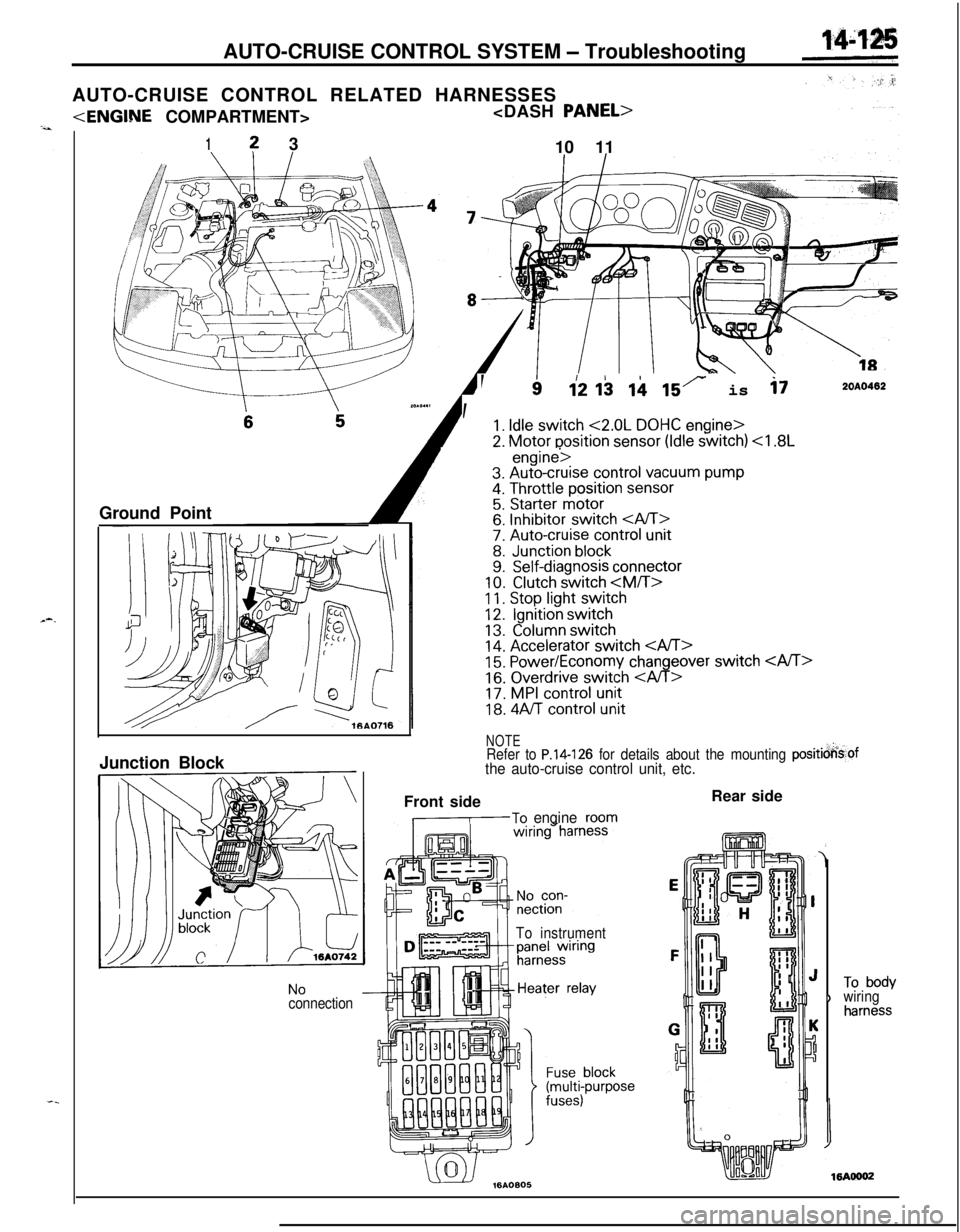

AUTO-CRUISE CONTROL SYSTEM - Troubleshooting

AUTO-CRUISE CONTROL RELATED HARNESSES

1? 3

10 11

Ground Point

--

, ’

112 I$ ii 15r is i72OAO402

1. Idle switch <2.0L DOHC engine>

2. Motor position sensor (Idle switch)

11. Stop light switch12.Ignition switch

13.Column switch14. Accelerator switch 15. Power/Economy changeover switch

16. Overdrive switch

18. 4Aff control unit

NOTERefer to P.14-126 for details about the mounting positicjkof

the auto-cruise control unit, etc.Junction Block

NoconnectionFront side

,-To engineroom

To instrumentRear side

)To bodywiringharness