suspension MITSUBISHI ECLIPSE 1991 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 84 of 1216

2-36FRONT SUSPENSION - Lower Arm

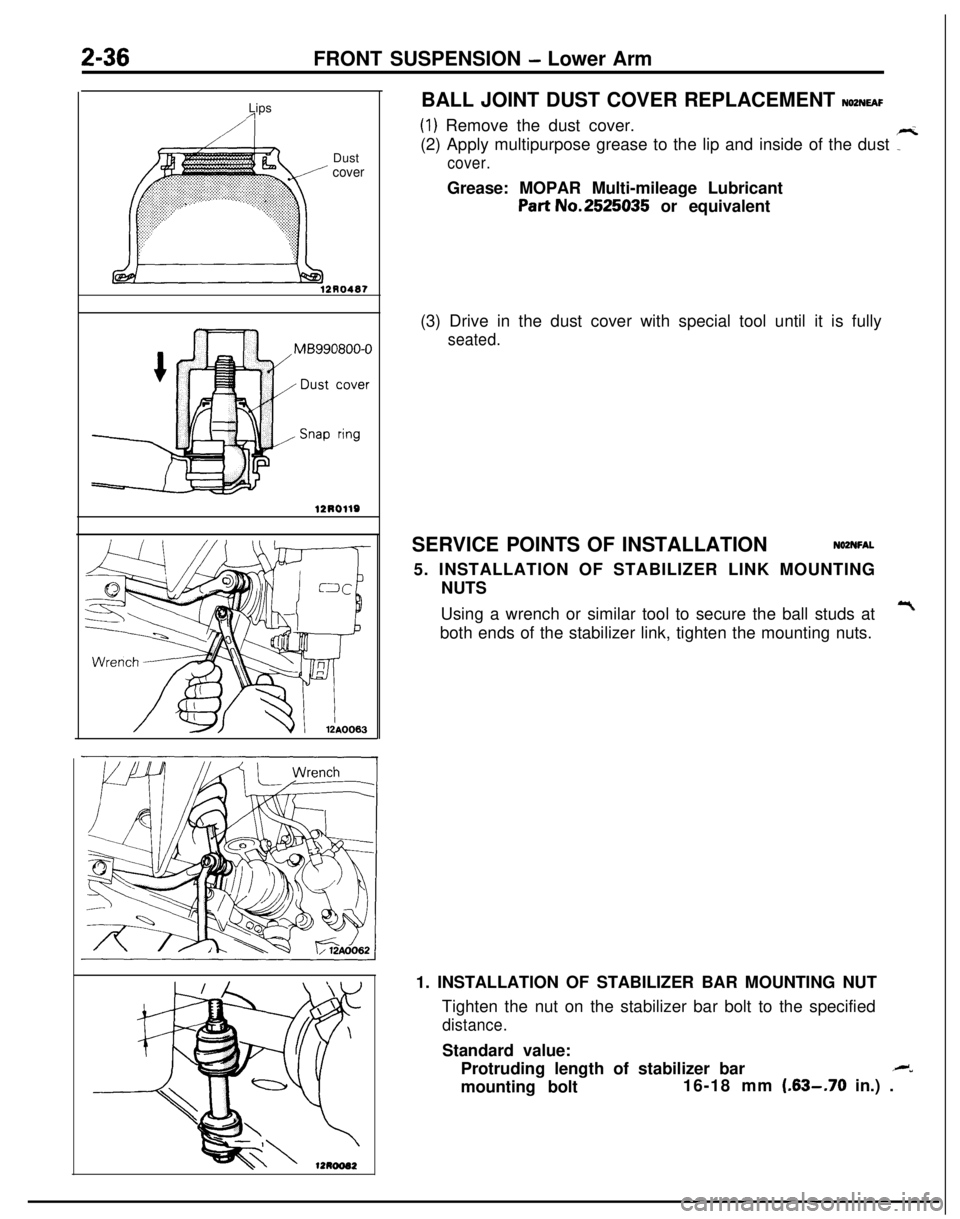

Lips

/IDust

cover

12R0487BALL JOINT DUST COVER REPLACEMENT

NOZNEAF

(1) Remove the dust cover.

(2) Apply multipurpose grease to the lip and inside of the dust

7

cover.Grease: MOPAR Multi-mileage Lubricant

Part No.2525035 or equivalent

(3) Drive in the dust cover with special tool until it is fully

seated.SERVICE POINTS OF INSTALLATION

NOZNFAL5. INSTALLATION OF STABILIZER LINK MOUNTING

NUTS

Using a wrench or similar tool to secure the ball studs at

Tboth ends of the stabilizer link, tighten the mounting nuts.

1. INSTALLATION OF STABILIZER BAR MOUNTING NUT

Tighten the nut on the stabilizer bar bolt to the specified

distance.Standard value:

Protruding length of stabilizer bar

.M”mounting bolt16-18 mm

(.63-.70 in.) .

Page 85 of 1216

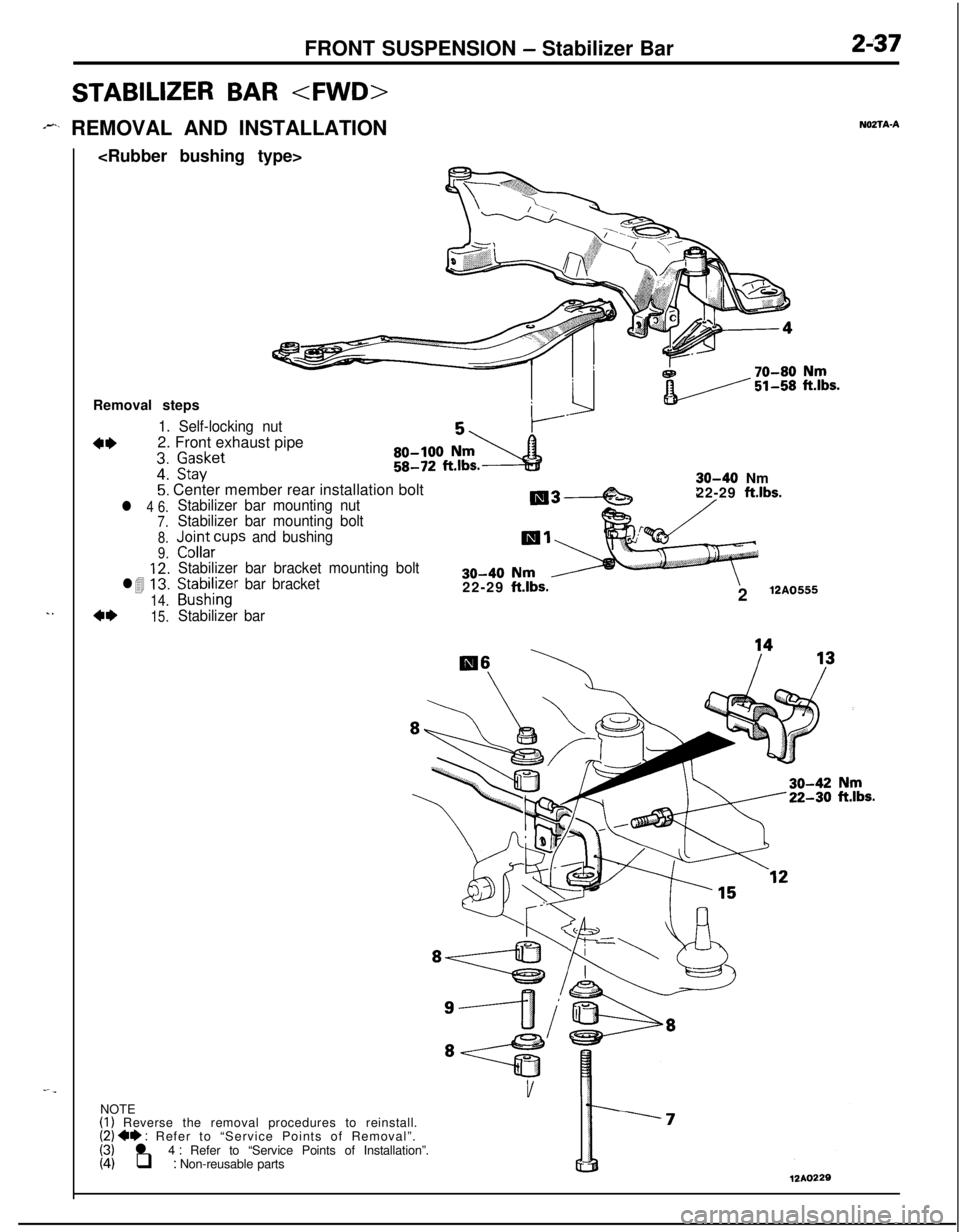

FRONT SUSPENSION - Stabilizer Bar2-37

STABILIZER BAR

-I*_ REMOVAL AND INSTALLATION

. .Removal steps

1. Self-locking nut

4*2. Front exhaust pipez’

gitket5: Center member rear installation bolt

l 4 6.Stabilizer bar mounting nut

7.Stabilizer bar mounting bolt

8.J&~;~cups and bushing

Stabilizer bar bracket mounting bolt

Sg:asAi;r bar bracket

Stabilizer bar

9.

l41::

14.4*15.22-29

ft.lbs.

30-40 Nm

22-29 ft.lbs.2

12A0555

NO2TAANOTE

(I) Reverse the removal procedures to reinstall.(2) 4* : Refer to “Service Points of Removal”.(3) l 4 : Refer to “Service Points of Installation”.(4) q : Non-reusable parts12*0229

Page 86 of 1216

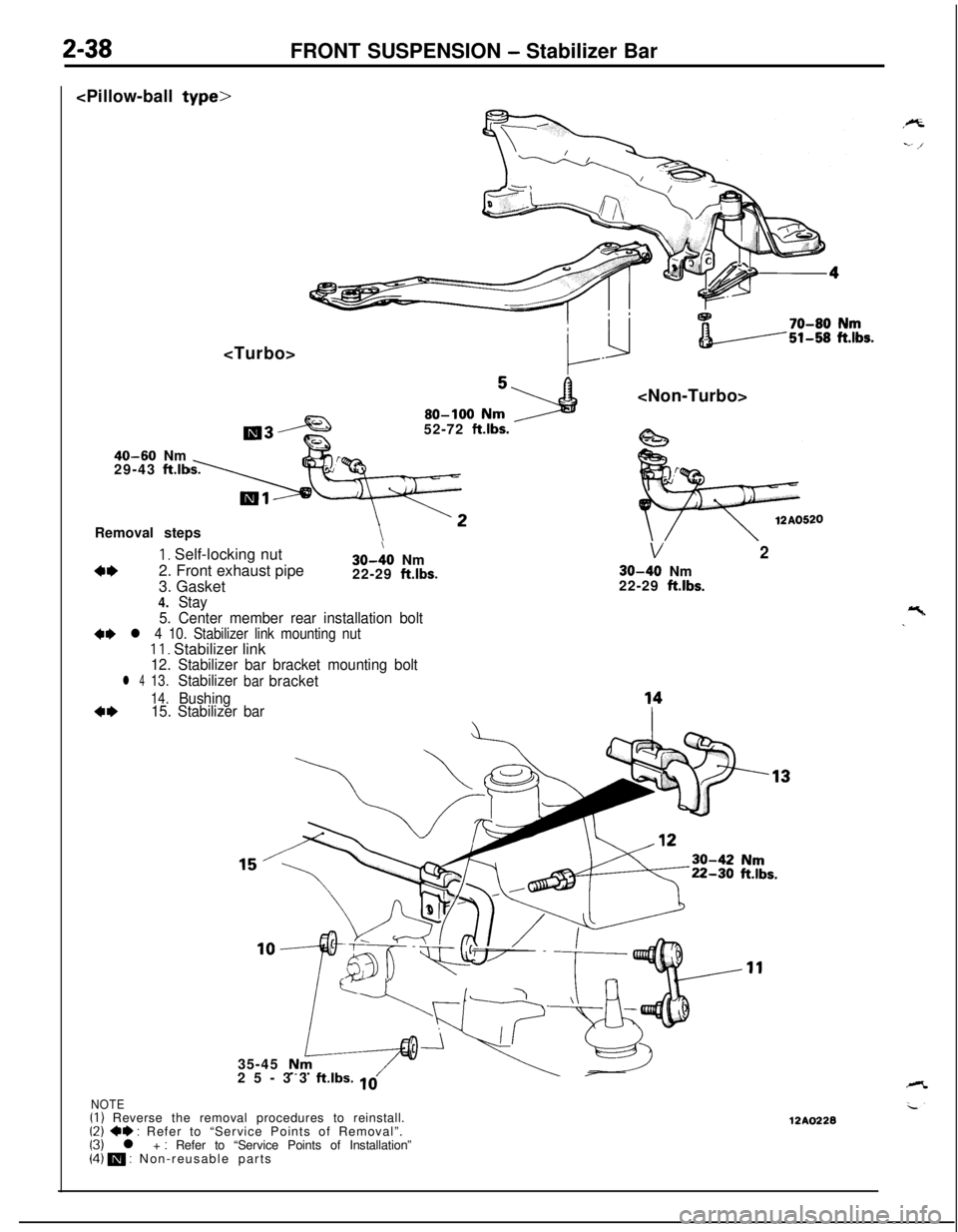

2-38FRONT SUSPENSION - Stabilizer Bar

40-60 Nm

29-43 fLlb52-72

klbs.

Removal steps

4*

1, Self-locking nut

2. Front exhaust pipe

3. Gasket30-:O Nm

22-29 ftlbs.

V2

30-40 Nm

22-29 ft.lbs.

4.Stay

5. Center member rear installation bolt

4e l 4 10. Stabilizer link mounting nutII. Stabilizer link12. Stabilizer bar bracket mounting bolt

l 413.Stabilizerbarbracket

14.Bushing4*15. Stabilizer bar

c- r35-45

25-33

ft.lbs. 10

NOTE(I) Reverse the removal procedures to reinstall.(2) 4e : Refer to “Service Points of Removal”.(3) l + : Refer to “Service Points of Installation”(4) m : Non-reusable parts12A0228

Page 87 of 1216

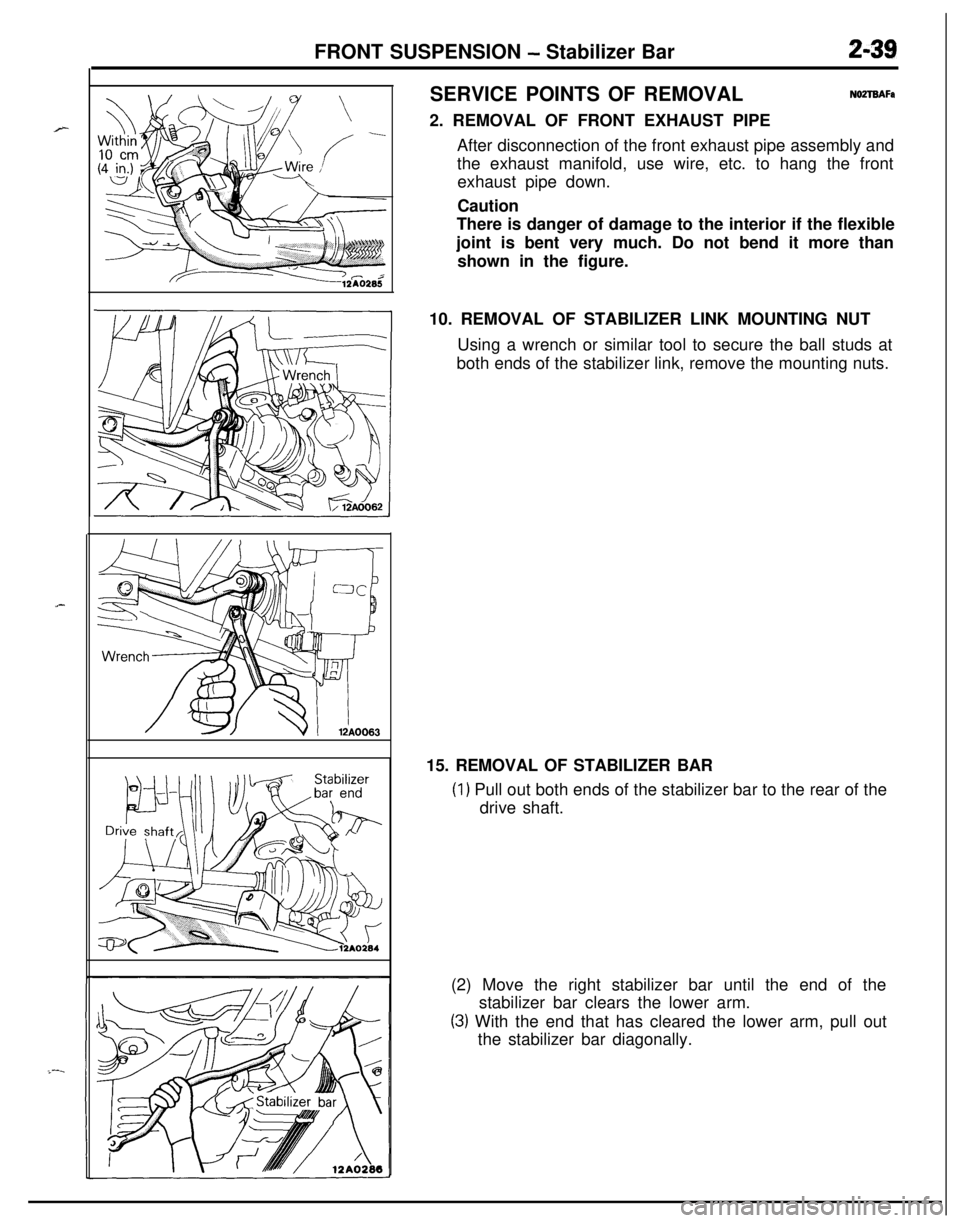

FRONT SUSPENSION - Stabilizer Bar2-39SERVICE POINTS OF REMOVAL

NOZTBAFa2. REMOVAL OF FRONT EXHAUST PIPE

After disconnection of the front exhaust pipe assembly and

the exhaust manifold, use wire, etc. to hang the front

exhaust pipe down.

Caution

There is danger of damage to the interior if the flexible

joint is bent very much. Do not bend it more than

shown in the figure.

10. REMOVAL OF STABILIZER LINK MOUNTING NUT

Using a wrench or similar tool to secure the ball studs at

both ends of the stabilizer link, remove the mounting nuts.

15. REMOVAL OF STABILIZER BAR

(1) Pull out both ends of the stabilizer bar to the rear of the

drive shaft.

(2) Move the right stabilizer bar until the end of the

stabilizer bar clears the lower arm.

(3) With the end that has cleared the lower arm, pull out

the stabilizer bar diagonally.

Page 88 of 1216

12LO244Z-40FRONT SUSPENSION - Stabilizer Bar

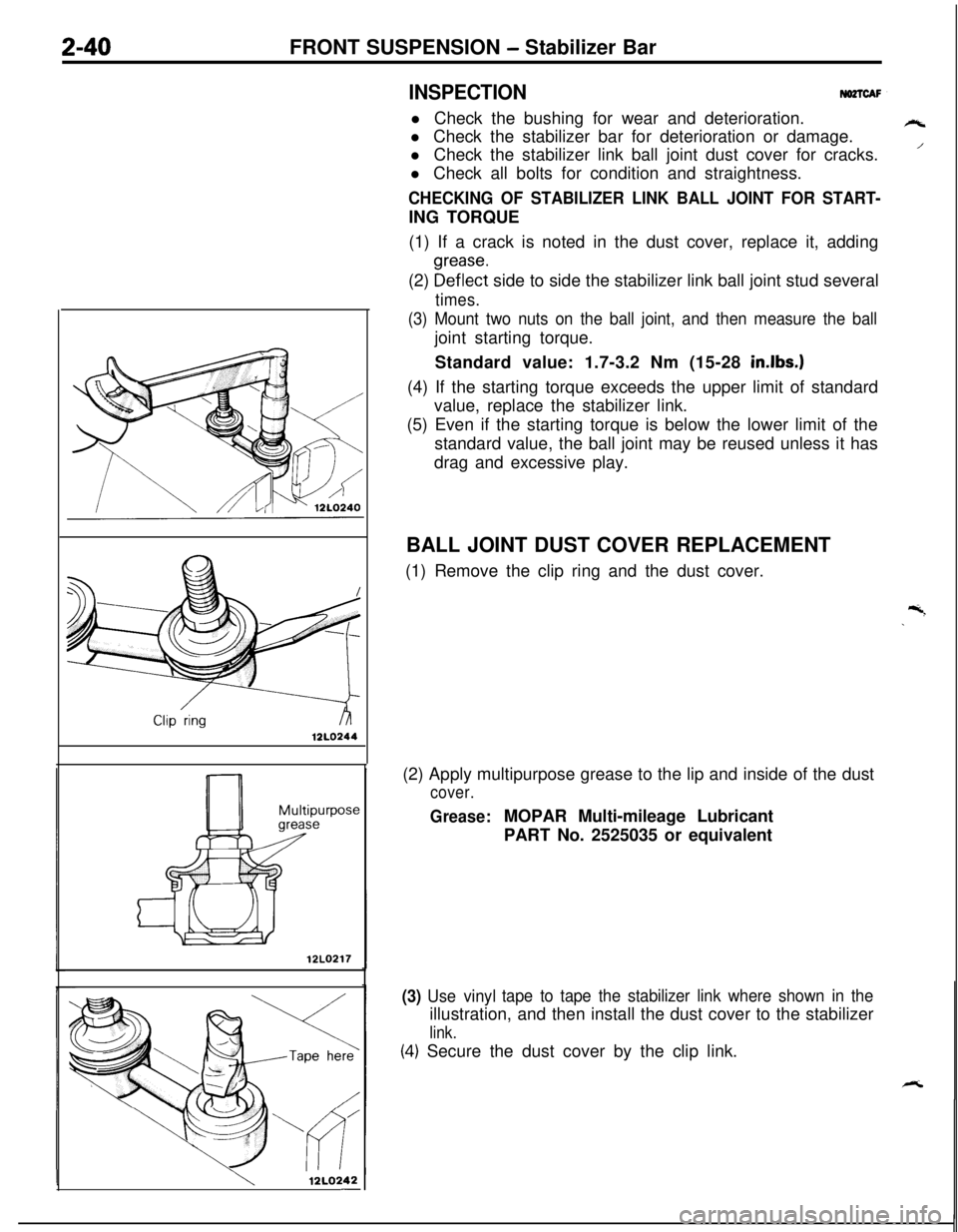

INSPECTIONNO2TCAFl Check the bushing for wear and deterioration.

l Check the stabilizer bar for deterioration or damage.

l Check the stabilizer link ball joint dust cover for cracks.

l Check all bolts for condition and straightness.

CHECKING OF STABILIZER LINK BALL JOINT FOR START-ING TORQUE

(1) If a crack is noted in the dust cover, replace it, adding

(2)

~~f~~~t side to side the stabilizer link ball joint stud several

times.

(3) Mount two nuts on the ball joint, and then measure the balljoint starting torque.

Standard value: 1.7-3.2 Nm (15-28

in.lbs.)(4) If the starting torque exceeds the upper limit of standard

value, replace the stabilizer link.

(5) Even if the starting torque is below the lower limit of the

standard value, the ball joint may be reused unless it has

drag and excessive play.

12LO217

12LQ242-BALL JOINT DUST COVER REPLACEMENT

(1) Remove the clip ring and the dust cover.

(2) Apply multipurpose grease to the lip and inside of the dust

cover.

Grease:MOPAR Multi-mileage Lubricant

PART No. 2525035 or equivalent

(3) Use vinyltape to tape the stabilizer link where shown in theillustration, and then install the dust cover to the stabilizer

link.

(4.) Secure the dust cover by the clip link.

rt

/

Page 89 of 1216

FRONT SUSPENSION - Stabilizer Bar241

3 *!-Marking

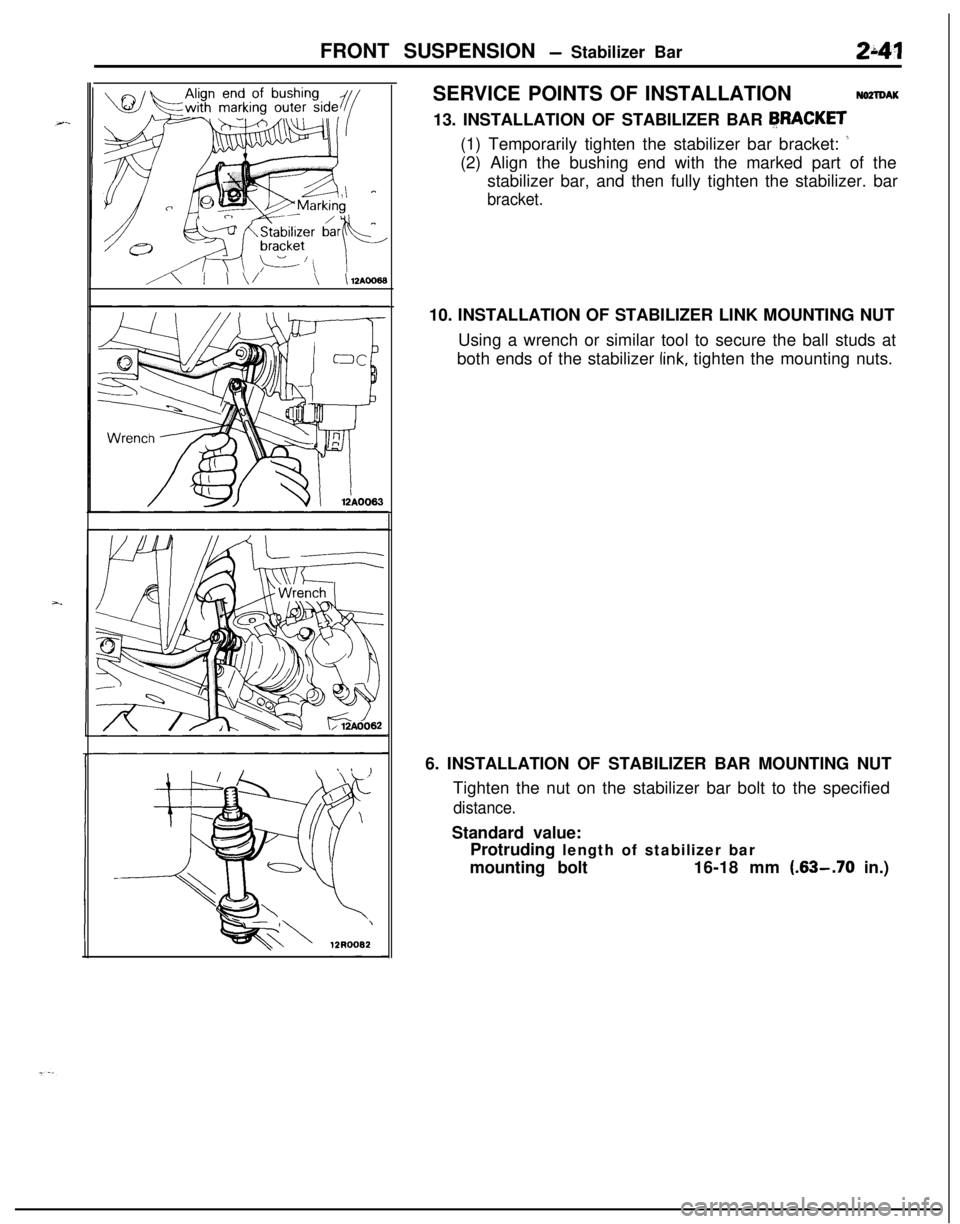

A I I\/\ \lZAOOOESERVICE POINTS OF INSTALLATION

NO2lDAK13. INSTALLATION OF STABILIZER BAR

FRACKET(1) Temporarily tighten the stabilizer bar bracket:

’(2) Align the bushing end with the marked part of the

stabilizer bar, and then fully tighten the stabilizer. bar

bracket.10. INSTALLATION OF STABILIZER LINK MOUNTING NUT

Using a wrench or similar tool to secure the ball studs at

both ends of the stabilizer

link, tighten the mounting nuts.

6. INSTALLATION OF STABILIZER BAR MOUNTING NUT

Tighten the nut on the stabilizer bar bolt to the specified

distance.Standard value:

Protruding length of stabilizer bar

mounting bolt16-18 mm

(.63-.70 in.)

Page 90 of 1216

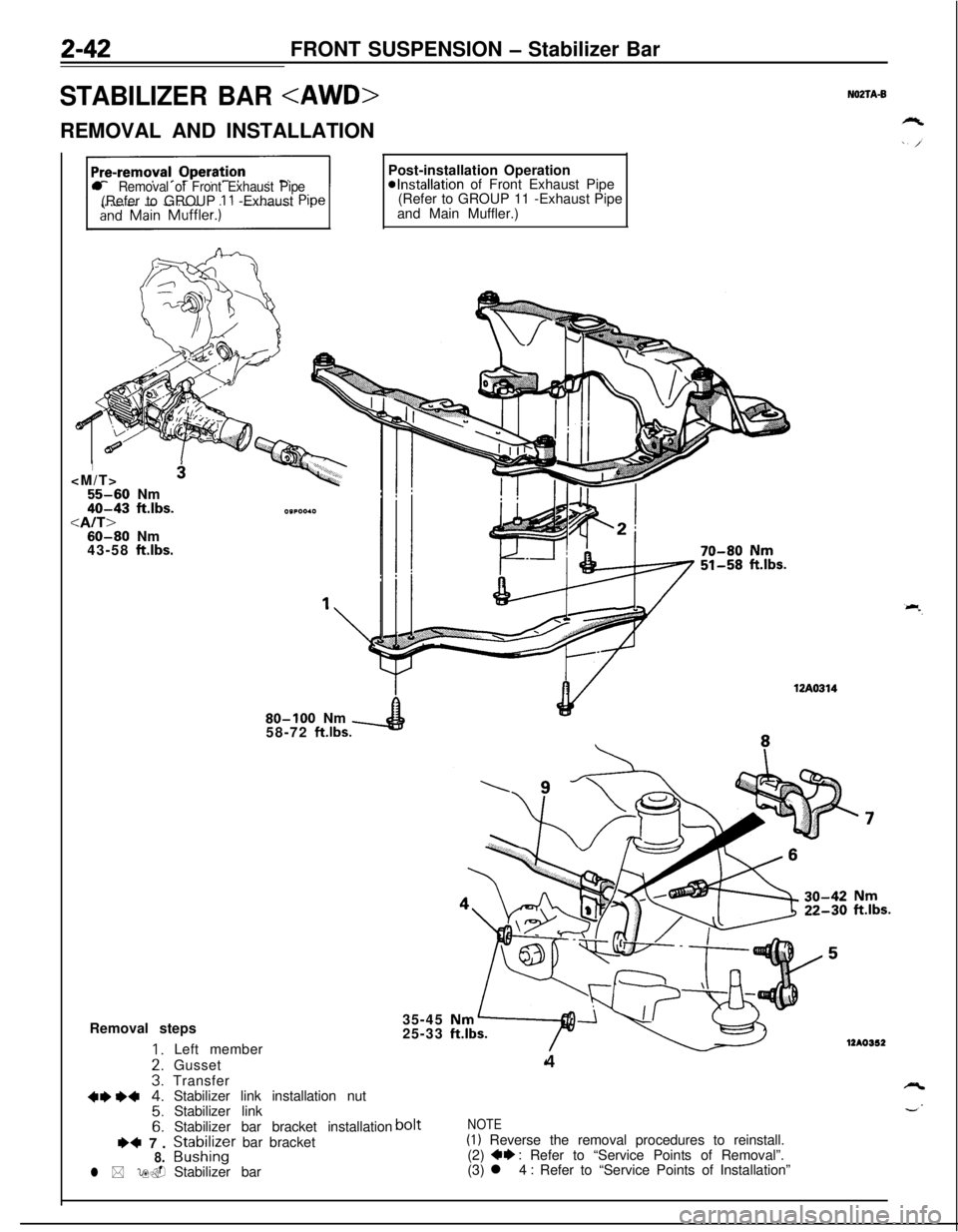

2-42FRONT SUSPENSION - Stabilizer Bar

N02TA-BSTABILIZER BAR

REMOVAL AND INSTALLATION

l Removal of Front Exhaust Pipe(Refer to GROUP 11 -Exhaust Pipe

I

55-60 Nm40-43 ftlbs.60-80 Nm

43-58 ft.lbs.Removal stepsPost-installation Operation

*Installation of Front Exhaust Pipe

(Refer to GROUP 11 -Exhaust Pipe

and Main Muffler.)

80-100 Nm

58-72 ft.lbs.--A

I)4 7.8.l * 9.Left member

Gusset

Transfer

Stabilizer link installation nut

Stabilizer link

Stabilizer bar bracket installation

Sgabibi~;r bar bracket

Stabilizer bar35-45

25-33

12A0314

12AO352

4

NOTE(I) Reverse the removal procedures to reinstall.

(2) 4* : Refer to “Service Points of Removal”.

(3) l 4 : Refer to “Service Points of Installation”

Page 91 of 1216

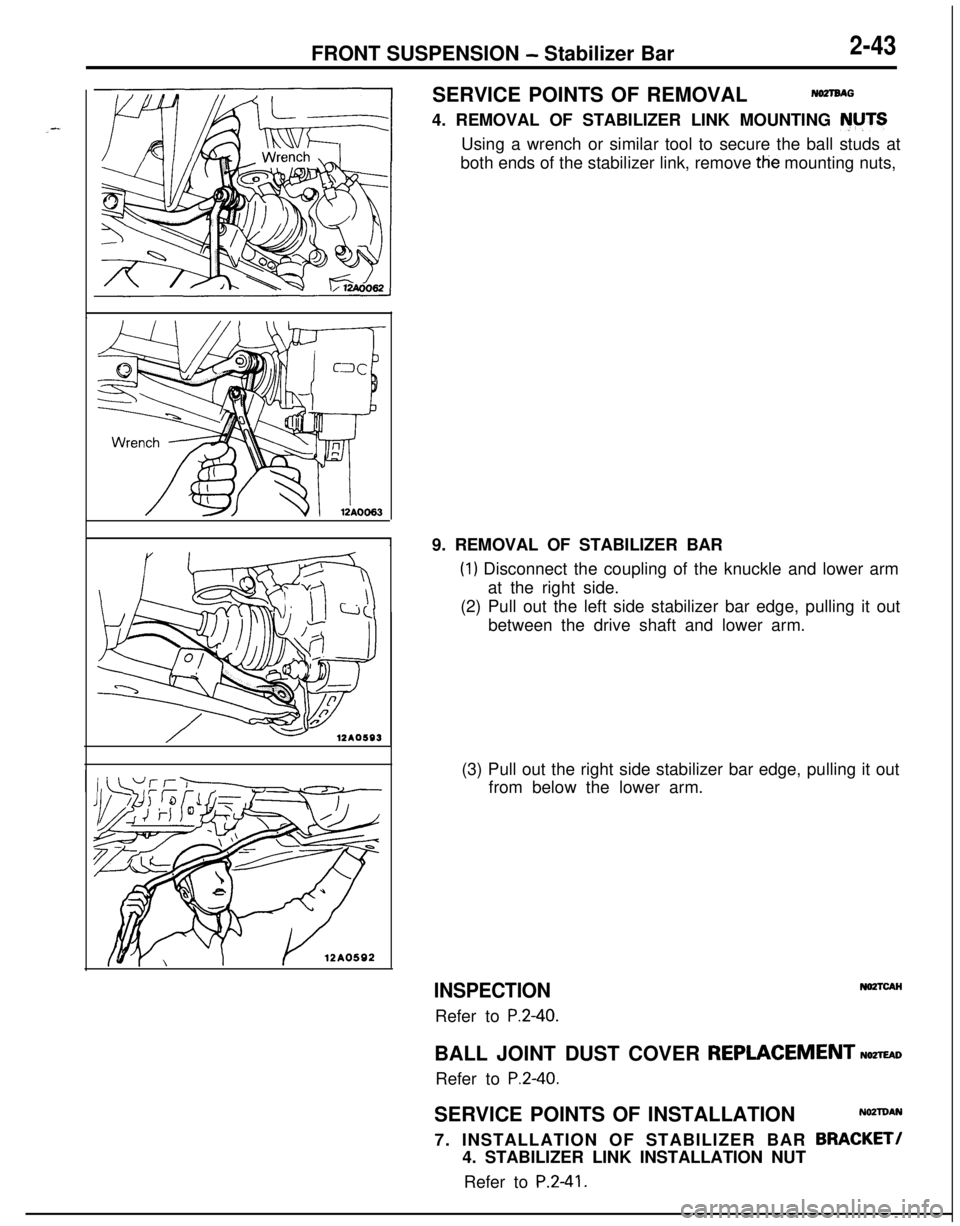

FRONT SUSPENSION - Stabilizer Bar2-43SERVICE POINTS OF REMOVAL

NOZlBAG4. REMOVAL OF STABILIZER LINK MOUNTING NUTS

Using a wrench or similar tool to secure the ball studs at

both ends of the stabilizer link, remove tfie mounting nuts,

19. REMOVAL OF STABILIZER BAR

(1) Disconnect the coupling of the knuckle and lower arm

at the right side.

(2) Pull out the left side stabilizer bar edge, pulling it out

between the drive shaft and lower arm.

(3) Pull out the right side stabilizer bar edge, pulling it out

from below the lower arm.

INSPECTIONRefer to

P.2-40.

NOZTCAHBALL JOINT DUST COVER

REPLACEMENTNomDRefer to

P.2-40.SERVICE POINTS OF INSTALLATION

NOZTDAN7. INSTALLATION OF STABILIZER BAR

BRACKET!4. STABILIZER LINK INSTALLATION NUT

Refer to

P.2-41.

Page 92 of 1216

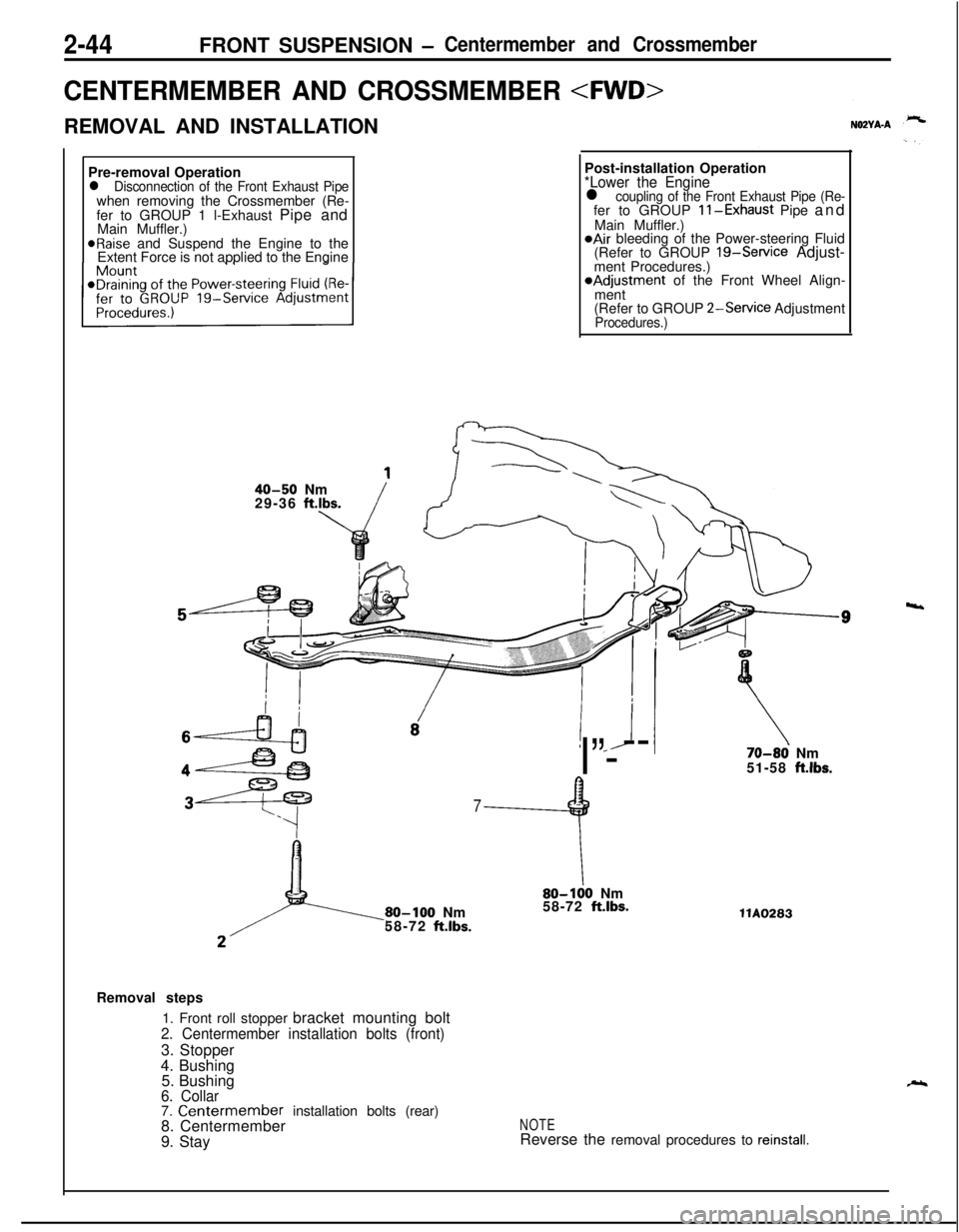

2-44FRONT SUSPENSION -Centermember and Crossmember

CENTERMEMBER AND CROSSMEMBER

REMOVAL AND INSTALLATION

Pre-removal Operation

l Disconnection of the Front Exhaust Pipewhen removing the Crossmember (Re-

fer to GROUP 1 l-Exhaust Pipe and

Main Muffler.)

@Raise and Suspend the Engine to the

Extent Force is not applied to the EnginePost-installation Operation

*Lower the Enginel coupling of the Front Exhaust Pipe (Re-fer to GROUP ll-Exhaust Pipe and

Main Muffler.)

@Air bleeding of the Power-steering Fluid

(Refer to GROUP 19-Service Adjust-

ment Procedures.)*Adjustment of the Front Wheel Align-

ment

(Refer to GROUP

2-Service AdjustmentProcedures.)

40-50 Nm

29-36 ft.lbs.

! *J

I”---

7

9

80-100 Nm

58-72 ft.lbs.

\80-100 Nm

58-72 ft.lbs.

70-86 Nm

51-58 ft.lbs.llA0283

Removal steps

1. Front roll stopper bracket mounting bolt

2. Centermember installation bolts (front)3. Stopper

4. Bushing

5. Bushing

6. Collar7. Centermember installation bolts (rear)

8. Centermember

9. StayNOTEReverse the removal procedures to reinstall.

4

Page 93 of 1216

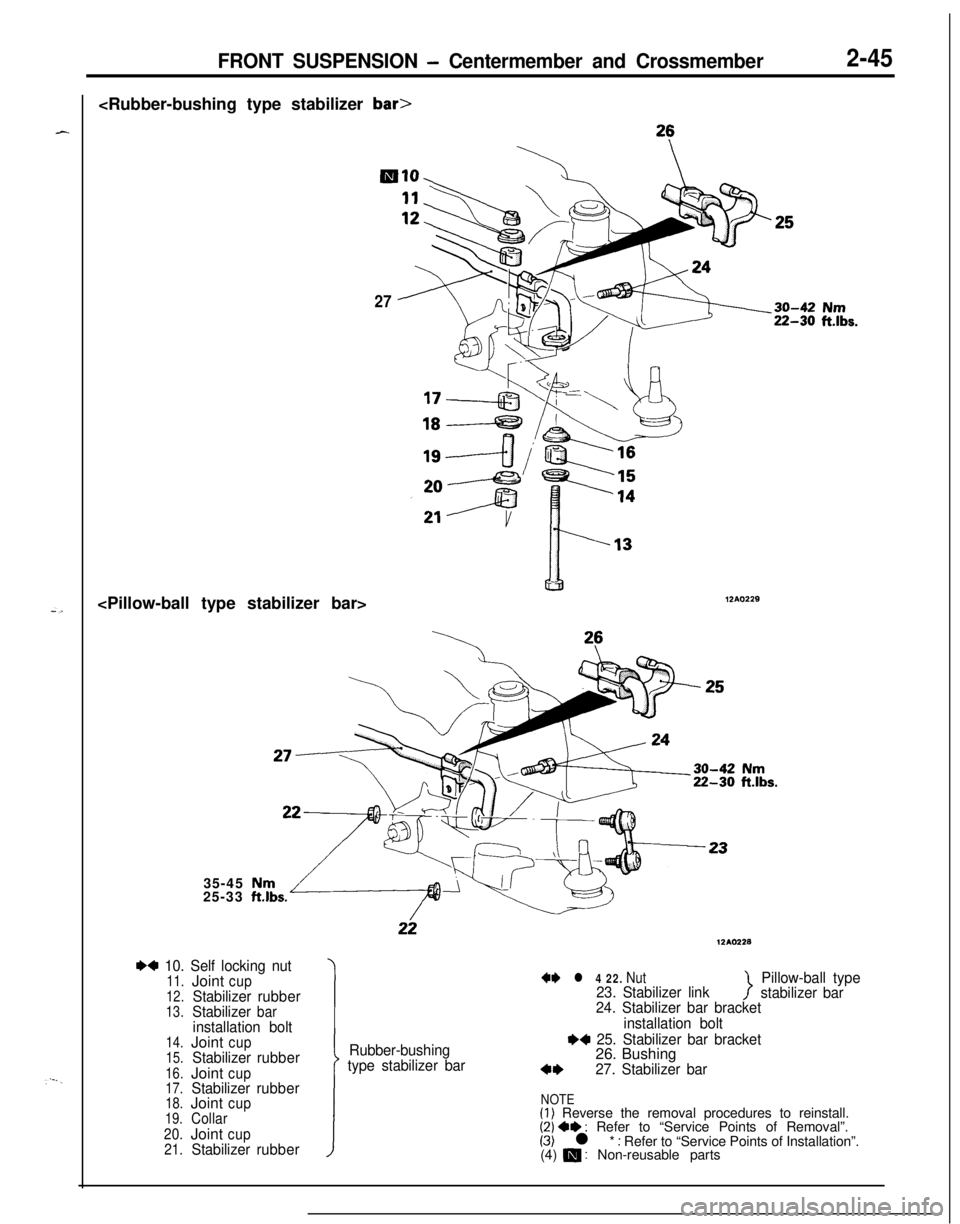

FRONT SUSPENSION - Centermember and Crossmember2-45

27X0-42 Nm.- .-___-ii-30 ft.lbs.

35-45

25-33

~~ 10. Self locking nut11.Jointcup12.Stabilizerrubber13.Stabilizerbarinstallation bolt14.Jointcup15.Stabilizerrubber

16.Jointcup17.Stabilizerrubber18.Jointcup19.Collar

20.Joint

cup

21.Stabilizerrubber:

+e l 4 22. Nut

>

Pillow-ball type

23. Stabilizer link

stabilizer bar

24. Stabilizer bar bracket

installation bolt

Rubber-bushing

type stabilizer bar

I)4 25. Stabilizer bar bracket26. Bushing

4*27. Stabilizer bar

NOTE(1) Reverse the removal procedures to reinstall.(21 4* : Refer to “Service Points of Removal”.i3j l * : Refer to “Service Points of Installation”.

(4) m : Non-reusable parts