tow MITSUBISHI ECLIPSE 1991 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 949 of 1216

AUTOMATIC TRANSAXLE - Transaxle Assemblv

Spacer

1700108

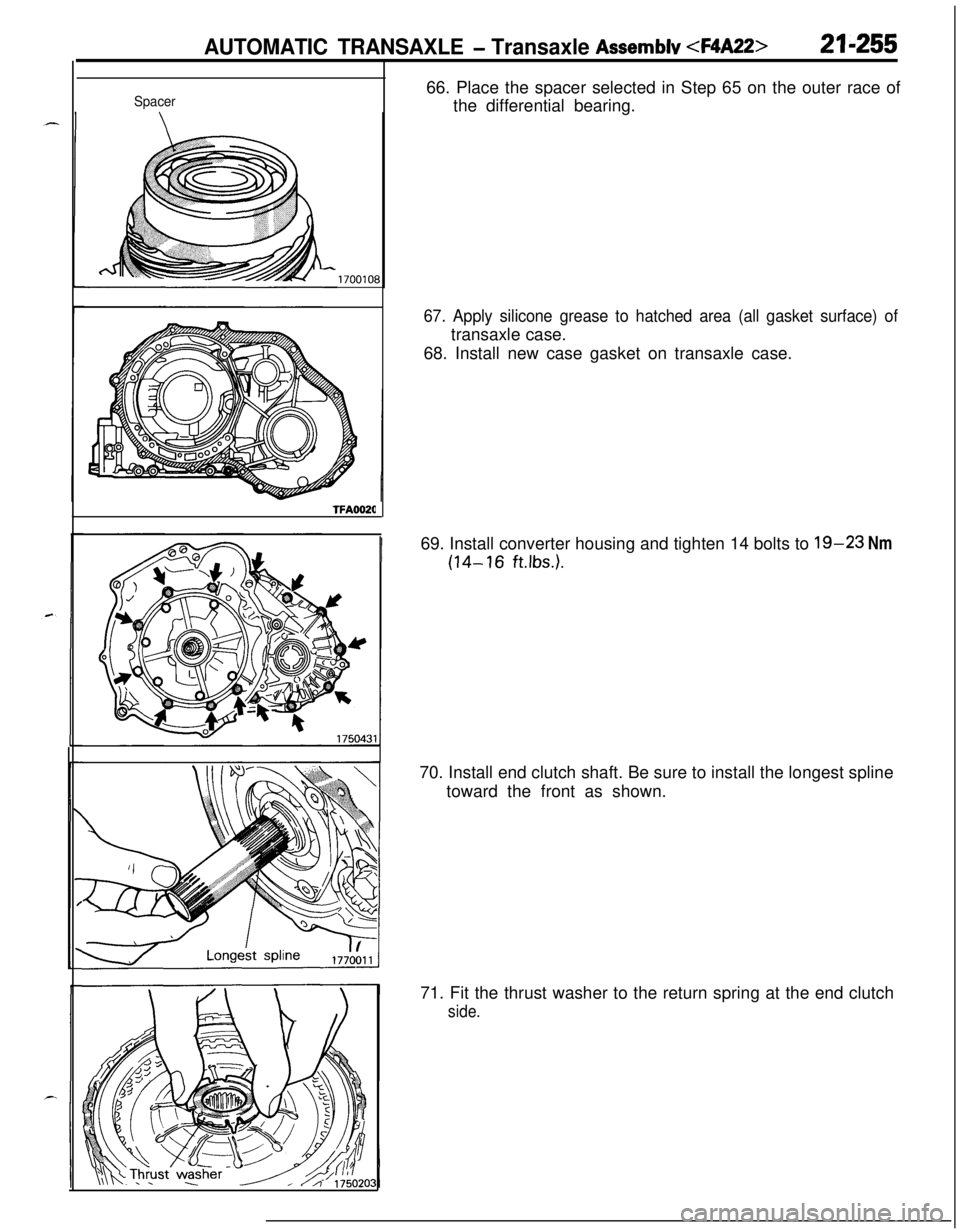

TFA002066. Place the spacer selected in Step 65 on the outer race of

the differential bearing.

67. Apply silicone grease to hatched area (all gasket surface) oftransaxle case.

68. Install new case gasket on transaxle case.

69. Install converter housing and tighten 14 bolts to

19-23 Nm

(14-16 ft.Ibs.).70. Install end clutch shaft. Be sure to install the longest spline

toward the front as shown.

71. Fit the thrust washer to the return spring at the end clutch

side.

Page 964 of 1216

-m-m AUTOMATIC TRANSAXLE -Transaxle Assembly

DISASSEMBLYN21WMCaution

%T1. Since the automatic transaxle is made of particularly

~_,high precision parts, be very careful when handling

them during disassembly and reassembly so that they

are not scratched.

2. Spread a rubber mat on the workbench and keep it

clean.3. Do not use cotton gloves or cloth rags during dis-

assembly. If they are needed, use nylon cloth or paper

towels.

4. Clean all disassembled parts. Clean metal

parts with

normal cleanser and completely dry with air.

5. Clean the clutch disc, resin thrust plate and rubber

parts with ATF (automatic transmission fluid) and do

not get any dirt on them.

6. If the transaxle itself is damaged, disassemble and

clean the cooler system also.

1. Remove the torque converter.

2. Mount the dial gauge on the transaxle case and measure

the end play of the input shaft.

3. Remove the brackets.

4. Remove the oil level gauge and oil level gauge guide.

1:5. Remove the pulse generator A and B.

6.First remove the manual control lever and then remove theinhibitor switch.

7. Remove the speedometer driven gear assembly.

Page 975 of 1216

AUTOMATIC TRANSAXLE - Transaxle Assembly

iWD (Front side)

MD998803

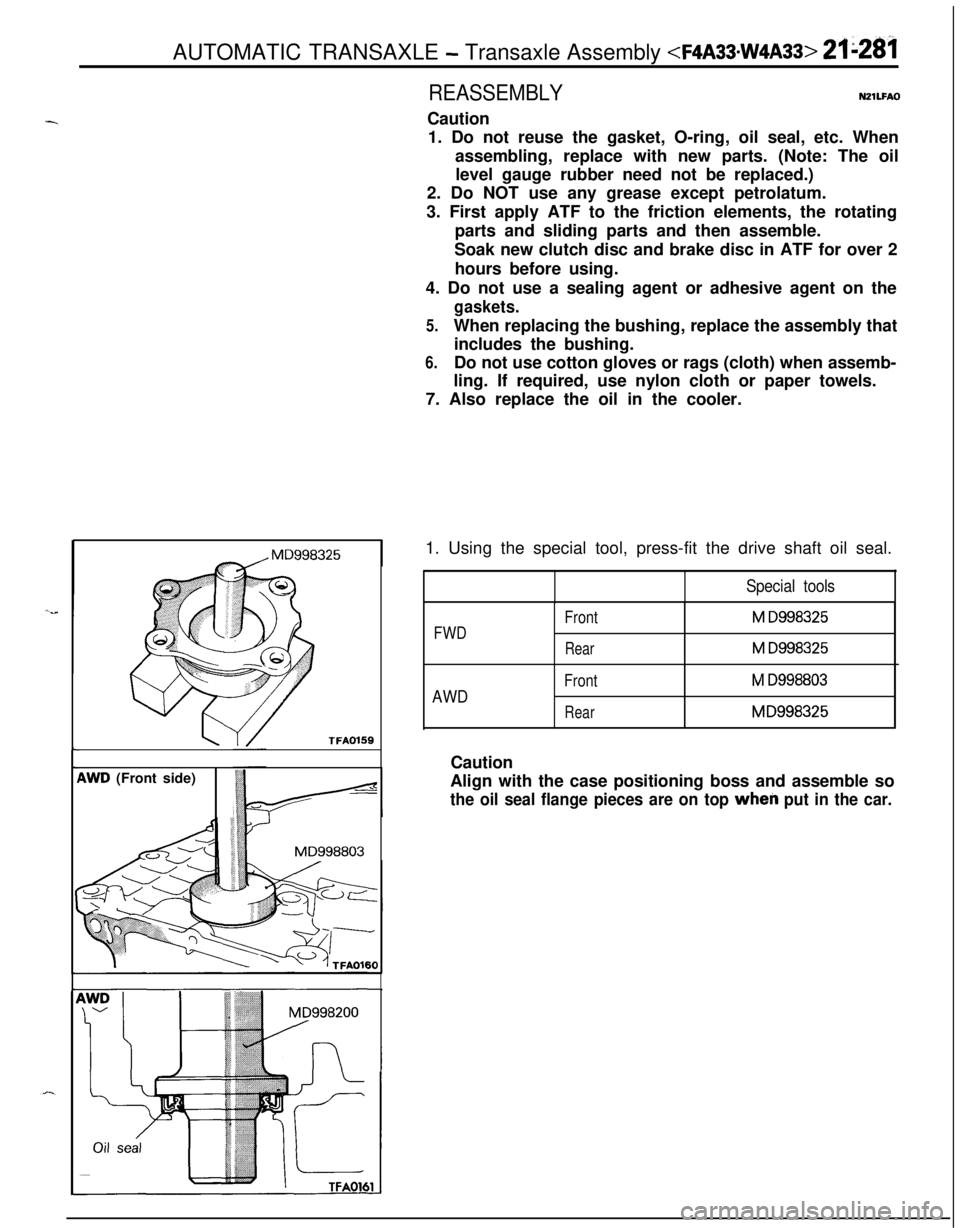

REASSEMBLYCautionNZlLFAO1. Do not reuse the gasket, O-ring, oil seal, etc. When

assembling, replace with new parts. (Note: The oil

level gauge rubber need not be replaced.)

2. Do NOT use any grease except petrolatum.

3. First apply ATF to the friction elements, the rotating

parts and sliding parts and then assemble.

Soak new clutch disc and brake disc in ATF for over 2

hours before using.

4. Do not use a sealing agent or adhesive agent on the

gaskets.

5.When replacing the bushing, replace the assembly that

includes the bushing.

6.Do not use cotton gloves or rags (cloth) when assemb-

ling. If required, use nylon cloth or paper towels.

7. Also replace the oil in the cooler.

1. Using the special tool, press-fit the drive shaft oil seal.

Special tools

FWD

AWD

FrontM D998325

RearM D998325

Front

M D998803

RearMD998325Caution

Align with the case positioning boss and assemble so

the oil seal flange pieces are on top wheh put in the car.

Page 985 of 1216

AUTOMATIC TRANSAXLE - Transaxle Assembly

49. Install the clutch assembly and kickdown drum at the sametime in the transaxle case.

Thrust race

#3I50. Stick thrust race #3 and thrust washer #l to the rear end

of the oil pump with petrolatum.

51. Using the special tool, install a new oil pump gasket and oilpump assembly.

Oil pump assembly mounting bolts:

19-23 Nm (14-16

klbs.)52. Measure the input shaft end play and, if it is outside the

standard value, replace thrust race

#3 and thrust washer

#I and adjust so it reaches the standard value.

Standard value:

0.3-1.0 mm (.012-.039 in.)

53. Install the spacer, idler gear and bearing and then insert theidler shaft.

Caution

Install so the identification groove on the end of the

idler gear is toward the back side.

Page 1110 of 1216

23-66BODY - Door Trim and Waterproof Film/Door Glass and Regulator

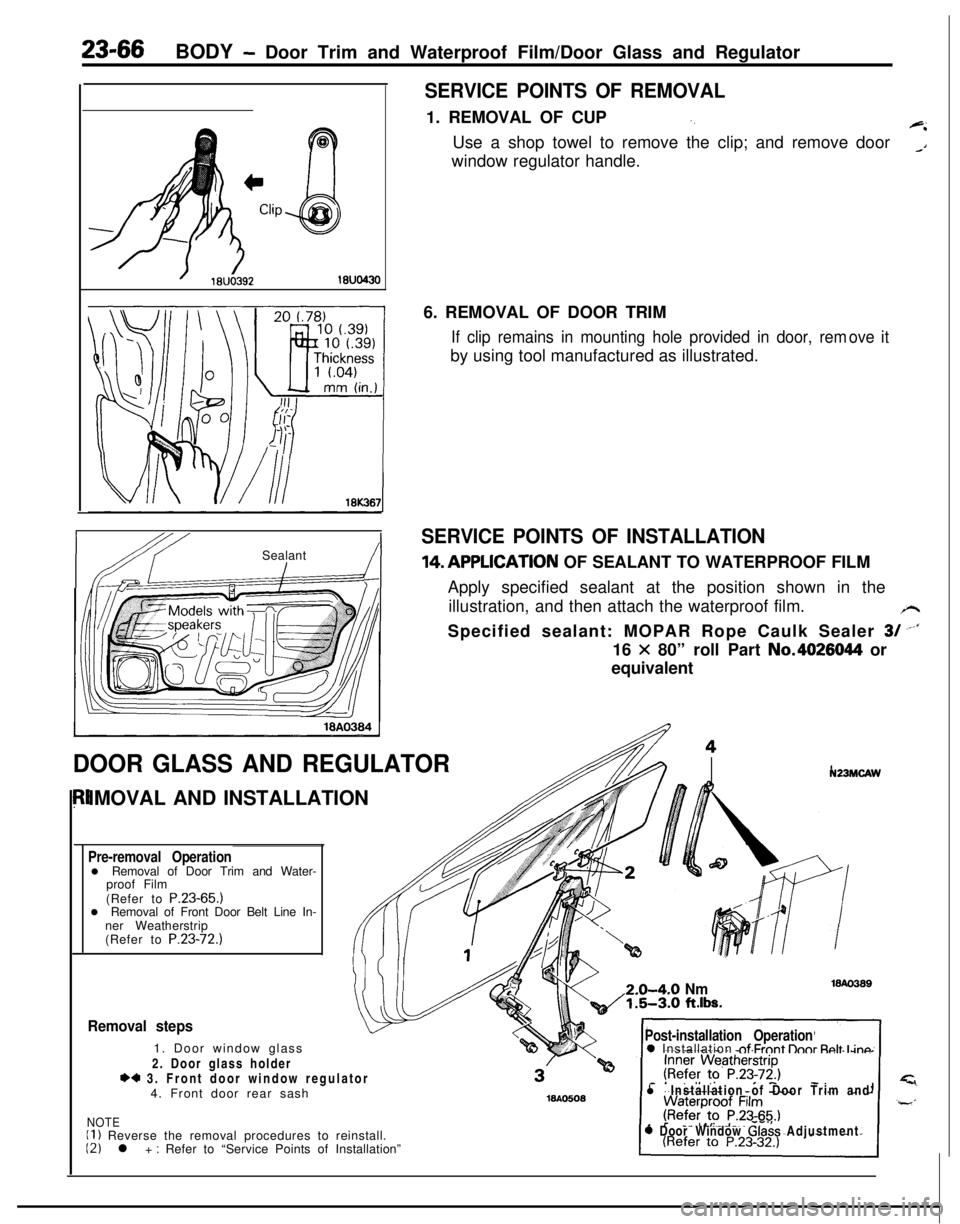

SERVICE POINTS OF REMOVAL1. REMOVAL OF CUP

‘.+iUse a shop towel to remove the clip; and remove door

_Awindow regulator handle.

IbY ISealant!I6. REMOVAL OF DOOR TRIM

If clip remains in mounting hole provided in door, remby using tool manufactured as illustrated.ove it

SERVICE POINTS OF INSTALLATION14,APPLlCATlON OF SEALANT TO WATERPROOF FILM

Apply specified sealant at the position shown in the

illustration, and then attach the waterproof film.

/rSpecified sealant: MOPAR Rope Caulk Sealer

3/ --‘I16

X 80” roll Part No.4026044 or

equivalent

DOOR GLASS AND REGULATORIMOVAL AND INSTALLATION

Pre-removal Operationl Removal of Door Trim and Water-

proof Film

(Refer to P.23-65.)

l Removal of Front Door Belt Line In-

ner Weatherstrip

(Refer to P.23-72.)

N23MCAW2.0-4-O

Nm1.5-3.0 ft.lbs.

Removal steps1. Door window glass

2. Door glass holder

*4 3. Front door window regulator

4. Front door rear sash

NOTEII ) Reverse the removal procedures to reinstall.12) l + : Refer to “Service Points of Installation”

Post-installation Operation0 Installation nf Frnnt lhnr Rnlt I inn

l Installation of Door Trim and

0 Door Window Glass Adjustment

Page 1121 of 1216

BODY - Sunroof2397

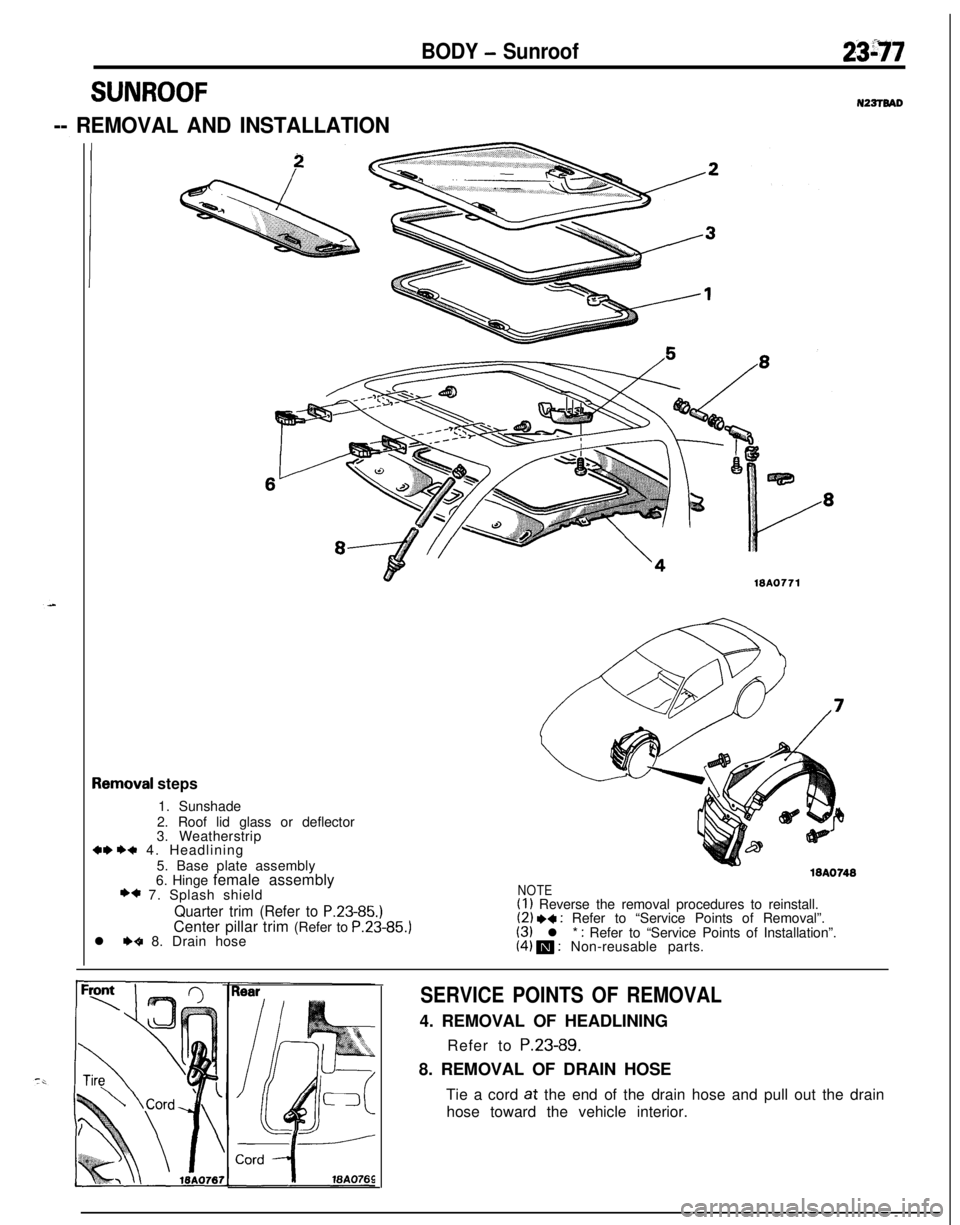

SUNROOFN22TTBAD

-- REMOVAL AND INSTALLATION

demoval steps

1. Sunshade

2. Roof lid glass or deflector

3. Weatherstrip

+w ++ 4. Headlining

5. Base plate assembly

6. Hinge female assembly

+* 7. Splash shield

Quarter trim (Refer to P.23-85.)Center pillar trim (Refer to P.23-85.)

l

++ 8. Drain hose

NOTE(I 1 Reverse the removal procedures to reinstall.(2) ** : Refer to “Service Points of Removal”.(3) l * : Refer to “Service Points of Installation”.(4) m : Non-reusable parts.

SERVICE POINTS OF REMOVAL4. REMOVAL OF HEADLINING

Refer to P.23-89.

8. REMOVAL OF DRAIN HOSE

Tie a cord

at the end of the drain hose and pull out the drain

hose toward the vehicle interior.

Page 1125 of 1216

BODY - Instrument Panel23-81

SECT. A-A

Flat-tip

( - ) screwdriver19A0274

1910267

SERVICE POINTS OF REMOVAL

10. REMOVAL OF CENTER AIR OUTLET ASSEMBLY

Removing the paw1 of the center air outlet assembly with aflat-tip

( - 1 screwdriver,remove the center air outlet

assembly with the plastic trim tool.

16. REMOVAL OF SPEEDOMETER CABLE ADAPTER

(1) Disconnect the speedometer cable at the transaxle endof the cable.

(2) Pull the speedometer cable slightly toward the vehicle

interior, release the lock by turning the adapter to the leftor right, and then remove the adapter.

Page 1132 of 1216

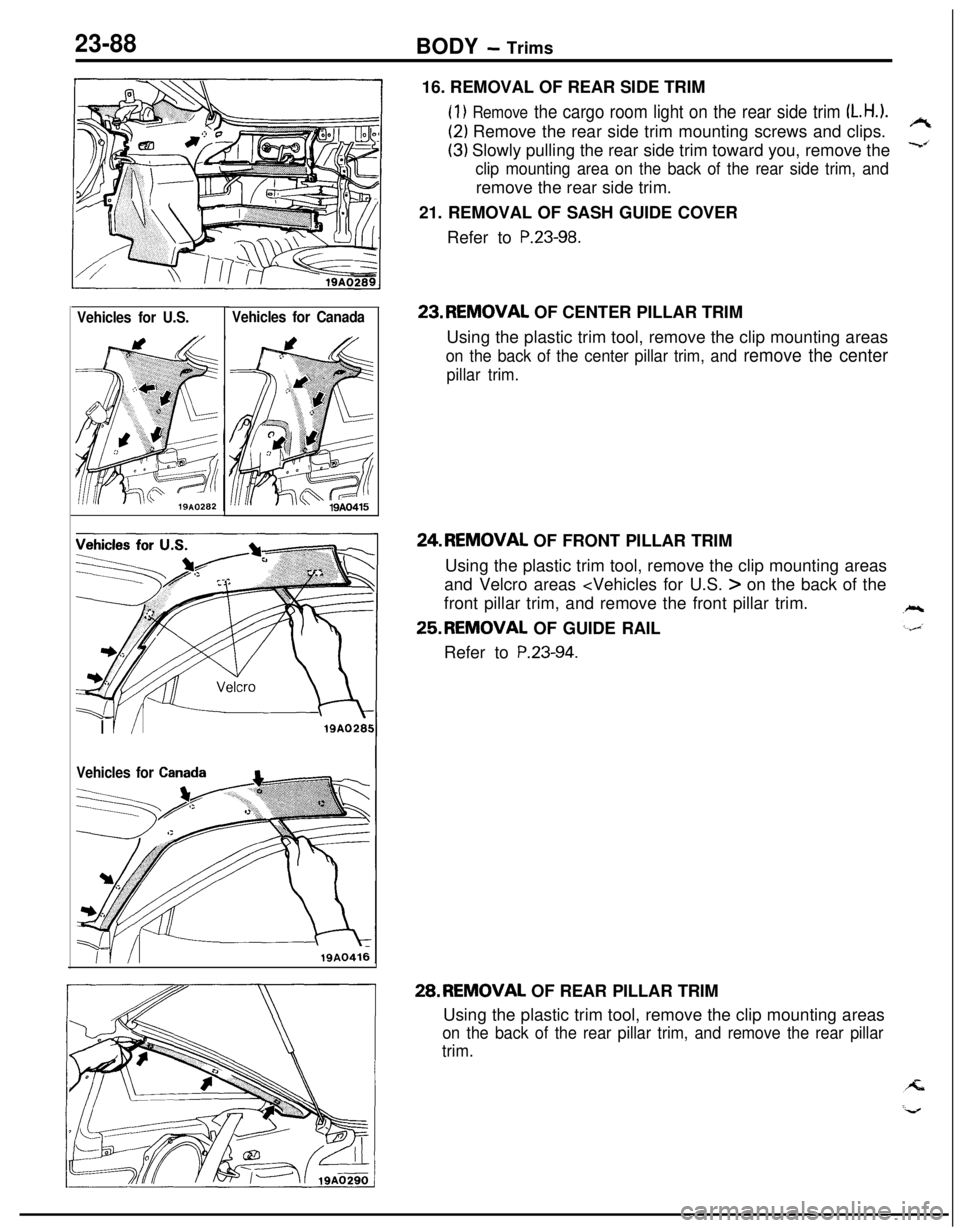

23-88BODY - Trims

Vehicles for U.S.Vehicles for CanadaI

I/IlQA028!

Vehicles for Ca16. REMOVAL OF REAR SIDE TRIM

(1) Remove the cargo room light on the rear side trim LH.).

(2) Remove the rear side trim mounting screws and clips.

(3) Slowly pulling the rear side trim toward you, remove the

clip mounting area on the back of the rear side trim, andremove the rear side trim.

21. REMOVAL OF SASH GUIDE COVER

Refer to

P.23-98.23.REMOVAL OF CENTER PILLAR TRIM

Using the plastic trim tool, remove the clip mounting areas

on the back of the center pillar trim, and remove the center

pillar trim.24.REMOVAL OF FRONT PILLAR TRIM

Using the plastic trim tool, remove the clip mounting areas

and Velcro areas

front pillar trim, and remove the front pillar trim.25.REMOVAL OF GUIDE RAIL

Refer to

P.23-94.28.REMOVAL OF REAR PILLAR TRIM

Using the plastic trim tool, remove the clip mounting areas

on the back of the rear pillar trim, and remove the rear pillar

trim.

Page 1174 of 1216

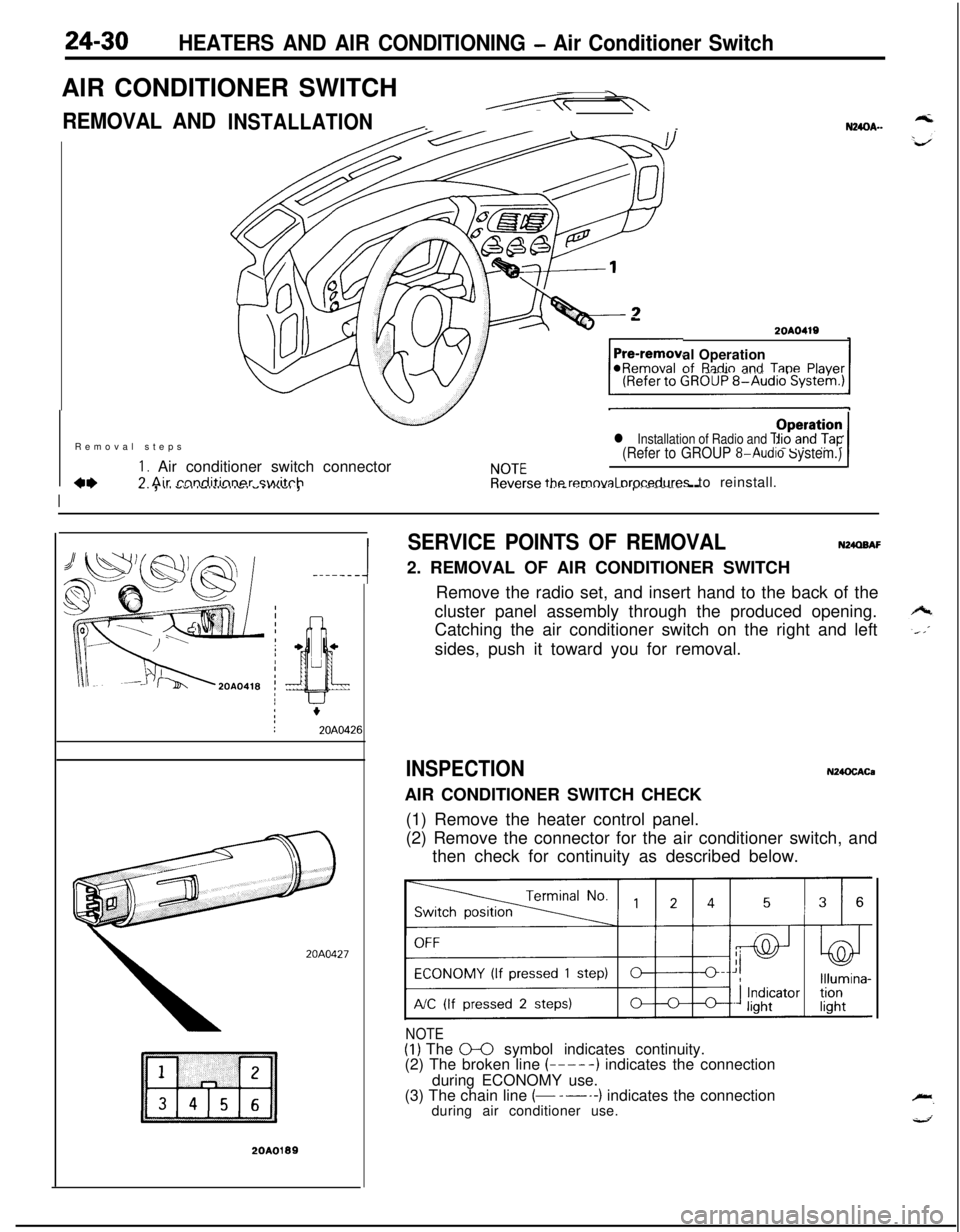

24-30HEATERS AND AIR CONDITIONING - Air Conditioner SwitchAIR CONDITIONER SWITCH

REMOVAL AND--N24OA..INSTALLATION

-2OAO419al Operationof

R;tdio and TanePlaver@Removal -..--._ _.-.-, -Removal steps

I. Air conditioner switch connectorCL7 Air rnnditinner switch

l Installation of Radio and Tape Player(Refer to GROUP 8-Audio System.)

NOTEOperation /Reverse

removal orocedures to reinstall.

I

77-. , .,a -.,a ,-,..-,.-. -.....,. ,.._._.__ _..- .-...-.-.r----- --

-----A

20A0427

20A0199

SERVICE POINTS OF REMOVALN24QBAF2. REMOVAL OF AIR CONDITIONER SWITCH

Remove the radio set, and insert hand to the back of the

cluster panel assembly through the produced opening.

Catching the air conditioner switch on the right and left

sides, push it toward you for removal.

INSPECTIONN24OCACaAIR CONDITIONER SWITCH CHECK

(1) Remove the heater control panel.

(2) Remove the connector for the air conditioner switch, and

then check for continuity as described below.

NOTE(1) The 0-0 symbol indicates continuity.

(2) The broken line (-----) indicates the connection

during ECONOMY use.

(3) The chain line

(- -----) indicates the connection

during air conditioner use.

Page 1180 of 1216

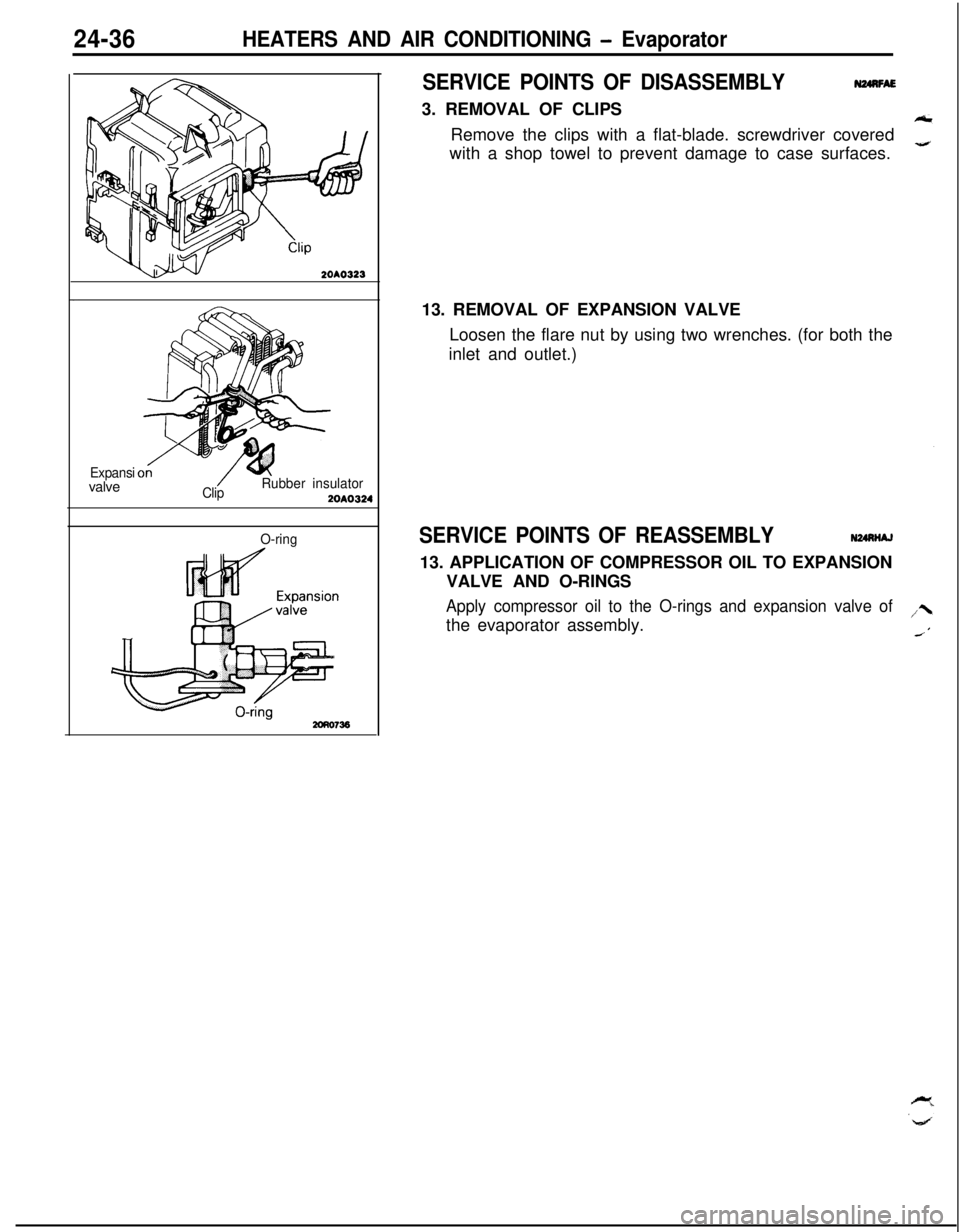

24-36HEATERS AND AIR CONDITIONING - Evaporator

SERVICE POINTS OF DISASSEMBLY3. REMOVAL OF CLIPS

N24nFAERemove the clips with a flat-blade. screwdriver covered

with a shop towel to prevent damage to case surfaces.

2OAO323

Expansivalve

ClipRubber insulator2OAO324

O-ring13. REMOVAL OF EXPANSION VALVE

Loosen the flare nut by using two wrenches. (for both the

inlet and outlet.)SERVICE POINTS OF REASSEMBLYN24nNAJ13. APPLICATION OF COMPRESSOR OIL TO EXPANSION

VALVE AND O-RINGS

Apply compressor oil to the O-rings and expansion valve ofthe evaporator assembly.