brake sensor MITSUBISHI ECLIPSE 1991 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 908 of 1216

21-214AUTOMATIC TRANSAXLE - Service Adjustment Procedures

'50157

F4

1

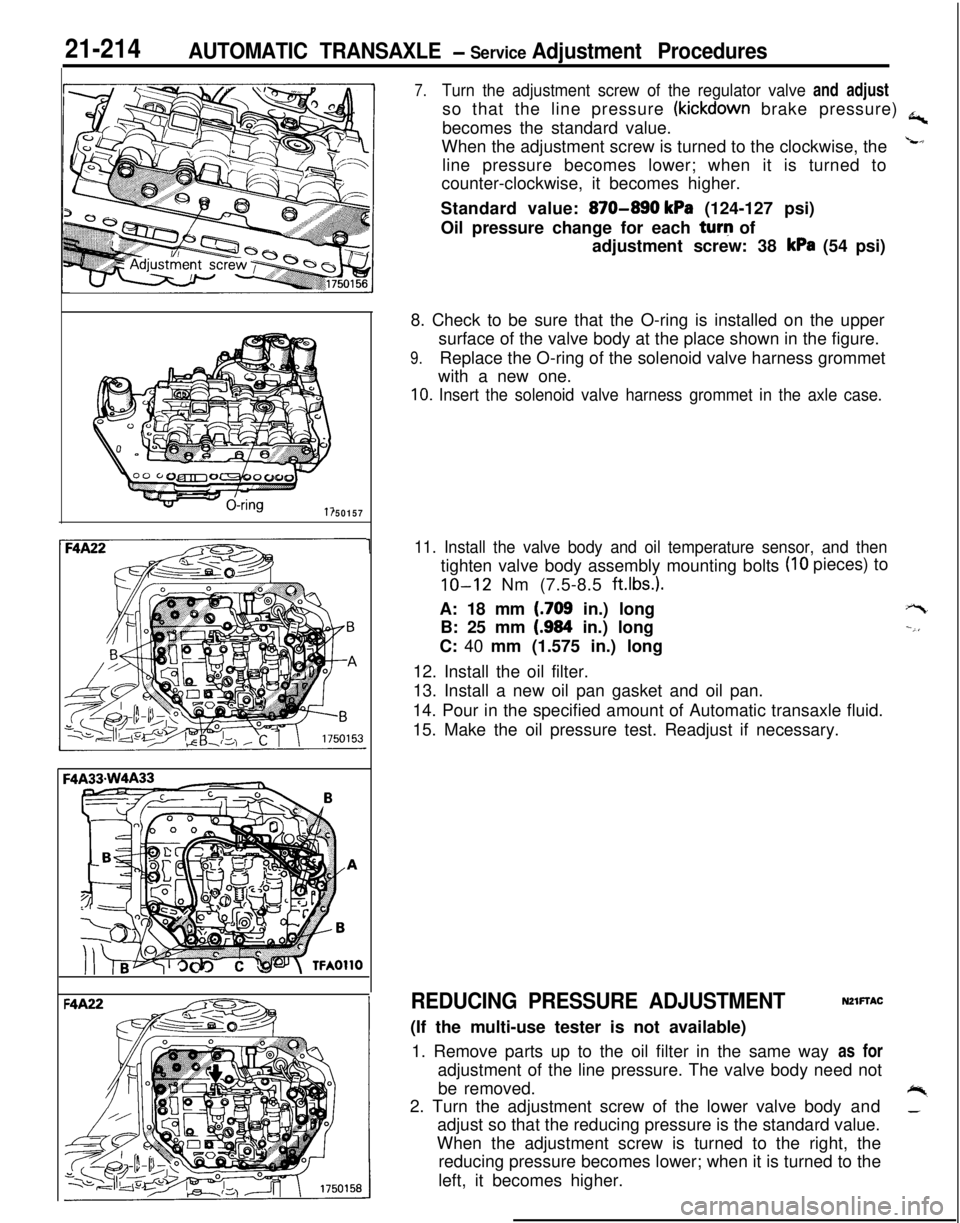

7.Turn the adjustment screw of the regulator valve and adjustso that the line pressure

(kickdown brake pressure) a,becomes the standard value.

When the adjustment screw is turned to the clockwise, the

Lline pressure becomes lower; when it is turned to

counter-clockwise, it becomes higher.

Standard value:

870-890 kPa (124-127 psi)

Oil pressure change for each turq of

adjustment screw: 38

kPa (54 psi)

8. Check to be sure that the O-ring is installed on the upper

surface of the valve body at the place shown in the figure.

9.Replace the O-ring of the solenoid valve harness grommet

with a new one.

10. Insert the solenoid valve harness grommet in the axle case.

11. Install the valve body and oil temperature sensor, and then

(IO pieces) to

tighten valve body assembly mounting bolts

IO-12 Nm (7.5-8.5 ft.lbs.).A: 18 mm

(.709 in.) long

B: 25 mm

(.984 in.) long

C: 40 mm (1.575 in.) long

12. Install the oil filter.

13. Install a new oil pan gasket and oil pan.

14. Pour in the specified amount of Automatic transaxle fluid.

15. Make the oil pressure test. Readjust if necessary.

+-t

--,,

REDUCING PRESSURE ADJUSTMENTNZlFTAC(If the multi-use tester is not available)

1. Remove parts up to the oil filter in the same way as for

adjustment of the line pressure. The valve body need not

be removed.

+%2. Turn the adjustment screw of the lower valve body and_adjust so that the reducing pressure is the standard value.

When the adjustment screw is turned to the right, the

reducing pressure becomes lower; when it is turned to the

left, it becomes higher.

Page 951 of 1216

AUTOMATIC TRANSAXLE - Transaxle Assembly

7750157

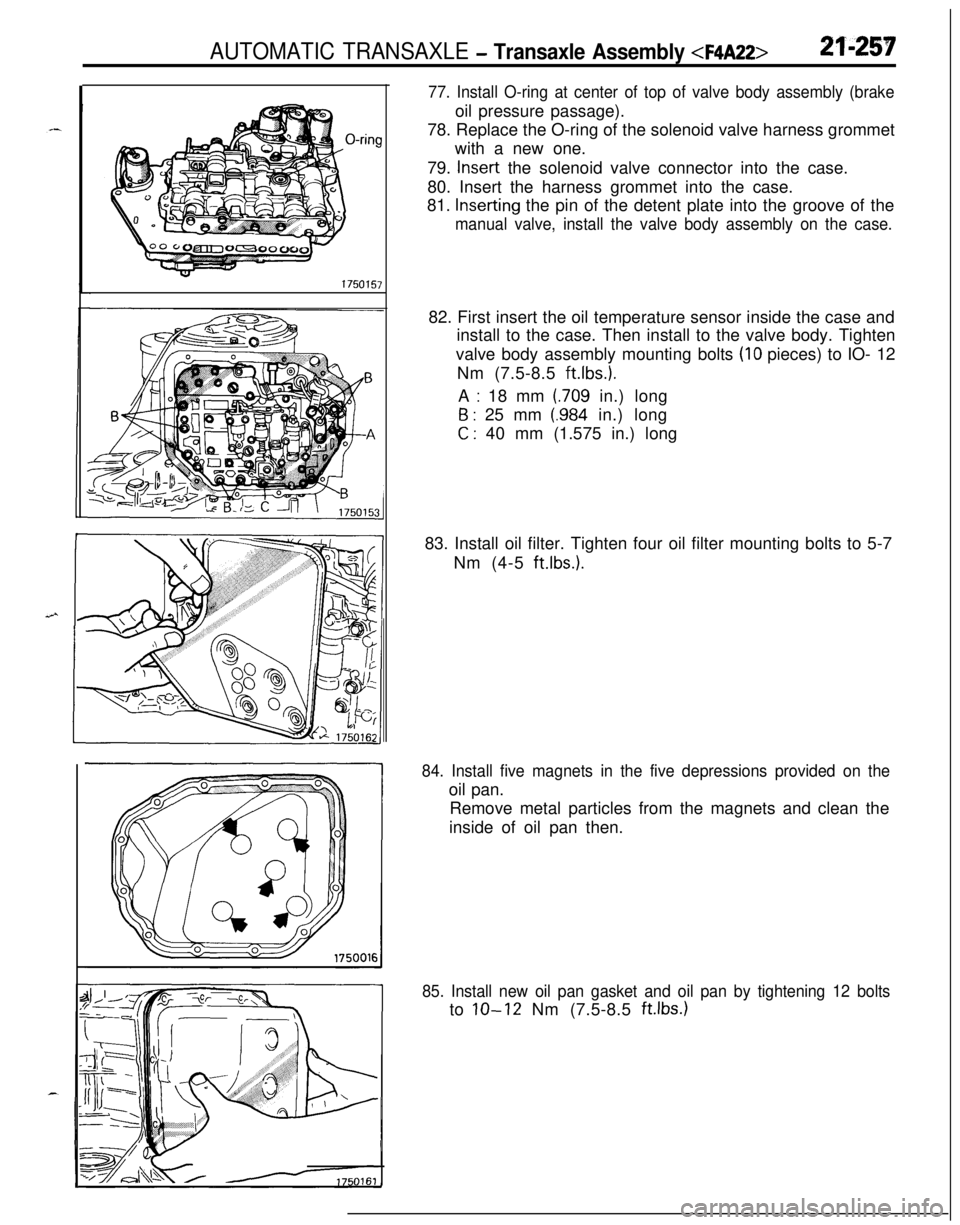

77. Install O-ring at center of top of valve body assembly (brakeoil pressure passage).

78. Replace the O-ring of the solenoid valve harness grommet

with a new one.

79.

Insert the solenoid valve connector into the case.

80. Insert the harness grommet into the case.

81.

Inserting the pin of the detent plate into the groove of the

manual valve, install the valve body assembly on the case.82. First insert the oil temperature sensor inside the case and

install to the case. Then install to the valve body. Tighten

valve body assembly mounting bolts

(IO pieces) to IO- 12

Nm (7.5-8.5

ft.lbs.).A

: 18 mm (709 in.) long

6 : 25 mm (.984 in.) long

C : 40 mm (1.575 in.) long

83. Install oil filter. Tighten four oil filter mounting bolts to 5-7

Nm (4-5

ft.lbs.1.

84. Install five magnets in the five depressions provided on theoil pan.

Remove metal particles from the magnets and clean the

inside of oil pan then.

85. Install new oil pan gasket and oil pan by tightening 12 boltsto

lo-12 Nm (7.5-8.5 ft.lbs.1

Page 960 of 1216

21-266 AUTOMATIC TRANSAXLE -Transaxle Assembly

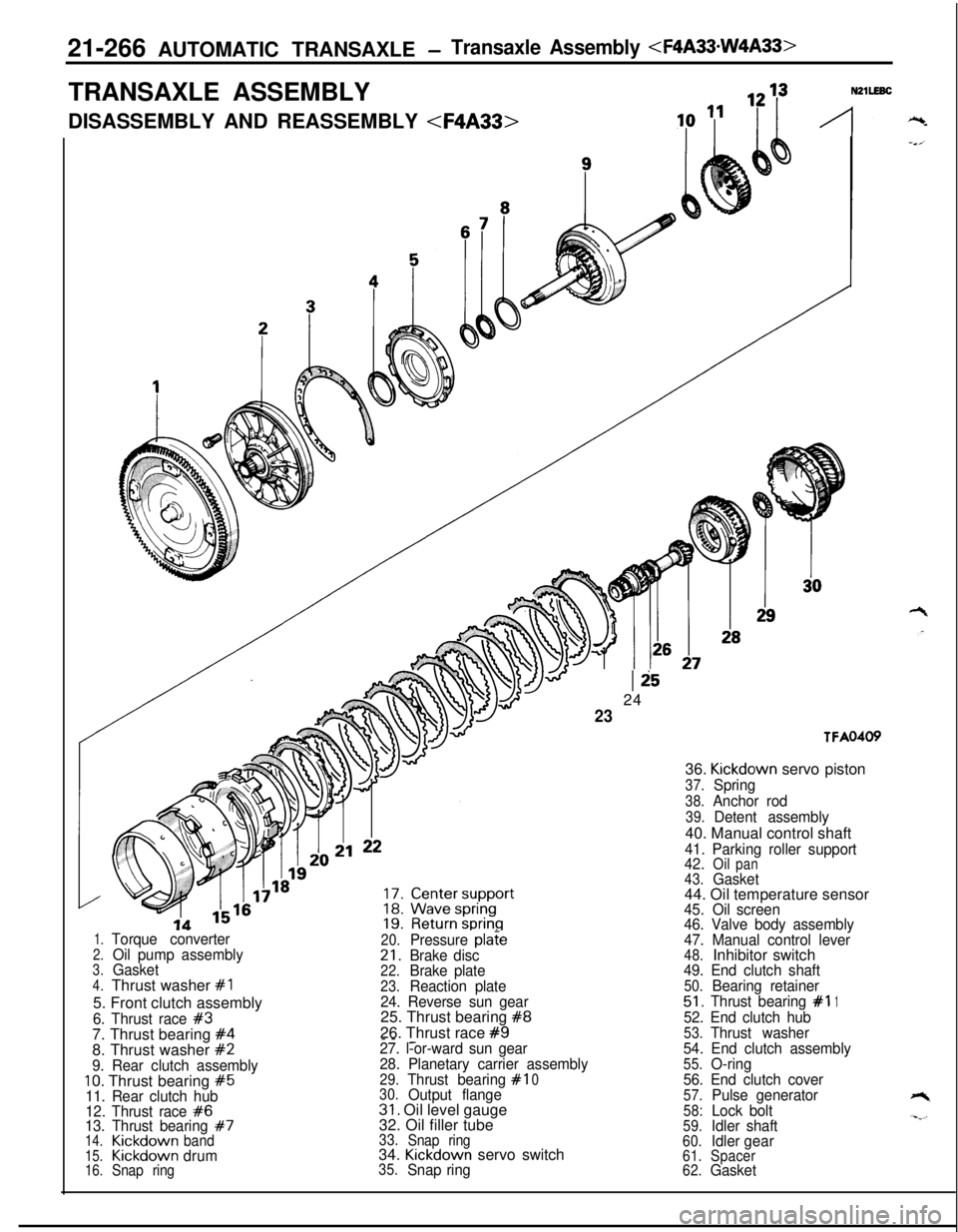

DISASSEMBLY AND REASSEMBLY

20.Pressure pla?e21.Brake disc22.Brake plate23.Reaction plate

24. Reverse sun gear25. Thrust bearing

#826. Thrust race

#9---

1.Torque converter2.Oil pump assembly3.Gasket4.Thrust washer #I5. Front clutch assembly

6. Thrust race #37. Thrust bearing #48. Thrust washer #227. l-or-ward sun gear

9. Rear clutch assembly28. Planetary carrier assembly

10. Thrust bearing #529.Thrust bearing#I0

11. Rear clutch hub30.Output flange

12. Thrust race

#631. Oil level gauge

13. Thrust bearing #732. Oil filler tube14.Kickdownband33.

Snap ring15.Kickdowndrum34. Kickdown servo switch16.Snap ring35.Snap ring

Ii524

23

TFA0405’36.

Kickdown servo piston

37.Spring

38.Anchor rod

39.Detent assembly40. Manual control shaft

41. Parking roller support

42.Oilpan43.Gasket44. Oil temperature sensor

45.Oil screen

46. Valve body assembly

47. Manual control lever

48.Inhibitor switch49. End clutch shaft50.Bearing retainer51.Thrust bearing #I152. End clutch hub53.Thrust washer

54. End clutch assembly

55.O-ring

56. End clutch cover

57.Pulse generator58:Lock bolt59.Idler shaft60.Idlergear61.Spacer

62.Gasket

Page 962 of 1216

21-268 AUTOMATIC TRANSAXLE -Transaxle Assembly

TFA0409

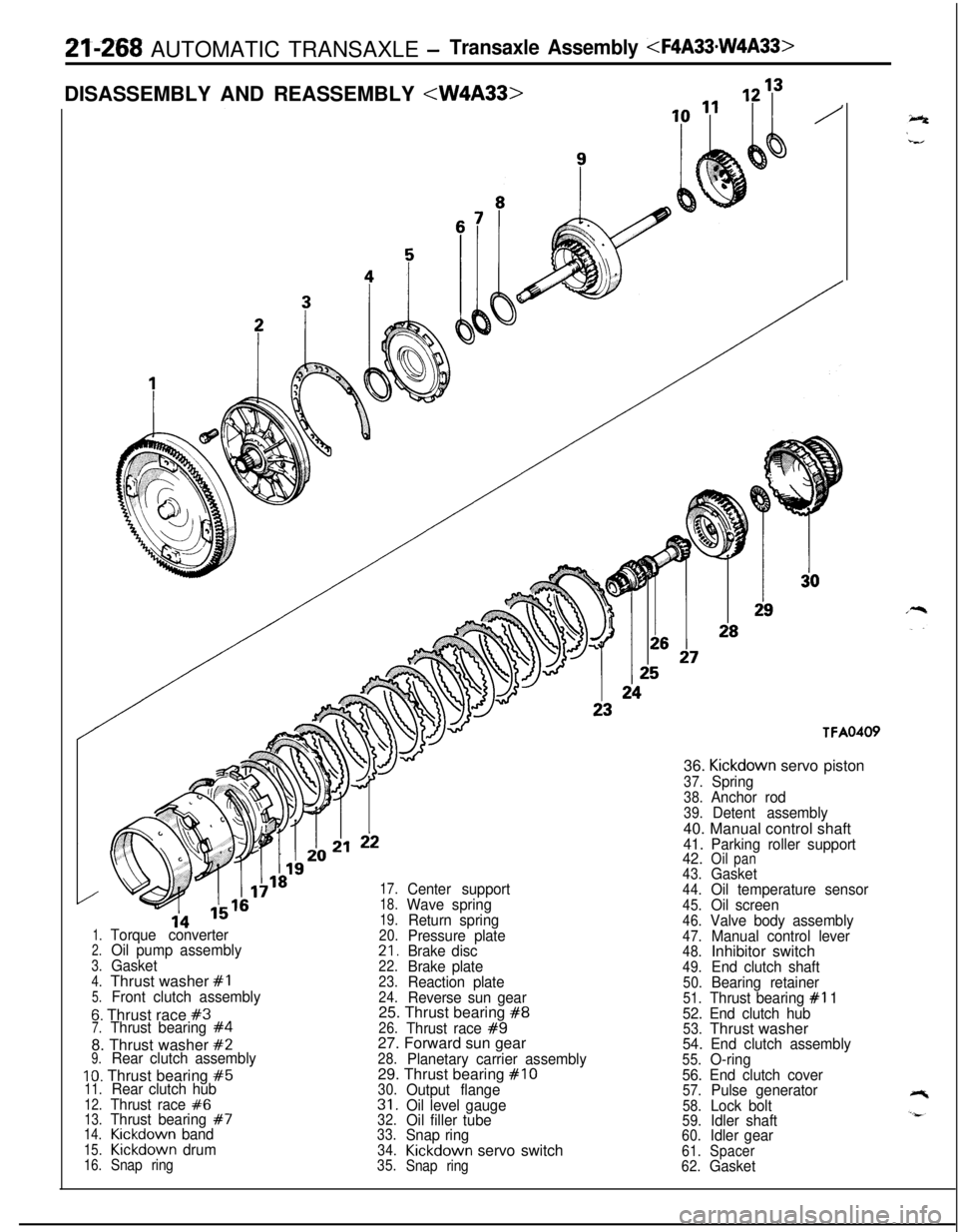

1.Torque converter2.Oil pump assembly3.Gasket4.Thrust washer #I5.Front clutch assembly

6. Thrust race #37.Thrust bearing #48. Thrust washer

#29.Rear clutch assembly

10. Thrust bearing #511.Rear clutch hub12.Thrust race #613.Thrust bearing #714.Kickdown band15.Kickdown drum16.Snap ring

17.Center support18.Wave spring19.Return spring20.Pressure plate21.Brake disc22.Brake plate23.Reaction plate24.Reverse sun gear25. Thrust bearing #826.Thrust race #927. Forward sun gear

28.Planetary carrier assembly29. Thrust bearing #IO30.Output flange31.Oil level gauge32.Oil filler tube33.Snap ring34.Kickdown servo switch35.

Snap ring36.

Kickdown servo piston

37.Spring38.Anchor rod39.Detent assembly40. Manual control shaft

41. Parking roller support

42.Oilpan43.Gasket44.Oil temperature sensor45.Oil screen46.Valve body assembly47.Manual control lever48.Inhibitor switch49.End clutch shaft50.Bearing retainer51.Thrust bearing #I 1

52. End clutch hub

53.Thrust washer54. End clutch assembly55.O-ring

56. End clutch cover

57.Pulse generator58.Lock bolt59.Idler shaft60.Idler gear61.Spacer

62.Gasket