brake sensor MITSUBISHI ECLIPSE 1991 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 198 of 1216

5-58BRAKES - Master Cylinder

IISASSEMBLY AND REASSEMBLYNOMA-

r------1

11414UO125

Iii

Brake master cylinder kit

6

:.5i340,b;m- . .

; .5F3h0,bfm

- . - +-10

.3.0 Nmft.lbs.

Disassembly steps

1. Reservoir cap assembly2.Diaphragm3.Reservoir cap4.Filter;: ;3r&e fluid level sensor

7.ReservoirI)+8.Nipple9.Reservoir seal

4+10. Piston stopper bolt

MAO57511. Gasket

aLI)12. Piston stopper ring+e ~~ 13. Primary piston assembly+e W 14. Secondary piston assembly

~~ 15. Master cylinder body

FrEeverse the disassembly procedures to reassemble.

(2) 4e : Refer to “Service Points of Disassembly”(3) l + : Refer to “Service Points of Reassembly”I;! m : Non-reusabje parts*: Vehicles with ABS

Page 200 of 1216

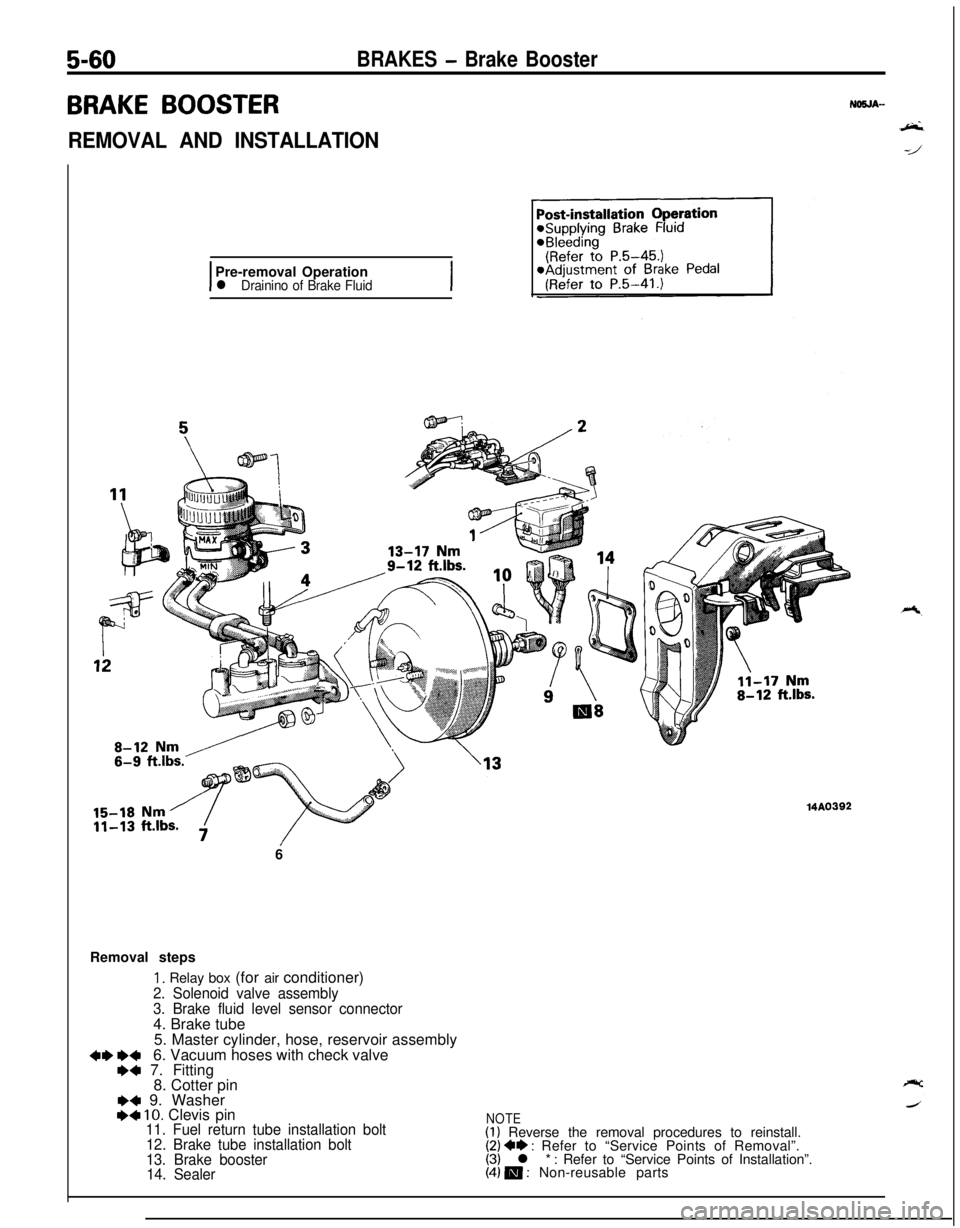

5-60BRAKES - Brake Booster

BRAKE BOOSTER

REMOVAL AND INSTALLATION

IPre-removal Operationl Drainino of Brake FluidI6

Removal steps

1. Relay box (for air conditioner)

2. Solenoid valve assembly

3. Brake fluid level sensor connector4. Brake tube

5. Master cylinder, hose, reservoir assembly

+I) e+6. Vacuum hoses with check valve+a 7. Fitting

8. Cotter pin

I)4 9. WasherI)4 10. Clevis pin11. Fuel return tube installation bolt

12. Brake tube installation bolt

13. Brake booster

14. Sealer

MA0392

NOTE(1) Reverse the removal procedures to reinstall.(2) ** : Refer to “Service Points of Removal”.(3) l * : Refer to “Service Points of Installation”.(4) m : Non-reusable parts

Page 210 of 1216

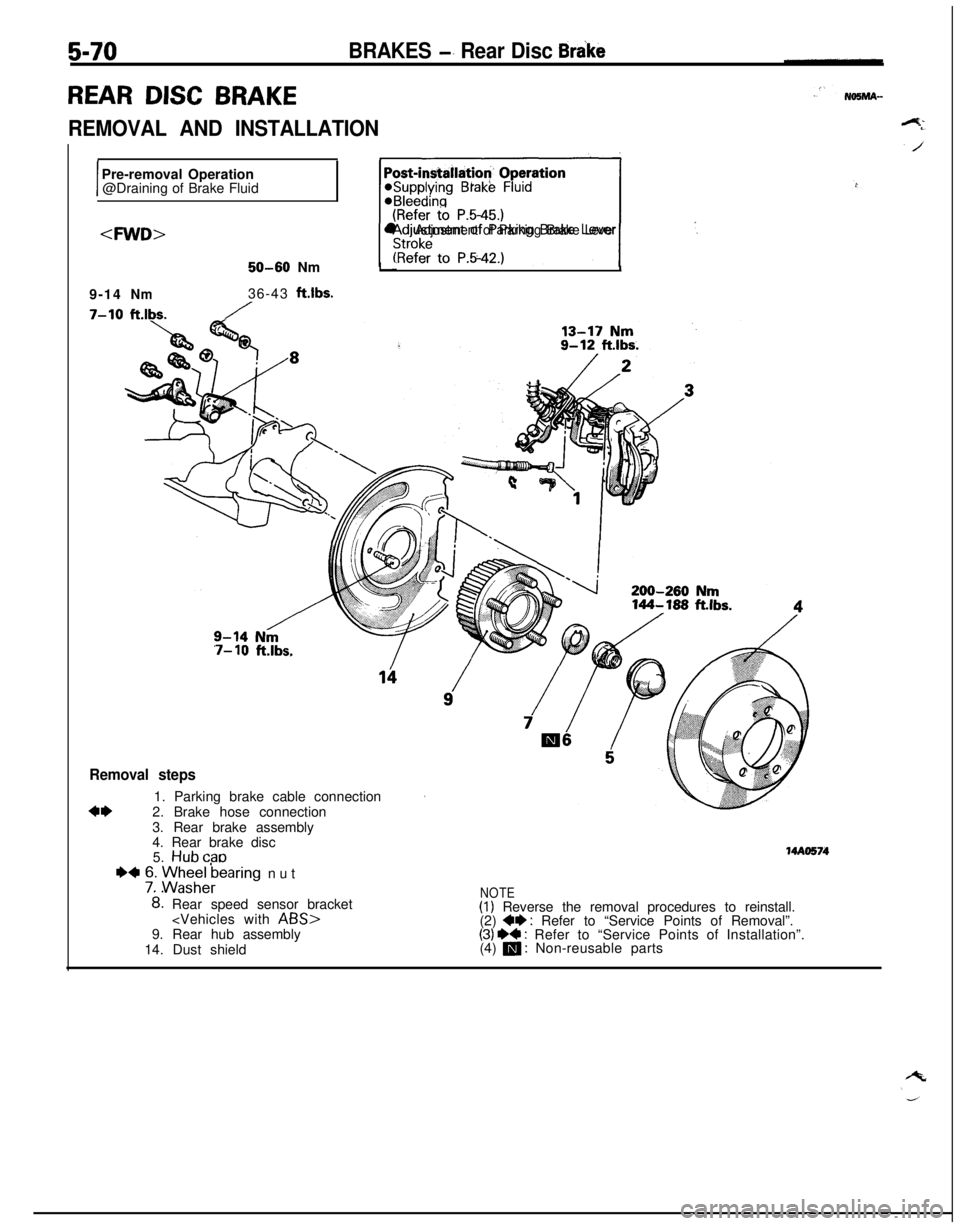

5-70

REAR DISC BRAKE

BRAKES -’ Rear Disc Brake

REMOVAL AND INSTALLATION

IPre-removal Operation

@Draining of Brake Fluid

~1 ,.

l Adjustment of Parking Brake Lever

1.150-60Nm

9-14

Nm36-43ft.lbs.

7-10ft.lbs./

7- 10ft.lbs.

Removal steps

4*1. Parking brake cable connection

2. Brake hose connection

3. Rear brake assembly

4. Rear brake disc

5.

Hubcab

+4 76. ME;AFearing nut

8: Rear speed sensor bracket

14. Dust shield

NOTE(1) Reverse the removal procedures to reinstall.

(2) +* : Refer to “Service Points of Removal”.(3) ** : Refer to “Service Points of Installation”.

(4) m : Non-reusable parts

MAO574

Page 211 of 1216

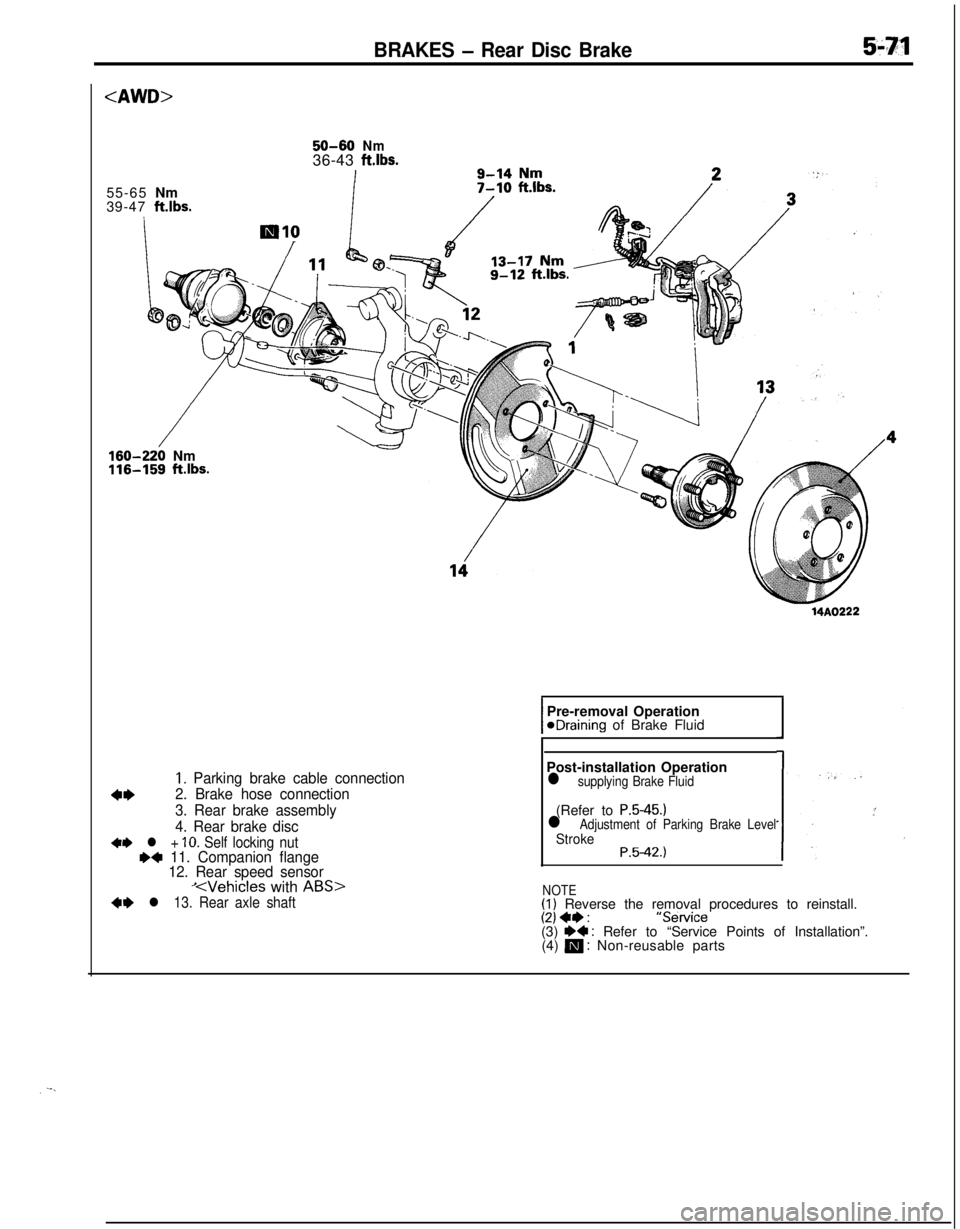

BRAKES - Rear Disc Brake59q!l

50-60Nm36-43ft.lbs.9-14Nm55-65Nm

39-47

klbs.

/160-220 Nm116-159 ft.lbs.14A0222

1. Parking brake cable connection

4*2. Brake hose connection

3. Rear brake assembly

4. Rear brake disc

+e l + IO. Self locking nutr)+ 11. Companion flange

12. Rear speed sensor

KVehicles with ABS>+e l 13. Rear axle shaftPre-removal Operation

@Draining of Brake Fluid

Post-installation Operation

l supplying Brake Fluid(Refer to

P.5-45.)l Adjustment of Parking Brake LevelStrokeP.5-42.)

NOTE

(1) Reverse the removal procedures to reinstall.(2) +e:“Service

(3) I)+ : Refer to “Service Points of Installation”.

(4) m : Non-reusable parts

Page 220 of 1216

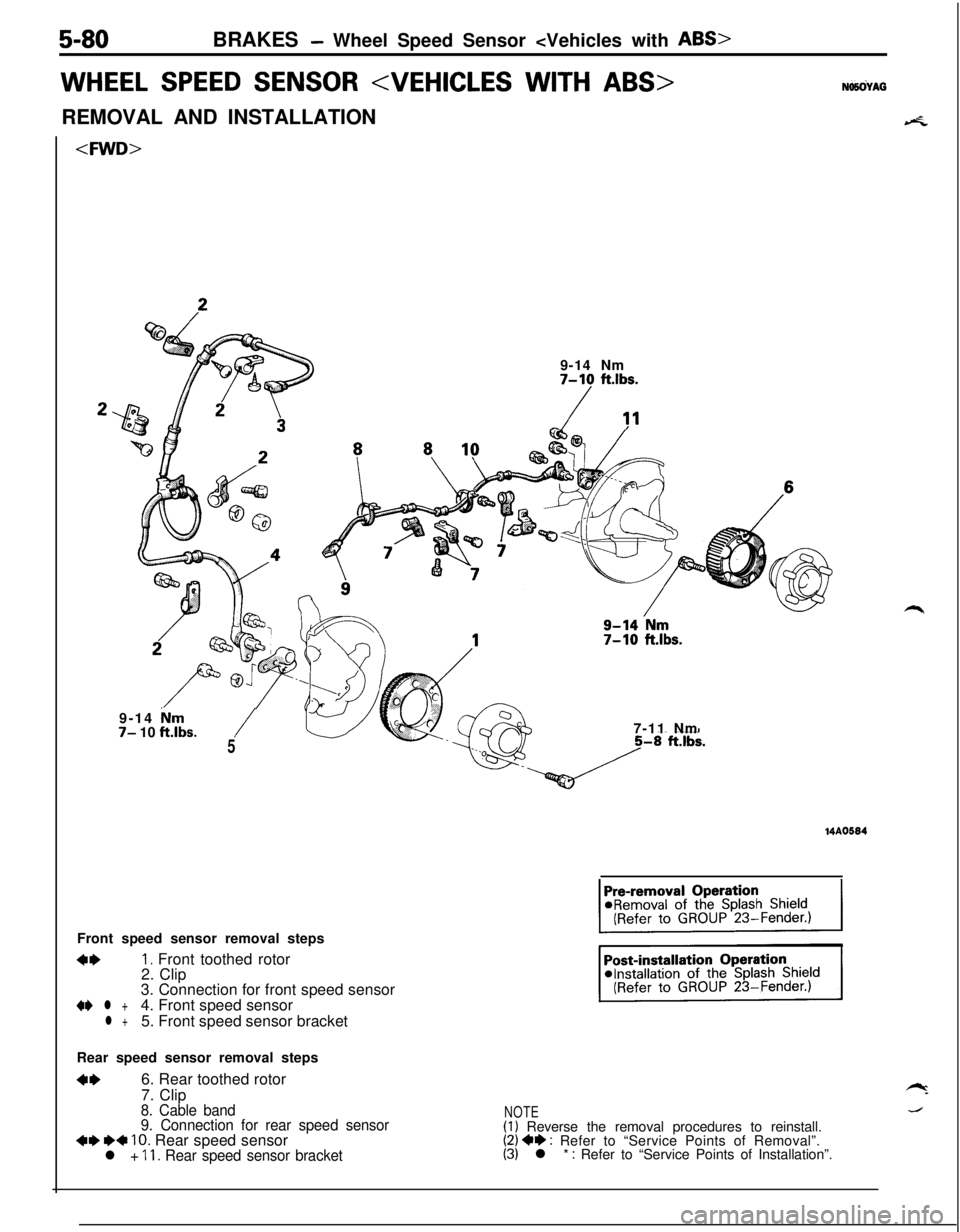

5-80BRAKES - Wheel Speed Sensor

WHEEL SPEED SENSOR

4.

7-10 ft.lbs.

-/?’9-14 Nm

7- 10 ft.lbs./5Front speed sensor removal steps

4*I. Front toothed rotor

2. Clip

3. Connection for front speed sensor

+e l +4. Front speed sensorl +5. Front speed sensor bracket7-11 Nm

14A0584Rear speed sensor removal steps

**6. Rear toothed rotor

7. Clip

8. Cable band

9. Connection for rear speed sensor

+e I)* 10. Rear speed sensorl + 11. Rear speed sensor bracket

NOTE(1) Reverse the removal procedures to reinstall.(2) 4* : Refer to “Service Points of Removal”.(3) l * : Refer to “Service Points of Installation”.

Page 221 of 1216

BRAKES - Wheel Speed Sensor

7-10 ft.lbs.

IPost-installation Operation@Installation of the Snlash ShieldI

1 (Refer to GROUP 23-Fender.)17-11 Nm

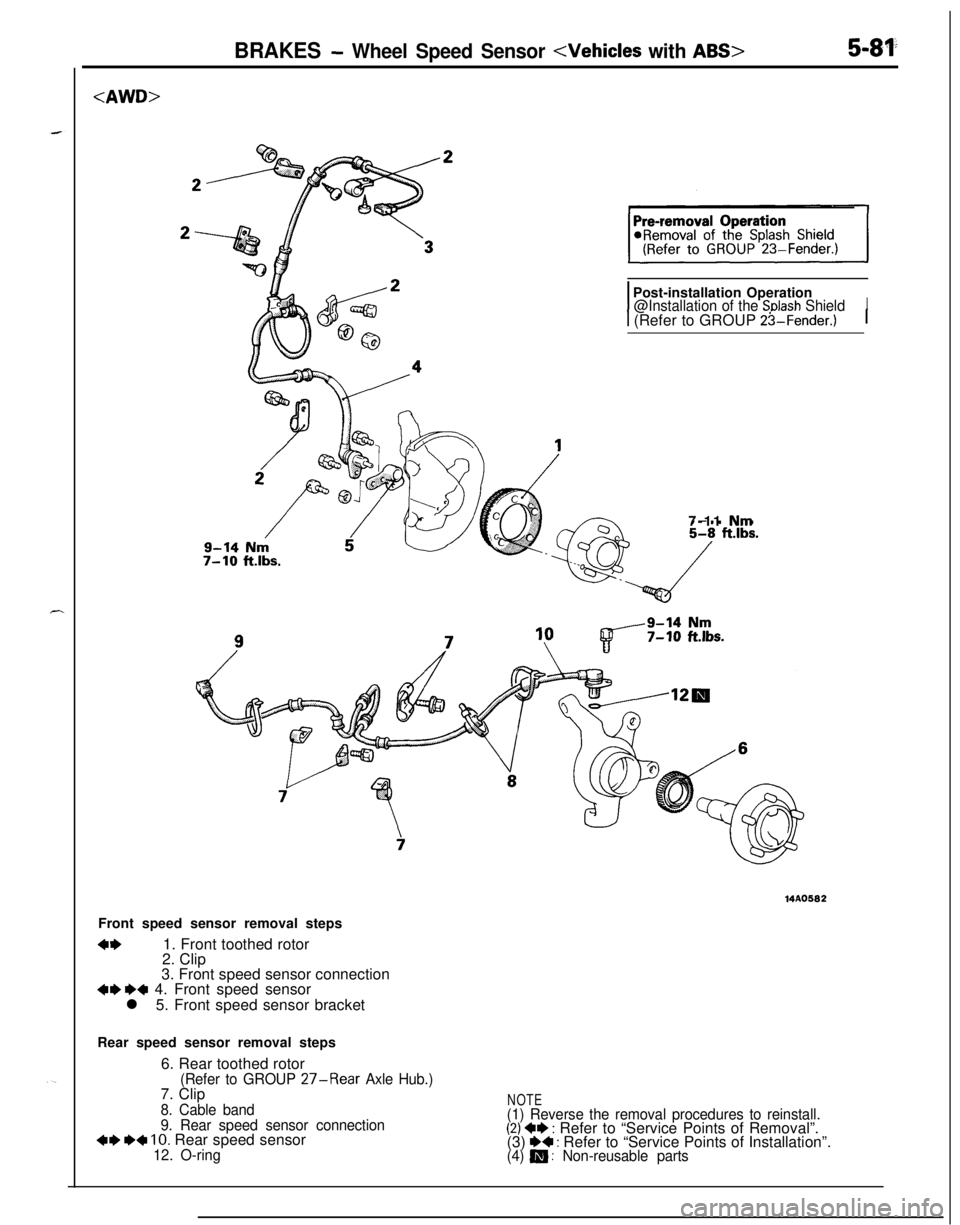

14A0582Front speed sensor removal steps

4*1. Front toothed rotor

2. Clip

3. Front speed sensor connection

4I) WI 4. Front speed sensor

l 5. Front speed sensor bracket

Rear speed sensor removal steps

6. Rear toothed rotor

(Refer to GROUP 27-Rear Axle Hub.)7. Clip

8. Cable band

9. Rear speed sensor connection

4I) W 10. Rear speed sensor12. O-ring

NOTE(1) Reverse the removal procedures to reinstall.(2) +e : Refer to “Service Points of Removal”.

(3) I)+ : Refer to “Service Points of Installation”.(4) m : Non-reusable parts

Page 222 of 1216

Care must be taken not to scratch or scar the rotor’stoothed surface, and not to drop it.

If the rotor’s toothed surface is chipped or the rotor is

deformed, it might not be able to accurately sense the

wheel rotation speed and the system as a result might

__ r-14A¬ perform normally.

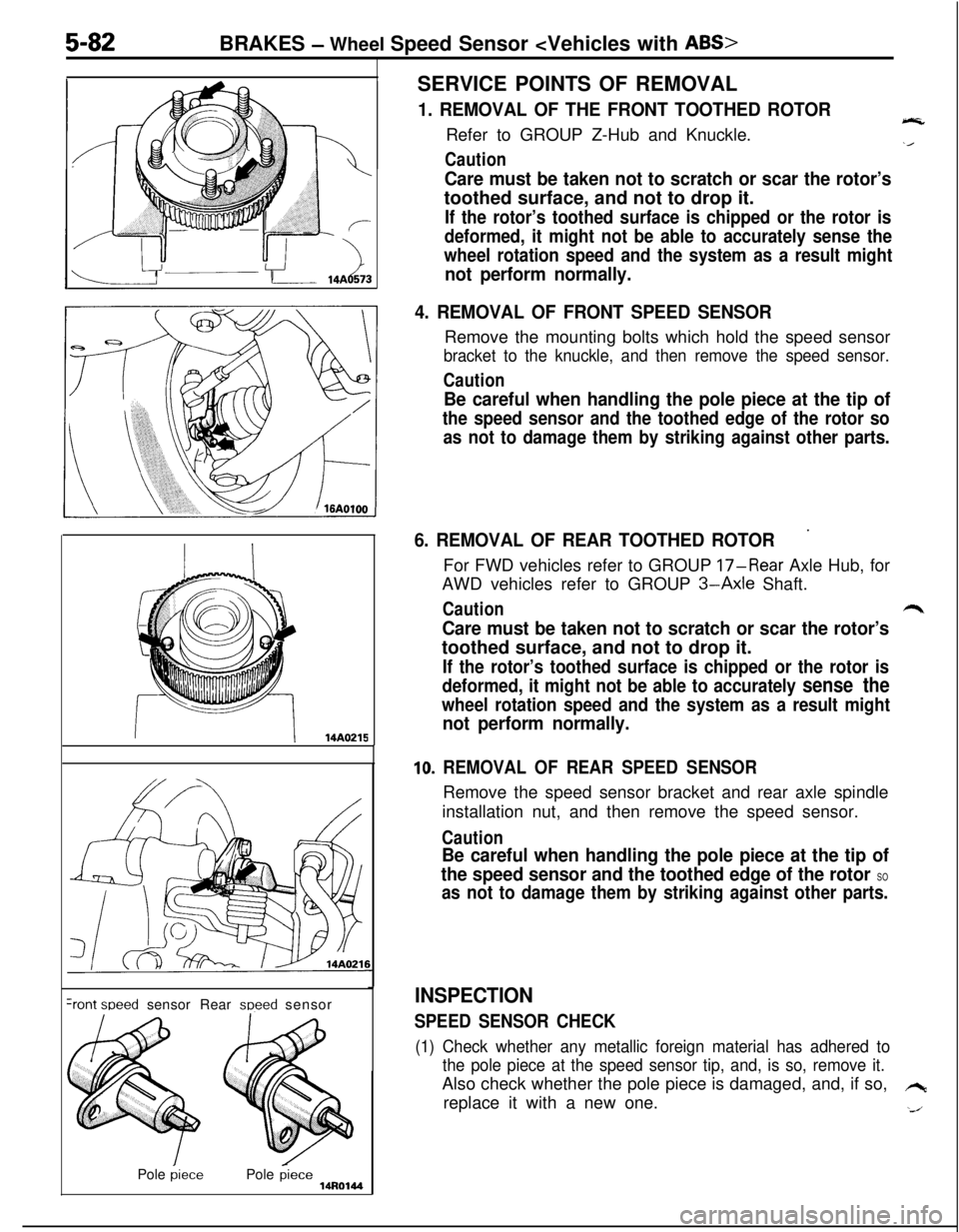

4. REMOVAL OF FRONT SPEED SENSORRemove the mounting bolts which hold the speed sensor

bracket to the knuckle, and then remove the speed sensor.

Caution

5-82BRAKES - Wheel Speed Sensor

1. REMOVAL OF THE FRONT TOOTHED ROTOReRefer to GROUP Z-Hub and Knuckle.

Caution

Be careful when handling the pole piece at the tip of

the speed sensor and the toothed edge of the rotor so

as not to damage them by striking against other parts.

II14A0215

+ont weed sensor Rear meed sensor

Pole

piecePole piece14R0144

6. REMOVAL OF REAR TOOTHED ROTOR’For FWD vehicles refer to GROUP

17-Rear Axle Hub, for

AWD vehicles refer to GROUP

3-Axle Shaft.

Cautionr*

Care must be taken not to scratch or scar the rotor’stoothed surface, and not to drop it.

If the rotor’s toothed surface is chipped or the rotor is

deformed, it might not be able to accurately

sense the

wheel rotation speed and the system as a result might

not perform normally.

10. REMOVAL OF REAR SPEED SENSORRemove the speed sensor bracket and rear axle spindle

installation nut, and then remove the speed sensor.

Caution

Be careful when handling the pole piece at the tip of

the speed sensor and the toothed edge of the rotor

SO

as not to damage them by striking against other parts.

INSPECTION

SPEED SENSOR CHECK

(1) Check whether any metallic foreign material has adhered to

the pole piece at the speed sensor tip, and, is so, remove it.Also check whether the pole piece is damaged, and, if so,

hreplace it with a new one.

‘J

Page 223 of 1216

BRAKES - Wheel Speed Sensor

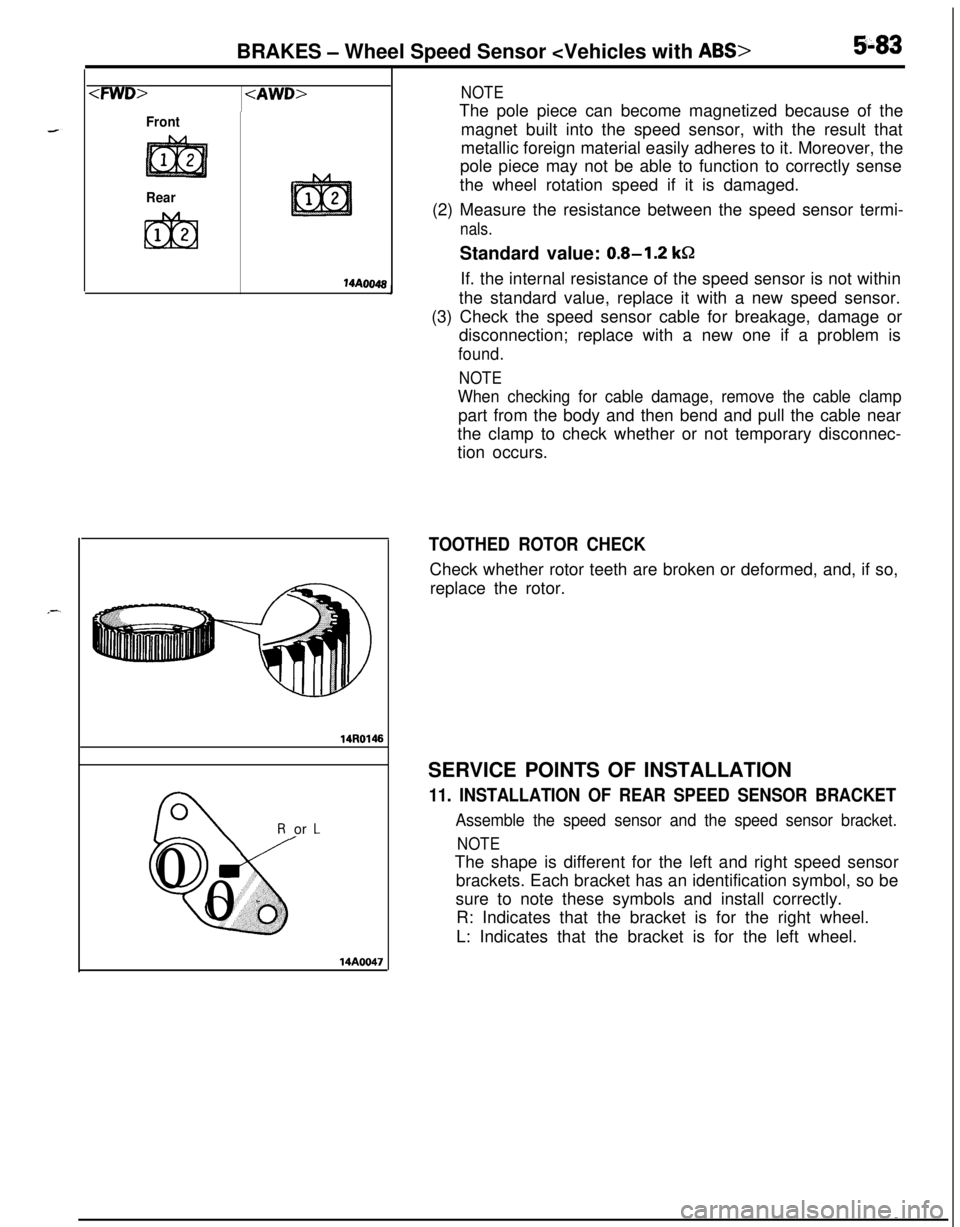

Front

Rear

14AO04814R0146

0R

Qfs0

0 (-Jor

L/

14AOO47

NOTEThe pole piece can become magnetized because of the

magnet built into the speed sensor, with the result that

metallic foreign material easily adheres to it. Moreover, the

pole piece may not be able to function to correctly sense

the wheel rotation speed if it is damaged.

(2) Measure the resistance between the speed sensor termi-

nals.Standard value:

0.8-1.2 kQIf. the internal resistance of the speed sensor is not within

the standard value, replace it with a new speed sensor.

(3) Check the speed sensor cable for breakage, damage or

disconnection; replace with a new one if a problem is

found.

NOTE

When checking for cable damage, remove the cable clamppart from the body and then bend and pull the cable near

the clamp to check whether or not temporary disconnec-

tion occurs.

TOOTHED ROTOR CHECKCheck whether rotor teeth are broken or deformed, and, if so,

replace the rotor.

SERVICE POINTS OF INSTALLATION

11. INSTALLATION OF REAR SPEED SENSOR BRACKET

Assemble the speed sensor and the speed sensor bracket.

NOTEThe shape is different for the left and right speed sensor

brackets. Each bracket has an identification symbol, so be

sure to note these symbols and install correctly.

R: Indicates that the bracket is for the right wheel.

L: Indicates that the bracket is for the left wheel.

Page 224 of 1216

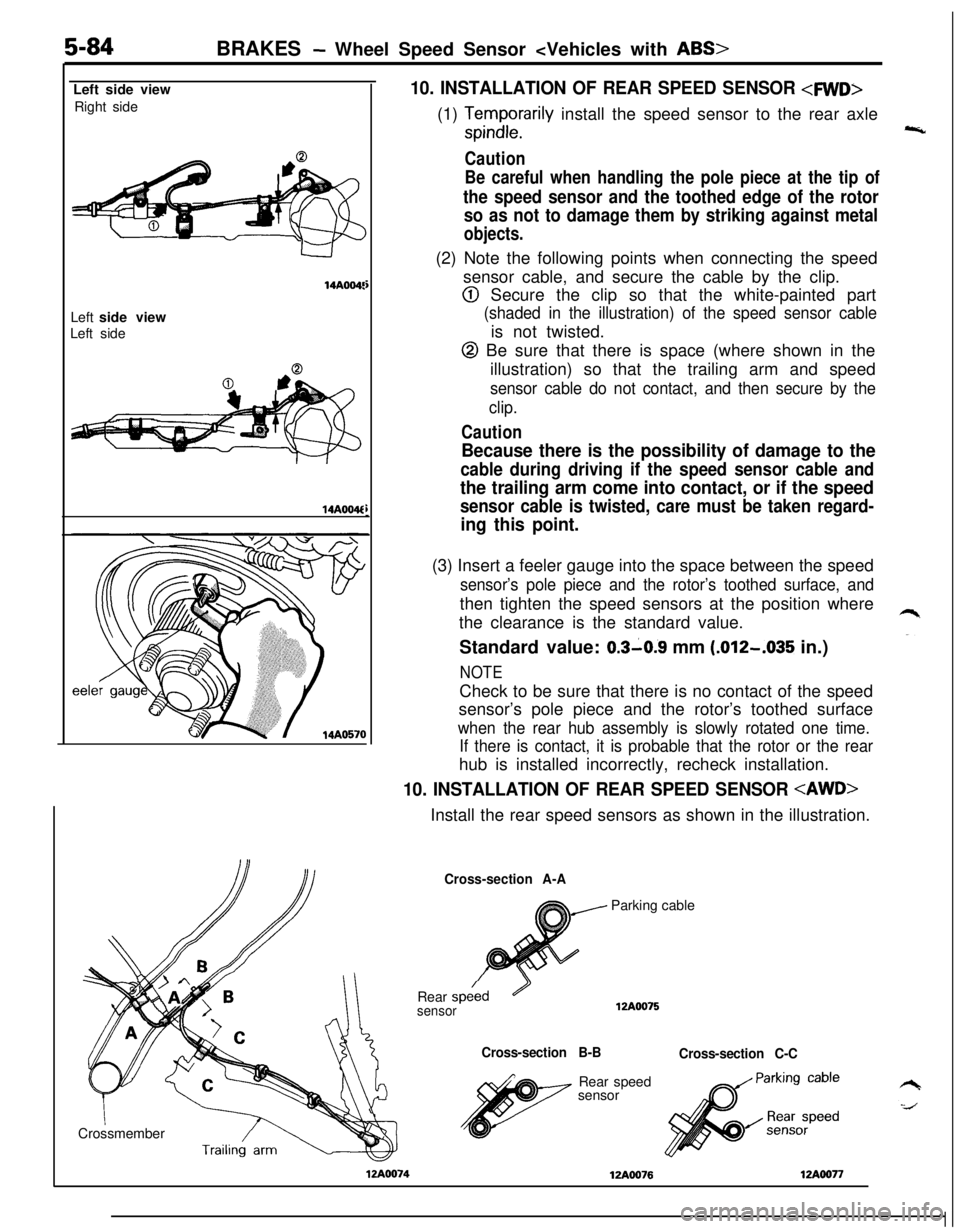

5-84BRAKES - Wheel Speed Sensor

Right side

14AOO4:Left side view

Left side

14A004.fCrossmember

10. INSTALLATION OF REAR SPEED SENSOR

Caution

Be careful when handling the pole piece at the tip of

the speed sensor and the toothed edge of the rotor

so as not to damage them by striking against metal

objects.(2) Note the following points when connecting the speed

sensor cable, and secure the cable by the clip.

@I Secure the clip so that the white-painted part

(shaded in the illustration) of the speed sensor cableis not twisted.

@ Be sure that there is space (where shown in the

illustration) so that the trailing arm and speed

sensor cable do not contact, and then secure by the

clip.

Caution

Because there is the possibility of damage to the

cable during driving if the speed sensor cable and

the trailing arm come into contact, or if the speed

sensor cable is twisted, care must be taken regard-

ing this point.(3) Insert a feeler gauge into the space between the speed

sensor’s pole piece and the rotor’s toothed surface, andthen tighten the speed sensors at the position where

the clearance is the standard value.

Standard value:

0.3-0.9 mm (.012-.035 in.)

NOTECheck to be sure that there is no contact of the speed

sensor’s pole piece and the rotor’s toothed surface

when the rear hub assembly is slowly rotated one time.

If there is contact, it is probable that the rotor or the rearhub is installed incorrectly, recheck installation.

10. INSTALLATION OF REAR SPEED SENSOR

Cross-section A-AParking cable

Rear

spe/edsensor12A0075

Cross-section B-B

Cross-section C-CRear speed

sensor

VA007412AOO7612AOO77

Page 225 of 1216

BRAKES - Wheel Speed Sensor

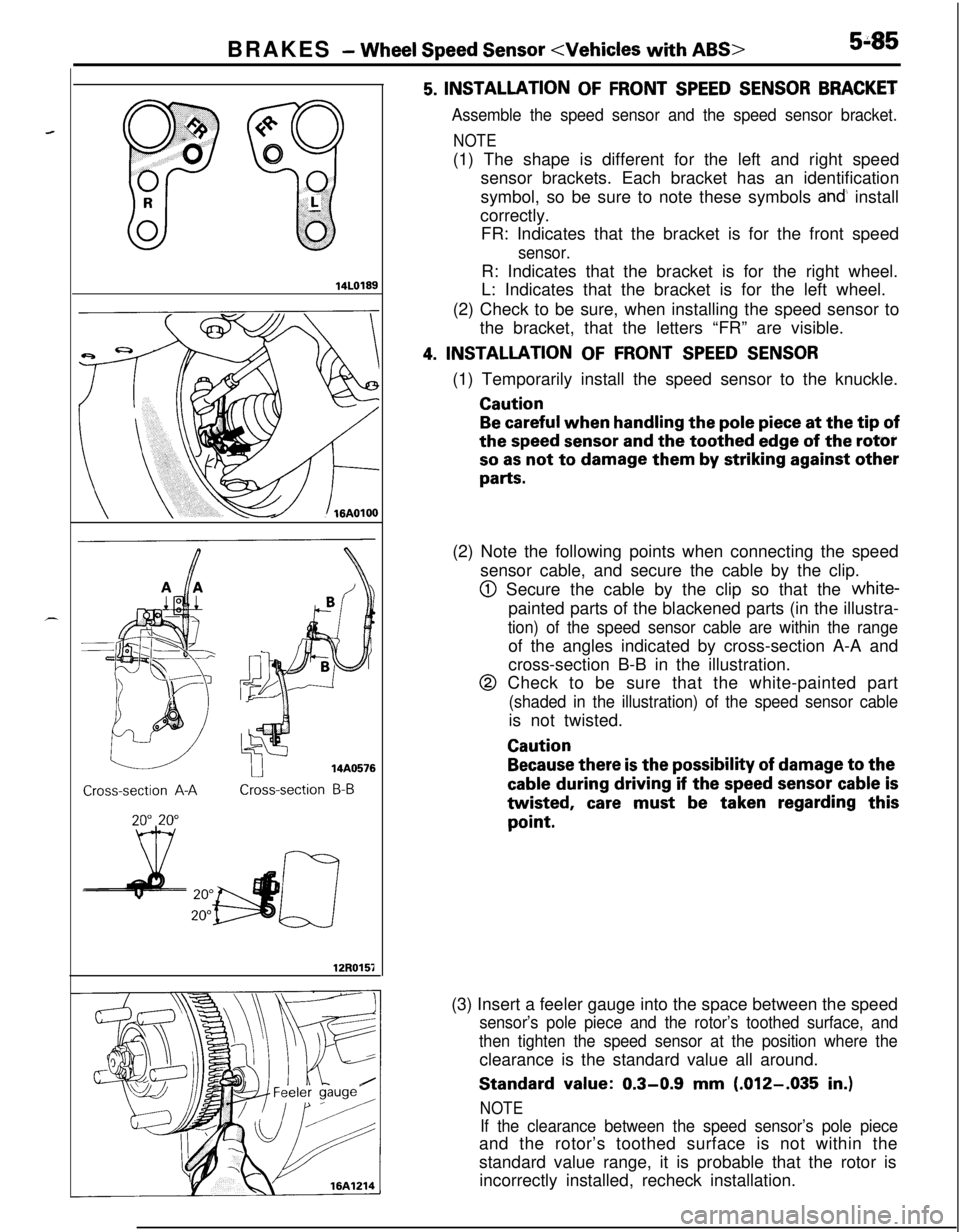

14LOl89

Cross-section A-ACross-section B-B

12R015i

5. INSTALLATION OF FRONT SPEED SENSOR BRACKET

Assemble the speed sensor and the speed sensor bracket.

NOTE(1) The shape is different for the left and right speed

sensor brackets. Each bracket has an identification

symbol, so be sure to note these symbols

ahd. install

correctly.

FR: Indicates that the bracket is for the front speed

sensor.R: Indicates that the bracket is for the right wheel.

L: Indicates that the bracket is for the left wheel.

(2) Check to be sure, when installing the speed sensor to

the bracket, that the letters “FR” are visible.

4. INSTALLATION OF FRONT SPEED SENSOR(1) Temporarily install the speed sensor to the knuckle.Caution

Be careful when handling the pole piece at the tip of

the speed sensor and the toothed edge of the rotor

so as not to damage them by striking against other

parts.(2) Note the following points when connecting the speed

sensor cable, and secure the cable by the clip.

@ Secure the cable by the clip so that the white-

painted parts of the blackened parts (in the illustra-

tion) of the speed sensor cable are within the rangeof the angles indicated by cross-section A-A and

cross-section B-B in the illustration.

@ Check to be sure that the white-painted part

(shaded in the illustration) of the speed sensor cableis not twisted.Caution

Because there is the possibility of damage to the

cable during driving if the speed sensor cable is

twisted, care must be taken regarding thispoint.

(3) Insert a feeler gauge into the space between the speed

sensor’s pole piece and the rotor’s toothed surface, and

then tighten the speed sensor at the position where theclearance is the standard value all around.Standard value:

0.3-0.9 mm (.012-.035 in.)

NOTE

If the clearance between the speed sensor’s pole pieceand the rotor’s toothed surface is not within the

standard value range, it is probable that the rotor is

incorrectly installed, recheck installation.