engine coolant MITSUBISHI ECLIPSE 1991 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 509 of 1216

FUEL SYSTEM - Service Adjustment Procedures <2.0L Engine>14-55

(18)Connect the high-pressure fuel hose,,to the delivery pipe

and tighten the screws to the specified torque.

(19)Check for fuel leaks.

@I Apply battery voltage to the fuel pump check terminal

to operate the fuel pump.

@ With fuel pressure acting, check the fuel line for leaks.

A

E2li:>

/ )

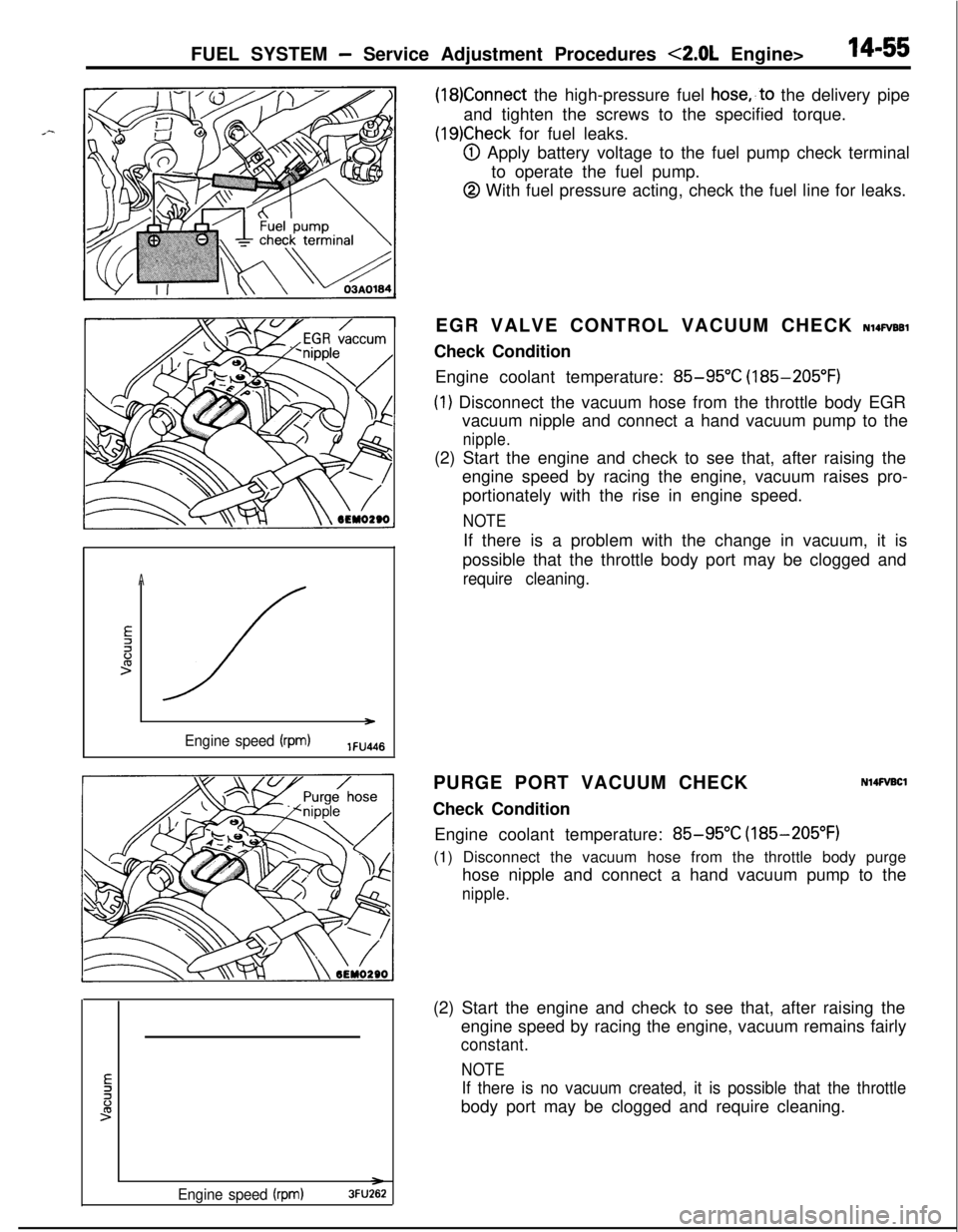

Engine speed (rpm)lFU4l6EGR VALVE CONTROL VACUUM CHECK

NlQFVBBlCheck Condition

Engine coolant temperature:

85-95°C (185-205°F)

(1) Disconnect the vacuum hose from the throttle body EGR

vacuum nipple and connect a hand vacuum pump to the

nipple.(2) Start the engine and check to see that, after raising the

engine speed by racing the engine, vacuum raises pro-

portionately with the rise in engine speed.

NOTEIf there is a problem with the change in vacuum, it is

possible that the throttle body port may be clogged and

require cleaning.PURGE PORT VACUUM CHECK

Check Condition

N14FVBClEngine coolant temperature:

85-95°C (185-205°F)

(1) Disconnect the vacuum hose from the throttle body purge

hose nipple and connect a hand vacuum pump to the

nipple.

Engine speed (rpm)3FU262(2) Start the engine and check to see that, after raising the

engine speed by racing the engine, vacuum remains fairly

constant.

NOTE

If there is no vacuum created, it is possible that the throttlebody port may be clogged and require cleaning.

Page 510 of 1216

IL SYSTEM -MPI Svstem InsDection 4.8L Enaine>14-56FUE- _ ~-~~~~~ ~~ ~,~.

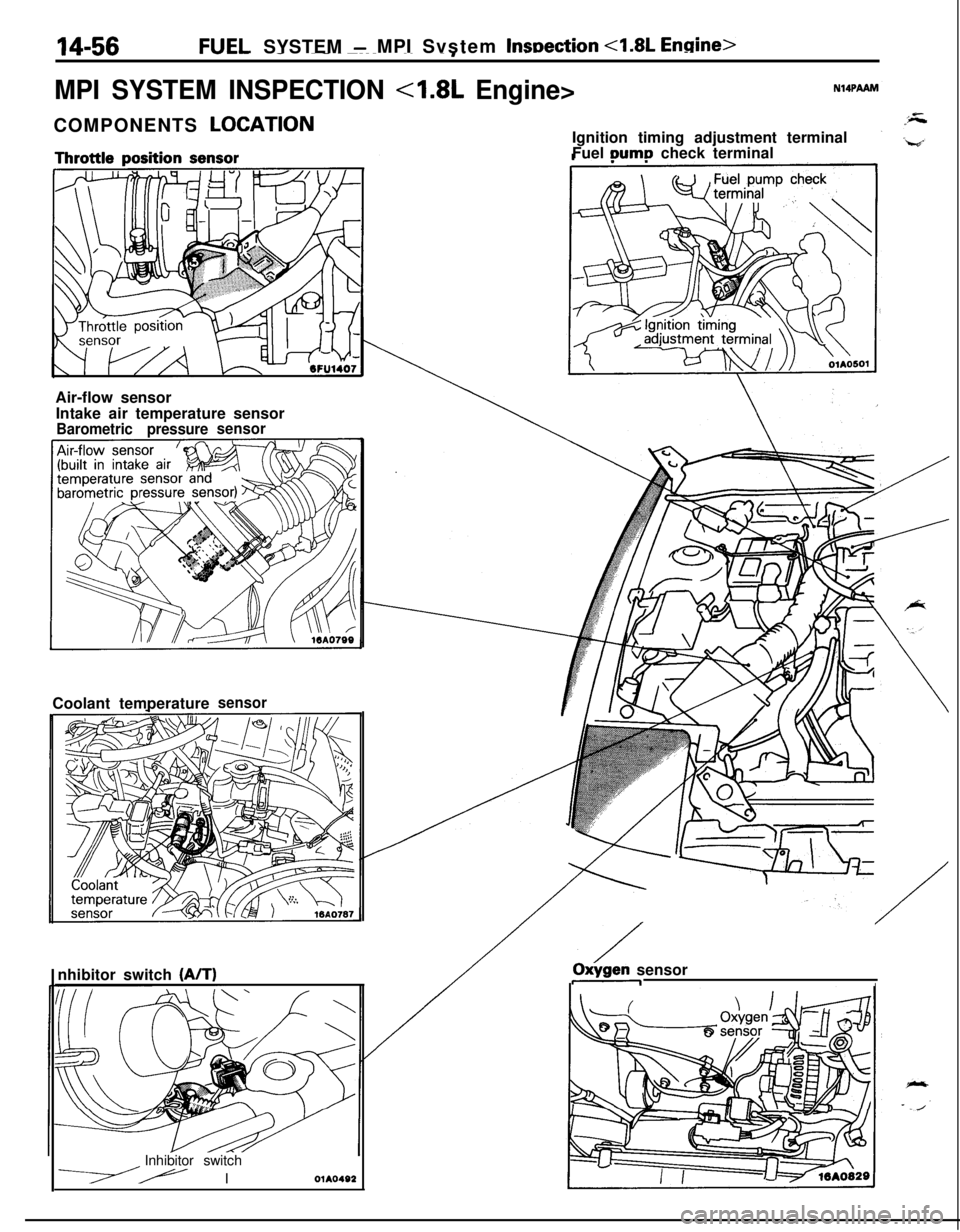

MPI SYSTEM INSPECTION <1.8L Engine>COMPONENTS

LncAT’n”’Ignition timing adjustment terminal

Fuel

ourno check terminal

Nl4PAAMAir-flow sensor

Intake air temperature sensor

Barometric pressuresensorCoolant temperature

sensornhibitor switch (A/T)

Inhibitor switch

-xT==-TL--==- IOlAO422

/Pxygen sensor

Page 512 of 1216

14-58FUEL SYSTEM -MPI System Inspection <1.8L Engine>

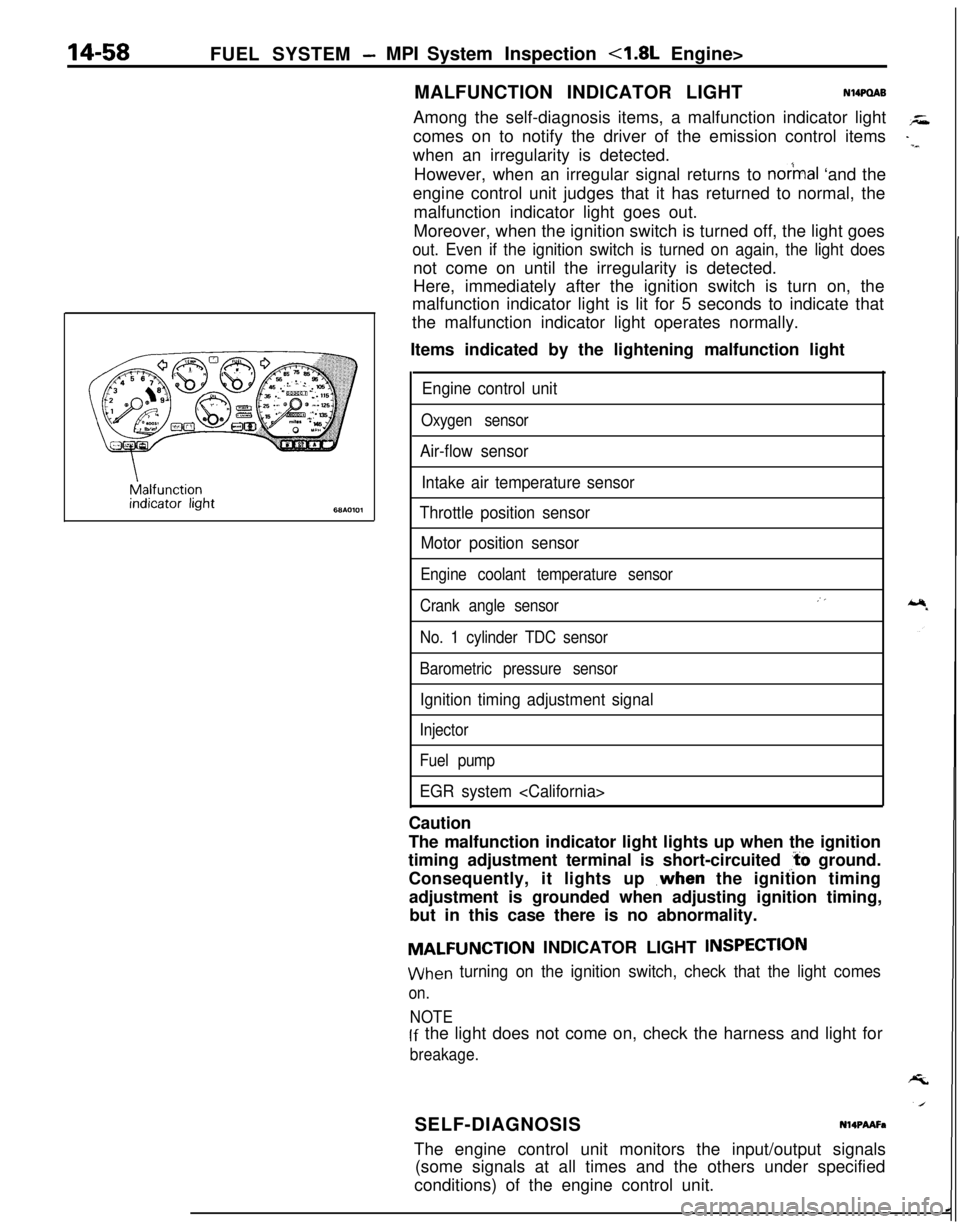

MALFUNCTION INDICATOR LIGHTNWQAB

Among the self-diagnosis items, a malfunction indicator light

comes on to notify the driver of the emission control items

when an irregularity is detected.

However, when an irregular signal returns to

notmal ‘and the

engine control unit judges that it has returned to normal, the

malfunction indicator light goes out.

Moreover, when the ignition switch is turned off, the light goes

out. Even if the ignition switch is turned on again, the light doesnot come on until the irregularity is detected.

Here, immediately after the ignition switch is turn on, the

malfunction indicator light is lit for 5 seconds to indicate that

the malfunction indicator light operates normally.

Items indicated by the lightening malfunction light

Engine control unit

Oxygen sensor

Air-flow sensor

Intake air temperature sensor

Throttle position sensor

Motor position sensor

Engine coolant temperature sensor

Crank angle sensor

No. 1 cylinder TDC sensor

Barometric pressure sensor

Ignition timing adjustment signal

Injector

Fuel pump

EGR system

The malfunction indicator light lights up when the ignition

timing adjustment terminal is short-circuited

,‘t’o ground.

Consequently, it lights up ,when the ignition timing

adjustment is grounded when adjusting ignition timing,

but in this case there is no abnormality.

MALFUNCTION INDICATOR LIGHT INSPECTlON

When turning on the ignition switch, check that the light comes

on.

NOTElf the light does not come on, check the harness and light for

breakage.SELF-DIAGNOSIS

Nl4PMFaThe engine control unit monitors the input/output signals

(some signals at all times and the others under specified

conditions) of the engine control unit.

Page 515 of 1216

FUEL SYSTEM - MPI System Inspection <1.8L Engine>

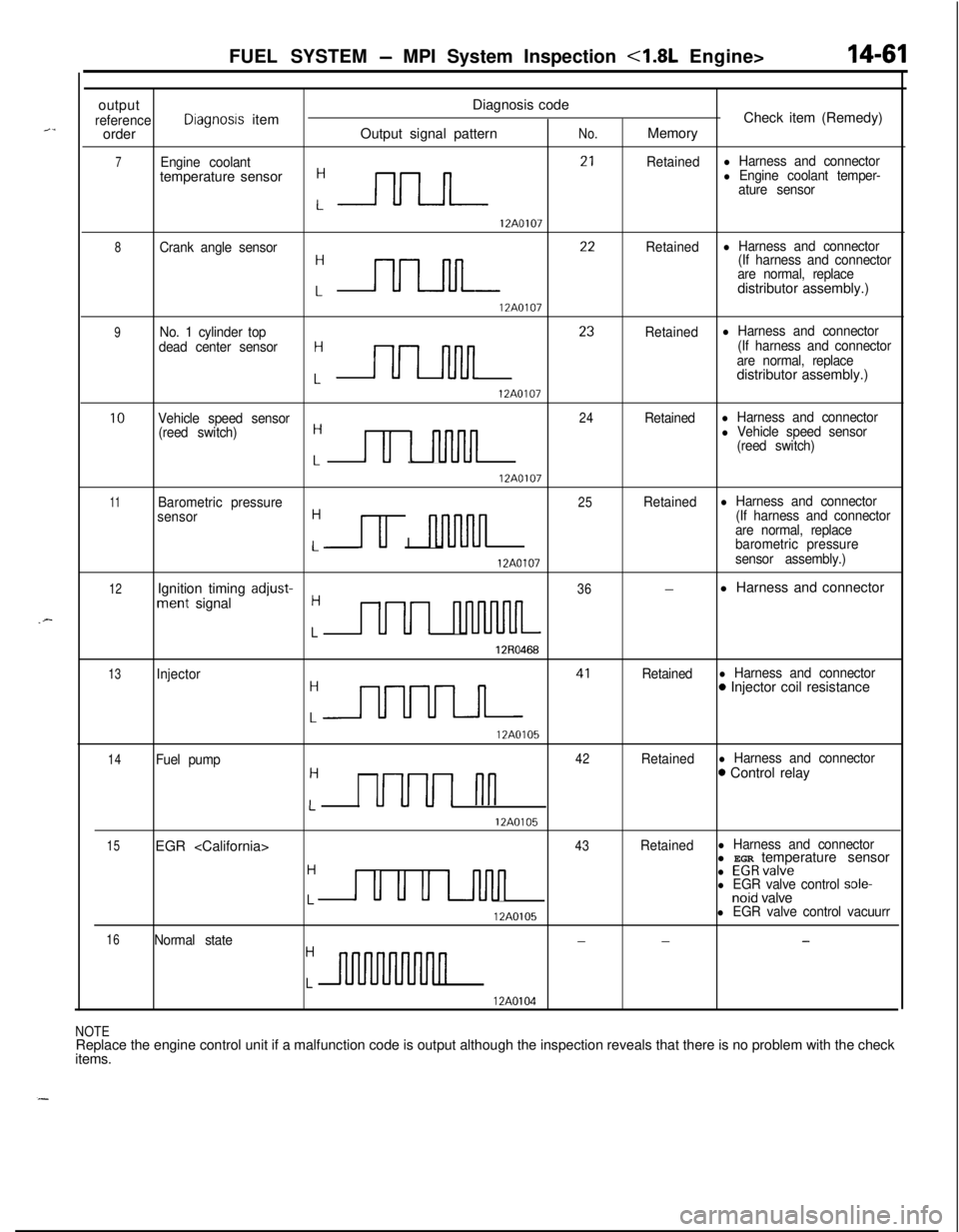

outputDiagnosis code

referenceDiagnosis itemCheck item (Remedy)

orderOutput signal patternNo.Memory

7Engine coolantRetainedl Harness and connectortemperature sensor

:-rlrLn- 2’

l Engine coolant temper-

ature sensor

12A0107

8Crank angle sensor

:nn 22

Retainedl Harness and connector

(If harness and connector

are normal, replacedistributor assembly.)

12A0107

9No. 1 cylinder top

dead center sensorH

Lnn 23

Retainedl Harness and connector

(If harness and connector

are normal, replacedistributor assembly.)

12A0107

10Vehicle speed sensor24Retainedl Harness and connector

(reed switch)H

Lu 1 nnJln

l Vehicle speed sensor

(reed switch)

12A0107

11Barometric pressure25Retainedl Harness and connector

sensorH

u I nl-uvln

(If harness and connector

are normal, replace

Lbarometric pressure

12A0107sensor assembly.)

12Ignition timing adjust-36-l Harness and connectorment signalH

LUUI nluvuuL

12R0468

13Injector

:m 41

Retainedl Harness and connector0 Injector coil resistance

12A0105

14Fuel pump42Retainedl Harness and connectorH0 Control relay

LUUUI nn

12A0105

15EGR

H

u u u u-inn

l EGRvalvel EGR valve control sole-Lnoid valve

12A0105l EGR valve control vacuurr

16Normal state---H

Ln

12A0104

NOTEReplace the engine control unit if a malfunction code is output although the inspection reveals that there is no problem with the check

items.

Page 516 of 1216

14-62FUEL SYSTEM - MPI System Inspection <1.8L Engine>

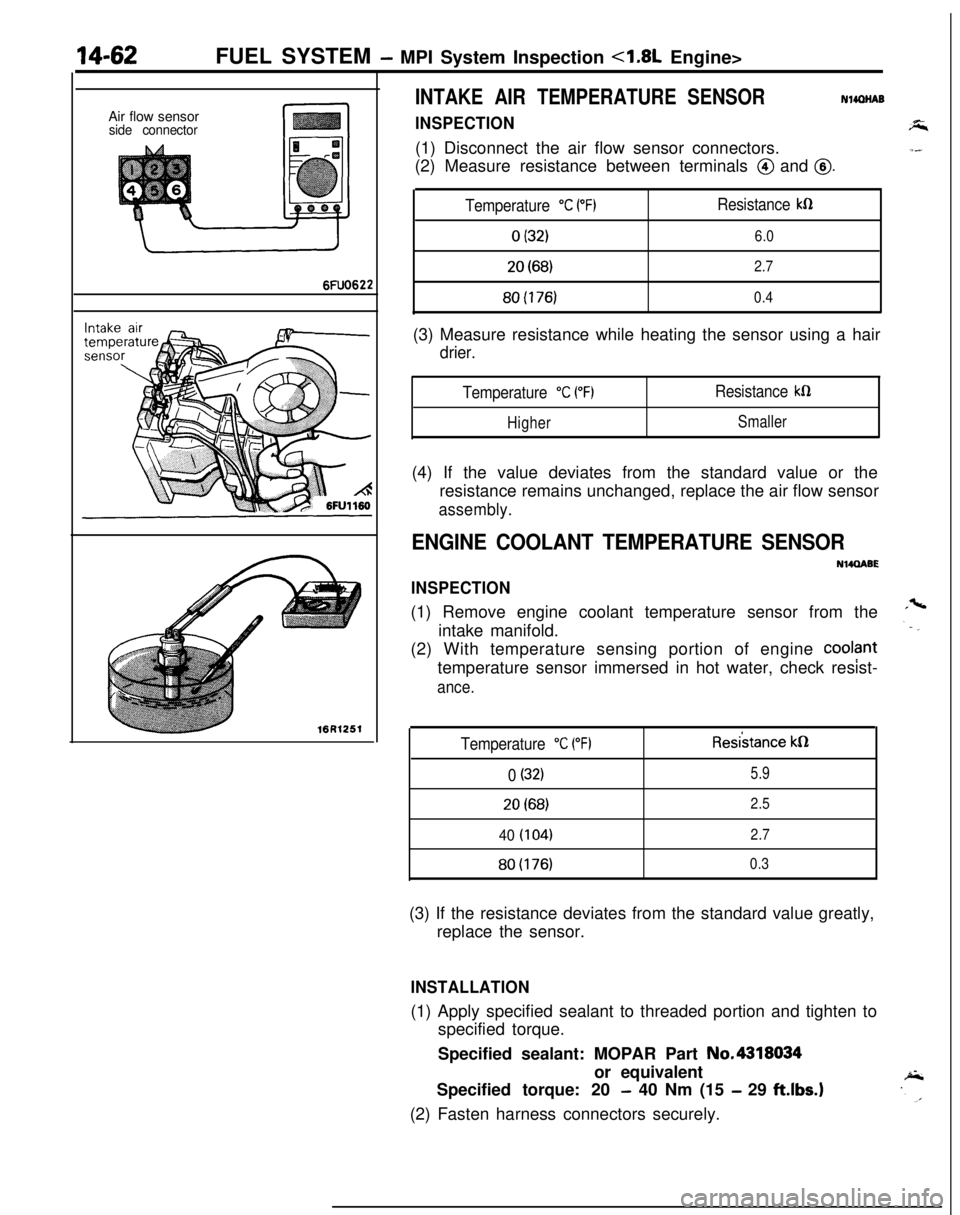

INTAKE AIR TEMPERATURE SENSORNlmNABAir flow sensor

side connectorINSPECTION(1) Disconnect the air flow sensor connectors.

(2) Measure resistance between terminals

@ and @.

6FUO622

Temperature “C PF)Resistance kR

0 (32)6.0

20(68)2.780(176)

0.4(3) Measure resistance while heating the sensor using a hair

drier.

Temperature “C (“F)Resistance kfi

HigherSmaller(4) If the value deviates from the standard value or the

resistance remains unchanged, replace the air flow sensor

assembly.

ENGINE COOLANT TEMPERATURE SENSOR

NWQABE

INSPECTION(1) Remove engine coolant temperature sensor from the

intake manifold.

(2) With temperature sensing portion of engine

cool?nttemperature sensor immersed in hot water, check resist-

ance.16R1251

Temperature “C (“F)Resi’stance kQ

0 (32)5.920(68)

2.5

40 (104)2.7

80(176)0.3(3) If the resistance deviates from the standard value greatly,

replace the sensor.

INSTALLATION(1) Apply specified sealant to threaded portion and tighten to

specified torque.

Specified sealant: MOPAR Part No.4318034

or equivalent

Specified torque: 20

- 40 Nm (15 - 29 ftlbs.)(2) Fasten harness connectors securely.

Page 518 of 1216

14-64FUEL SYSTEM -MPI System Inspection <1.8L Engine>

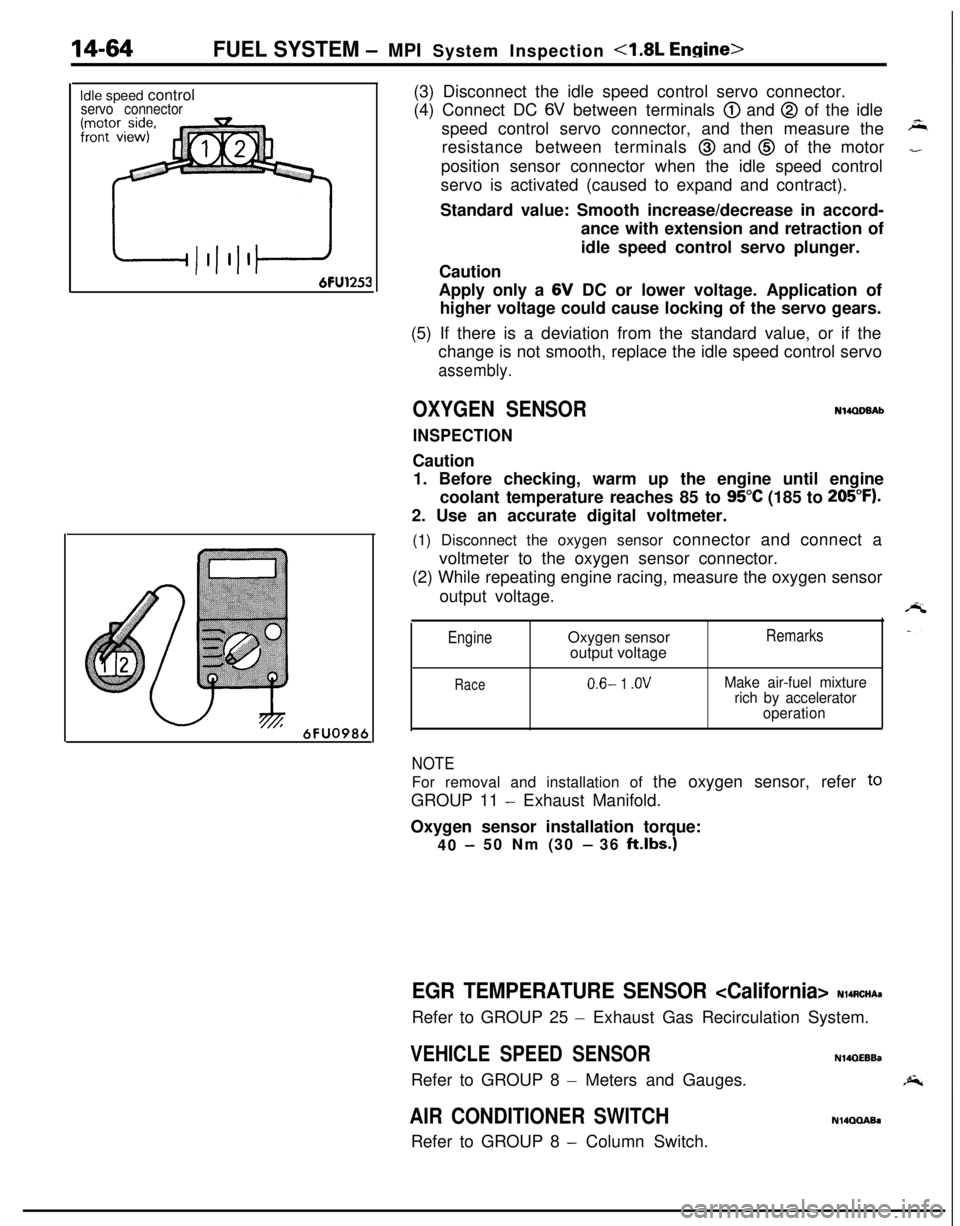

Idle speed controlservo connector

6FU098t(3) Disconnect the idle speed control servo connector.

(4) Connect DC

6V between terminals @) and @ of the idle

speed control servo connector, and then measure the

resistance between terminals

@ and @ of the motor

position sensor connector when the idle speed control

servo is activated (caused to expand and contract).

Standard value: Smooth increase/decrease in accord-

ance with extension and retraction of

idle speed control servo plunger.

Caution

Apply only a 6V DC or lower voltage. Application of

higher voltage could cause locking of the servo gears.

(5) If there is a deviation from the standard value, or if the

change is not smooth, replace the idle speed control servo

assembly.

OXYGEN SENSORN14QDBAb

INSPECTIONCaution

1. Before checking, warm up the engine until engine

coolant temperature reaches 85 to

95°C (185 to 205°F).2. Use an accurate digital voltmeter.

(1) Disconnect the oxygen sensor connector and connect a

voltmeter to the oxygen sensor connector.

(2) While repeating engine racing, measure the oxygen sensor

output voltage.

EngineOxygen sensor

output voltageRemarks

Race0.6- 1 .OVMake air-fuel mixture

rich by accelerator

operation

NOTEFor removal and installation of the oxygen sensor, refer

toGROUP 11

- Exhaust Manifold.

Oxygen sensor installation torque:

40

-50 Nm (30 - 36 klbs.)

EGR TEMPERATURE SENSOR

- Exhaust Gas Recirculation System.

VEHICLE SPEED SENSORN14QEEBaRefer to GROUP 8

- Meters and Gauges.

AIR CONDITIONER SWITCHRefer to GROUP 8

- Column Switch.

N14QQABa

Page 523 of 1216

![MITSUBISHI ECLIPSE 1991 Workshop Manual FUEL SYSTEM - MPI System Inspection <2.0L DOHC Engine>

EGR control solenoid valve

[Calif. only]

Purge control solenoid valve

1

/AF--Y:rIgnition coil, Power transistor

Oxygen sensorPower

steering flu MITSUBISHI ECLIPSE 1991 Workshop Manual FUEL SYSTEM - MPI System Inspection <2.0L DOHC Engine>

EGR control solenoid valve

[Calif. only]

Purge control solenoid valve

1

/AF--Y:rIgnition coil, Power transistor

Oxygen sensorPower

steering flu](/img/19/57104/w960_57104-522.png)

FUEL SYSTEM - MPI System Inspection <2.0L DOHC Engine>

EGR control solenoid valve

[Calif. only]

Purge control solenoid valve

1

/AF--Y:rIgnition coil, Power transistor

Oxygen sensorPower

steering fluid Dressure switch

Coolant temDerature sensor

Page 526 of 1216

14-72FUEL SYSTEM - MPI Svstem InsDection <2.0L DOHC Engine>

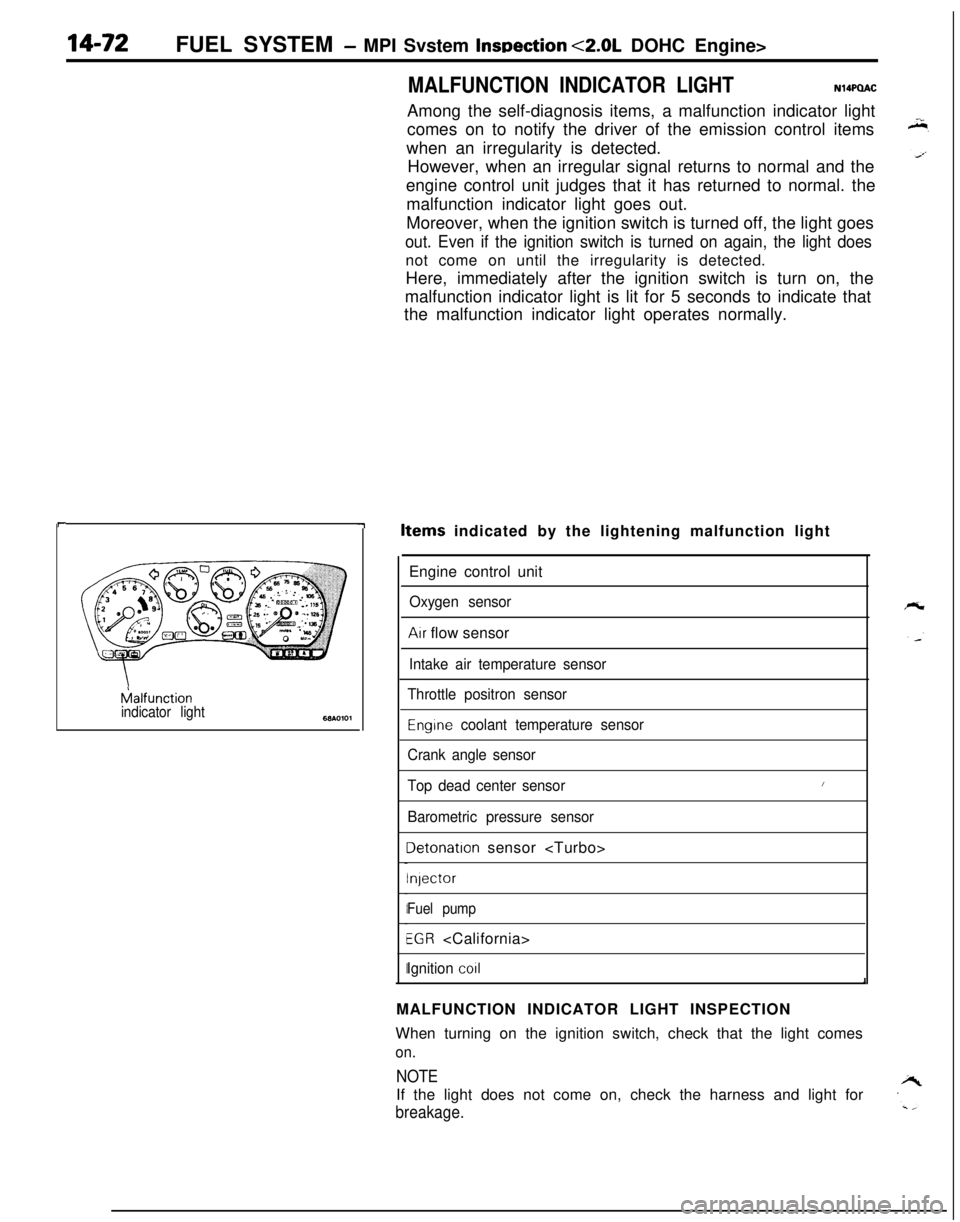

MALFUNCTION INDICATOR LIGHTAmong the self-diagnosis items, a malfunction indicator light

comes on to notify the driver of the emission control items

when an irregularity is detected.

However, when an irregular signal returns to normal and the

engine control unit judges that it has returned to normal. the

malfunction indicator light goes out.

Moreover, when the ignition switch is turned off, the light goes

out. Even if the ignition switch is turned on again, the light doesnot come on until the irregularity is detected.

Here, immediately after the ignition switch is turn on, the

malfunction indicator light is lit for 5 seconds to indicate that

the malfunction indicator light operates normally.

I--l

klfunctionindicator light

Items indicated by the lightening malfunction light

Engine control unit

Oxygen sensor

Air flow sensor

Intake air temperature sensor

Throttle positron sensor

Engrne coolant temperature sensor

Crank angle sensor

Top dead center sensor

Barometric pressure sensor

Detonatron sensor

Injector

Fuel pump

EGR

Ignition co11

/

iMALFUNCTION INDICATOR LIGHT INSPECTION

When turning on the ignition switch, check that the light comes

on.

NOTEIf the light does not come on, check the harness and light for

breakage.

Page 528 of 1216

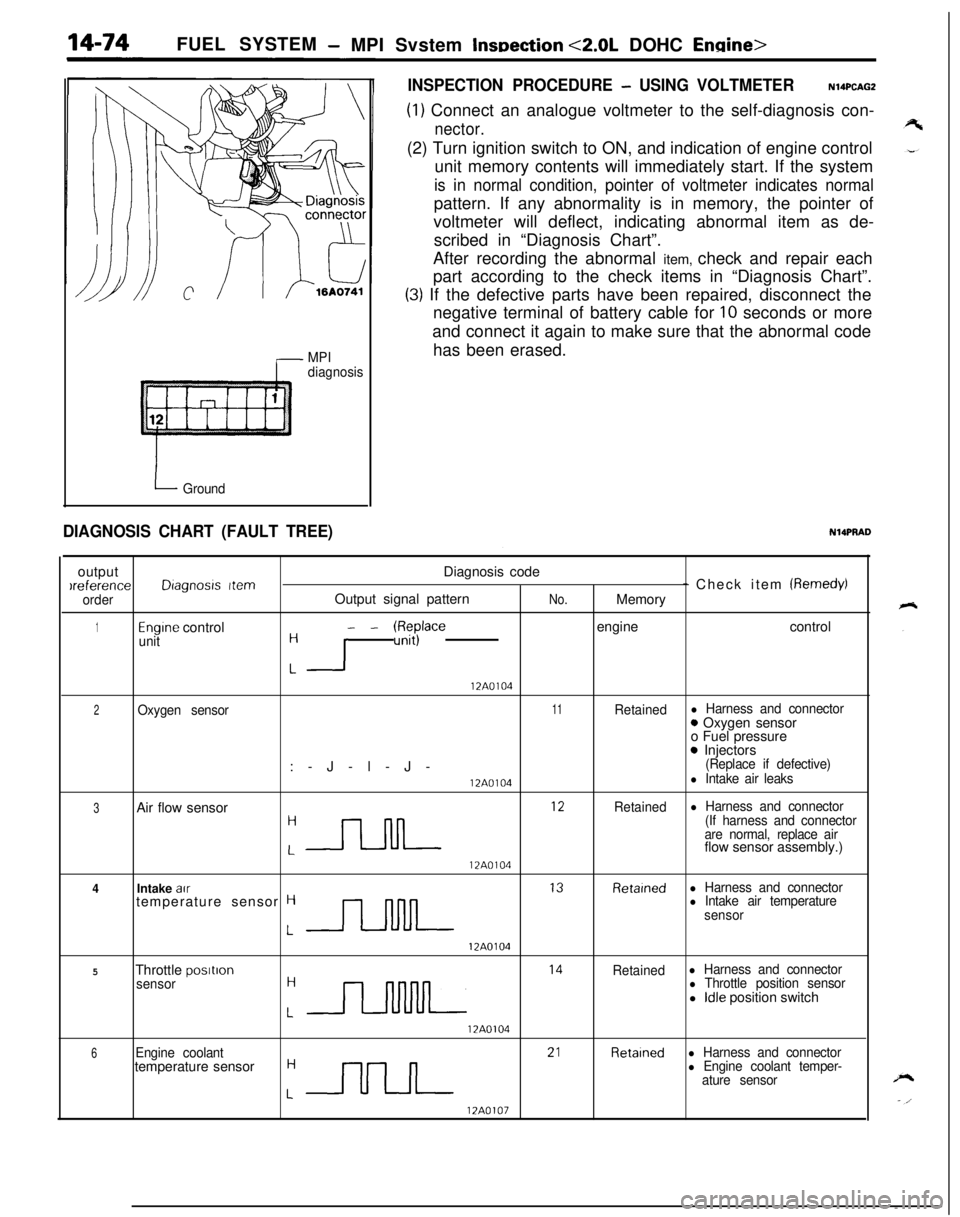

FUEL SYSTEM- MPI Svstem InsDection <2.0L DOHC Engine>

MPI

diagnosis

I Ground

INSPECTION PROCEDURE - USING VOLTMETERN14PCAGZ

(1) Connect an analogue voltmeter to the self-diagnosis con-

nector.(2) Turn ignition switch to ON, and indication of engine control

unit memory contents will immediately start. If the system

is in normal condition, pointer of voltmeter indicates normalpattern. If any abnormality is in memory, the pointer of

voltmeter will deflect, indicating abnormal item as de-

scribed in “Diagnosis Chart”.

After recording the abnormal item, check and repair each

part according to the check items in “Diagnosis Chart”.

(3) If the defective parts have been repaired, disconnect the

negative terminal of battery cable for

10 seconds or more

and connect it again to make sure that the abnormal code

has been erased.

DIAGNOSIS CHART (FAULT TREE)NlQPRADoutputDiagnosis codeIreference

Dragnosrs Item- Check item (Remedy)

orderOutput signal patternNo.Memory

1Engine controlunit- - W$$ace engine control: I

12A0104

2Oxygen sensor11Retainedl Harness and connector:-J-l-J-0 Oxygen sensor

o Fuel pressure

0 Injectors(Replace if defective)

12A0104l Intake air leaks

3Air flow sensor

:-rLJL ‘*

Retainedl Harness and connector

(If harness and connector

are normal, replace airflow sensor assembly.)

12A0104

4Intake au

J--lNlL l3

Retarnedl Harness and connectortemperature sensor Hl Intake air temperature

sensor

12A0104

5Throttle postron

:n l4

Retainedl Harness and connector

sensorl Throttle position sensorl Idle position switch

17A0104

6Engine coolant

:nn 2’

Retainedl Harness and connectortemperature sensorl Engine coolant temper-

ature sensor

12A0107

Page 530 of 1216

14-76FUEL SYSTEM - MPI Svstem InsDection <2.0L DOHC Enaine>

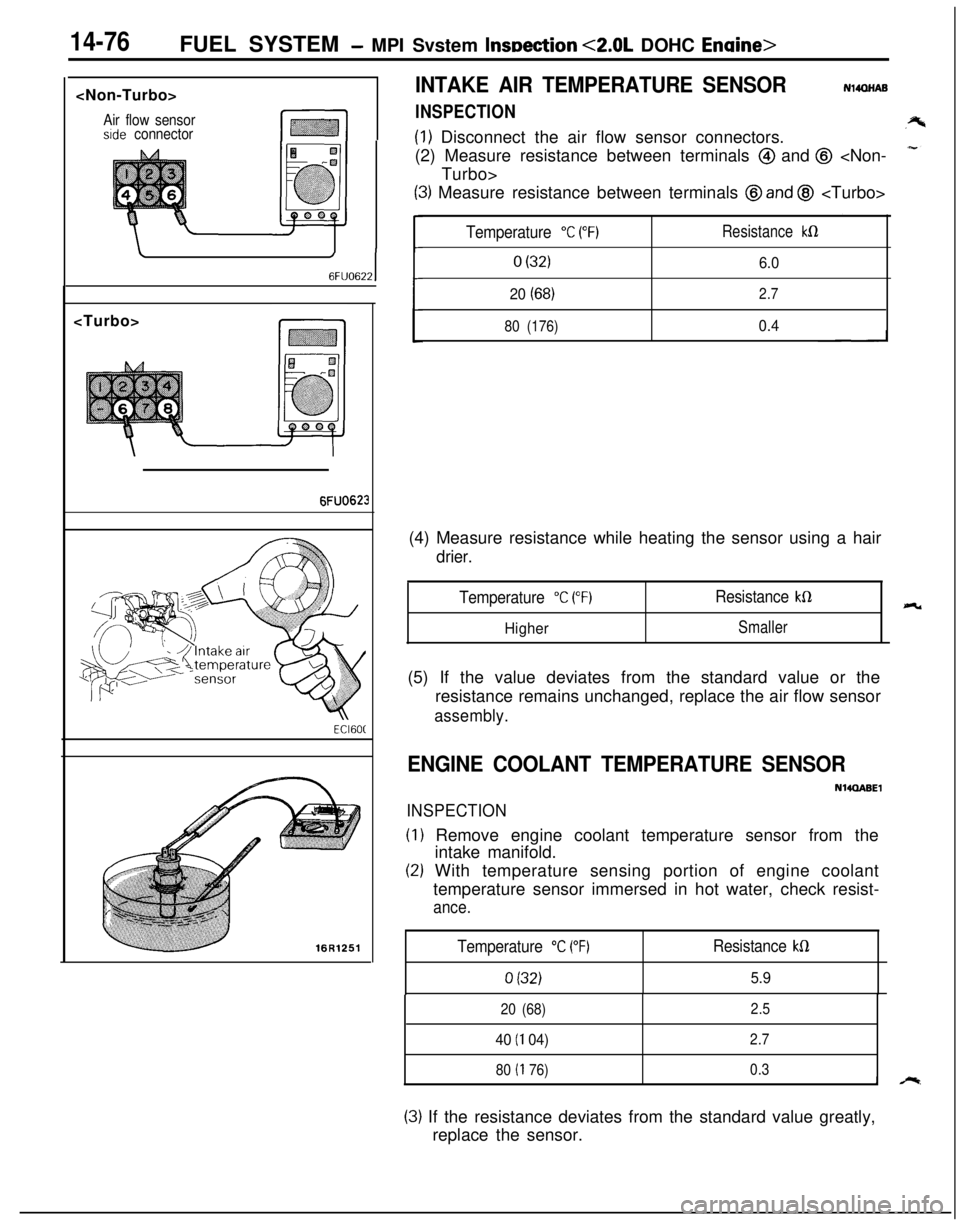

Air flow sensorsrde connector

6FUO622

6FUO623

16Rl251

INTAKE AIR TEMPERATURE SENSOR

INSPECTION

Nl4OHAB

(1) Disconnect the air flow sensor connectors.

(2) Measure resistance between terminals

@ and @I

(3) Measure resistance between terminals @and @I

Temperature “C (“F)Resistance kR

0 (32)6.0

20

(68)2.7

80 (176)

0.4(4) Measure resistance while heating the sensor using a hair

drier.

Temperature “C (“F)

Higher

Resistance k0

Smaller(5) If the value deviates from the standard value or the

resistance remains unchanged, replace the air flow sensor

assembly.

ENGINE COOLANT TEMPERATURE SENSOR

NlMABEl

INSPECTION

(1) Remove engine coolant temperature sensor from the

intake manifold.

(2) With temperature sensing portion of engine coolant

temperature sensor immersed in hot water, check resist-

ance.

Temperature

“C (“F)

0 (32)

Resistance kfl

5.9

20 (68)2.5

40 (I 04)2.7

80

(I 76)0.3

(3) If the resistance deviates from the standard value greatly,

replace the sensor.