engine coolant MITSUBISHI ECLIPSE 1991 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 532 of 1216

FUEL SYSTEM - MPI System Inspection <2.0L DOHC Engine>

6FUO999

Accelerator pedal

DepressedContinuity .

Non-conductive

(03 fl)

ReleasedIConductive (0 fl)I(4) Replace the idle position switch if faulty.

NOTE

For replacement procedure, refer to the idle position switch(fixed speed adjusting screw) adjustment section

(P.14-

52.).OXYGEN SENSOR

NllQDeJ

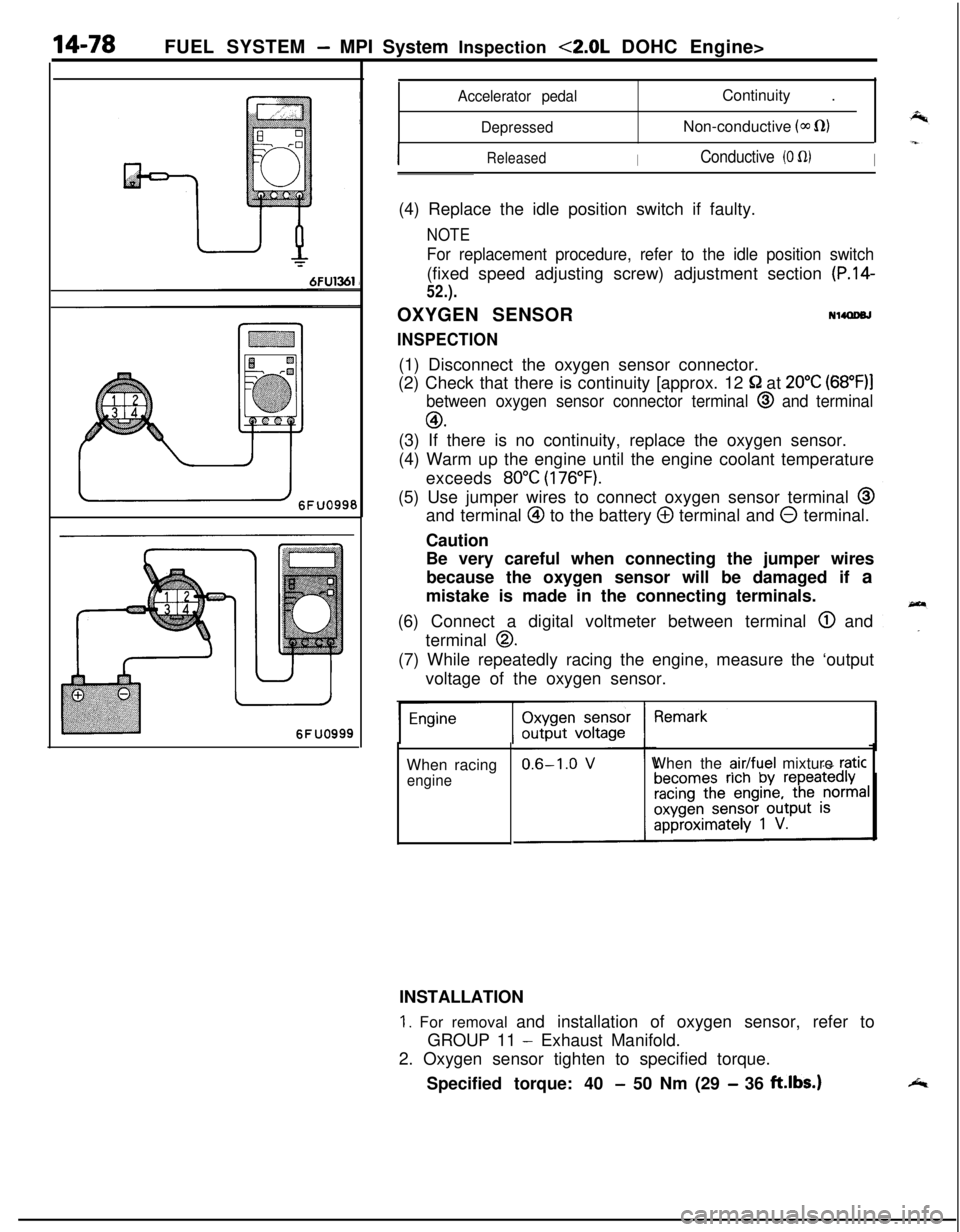

INSPECTION(1) Disconnect the oxygen sensor connector.

(2) Check that there is continuity [approx. 12

52 at 20°C (68”F)l

between oxygen sensor connector terminal @ and terminal

GO.(3) If there is no continuity, replace the oxygen sensor.

(4) Warm up the engine until the engine coolant temperature

exceeds

80°C (176°F).(5) Use jumper wires to connect oxygen sensor terminal

@and terminal

@ to the battery @ terminal and 0 terminal.

Caution

Be very careful when connecting the jumper wires

because the oxygen sensor will be damaged if a

mistake is made in the connecting terminals.

(6) Connect a digital voltmeter between terminal

@ and

terminal

0.(7) While repeatedly racing the engine, measure the ‘output

voltage of the oxygen sensor.

When racing

engineWhen the

air/fuel mixture raticINSTALLATION

1. For removal and installation of oxygen sensor, refer to

GROUP 11

- Exhaust Manifold.

2. Oxygen sensor tighten to specified torque.

Specified torque: 40

- 50 Nm (29 - 36 ft.lbs.)

Page 896 of 1216

21-202AUTOMATIC TRANSAXLE - Troubleshooting

CONVERTER STALL TESTStall test consist of determining maximum engine

speed obtained at full throttle in “D” and “R”

positions. This test checks torque converter stator

overrunning clutch operation, and holding ability of

transaxle clutches and low-reserve brake.

CautionDuring this test, make sure that no one stand in

front of or behind vehicle.

1. Check transaxle fluid level. Fluid should be at

normal operating temperature

[70-80°C (160-

18O”F)]. Engine coolant should also be at normaloperating temperature

[80-90°C (180- 19O”F)l.2. Apply chocks to both rear wheels.

3. Attach engine tachometer.

4. Apply parking and service brakes fully.

5. Start engine.

6. With selector lever in “D” position, depress

accelerator pedal fully to read engine maximum

rpm. Do not hold throttle wide open any longer

than is necessary to obtain maximum engine

rpm reading, and never longer than 5 seconds ata time. If more than one stall test is required,

operate engine at approximatey 1,000 rpm in

neutral for 2 minutes to cool transaxle fluid

between tests.

Stall speed:

1,800-3,200 rpm

TRANSAXLE CONTROL7. Place selector lever to “R” position and perform

?+stall test by the same procedure as in foregoing

-,

item.Stall Speed Above Specification in “D”

If stall speed is higher than specification, rear clutchor overrunning clutch of transaxle is slipping. In this

case, perform hydraulic test to locate cause of

slippage.Stall Speed Above Specifjcation in “R”

If stall speed is higher than specification, front

clutch of transaxle or low-reverse brake is slipping.

In this case, perform hydraulic test to locate cause

of slippage.

Stall Speed Below Specification in “D” and “R”

If stall speed is lower than specification, insufficient

engine output or faulty torque converter is sus-

pected. Check for engine misfiring, ignition timing,

valve clearance etc. If these are good, torque

converter is faulty.

Symptom

Selector lever operation isstiff

Probable causeIncorrect adjustment of sleeve

Incorrect adjustment of control cable

Excessive wear of detent plate

Worn contact surfaces of pushbutton and sleeveRemedyAdjust

Replace

Starter motor does notoperate with the selector

lever in the “N” or

“P”position

Will not shift to

4-speedMalfunction in inhibitor switch

Malfunction of starter relay

Incorrect adjustment of control cableMalfunction of OD switch

Replace

Adjust

Replace

Page 1145 of 1216

24-l

HEATERS ANDAIR CONDITIONING

CONTENTSN24M--AIR CONDITIONER SWITCH

..........................30BLOWER ASSEMBLY

.....................................33

COMPRESSOR.................................................37CONDENSER AND CONDENSER FAN

MOTOR............................................................45ENGINE COOLANT TEMPERATURE

-‘-.,SWITCH............................................................51

EVAPORATOR.................................................

34

HEATERCONTROLASSEMBLY....................

26HEATER UNIT

.................................................31

REFRIGERANTLINE........................................47

RESISTOR........................................................29SAFETY PRECAUTIONS

.................................10SERVICE ADJUSTMENT PROCEDURES..

.....11Compressor Drive

Belt Adjustment

.............

23

CompressorNoise........................................24

Handling

TubingandFittings.......................22Idle-up

OperationCheck..............................25Manifold

GaugeSetInstallation..................11Performance Test

.........................................16Power Relay Check

......................................24Refrigerant Leak Repair Procedure

.............17

TestingSystemforLeaks...........................15Test Procedures

...........................................11

SPECIFICATIONS.............................................2

General Specifications..................................2

Lubricants......................................................3Sealant and Adhesives

.................................3Service Specifications

...................................2

TorqueSpecifications...................................2

TROUBLESHOOTING. . . ..a................................3

VENTILATORS(AIR INLET AND AIR OUTLET)

..,....s............. 50

VENTILATORS(INSTRUMENT PANEL)

..,...................*...........49

Page 1146 of 1216

24-2HEATERS AND AIR CONDITIONING - Specifications

SPECIFICATIONS

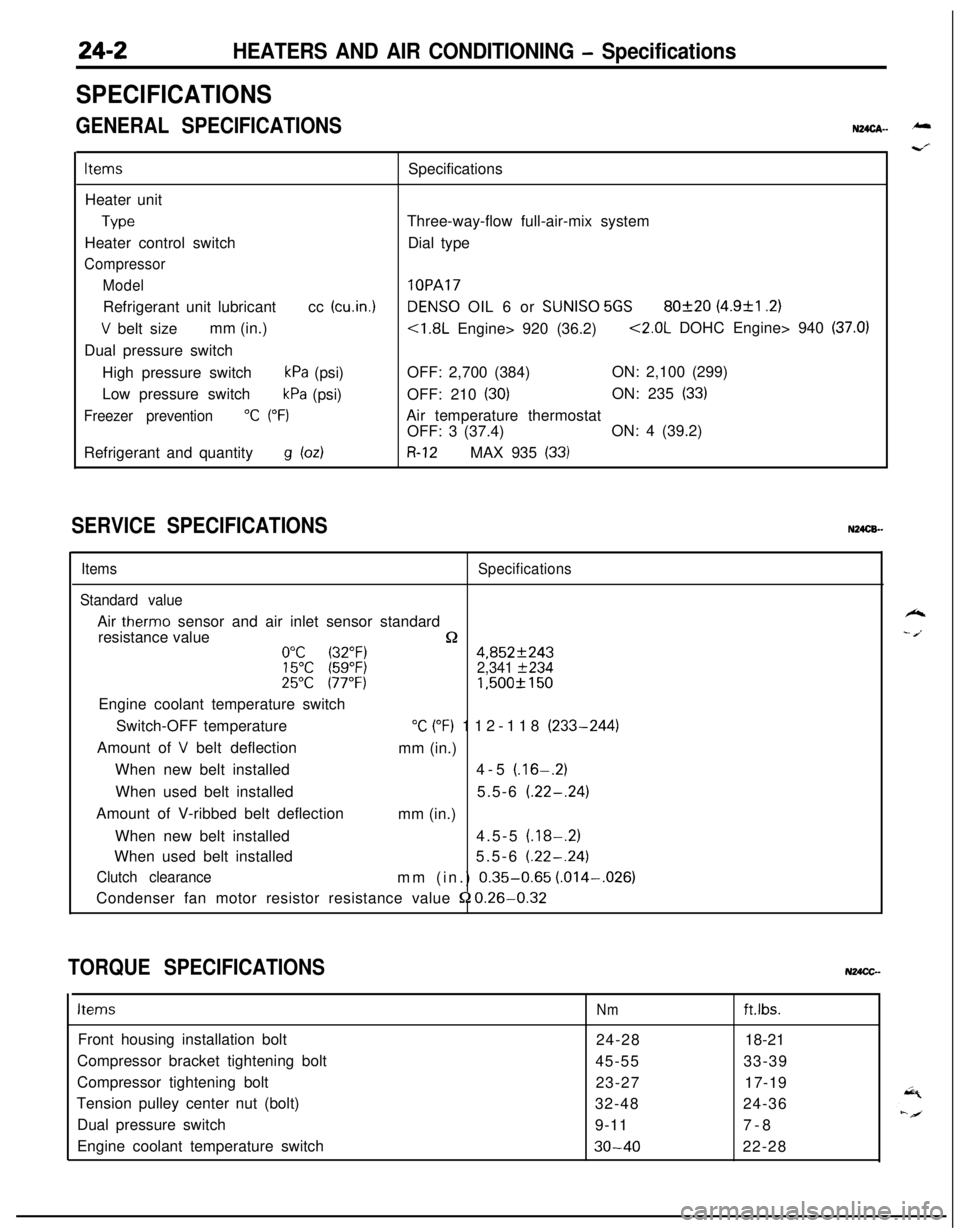

GENERAL SPECIFICATIONSN24cA- -

ItemsSpecifications

Heater unit

TypeThree-way-flow full-air-mix system

Heater control switchDial type

Compressor

Model

lOPARefrigerant unit lubricantcc

(cu.in.1DENS0 OIL 6 or SUNISO 5GS80f20 (4.9&l .2)

V belt sizemm (in.)<1.8L Engine> 920 (36.2)<2.0L DOHC Engine> 940 (37.0)Dual pressure switch

High pressure switch

kPa (psi)OFF: 2,700 (384)ON: 2,100 (299)

Low pressure switch

kPa (psi)OFF: 210 (30)ON: 235 (33)

Freezer prevention“C (“F)Air temperature thermostat

OFF: 3 (37.4)ON: 4 (39.2)

Refrigerant and quantity

g bdR-12MAX 935 (33)

SERVICE SPECIFICATIONSN24CB.-

ItemsSpecifications

Standard valueAir

therm0 sensor and air inlet sensor standard

resistance value

n0°C (32°F)4,852f24315°C (59°F)2,341 f23425°C 177°F)1,500f 150Engine coolant temperature switch

Switch-OFF temperature

“C (“F) 112-118 (233-244)

Amount of

V belt deflection

mm (in.)

When new belt installed4-5

(.16-.2)When used belt installed5.5-6

(.22-.24)Amount of V-ribbed belt deflection

mm (in.)

When new belt installed4.5-5

(.18-.2)When used belt installed5.5-6

(.22-.24)

Clutch clearancemm (in.) 0.35-0.65 (.014-,026)

Condenser fan motor resistor resistance value

52 0.26-0.32

TORQUE SPECIFICATIONSN24CC-

ItemsNmft.lbs.Front housing installation bolt

24-2818-21

Compressor bracket tightening bolt

45-5533-39

Compressor tightening bolt

23-2717-19

Tension pulley center nut (bolt)

32-4824-36

Dual pressure switch

9-117-8

Engine coolant temperature switch

30-4022-28

k

- /.

Page 1147 of 1216

HEATERS AND AIR CONDITIONING - Specifications/Troubleshooting24-3LUBRICANTS

u24as-

;xiItemsSpecified lubricantsQuantity

Each connection of refrigerant lineDENS0 OIL 6 or

SUNISO 5GSAs required

Shaft seal of the compressor

SEALANT AND ADHESIVES, Items

Engine coolant temperature switch threaded partSpecified sealant and adhesive

MOPAR Part No.4318034 or equivalentN24CE-

TROUBLESHOOTINGN24EBAQ

SymptomHeater insufficient heat

No ventilation even when

mode selection knob is

operatedBlower motor inoperative

Probable causeObstructed heater outlets

Blend air dampers improperly adjusted or bindingThermostat malfunction

Obstructed heater hoses

Improperly adjusted control cables

Plugged or partially plugged heater core

Incorrect adjustment of mode selection dampersIncorrect installation of mode selection control wire

Ducts are incorrectly/incompletely connected, crushed,

bent or clogged.

Poor grounding

Burnt-out fuseMalfunction blower switch

Malfunction resister

Malfunction blower motor

Malfunction heater relay

Remedy

Correct

ReplaceAdjust

Clean or replaceAdjust

Repair or replace

Correct

Replace

Page 1152 of 1216

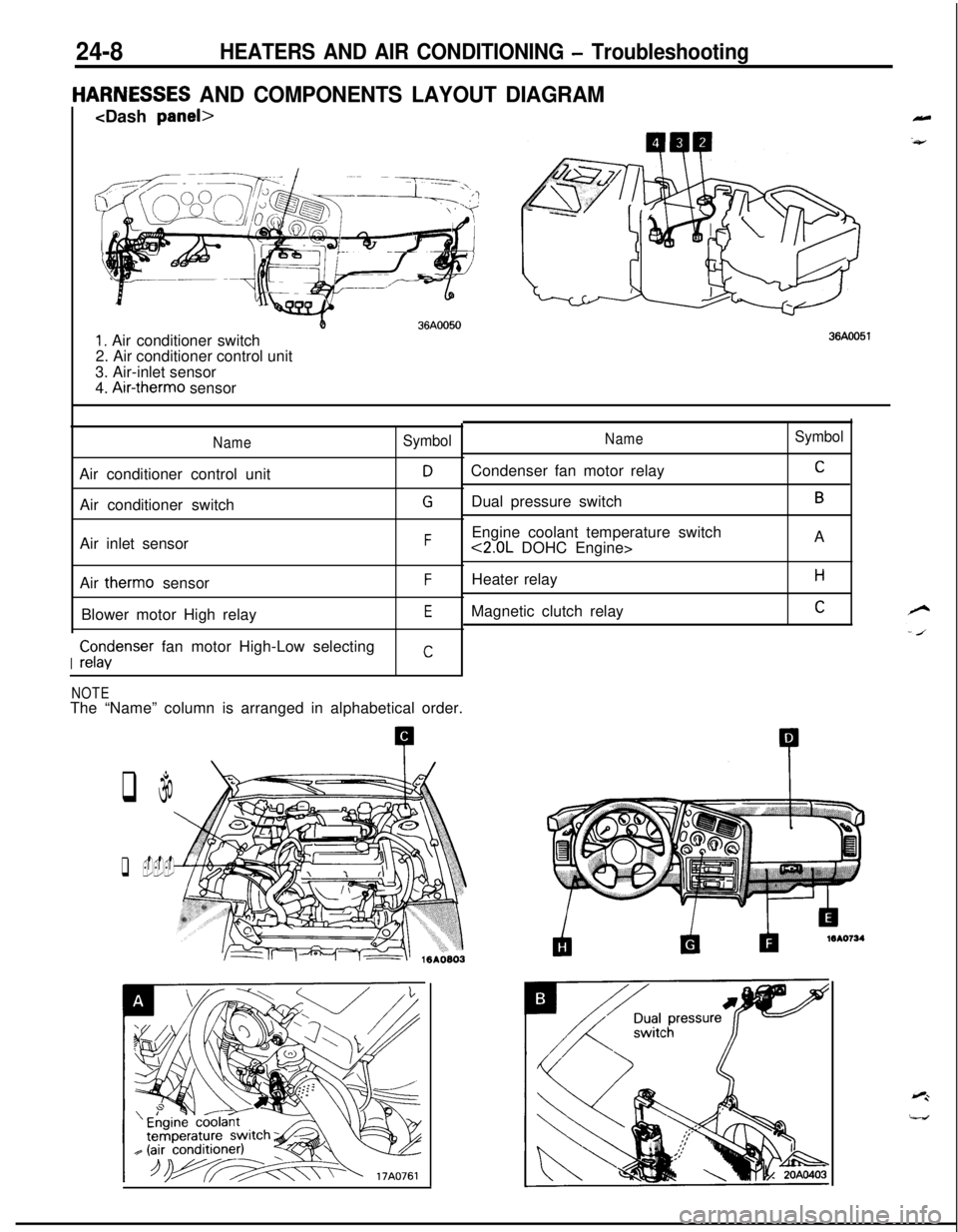

24-8HEATERS AND AIR CONDITIONING - Troubleshooting

IARNESSES AND COMPONENTS LAYOUT DIAGRAM

1. Air conditioner switch

2. Air conditioner control unit

3. Air-inlet sensor

4.

Air-therm0 sensor

36AOO51

NameSymbolAir conditioner control unit

DAir conditioner switch

GAir inlet sensor

FAir

therm0 sensorFBlower motor High relay

E

IrrIor:enser fan motor High-Low selecting

C

NameCondenser fan motor relay

Dual pressure switch

Engine coolant temperature switch

<2.0L DOHC Engine>

Heater relay

Magnetic clutch relay

Symbol

C

BA

H

C

NOTEThe “Name” column is arranged in alphabetical order.

q \

q ---

Page 1157 of 1216

HEATERS AND AIR CONDITIONING - Service Adjustment Procedures 249*I3

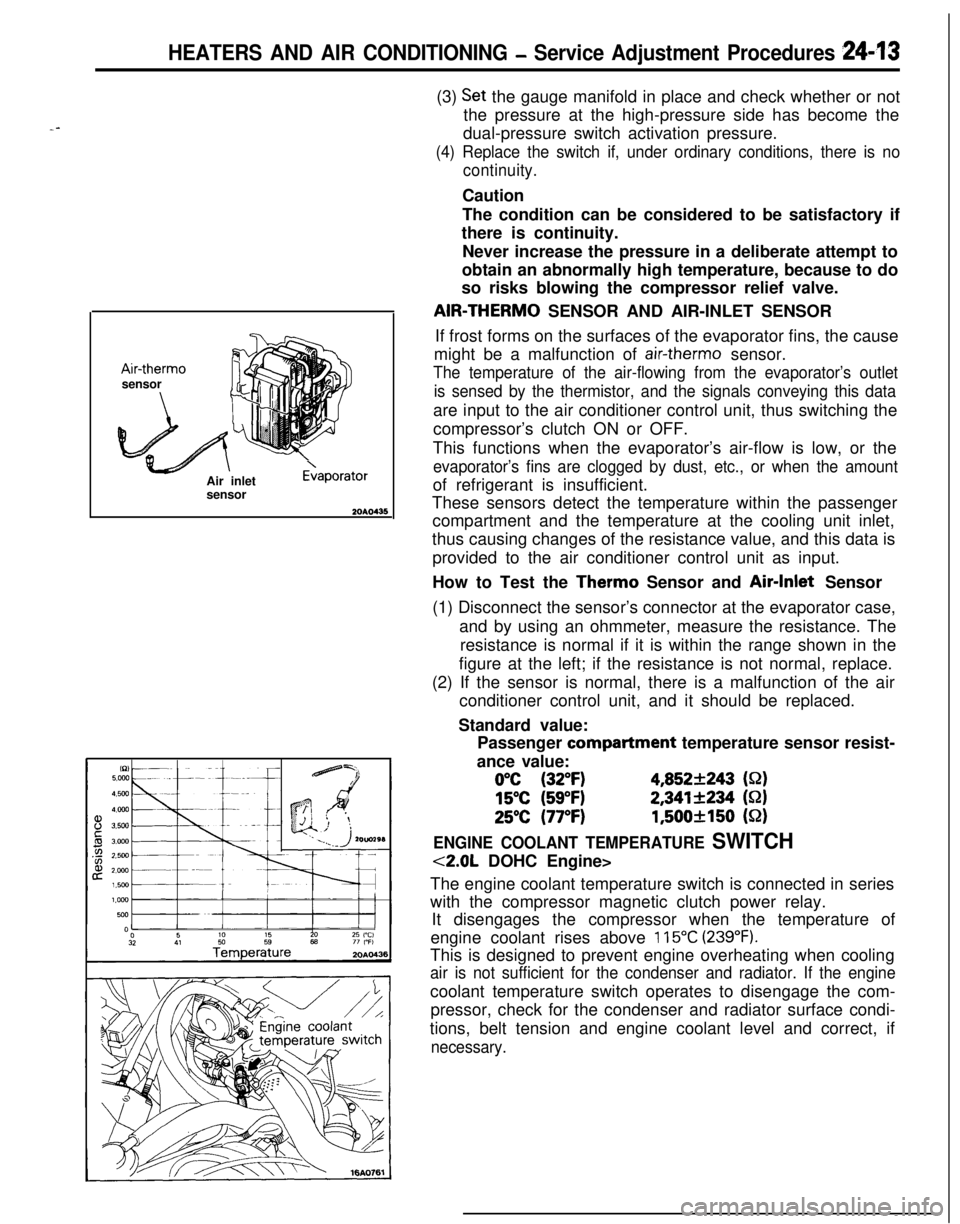

--Air-therm0

sensor

Air inlet

sensor

E>aporator(3)

Set the gauge manifold in place and check whether or not

the pressure at the high-pressure side has become the

dual-pressure switch activation pressure.

(4) Replace the switch if, under ordinary conditions, there is no

continuity.Caution

The condition can be considered to be satisfactory if

there is continuity.

Never increase the pressure in a deliberate attempt to

obtain an abnormally high temperature, because to do

so risks blowing the compressor relief valve.AIR-THERM0 SENSOR AND AIR-INLET SENSOR

If frost forms on the surfaces of the evaporator fins, the cause

might be a malfunction of

air-therm0 sensor.

The temperature of the air-flowing from the evaporator’s outlet

is sensed by the thermistor, and the signals conveying this dataare input to the air conditioner control unit, thus switching the

compressor’s clutch ON or OFF.

This functions when the evaporator’s air-flow is low, or the

evaporator’s fins are clogged by dust, etc., or when the amountof refrigerant is insufficient.

These sensors detect the temperature within the passenger

compartment and the temperature at the cooling unit inlet,

thus causing changes of the resistance value, and this data is

provided to the air conditioner control unit as input.

How to Test the Therm0 Sensor and Air-Inlet Sensor

(1) Disconnect the sensor’s connector at the evaporator case,

and by using an ohmmeter, measure the resistance. The

resistance is normal if it is within the range shown in the

figure at the left; if the resistance is not normal, replace.

(2) If the sensor is normal, there is a malfunction of the air

conditioner control unit, and it should be replaced.

Standard value:

Passenger compartment temperature sensor resist-

ance value:

0°C (32°F)4,852+243 (S-2)

15°C (59°F)2,341+234 (S-2)

25°C (77°F)1,500+150 (52)

ENGINE COOLANT TEMPERATURE SWITCH

<2.0L DOHC Engine>

The engine coolant temperature switch is connected in series

with the compressor magnetic clutch power relay.

It disengages the compressor when the temperature of

engine coolant rises above

115°C (239°F).This is designed to prevent engine overheating when cooling

air is not sufficient for the condenser and radiator. If the enginecoolant temperature switch operates to disengage the com-

pressor, check for the condenser and radiator surface condi-

tions, belt tension and engine coolant level and correct, if

necessary.

Page 1169 of 1216

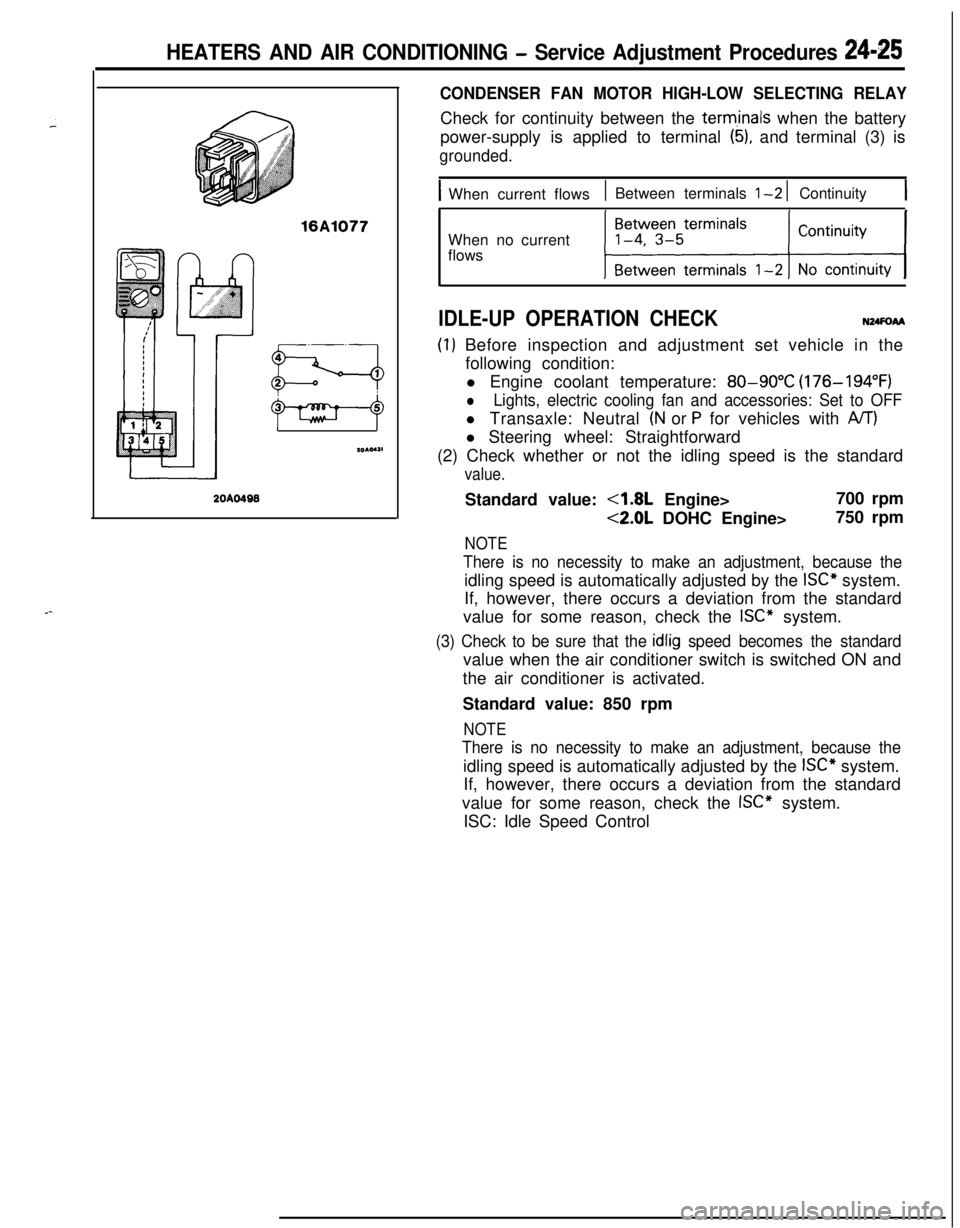

HEATERS AND AIR CONDITIONING - Service Adjustment Procedures 24-25

16A1077

20AO499

CONDENSER FAN MOTOR HIGH-LOW SELECTING RELAYCheck for continuity between the

term,inals when the battery

power-supply is applied to terminal

(5), and terminal (3) is

grounded.

IWhen current flows1 Between terminals l-2 1 Continuity1When no current

flows

IDLE-UP OPERATION CHECKN24FoAA

(I) Before inspection and adjustment set vehicle in the

following condition:

l Engine coolant temperature:

80-90°C (176-194°F)

lLights, electric cooling fan and accessories: Set to OFFl Transaxle: Neutral

(N or P for vehicles with A/T)l Steering wheel: Straightforward

(2) Check whether or not the idling speed is the standard

value.Standard value:

4.8L Engine>700 rpm

<2.0L DOHC Engine>750 rpm

NOTE

There is no necessity to make an adjustment, because theidling speed is automatically adjusted by the

ISC” system.

If, however, there occurs a deviation from the standard

value for some reason, check the

ISC” system.

(3) Check to be sure that the idlig speed becomes the standardvalue when the air conditioner switch is switched ON and

the air conditioner is activated.

Standard value: 850 rpm

NOTE

There is no necessity to make an adjustment, because theidling speed is automatically adjusted by the

ISC” system.

If, however, there occurs a deviation from the standard

value for some reason, check the

ISC” system.

ISC: Idle Speed Control

Page 1175 of 1216

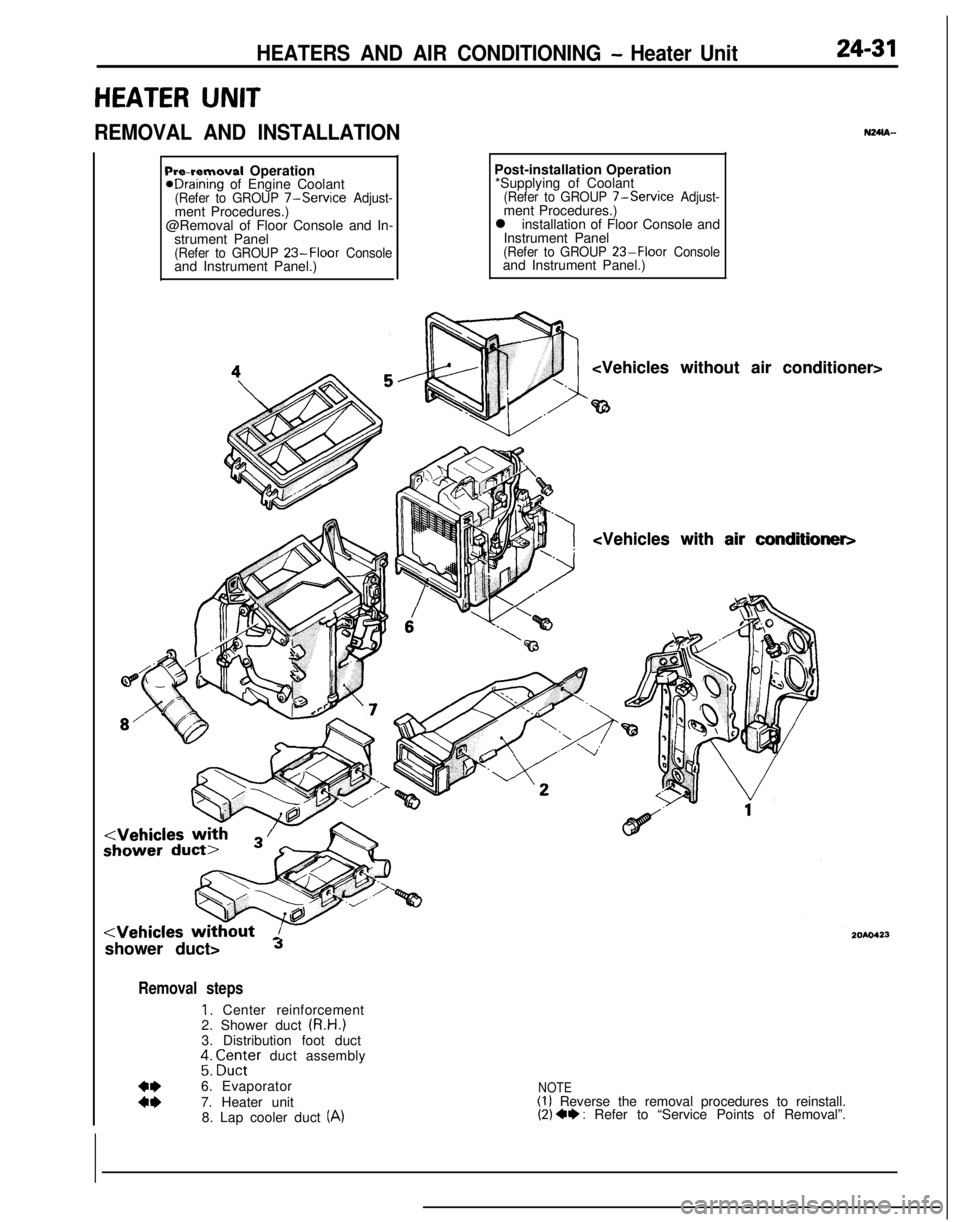

HEATERS AND AIR CONDITIONING - Heater Unit24-31

HEATER UNIT

REMOVAL AND INSTALLATIONN24m-

Pre-removal OperationeDraining of Engine Coolant(Refer to GROUP 7-Service Adjust-ment Procedures.)

@Removal of Floor Console and In-

strument Panel

(Refer to GROUP 23-Floor Consoleand Instrument Panel.)Post-installation Operation

*Supplying of Coolant

(Refer to GROUP 7-Service Adjust-ment Procedures.)

l installation of Floor Console and

Instrument Panel

(Refer to GROUP 23-Floor Consoleand Instrument Panel.)

shower duct>

Jshower duct>

Removal steps

1. Center reinforcement

2. Shower duct (R.H.)

3. Distribution foot duct

;: ;Z;;er duct assembly

:z6. Evaporator

7. Heater unit

8. Lap cooler duct (A)

NOTE(1) Reverse the removal procedures to reinstall.(2) 4* : Refer to “Service Points of Removal”.

Page 1195 of 1216

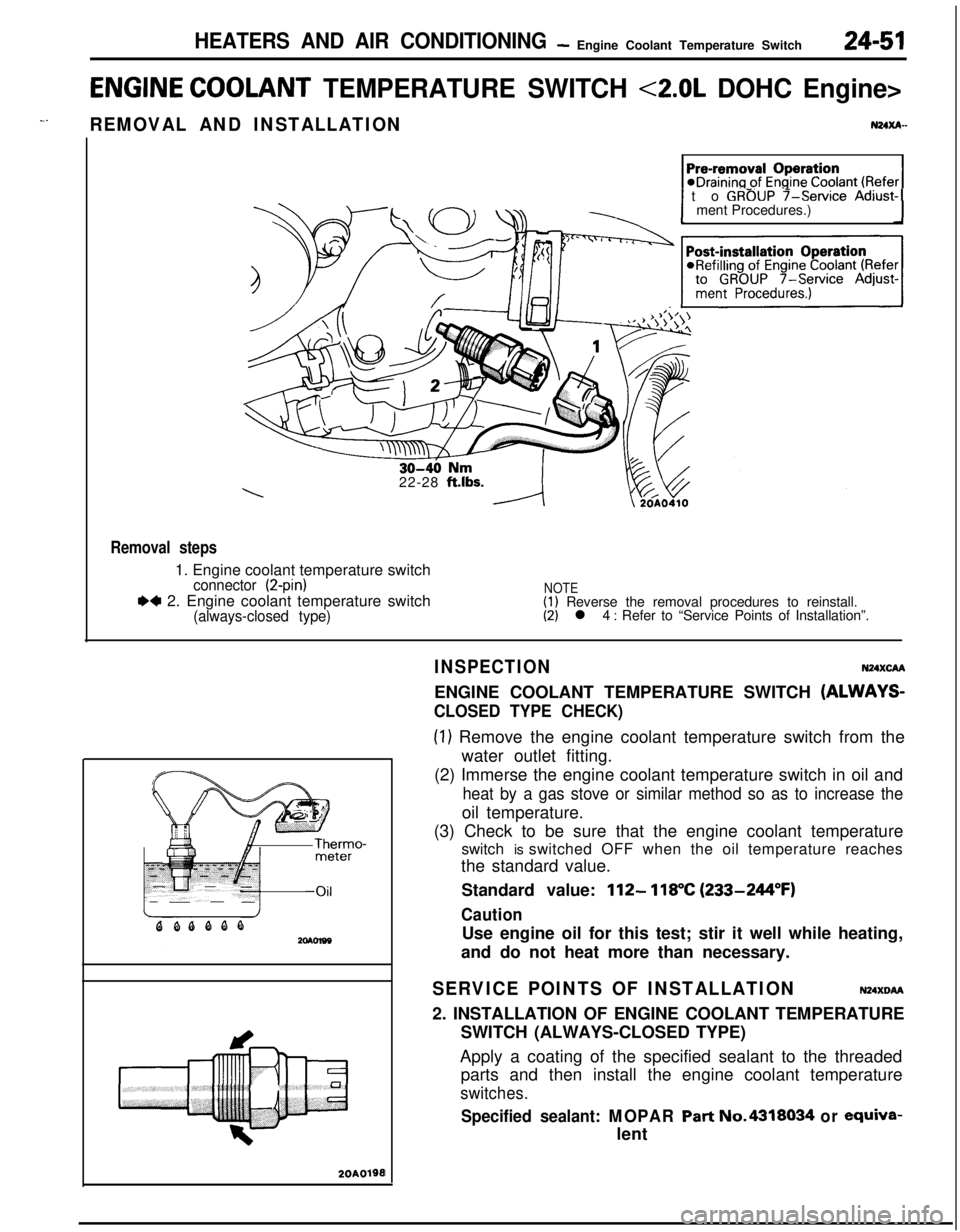

HEATERS AND AIR CONDITIONING- Engine Coolant Temperature Switch24-51

ENGINE COOLANT TEMPERATURE SWITCH <2.0L DOHC Engine>

-.REMOVAL AND INSTALLATIONN24xA-

1 to GROUP f-service Adjust-1ment Procedures.)

22-28

ft.lbs.

Removal steps1. Engine coolant temperature switch

connector (2-pin)

.4 2. Engine coolant temperature switch(always-closed type)

NOTE(1) Reverse the removal procedures to reinstall.(2) l 4 : Refer to “Service Points of Installation”.

20A0190I

INSPECTIONN24XcAAENGINE COOLANT TEMPERATURE SWITCH

(ALWAYS-

CLOSED TYPE CHECK)

(1) Remove the engine coolant temperature switch from the

water outlet fitting.

(2) Immerse the engine coolant temperature switch in oil and

heat by a gas stove or similar method so as to increase theoil temperature.

(3) Check to be sure that the engine coolant temperature

switch is switched OFF when the oil temperature reaches

the standard value.

Standard value:

112- 118°C (233-244°F)

CautionUse engine oil for this test; stir it well while heating,

and do not heat more than necessary.

SERVICE POINTS OF INSTALLATIONN24XDM2. INSTALLATION OF ENGINE COOLANT TEMPERATURE

SWITCH (ALWAYS-CLOSED TYPE)

Apply a coating of the specified sealant to the threaded

parts and then install the engine coolant temperature

switches.

Specified sealant: MOPAR Part No.4318034 or ewiva-lent