air bleeding MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 92 of 1216

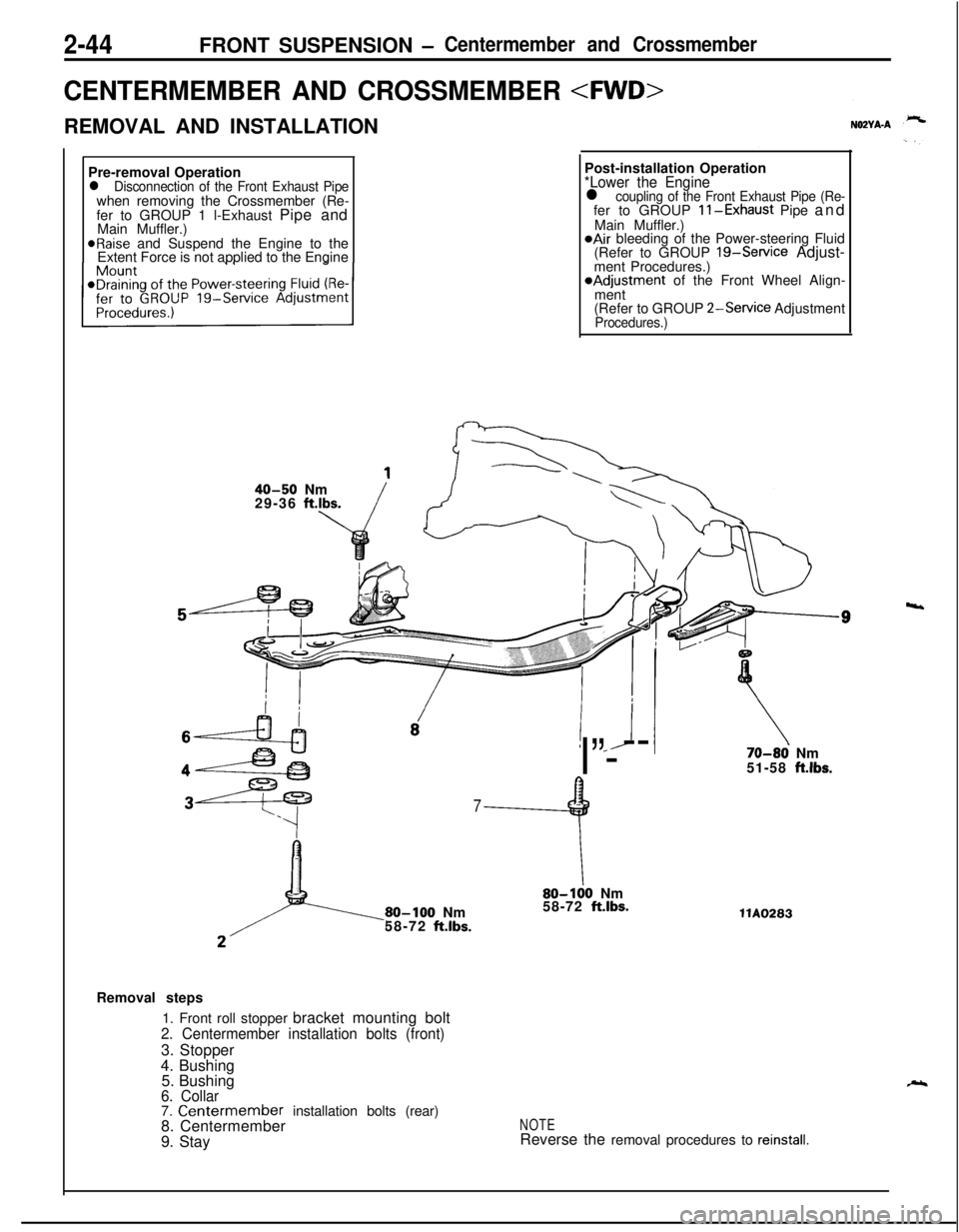

2-44FRONT SUSPENSION -Centermember and Crossmember

CENTERMEMBER AND CROSSMEMBER

REMOVAL AND INSTALLATION

Pre-removal Operation

l Disconnection of the Front Exhaust Pipewhen removing the Crossmember (Re-

fer to GROUP 1 l-Exhaust Pipe and

Main Muffler.)

@Raise and Suspend the Engine to the

Extent Force is not applied to the EnginePost-installation Operation

*Lower the Enginel coupling of the Front Exhaust Pipe (Re-fer to GROUP ll-Exhaust Pipe and

Main Muffler.)

@Air bleeding of the Power-steering Fluid

(Refer to GROUP 19-Service Adjust-

ment Procedures.)*Adjustment of the Front Wheel Align-

ment

(Refer to GROUP

2-Service AdjustmentProcedures.)

40-50 Nm

29-36 ft.lbs.

! *J

I”---

7

9

80-100 Nm

58-72 ft.lbs.

\80-100 Nm

58-72 ft.lbs.

70-86 Nm

51-58 ft.lbs.llA0283

Removal steps

1. Front roll stopper bracket mounting bolt

2. Centermember installation bolts (front)3. Stopper

4. Bushing

5. Bushing

6. Collar7. Centermember installation bolts (rear)

8. Centermember

9. StayNOTEReverse the removal procedures to reinstall.

4

Page 97 of 1216

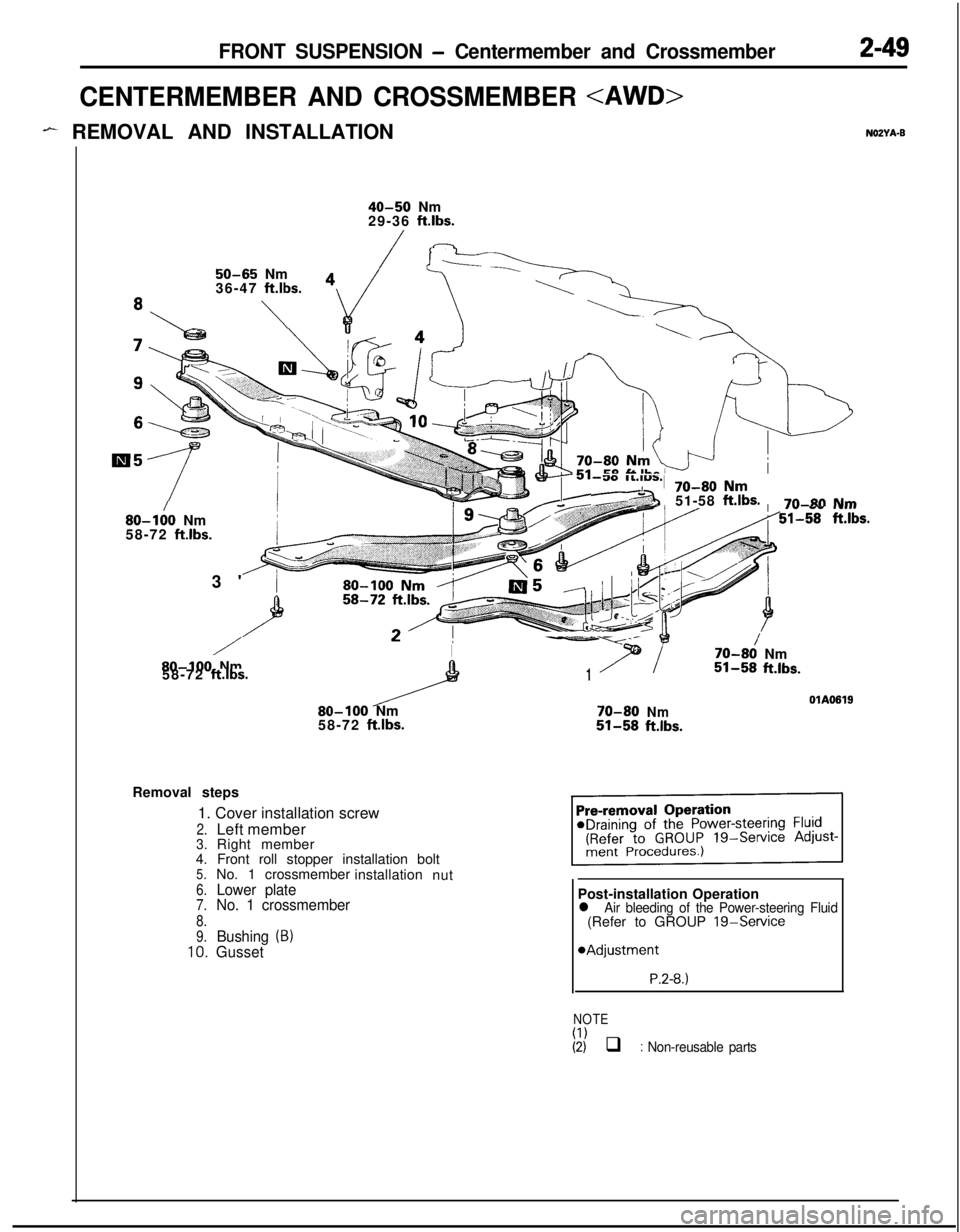

FRONT SUSPENSION - Centermember and Crossmember2-49

CENTERMEMBER AND CROSSMEMBER

- REMOVAL AND INSTALLATIONNOZYA-B

40-50 Nm

29-36 ft.lbs.

50-65 Nm

36-47 ft.lbs.

\

80-I:0 Nm

58-72 ft.lbs.3'

/I-Y--

7t

/70-80Nm80-100 Nm151-58ft.lbs.58-72 ft.lbs.OlA0619

80-100 Nm70-80Nm58-72 ftlbs.51-58ftlbs.

-30 ll.l”S.,

e ~

70-80 Nm51-58

ft.lbs.7n-~0 NmI” .s- .w...51-58 ft.lbs.Removal steps

1. Cover installation screw

2.Left member3.Right member

4. Front roll stopper installation bolt

5.No. 1 crossmember

installation

nut

6.Lower plate7.No. 1 crossmember

8.

9.Bushing (B)10.GussetPost-installation Operation

l Air bleeding of the Power-steering Fluid(Refer to GROUP 19-Service

*Adjustment

P.2-8.)

NOTE

(I)(2) q : Non-reusable parts

Page 141 of 1216

BRAKES

SERVICE AND PARKING

CONTENTS

ANTI-LOCK BRAKING SYSTEM

TROUBLESHOOTING

......................................

9

BRAKEBOOSTER...........................................

60BRAKE LINE

....................................................

62

BRAKE PEDAL.................................................

53ELECTRONIC CONTROL UNIT

- FRONT DISC BRAKE......................................

65G-SENSOR

HYDRAULIC UNIT

77

MASTERCYLINDER

........................................56

PARKING BRAKES

..........................................88

REAR

DISC BRAKE.........................................70SERVICE ADJUSTMENT PROCEDURES..

.....41

ABSPowerRelayCheck.............................52

Bleeding........................................................

45Brake Booster Operating

Inspection...........43

BrakeFluidLevelSensor Check.................

42Brake Pedal Inspection and Adjustment

.....41Check Valve

OperationCheck.....................

44

FlatBattery

Remedy....................................52

FrontBrakeDiscRun-out Check................47Front Brake Disc Run-out Correction

..........48Front Brake

Disc Thickness Check

.............47Front Disc Brake Pad Check and

Replacement.................................................46

Parking

BrakeLever Stroke Check.............42

Parking

BrakeSwitchCheck.......................43

Proportioning

ValveFunctionTest...............44Rear Brake

DiscRun-out Check.................50Rear Brake Disc Run-out Correction

...........50Rear Brake

Disc Thickness

Check..............49Rear Disc Brake Pad Check and

Replacement.................................................48Observation of Wheel Speed Sensor

Output Voltage Variations

ABS>..................................51

SPECIAL TOOLS.............................................6

SPECIFICATIONS.............................................

2General Specifications

..................................2

Lubricants

......................................................5

Service

Specifications...................................4

Torque

Specifications...................................4

TROUBLESHOOTING......................................7WHEEL SPEED SENSOR

_ CAUTION

When servicing brake assemblies or components, do not create dust by sanding, grinding or by cleaning

brake parts with a dry brush or with compressed air. A WATER DAMPENED CLOTH SHOULD BE USED.

Many brake components contain asbestos fibers which can become air-borne if dust is created duringservice operations. Breathing dust which contains asbestos fibers can cause serious bodily harm.

Page 185 of 1216

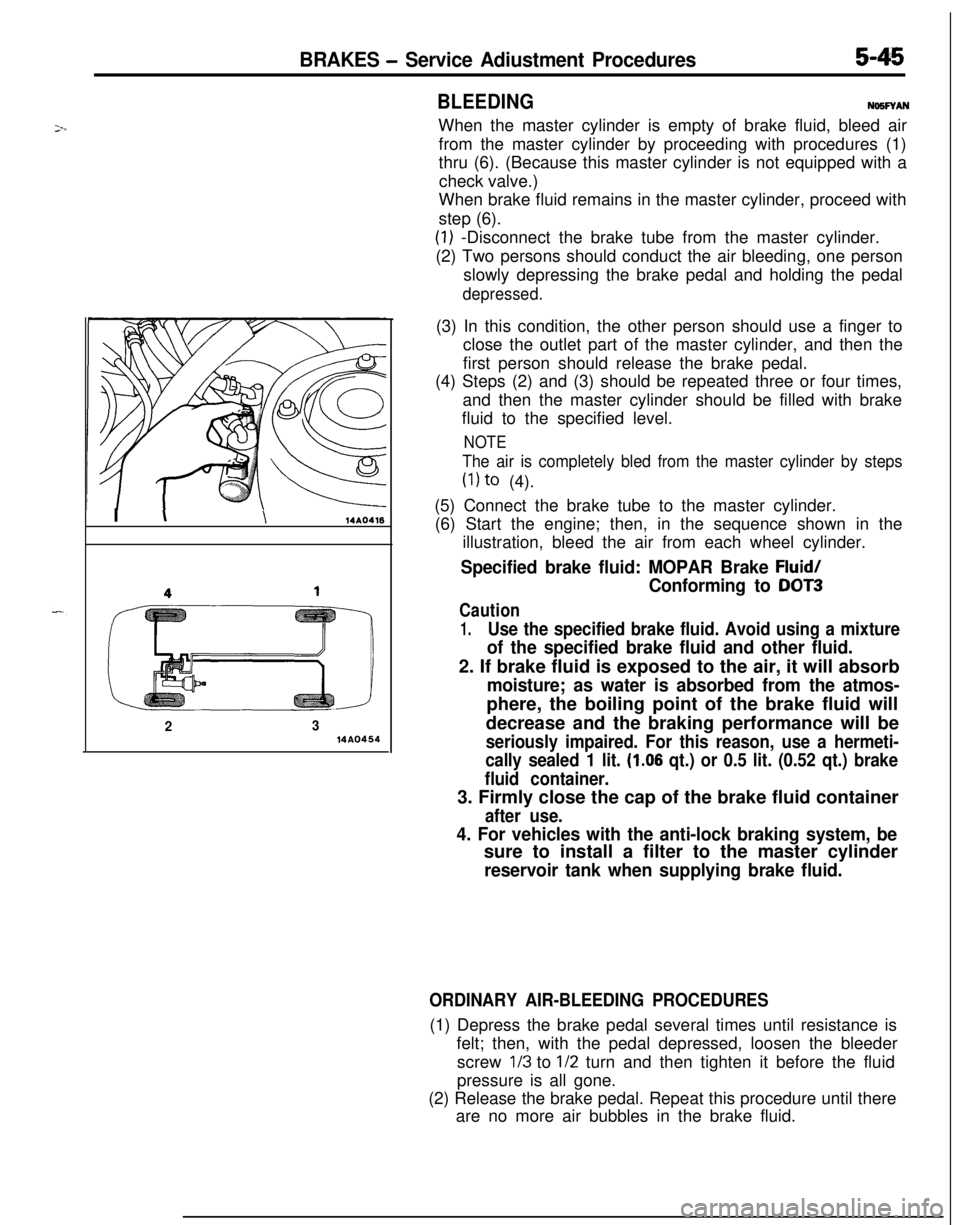

BRAKES - Service Adiustment Procedures5-45I

\\14A0416

2314A04.54

BLEEDINGN65FYAN

When the master cylinder is empty of brake fluid, bleed air

from the master cylinder by proceeding with procedures (1)

thru (6). (Because this master cylinder is not equipped with a

check valve.)

When brake fluid remains in the master cylinder, proceed with

step (6).

(1) -Disconnect the brake tube from the master cylinder.

(2) Two persons should conduct the air bleeding, one person

slowly depressing the brake pedal and holding the pedal

depressed.(3) In this condition, the other person should use a finger to

close the outlet part of the master cylinder, and then the

first person should release the brake pedal.

(4) Steps (2) and (3) should be repeated three or four times,

and then the master cylinder should be filled with brake

fluid to the specified level.

NOTE

The air is completely bled from the master cylinder by steps

(1) to (4).

(5) Connect the brake tube to the master cylinder.

(6) Start the engine; then, in the sequence shown in the

illustration, bleed the air from each wheel cylinder.

Specified brake fluid: MOPAR Brake Fluid/

Conforming to DOT3

Caution

1.Use the specified brake fluid. Avoid using a mixture

of the specified brake fluid and other fluid.2. If brake fluid is exposed to the air, it will absorb

moisture; as water is absorbed from the atmos-phere, the boiling point of the brake fluid will

decrease and the braking performance will be

seriously impaired. For this reason, use a hermeti-

cally sealed 1 lit.

(1.06 qt.) or 0.5 lit. (0.52 qt.) brake

fluid container.3. Firmly close the cap of the brake fluid container

after use.

4. For vehicles with the anti-lock braking system, besure to install a filter to the master cylinder

reservoir tank when supplying brake fluid.

ORDINARY AIR-BLEEDING PROCEDURES(1) Depress the brake pedal several times until resistance is

felt; then, with the pedal depressed, loosen the bleeder

screw

l/3 to l/2 turn and then tighten it before the fluid

pressure is all gone.

(2) Release the brake pedal. Repeat this procedure until there

are no more air bubbles in the brake fluid.

Page 217 of 1216

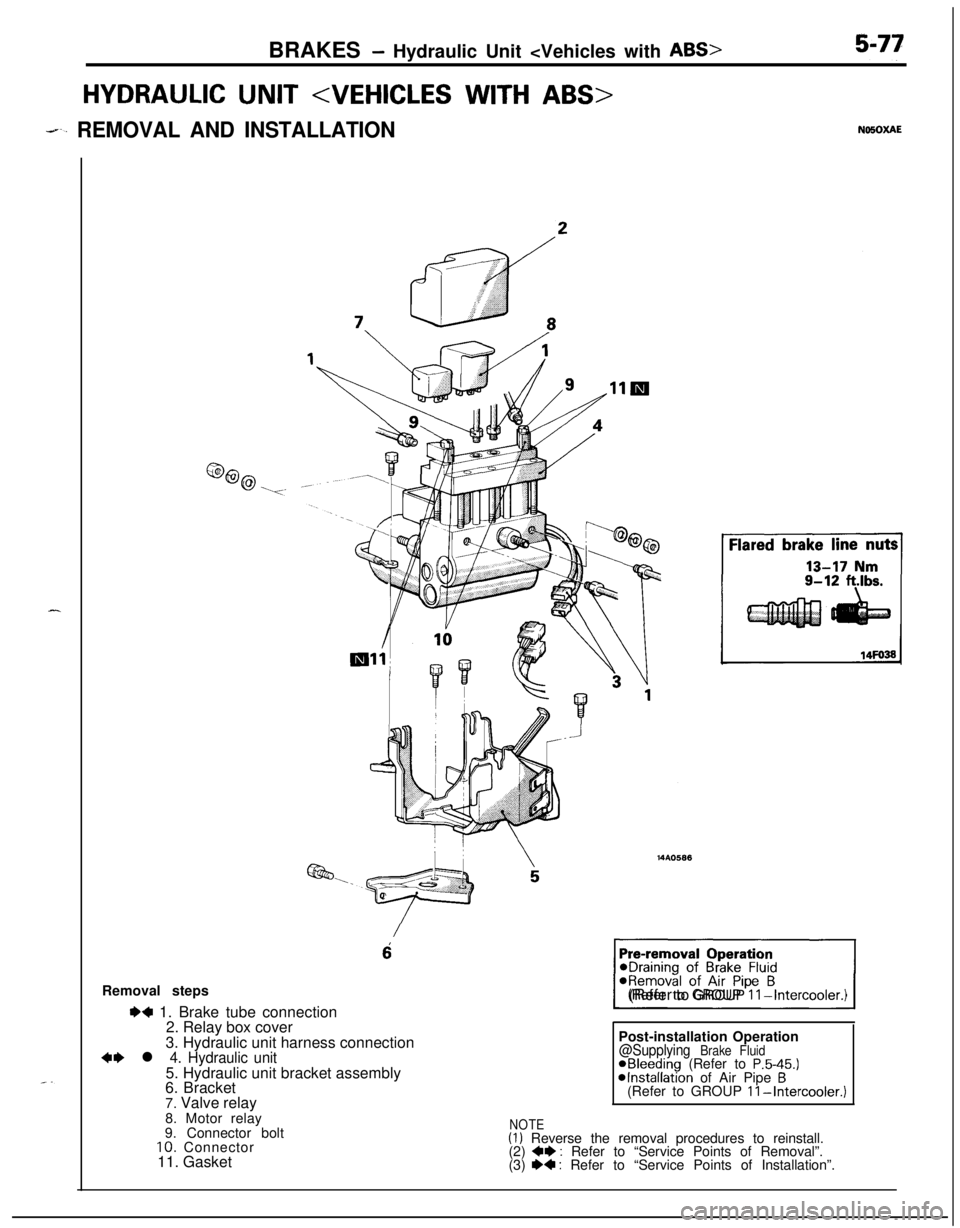

BRAKES - Hydraulic Unit

HYDRAULIC UNIT

--. REMOVAL AND INSTALLATION

6Removal steps

I)+ 1. Brake tube connection

2. Relay box cover

3. Hydraulic unit harness connection

~~ l 4. Hydraulic unit5. Hydraulic unit bracket assembly

6. Bracket

7. Valve relay

1(Refer to GROUP

II-Intercooler.)Post-installation Operation

@Supplying Brake FluidaBleeding (Refer to P.5-45.)@Installation of Air Pipe B(Refer to GROUP II-Intercooler.)8. Motor relay

9. Connector bolt

10. Connector

11. Gasket

NOTE(1) Reverse the removal procedures to reinstall.

(2) +e : Refer to “Service Points of Removal”.

(3) e+ : Refer to “Service Points of Installation”.

Page 231 of 1216

6-I

CLUTCH

CONTENTS

CLUTCH CONTROL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9SPECIFICATIONS. . . . . . . . . . . . . . . . . . ..m........................2

GeneralSpecifications..................................2CLUTCH COVER AND DISC..........................16Lubricants......................................................3

CLUTCH MASTER CYLINDER........................11Service Specifications...................................2Torque Specifications

...................................3

CLUTCH PEDAL..............................................7

TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . ..*............4

CLUTCHRELEASE CYLINDER . . . . . . . ..a.............13Clutch chatters

SERVICE ADJUSTMENT PROCEDURES . . . . . . .5Clutch noise

Bleeding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6Clutch pedal feels “heavy”

Clutch Pedal Inspection and Adjustment . . . .

5Clutch slips

SPECIAL TOOL,.,#mmm,.*......B......................*........3Gear shift malfunctionCAUTIONWhen

servicing clutch assemblies or com-

ponents for vehicles with 1.8L engine, doNOT

create dust by sanding or by cleaning

clutch parts with a dry brush or with

compressed air. (A water dampened cloth

should be used). The clutch disc contains

“Asbestos Fibers” which can become air-

borne if dust is created during serviceoperations. Breathing dust containing

“Asbestos Fibers”may cause seriousbodily

harm.

Page 236 of 1216

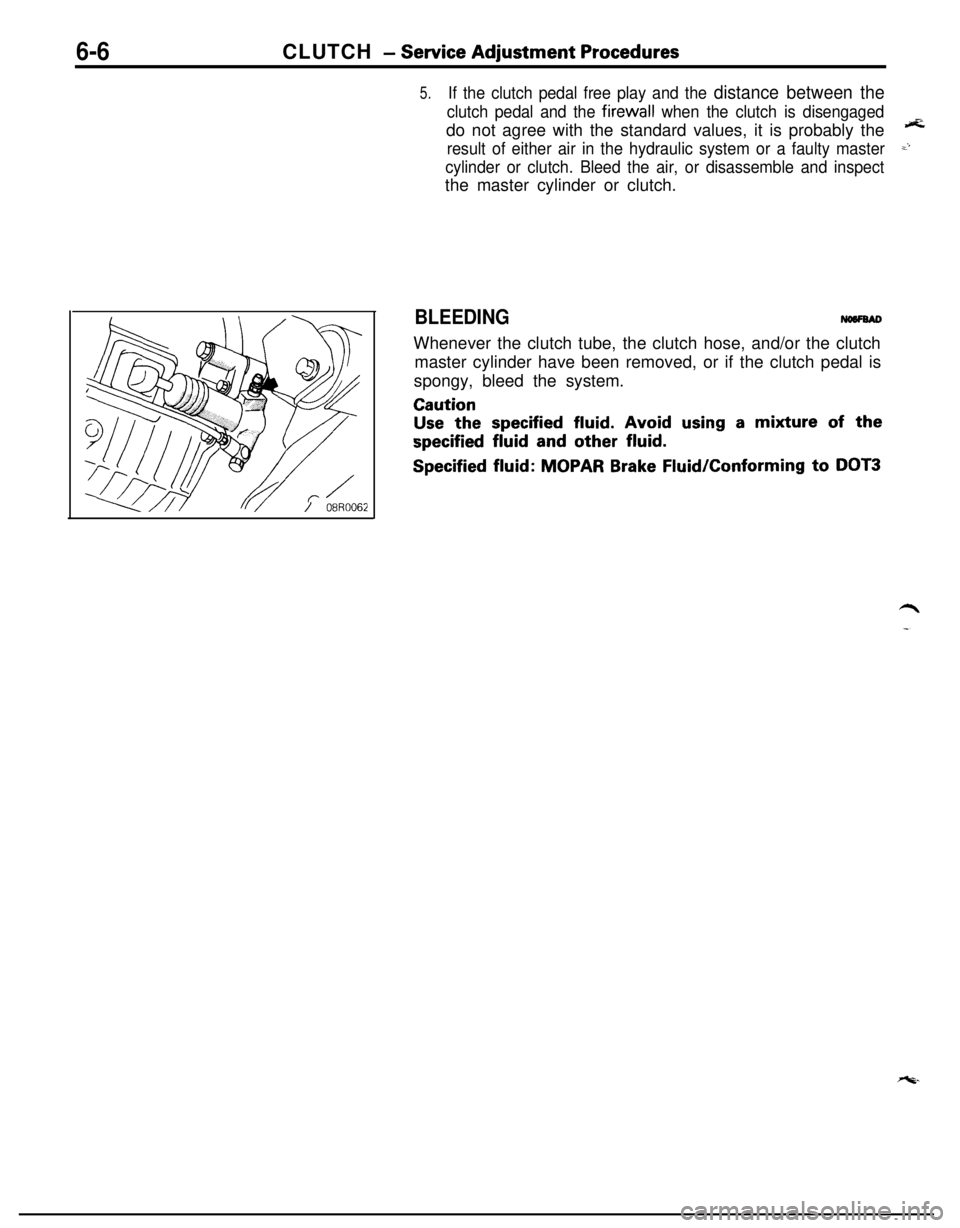

6-6CLUTCH - Service Adjustment Procedures

5.If the clutch pedal free play and the distance between the

clutch pedal and the firewall when the clutch is disengageddo not agree with the standard values, it is probably the

A

result of either air in the hydraulic system or a faulty master2

cylinder or clutch. Bleed the air, or disassemble and inspectthe master cylinder or clutch.

BLEEDINGWhenever the clutch tube, the clutch hose, and/or the clutch

master cylinder have been removed, or if the clutch pedal is

spongy, bleed the system.

Caution

Use the specified fluid. Avoid using a mixture of the

specified fluid and other fluid.

Specified fluid: MOPAR Brake Fluid/Conforming to DOT3

Page 239 of 1216

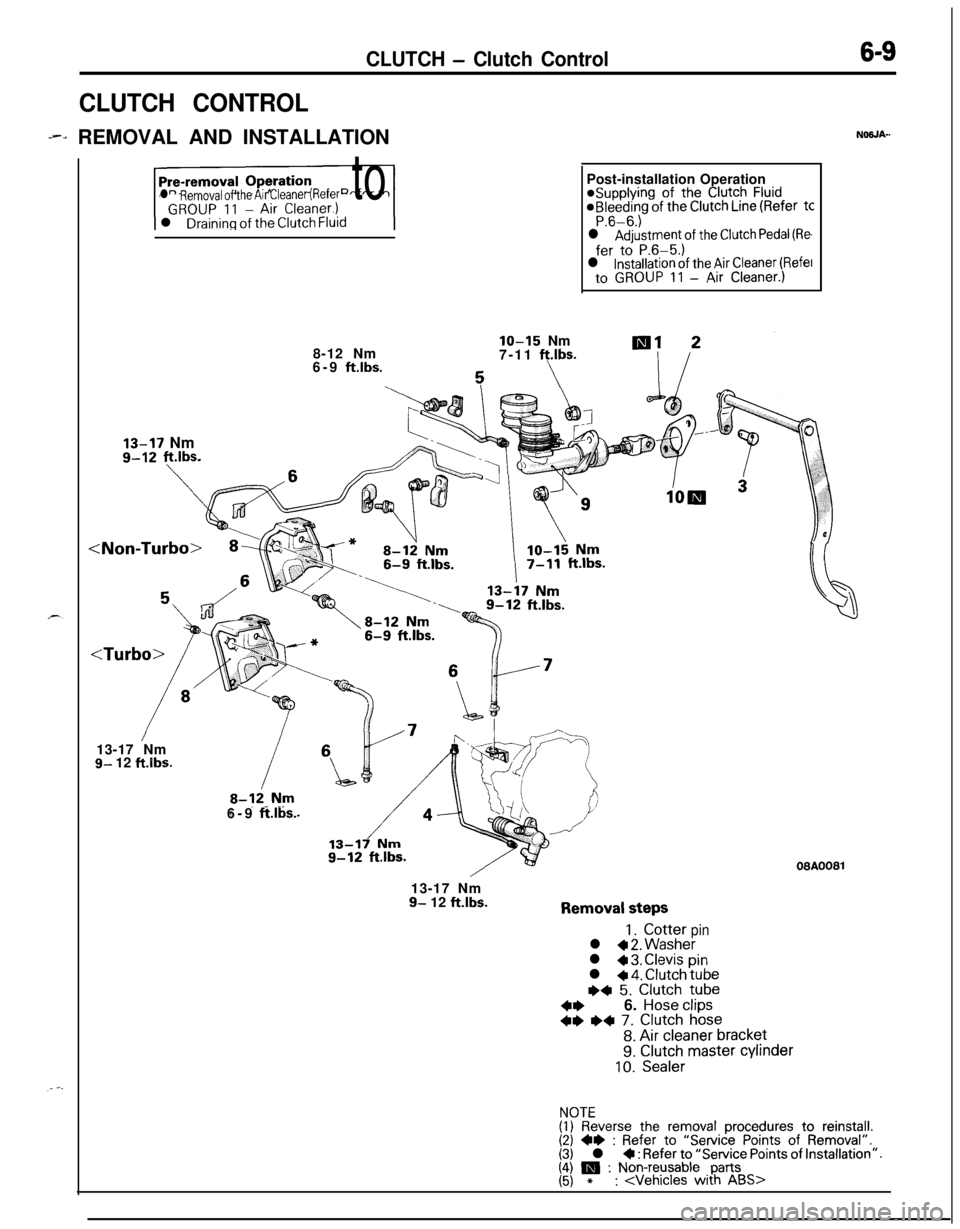

CLUTCH - Clutch Control6-9

CLUTCH CONTROL

--., REMOVAL AND INSTALLATIONNOSJA-

l Removal of the Air Cleaner (Refer tol

Draining of the Clutch Fluid8-12 Nm

6-9

ftlbs.

IO-15 Nm

7-11 ft.lbs.

13-17 Nmg-12 ft.lbs.Post-installation Operation*Supplying of the

Clutch Fluid@Bleeding of the Clutch Line (Refer tCP.6-6.)l Adjustment of the Clutch Pedal (Re

fer to P.6-5.)l installation of the Air Cleaner (Refelto GROUP 11 - Air Cleaner.)

g- 12 ft.ibs.6-9

ft.lbs.

08A008113-17 Nm

9- 12 ft.lbs.Removal steps

1. Cotterpinl + 2. Washerl 4 3. Clevispinl + 4. Clutch tube~~ 5. Clutch tube

4*6. Hose clips+e I)+ 7. Clutch hose

8. Air cleaner bracket9. Clutch master cylinder10. Sealer

NOTE(1) Reverse the removal procedures to reinstall.(2) +e : Refer to “Service Points of Removal”.(3) l * : Refer to “Service Points of Installation”.I;\ m : Non-reusable, parts*:

Page 660 of 1216

19-12STEERING - Service Adjustment Procedures

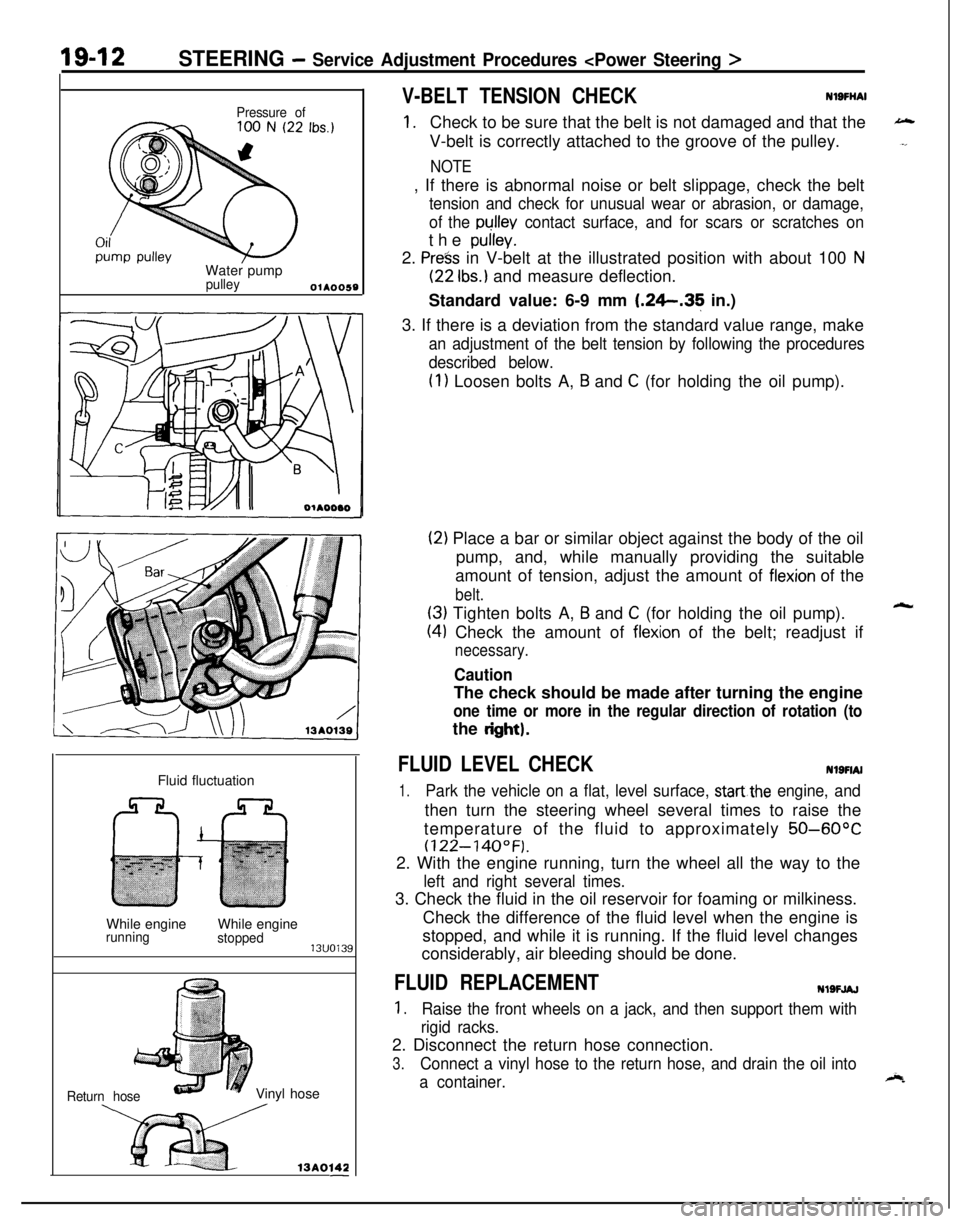

Pressure ofWater pump

pulleyOlA0059Fluid fluctuation

While engine

runningWhile enginestopped13uo139

Return hoseVinyl hose

x ,3Ao,42-

V-BELT TENSION CHECKNlSFliAl

1.Check to be sure that the belt is not damaged and that the

V-belt is correctly attached to the groove of the pulley.

NOTE, If there is abnormal noise or belt slippage, check the belt

tension and check for unusual wear or abrasion, or damage,

of the

pullev contact surface, and for scars or scratches onthe

pulley.2.

Press in V-belt at the illustrated position with about 100 N

(22 Ibs.) and measure deflection.

Standard value: 6-9 mm

1.26.35 in.)

3. If there is a deviation from the standard value range, make

an adjustment of the belt tension by following the procedures

described below.

(1) Loosen bolts A, B and C (for holding the oil pump).

(2) Place a bar or similar object against the body of the oil

pump, and, while manually providing the suitable

amount of tension, adjust the amount of

flexion of the

belt.

(3) Tighten bolts A, B and C (for holding the oil pump).

(4) Check the amount of flexion of the belt; readjust if

necessary.

CautionThe check should be made after turning the engine

one time or more in the regular direction of rotation (tothe

dght).

FLUID LEVEL CHECKNlSFIAI

1.Park the vehicle on a flat, level surface, startthe engine, andthen turn the steering wheel several times to raise the

temperature of the fluid to approximately

50-60°C

(122-140°F).2. With the engine running, turn the wheel all the way to the

left and right several times.3. Check the fluid in the oil reservoir for foaming or milkiness.

Check the difference of the fluid level when the engine is

stopped, and while it is running. If the fluid level changes

considerably, air bleeding should be done.

FLUID REPLACEMENTNlSFJAJ

1.Raise the front wheels on a jack, and then support them with

rigid racks.2. Disconnect the return hose connection.

3.Connect a vinyl hose to the return hose, and drain the oil into

a container.

Page 661 of 1216

STEERING - Service -Adjustment Procedures < Power Steering >IgJf~

4.Disconnect the high-tension cable, and then while operating

the starting motor intermittently, turn the steering wheel all;

the way to the left and right several times to drain all of the

fluid.

Caution, 35

Be careful not to position thq high-tension able ye&r the

carburetor or the delivery pipe.5. Connect the return hoses securely, and then

secur& it ,with

the clip.6. Fill the oil reservoir with the specified fluid up

td the Ibwerposition of the filter, and then bleed the air.

.’

Specified fluid:MOPAR ATF PLUS (Automatic Transmis-sion Fluid Type 7176)/Automatic trans-

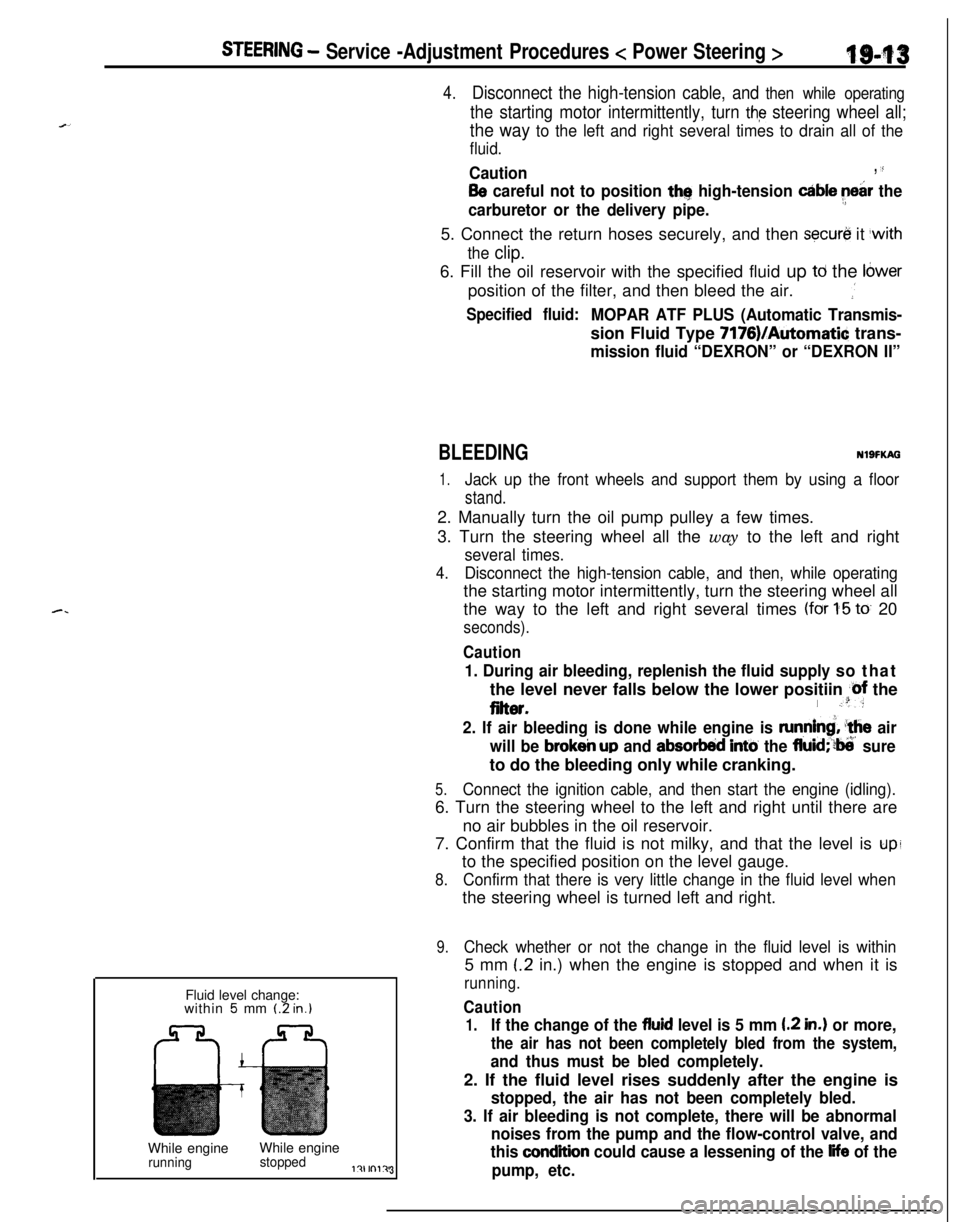

mission fluid “DEXRON” or “DEXRON II”Fluid level change:

within

5 mm (2 in.)While engineWhile engine

runningstoppedl?lrnl?J3

BLEEDINGNlSFKAG

1.Jack up the front wheels and support them by using a floor

stand.2. Manually turn the oil pump pulley a few times.

3. Turn the steering wheel all the way to the left and right

several times.

4.Disconnect the high-tension cable, and then, while operatingthe starting motor intermittently, turn the steering wheel all

the way to the left and right several times

(for 1-5 to 20

seconds).

Caution

1. During air bleeding, replenish the fluid supply so thatthe level never falls below the lower positiin

@f the

eiter.I .“:

2. If air bleeding is done while engine is runnind, ‘the air

will be

brokeir up and absorbed intti the fluid;‘?ti’ sureto do the bleeding only while cranking.

5.Connect the ignition cable, and then start the engine (idling).6. Turn the steering wheel to the left and right until there are

no air bubbles in the oil reservoir.

7. Confirm that the fluid is not milky, and that the level is

upito the specified position on the level gauge.

8.Confirm that there is very little change in the fluid level whenthe steering wheel is turned left and right.

9.Check whether or not the change in the fluid level is within5 mm

(.2 in.) when the engine is stopped and when it is

running.

Caution

1.If the change of the fluid level is 5 mm I.2 in.) or more,

the air has not been completely bled from the system,

and thus must be bled completely.2. If the fluid level rises suddenly after the engine is

stopped, the air has not been completely bled.

3. If air bleeding is not complete, there will be abnormal

noises from the pump and the flow-control valve, and

this

condition could cause a lessening of the life of the

pump, etc.