Mpi MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 2 of 1216

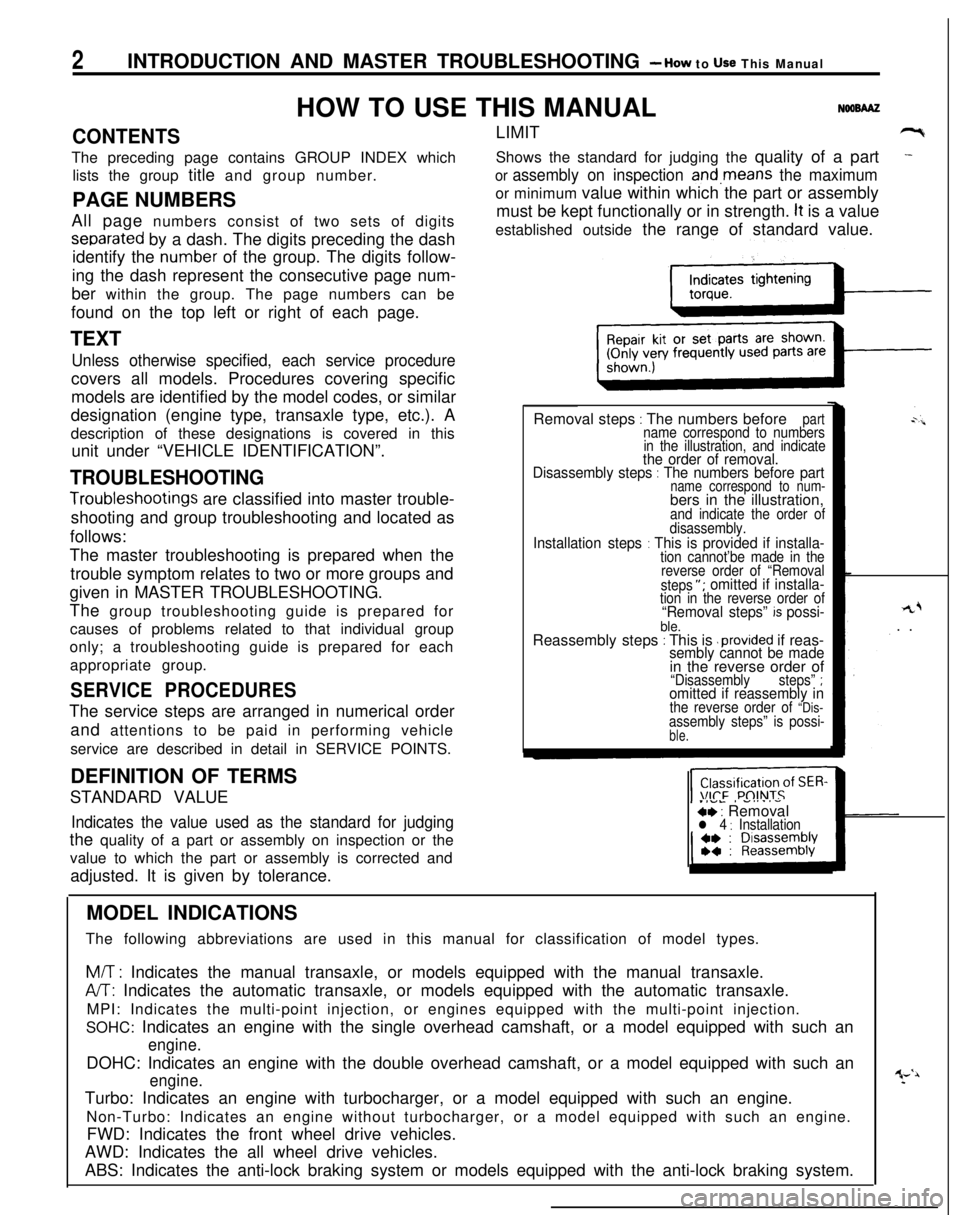

2INTRODUCTION AND MASTER TROUBLESHOOTING - How to Use This Manual

HOW TO USE THIS MANUALNOaM

CONTENTSThe preceding page contains GROUP INDEX which

lists the group title and group number.

PAGE NUMBERS

All page numbers consist of two sets of digits

separated by a dash. The digits preceding the dash

identify the

number of the group. The digits follow-

ing the dash represent the consecutive page num-

ber within the group. The page numbers can be

found on the top left or right of each page.

TEXT

Unless otherwise specified, each service procedurecovers all models. Procedures covering specific

models are identified by the model codes, or similar

designation (engine type, transaxle type, etc.). A

description of these designations is covered in this

unit under “VEHICLE IDENTIFICATION”.

TROUBLESHOOTING

Troubleshootings are classified into master trouble-

shooting and group troubleshooting and located as

follows:

The master troubleshooting is prepared when the

trouble symptom relates to two or more groups and

given in MASTER TROUBLESHOOTING.

The group troubleshooting guide is prepared for

causes of problems related to that individual group

only; a troubleshooting guide is prepared for each

appropriate group.LIMIT

-9Shows the standard for judging the quality of a part

-

or assembly on inspection and,means the maximumor minimum value within which the part or assembly

must be kept functionally or in strength.

It is a value

established outside the range of standard value.

Removal steps

: The numbers beforepartname correspond to numbers

in the illustration, and indicate

the order of removal.

Disassembly steps : The numbers before partname correspond to num-bers in the illustration,

and indicate the order of

disassembly.

Installation steps : This is provided if installa-tion cannot’be made in the

reverse order of “Removal

steps

“; omitted if installa-tion in the reverse order of“Removal steps” k possi-ble.Reassembly steps : This is .provided if reas-sembly cannot be made

rL+. .

in the reverse order of

“Disassemblysteps” ;omitted if reassembly inthe reverse order of “Dis-assembly steps” is possi-ble.

SERVICE PROCEDURESThe service steps are arranged in numerical order

and attentions to be paid in performing vehicle

service are described in detail in SERVICE POINTS.

.IVL, -....-ce : Removall 4 : InstallationDEFINITION OF TERMS

STANDARD VALUEIndicates the value used as the standard for judgingthe quality of a part or assembly on inspection or the

value to which the part or assembly is corrected and

adjusted. It is given by tolerance.

MODEL INDICATIONS

The following abbreviations are used in this manual for classification of model types.

M/T : Indicates the manual transaxle, or models equipped with the manual transaxle.

A/T: Indicates the automatic transaxle, or models equipped with the automatic transaxle.

MPI: Indicates the multi-point injection, or engines equipped with the multi-point injection.

SOHC: Indicates an engine with the single overhead camshaft, or a model equipped with such an

engine.DOHC: Indicates an engine with the double overhead camshaft, or a model equipped with such an

engine.Turbo: Indicates an engine with turbocharger, or a model equipped with such an engine.

Non-Turbo: Indicates an engine without turbocharger, or a model equipped with such an engine.

FWD: Indicates the front wheel drive vehicles.

AWD: Indicates the all wheel drive vehicles.

ABS: Indicates the anti-lock braking system or models equipped with the anti-lock braking system.

Page 6 of 1216

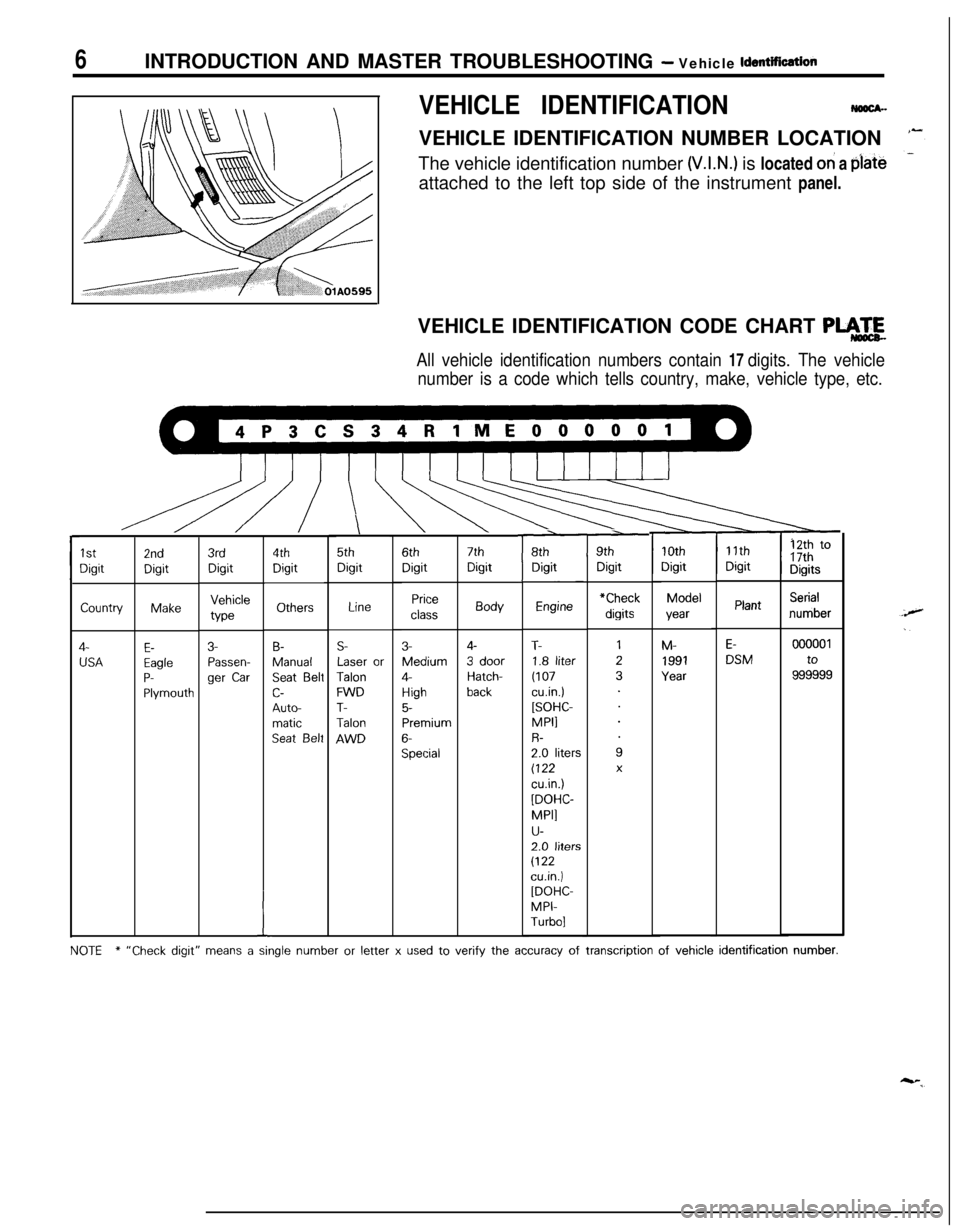

6INTRODUCTION AND MASTER TROUBLESHOOTING - Vehicle Identificetion

VEHICLE IDENTIFICATIONNmx-VEHICLE IDENTIFICATION NUMBER LOCATION

The vehicle identification number

(V.I.N.) is located oh a plate

attached to the left top side of the instrument panel.

VEHICLE IDENTIFICATION CODE CHART

PLA.4

All vehicle identification numbers contain 17 digits. The vehicle

number is a code which tells country, make, vehicle type, etc.

\5thDigit

r8thDigitr9thDigit

11thDigit12th to17thDigits

10thDigitModelyearM-

1991Year

7thDigitBody

4-

3 doorHatch-back

Engine

T-1.8 liter

(107cu.in.)[SOHC-MPI1R-2.0 liters(122

cu.in.)

[DOHC-

MPI]

u-2.0 liters

(122cuin.)[DOHC-MPI-Turbo]6thDigit

Price

class

3-Medium

4-

High5-Premium

6-Special

4thDigit

Others

B-Manual

Seat Beltc-

Auto-matic

Seat Belt

3rdDigitVehicleWe

3-Passen-ger

Car

2ndDigitMake

E-EagleP-Plymouth

1stDigitCountry

4-

USA

Serialnumber*CheckPlantLine

E-DSMS-Laser or

TalonFWDT-Talon

AWD

000001to

999999

I

NOTE* “Check digit” means a single number or letter x used to verify the accuracy of transcription of vehicle identification number.

Page 7 of 1216

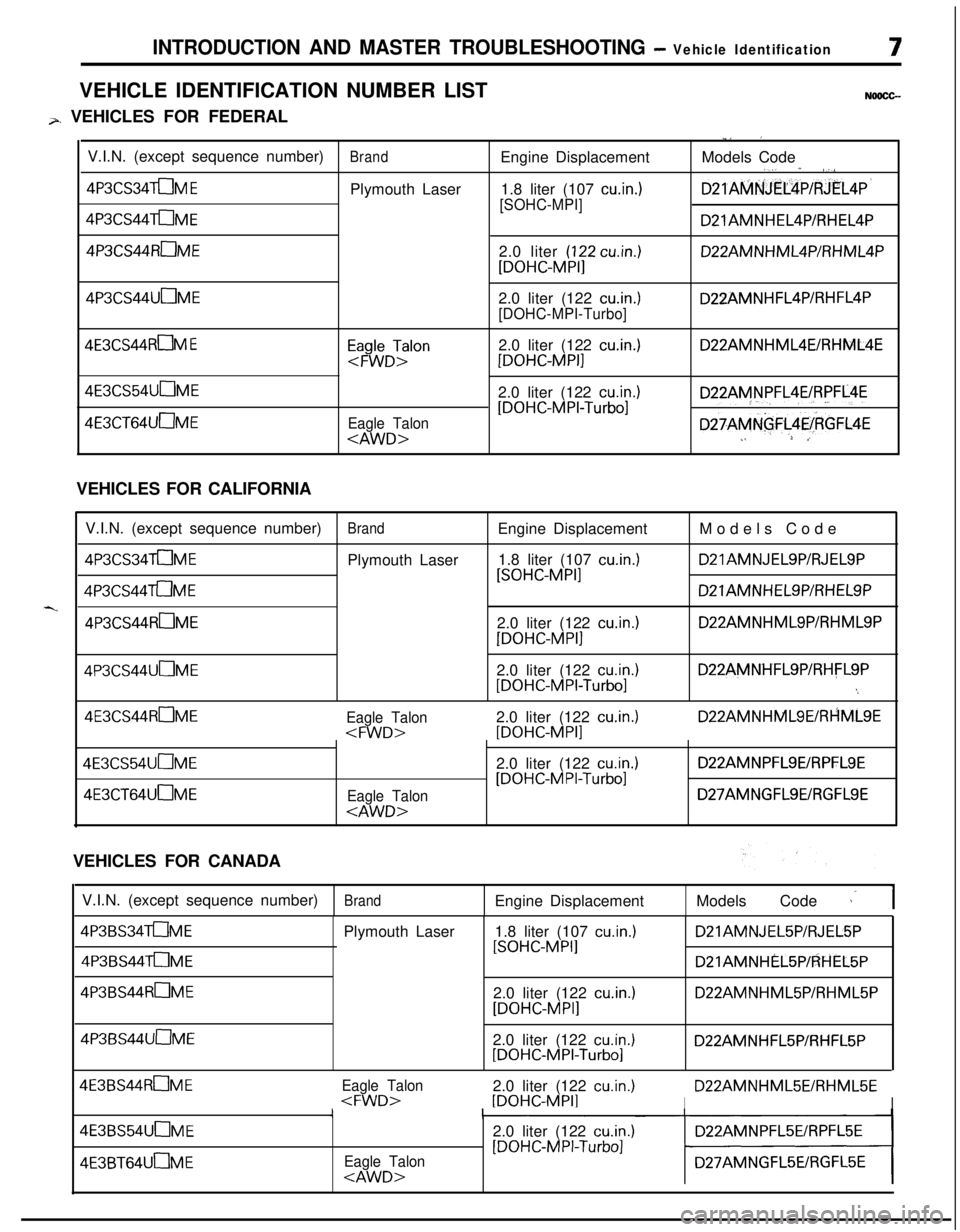

INTRODUCTION AND MASTER TROUBLESHOOTING - Vehicle IdentificationVEHICLE IDENTIFICATION NUMBER LIST

NOOCC--

p, VEHICLES FOR FEDERAL

,.. IV.I.N. (except sequence number)

BrandEngine DisplacementModels Code,,; * /./

4P3CS34aM EPlymouth Laser1.8 liter (107 cuin.)D21AMNJElXP/RJEL4P’

4P3CS44aME[SOHC-MPI]

D21AMNHEL4P/RHEL4P4P3CS44ROME2.0 liter

(122 cuin.)

[DOHC-MPI]D22AMNHML4P/RHML4P4P3CS44UuME2.0 liter (122

cu.in.)

[DOHC-MPI-Turbo]D22AMNHFL4P/RHFL4P

4E3CS44ROM EEap$DTrlon2.0 liter (122 cu.in.)

[DOHC-MPI]D22AMNHML4EIRHML4E4E3CS54UnME4E3CT64UOME

Eagle Talon

cu.in.)

[DOHC-MPI-Turbo]D22AMNPFL4EIRPFL4E

D27AMNGFL4E/kGFL4E.1L *,VEHICLES FOR CALIFORNIA

V.I.N. (except sequence number)

BrandEngine DisplacementModels Code

4P3CS34aMEPlymouth Laser1.8 liter (107 cu.in.)D21AMNJELSP/RJELSP

4P3CS44aME

[SOHC-MPI]D21AMNHELSP/RHELSP

4P3CS44RmME2.0 liter (122 cuin.)

[DOHC-MPI]

D22AMNHMLSP/RHMLSP4P3CS44UOME2.0 liter (122

cu.in.1[DOHC-MPI-Turbo]

D22AMNHFLSP/RHFLSP

‘.4E3CS44RuME

Eagle Talon2.0 liter (122 cu.in.1

D22AMNHMLSE/RHMLSE4E3CS54UOME4E3CT64UOME

Eagle Talon

cu.in.1[DOHC-MPI-Turbo]

D22AMNPFLSElRPFLSE

D27AMNGFLSE/RGFLSEVEHICLES FOR CANADA

V.I.N. (except sequence number)

BrandEngine DisplacementModels Code 1’1

4P3BS34aME

4P3BS44aMEPlymouth Laser1.8 liter (107

cu.in.1[SOHC-MPI]D21AMNJEL5P/RJEL5PD21AMNHiL5P/RHEL5P4P3BS44ROME

2.0 liter (122

cuin.)

[DOHC-MPI]D22AMNHML5P/RHML5P4P3BS44UuME

2.0 liter (122

cu.in.)[DOHC-MPI-Turbo]D22AMNHFL5P/RHFL5P4E3BS44ROME

Eagle Talon2.0 liter (122 cu.in.)D22AMNHML5EiRHML5E

Eagle Talon

cu.in.1

[DOHC-MPI-Turbo]

Page 8 of 1216

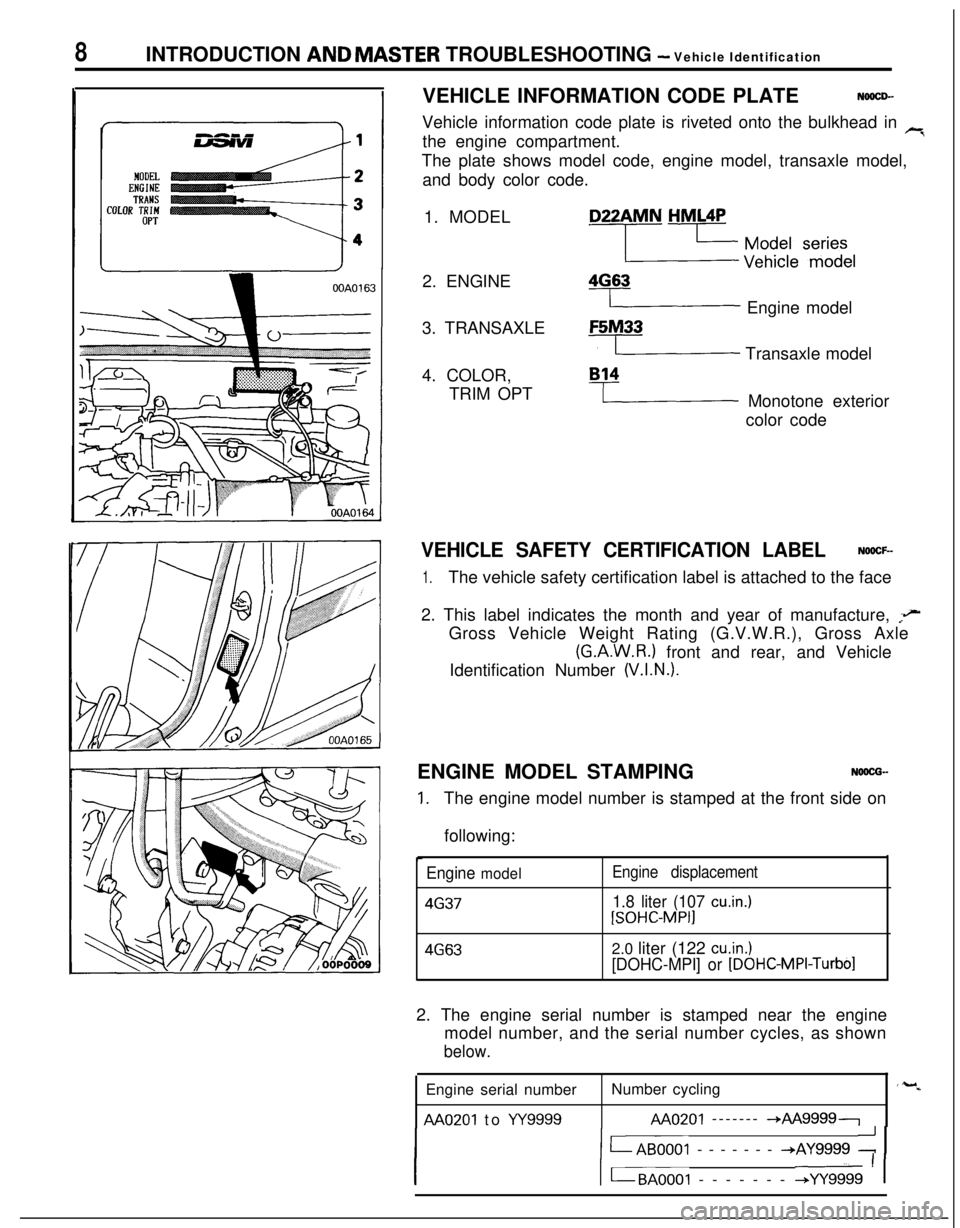

8INTRODUCTION AND MASTER TROUBLESHOOTING - Vehicle Identification

VEHICLE INFORMATION CODE PLATE

NOOCD-Vehicle information code plate is riveted onto the bulkhead in

rithe engine compartment.

The plate shows model code, engine model, transaxle model,

and body color code.

1. MODEL

2. ENGINE

3. TRANSAXLE

4. COLOR,

TRIM OPTD22AMN

HML4P

2 y$y:/e ‘f$$l

4G63

I Engine modelF5M33

y Transaxle model

B14

I Monotone exterior

color code

VEHICLE SAFETY CERTIFICATION LABELNOOCF-

1.The vehicle safety certification label is attached to the face

2. This label indicates the month and year of manufacture,

;eGross Vehicle Weight Rating (G.V.W.R.), Gross Axle

(G.A.W.R.) front and rear, and Vehicle

Identification Number

(V.I.N.).ENGINE MODEL STAMPING

NOOCG-

1.The engine model number is stamped at the front side on

following:

Engine model4637Engine displacement

1.8 liter (107 cu.in.)

[SOHC-MPI]

4G632.0 liter (122 cuin.)

[DOHC-MPI] or

[DOHC-MPI-Turbo]2. The engine serial number is stamped near the engine

model number, and the serial number cycles, as shown

below.Engine serial numberNumber cycling

AA0201 to w9999AA0201 ------- -*AA99997

I1 LAB0001 ------- +AY9999 : 1

I1 t-BAOOOI ------- +YY9999 ’ 1

‘-w

Page 14 of 1216

I4INTRODUCTION AND MASTER TROUBLESHOOTING - Precautions before Service

mm (In.1smo59

PARTSWhen replacing parts, use MOPAR genuine parts.

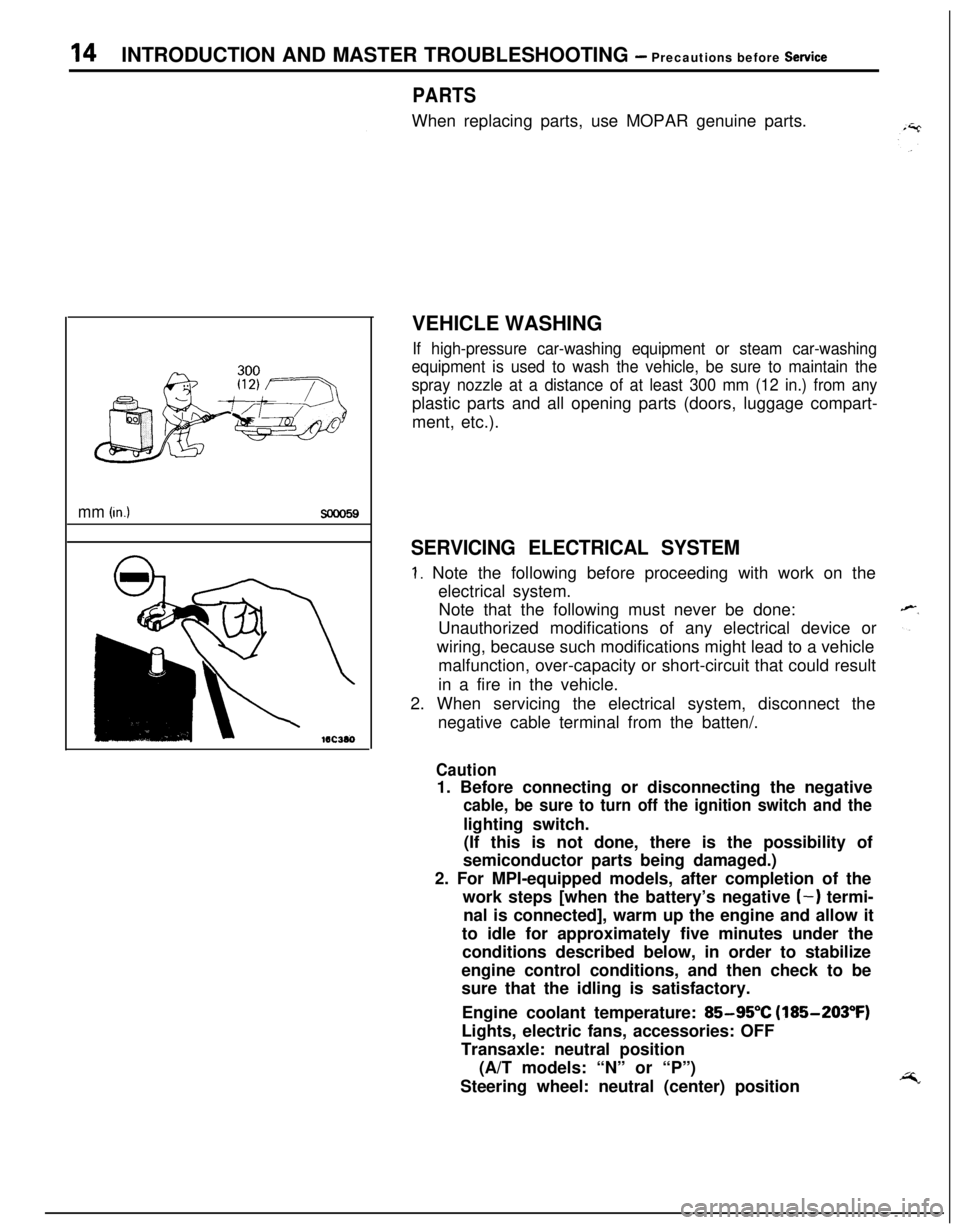

VEHICLE WASHING

If high-pressure car-washing equipment or steam car-washing

equipment is used to wash the vehicle, be sure to maintain the

spray nozzle at a distance of at least 300 mm (12 in.) from anyplastic parts and all opening parts (doors, luggage compart-

ment, etc.).

SERVICING ELECTRICAL SYSTEM

1. Note the following before proceeding with work on the

electrical system.

Note that the following must never be done:

Unauthorized modifications of any electrical device or

wiring, because such modifications might lead to a vehicle

malfunction, over-capacity or short-circuit that could result

in a fire in the vehicle.

2. When servicing the electrical system, disconnect the

negative cable terminal from the batten/.

Caution1. Before connecting or disconnecting the negative

cable, be sure to turn off the ignition switch and thelighting switch.

(If this is not done, there is the possibility of

semiconductor parts being damaged.)

2. For MPI-equipped models, after completion of the

work steps [when the battery’s negative

(-) termi-

nal is connected], warm up the engine and allow it

to idle for approximately five minutes under the

conditions described below, in order to stabilize

engine control conditions, and then check to be

sure that the idling is satisfactory.

Engine coolant temperature:

85-95°C (185-203°F)

Lights, electric fans, accessories: OFF

Transaxle: neutral position

(A/T models: “N” or “P”)

Steering wheel: neutral (center) position

Page 19 of 1216

c

--INTRODUCTION AND MASTER

TROUBLESHOOTtNG - Towing and Hoi&gT9

I-

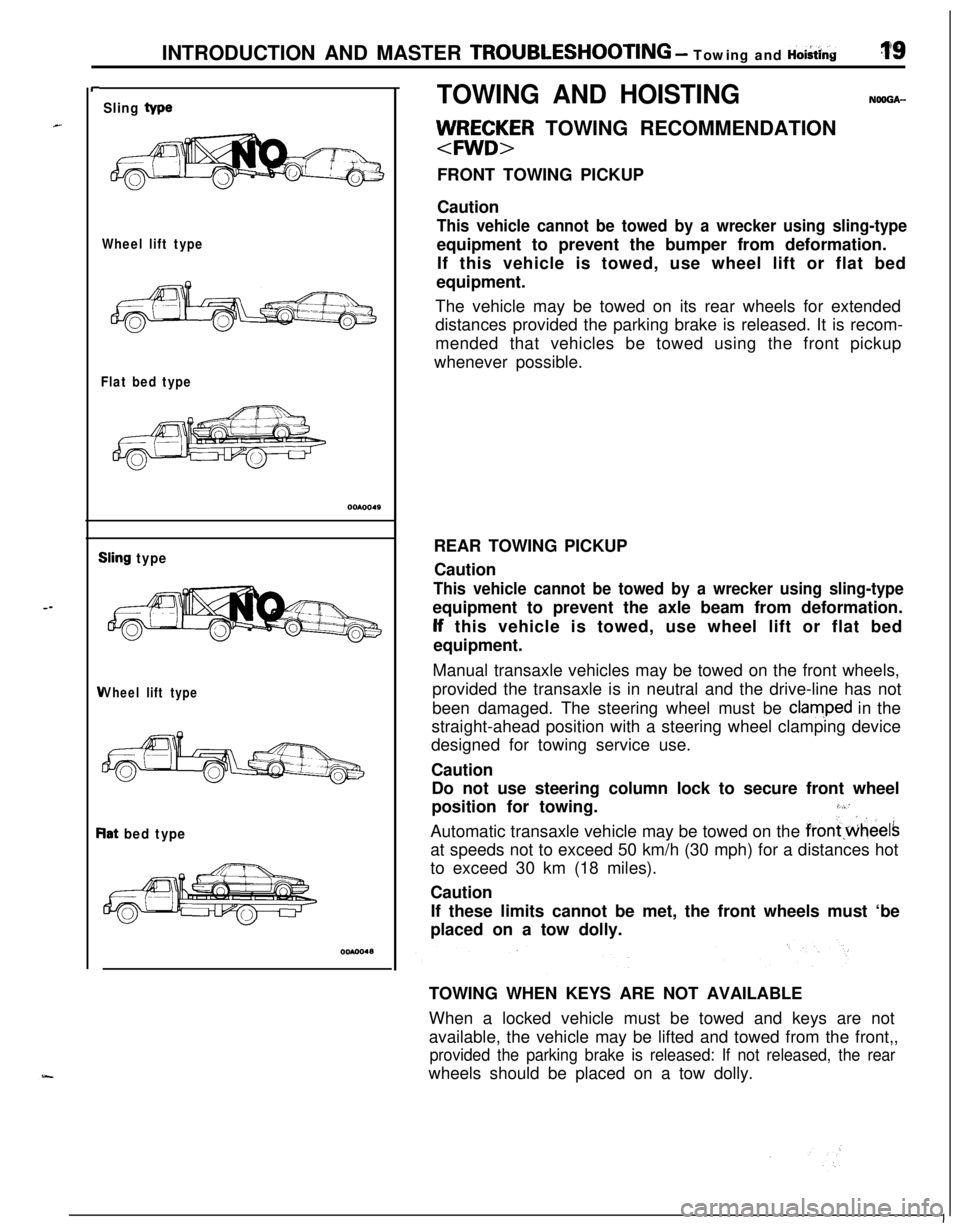

Sling type

Wheel lift type

Flat bed type

iling type

Vheel lift type

lat bed type

TOWING AND HOISTINGNOOGA-

llJ/RE;~R TOWING RECOMMENDATION

FRONT TOWING PICKUP

Caution

This vehicle cannot be towed by a wrecker using sling-typeequipment to prevent the bumper from deformation.

If this vehicle is towed, use wheel lift or flat bed

equipment.

The vehicle may be towed on its rear wheels for extended

distances provided the parking brake is released. It is recom-

mended that vehicles be towed using the front pickup

whenever possible.

REAR TOWING PICKUP

Caution

This vehicle cannot be towed by a wrecker using sling-typeequipment to prevent the axle beam from deformation.lf this vehicle is towed, use wheel lift or flat bed

equipment.

Manual transaxle vehicles may be towed on the front wheels,

provided the transaxle is in neutral and the drive-line has not

been damaged. The steering wheel must be

clam,ped in the

straight-ahead position with a steering wheel clamping device

designed for towing service use.

Caution

Do not use steering column lock to secure front wheel

position for towing.

3,“’Automatic transaxle vehicle may be towed on the

frontwheelsat speeds not to exceed 50 km/h (30 mph) for a distances hot

to exceed 30 km (18 miles).

Caution

If these limits cannot be met, the front wheels must ‘be

placed on a tow dolly.

TOWING WHEN KEYS ARE NOT AVAILABLE

When a locked vehicle must be towed and keys are not

available, the vehicle may be lifted and towed from the front,,

provided the parking brake is released: If not released, the rearwheels should be placed on a tow dolly.

I

Page 36 of 1216

o-2LUBRICATION AND MAINTENANCE - General Information

GENERAL INFORMATIONNGQPA--Maintenance and lubrication service recommenda-

tions have been compiled to provide maximum

protection for the vehicle owner’s investment

against all reasonable types of driving conditions.

Since these conditions vary with the individual

vehicle owner’s driving habits, the area in which the

vehicle is operated and the type of driving to which

the vehicle is subjected, it is necessary to prescribe

lubrication and maintenance service on a time

frequency as well as mileage interval basis.

Oils, lubricants and greases are classified and

graded according to standards recommended by theSociety of Automotive Engineers (SAE), the Amer-

ican Petroleum Institute (API) and the National

Lubricating Grease Institute

(NLGI).MAINTENANCE SCHEDULES

Information for service maintenance is provided

under “SCHEDULED MAINTENANCE TABLE”.

Three schedules are provided; one for “Required

Maintenance”, one for “General Maintenance” and

one for “Severe Usage Service”.

Item numbers in the “SCHEDULED MAINTE-

NANCE TABLE” correspond to the item numbers in

the “MAINTENANCE SERVICE” section.

SEVERE SERVICEVehicles operating under severe service conditions

will require more frequent service.

Component service information is included in

appropriate units for vehicles operating under one ormore of the following conditions:

1.Trailer towing or police, taxi, or commercial type

operation2. Operation of Vehicle

(1) Short-trip operation at freezing temperature

(engine not thoroughly warmed up)

(2) More than 50% operation in heavy city

traffic during hot weather above

32°C (90°F)(3) Extensive idling

(4) Driving in sandy areas

(5) Driving in salty areas

(6) Driving in dusty conditions

ENGINE OIL

The SAE grade number indicates the viscosity of

engine oils, for example, SAE 30, which is a single

grade oil. Engine oils are also identified by a dual

number, for example, SAE

lOW-30, which indicates

a multigrade oil.

The API classification system defines oil perform-

ance in terms of engine usage. Only engine oil

designed “For Service SG” or “For Service

SGKD”,when available, should be used. These oils contain

sufficient chemical additives to provide maximum

engine protection. Both the SAE grade and the API

designation can be found on the container.Caution

Test results submitted to EPA have shown thatlaboratory animals develop skin cancer after

prolonged contact with used engine oil. Accor-

dingly, the potential exists for humans

to de-

velop a number of skin disorders, including

cancer, from such exposure to used engine oil.

Care should be’ taken, therefore, when changingengine oil, to minimize the amount and length of

exposure time to used engine

pi! on your skin.

Protective clothing and gloves, that cannot be

penetrated by oil, should be worn. The skin

should be thoroughly washed with soap and

water, or use waterless hand cleaner, to removeany used engine oil. Do not use gasoline,

thinners, or solvents.

GEAR LUBRICANTSThe SAE grade number also indicates the viscosity

of Multi-Purpose Gear Lubricants.

The API classfication system defines gear lubricants

in terms of usage. Typically gear lubricants conform-ing to API

GL-4 or GL-5 with a viscosity of SAE

75W-85W are recommended for manual transaxle.

LUBRICANTS

- GREASES

Semi-solid lubricants, bear the NLGI designation andare further classified as grades 0, 1, 2, 3 etc.

Whenever “Chassis Lubricant” is specified, Multi-

Purpose Grease,

NLGI grade 2 should be used.

MOPAR Multi-Mileage Lubricant, P&t Number

2525035 or equivalent, meets these requirement

and is recommended.

FUEL USAGE STATEMENT

Use gasolines having a minimum anti-knock index

(Octane Value) of 87,

(R + M)/2. This designation is

comparable to a Research Octane Number of 91.

Unleaded gasolines only must be used in vehicles

equipped with catalyst emission control systems.

All vehicles, so equipped, have labels located on the

instrument panel and on the back of fuel filler lid that

state, “UNLEADED GASOLINE ONLY”. These vehi-

cles also have fuel filler tubes especially designed toaccept the smaller diameter unleaded gasoline

dispensing nozzles only.

MATERIALS ADDED

TO FUELIndiscriminate use of fuel system cleanng agents

should be avoided. Many of these materials in-

tended for gum and varnish removal may contain

highly active solvents or similar ingredients that can

be harmful to gasket and diaphragm materials usedin fuel system component parts.

Page 50 of 1216

2-2FRONT SUSPENSION - Specifications

SPECIFICATIONS

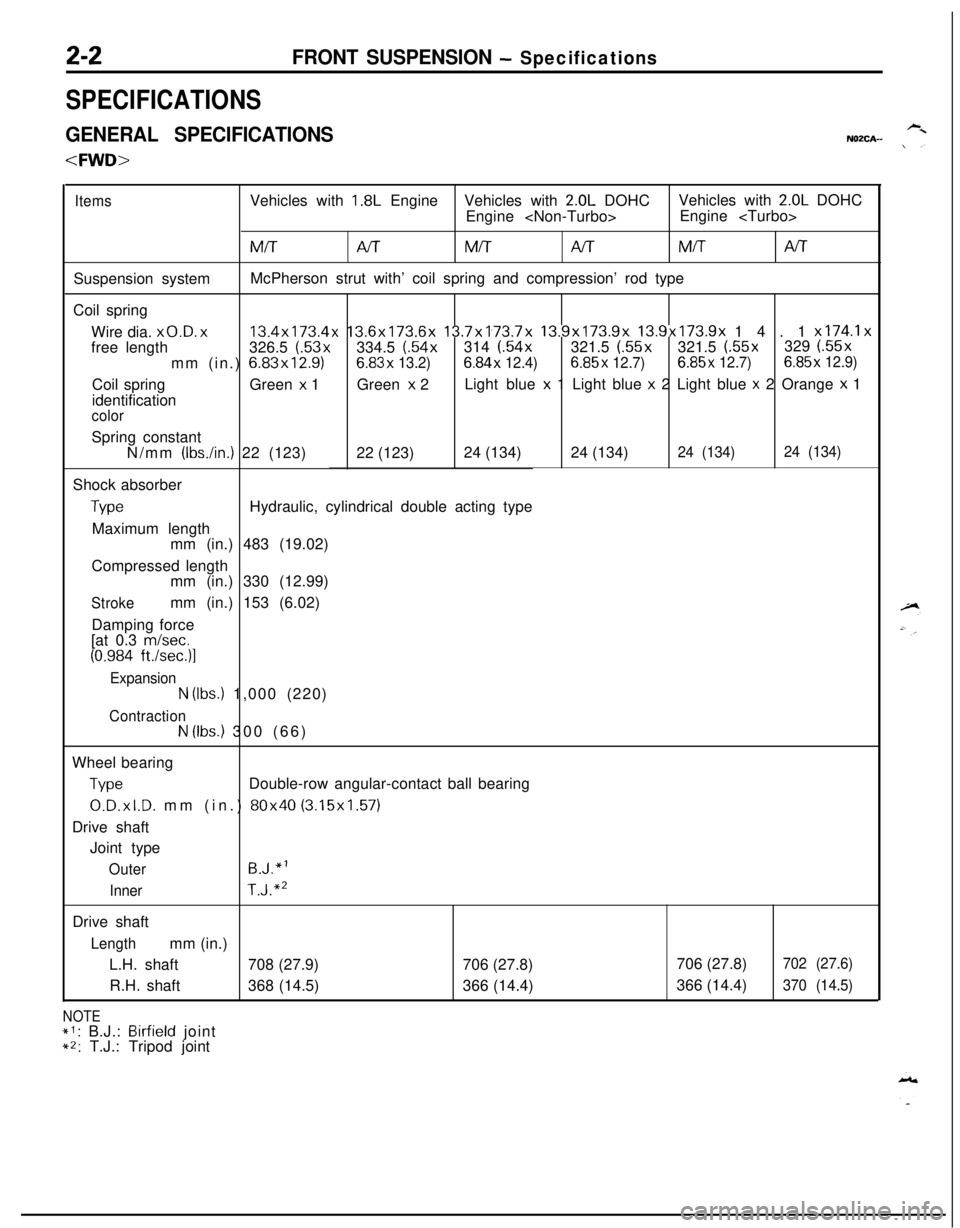

GENERAL SPECIFICATIONSNOZCA-

ItemsVehicles with 1.8L EngineVehicles with 2.0L DOHCVehicles with 2.0L DOHC

Engine

MM/TAITMITNTSuspension systemMcPherson strut with’ coil spring and compression’ rod type

Coil spring

Wire dia.

x0.D. x13.4x173.4x 13.6x173.6x 13.7x173.7x 13.9x173.9x 13.9x173.9x 14.1 x174.1xfree length326.5 (.53x334.5 (.54x314 (.54x321.5 (.55x321.5 (.55x329 (.55x

mm (in.) 6.83x12.9)6.83x

13.2)6.84x 12.4)6.85x 12.7)6.85x 12.7)6.85x 12.9)Coil springGreen

x 1Green x 2Light blue x 1 Light blue x 2 Light blue x 2 Orange x 1

identification

colorSpring constant

N/mm

(IbsAn.) 22 (123)22 (123)24 (134)24 (134)24 (134)24 (134)Shock absorber

TypeHydraulic, cylindrical double acting type

Maximum length

mm (in.) 483 (19.02)

Compressed length

mm (in.) 330 (12.99)

Strokemm (in.) 153 (6.02)

Damping force

[at 0.3

m/set.

(0.984 ft./sec.)l

Expansion

N (Ibs.) 1,000 (220)

ContractionN (Ibs.) 300 (66)

Wheel bearing

TypeDouble-row angular-contact ball bearing

0.D.xl.D. mm (in.) 80x40 (3.15x1.57)

Drive shaft

Joint type

OuterB.J.“l

InnerT.J.“’Drive shaft

Lengthmm (in.)

L.H. shaft708 (27.9)706 (27.8)

R.H. shaft368 (14.5)366 (14.4)

NOTE*1: B.J.: Birfield joint*2: T.J.: Tripod joint706 (27.8)

702 (27.6)366 (14.4)

370 (14.5)

Page 51 of 1216

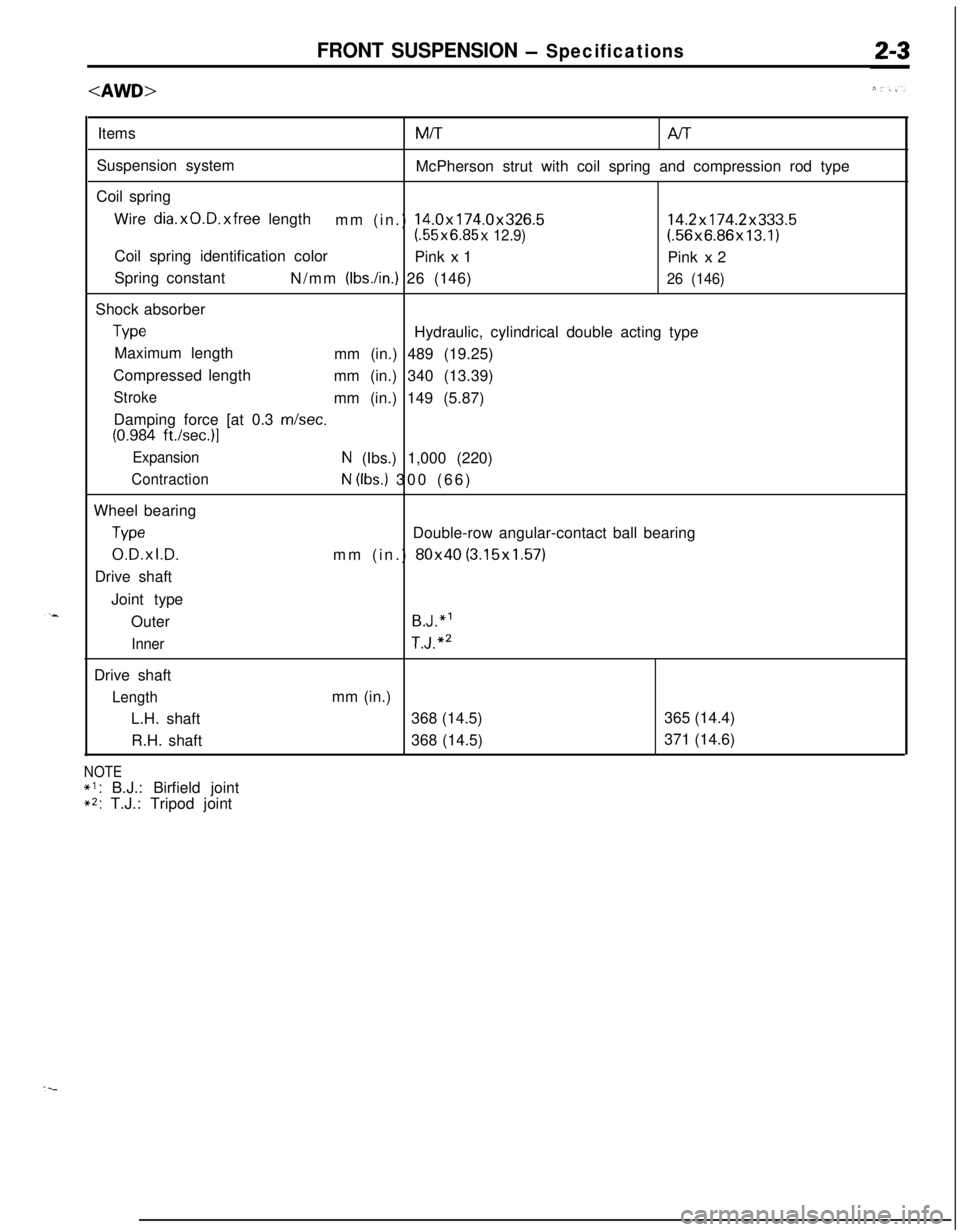

FRONT SUSPENSION - SpecificationsItemsMiT

Al-rSuspension system

McPherson strut with coil spring and compression rod type

Coil spring

Wire

dia.xO.D.xfree length

mm (in.) 14.0x174.0x326.514.2x174.2x333.5(.55x6.85x 12.9)(.56x6.86x13.1)

Coil spring identification color

Pink

x 1

Pink x 2

Spring constant

N/mm

(Ibs./in.) 26 (146)26 (146)Shock absorber

TypeHydraulic, cylindrical double acting type

Maximum length

mm (in.) 489 (19.25)

Compressed length

mm (in.) 340 (13.39)

Strokemm (in.) 149 (5.87)

Damping force [at 0.3 m/set.

(0.984 ft./set.)]

ExpansionN (Ibs.) 1,000 (220)

ContractionN (Ibs.) 300 (66)

Wheel bearing

TypeDouble-row angular-contact ball bearing

0.D.xl.D.mm (in.) 80x40 (3.15x1.57)

Drive shaft

Joint type

Outer

B.J.“’

InnerT.J.“’Drive shaft

Lengthmm (in.)

L.H. shaft368 (14.5)365 (14.4)

R.H. shaft368 (14.5)371 (14.6)

NOTE

*I: B.J.: Birfield joint**: T.J.: Tripod joint

Page 109 of 1216

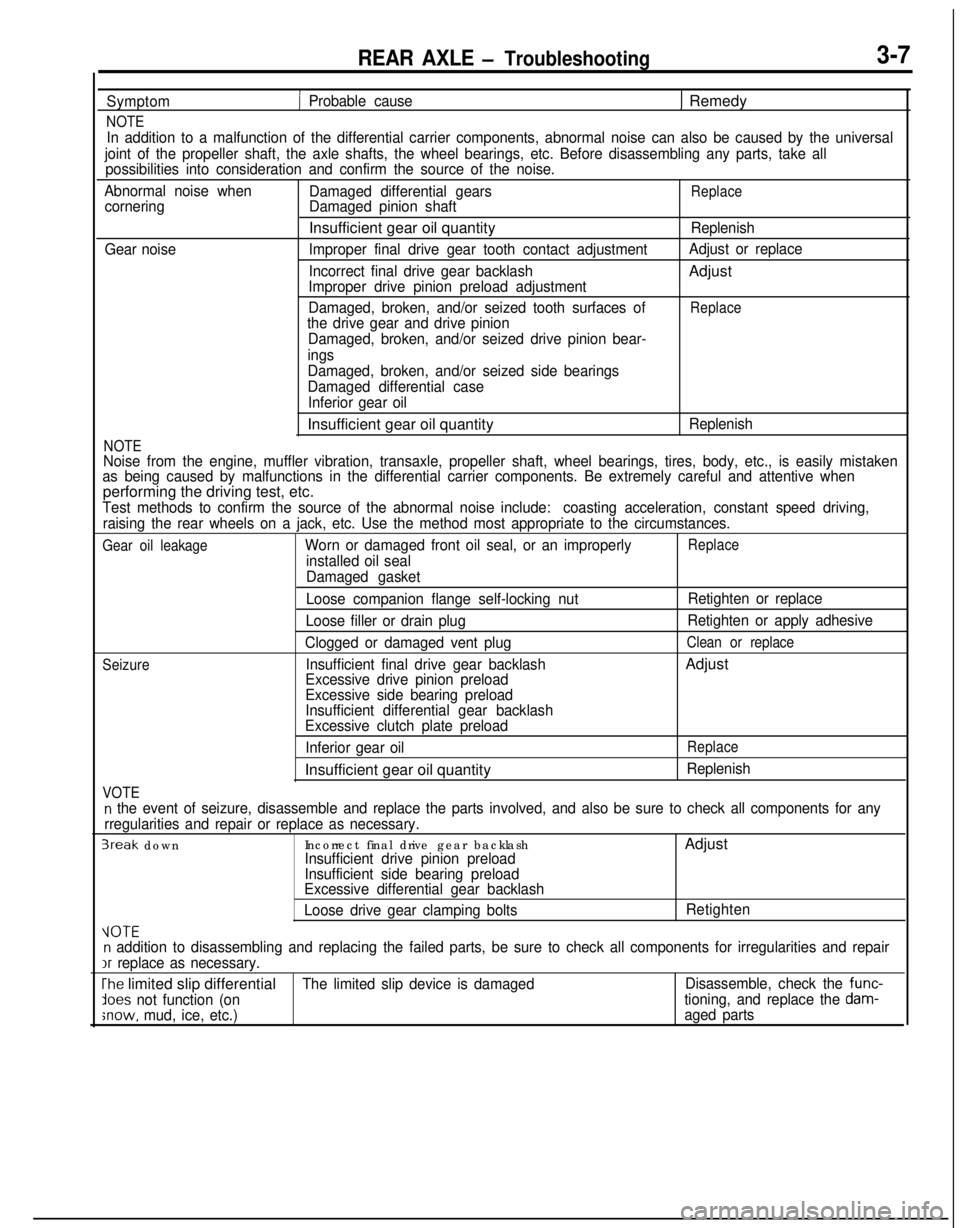

REAR AXLE - Troubleshooting3-7

Symptom

NOTE

1 Probable cause1 Remedy

In addition to a malfunction of the differential carrier components, abnormal noise can also be caused by the universal

joint of the propeller shaft, the axle shafts, the wheel bearings, etc. Before disassembling any parts, take all

possibilities into consideration and confirm the source of the noise.

Abnormal noise when

Damaged differential gears

ReplacecorneringDamaged pinion shaftInsufficient gear oil quantity

Replenish

Gear noiseImproper final drive gear tooth contact adjustmentAdjust or replace

Incorrect final drive gear backlashAdjust

Improper drive pinion preload adjustment

Damaged, broken, and/or seized tooth surfaces of

Replacethe drive gear and drive pinion

Damaged, broken, and/or seized drive pinion bear-

ings

NOTE

Damaged, broken, and/or seized side bearings

Damaged differential case

Inferior gear oilInsufficient gear oil quantity

Replenish

Noise from the engine, muffler vibration, transaxle, propeller shaft, wheel bearings, tires, body, etc., is easily mistaken

as being caused by malfunctions in the differential carrier components. Be extremely careful and attentive whenperforming the driving test, etc.

Test methods to confirm the source of the abnormal noise include:coasting acceleration, constant speed driving,

raising the rear wheels on a jack, etc. Use the method most appropriate to the circumstances.

Gear oil leakageWorn or damaged front oil seal, or an improperlyReplace

installed oil seal

Damaged gasket

Seizure

VOTE

Loose companion flange self-locking nut

Loose filler or drain plug

Clogged or damaged vent plug

Insufficient final drive gear backlash

Excessive drive pinion preload

Excessive side bearing preload

Insufficient differential gear backlash

Excessive clutch plate preload

Inferior gear oilInsufficient gear oil quantityRetighten or replace

Retighten or apply adhesive

Clean or replaceAdjust

Replace

Replenish

n the event of seizure, disassemble and replace the parts involved, and also be sure to check all components for any

rregularities and repair or replace as necessary.

3reak downIncorrect final drive gear backlashAdjustInsufficient drive pinion preload

Insufficient side bearing preload

Excessive differential gear backlash

Loose drive gear clamping boltsRetighten

VOTEn addition to disassembling and replacing the failed parts, be sure to check all components for irregularities and repairIr

replace as necessary.

The limited slip differentialThe limited slip device is damagedDisassemble, check the func-

lees not function (ontioning, and replace the dam-

;now, mud, ice, etc.)aged parts