Mpi MITSUBISHI ECLIPSE 1991 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 612 of 1216

17-2REAR SUSPENSION

GENERAL SPECIFICATIONS

LN17CAA

ItemsVehicles with 1.8L EngineVehicles with 2.0L DOHC

Engine

jSuspension system

3-link, torsion axle with coil spring type

Coil spring

Wire dia.

x O.D. x free length

mm (in.) 10.1 x 105.1 x 336.510.2 x 105.2 x 316.5

(40 x 4.14 x 13.25)(40 x 4.14 x 12.46)

[Coil spring identification color]

[Light Blue

x 11[Orange x 11Spring constant

N/mm

(Ibs./in.) 20 (112.0)23 (128.8)

Shock absorber

TypeHydraulic, cylindrical, double-acting type

Max. length

mm (in.) 495 (19.5)485 (19.1)

Min. length

mm (in.) 315 (12.4)315 (12.4)

Strokemm (in.) 180 (7.1)170 (6.7)Damping force [at 0.3 m/set. (0.9

ft./set.)]

ExpansionN (Ibs.)800 (176)

ContractionN (Ibs.)300 (66)

Wheel bearing

TypeUnit ball bearing

SERVICE SPECIFICATIONS

Items

Standard valueToe-in (Left-right difference)

Camber

LimitWheel bearing end play

Rear hub rotary-sliding resistance

Rear hub rotary-sliding torque

NOTEToe-in and camber cannot be adjusted.mm (in.)

mm (in.)

N (Ibs.)

Nm

(ftlbs.)

TORQUE SPECIFICATIONS

Specifications

0+3 (Of.1 18)

-45’

f 30’

0.01 (004) or less

31

(7) or less

1.8

(1.30) or lessNI’ICB-A

ItemsNmft.lbs.

Wheel bearing nut

Shock absorber upper mounting nut

Shock absorber lower mounting nut

Lateral rod mounting nut (body side)

Lateral rod mounting bolt (axle beam side)

Trailing arm mounting bolt

Piston rod tightening nut

Brake hose and tube bracket mounting bolt

Caliper assembly mounting nut

Rear speed sensor mounting bolt

200-260

40-50

80- 100

80-100

100-120

100-120

20-2517-26

50-609-14144-188

29-36

58-72

58-72

72-87

72-87

14-18

12-19

36-43

I7-10

Nl7CGA

Page 626 of 1216

17-16REAR SUSPENSION

SPECIFICATIONS

GENERAL SPECIFICATIONSNl’ICA-B jG

ItemsSpecifications

Suspension systemDouble wishbone suspension type

Coil spring

Wire dia. x O.D.

x free lengthmm (in.)11.0 x 106.0 x 332.5 (.43 x 4.17 x 13.1)Coil spring identification colorPurple

x 1Spring constantN/mm

(Ibs./in.) 25.0 (140)

Shock absorber

TypeHydraulic, cylindrical, double-acting type

Max. lengthmm (in.) 568

(22.4)Min. lengthmm (in.) 380

(15.0)

Strokemm (in.) 188 (7.4)

Damping force [at 0.3 m/set. (0.9

ft./set.)]

ExpansionN (Ibs.) 900 (198)

ContractionN (Ibs.) 300 (66)

SERVICE SPECIFICATIONS

Items

Standard value

Toe-in

CamberSpecificationsmm (in.) 3.6+3 (.14f.l18)

-1"33'f30'

Nl7CEB

:&

Page 901 of 1216

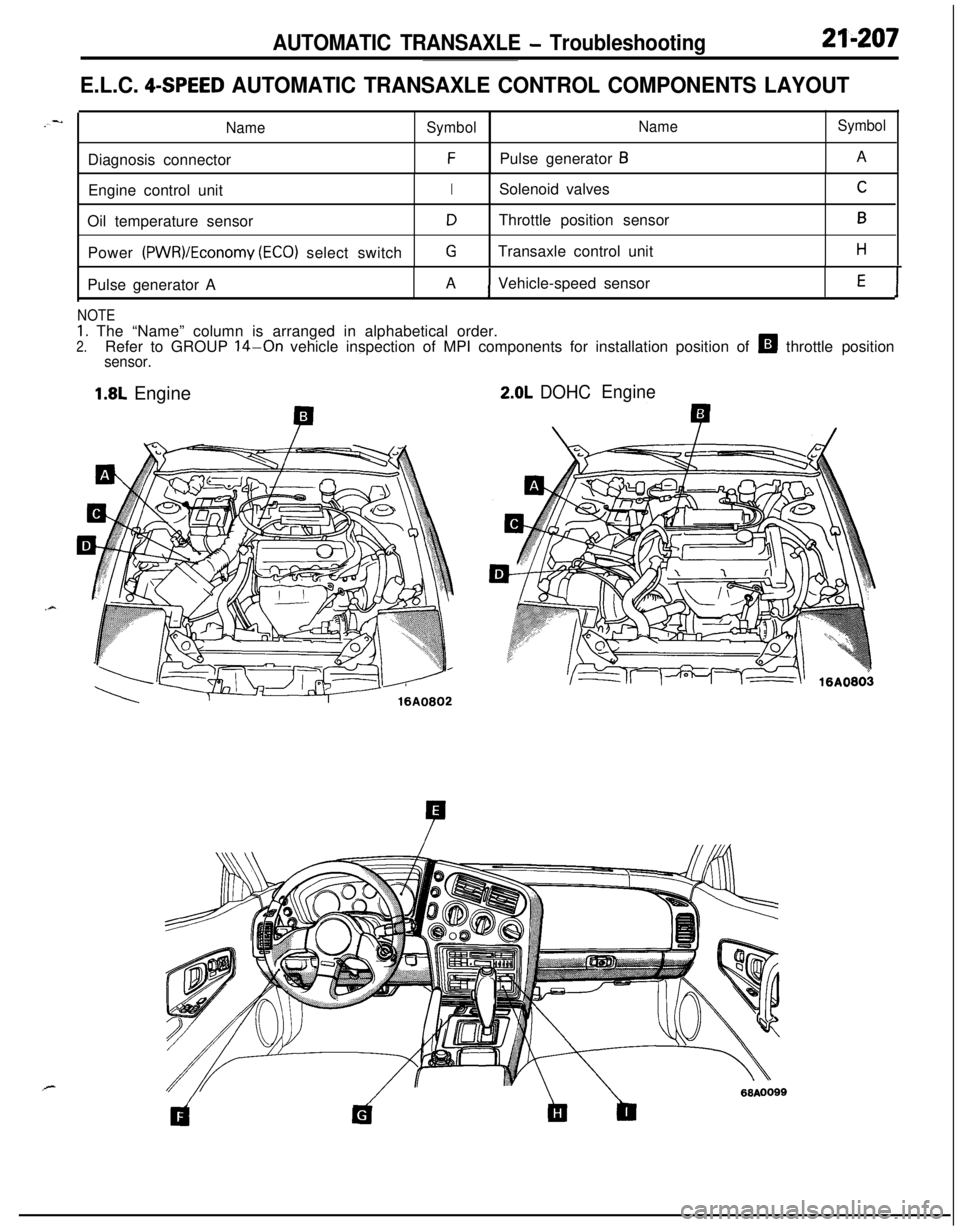

AUTOMATIC TRANSAXLE - Troubleshooting21-207

E.L.C. 4-SPEED AUTOMATIC TRANSAXLE CONTROL COMPONENTS LAYOUT

NameSymbolNameSymbolDiagnosis connector

FPulse generator BA

Engine control unit

ISolenoid valvesCOil temperature sensor

DThrottle position sensorBPower

(PWR)/Economy (ECO) select switchGTransaxle control unitHPulse generator AAVehicle-speed sensor

E1

NOTE

1. The “Name” column is arranged in alphabetical order.2.Refer to GROUP 14-On vehicle inspection of MPI components for installation position of H throttle positionsensor.

1.8L Engine2.0L DOHCEngine

Page 1149 of 1216

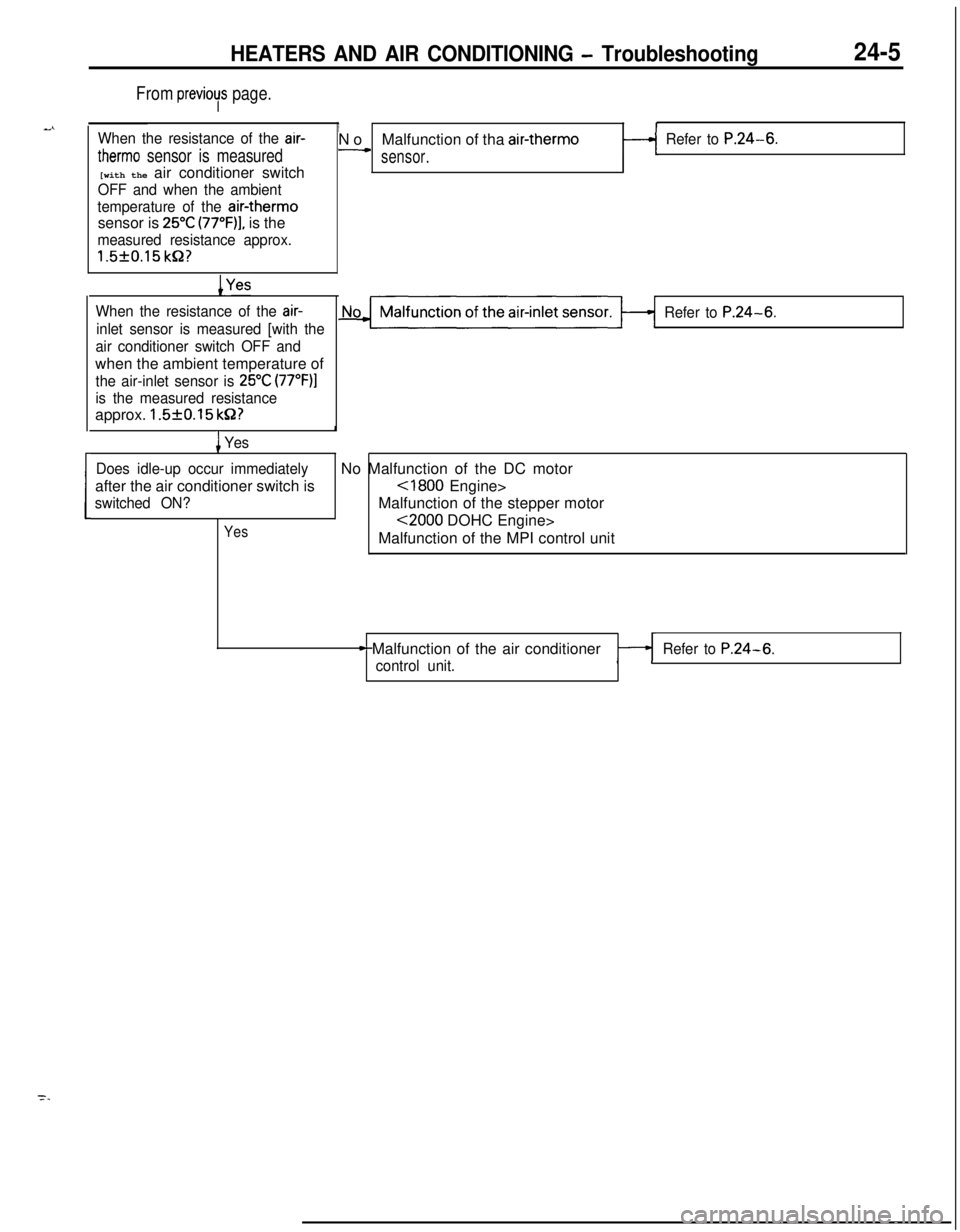

HEATERS AND AIR CONDITIONING - Troubleshooting24-5

From previoys page.

When the resistance of the air-

therm0 sensor is measured[with the air conditioner switch

OFF and when the ambient

temperature of the

air-therm0sensor is

25°C (77“F)], is the

measured resistance approx.

1.5f0.15 kP?

INoMalfunction of tha air-therm0Refer to P.24-6.-sensor.

Refer to P.24-6.

1Yes

When the resistance of the air-

inlet sensor is measured [with the

air conditioner switch OFF andwhen the ambient temperature of

the air-inlet sensor is 25°C (77”F)l

is the measured resistanceapprox.

1.5f0.15 k&2?I

1 Yes

Does idle-up occur immediatelyNo Malfunction of the DC motor

after the air conditioner switch is

cl800 Engine>

switched ON?Malfunction of the stepper motor

Yes~2000 DOHC Engine>

Malfunction of the MPI control unit

* Malfunction of the air conditioner

control unit.Refer to P.24-6.

Page 1150 of 1216

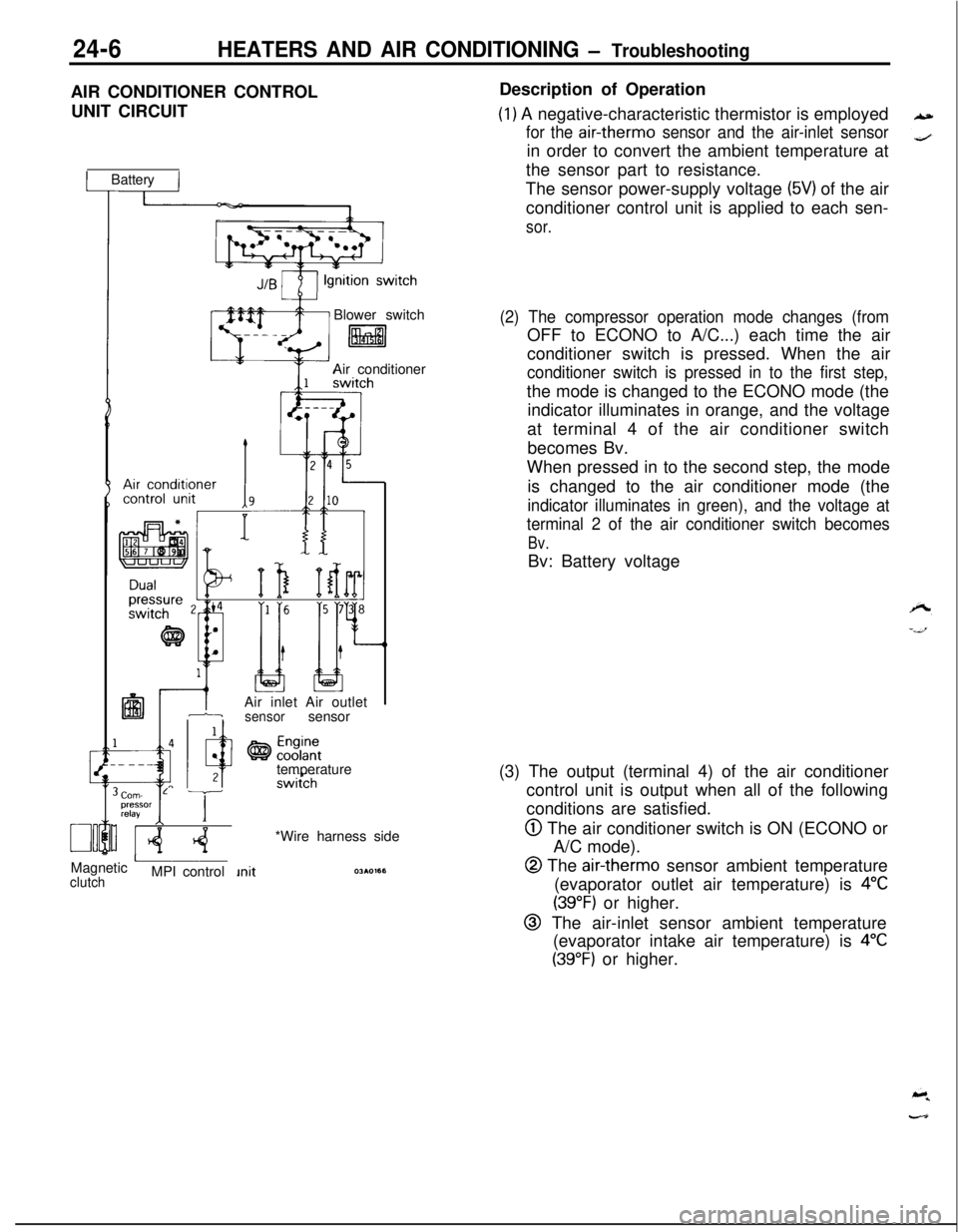

24-6HEATERS AND AIR CONDITIONING - TroubleshootingAIR CONDITIONER CONTROL

UNIT CIRCUIT

1 Battery IBlower switch

litalAir conditioner

IAir inlet Air outlet1-isensorsensor

temperature

Corn- L Tpressor

relayI IMagnetic

AclutchMPI control*Wire harness sideDescription of Operation

(1) A negative-characteristic thermistor is employed

for the air-therm0 sensor and the air-inlet sensorin order to convert the ambient temperature at

the sensor part to resistance.

The sensor power-supply voltage

(5V) of the air

conditioner control unit is applied to each sen-

sor.

(2) The compressor operation mode changes (fromOFF to ECONO to A/C...) each time the air

conditioner switch is pressed. When the air

conditioner switch is pressed in to the first step,the mode is changed to the ECONO mode (the

indicator illuminates in orange, and the voltage

at terminal 4 of the air conditioner switch

becomes Bv.

When pressed in to the second step, the mode

is changed to the air conditioner mode (the

indicator illuminates in green), and the voltage at

terminal 2 of the air conditioner switch becomes

Bv.Bv: Battery voltage

(3) The output (terminal 4) of the air conditioner

control unit is output when all of the following

conditions are satisfied.

@ The air conditioner switch is ON (ECONO or

A/C mode).

@ The air-therm0 sensor ambient temperature

(evaporator outlet air temperature) is

4°C

(39°F) or higher.

@ The air-inlet sensor ambient temperature

(evaporator intake air temperature) is

4°C

(39°F) or higher.

Page 1187 of 1216

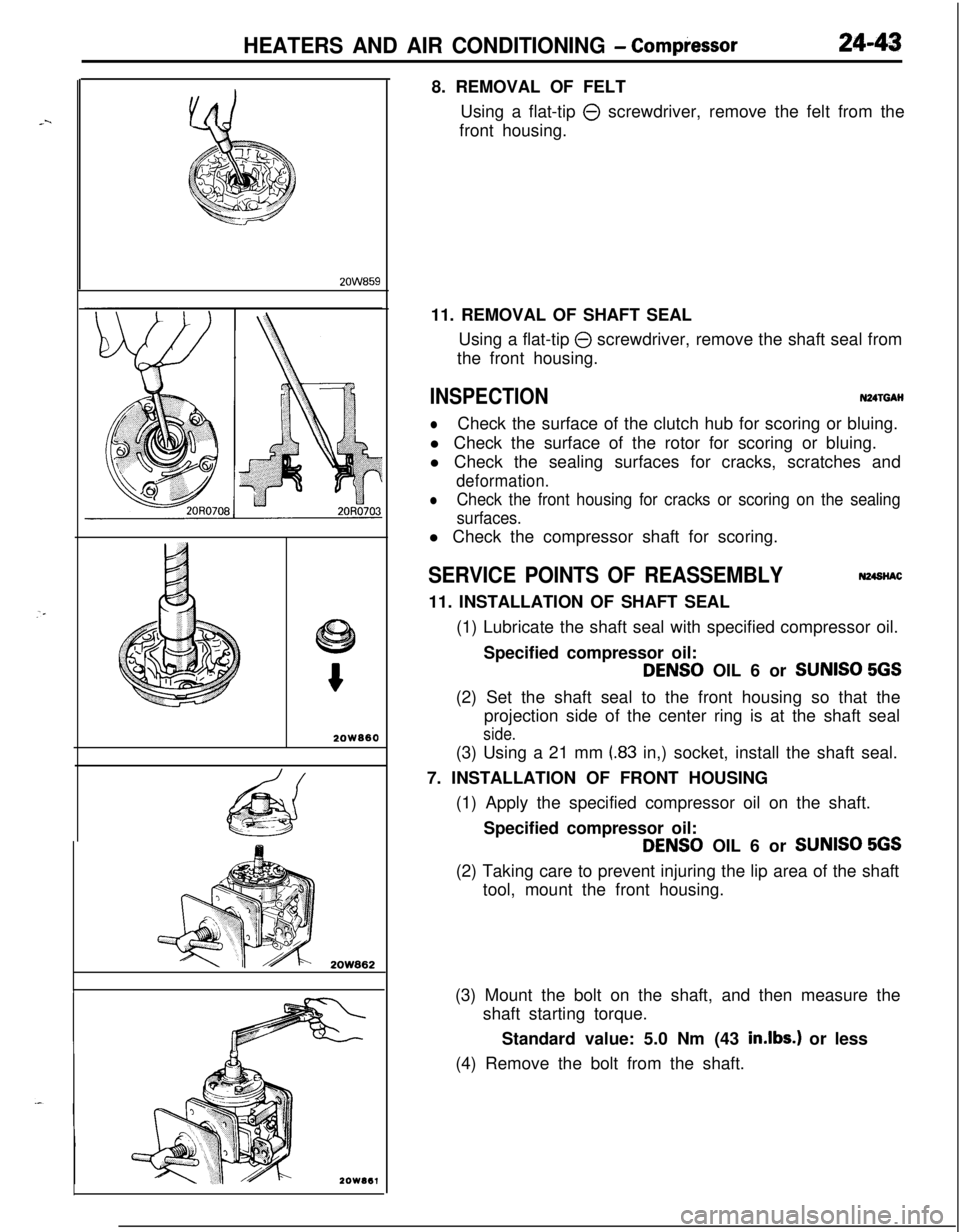

HEATERS AND AIR CONDITIONING - Compiessor24-43

2OW660

2OW8628. REMOVAL OF FELT

Using a flat-tip

0 screwdriver, remove the felt from the

front housing.

11. REMOVAL OF SHAFT SEAL

Using a flat-tip

0 screwdriver, remove the shaft seal from

the front housing.

INSPECTIONN24TGAH

lCheck the surface of the clutch hub for scoring or bluing.

l Check the surface of the rotor for scoring or bluing.

l Check the sealing surfaces for cracks, scratches and

deformation.

lCheck the front housing for cracks or scoring on the sealing

surfaces.l Check the compressor shaft for scoring.

SERVICE POINTS OF REASSEMBLYN24StiAC11. INSTALLATION OF SHAFT SEAL

(1) Lubricate the shaft seal with specified compressor oil.

Specified compressor oil:

DENS0 OIL 6 or SUNISO 5GS(2) Set the shaft seal to the front housing so that the

projection side of the center ring is at the shaft seal

side.(3) Using a 21 mm

(.83 in,) socket, install the shaft seal.

7. INSTALLATION OF FRONT HOUSING

(1) Apply the specified compressor oil on the shaft.

Specified compressor oil:

DENS0 OIL 6 or SUNISO 5GS(2) Taking care to prevent injuring the lip area of the shaft

tool, mount the front housing.

(3) Mount the bolt on the shaft, and then measure the

shaft starting torque.

Standard value: 5.0 Nm (43

in.lbs.) or less

(4) Remove the bolt from the shaft.

Page 1191 of 1216

HEATERS AND AIR CONDITIONING - Refrigerant Line24-47

REFRIGERANT LINE

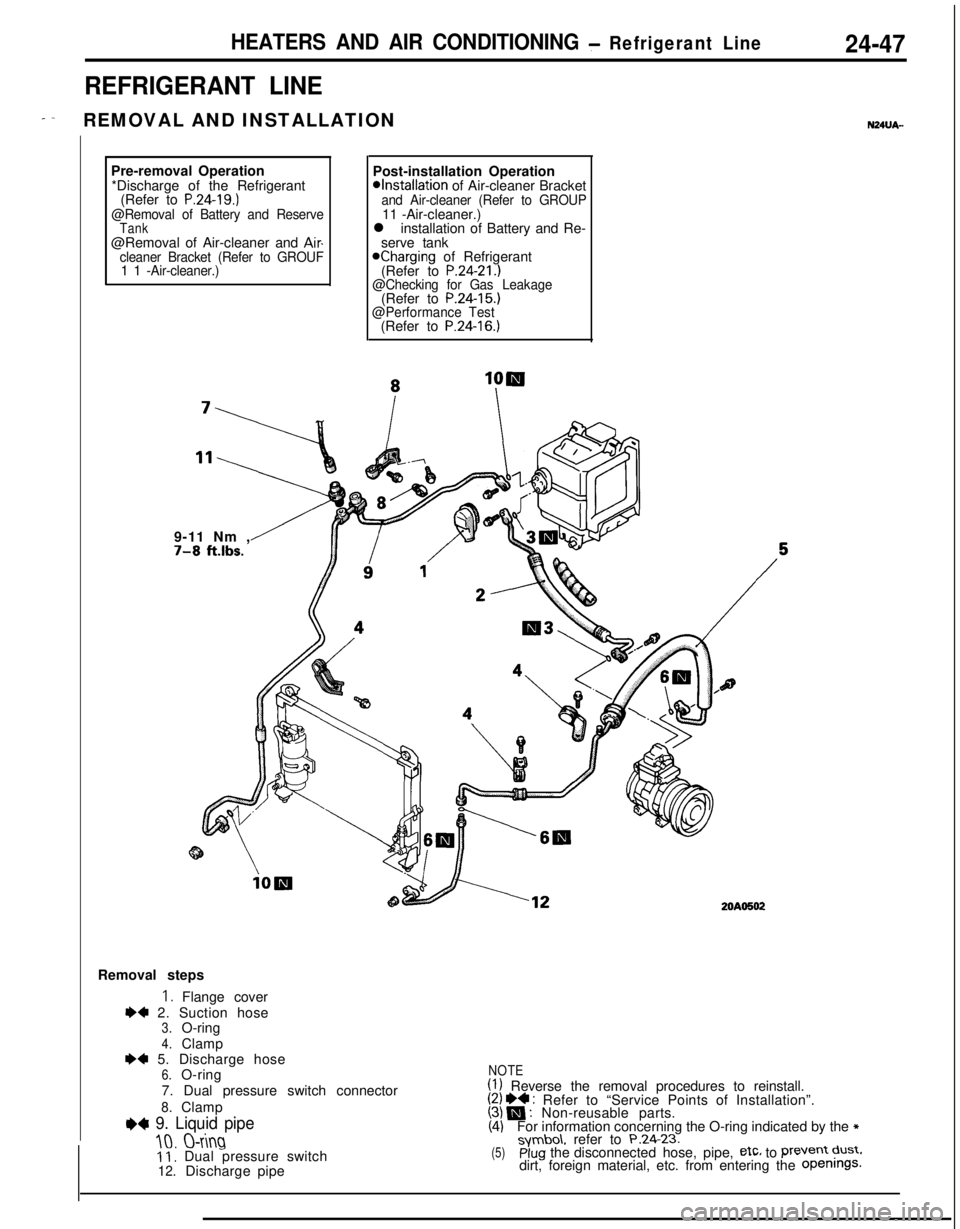

- -REMOVAL AND INSTALLATIONN24UA-Pre-removal Operation

*Discharge of theRefrigerant

(Refer to

P.24-19.)@Removal of Battery and ReserveTank@Removal of Air-cleaner and Aircleaner Bracket (Refer to GROUF

1 1 -Air-cleaner.)Post-installation Operation

@Installation of Air-cleaner Bracketand Air-cleaner (Refer to GROUP11 -Air-cleaner.)

l installation of Battery and Re-

serve tank

Kharging of Refrigerant

(Refer to P.24-21.)@Checking for Gas(Refer to P.24-15.)Leakage

@Performance Test(Refer to

P.24-16.)9-11 Nm ,

7-8 ft.lbs.

20AO502Removal steps

I. Flange cover

I)+ 2. Suction hose3.O-ring

4.ClampI)* 5. Discharge hose6.O-ring

7. Dual pressure switch connector

8.Clamp

e+ 9. Liquid pipe

10.O-ring11, Dual pressure switch12.Dischargepipe

NOTE(1) Reverse the removal procedures to reinstall.(2) I)4 : Refer to “Service Points of Installation”.(3) N : Non-reusable parts.(4)For information concerning the O-ring indicated by the *symbo\. refer to P.24.23.(5)plug the disconnected hose, pipe, etc, to Prevent dust.dirt, foreign material, etc. from entering the Openings.

Page 1197 of 1216

.^

EMISSION CONTROL

SYSTEMS

CONTENTSN25AA-

CATALYTICCONVERTER...............................20CRANKCASE EMISSION CONTROL

SYSTEM...........................................................7Components Location

...................................7Crankcase Ventilation System

Inspection......................................................8Positive Crankcase Ventilation Valve

...........8EVAPORATIVE EMISSION CONTROL

SYSTEM...........................................................9

AirConditionerSwitch.................................14Air Flow Sensor, Engine Coolant

Temperature Sensor and Intake Air

Temperature Sensor

.....................................14

Canister.........................................................14Components Location

...................................9

FuelFillerCapInspection............................14Overfill Limiter (Two-way Valve)

..................14

PurgeControlSolenoidValve......................13Purge Control

SystemInspection................11

PurgeControlValve

SYSTEM...........................................................15Air-fuel Ratio Control (MPI) System

............20Components Location

...................................15EGR Control Solenoid Valve

.................................................19

EGR

SystemInspection...............................17EGR Temperature Sensor

......19

EGR Valve.....................................................18

Therm0 Valve

SPECIFICATIONS.............................................2General Specifications

..................................2

Sealant..........................................................2Service Specifications

...................................2

TorqueSpecifications...................................2

TROUBLESHOOTING......................................3

VACUUMHOSES...........................................4

VacuumHosesRouting...............................4

Page 1210 of 1216

![MITSUBISHI ECLIPSE 1991 Repair Manual 25-14EMISSION CONTROL SYSTEMS- Evaporative Emission Control System

(5) Measure the resistance between the terminals of the

solenoid valve.

Standard value: 36-44

Q [at 20°C (68OF)]_

6EM137

AIR FLOW S MITSUBISHI ECLIPSE 1991 Repair Manual 25-14EMISSION CONTROL SYSTEMS- Evaporative Emission Control System

(5) Measure the resistance between the terminals of the

solenoid valve.

Standard value: 36-44

Q [at 20°C (68OF)]_

6EM137

AIR FLOW S](/img/19/57104/w960_57104-1209.png)

25-14EMISSION CONTROL SYSTEMS- Evaporative Emission Control System

(5) Measure the resistance between the terminals of the

solenoid valve.

Standard value: 36-44

Q [at 20°C (68OF)]_

6EM137

AIR FLOW SENSOR, ENGINE COOLANT TEMPER-

ATURE SENSOR AND INTAKE AIR TEMPERA-

TURE SENSORTo inspect these parts, refer to GROUP

14-MPI System

Components.‘.

AIR CONDITIONER SWITCHTo inspect the air conditioner switch, refer to GROUP

24’--AirConditioner Switch.

OVERFILL LIMITER (TWO-WAY VALVE)N2BlBE&To inspect the overfill limiter (two-way valve), refer to GROUP

14-Fuel Tank.

CANISTERNzslBmTo inspect the canister, refer to GROUP

14-Fuel Line and

Vapor Line.

FUEL FILLER CAP INSPECTIONNZSIBJACheck the gasket of the fuel filler cap, and, the filler cap itself,

for damage or deformation; replace the cap if necessary.

Page 1216 of 1216

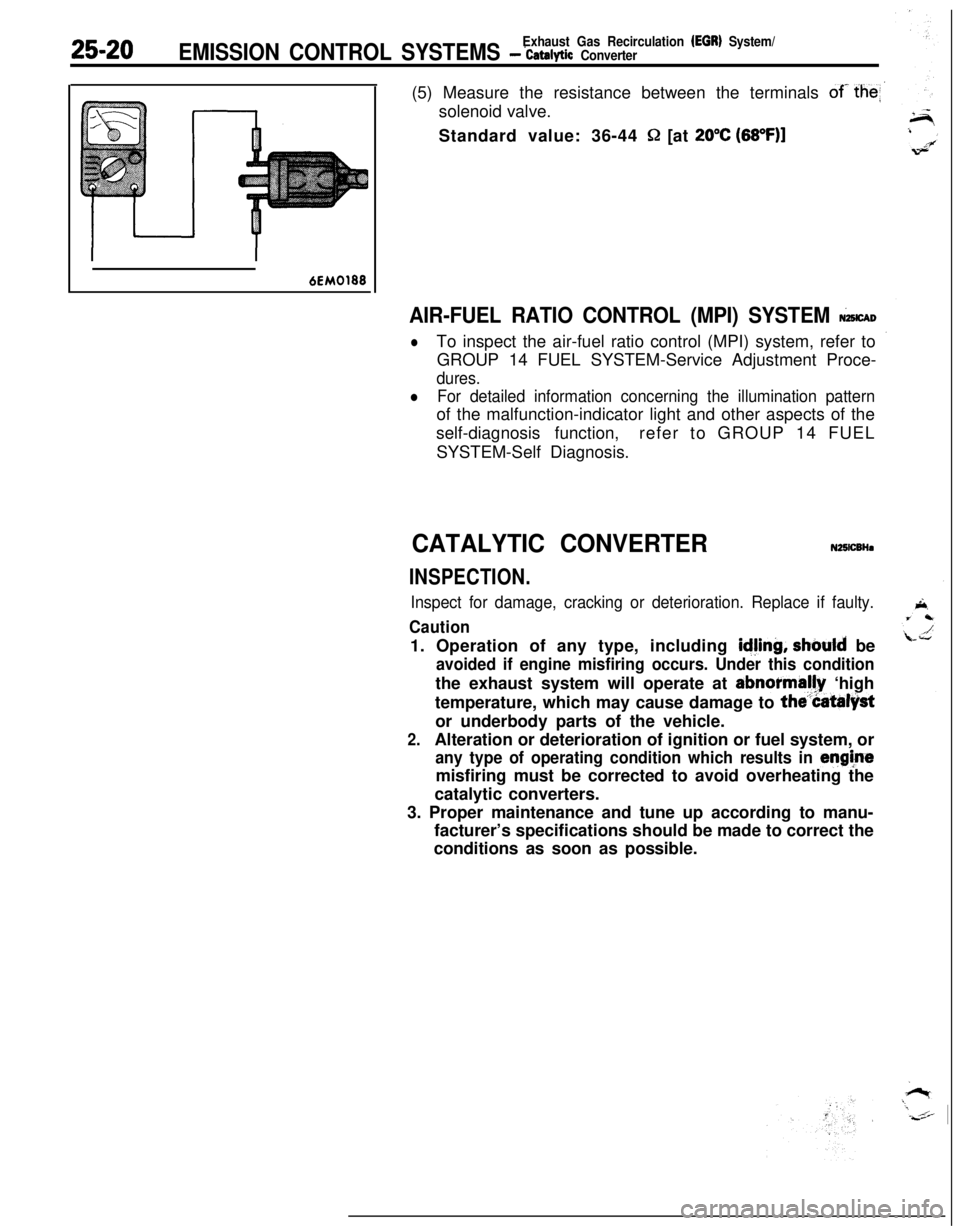

25-20Exhaust Gas Recirculation (EGR) System/EMISSION CONTROL SYSTEMS - ‘catalytic Converter(5) Measure the resistance between the terminals

of- the

Q [at 20°C (68OF)l

6EM0188

AIR-FUEL RATIO CONTROL (MPI) SYSTEM &CAD

lTo inspect the air-fuel ratio control (MPI) system, refer to

GROUP 14 FUEL SYSTEM-Service Adjustment Proce-

dures.

lFor detailed information concerning the illumination patternof the malfunction-indicator light and other aspects of the

self-diagnosis function,refer to GROUP 14 FUEL

SYSTEM-Self Diagnosis.

CATALYTIC CONVERTERN25lCBHa

INSPECTION.

Inspect for damage, cracking or deterioration. Replace if faulty.

Caution1. Operation of any type, including

idjing, should be

avoided if engine misfiring occurs. Under this conditionthe exhaust system will operate at abnormally ‘high

temperature, which may cause damage to

the”Catalystor underbody parts of the vehicle.

2.Alteration or deterioration of ignition or fuel system, or

any type of operating condition which results in enghtemisfiring must be corrected to avoid overheating the

catalytic converters.

3. Proper maintenance and tune up according to manu-

facturer’s specifications should be made to correct the

conditions as soon as possible.