adding oil MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 311 of 1216

ENGINE <1.8L Engine> -Service Adjustment Procedures9-27

I.

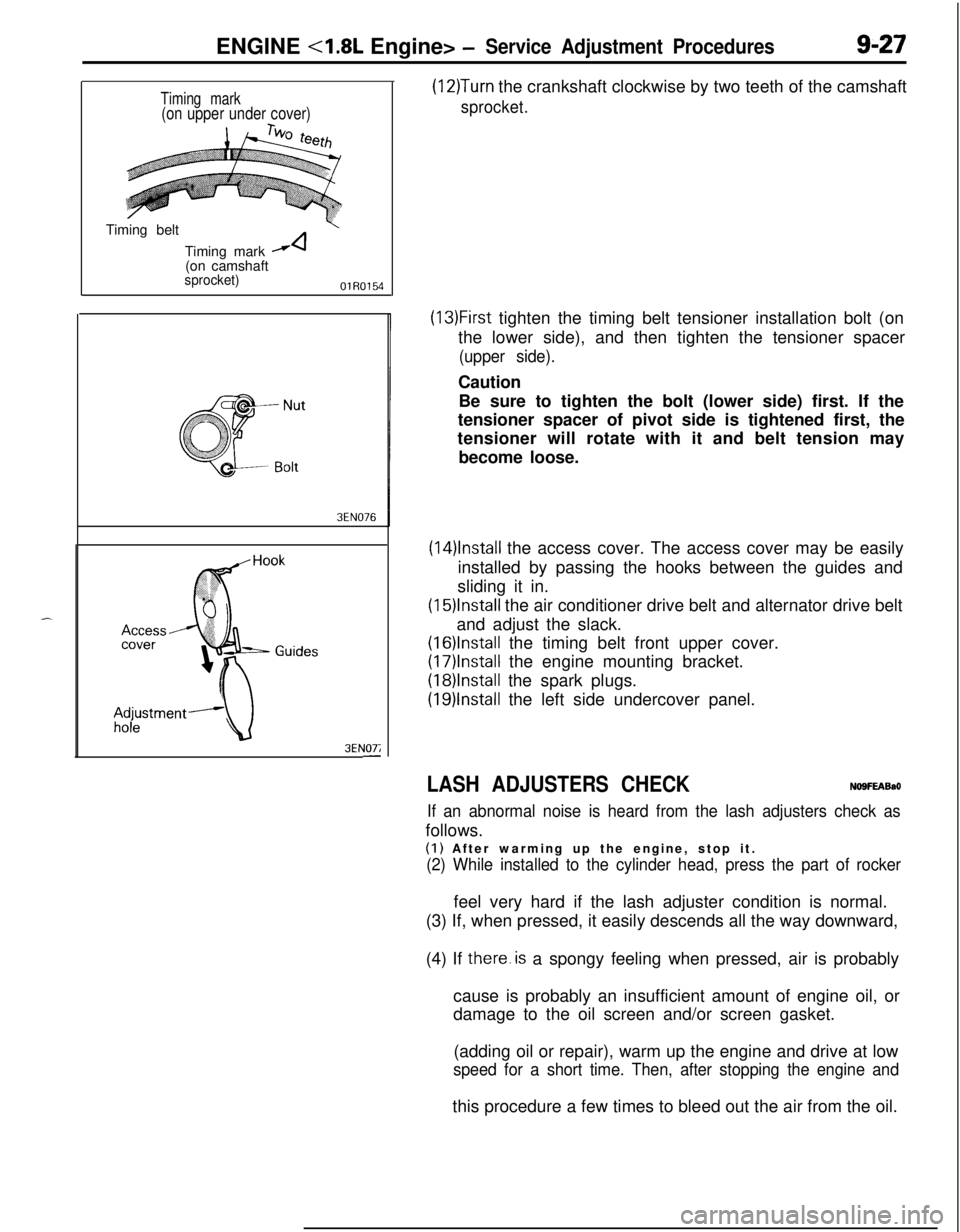

Timing mark(on upper under cover)Timing belt

Timing mark

A(on camshaft

sprocket)OlR0154

3EN076

3EN07;-

(12)Turn the crankshaft clockwise by two teeth of the camshaft

sprocket.

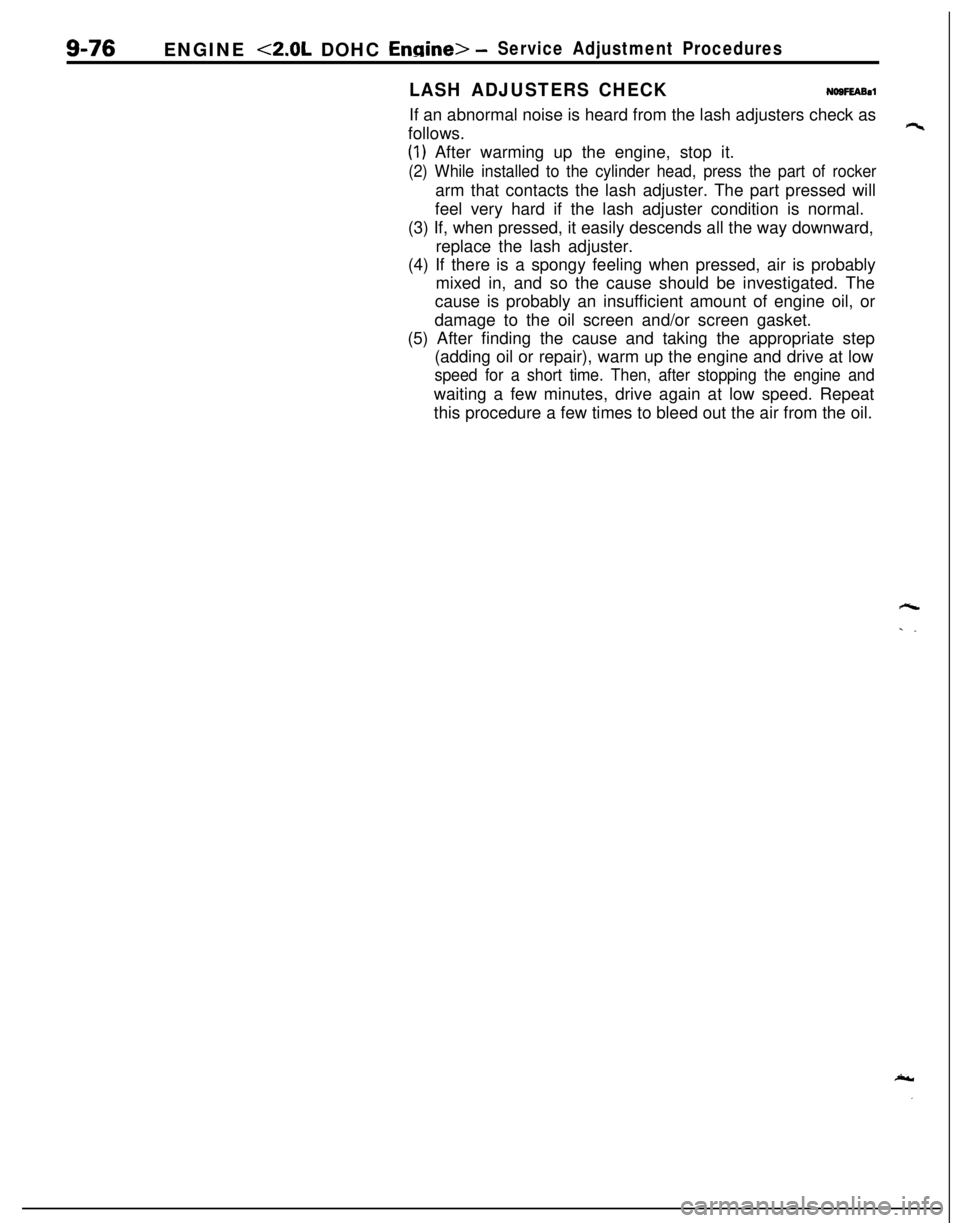

(13)First tighten the timing belt tensioner installation bolt (on

the lower side), and then tighten the tensioner spacer

(upper side).Caution

Be sure to tighten the bolt (lower side) first. If the

tensioner spacer of pivot side is tightened first, the

tensioner will rotate with it and belt tension may

become loose.

(14)lnstall the access cover. The access cover may be easily

installed by passing the hooks between the guides and

sliding it in.

(15)lnstall the air conditioner drive belt and alternator drive belt

and adjust the slack.

(16)lnstalI the timing belt front upper cover.

(17)lnstall the engine mounting bracket.

(18)lnstalI the spark plugs.

(19)lnstall the left side undercover panel.

LASH ADJUSTERS CHECKNO9FEABaO

If an abnormal noise is heard from the lash adjusters check asfollows.

(I) After warming up the engine, stop it.

(2) While installed to the cylinder head, press the part of rockerfeel very hard if the lash adjuster condition is normal.

(3) If, when pressed, it easily descends all the way downward,

(4) If there.is a spongy feeling when pressed, air is probably

cause is probably an insufficient amount of engine oil, or

damage to the oil screen and/or screen gasket.

(adding oil or repair), warm up the engine and drive at low

speed for a short time. Then, after stopping the engine andthis procedure a few times to bleed out the air from the oil.

Page 360 of 1216

9-76ENGINE <2.0L DOHC Engine> -Service Adjustment Procedures

LASH ADJUSTERS CHECKNOBFEABalIf an abnormal noise is heard from the lash adjusters check as

follows.

(1) After warming up the engine, stop it.

(2) While installed to the cylinder head, press the part of rockerarm that contacts the lash adjuster. The part pressed will

feel very hard if the lash adjuster condition is normal.

(3) If, when pressed, it easily descends all the way downward,

replace the lash adjuster.

(4) If there is a spongy feeling when pressed, air is probably

mixed in, and so the cause should be investigated. The

cause is probably an insufficient amount of engine oil, or

damage to the oil screen and/or screen gasket.

(5) After finding the cause and taking the appropriate step

(adding oil or repair), warm up the engine and drive at low

speed for a short time. Then, after stopping the engine andwaiting a few minutes, drive again at low speed. Repeat

this procedure a few times to bleed out the air from the oil.

Page 1154 of 1216

24-10HEATERS AND AIR CONDITIONING - Safety Precautions

SAFETY PRECAUTIONSN24PAAD

The refrigerant used in all air conditioner is R-l 2. It istransparent and colorless in both the liquid and

vapor state. Since it has a boiling point of

-29.8”C(-85.6”F).

at atmospheric pressure, it will be a vapor

at all normal temperatures and pressures. The vaporis heavier than air, non-flammable, and nonexplo-

sive. It is nonpoisonous except when it is in direct

contact with open flame. It

ia noncorrosive except

when combined with water. The following precau-

tions must be observed when handling

R-12.Caution

Wear safety goggles when servicing the refriger-ation system.

R-12 evaporates so rapidly at normal atmospheric

pressures and temperatures that it tends to freeze

anything it contacts. For this reason, extreme care

must be taken to prevent any liquid refrigerant from

contacting the skin and especially the eyes. Always

wear safety goggles when servicing the refrigera-

tion part of the air conditioning system. Keep a

bottle of sterile mineral oil handy when working on

the refrigeration system. Should any liquid re-

frigerant get into the eyes, use a few drops of

mineral oil to wash them out.

R-12 is rapidly

absorbed by the oil. Next splash the eyes with

plenty of cold water. Call your doctor immediately

even though irritation has ceased after treatment.

Caution

Do not heat

R-12 above 40°C (104°F).In most instances, moderate heat is required to

bring the pressure of the refrigerant in its container

above the pressure of the system when charging or

adding refrigerant. A bucket or large pan of hot

water not over

40°C (104°F) is all the heat required

for this purpose. Do not heat the refrigerant contain-

er with a blow torch or any other means that would

raise temperature and pressure above this tempera-ture. Do not weld or steam clean on or near the

system components or refrigerant lines.

Caution

Keep

R-12 containers upright when charging the

system.When metering

R-12 into the refrigeration system,

keep the supply tank or cans in an upright position. Ifthe refrigerant container is on its side or upside

down, liquid refrigerant will enter the system and

damage the compressor.Caution

Always work in a well-ventilated room.

‘irrGood ventilation is vital in the working area. Always

discharge the refrigerant into the service bay ex-

haust system or outside the building. Large quanti-

ties of refrigerant vapor in a small, poorly ventilated

room can displace the air and cause suffocation.

Although

R-12 vapor is normally nonpoisonous,

contact with an open flame can cause the vapor to

become very poisonous. Do not discharge large

quantities of refrigerant in an area having an open

flame. A poisonous gas is produced when using theflame-type leak detector. Avoid inhaling the fumes

from the leak detector.

Caution

Do not allow liquid refrigerant to touch bright

metal.

Refrigerant will tarnish bright metal and chrome

surfaces, and in combination with moisture can

severely corrode all metal surfaces.

R-12 Refrigerant Bundling

Refrigerant Recycling

R-12 refrigerant is a chloro-floro-carbon (CFC) that

can contribute to the depletion of the ozone layer in

the upper atmosphere.A

Ozone filters out harmful radiation from the sun.

- -/.To assist in protecting the ozone layer, Mitsubishi

Motors Corporation

recomends that a R-12 re-

frigerant recycling device that meets SAE standard

J1991 be used.

Contact an automotive service equipment supplier

for refrigerant recycling equipment that is available

in your area.

Refer to the operating instructions provided with therecycling equipment for proper operation.