coolant temperature MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 14 of 1216

I4INTRODUCTION AND MASTER TROUBLESHOOTING - Precautions before Service

mm (In.1smo59

PARTSWhen replacing parts, use MOPAR genuine parts.

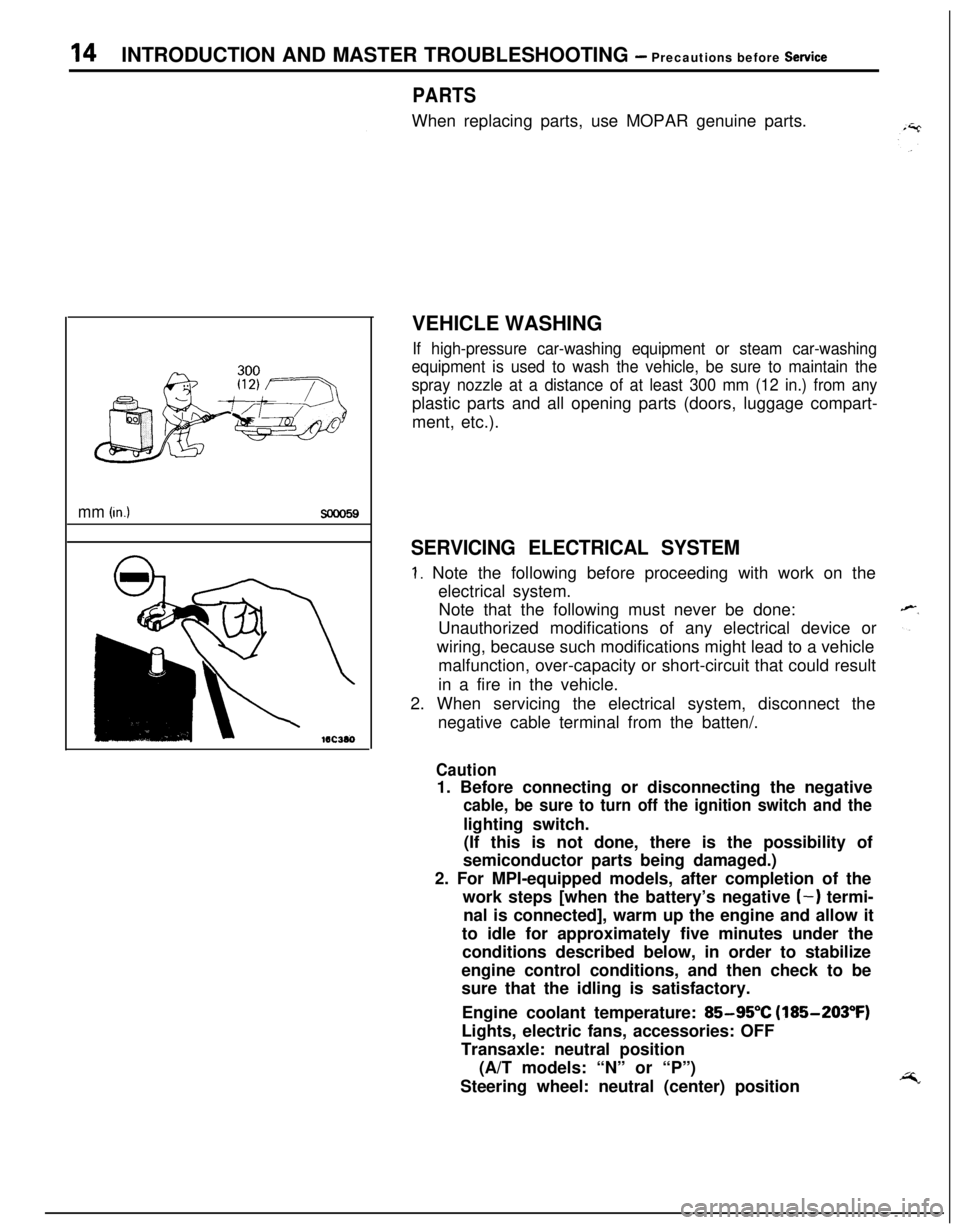

VEHICLE WASHING

If high-pressure car-washing equipment or steam car-washing

equipment is used to wash the vehicle, be sure to maintain the

spray nozzle at a distance of at least 300 mm (12 in.) from anyplastic parts and all opening parts (doors, luggage compart-

ment, etc.).

SERVICING ELECTRICAL SYSTEM

1. Note the following before proceeding with work on the

electrical system.

Note that the following must never be done:

Unauthorized modifications of any electrical device or

wiring, because such modifications might lead to a vehicle

malfunction, over-capacity or short-circuit that could result

in a fire in the vehicle.

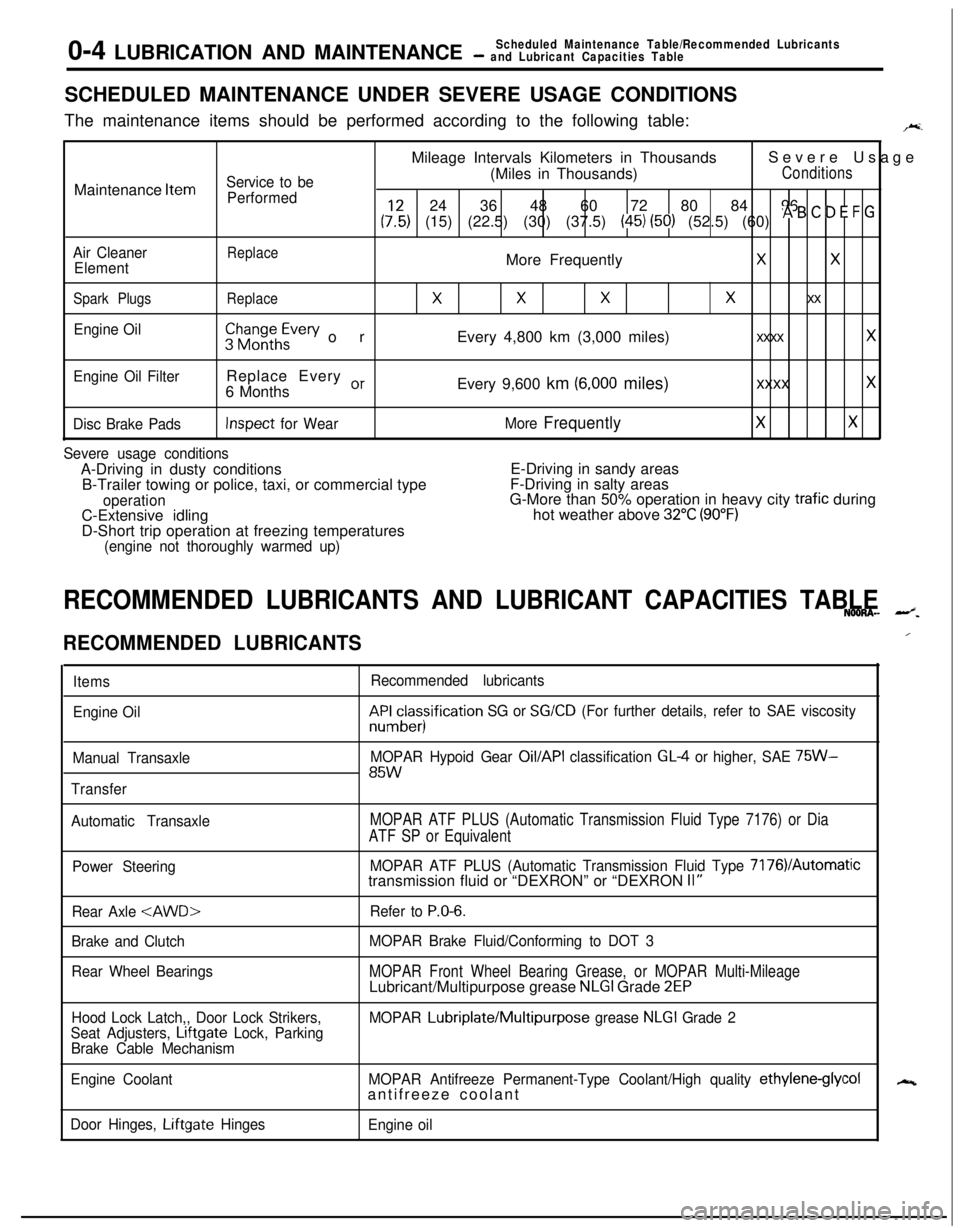

2. When servicing the electrical system, disconnect the

negative cable terminal from the batten/.

Caution1. Before connecting or disconnecting the negative

cable, be sure to turn off the ignition switch and thelighting switch.

(If this is not done, there is the possibility of

semiconductor parts being damaged.)

2. For MPI-equipped models, after completion of the

work steps [when the battery’s negative

(-) termi-

nal is connected], warm up the engine and allow it

to idle for approximately five minutes under the

conditions described below, in order to stabilize

engine control conditions, and then check to be

sure that the idling is satisfactory.

Engine coolant temperature:

85-95°C (185-203°F)

Lights, electric fans, accessories: OFF

Transaxle: neutral position

(A/T models: “N” or “P”)

Steering wheel: neutral (center) position

Page 38 of 1216

0-4 LUBRICATION AND MAINTENANCEScheduled Maintenance Table/Recommended Lubricants- and Lubricant Capacities TableSCHEDULED MAINTENANCE UNDER SEVERE USAGE CONDITIONS

The maintenance items should be performed according to the following table:

F.Mileage Intervals Kilometers in ThousandsSevere Usage

Service to be(Miles in Thousands)ConditionsMaintenance

Item

Performed24 36 48 60 72 80 84 96

(:,:) (15) (22.5) (30) (37.5) (45) (50) (52.5) (60) * B ’ D E F G

Air CleanerReplaceElementMore FrequentlyXX

Spark PlugsReplace

XXXx xx

Engine Oil$$~~~h~vev orEvery 4,800 km (3,000 miles)xxxx x

Engine Oil FilterReplace Every or6 MonthsEvery 9,600 km (6,000 miles)xxxx x

Disc Brake PadsInspect for WearMore FrequentlyXX

Severe usage conditionsA-Driving in dusty conditionsE-Driving in sandy areas

B-Trailer towing or police, taxi, or commercial typeF-Driving in salty areas

operationG-More than 50% operation in heavy city trafic during

C-Extensive idlinghot weather above 32°C (90°F)D-Short trip operation at freezing temperatures

(engine not thoroughly warmed up)

RECOMMENDED LUBRICANTS AND LUBRICANT CAPACITIES TABLENOONA- --z.

RECOMMENDED LUBRICANTS

Items

Engine Oil

Manual Transaxle

TransferRecommended lubricantskF&cesisification

SG or SG/CD (For further details, refer to SAE viscosity

MOPAR Hypoid Gear

Oil/API classification GL4 or higher, SAE 75W-85W

Automatic TransaxleMOPAR ATF PLUS (Automatic Transmission Fluid Type 7176) or Dia

ATF SP or Equivalent

Power SteeringMOPAR ATF PLUS (Automatic Transmission Fluid Type 7176VAutomatictransmission fluid or “DEXRON” or “DEXRON II”

Rear Axle

Brake and Clutch

Rear Wheel BearingsRefer to

P.O-6.

MOPAR Brake Fluid/Conforming to DOT 3

MOPAR Front Wheel Bearing Grease, or MOPAR Multi-MileageLubricant/Multipurpose grease NLGI Grade 2EP

Hood Lock Latch,, Door Lock Strikers,

Seat Adjusters, Lrftgate Lock, Parking

Brake Cable MechanismMOPAR Lubriplate/Multipurpose grease NLGI Grade 2

Engine CoolantMOPAR Antifreeze Permanent-Type Coolant/High quality

ethylene-glycolantifreeze coolant

Door Hinges, Liftgate Hinges

Engine oil

/

N

Page 39 of 1216

LUBRICATION AND MAINTENANCE - Recommended Lubrie’ntsand Lubrtcant Capacttles Table

LUBRICANT CAPACITIES TABLE

Description

Engine Oil Engine Oil

Crankcase (including oil filter) Crankcase (including oil filter)

<1.8L Engine><1.8L Engine><2.0L DOHC Engine><2.0L DOHC Enaine>Oil filter Oil filter

Oil cooler (Turbo) Oil cooler (Turbo)

Metric measureU.S. measure

3.9 liters’.4.4 liters

0.4 liter

0.3 liter

4.‘1 qts.4.6 qts.

‘h qt.Y2 qt.

Cooling System (including heater and coolant reserve system)

<2.0L DOHC Engine>6.2 liters

7.2 liters6.6

qts.

7.6 qts.

Manual Transaxle

1.8liters1.9qts.2.2liters2.3qts.

2.3liters

2.4qts.

Transfer

I0.6 literI.63 qt.

Au:oFmqaAtF2pnsaxle

Rear Axle

Power Steering

Fuel Tank

"C“F4912040

104

27

80

1660

1050

032-10

14-15

5-20-4

-23-10

-29-20

6.1 liters6.4 qts.

7.0 liters7.4 qts.

0.7 liter.74 qt.

0.9 liter.95 sf.60 liters

15.9 gal?.

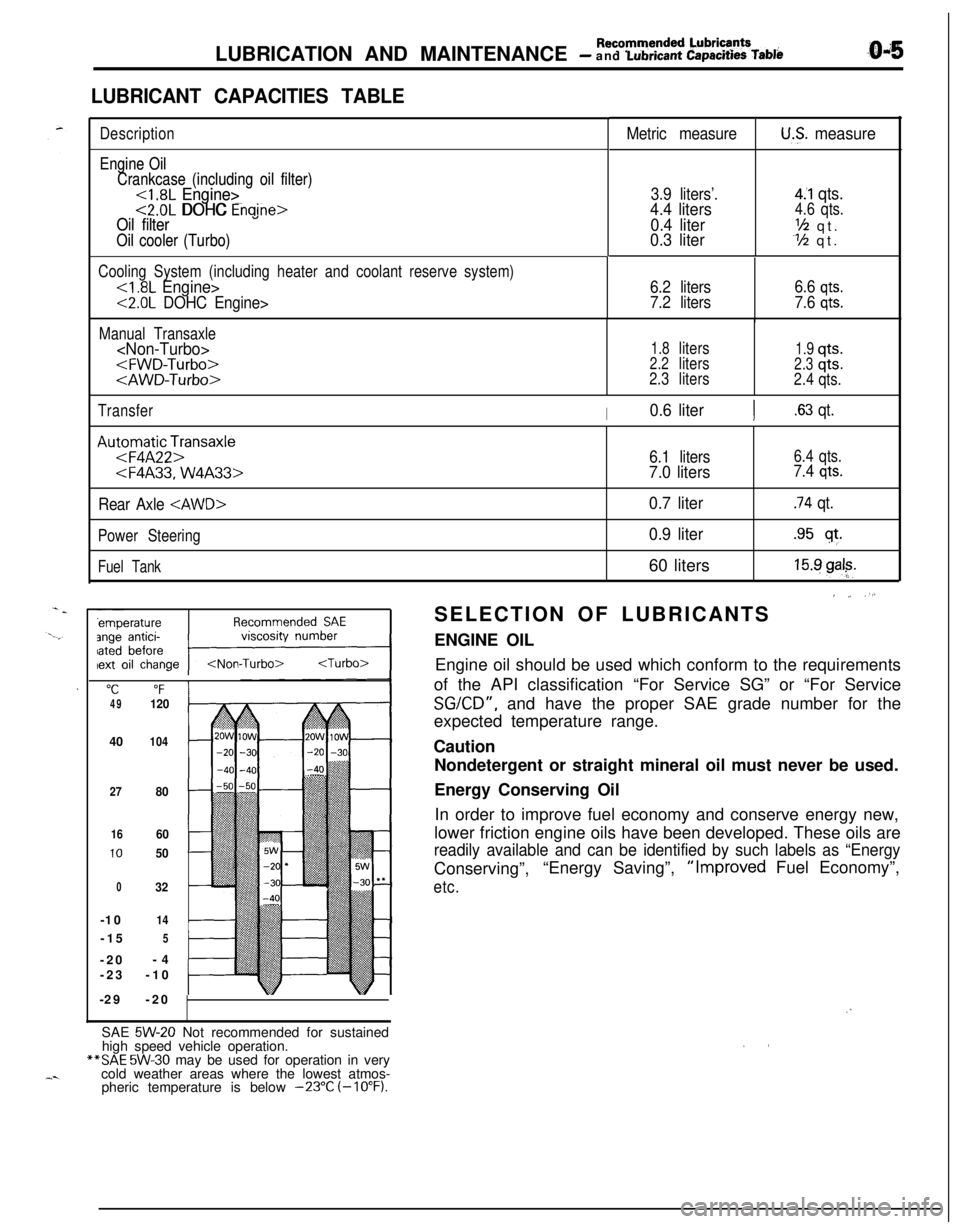

’ ~ “.SELECTION OF LUBRICANTS

ENGINE OIL

Engine oil should be used which conform to the requirements

of the API classification “For Service SG” or “For Service

SGKD”, and have the proper SAE grade number for the

expected temperature range.

Caution

Nondetergent or straight mineral oil must never be used.

Energy Conserving Oil

In order to improve fuel economy and conserve energy new,

lower friction engine oils have been developed. These oils are

readily available and can be identified by such labels as “EnergyConserving”,“Energy Saving”,“Improved Fuel Economy”,

etc.

/”SAE

5W-20 Not recommended for sustained

high speed vehicle operation.**SAE

5W-30 may be used for operation in very

cold weather areas where the lowest atmos-

pheric temperature is below

-23°C (-10°F).

Page 40 of 1216

O-6LUBRICATION AND MAINTENANCE - Capacities TableRecommended Lubricants and Lubricant

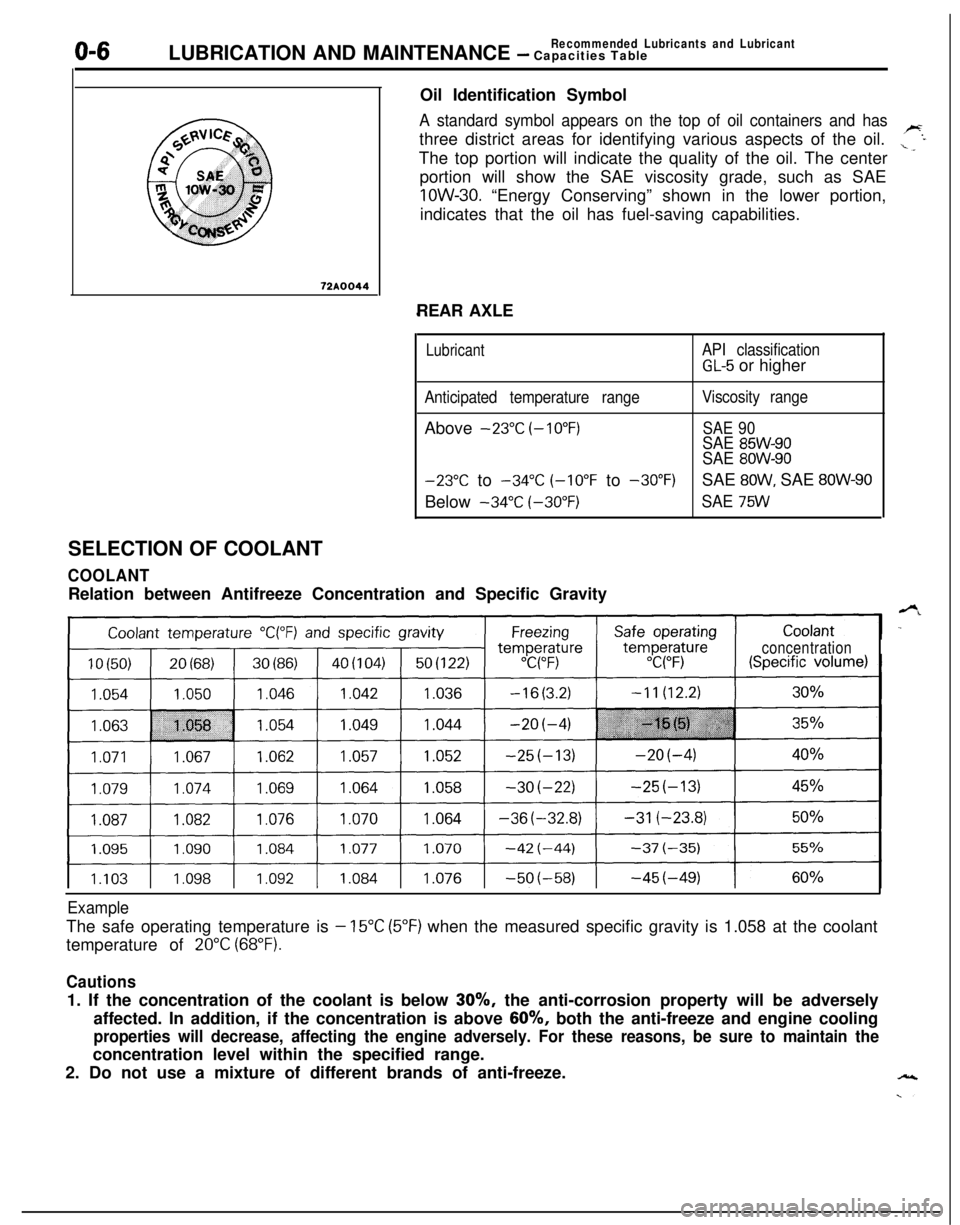

72A0044Oil Identification Symbol

A standard symbol appears on the top of oil containers and hasthree district areas for identifying various aspects of the oil.

The top portion will indicate the quality of the oil. The center

portion will show the SAE viscosity grade, such as SAE

IOW-30. “Energy Conserving” shown in the lower portion,

indicates that the oil has fuel-saving capabilities.

REAR AXLE

LubricantAPI classification

GL-5 or higher

Anticipated temperature rangeViscosity rangeAbove -23°C

(-10°F)SAE 90SAE 85W-90SAE 8OW-90

-23°C to -34°C (-10°F to -30°F)SAE 8OW, SAE 8OW-90Below -34°C

(-30°F)SAE 75WSELECTION OF COOLANT

COOLANTRelation between Antifreeze Concentration and Specific Gravity

concentration

ExampleThe safe operating temperature is

- 15°C (5°F) when the measured specific gravity is 1.058 at the coolant

temperature of

20°C (68°F).

Cautions1. If the concentration of the coolant is below 30%, the anti-corrosion property will be adversely

affected. In addition, if the concentration is above 60%, both the anti-freeze and engine cooling

properties will decrease, affecting the engine adversely. For these reasons, be sure to maintain theconcentration level within the specified range.

2. Do not use a mixture of different brands of anti-freeze.

Page 46 of 1216

LUBRICATION AND MAINTENANCE - Maintenance Service

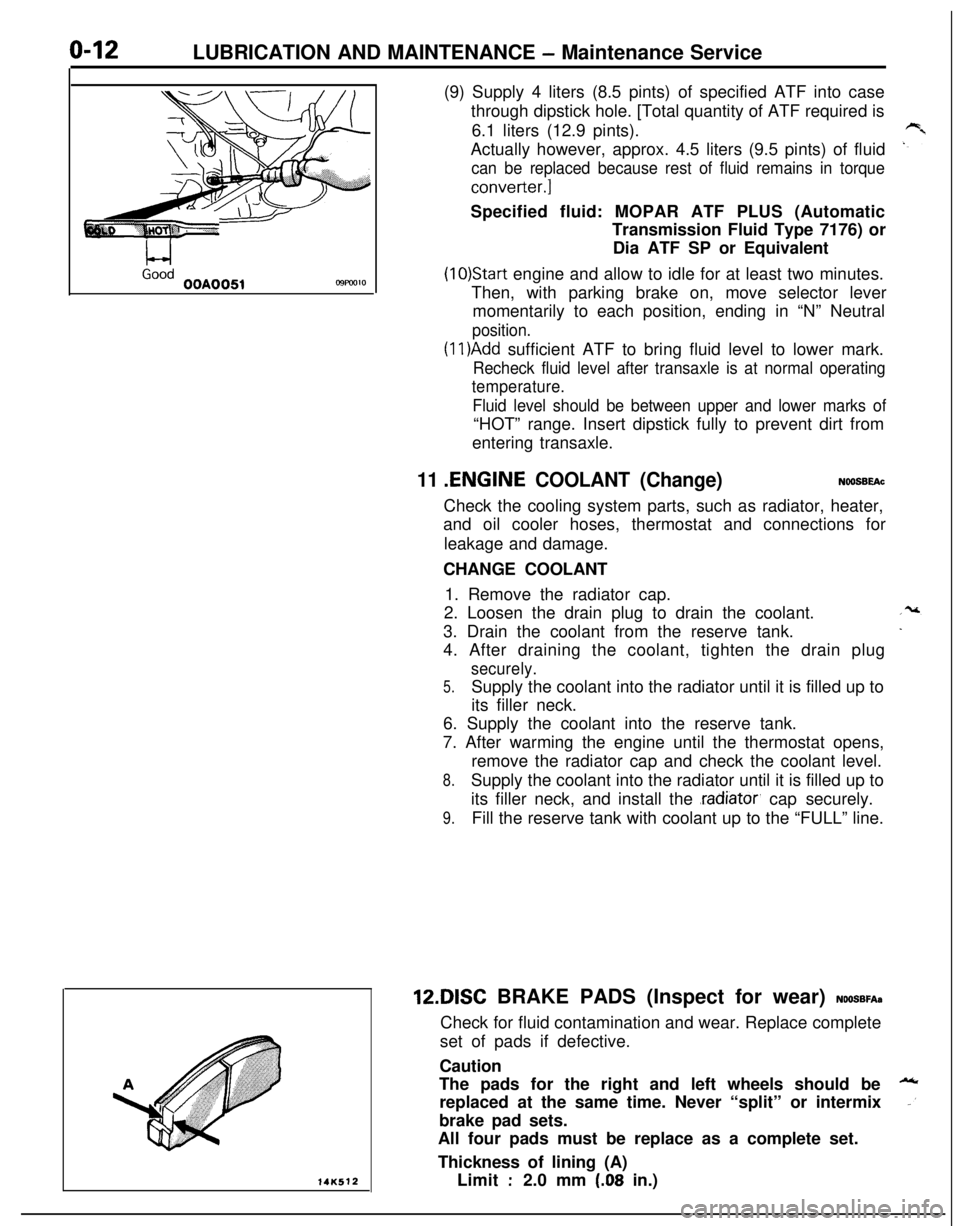

L-4GoodOOA0051C9FW1014K512(9) Supply 4 liters (8.5 pints) of specified ATF into case

through dipstick hole. [Total quantity of ATF required is

6.1 liters (12.9 pints).

Actually however, approx. 4.5 liters (9.5 pints) of fluid

can be replaced because rest of fluid remains in torque

converter.]Specified fluid: MOPAR ATF PLUS (Automatic

Transmission Fluid Type 7176) or

Dia ATF SP or Equivalent

(10)Start engine and allow to idle for at least two minutes.

Then, with parking brake on, move selector lever

momentarily to each position, ending in “N” Neutral

position.

(1 l)Add sufficient ATF to bring fluid level to lower mark.

Recheck fluid level after transaxle is at normal operating

temperature.

Fluid level should be between upper and lower marks of“HOT” range. Insert dipstick fully to prevent dirt from

entering transaxle.

11 .ENGINE COOLANT (Change)NOOSBEAcCheck the cooling system parts, such as radiator, heater,

and oil cooler hoses, thermostat and connections for

leakage and damage.

CHANGE COOLANT

1. Remove the radiator cap.

2. Loosen the drain plug to drain the coolant.

3. Drain the coolant from the reserve tank.

4. After draining the coolant, tighten the drain plug

securely.

5.Supply the coolant into the radiator until it is filled up to

its filler neck.

6. Supply the coolant into the reserve tank.

7. After warming the engine until the thermostat opens,

remove the radiator cap and check the coolant level.

8.Supply the coolant into the radiator until it is filled up to

its filler neck, and install the

.radiator, cap securely.

9.Fill the reserve tank with coolant up to the “FULL” line.12DISC BRAKE PADS (Inspect for wear)

NOOSBFA~Check for fluid contamination and wear. Replace complete

set of pads if defective.

Caution

The pads for the right and left wheels should be

replaced at the same time. Never “split” or intermix

brake pad sets.

All four pads must be replace as a complete set.

Thickness of lining (A)

Limit

:2.0 mm (.08 in.)

Page 249 of 1216

7-l

COOLING

CONTENTS

ENGINE COOLANT TEMPERATURE GAUGEUNIT,

ENGINE COOLANT TEMPERATURE

SENSOR AND ENGINE COOLANT

TEMPERATURE SWITCH................................34

RADIATOR.......................................................12

RADIATORFANMOTOR ASSEMBLY..........15

SERVICE ADJUSTMENT PROCEDURES.......8

Alternatormater Pump Drive Belt Tension

Adjustment

....................................................9Alternator/Water Pump Drive Belt Tension

Inspection..

....................................................8Cap Pressure Test

.......................................8Engine Coolant Concentration Test

.............8

EngineCoolantLeakCheck........................8Engine Coolant Replacement

.......................8

SPECIFICATIONS.............................................2

GeneralSpecifications..................................2

Lubricant.......................................................4

Sealant..........................................................4Service Specifications

...................................2Torque Specifications

...................................3THERMOSTAT

.................................................15

TROUBLESHOOTING......................................5

Noriseintemperature................................5

Overheat.......................................................5

WATER HOSE AND WATER PIPE

<1.8L Engine>................................................25

WATER HOSE AND WATER PIPE

<2.0LDOHCEngine(Non-Turbo)>.............28

WATER HOSE AND WATER PIPE

<2.0LDOHCEngine(Turbo)>....................31

WATERPUMP<1.8LEngine>.....................17

WATER PUMP <2.0L DOHC Engine>.........21

Page 250 of 1216

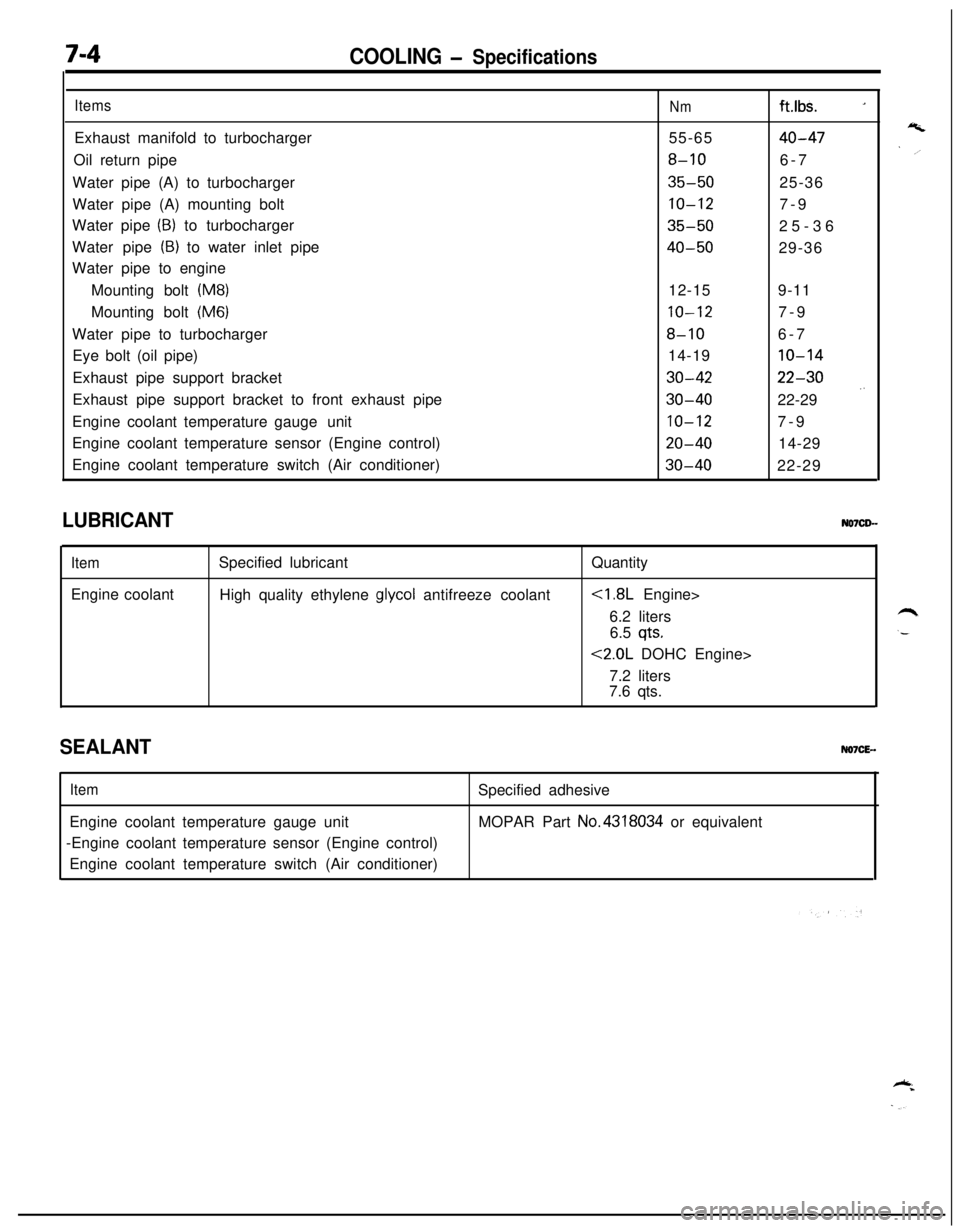

7-2COOLING - Specifications

SPECIFICATIONS

GENERAL SPECIFICATIONSIcNQ7cA- I

ItemsCooling method

Radiator

TypeRadiator fan motor

TypeWater pump

Type

Thermostat

TypeIdentification mark

Drive belt

TypeEngine coolant temperature gauge unit

WeEngine coolant temperature sensor (Engine control)

TypeEngine coolant temperature switch (Air conditioner)

WeSpecifications

Water-cooled, pressurized, forced circulation

with electrical fan

Pressurized corrugated fin type

Direct current ferrite type

Impeller of centrifugal type

Wax pellet type with jiggle valve

88 (Stamped on flange)

V-ribbed belt

Thermistor type

Thermistor type

Thermistor type

SERVICE SPECIFICATIONSN07CB.-

Items

Standard valueRange of coolant antifreeze concentration

%

ThermostatValve opening temperature of thermostat

“C (“F)Full-opening temperature of thermostat

“C (“F)Opening pressure of cap high pressure valve

kPa (psi)

Therm0 sensor (on radiator)

Operating temperature

OFF

+ ON“C (“F)ON

--P OFF“C (“F)Engine coolant temperature gauge unit

ResistanceAt

70°C (158°F) QEngine coolant temperature sensor (Engine control)

ResistanceAt

20°C (68°F) kQAt

80°C (176°F) QEngine coolant temperature

switch (Air conditioner)

ON -+ OFF operating temperature

“C (“F)Limit

Opening pressure cap high pressure valve

kPa (psi)

Specifications

30-6088 (190)

100 (212) or more

75-105 (11-15)

82-88 (180-190)

78 (172) or less

104f 13.5

2.45

I!I 0.24

296

+ 32

112-l 18 (234-244)

65 (9.2)

Page 252 of 1216

7-4COOLING - Specifications

ItemsExhaust manifold to turbocharger

Oil return pipe

Water pipe (A) to turbocharger

Water pipe (A) mounting bolt

Water pipe

(B) to turbocharger

Water pipe

(B) to water inlet pipe

Water pipe to engine

Mounting bolt

(M8)Mounting bolt

(M6)Water pipe to turbocharger

Eye bolt (oil pipe)

Exhaust pipe support bracket

Exhaust pipe support bracket to front exhaust pipe

Engine coolant temperature gaugeunit

Engine coolant temperature sensor (Engine control)

Engine coolant temperature switch (Air conditioner)

Nmft.lbs. _155-65

40-47

8-106-7

35-5025-36

10-127-9

35-5025-36

40-5029-36

12-159-11

10-127-9

8-106-7

14-19

10-14

30-4222-30

30-4022-29 .’

10-127-9

20-4014-29

30-4022-29

LUBRICANT

ItemEngine coolantSpecified lubricant

High quality ethylene

glycol antifreeze coolantQuantity

6.2 liters

6.5

qts.

<2.0L DOHC Engine>

7.2 liters

7.6 qts.

SEALANTNO7CE-.

ItemEngine coolant temperature gauge unit

-Engine coolant temperature sensor (Engine control)

Engine coolant temperature switch (Air conditioner)Specified adhesive

MOPAR Part No.4318034 or equivalent

Page 253 of 1216

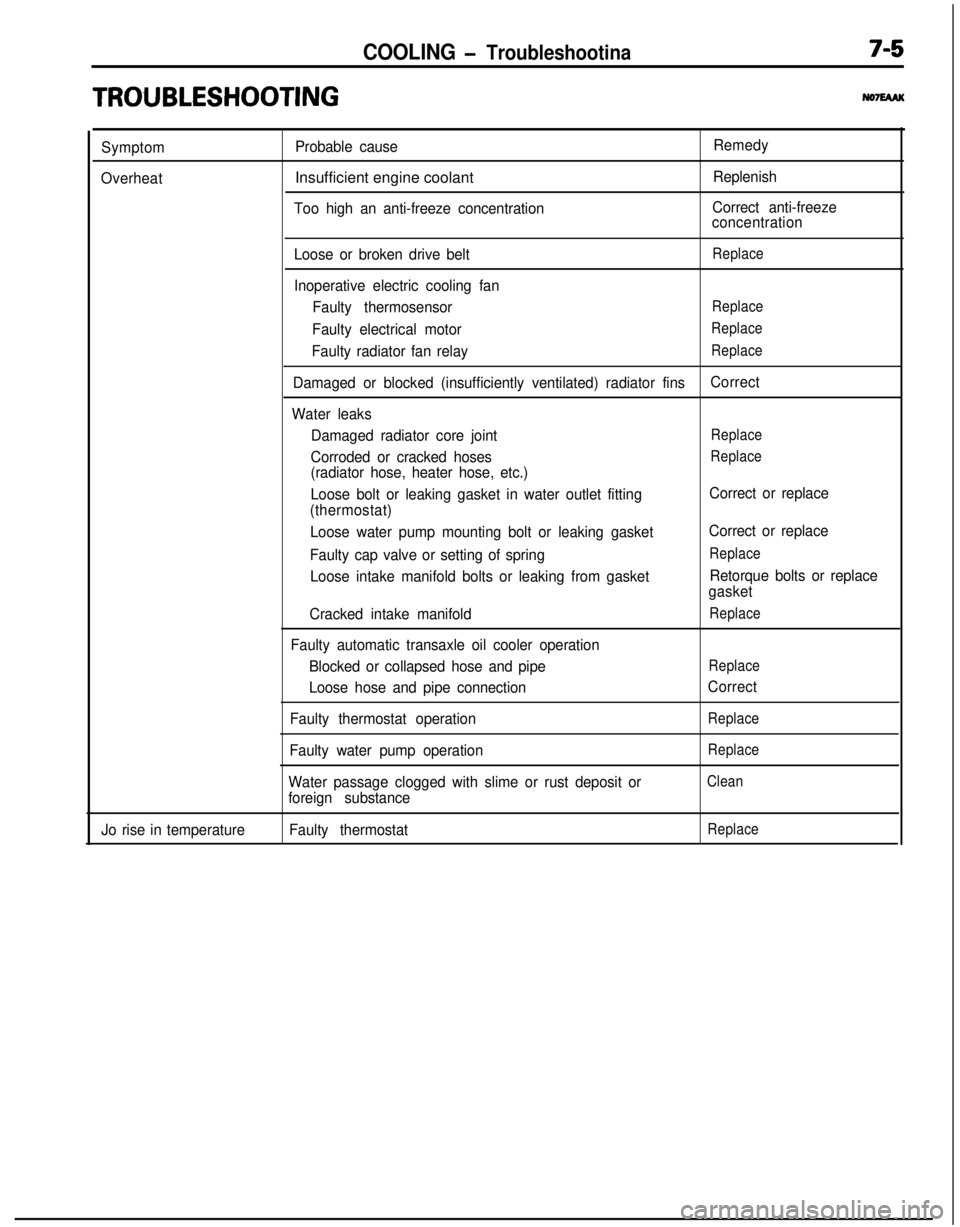

COOLING - Troubleshootina7-5

TRO,UBLESHOOTlNG

Symptom

OverheatProbable causeInsufficient engine coolant

Too high an anti-freeze concentrationRemedy

Replenish

Correct anti-freeze

concentration

Loose or broken drive belt

Replace

Inoperative electric cooling fan

Faulty thermosensor

Replace

Faulty electrical motorReplace

Faulty radiator fan relayReplace

Damaged or blocked (insufficiently ventilated) radiator finsCorrect

Water leaks

Damaged radiator core joint

Replace

Corroded or cracked hosesReplace

(radiator hose, heater hose, etc.)

Loose bolt or leaking gasket in water outlet fitting

(thermostat)

Loose water pump mounting bolt or leaking gasket

Faulty cap valve or setting of spring

Loose intake manifold bolts or leaking from gasket

Cracked intake manifold

Faulty automatic transaxle oil cooler operation

Blocked or collapsed hose and pipe

Loose hose and pipe connection

Faulty thermostat operation

Faulty water pump operation

Water passage clogged with slime or rust deposit or

foreign substanceCorrect or replace

Correct or replace

Replace

Retorque bolts or replace

gasket

Replace

Replace

Correct

Replace

Replace

Clean

Jo rise in temperatureFaulty thermostatReplace

Page 255 of 1216

COOLING - Troubleshooting7A7

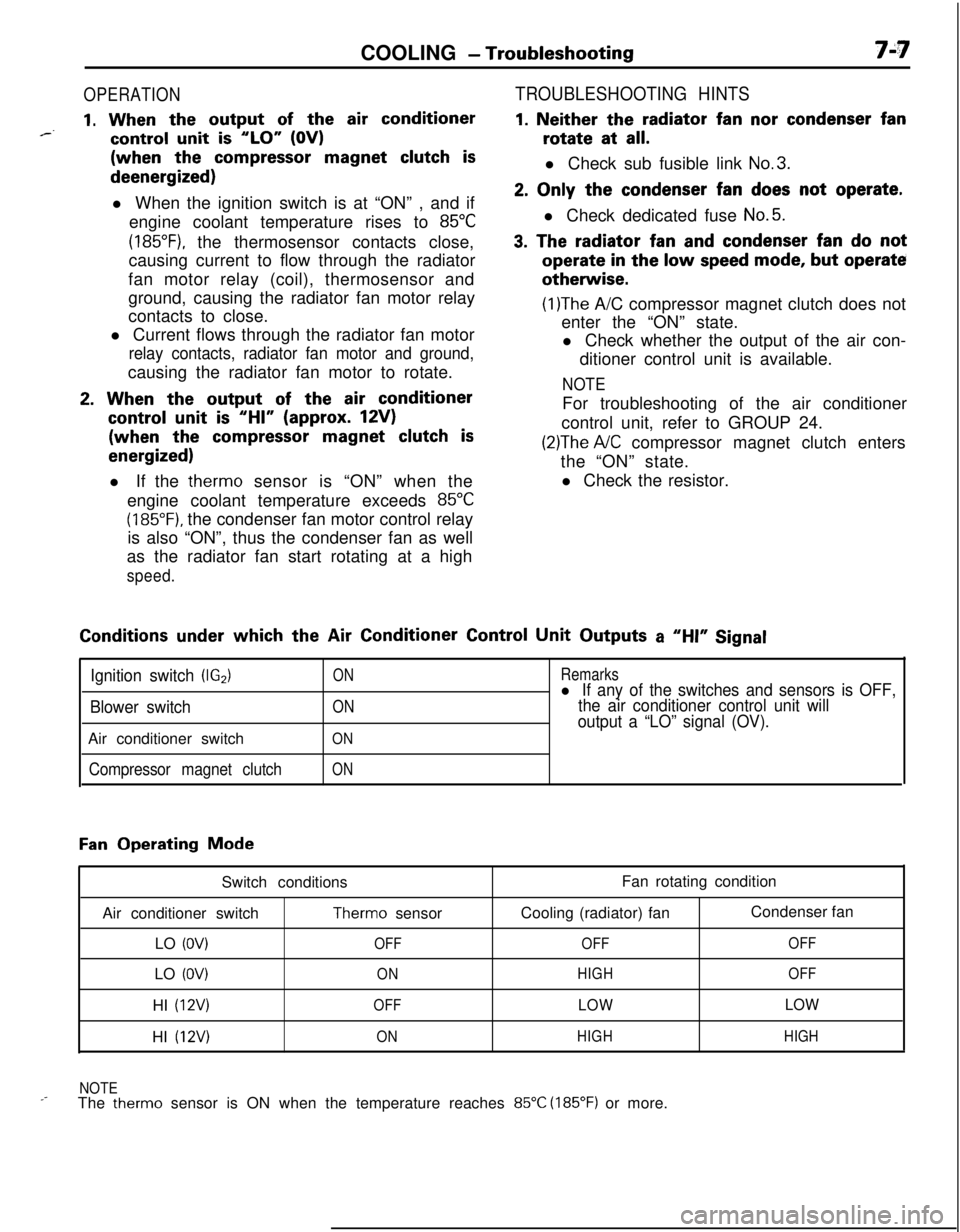

OPERATION

1. When the output of the air conditioner*--control unit is “LO” (OV)(when the

compressor magnet clutch isdeenergized)

l When the ignition switch is at “ON” , and if

engine coolant temperature rises to

85°C

(185”F), the thermosensor contacts close,

causing current to flow through the radiator

fan motor relay (coil), thermosensor and

ground, causing the radiator fan motor relay

contacts to close.

l Current flows through the radiator fan motor

relay contacts, radiator fan motor and ground,causing the radiator fan motor to rotate.

2. When the output of the air conditioner

control unit is “HI” (approx. 12V)(when the

compressor magnet clutch is

energized)l If the therm0 sensor is “ON” when the

engine coolant temperature exceeds

85°C

(185°F). the condenser fan motor control relay

is also “ON”, thus the condenser fan as well

as the radiator fan start rotating at a high

speed.

TROUBLESHOOTING HINTS

1. Neither the radiator fan nor condenser fanrotate at

all.l Check sub fusible link

No.3.

2. Only the condenser fan does not operate.l Check dedicated fuse

No.5.

3. The radiator fan and condenser fan do notoperate

in the low speed mode, but operateotherwise.

(1)The A/C compressor magnet clutch does not

enter the “ON” state.

l Check whether the output of the air con-

ditioner control unit is available.

NOTEFor troubleshooting of the air conditioner

control unit, refer to GROUP 24.

(2)The A/C compressor magnet clutch enters

the “ON” state.

l Check the resistor.Conditions

under which the Air Conditioner Control Unit Outputs a “HI” Signal

Ignition switch (IG2)

Blower switchAir conditioner switch

Compressor magnet clutch

ON

ON

ON

ON

Remarksl If any of the switches and sensors is OFF,

the air conditioner control unit will

output a “LO” signal (OV).

Fan Operating Mode

Switch conditions

Air conditioner switch

Therm0 sensor

LO

(OV)OFFLO

(OV)ONHI

(12V)OFFHI

(12V)ONFan rotating condition

Cooling (radiator) fanCondenser fan

OFFOFF

HIGHOFF

LOWLOW

HIGHHIGH

NOTE

_-The therm0 sensor is ON when the temperature reaches 85°C (185°F) or more.