reset MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 242 of 1216

6-12CLUTCH - Clutch Master CylinderResew&r

bandk

oaA0058

08Y517

Grease

SERVICE POINTS OF REASSEMBLYNaaNciAN

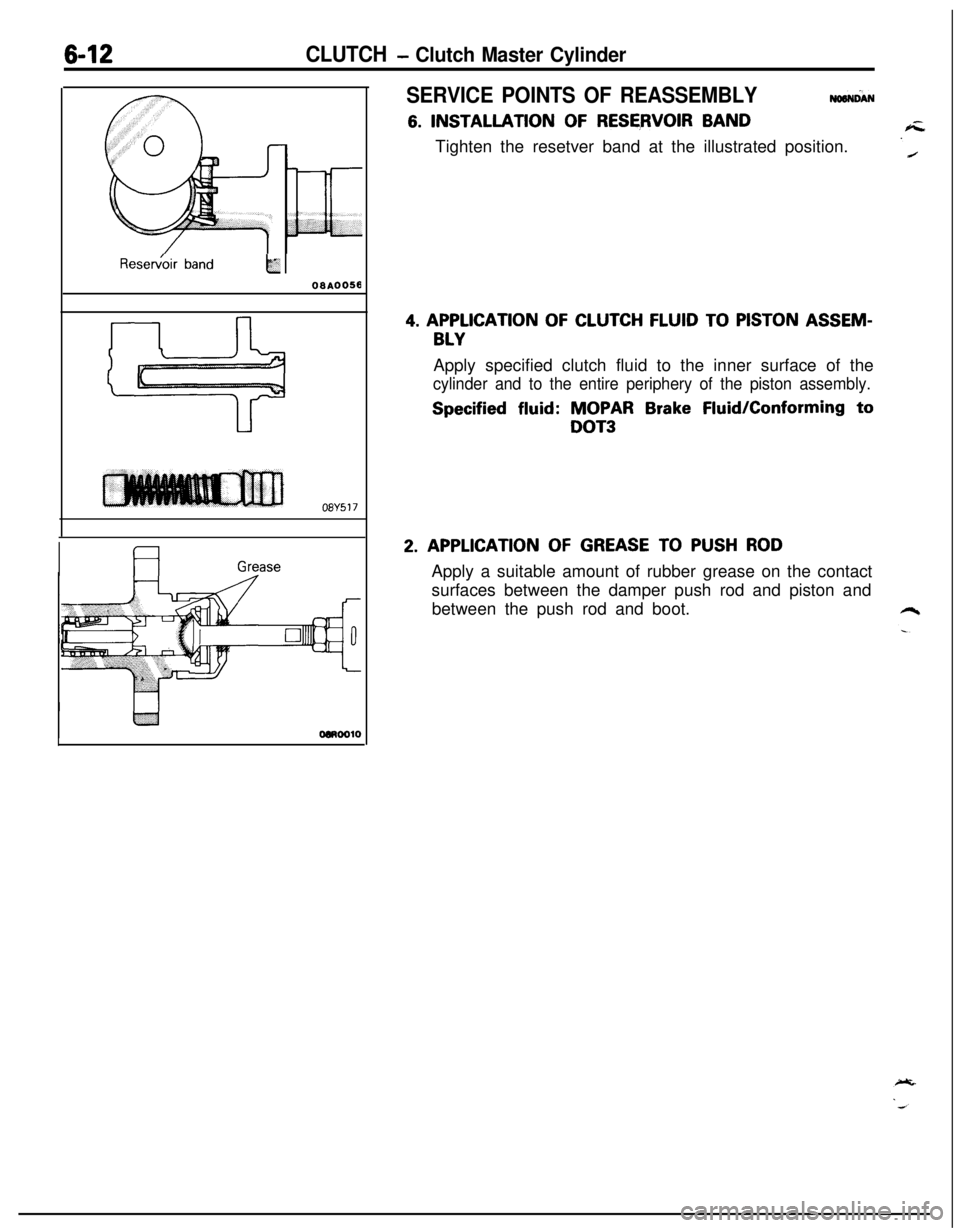

6. INSTALLATION OF RESERVOIR BAND

Tighten the resetver band at the illustrated position.

4. APPLICATION OF CLUTCH FLUID TO PISTON ASSEM-

BLYApply specified clutch fluid to the inner surface of the

cylinder and to the entire periphery of the piston assembly.

Specified fluid: MOPAR Brake Fluid/Conforming to

DOT3

2. APPLICATION OF GREASE TO PUSH RODApply a suitable amount of rubber grease on the contact

surfaces between the damper push rod and piston and

between the push rod and boot.

Page 387 of 1216

ENGINE <2.0L DOHC Engine> - Timing Belts-103

--

Plug

6EN0281Center bolt

I

6EN028321. INSTALLATION OF AUTO TENSIONER

(1) If the auto tensioner rod is in its fully extended position,reset it as follows.

@ Keep the a t tu oensioner level and, in that position,

clamp it in the vise with soft jaws.

If the plug at the bottom of the auto tensioner

protrudes, surround it with a plain washer as

illustrated to prevent the plug from being in direct

contact with the vise.

@I Push in the rod little by little with the vise until the

set hole

@ in the rod is aligned with that @I in the

cylinder.

@ Insert a wire [1.4 mm (055 in.) in diameter] into the

set holes.

@I Unclamp the auto tensioner from the vise.

(2) Install the auto tensioner.

Caution

Leave the wire installed in the auto tensioner.

23. INSTALLATION OF TENSIONER PULLEY

(1) Install the tensioner pulley onto the tensioner arm.

(2) Locate the pinhole in the tensioner pulley shaft to the

left of the center bolt. Then, tighten the center bolt

finger-tight.Caution

Leave the wire installed in the auto tensioner.

Page 576 of 1216

14-122AUTO-CRUISE CONTROL SYSTEM - Troubleshooting

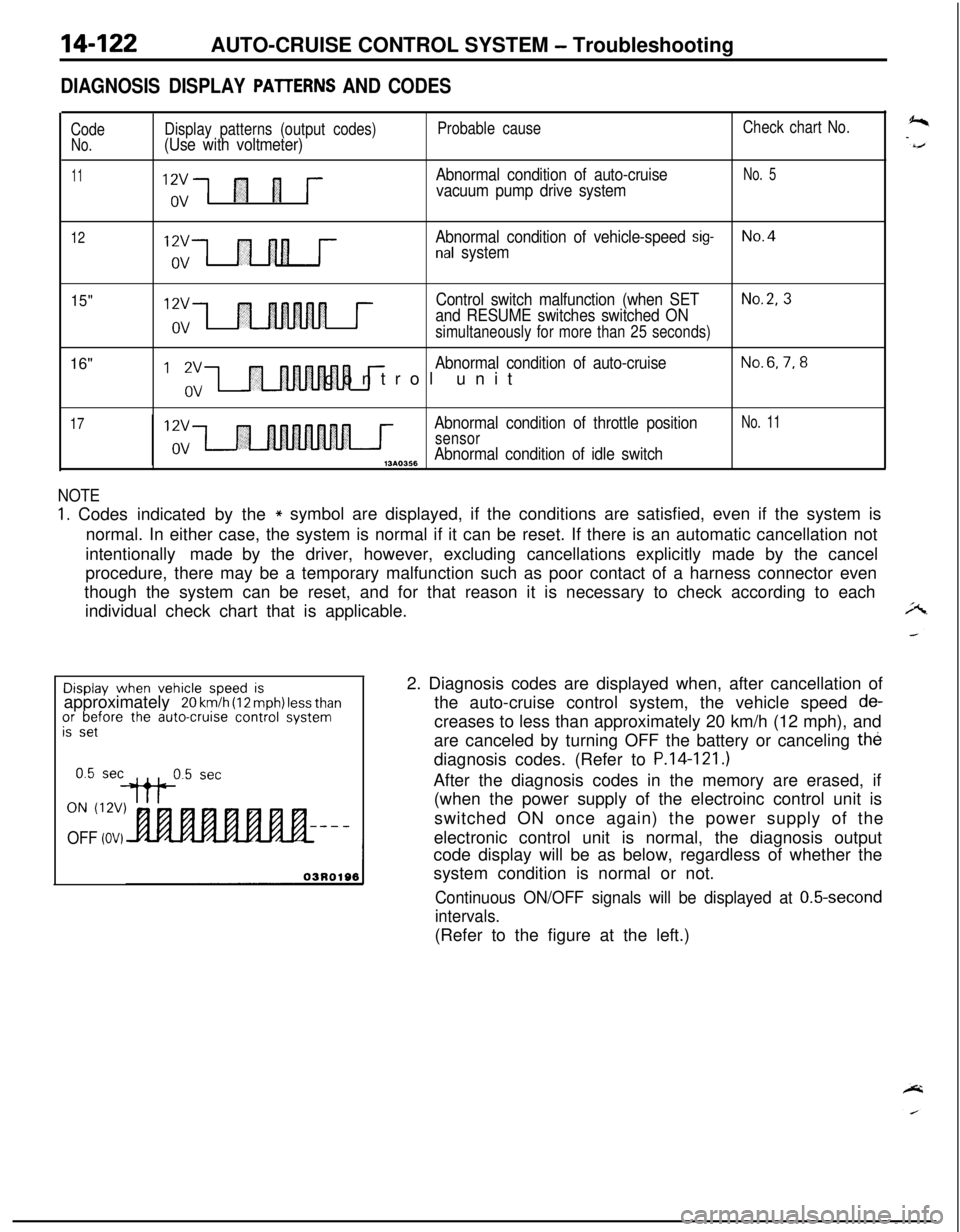

DIAGNOSIS DISPLAY PAlTERNS AND CODES

CodeNo.

11

Display patterns (output codes)(Use with voltmeter)

“,;1 fl 1 j--

Probable cause

Abnormal condition of auto-cruise

vacuum pump drive system

Check chart No.

No. 5

12Abnormal condition of vehicle-speed sig-No.4nal system

15"16"12vControl switch malfunction (when SETNo.2, 3

and RESUME switches switched ONovsimultaneously for more than 25 seconds)

I ‘,“,-I r

Abnormal condition of auto-cruiseNo.6,7,8control unit

17Abnormal condition of throttle positionNo. 11

sensorAbnormal condition of idle switch,3*0356

NOTE

1. Codes indicated by the* symbol are displayed, if the conditions are satisfied, even if the system is

normal. In either case, the system is normal if it can be reset. If there is an automatic cancellation not

intentionally made by the driver, however, excluding cancellations explicitly made by the cancel

procedure, there may be a temporary malfunction such as poor contact of a harness connector even

though the system can be reset, and for that reason it is necessary to check according to each

individual check chart that is applicable.Display

when vehicle speed isapproximately 20 km/h (12 mph) less thanor before the auto-cruise control systemis set

ON (12V)

OFF (OV)2. Diagnosis codes are displayed when, after cancellation of

the auto-cruise control system, the vehicle speed

de-creases to less than approximately 20 km/h (12 mph), and

are canceled by turning OFF the battery or canceling the

diagnosis codes. (Refer to

P.14-121.)After the diagnosis codes in the memory are erased, if

(when the power supply of the electroinc control unit is

switched ON once again) the power supply of the

electronic control unit is normal, the diagnosis output

code display will be as below, regardless of whether the

system condition is normal or not.

Continuous ON/OFF signals will be displayed at 0.5-second

intervals.(Refer to the figure at the left.)

Page 1046 of 1216

23-2

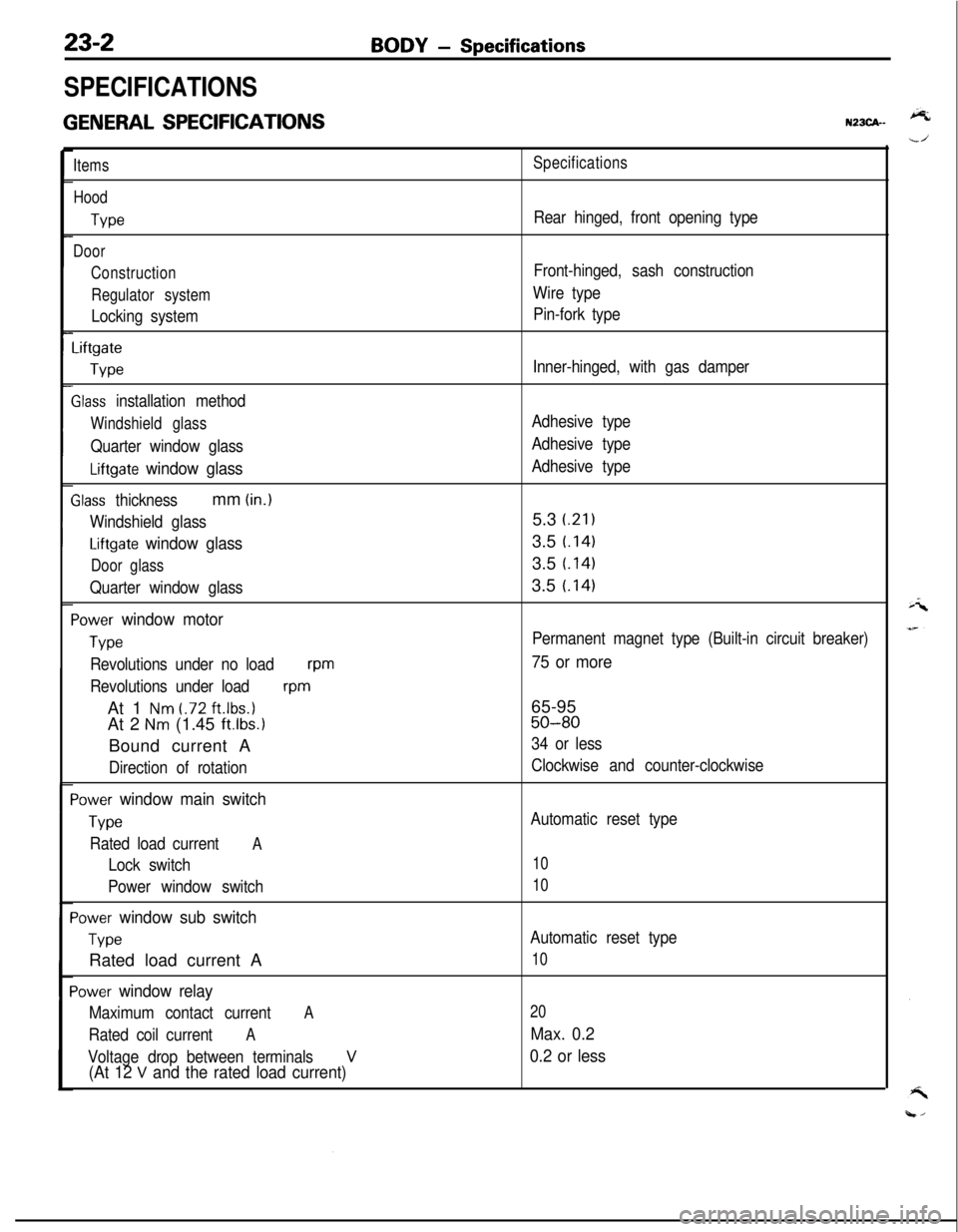

SPECIFICATIONS

GENERAL SPECIFICATIONS

BODY - Specifications

N23CA--

Items

Hood

We

Door

Construction

Regulator system

Locking system

Liftgate

We

Slass installation method

Windshield glass

Quarter window glass

Liftgate window glass

Zlass thicknessmm (in.)

Windshield glass

Liftgate window glass

Door glass

Quarter window glass

‘ower window motor

Type

Revolutions under no loadwm

Revolutions under load

wmAt 1

Nm t.72 ft.lbs.1At 2

Nm (1.45 ft.lbs.1Bound current A

Direction of rotation

‘ower window main switch

Type

Rated load currentA

Lock switch

Power window switch

‘ower window sub switch

TvwRated load current A

‘ower window relay

Maximum contact currentA

Rated coil currentA

Voltage drop between terminalsV(At 12 V and the rated load current)

Specifications

Rear hinged, front opening type

Front-hinged, sash construction

Wire type

Pin-fork type

Inner-hinged, with gas damper

Adhesive type

Adhesive type

Adhesive type5.3

i.21)3.5

t.1413.5

t.1413.5

t.141

Permanent magnet type (Built-in circuit breaker)

75 or more65-95

50-80

34 or less

Clockwise and counter-clockwise

Automatic reset type

10

10

Automatic reset type

10

20

Max. 0.2

0.2 or less

Page 1054 of 1216

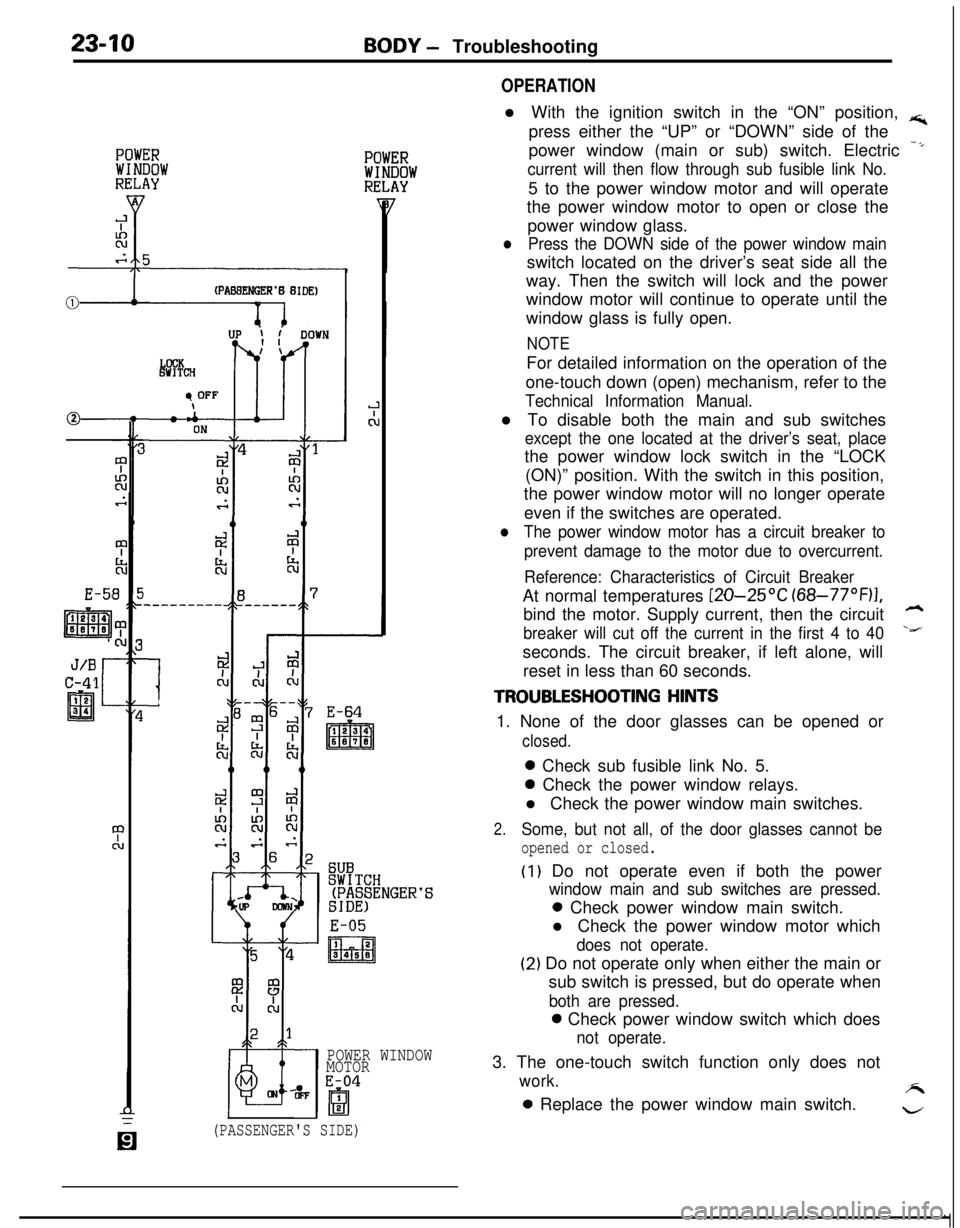

23-10BODY - Troubleshooting

(PABBENGER’B BIDE)v 1

E-51

‘S

E-05

I2

m3458

POWER WINDOW

MOTOR

E-04

OPERATIONl With the ignition switch in the “ON” position,

rs;,press either the “UP” or “DOWN” side of the

power window (main or sub) switch. Electric

-*

current will then flow through sub fusible link No.5 to the power window motor and will operate

the power window motor to open or close the

power window glass.

lPress the DOWN side of the power window mainswitch located on the driver’s seat side all the

way. Then the switch will lock and the power

window motor will continue to operate until the

window glass is fully open.

NOTEFor detailed information on the operation of the

one-touch down (open) mechanism, refer to the

Technical Information Manual.l To disable both the main and sub switches

except the one located at the driver’s seat, placethe power window lock switch in the “LOCK

(ON)” position. With the switch in this position,

the power window motor will no longer operate

even if the switches are operated.

lThe power window motor has a circuit breaker to

prevent damage to the motor due to overcurrent.

Reference: Characteristics of Circuit BreakerAt normal temperatures

[ZO-25OC (68-77”F)I,bind the motor. Supply current, then the circuit

h

breaker will cut off the current in the first 4 to 40\&’seconds. The circuit breaker, if left alone, will

reset in less than 60 seconds.

TROUBLESHOOTING HINTS1. None of the door glasses can be opened or

closed.0 Check sub fusible link No. 5.0 Check the power window relays.

l Check the power window main switches.

2.Some, but not all, of the door glasses cannot be

opened or closed.

(I) Do not operate even if both the power

window main and sub switches are pressed.0 Check power window main switch.

l Check the power window motor which

does not operate.

(2) Do not operate only when either the main or

sub switch is pressed, but do operate when

both are pressed.0 Check power window switch which does

not operate.3. The one-touch switch function only does not

work.A0 Replace the power window main switch.

w

(PASSENGER'S SIDE)