compression ratio MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 27 of 1216

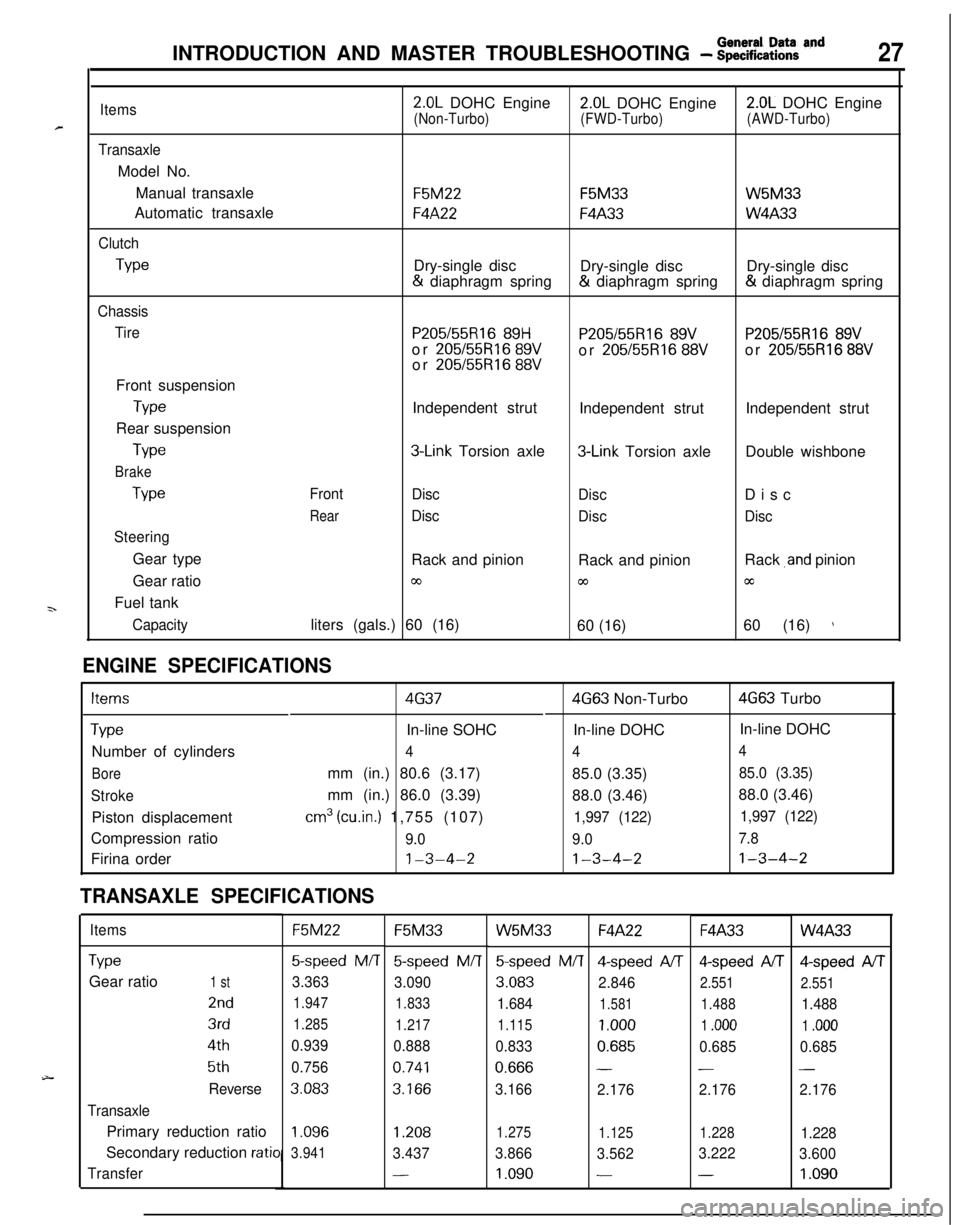

INTRODUCTION AND MASTER TROUBLESHOOTING - f~EEaZ% acld27

=r

9..

Items

TransaxleModel No.

Manual transaxle

Automatic transaxle

Clutch

Type

Chassis

TireFront suspension

TypeRear suspension

Type

Brake

Type

SteeringGear type

Gear ratio

Fuel tank

Capacity

2.0L DOHC Engine2.0L DOHC Engine2.0L DOHC Engine

(Non-Turbo)(FWD-Turbo)(AWD-Turbo)

F5M22F5M33W5M33

F4A22F4A33W4A33Dry-single disc

Dry-single discDry-single disc& diaphragm spring& diaphragm spring& diaphragm spring

P205/55R16 89HP205155R16 89VP205/55R16 89Vor 205/55R16 89Vor 205/55R16 88Vor 205/55R16 88Vor 205/55R16 88VIndependent strut

Independent strutIndependent strut

3-Link Torsion axle3-Link Torsion axleDouble wishbone

Front

Disc

DiscDisc

RearDisc

DiscDiscRack and pinion

Rack and pinionRack

,and pinion

03coccliters (gals.) 60 (16)

60 (16)60 (16)

)

ENGINE SPECIFICATIONS

Items4G374G63 Non-Turbo4G63 Turbo

TypeIn-line SOHCIn-line DOHCIn-line DOHC

Number of cylinders

444

Boremm (in.) 80.6 (3.17)

85.0 (3.35)85.0 (3.35)

Strokemm (in.) 86.0 (3.39)

88.0 (3.46)88.0 (3.46)

Piston displacement

cm3 (cu.in.) 1,755 (107)1,997 (122)1,997 (122)Compression ratio

9.09.07.8Firina order

1-3-4-21-3-4-21-3-4-2

TRANSAXLE SPECIFICATIONS

ItemsF5M22F5M33W5M33F4A22F4A33W4A33

TypeGear ratio

1 st

2nd

3rd

4th

5th

Reverse

TransaxlePrimary reduction ratio

Secondary reduction

ratio

Transfer

5-speed M/T5-speed M/T

3.363

3.090

1.947

1.833

1.285

1.217

0.939

0.888

0.756

0.741

3.0833.166

5speed M/T4-speed A/T4-speed AIT

3.083

2.8462.551

1.6841.5811.488

1.115

1.0001 .ooo

0.8330.6850.685

0.666--

3.166

2.1762.176

Qspeed AIT

2.551

1.488

1 .ooo

0.685

-

2.176

1.096

3.9411.2081.275

1.1251.2281.228

3.4373.866

3.5623.222

3.600

-1.090--1.090

Page 30 of 1216

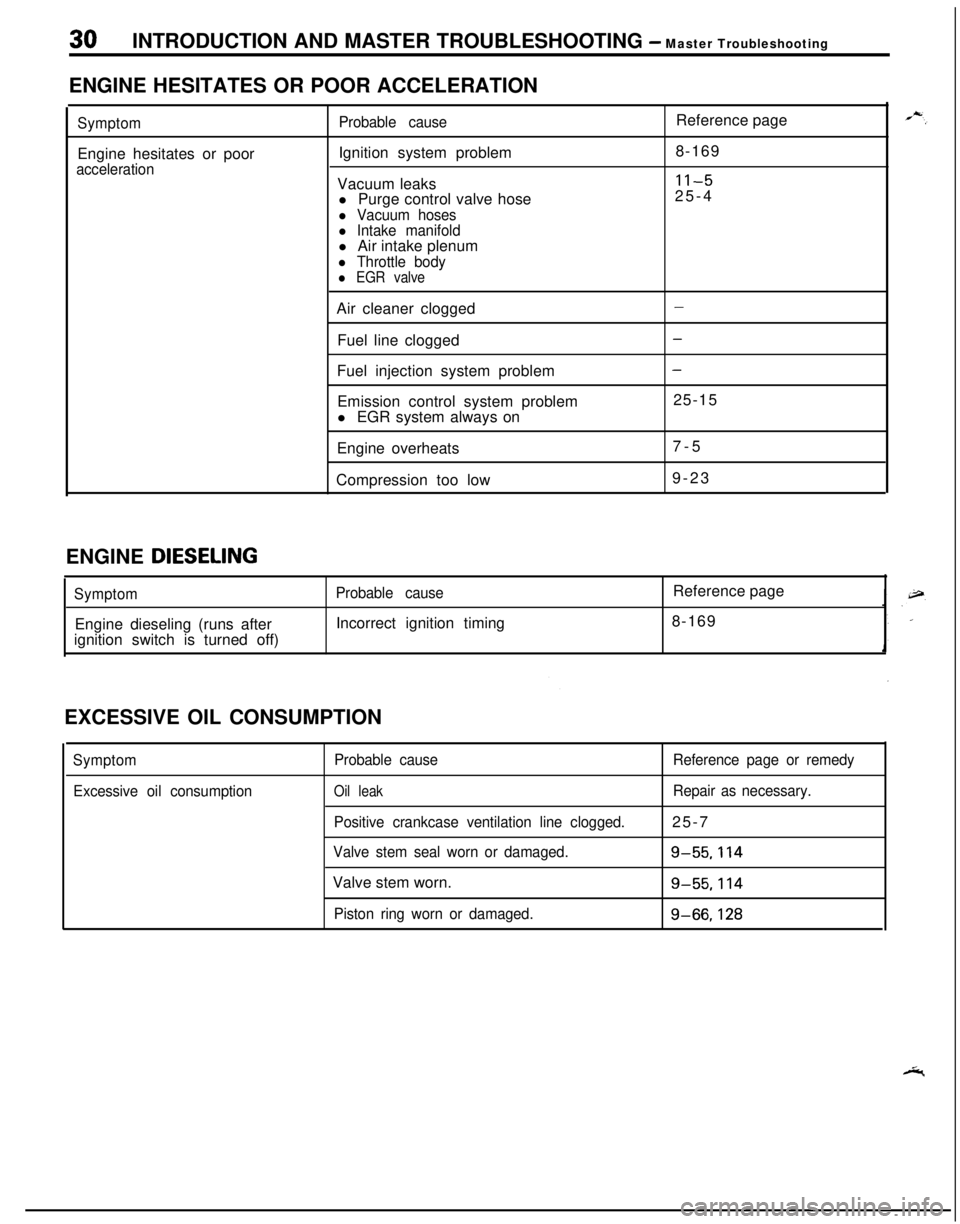

30INTRODUCTION AND MASTER TROUBLESHOOTING - Master Troubleshooting

ENGINE HESITATES OR POOR ACCELERATION

SymptomEngine hesitates or poor

accelerationProbable causeIgnition system problem

Vacuum leaks

l Purge control valve hose

l Vacuum hosesl Intake manifoldl Air intake plenum

l Throttle bodyl EGR valveReference page

8-169

11-525-4

Air cleaner clogged

Fuel line clogged

Fuel injection system problem

Emission control system problem

l EGR system always on

Engine overheats

Compression too low

-

-

-25-15

7-5

9-23

ENGINE

DIESELING

SymptomEngine dieseling (runs after

ignition switch is turned off)Probable causeIncorrect ignition timingReference page

8-169

EXCESSIVE OIL CONSUMPTION

Symptom

Excessive oil consumptionProbable cause

Oil leak

Positive crankcase ventilation line clogged.

Valve stem seal worn or damaged.Valve stem worn.

Piston ring worn or damaged.Reference page or remedy

Repair as necessary.25-7

g-55.114

g-55.114

g-66,128

Page 142 of 1216

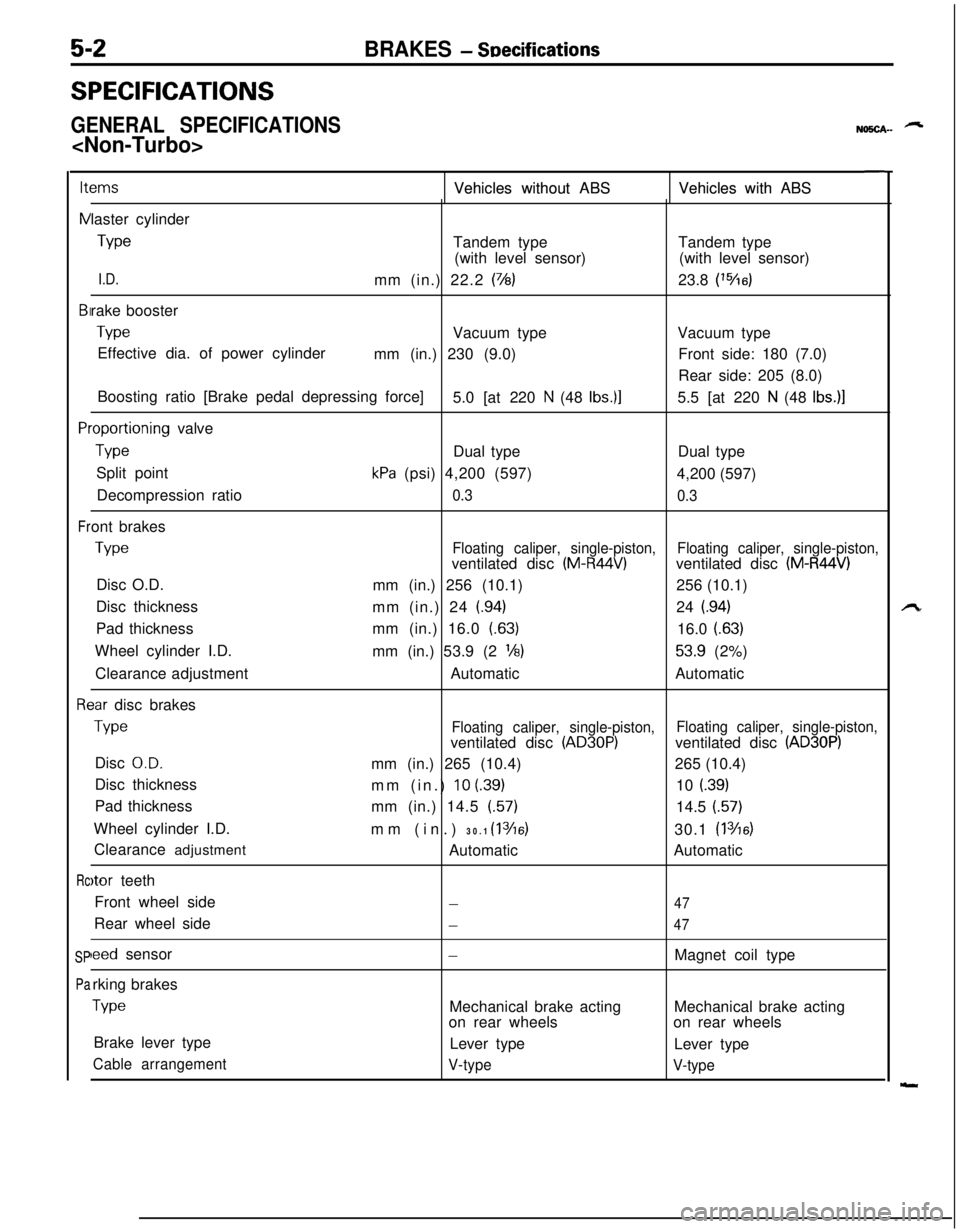

5-2BRAKES - SDecifications

SPECIFICATIONS

GENERAL SPECIFICATIONS

NO!iCA-- -

ItemsItems

NNVehicles without ABS Vehicles without ABSVehicles with ABS Vehicles with ABS

BIBI

PlPl

Fr Frlaster cylinder

TypeTandem typeTandem type

(with level sensor)(with level sensor)

I.D.mm (in.) 22.2 (7/8)23.8 (‘%6)rake booster

TypeVacuum typeVacuum type

Effective dia. of power cylinder

mm (in.) 230 (9.0)Front side: 180 (7.0)

Rear side: 205 (8.0)

Boosting ratio [Brake pedal depressing force]

5.0 [at 220

N (48 Ibs.)]5.5 [at 220 N (48 Ibs.)]

.oportioning valve

TypeDual typeDual type

Split point

kPa (psi) 4,200 (597)

4,200 (597)

Decompression ratio

0.3

0.3ont brakes

TypeFloating caliper, single-piston,ventilated disc (M-R44V)Floating caliper, single-piston,ventilated disc (M-R44V)Disc O.D.

mm (in.) 256 (10.1)256 (10.1)

Disc thickness

mm (in.) 24

(.94)24 (.94)Pad thicknessmm (in.) 16.0 (63)

16.0

(.63)Wheel cylinder I.D.

mm (in.) 53.9 (2

l/8)53.9 (2%)

Clearance adjustmentAutomaticAutomatic

3ar disc brakes

TypeFloating caliper, single-piston,Floating caliper, single-piston,ventilated disc (AD30P)ventilated disc (AD30P)Disc

O.D.mm (in.) 265 (10.4)265 (10.4)

Disc thickness

mm (in.)

10 (39)10 i.39)Pad thickness

mm (in.) 14.5 (57)

14.5 (57)

Wheel cylinder I.D.

mm (in.) 30.1

(1 3/16)30.1 (1 346)Clearance adjustment

AutomaticAutomatic

)tor teeth

Front wheel side

-47Rear wheel side

-47

leed sensor-Magnet coil type

rking brakes

TypeMechanical brake actingMechanical brake acting

on rear wheelson rear wheels

Brake lever type

Lever type

Lever type

Cable arrangement

V-type

V-type

Rc Rc

SP SP

Pa Pa

Page 143 of 1216

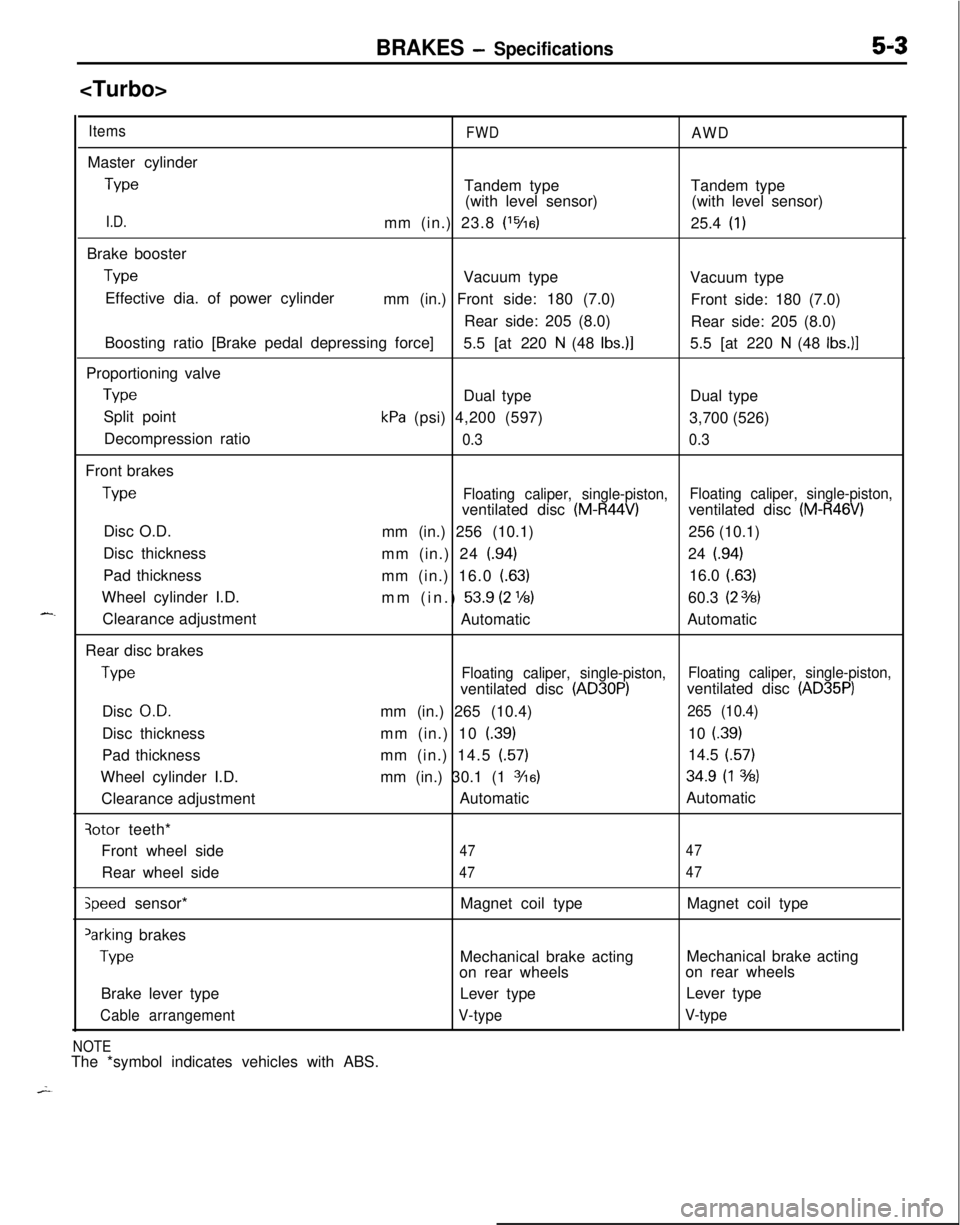

BRAKES - Specifications5-3

ItemsFWDAWDMaster cylinder

TypeTandem type

(with level sensor)Tandem type

(with level sensor)

I.D.mm (in.) 23.8 (‘%a)25.4 (1)Brake booster

TypeVacuum type

Vacuum type

Effective dia. of power cylinder

mm (in.) Front side: 180 (7.0)

Front side: 180 (7.0)

Rear side: 205 (8.0)

Rear side: 205 (8.0)

Boosting ratio [Brake pedal depressing force]

5.5 [at 220

N (48 Ibs.)]5.5 [at 220 N (48 Ibs.)]Proportioning valve

TypeDual typeDual type

Split point

kPa (psi) 4,200 (597)

3,700 (526)

Decompression ratio

0.30.3Front brakes

TypeFloating caliper, single-piston,Floating caliper, single-piston,ventilated disc (M-R44V)ventilated disc (M-R46V)Disc O.D.

mm (in.) 256 (10.1)256 (10.1)

Disc thickness

mm (in.) 24

(.94)24 (.94)Pad thickness

mm (in.) 16.0

(.63)16.0 (.63)Wheel cylinder I.D.

mm (in.)

53.9 (2 ‘16)60.3 (23%3)Clearance adjustment

AutomaticAutomatic

Rear disc brakes

TypeFloating caliper, single-piston,Floating caliper, single-piston,ventilated disc (AD30P)ventilated disc (AD35P)Disc

O.D.mm (in.) 265 (10.4)265 (10.4)Disc thicknessmm (in.) 10

(.39)10 f.39)Pad thicknessmm (in.) 14.5

(.57)14.5 (.57)Wheel cylinder I.D.mm (in.) 30.1 (1

3/16)34.9 (1 3h)Clearance adjustmentAutomaticAutomatic

qotor teeth*

Front wheel side

4747Rear wheel side

4747

speed sensor*Magnet coil typeMagnet coil type‘arking brakes

TypeMechanical brake actingMechanical brake acting

on rear wheelson rear wheels

Brake lever typeLever typeLever type

Cable arrangementV-typeV-type

NOTEThe *symbol indicates vehicles with ABS.

Page 285 of 1216

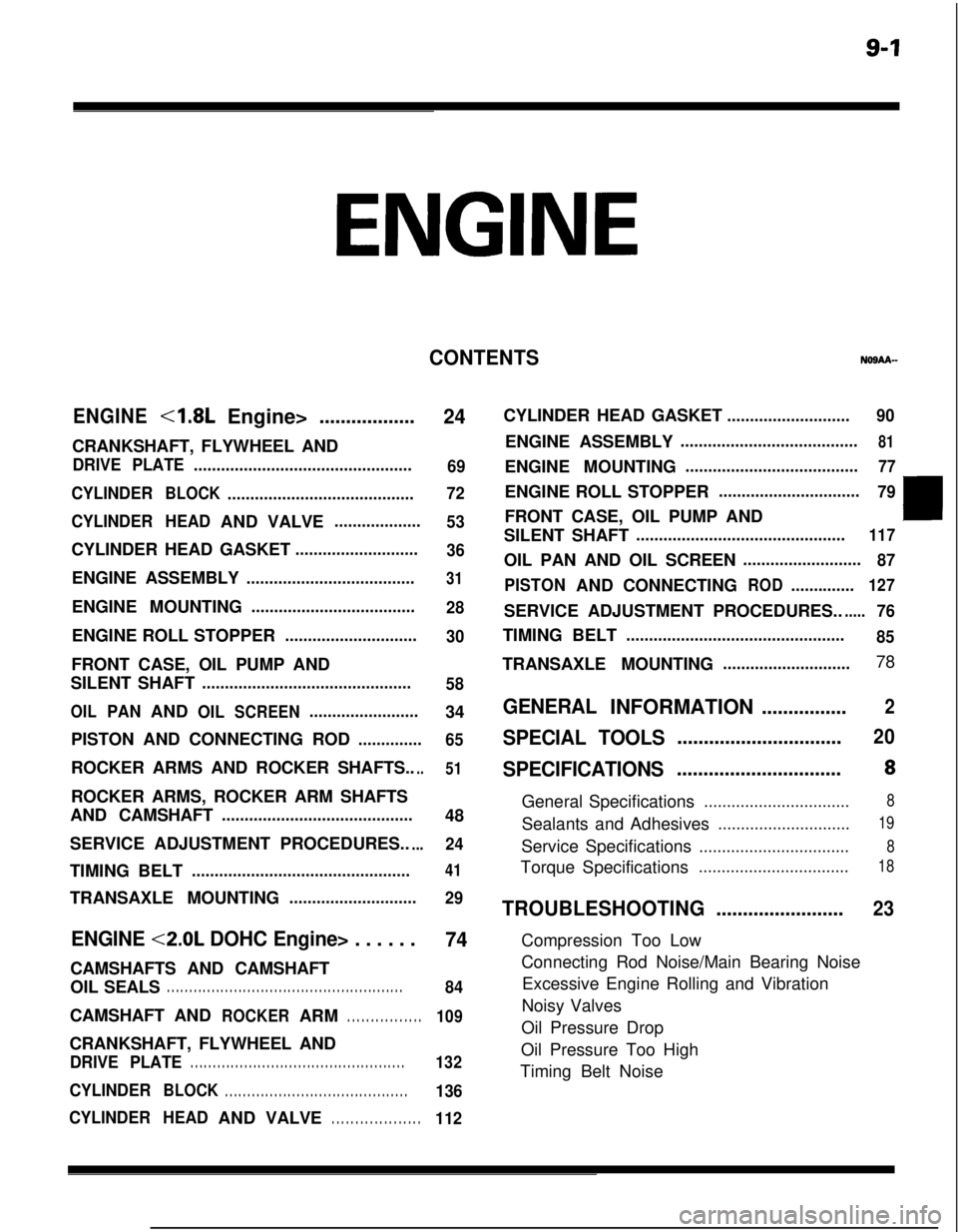

9-1

ENGINE

CONTENTSNOSAA-

ENGINE<1.8L

Engine>..................

24CRANKSHAFT, FLYWHEEL AND

DRIVE PLATE................................................

69

CYLINDER

BLOCK.........................................72

CYLINDERHEADANDVALVE

...................

53CYLINDER HEAD GASKET

...........................

36ENGINE ASSEMBLY

.....................................31ENGINE MOUNTING

....................................

28ENGINE ROLL STOPPER

.............................

30FRONT CASE, OIL PUMP AND

SILENT SHAFT

..............................................

58

OILPANANDOILSCREEN........................34

PISTON AND CONNECTING ROD

..............

65ROCKER ARMS AND ROCKER SHAFTS..

..51ROCKER ARMS, ROCKER ARM SHAFTS

AND CAMSHAFT

..........................................48

SERVICE ADJUSTMENT PROCEDURES..

...24TIMING BELT

................................................41TRANSAXLE MOUNTING

............................

29

ENGINE <2.0L DOHC Engine> . . . . . .

74CAMSHAFTS AND CAMSHAFT

OIL SEALS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84CAMSHAFTAND

ROCKERARM. . . . . . . . . . . . . . . .109CRANKSHAFT, FLYWHEEL AND

DRIVE PLATE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .132

CYLINDERBLOCK. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .136

CYLINDERHEADANDVALVE

. . . . . . . . . . . . . . . . . . .112CYLINDER HEAD GASKET

...........................90ENGINE ASSEMBLY

.......................................81ENGINE MOUNTING

......................................77ENGINE ROLL STOPPER

...............................

79FRONT CASE, OIL PUMP AND

SILENT SHAFT

..............................................117OIL PAN AND OIL SCREEN

..........................

87

PISTONANDCONNECTING

ROD..............127SERVICE ADJUSTMENT PROCEDURES..

.....76TIMING BELT

................................................

85TRANSAXLE MOUNTING

............................78

GENERALINFORMATION................2

SPECIAL TOOLS...............................20

SPECIFICATIONS...............................8General Specifications

................................8Sealants and Adhesives

.............................19Service Specifications

.................................8Torque Specifications

.................................18

TROUBLESHOOTING........................23Compression Too Low

Connecting Rod Noise/Main Bearing Noise

Excessive Engine Rolling and Vibration

Noisy Valves

Oil Pressure Drop

Oil Pressure Too High

Timing Belt Noise

Page 292 of 1216

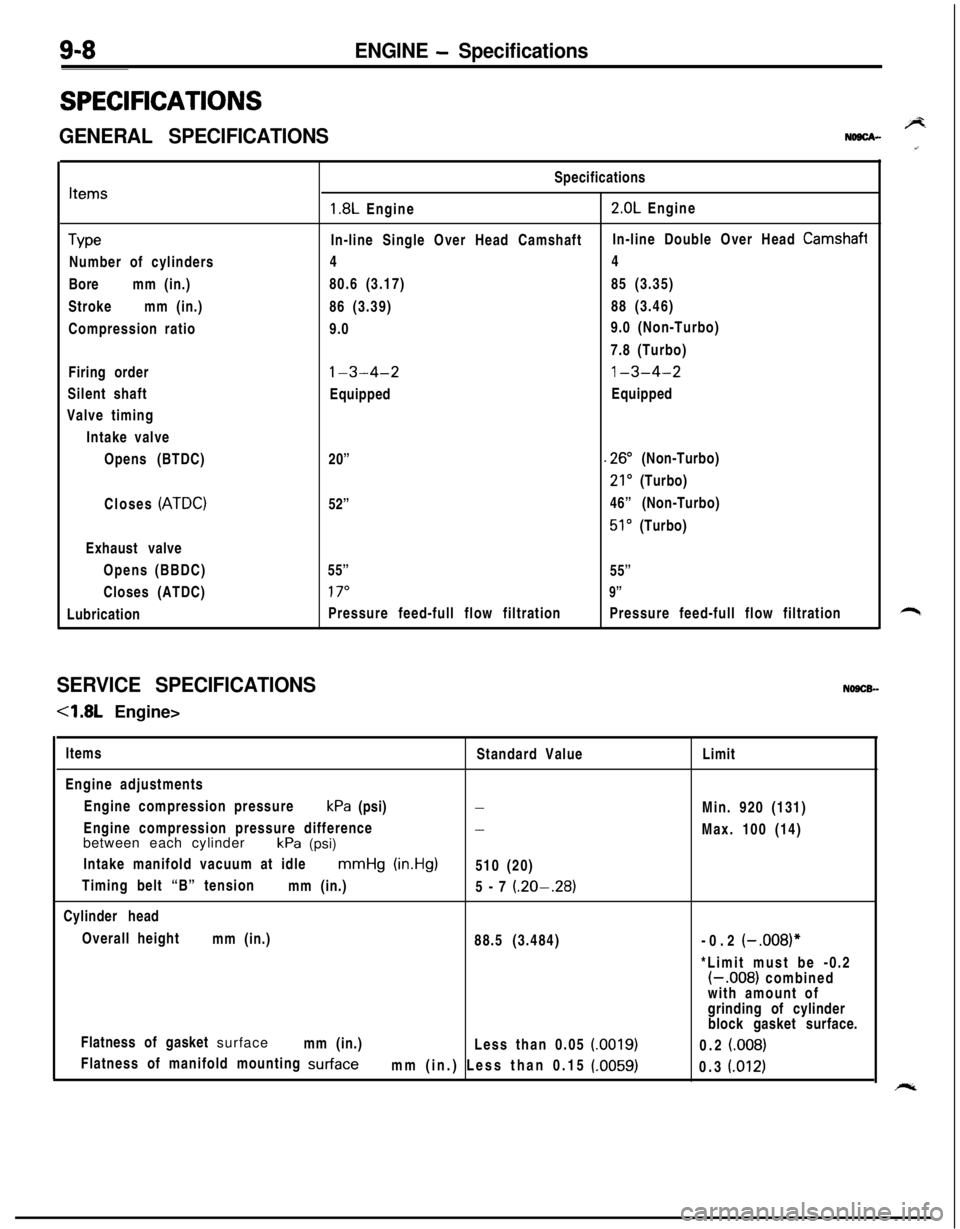

9-8ENGINE - Specifications

SPECIFICATIONS

GENERAL SPECIFICATIONSBNDBCA-

Items

TypeNumber of cylinders

Boremm (in.)

Strokemm (in.)

Compression ratio

Firing order

Silent shaft

Valve timing

Intake valve

Opens (BTDC)

Closes

(ATDC)Exhaust valve

Opens (BBDC)

Closes (ATDC)

LubricationSpecifications

1.8L Engine2.0L Engine

In-line Single Over Head CamshaftIn-line Double Over Head

Camshafi44

80.6 (3.17)85 (3.35)

86 (3.39)88 (3.46)

9.09.0 (Non-Turbo)

7.8 (Turbo)

l-3-4-21-3-4-2EquippedEquipped

20”

.26” (Non-Turbo)

21’ (Turbo)

52”46” (Non-Turbo)

51’ (Turbo)

55”

55”

17”9”Pressure feed-full flow filtrationPressure feed-full flow filtration

SERVICE SPECIFICATIONSNOSCB-

-4.8L Engine>

Items

Standard Value

Engine adjustments

Engine compression pressurekPa (psi)

-Engine compression pressure difference

-between each cylinder

kPa (psi)

Intake manifold vacuum at idle

mmHg (in.Hg)510 (20)

Timing belt “B” tension

mm (in.)

5-7

(.20-.28)Cylinder head

Overall height

mm (in.)

88.5 (3.484)

Flatness of gasket surface

mm (in.)

Less than 0.05

(0019)Flatness of manifold mounting

surfacemm (in.) Less than 0.15 (.0059)Limit

Min. 920 (131)

Max. 100 (14)

-0.2

(-.008)**Limit must be -0.2

(-.008) combined

with amount of

grinding of cylinder

block gasket surface.

0.2

(008)0.3

(.012)

Page 307 of 1216

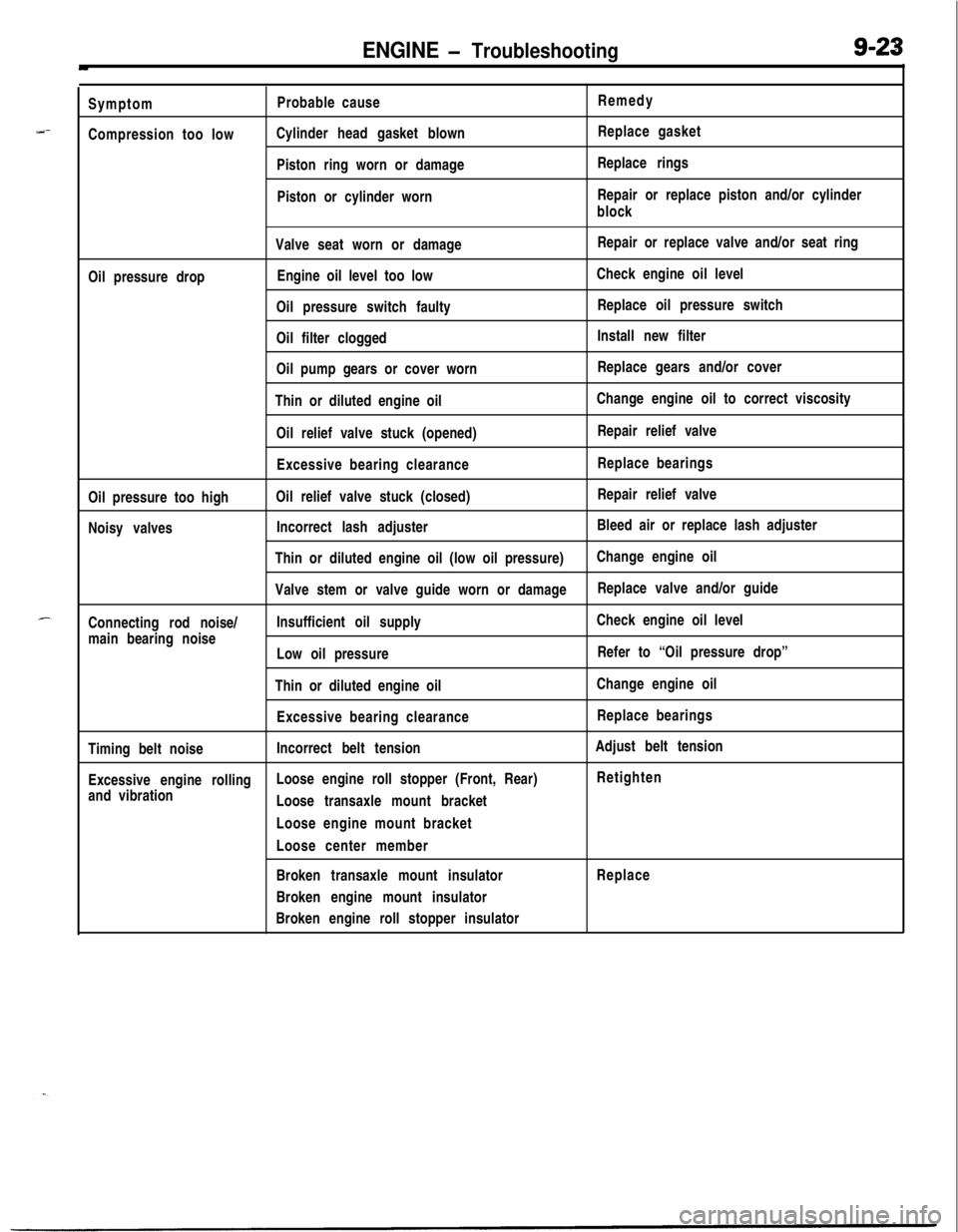

ENGINE - Troubleshooting9-23

--Symptom

Compression too lowProbable cause

Cylinder head gasket blown

Piston ring worn or damage

Piston or cylinder wornRemedy

Replace gasket

Replace rings

Repair or replace piston and/or cylinder

block

Valve seat worn or damageRepair or replace valve and/or seat ring

Oil pressure dropEngine oil level too lowCheck engine oil level

Oil pressure switch faultyReplace oil pressure switch

Oil filter cloggedInstall new filter

Oil pump gears or cover wornReplace gears and/or cover

Thin or diluted engine oilChange engine oil to correct viscosity

Oil relief valve stuck (opened)Repair relief valve

Excessive bearing clearanceReplace bearings

Oil pressure too highOil relief valve stuck (closed)Repair relief valve

Noisy valvesIncorrect lash adjusterBleed air or replace lash adjuster

Thin or diluted engine oil (low oil pressure)Change engine oil

Valve stem or valve guide worn or damageReplace valve and/or guide

Connecting rod noise/Insufficient oil supplyCheck engine oil level

main bearing noise

Low oil pressureRefer to “Oil pressure drop”

Thin or diluted engine oilChange engine oil

Excessive bearing clearanceReplace bearings

Timing belt noiseIncorrect belt tensionAdjust belt tension

Excessive engine rollingLoose engine roll stopper (Front, Rear)Retighten

and vibration

Loose transaxle mount bracket

Loose engine mount bracket

Loose center member

Broken transaxle mount insulatorReplace

Broken engine mount insulator

Broken engine roll stopper insulator

Page 1158 of 1216

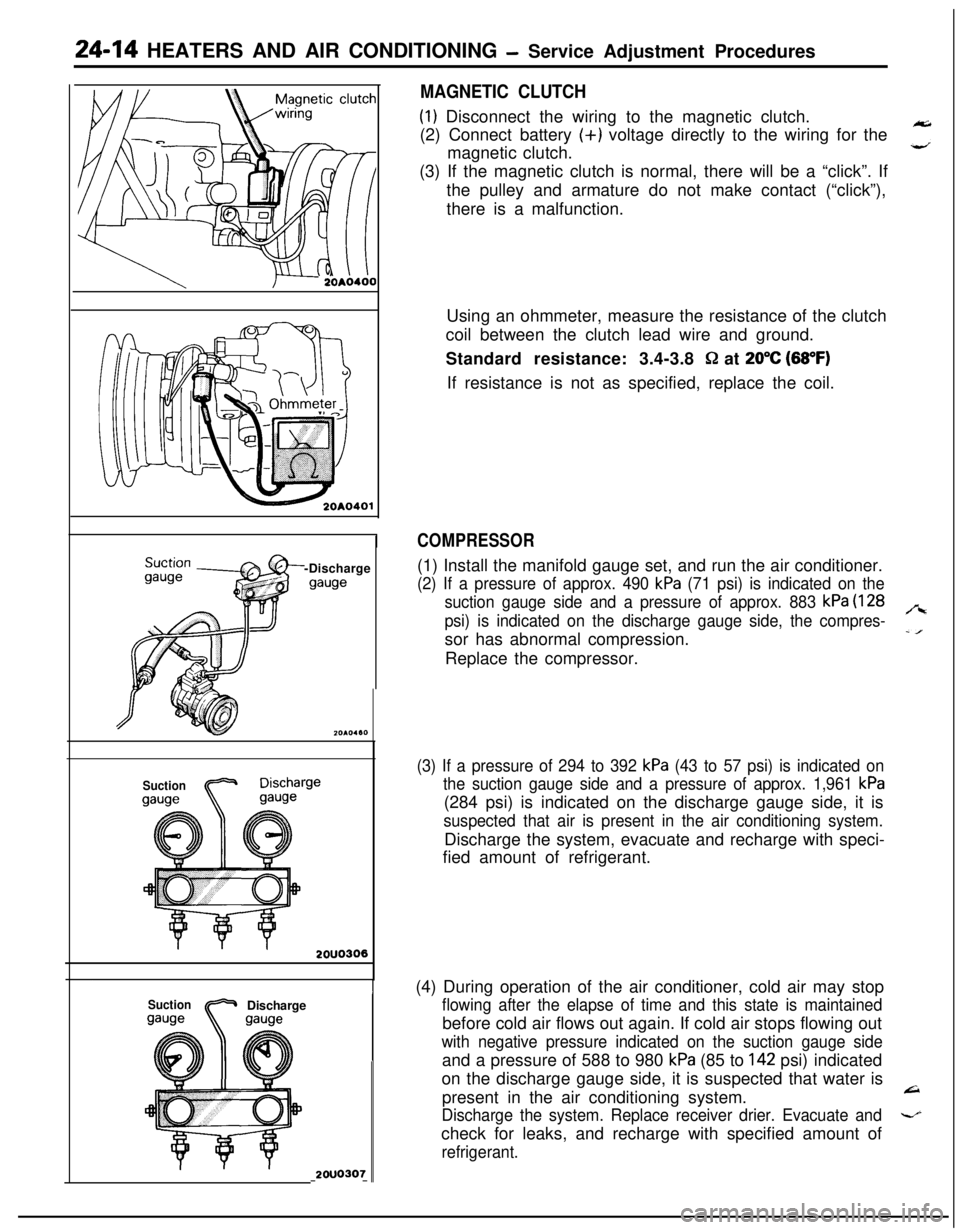

24-14 HEATERS AND AIR CONDITIONING - Service Adjustment Procedures

-Discharge

w-w

SuctiongaugeDischalgauge

2OUO306

SuctiongaugeDischargegauge

2OUO307--

MAGNETIC CLUTCH(I) Disconnect the wiring to the magnetic clutch.

(2) Connect battery (+) voltage directly to the wiring for the

magnetic clutch.

,”(3) If the magnetic clutch is normal, there will be a “click”. If

the pulley and armature do not make contact (“click”),

there is a malfunction.

Using an ohmmeter, measure the resistance of the clutch

coil between the clutch lead wire and ground.

Standard resistance: 3.4-3.8

Q at 20°C (88°F)If resistance is not as specified, replace the coil.

COMPRESSOR(1) Install the manifold gauge set, and run the air conditioner.

(2) If a pressure of approx. 490 kPa (71 psi) is indicated on the

suction gauge side and a pressure of approx. 883

kPa (128

psi) is indicated on the discharge gauge side, the compres-

,“ssor has abnormal compression.

-IReplace the compressor.

(3) If a pressure of 294 to 392 kPa (43 to 57 psi) is indicated on

the suction gauge side and a pressure of approx. 1,961

kPa(284 psi) is indicated on the discharge gauge side, it is

suspected that air is present in the air conditioning system.Discharge the system, evacuate and recharge with speci-

fied amount of refrigerant.

(4) During operation of the air conditioner, cold air may stop

flowing after the elapse of time and this state is maintainedbefore cold air flows out again. If cold air stops flowing out

with negative pressure indicated on the suction gauge sideand a pressure of 588 to 980

kPa (85 to 142 psi) indicated

on the discharge gauge side, it is suspected that water is

present in the air conditioning system.

L=I

Discharge the system. Replace receiver drier. Evacuate and-check for leaks, and recharge with specified amount of

refrigerant.