timing belt MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 35 of 1216

LUBRICATION AND’ I

MAINTENANCE

CONTENTSGENERAL INFORMATION

..............................2MAINTENANCE SERVICE

...............................7Air

CleanerElement.....................................7Automatic Transaxle....................................

11Ball Joint and Steering Linkage Seals

........13Brake Hoses

.................................................12

DiscBrakePads...........................................12-lbDrive Belt (For Water Pump and

Alternator).....................................................8

DriveShaftBoots.........................................13

EngineCoolant.............................................12

EngineOil.....................................................9

EngineOilFilter...........................................9Exhaust System

............................................13

FuelHose.....................................................7

FuelSystem.................................................7

ManualTransaxle..........................................10

RearAxle......................................................13

SparkPlugs...................................................8

TimingBelt......................................................8RECOMMENDED LUBRICANTS AND

LUBRICANT CAPACITIES TABLE

..................4SCHEDULED MAINTENANCE TABLE

............3

Page 37 of 1216

LUBRICATION AND MAINTENANCE - Scheduled MaintenanCe Table. &3

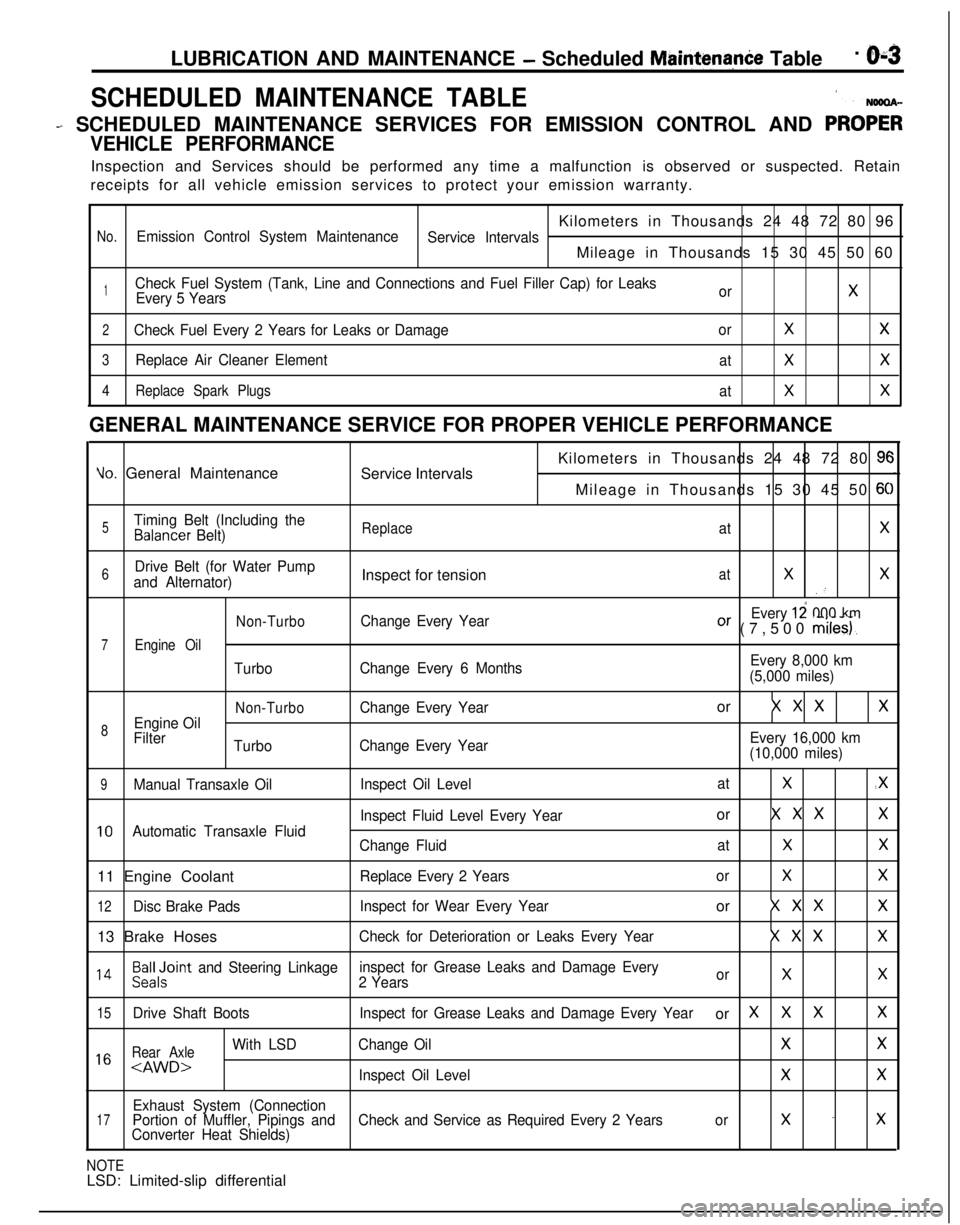

SCHEDULED MAINTENANCE TABLE1

- SCHEDULED MAINTENANCE SERVICES FOR EMISSION CONTROL AND PRO;;

VEHICLE PERFORMANCEInspection and Services should be performed any time a malfunction is observed or suspected. Retain

receipts for all vehicle emission services to protect your emission warranty.

Kilometers in Thousands 24 48 72 80 96

No.Emission Control System Maintenance

Service IntervalsMileage in Thousands 15 30 45 50 60

1Check Fuel System (Tank, Line and Connections and Fuel Filler Cap) for Leaks

Every 5 YearsorX

2Check Fuel Every 2 Years for Leaks or DamageorXX

3Replace Air Cleaner Element

atXX

4Replace Spark Plugs

atXXGENERAL MAINTENANCE SERVICE FOR PROPER VEHICLE PERFORMANCE

Yo. General Maintenance

Service IntervalsKilometers in Thousands 24 48 72 80 9cMileage in Thousands 15 30 45 50

6C

5Timing Belt (Including theBalancer Belt)ReplaceatX

6Drive Belt (for Water Pump

and Alternator)Inspect for tensionatXX.’

Non-TurboChange Every YearEvery 12 000 kmOr (7,500 miles).

7Engine Oil

TurboChange Every 6 MonthsEvery 8,000 km

(5,000 miles)

Non-TurboChange Every Yearor X X XX

8Engine Oil

Filter

TurboChange Every YearEvery 16,000 km

(10,000 miles)

9Manual Transaxle OilInspect Oil LevelatX.X

Inspect Fluid Level Every Yearor X X XX

10Automatic Transaxle Fluid

Change FluidatXX11 Engine Coolant

Replace Every 2 YearsorXX

12Disc Brake PadsInspect for Wear Every Yearor X X XX13 Brake Hoses

Check for Deterioration or Leaks Every YearX X XX

l 4Beiloint and Steering Linkageinspect for Grease Leaks and Damage Every

2 YearsorXX

15Drive Shaft BootsInspect for Grease Leaks and Damage Every Yearor XXXX

Rear Axle

With LSDChange OilXX1 6

Exhaust System (Connection17Portion of Muffler, Pipings andCheck and Service as Required Every 2 Yearsorx -xConverter Heat Shields)

NOTELSD: Limited-slip differential

Page 42 of 1216

O-8LUBRICATION AND MAINTENANCE - Maintenance Service

0-L

I-TOlLO182

-

, ,6COOO9

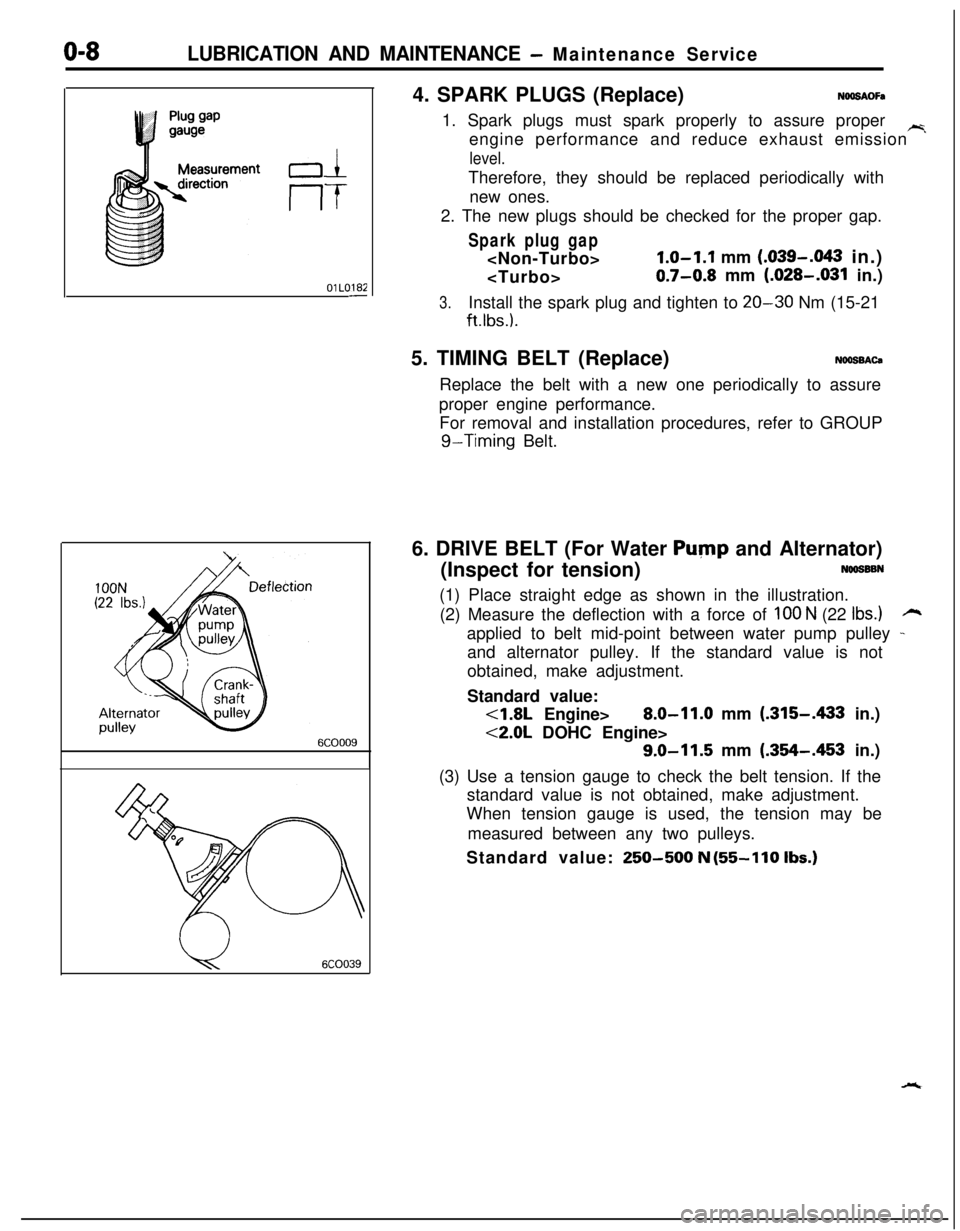

u6COO394. SPARK PLUGS (Replace)

NOOSAOFa1. Spark plugs must spark properly to assure proper

~engine performance and reduce exhaust emission

level.Therefore, they should be replaced periodically with

new ones.

2. The new plugs should be checked for the proper gap.

Spark plug gap

1.0-1.1 mm (.039-.043 in.)

0.7-0.8 mm (.028-.031 in.)

3.Install the spark plug and tighten to 20-30 Nm (15-21

ft.lbs.).5. TIMING BELT (Replace)

NOOSBACaReplace the belt with a new one periodically to assure

proper engine performance.

For removal and installation procedures, refer to GROUP

g-Timing Belt.

6. DRIVE BELT (For Water

Pump and Alternator)

(Inspect for tension)

NOOSSBN(1) Place straight edge as shown in the illustration.

(2) Measure the deflection with a force of

100 N (22 Ibs.)rzapplied to belt mid-point between water pump pulley

-and alternator pulley. If the standard value is not

obtained, make adjustment.

Standard value:

<1.8L Engine>8.0-11.0 mm (.315-A33 in.)

<2.0L DOHC Engine>

9.0-11.5 mm (.354-.453 in.)

(3) Use a tension gauge to check the belt tension. If the

standard value is not obtained, make adjustment.

When tension gauge is used, the tension may be

measured between any two pulleys.

Standard value:

250-500 N (55-110 Ibs.)

Page 251 of 1216

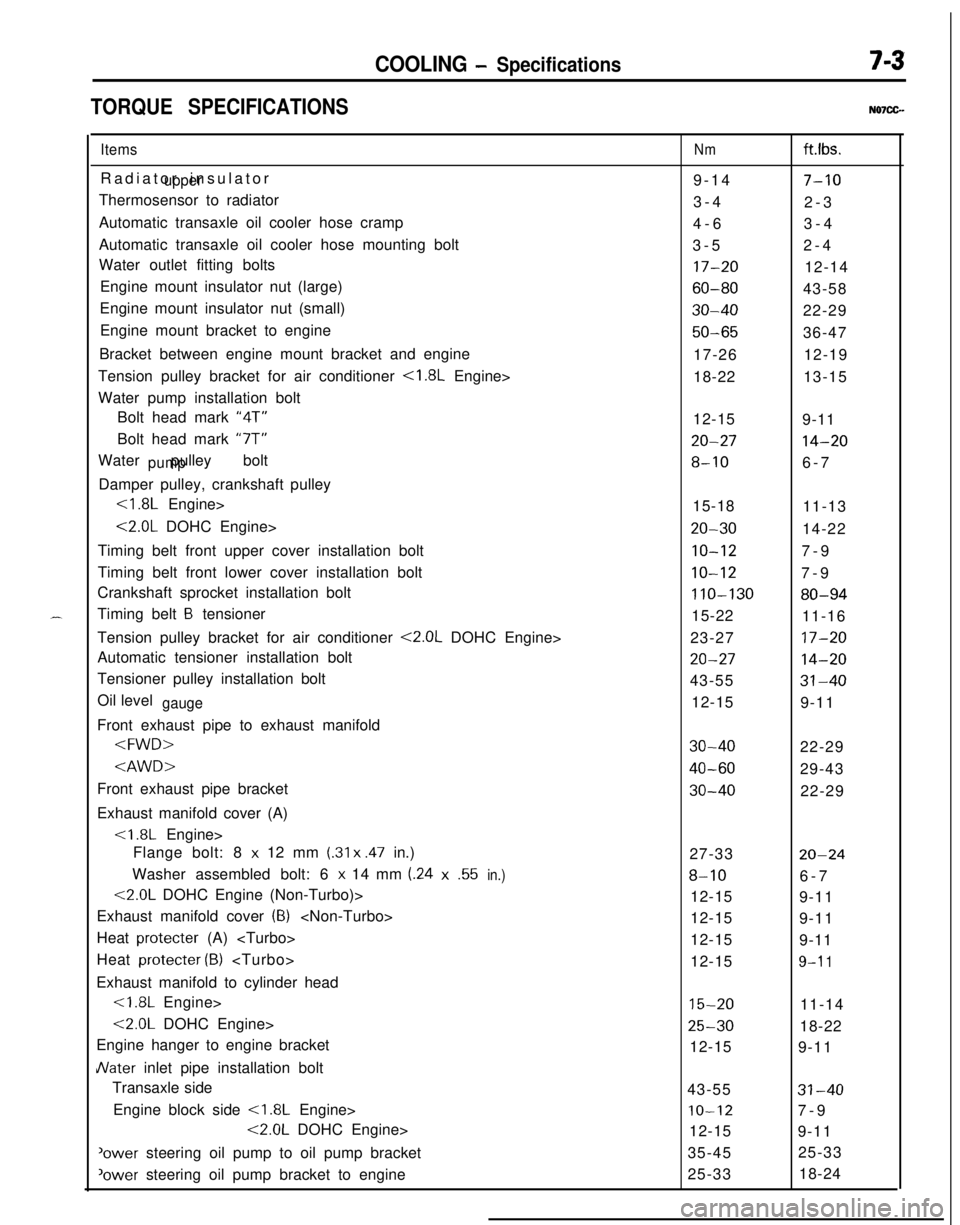

COOLING - Specifications7-3

TORQUE SPECIFICATIONSN07CG.

ItemsRadiator insulator

upperThermosensor to radiator

Automatic transaxle oil cooler hose cramp

Automatic transaxle oil cooler hose mounting bolt

Water outlet fitting bolts

Engine mount insulator nut (large)

Engine mount insulator nut (small)

Engine mount bracket to engine

Bracket between engine mount bracket and engine

Tension pulley bracket for air conditioner

<1.8L Engine>

Water pump installation bolt

Bolt head mark “4T”

Bolt head mark “7T”

Water pulley bolt

pumpDamper pulley, crankshaft pulley

<1.8L Engine>

<2.0L DOHC Engine>

Timing belt front upper cover installation bolt

Timing belt front lower cover installation bolt

Crankshaft sprocket installation bolt

Timing belt

B tensioner

Tension pulley bracket for air conditioner

<2.0L DOHC Engine>

Automatic tensioner installation bolt

Tensioner pulley installation bolt

Oil level

gaugeFront exhaust pipe to exhaust manifold

Exhaust manifold cover (A)

Flange bolt: 8

x 12 mm (.31 x .47 in.)

Washer assembled bolt: 6

x 14 mm (.24x.55in.)

<2.0L DOHC Engine (Non-Turbo)>

Exhaust manifold cover

(8)

Heat protecter (A)

Heat protecter

(B)

Exhaust manifold to cylinder head<1.8L Engine>

<2.0L DOHC Engine>

Engine hanger to engine bracket

JVater inlet pipe installation bolt

Transaxle side

Engine block side

<1.8L Engine>

<2.0L DOHC Engine>

'ower steering oil pump to oil pump bracket

‘ower steering oil pump bracket to engine

Nmft.lbs.

9-14

7-103-4

2-3

4-63-4

3-52-4

17-2012-14

60-8043-58

30-4022-29

50-6536-47

17-2612-19

18-2213-15

12-15

9-11

20-2714-20

8-106-7

15-18

11-13

20-3014-22

IO-127-9

10-127-9

110-13080-9415-22

11-16

23-27

17-20

20-2714-2043-55

31-4012-15

9-11

30-4022-29

40-6029-43

30-4022-29

27-33

20-24

8-106-7

12-15

9-11

12-15

9-11

12-15

9-11

12-15

9-l 1

15-2011-14

25-3018-22

12-15

9-11

43-55

31-40

IO-127-9

12-15

9-11

35-4525-33

25-3318-24

Page 266 of 1216

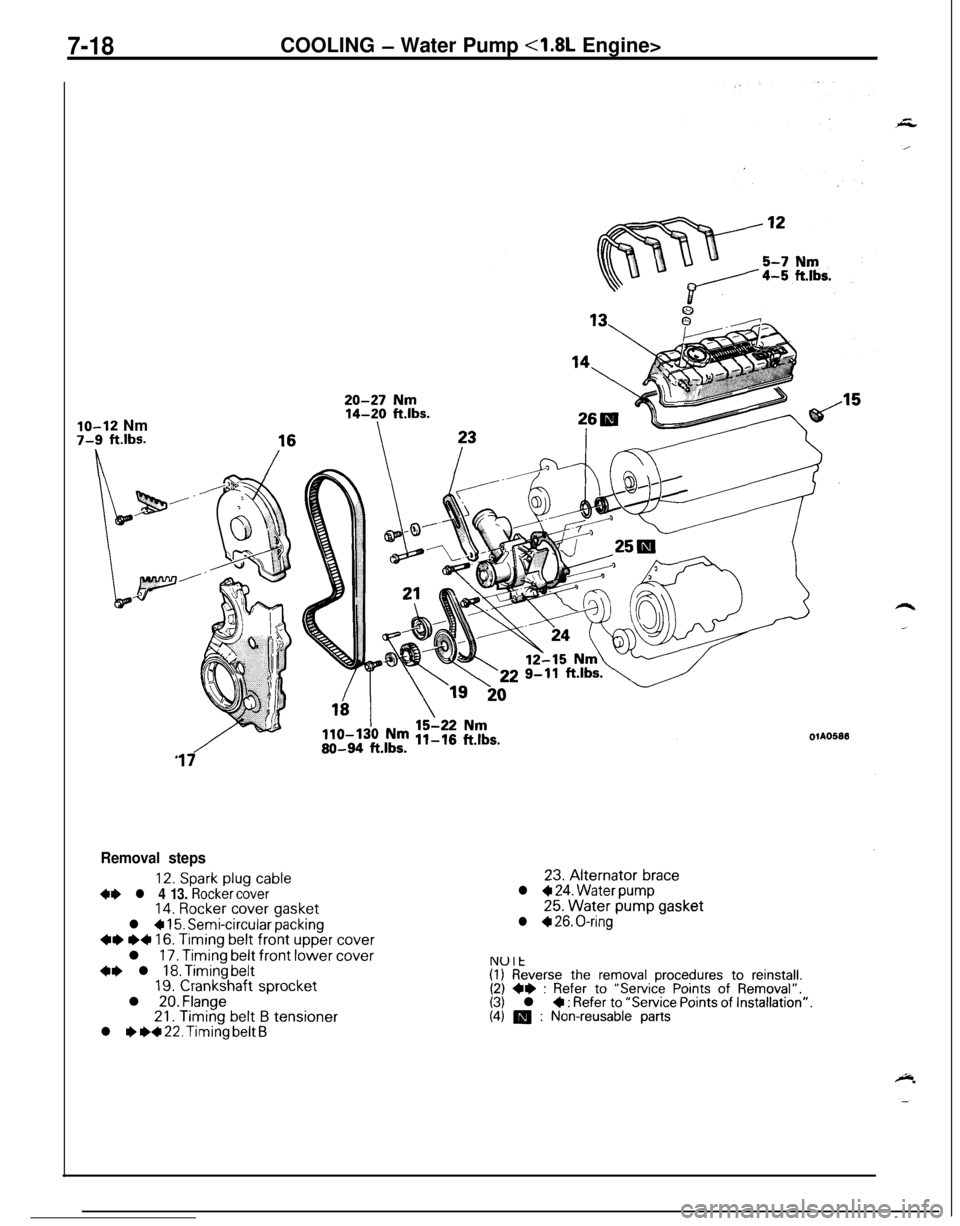

7-18COOLING - Water Pump <1.8L Engine>

lo-12 Nm7-9 ft.lbs.OlA05813

17

Removal steps

12. Spark plug cable+e l 4 13. Rocker cover14. Rocker cover gasket

l + 15. Semi-circular packing~~ e+ 16. Timing belt front upper coverl

17. Timing belt front lower cover+e l 18. Timing belt19. Crankshaft sprocketl 20. Flange21.

Timing belt B tensionerl I) ~~ 22. Timing belt B23.

Alternator bracel + 24. Water pump25.

Water pump gasketl + 26. O-ring

NUlt(I) Reverse the removal procedures to reinstall.(2) ** : Refer to “Service Points of Removal”.(3) l 4 : Refer to “Service Points of Installation”.(4) m : Non-reusable parts

Page 267 of 1216

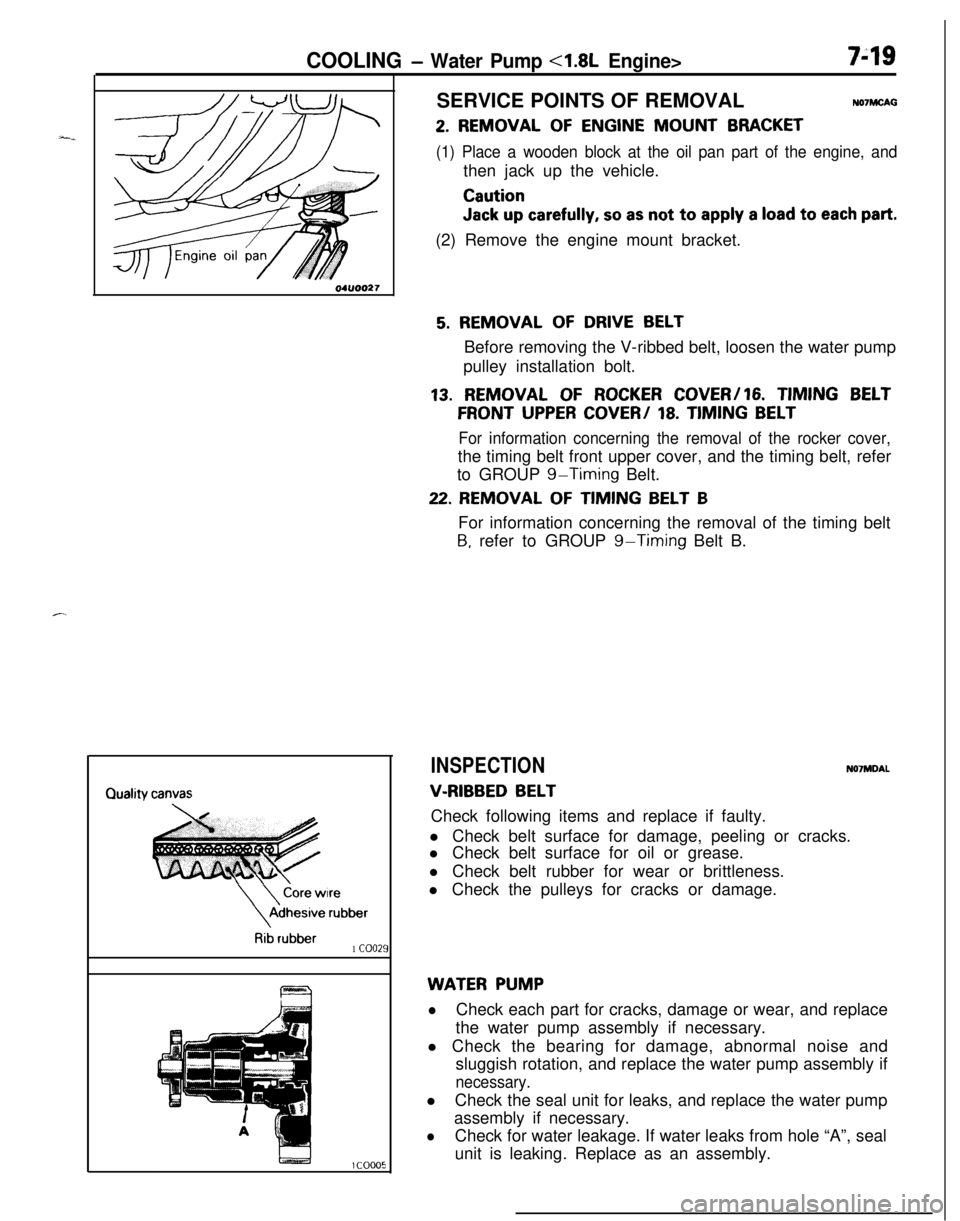

COOLING - Water Pump <1.8L Engine>749SERVICE POINTS OF REMOVAL

NO’IMCAG

2. REMOVAL OF ENGINE MOUNT BRACKET

(1) Place a wooden block at the oil pan part of the engine, andthen jack up the vehicle.

Caution

Jack up carefully, so as not to apply a load to each part.(2) Remove the engine mount bracket.

\

\

Core wireAdhesive

rubber

Rib rubber1 coo21

5. REMOVAL OF DRIVE BELTBefore removing the V-ribbed belt, loosen the water pump

pulley installation bolt.

13. REMOVAL OF ROCKER COVER/16. TIMING BELT

FRONT UPPER COVER/ 18. TIMING BELT

For information concerning the removal of the rocker cover,the timing belt front upper cover, and the timing belt, refer

to GROUP

g-Timing Belt.

22. REMOVAL OF TIMING BELT BFor information concerning the removal of the timing belt

B, refer to GROUP g-Timing Belt B.

INSPECTIONN07MDAL

V-RIBBED BELTCheck following items and replace if faulty.

l Check belt surface for damage, peeling or cracks.

l Check belt surface for oil or grease.

l Check belt rubber for wear or brittleness.

l Check the pulleys for cracks or damage.

WATER PUMP

lCheck each part for cracks, damage or wear, and replace

the water pump assembly if necessary.

l Check the bearing for damage, abnormal noise and

sluggish rotation, and replace the water pump assembly if

necessary.lCheck the seal unit for leaks, and replace the water pump

assembly if necessary.

lCheck for water leakage. If water leaks from hole “A”, seal

unit is leaking. Replace as an assembly.

Page 268 of 1216

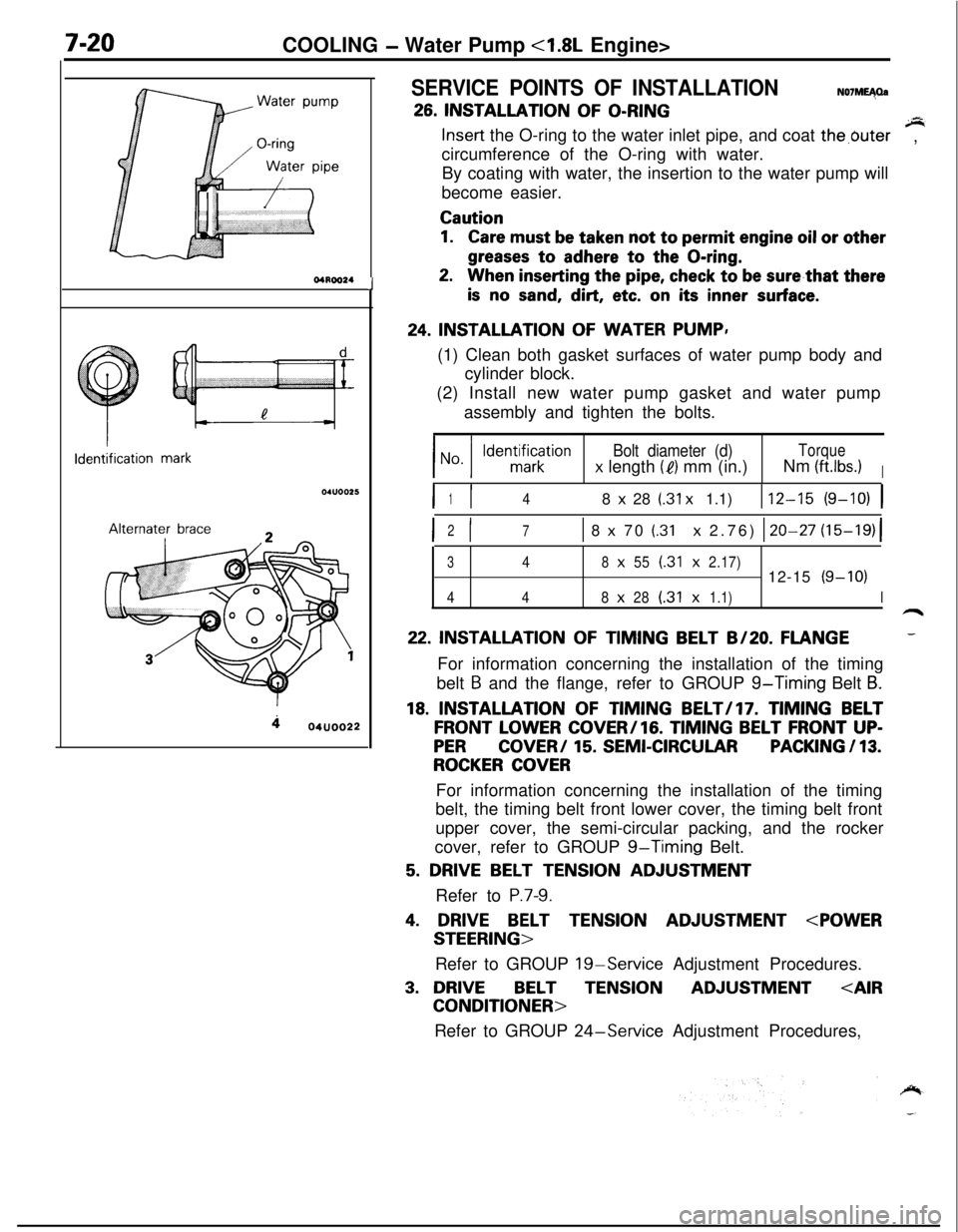

7-20COOLING - Water Pump <1.8L Engine>

aWater pump*<

l-----r,//

O-ringWater

pipe

04ROO24Identification

mark04lJoo25Alternater

brace

404uoo22

J

SERVICE POINTS OF INSTALLATIONN07ME40a

26. INSTALLATION OF O-RINGsInsert the O-ring to the water inlet pipe, and coat the,buter

circumference of the O-ring with water.,

By coating with water, the insertion to the water pump will

become easier.

Caution

1.Care must be taken not to permit engine oil or other

greases to adhere to the O-ring.

2.When inserting the pipe, check to be sure,that there

is no sand, dirt, etc. on its inner surface.

24. INSTALLATION OF WATER PUMP,

(1) Clean both gasket surfaces of water pump body and

cylinder block.

(2) Install new water pump gasket and water pump

assembly and tighten the bolts.

Bolt diameter (d)Torque

x length (e) mm (in.)Nm (ftlbs.)I

I I148 x 28 (.31 x 1.1)112-15 (9-10) 1

I I2

71 8 x 70 (.31 x 2.76) 120-27 (15-19)(

348x55(.31x2.17)12-15(9-10)

448x28(.31x1.1)I

22. INSTALLATION OF TIMING BELT B/20. FLANGE-For information concerning the installation of the timing

belt

B and the flange, refer to GROUP g-Timing Belt B.

18. INSTALLATION OF TIMING BELT/l7. TIMING BELT

FRONT LOWER COVER/lG. TIMING BELT FRONT UP-

PERCOVER/ 15. SEMI-CIRCULARPACKING / 13.

ROCKER COVERFor information concerning the installation of the timing

belt, the timing belt front lower cover, the timing belt front

upper cover, the semi-circular packing, and the rocker

cover, refer to GROUP

g-Timing Belt.

5. DRIVE BELT TENSION ADJUSTMENT

Refer to

P.7-9.

4. DRIVE BELT TENSION ADJUSTMENT

Refer to GROUP

19-Service Adjustment Procedures.

3. DRIVEBELTTENSIONADJUSTMENT

Refer to GROUP

24-Service Adjustment Procedures,

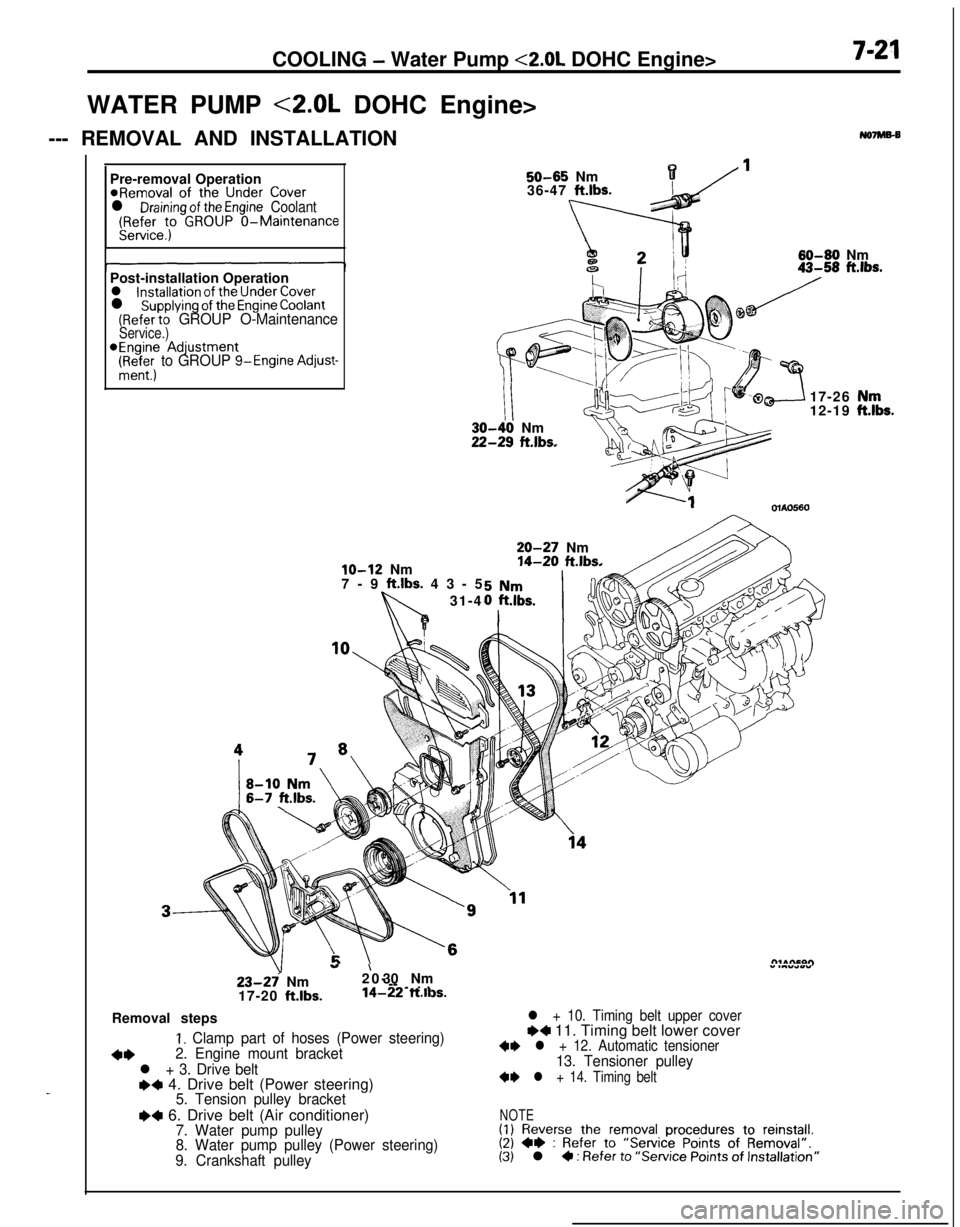

Page 269 of 1216

COOLING - Water Pump <2.0L DOHC Engine>7-21WATER PUMP <2.0L DOHC Engine>

--- REMOVAL AND INSTALLATION

No7Ms-B

_Pre-removal Operation

@Removal of the Under Coverl Draining of the Engine Coolant(Refer to GROUP O-MaintenanceService.)

50-65 Nm136-47 ft.lbs.

60-60 Nm

Post-installation Operation

l installation of the Under Coverl supplying of the Engine Coolant(Refer to GROUP O-MaintenanceService.)*Engine Adjustment

(Ri+&; to GROUP g-Engine Adjust-

lo-12 Nm

7-9 ft.lbs. 43-5

31-4

III-40 Nm!-29 ft.lbs.17-26

12-19OlAO560

20-27 Nm14-20 ft.lbs.

23-27 Nm

17-20 ft.lbs.

”20-’ 30 Nm” .““*wY--

-~ . .14-22 ft.ll3s.Removal steps

I. Clamp part of hoses (Power steering)

+*2. Engine mount bracket

l + 3. Drive belte+ 4. Drive belt (Power steering)5. Tension pulley bracket

I)4 6. Drive belt (Air conditioner)7. Water pump pulley

8. Water pump pulley (Power steering)

9. Crankshaft pulley

l + 10. Timing belt upper coverI)4 11. Timing belt lower cover+I) l + 12. Automatic tensioner13. Tensioner pulley

+I) l + 14. Timing belt

NOTE(1) Reverse the removal procedures to reinstall.(2) +e : Refer to “Service Points of Removal”.(3) l 4 : Refer to “Service Points of Installation”

,“k.

Page 270 of 1216

7-22COOLING - Water Pump <2.0L DOHC Engine>

20-27-Nm12-15 Nm14-20 ft.lbs.9- 11 ftlbs.\,/”

110-130 Nm@80-94 ftlbs. -04A0094

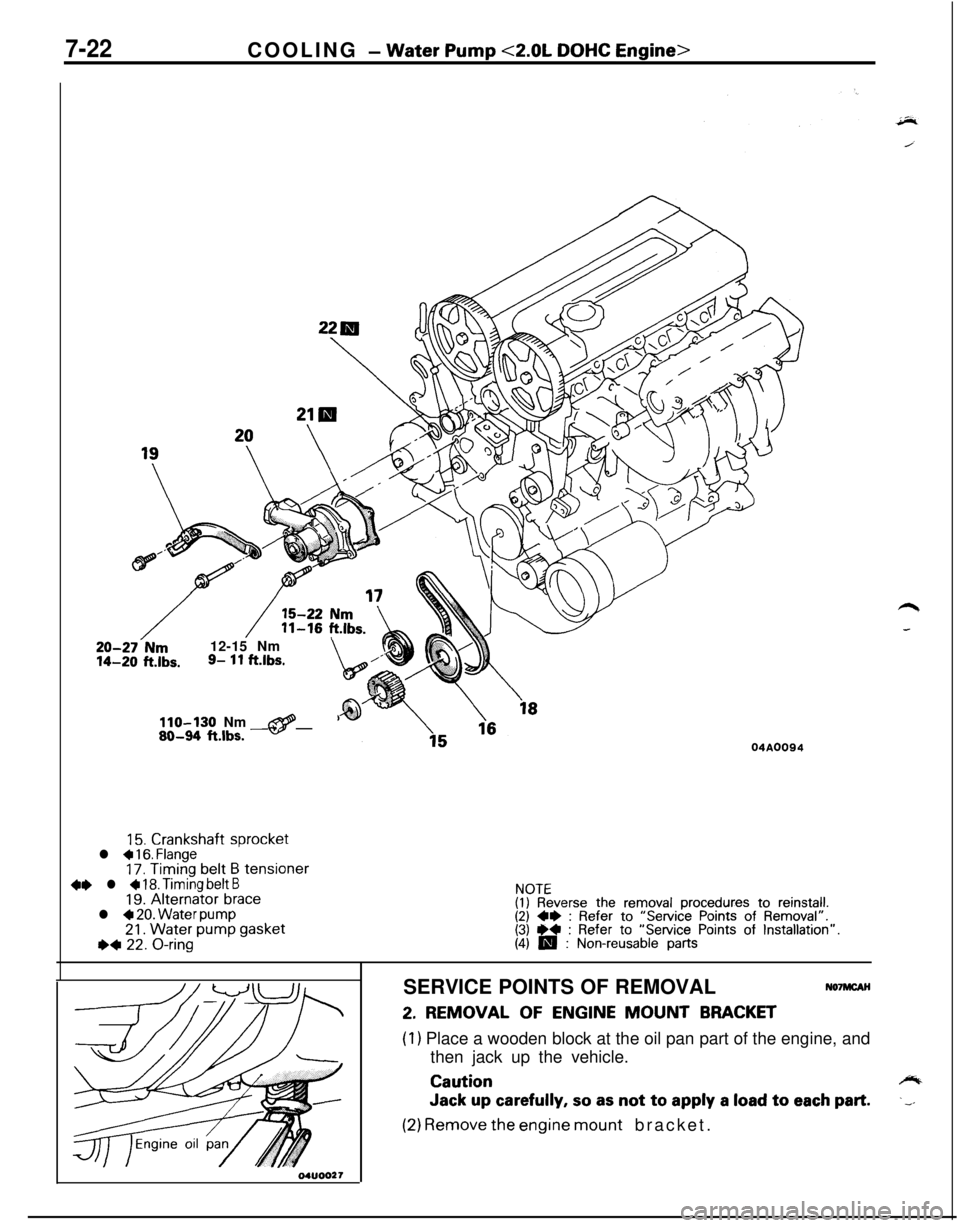

15. Crankshaft sprocketl a 16. Flange17. Timing belt B tensioner4e l + 18. Timing belt B19. Alternator bracel 4 20. Water pump21. Water pump gasketI)* 22. O-ring

NOTE(I) Reverse the removal procedures to reinstall.(2) 4* : Refer to “Service Points of Removal”.(3) ** : Refer to “Service Points of Installation”.(4) m : Non-reusable partsSERVICE POINTS OF REMOVAL

NO’IMCAH

2. REMOVAL OF ENGINE MOUNT BRACKET

(1) Place a wooden block at the oil pan part of the engine, and

then jack up the vehicle.

Cautioncylb

Jack up carefully, so as not to apply a load to each part..__

(2) Remove the engine mount bracket.

Page 271 of 1216

COOLING - Water Pump <2.0L DOHC Engine>7-2’3

12. REMOVAL OF AUTOMATIC TENSIONERI14. TIMING

BELTFor information concerning removal of the automatic

tensioner and the timing belt, refer to GROUP

g-Timing

Belt.

18. REMOVAL OF TIMING BELT BFor information concerning the removal of timing belt

6,refer to GROUP

g-Timing Belt B.Quality

canvas

\

\

Core wireAdhesive

rubber

Rib rubberlCOO2I

MRM2.

INSPECTION

V-RIBBED BELT

No7mDA.lCheck following items and replace if faulty.

l Check belt surface for damage, peeling or cracks.

l Check belt surface for oil or grease.

l Check belt rubber for wear or brittleness.

‘0 Check the pulleys for cracks or damage.

WATER PUMP

lCheck each part for cracks, damage or wear, and replace

the water pump assembly if necessary.

l Check the bearing for damage, abnormal noise and

sluggish rotation, and replace the water pump assembly if

necessary.

lCheck the seal unit for leaks, and replace the water pump

assembly if necessary.

l Check for water leakage.

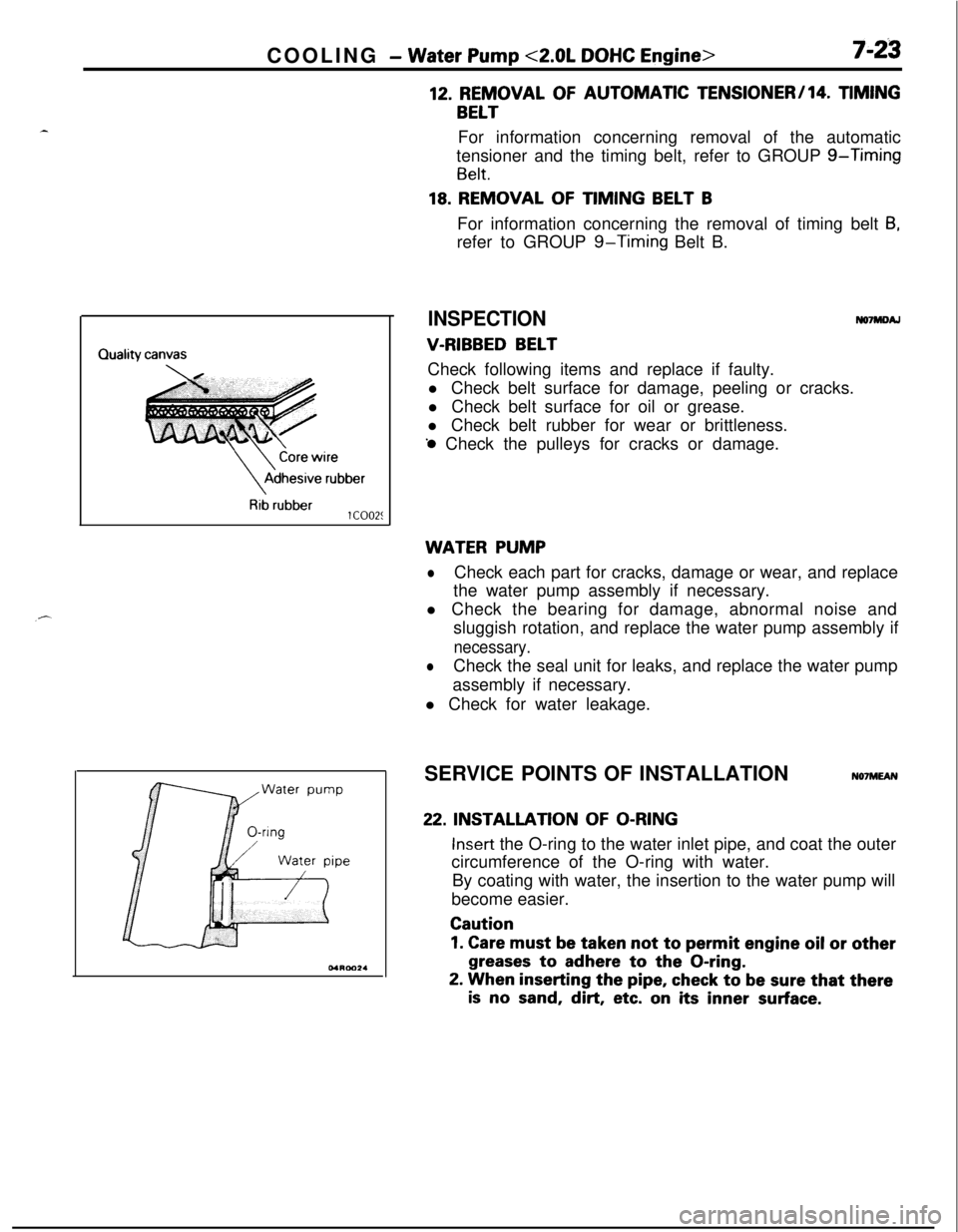

SERVICE POINTS OF INSTALLATION

N07MEAN

22. INSTALLATION OF O-RING

Insert the O-ring to the water inlet pipe, and coat the outer

circumference of the O-ring with water.

By coating with water, the insertion to the water pump will

become easier.

Caution

1. Care must be taken not to permit engine oil or other

greases to adhere to the O-ring.

2. When inserting the pipe, check to be sure that there

is no sand, dirt, etc. on its inner surface.