brake MITSUBISHI ECLIPSE 1993 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1993, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1993Pages: 57, PDF Size: 4.18 MB

Page 13 of 57

: : :.. t,:...!b

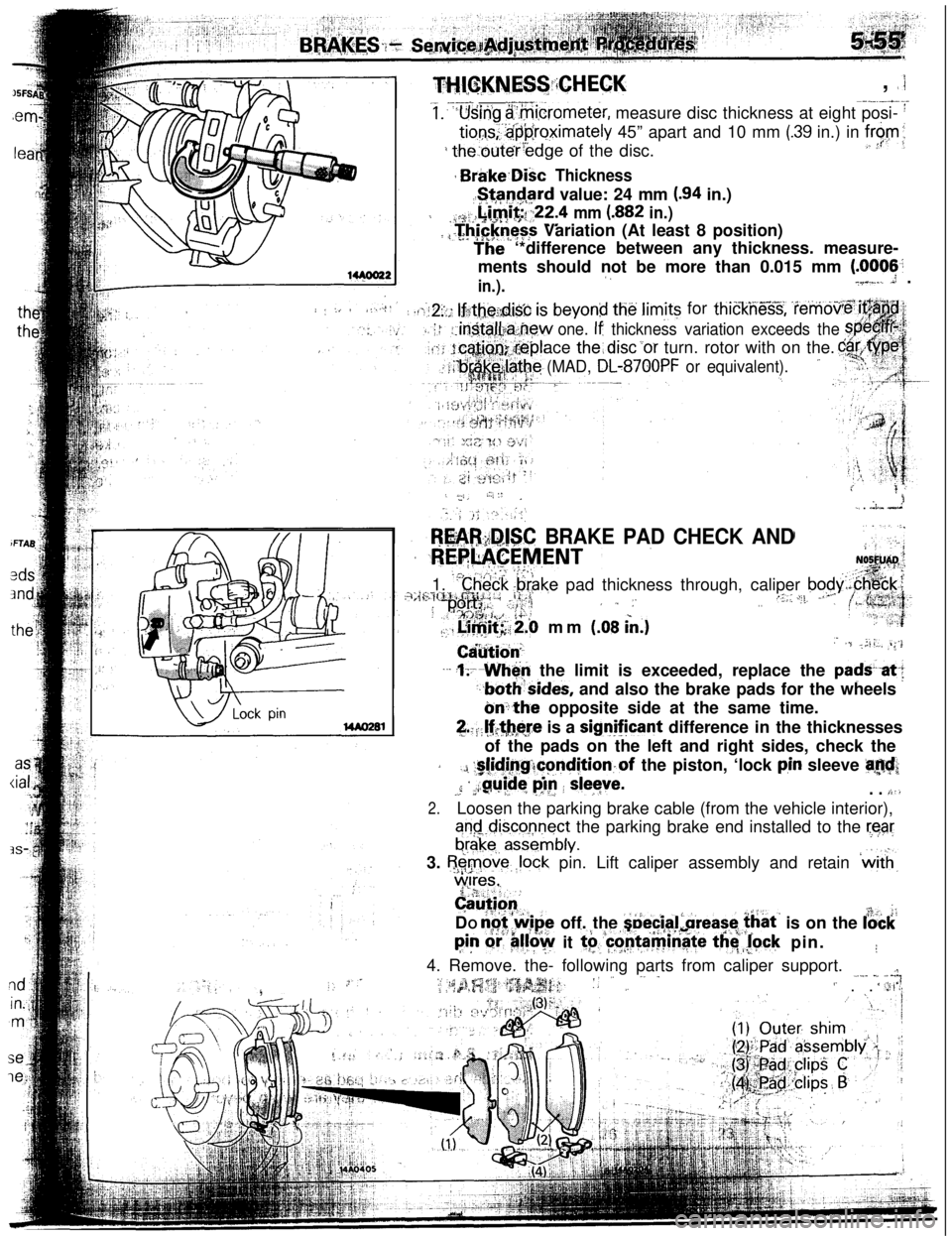

THl,~,KNES~i;CHECK, .‘i.- _d--.-.--.

1: ‘Using $.$i,crometer, measure disc thickness at eight posi- I

tions;:‘.@‘proximately 45” apart and 10 mm (.39 in.) in f,r$,m;,

i theouter’edge of the disc.‘I

+ Brbke.Disc Thickness..!+@Card value: 24 mm

(94 in.)

i,,~~~:-~4!-~~~t;:22.4 mm (.882 in.)

: ,aThrckness Variation (At least 8 position)

_ The ‘*difference between any thickness. measure-

ments should not be more than 0.015 mm

(.0006:

in.).,,7.9’-,... .J .

: .A12fi: If~thei;di& is beyond t& Jim@ for thickneT.%, ‘ie’mdv.,.

one. If thickness variation exceeds theace the:disc”or turn. rotor with on the.

(MAD, DL-87OOPF or equivalent).-

;_:.j ::!‘_, Ii..;, ‘I

t&;&C BRAKE PAD CHECK AND

., . .:L”” cn:

,.,1. ~:“ch&ii -brake pad thickness through, caliper body$%ck.~:?;{&:?p., d ii,; ,i..i; I&+# ~4:‘ ” :’/I..: “j.. .

~~Tl$$$‘~&b mm (08 cn.)

-.‘-‘: (~~#&q,,I,.:: y;./.

C&&ion”,- ‘-, -, iii,,, I.“‘?,t

--. +-When the limit is exceeded, replace the pad&at-:

,--both&sides, and also the brake pads for the wheels

onth-e opposite side at the same time.&.Jf,tb@re is a

signjfjcant difference in the thicknesses

of the pads on the left and right sides, check the

A.J. :%!idi,~g!~ondStion.of the piston, ‘lock p,in sleeve ;a,$$

f * ,midq py I sleye._, ,: .’ i.. . ii’.

2.Loosen the parking brake cable (from the vehicle interior),

an$dis.co-nnect the parking brake end installed to the rearI II Iorake,. assemory.3.

f5$_move.,lock pin. Lift caliper assembly and retain ‘&h,

yps..,(y&on,DO

r$$v$e off. the stiecial!.grease. that’ is on the &ckpi”

cii’@!fow it to..c,ontait;inate tl;

f :.,3-:: ” ,, ” -_.__ _, .“_,./‘7,.< :$, ~. . 6

Page 14 of 57

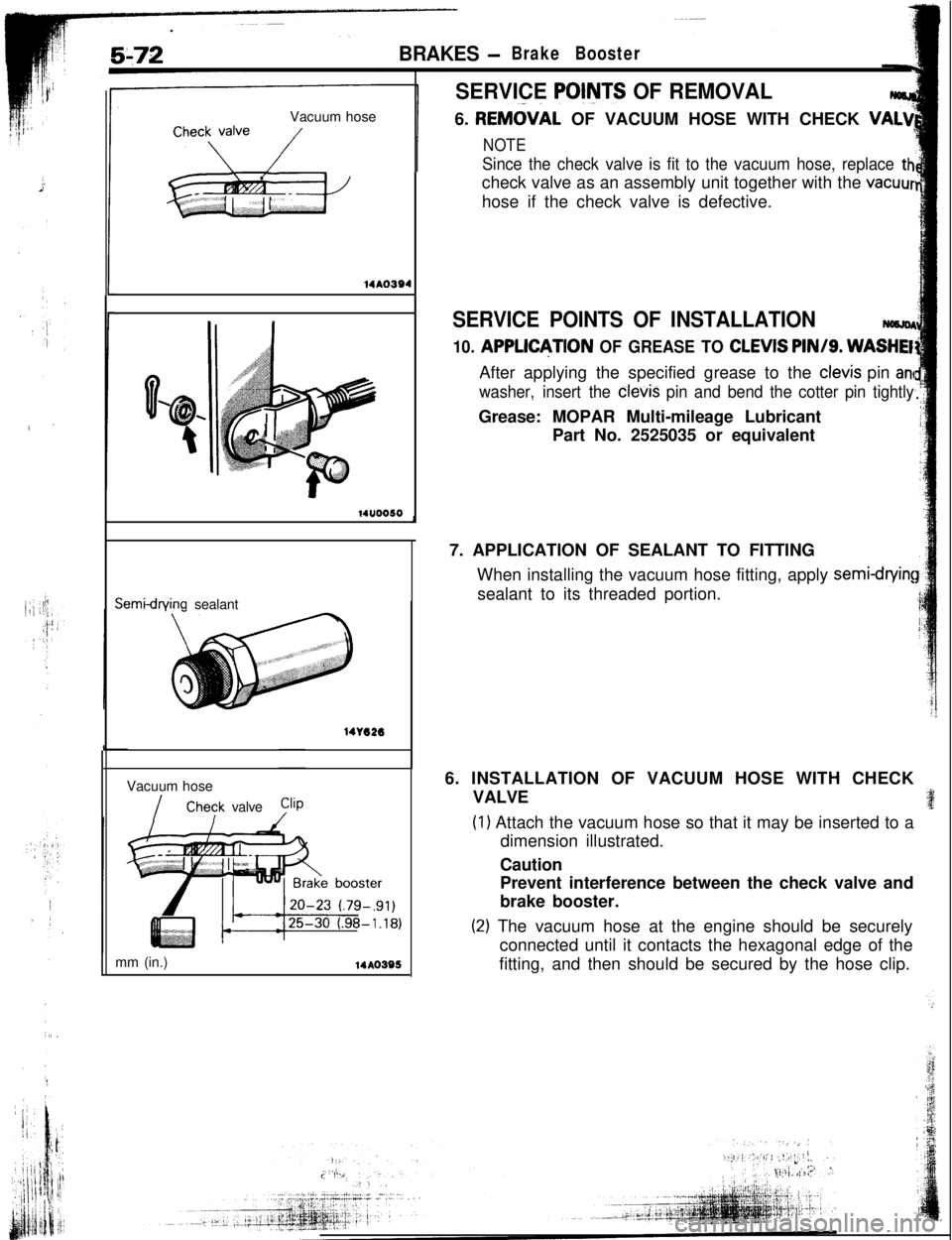

BRAKES -Brake BoosterVacuum hose

14AO39414u0050Semidrvina sealant

141626Vacuum hose

IChevk valve

mm (in.)

14AO395

SERVICE PO@JTS OF REMOVALNocm6.

REM&AL OF VACUUM HOSE WITH CHECK VA+

NOTE

Since the check valve is fit to the vacuum hose, replace thcheck valve as an assembly unit together with the

vacuurhose if the check valve is defective.

SERVICE POINTS OF INSTALLATION

10. APPLDJTION OF GREASE TO CLEVIS PIN/g. WASHEIAfter applying the specified grease to the

clevis pin an

washer, insert the

cievis pin and bend the cotter pin tightlyGrease: MOPAR Multi-mileage Lubricant

Part No. 2525035 or equivalent

7. APPLICATION OF SEALANT TO FITTING

When installing the vacuum hose fitting, apply

semi-cfryin!sealant to its threaded portion.

6. INSTALLATION OF VACUUM HOSE WITH CHECK

VALVE

(1) Attach the vacuum hose so that it may be inserted to a

dimension illustrated.

Caution

Prevent interference between the check valve and

brake booster.

(2) The vacuum hose at the engine should be securely

connected until it contacts the hexagonal edge of the

fitting, and then should be secured by the hose clip.

Page 15 of 57

N0sJa

4LVI

:e the

cuu<

‘=JD4\

;HER

and

!htly.

Wg

CK3a

nd

3ly

he

P.BRAKES

- Brake Line

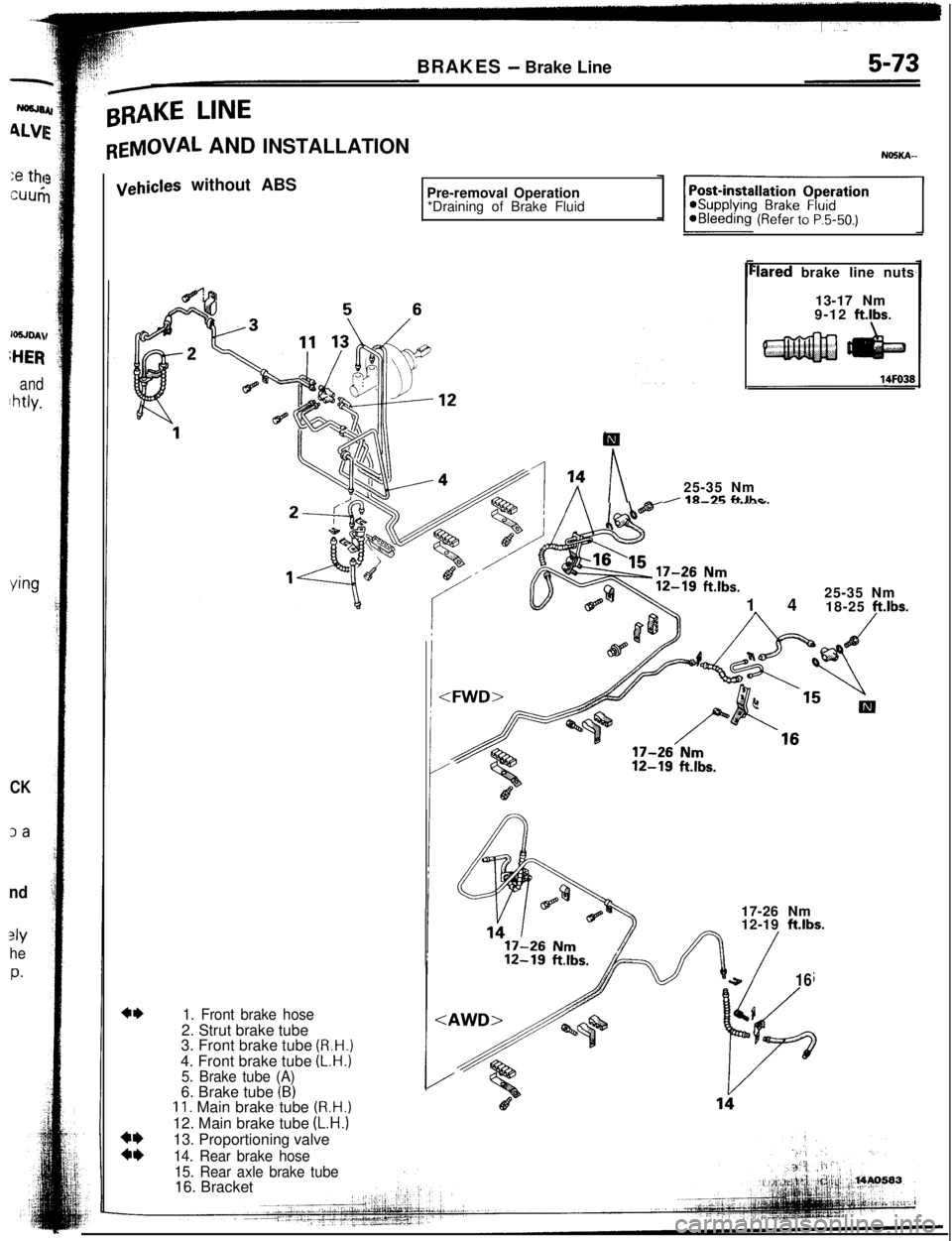

BRAKE LINE

REMOVAL AND INSTALLATIONNOSKA--

1. Front brake hose2. Strut brake tube

3. Front brake tube

(R.H.)4. Front brake tube

(L.H.)5. Brake tube (A)6. Brake tube (B)11. Main brake tube (R.H.)12. Main brake tube

(L.H.)13. Proportioning valve

14. Rear brake hose

15. Rear axle brake tube

._-

Ill

n25-35 NmI 111-7G f-t Ihr:lared brake line nuts

13-17 Nm

9-12

ftlbs.

vehicles without ABS

Pre-removal Operation

*Draining of Brake Fluid

1425-35 Nm

18-25

ft.lbs.17-26 Nm

12-19

ft.lbs.

+1616. Bracket

Page 16 of 57

a-.

i.-J

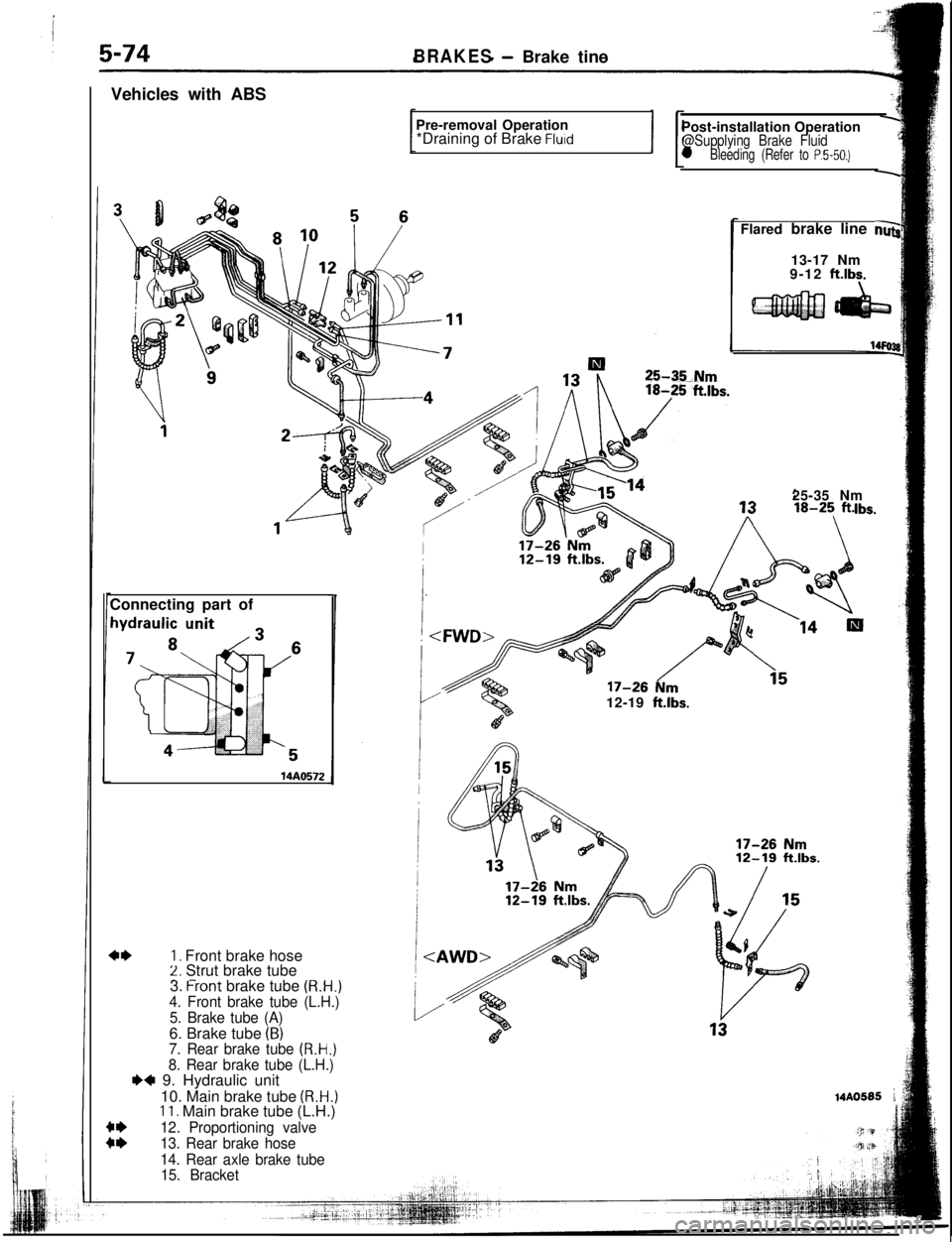

5-74BRAKES- Brake tine

Vehicles with ABS

Pre-removal Operation

*Draining of Brake

Fluid

,“iPost-installation OperationA

@Supplying Brake Fluid1

l Bleeding (Refer to P.5-50.)

-Connecting part of

14AO572

I. Front brake hose2. Strut brake tube- -25-35 Nm

Ibs.12-19

ft.lbs.Flared brake line

ns13-17 Nm

9-12

ftlbs.

15. Bracket3.

f-ront brake tube (R.H.)

4. Front brake tube (L.H.)

5. Brake tube (A)6. Brake tube

(B)7. Rear brake tube (R.H.)

8. Rear brake tube (L.H.)I)+ 9. Hydraulic unit

10. Main brake tube

(R.H.)11. Main brake tube (L.H.)

::

12. Proportioning valve

13. Rear brake hose

14. Rear axle brake tube

14AO585 ;

Page 17 of 57

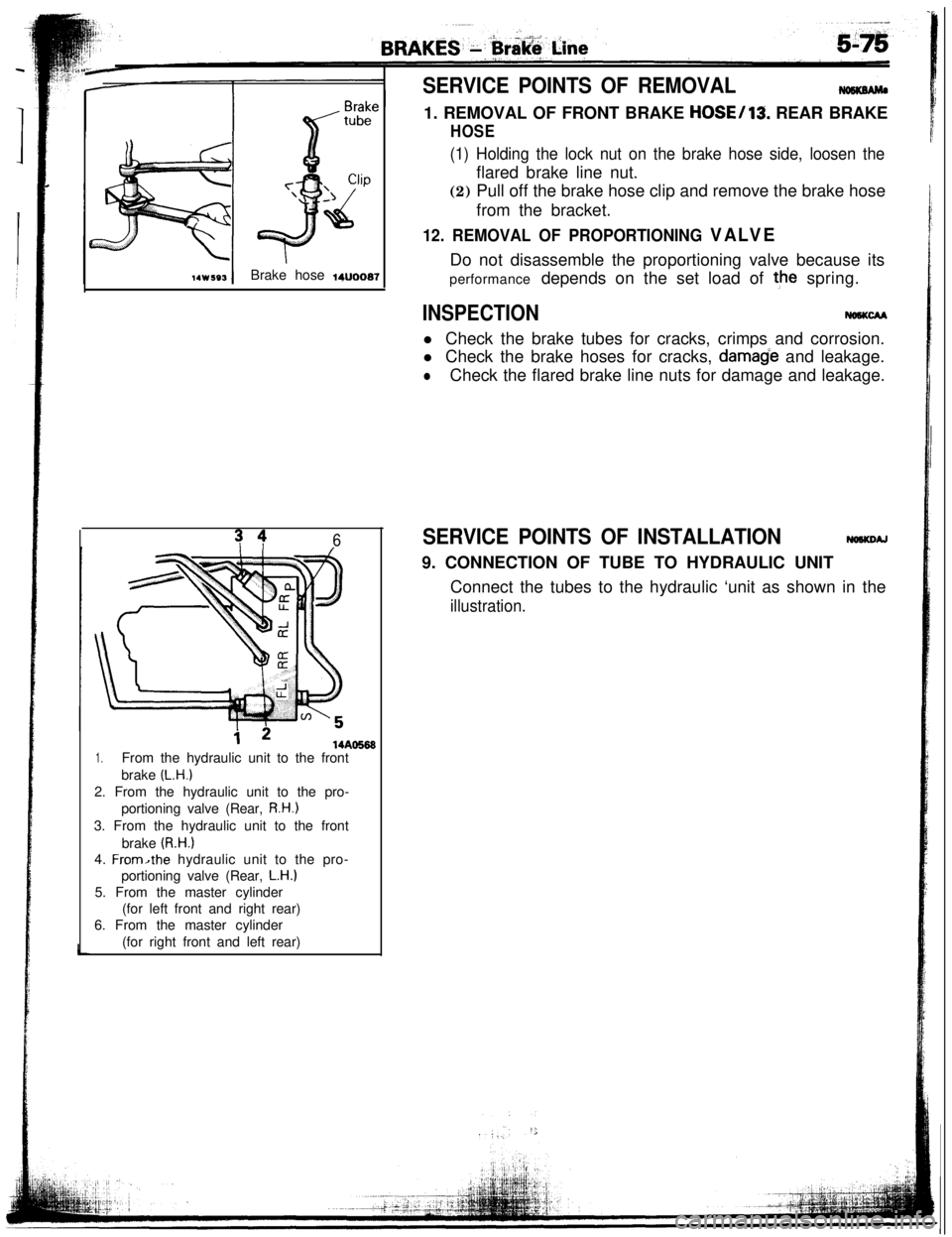

SERVICE POINTS OF REMOVAL

14w593Brake hose woo07

s 461. REMOVAL OF FRONT BRAKE

HOSE/13. REAR BRAKE

HOSE

(1) Holding the lock nut on the brake hose side, loosen theflared brake line nut.

(2) Pull off the brake hose clip and remove the brake hose

from the bracket.

12. REMOVAL OF PROPORTIONING VALVEDo not disassemble the proportioning valve because its

performance depends on the set load of the spring.

INSPECTIONNo6KcMl Check the brake tubes for cracks, crimps and corrosion.

l Check the brake hoses for cracks,

damade and leakage.

lCheck the flared brake line nuts for damage and leakage.

SERVICE POINTS OF INSTALLATIONNOSKOAJ9. CONNECTION OF TUBE TO HYDRAULIC UNIT

Connect the tubes to the hydraulic ‘unit as shown in the

illustration.

i 214AO5681.From the hydraulic unit to the front

brake

(L.H.)2. From the hydraulic unit to the pro-

portioning valve (Rear,

R.H.)3. From the hydraulic unit to the front

brake

(R.H.)4. From,the hydraulic unit to the pro-

portioning valve (Rear,

L.H.)5. From the master cylinder

(for left front and right rear)

6. From the master cylinder

(for right front and left rear)

Page 18 of 57

! -;-596

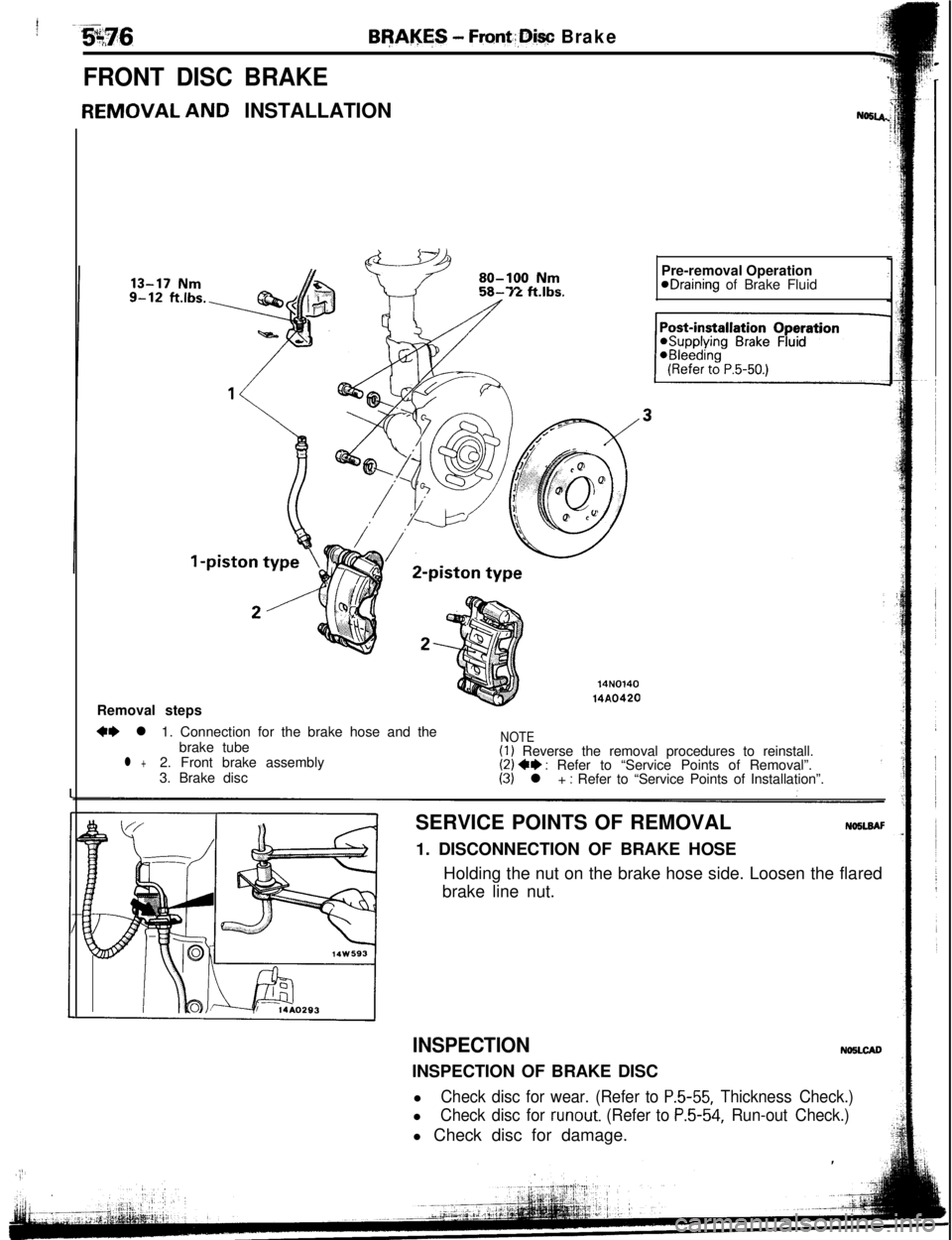

FRONT DISC BRAKE

Bf?Al$ES - Front.:,Diw Brake

REMOVAL AND INSTALLATIONN=U.

3U- IL l-LIDS.Y-i A

14N014014A0420Pre-removal Operation

eDraining of Brake Fluid

Removal steps

+e l1. Connection for the brake hose and the

brake tubeNOTE

l +2. Front brake assembly(1) Reverse the removal procedures to reinstall.

3. Brake disc(2) ++ : Refer to “Service Points of Removal”.(3) l + : Refer to “Service Points of Installation”.

SERVICE POINTS OF REMOVAL

No5LsAF1. DISCONNECTION OF BRAKE HOSE

Holding the nut on the brake hose side. Loosen the flared

brake line nut.

INSPECTIONNNiLCIDINSPECTION OF BRAKE DISC

l

Check disc for wear. (Refer to P.5-55, Thickness Check.)l

Check disc for runout. (Refer to P.5-54, Run-out Check.)l Check disc for damage.

Page 19 of 57

-

3AF

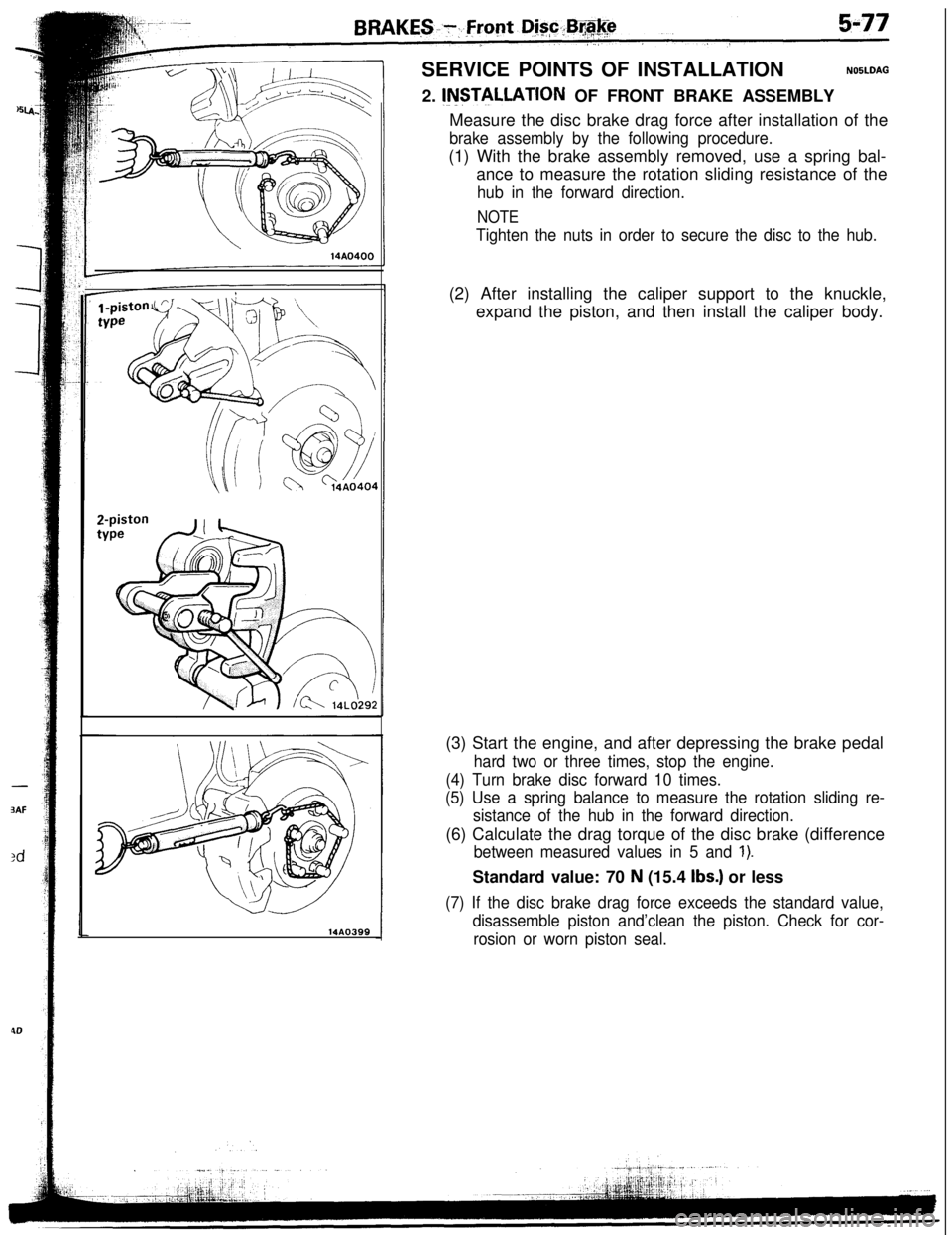

:dSERVICE POINTS OF INSTALLATION

NOBLDAG2.

INSTILLATION OF FRONT BRAKE ASSEMBLY

14AO399Measure the disc brake drag force after installation of the

brake assembly by the following procedure.(1) With the brake assembly removed, use a spring bal-

ance to measure the rotation sliding resistance of the

hub in the forward direction.

NOTE

Tighten the nuts in order to secure the disc to the hub.(2) After installing the caliper support to the knuckle,

expand the piston, and then install the caliper body.

(3) Start the engine, and after depressing the brake pedal

hard two or three times, stop the engine.

(4) Turn brake disc forward 10 times.

(5) Use a spring balance to measure the rotation sliding re-

sistance of the hub in the forward direction.(6) Calculate the drag torque of the disc brake (difference

between measured values in 5 and 1).Standard value: 70

N (15.4 Ibs.) or less

(7) If the disc brake drag force exceeds the standard value,

disassemble piston and’clean the piston. Check for cor-

rosion or worn piston seal.

Page 20 of 57

-.

t

5-78BRAKES - Front Disc Bra&.iDISASSEMBLY AND REASSEMBLY

NO51

< 1 -piston type>

64-86

46-62

64-86

46-6216

/

w”! 14N0284

Caliper assembly disassembly steps

M 1. Guide pin

l + 2. Lock pin

l + 3. Bushing

4. Caliper support (Pad, clip, shim)

l + 5. Guide pin bootMI 6. Lock pin boot

**7. Boot ring4*8. Piston boot

l *** 9. Piston

+I) l * IO. Piston seal11. Brake hosel + 12. Caliper body

Pad assembly disassembly steps

e+ 1. Guide pin

l + 2. Lock pin*+ 3. Bushing4. Caliper support (Pad, clip, shim)

13. Pad and wear indicator assembly

14. Pad assembly

++ 15. Outer shim16. Clip

e+ 17. Inner shim

NOTE

(1) Reverse the disassembly procedures to reassemble.(2)

~~ : Refer to “Service Points of Disassembly”.(3) l + : Refer to “Service Points of Reassembly”.

(4) m : Non-reusable parts

1

i14AO537Brake caliper kit

Pad repair kitSeal and boots

repair kit

10 6

5’ 8 7

-.I.14AD54(

Page 21 of 57

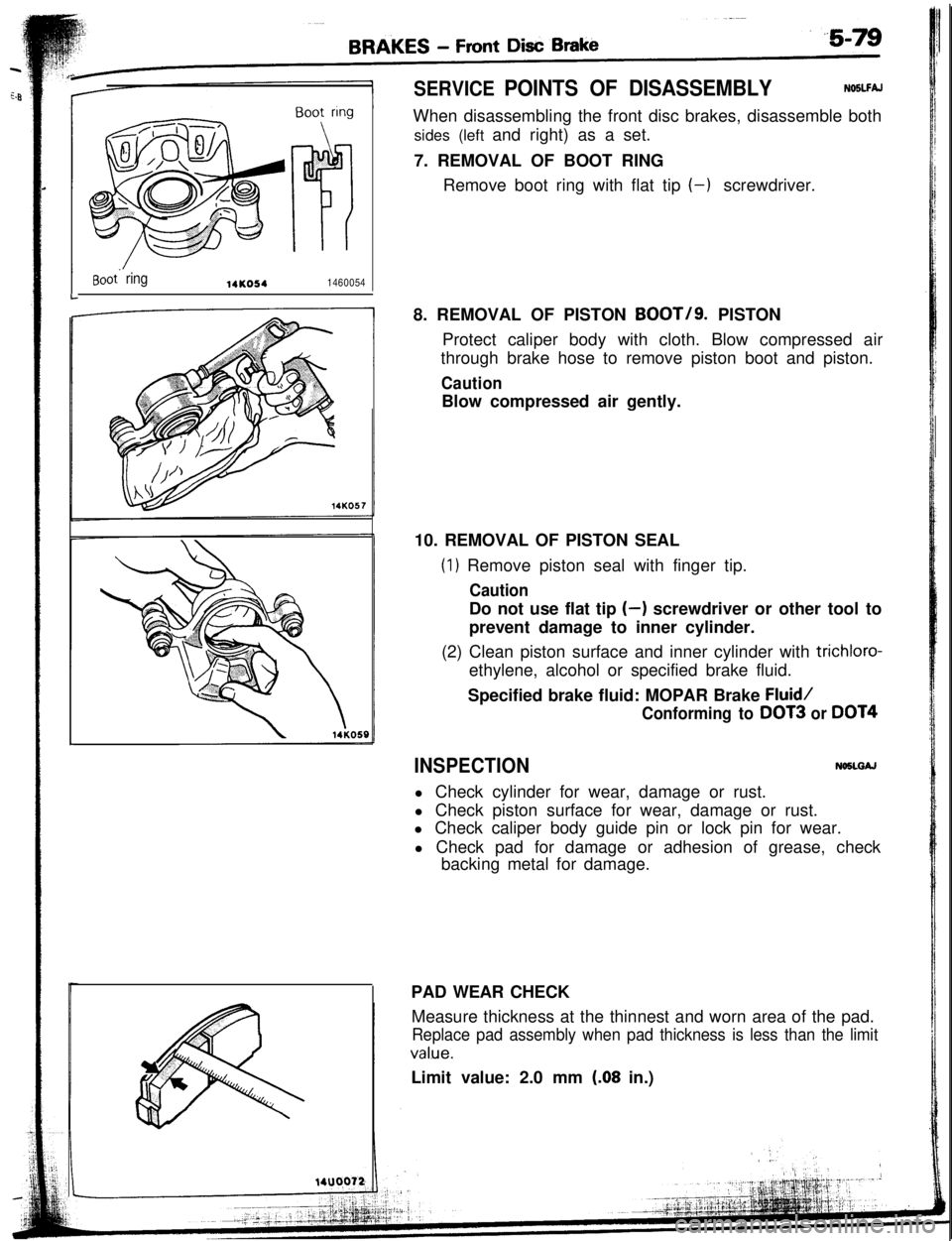

Boot. ring14KO541460054L

SERVICE POINTS OF DISASSEMBLYNOSLFAJWhen disassembling the front disc brakes, disassemble both

sides (left and right) as a set.

7. REMOVAL OF BOOT RING

Remove boot ring with flat tip (-1 screwdriver.

8. REMOVAL OF PISTON BOOT/g. PISTON

Protect caliper body with cloth. Blow compressed air

through brake hose to remove piston boot and piston.

CautionBlow compressed air gently.

10. REMOVAL OF PISTON SEAL

(1) Remove piston seal with finger tip.

CautionDo not use flat tip

(-) screwdriver or other tool to

prevent damage to inner cylinder.

(2) Clean piston surface and inner cylinder with

trichloro-ethylene, alcohol or specified brake fluid.

Specified brake fluid: MOPAR Brake

Fluid/

Conforming to DOT3 or DOT4

INSPECTIONNOXGAJ

l Check cylinder for wear, damage or rust.

l Check piston surface for wear, damage or rust.

l Check caliper body guide pin or lock pin for wear.

l Check pad for damage or adhesion of grease, check

backing metal for damage.

PAD WEAR CHECK

Measure thickness at the thinnest and worn area of the pad.

Replace pad assembly when pad thickness is less than the limit

value.Limit value: 2.0 mm

(.08 in.)

Page 22 of 57

----aI’-I

5-80BRAKES - Front Disc Brake

I-

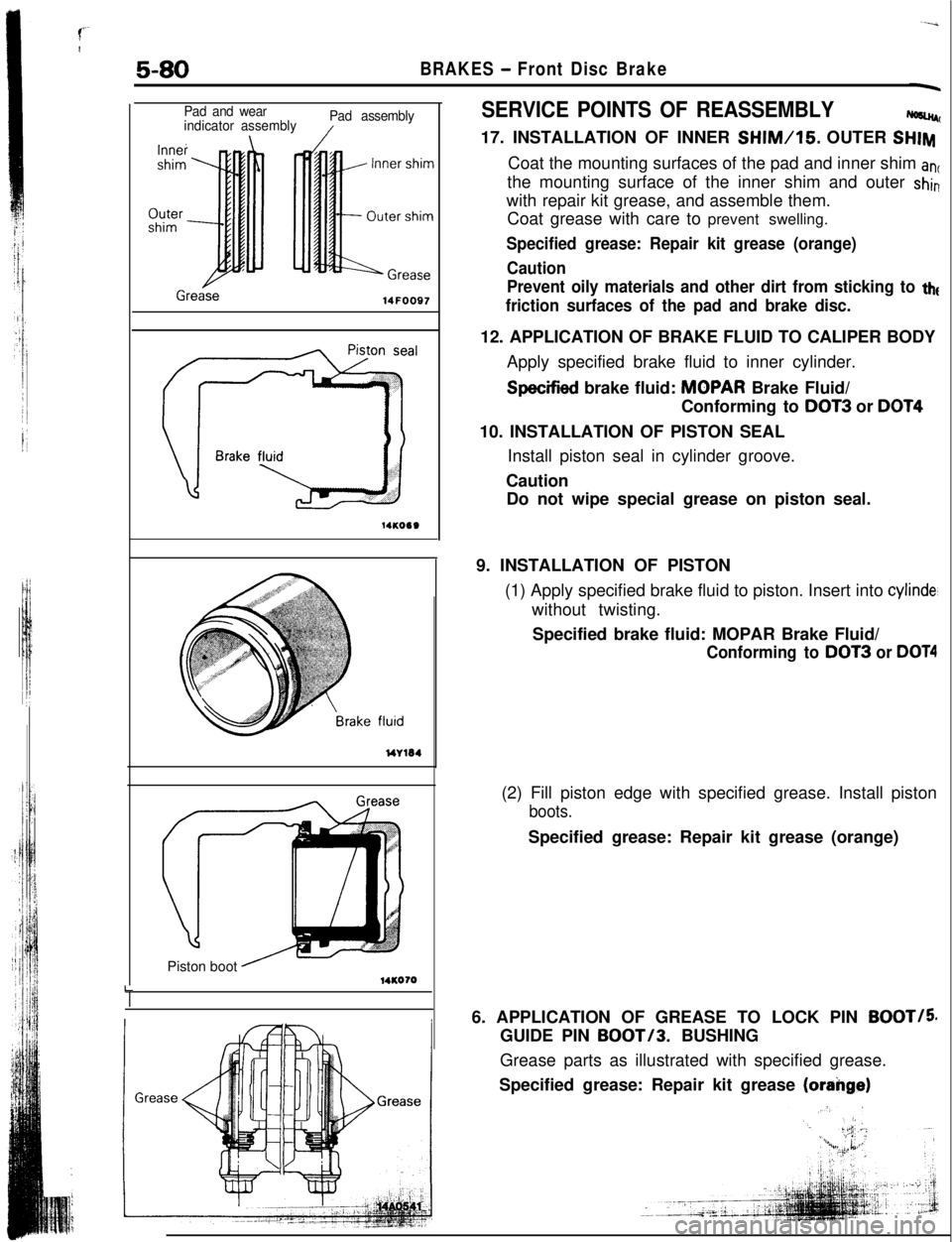

Pad and wear

indicator assemblyPad assembly

Grease14FOO97

14KOIQPiston boot

’14KO70

Grease

L

SERVICE POINTS OF REASSEMBLYWC17. INSTALLATION OF INNER

SHIM/15. OUTER SHIMCoat the mounting surfaces of the pad and inner shim

antthe mounting surface of the inner shim and outer

shinwith repair kit grease, and assemble them.

Coat grease with care to prevent swelling.

Specified grease: Repair kit grease (orange)

Caution

Prevent oily materials and other dirt from sticking to

tht

friction surfaces of the pad and brake disc.12. APPLICATION OF BRAKE FLUID TO CALIPER BODY

Apply specified brake fluid to inner cylinder.

Specified brake fluid: MDPAR Brake Fluid/

Conforming to DOT3 or

DOT410. INSTALLATION OF PISTON SEAL

Install piston seal in cylinder groove.

Caution

Do not wipe special grease on piston seal.

9. INSTALLATION OF PISTON

(1) Apply specified brake fluid to piston. Insert into

cylinde’without twisting.

Specified brake fluid: MOPAR Brake Fluid/

Conforming to DOT3 or DOT4(2) Fill piston edge with specified grease. Install piston

boots.Specified grease: Repair kit grease (orange)

6. APPLICATION OF GREASE TO LOCK PIN

BOOT/5GUIDE PIN BOOT/3. BUSHING

Grease parts as illustrated with specified grease.

Specified grease: Repair kit grease

(orange)