ECU MITSUBISHI ECLIPSE 1993 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1993, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1993Pages: 57, PDF Size: 4.18 MB

Page 10 of 57

5-52

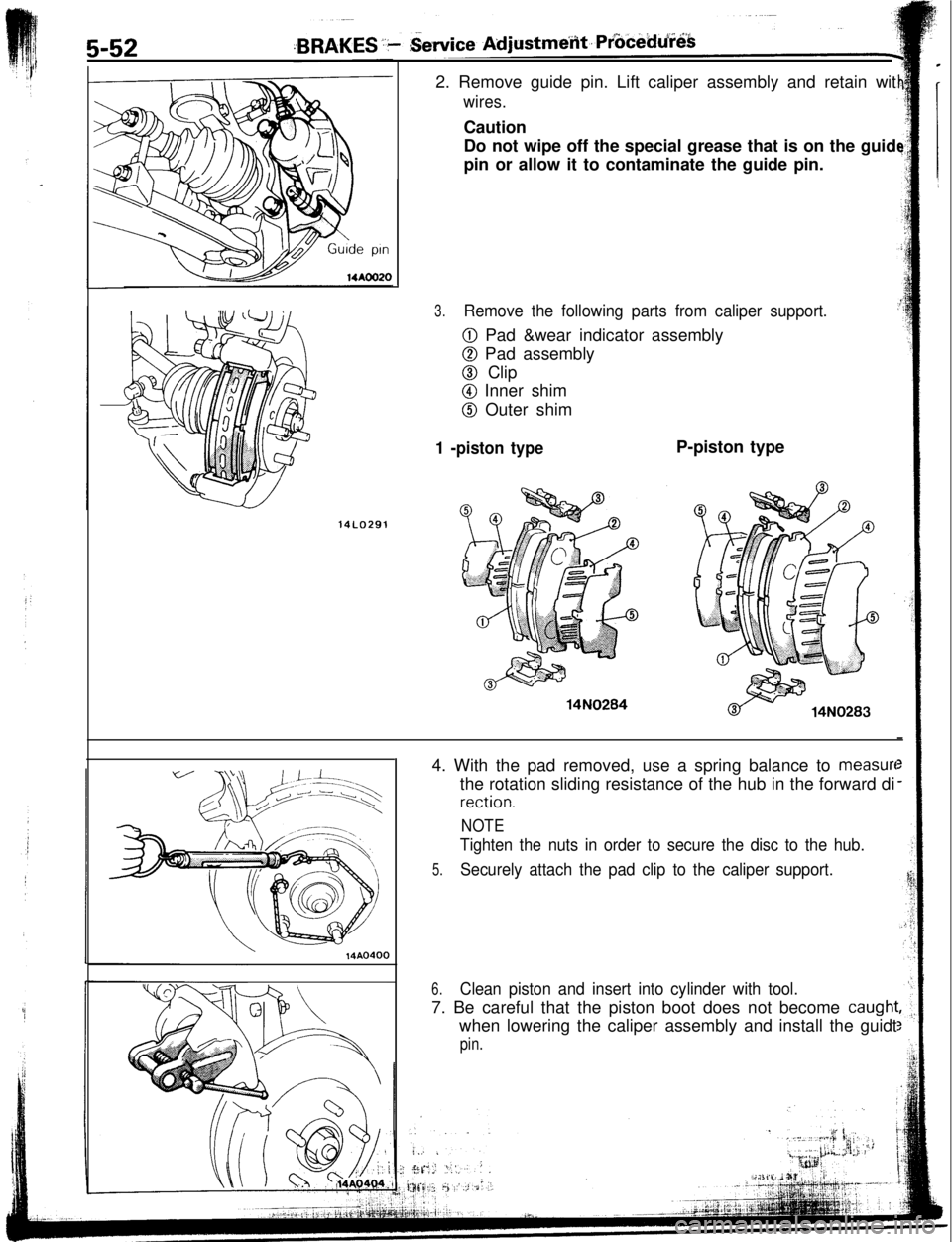

14LO2912. Remove guide pin. Lift caliper assembly and retain wit

wires.Caution

Do not wipe off the special grease that is on the guid

pin or allow it to contaminate the guide pin.

3.Remove the following parts from caliper support.

0 Pad &wear indicator assembly

0 Pad assembly

@ Clip

@I Inner shim

@ Outer shim

1 -piston type14N0284P-piston type

\14AO4004. With the pad removed, use a spring balance to

measurethe rotation sliding resistance of the hub in the forward di

rection.

NOTE

Tighten the nuts in order to secure the disc to the hub.

5.Securely attach the pad clip to the caliper support.

6.Clean piston and insert into cylinder with tool.7. Be careful that the piston boot does not become

caughlwhen lowering the caliper assembly and install the guidt

pin.

Page 12 of 57

14A0391

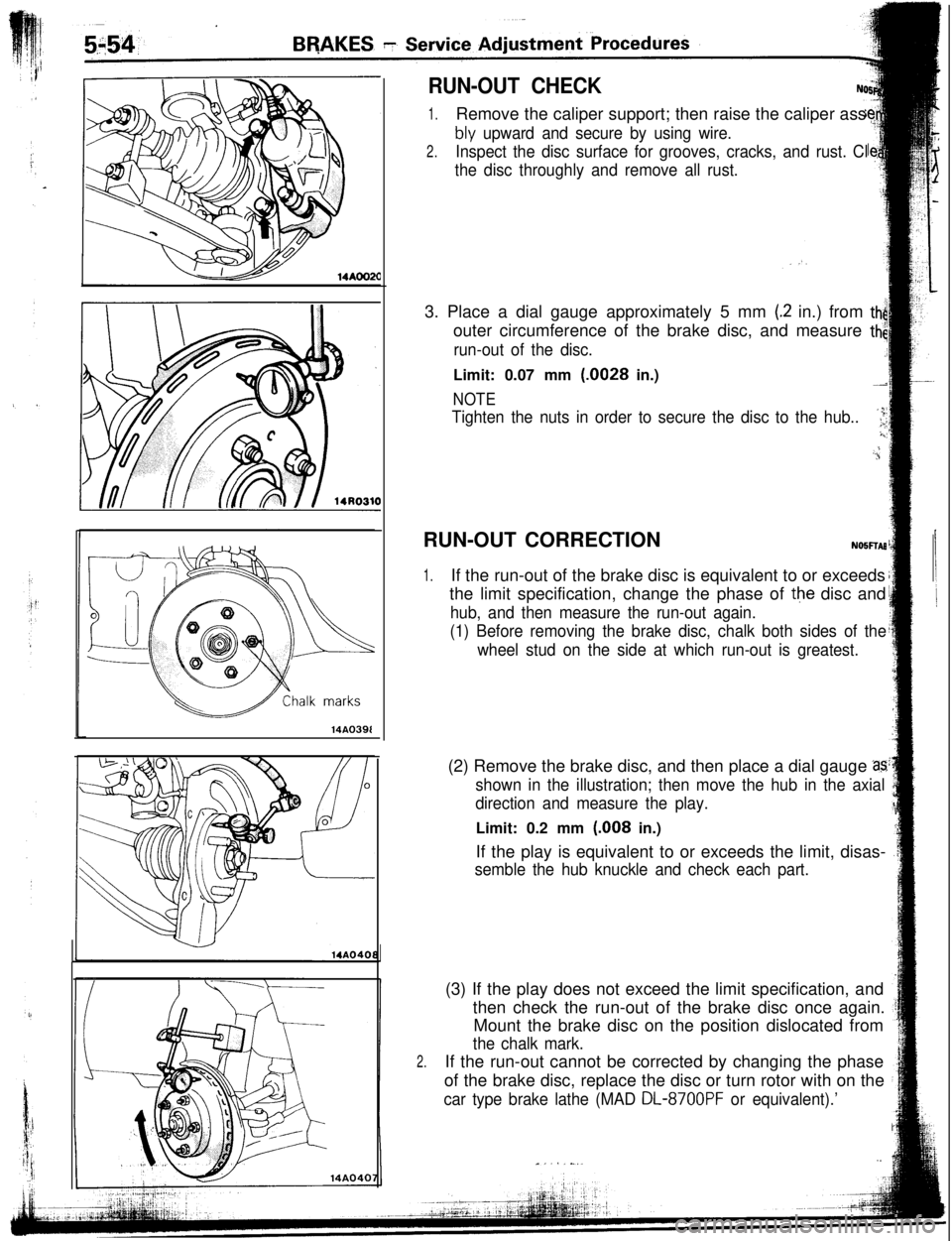

RUN-OUT CHECK

1.Remove the caliper support; then raise the caliper ass

bly upward and secure by using wire.

2.Inspect the disc surface for grooves, cracks, and rust. Cl

the disc throughly and remove all rust.3. Place a dial gauge approximately 5 mm

(.2 in.) from thiouter circumference of the brake disc, and measure

tt$

run-out of the disc._iLimit: 0.07 mm

(.0028 in.)-2

NOTE

Tighten the nuts in order to secure the disc to the hub..‘l;i,!

..,;RUN-OUT CORRECTION

NOSFTAB

1.If the run-out of the brake disc is equivalent to or exceeds

the limit specification, change the phase of

the disc and

hub, and then measure the run-out again.

(1) Before removing the brake disc, chalk both sides of the

wheel stud on the side at which run-out is greatest.(2) Remove the brake disc, and then place a dial gauge

2s

shown in the illustration; then move the hub in the axial

direction and measure the play.Limit: 0.2 mm

(.008 in.)

If the play is equivalent to or exceeds the limit, disas-

semble the hub knuckle and check each part.

2.(3) If the play does not exceed the limit specification, and

then check the run-out of the brake disc once again.

Mount the brake disc on the position dislocated from

the chalk mark.If the run-out cannot be corrected by changing the phase

of the brake disc, replace the disc or turn rotor with on the

car type brake lathe (MAD DL-8700PF or equivalent).’

.,“, . . . -..

Page 14 of 57

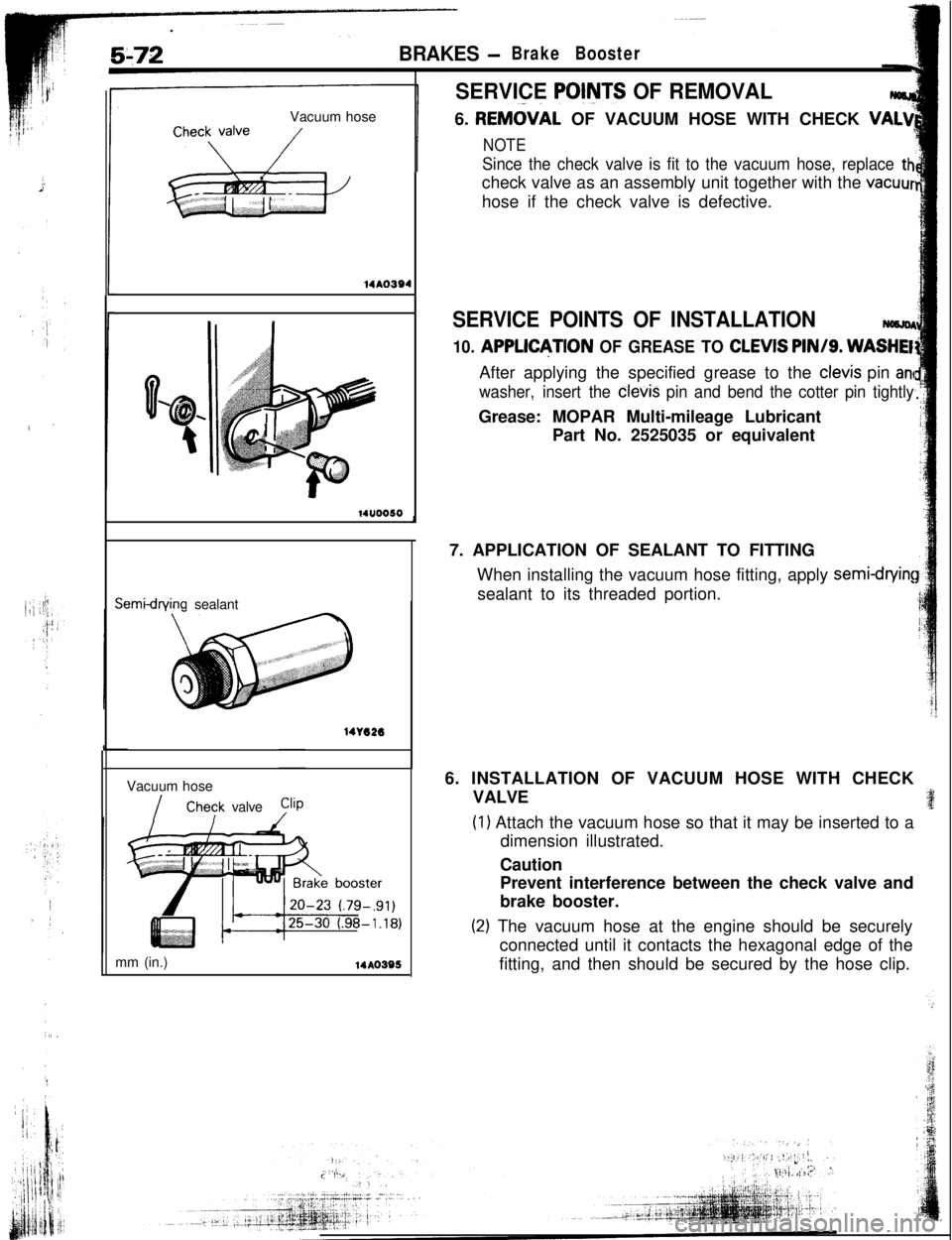

BRAKES -Brake BoosterVacuum hose

14AO39414u0050Semidrvina sealant

141626Vacuum hose

IChevk valve

mm (in.)

14AO395

SERVICE PO@JTS OF REMOVALNocm6.

REM&AL OF VACUUM HOSE WITH CHECK VA+

NOTE

Since the check valve is fit to the vacuum hose, replace thcheck valve as an assembly unit together with the

vacuurhose if the check valve is defective.

SERVICE POINTS OF INSTALLATION

10. APPLDJTION OF GREASE TO CLEVIS PIN/g. WASHEIAfter applying the specified grease to the

clevis pin an

washer, insert the

cievis pin and bend the cotter pin tightlyGrease: MOPAR Multi-mileage Lubricant

Part No. 2525035 or equivalent

7. APPLICATION OF SEALANT TO FITTING

When installing the vacuum hose fitting, apply

semi-cfryin!sealant to its threaded portion.

6. INSTALLATION OF VACUUM HOSE WITH CHECK

VALVE

(1) Attach the vacuum hose so that it may be inserted to a

dimension illustrated.

Caution

Prevent interference between the check valve and

brake booster.

(2) The vacuum hose at the engine should be securely

connected until it contacts the hexagonal edge of the

fitting, and then should be secured by the hose clip.

Page 19 of 57

-

3AF

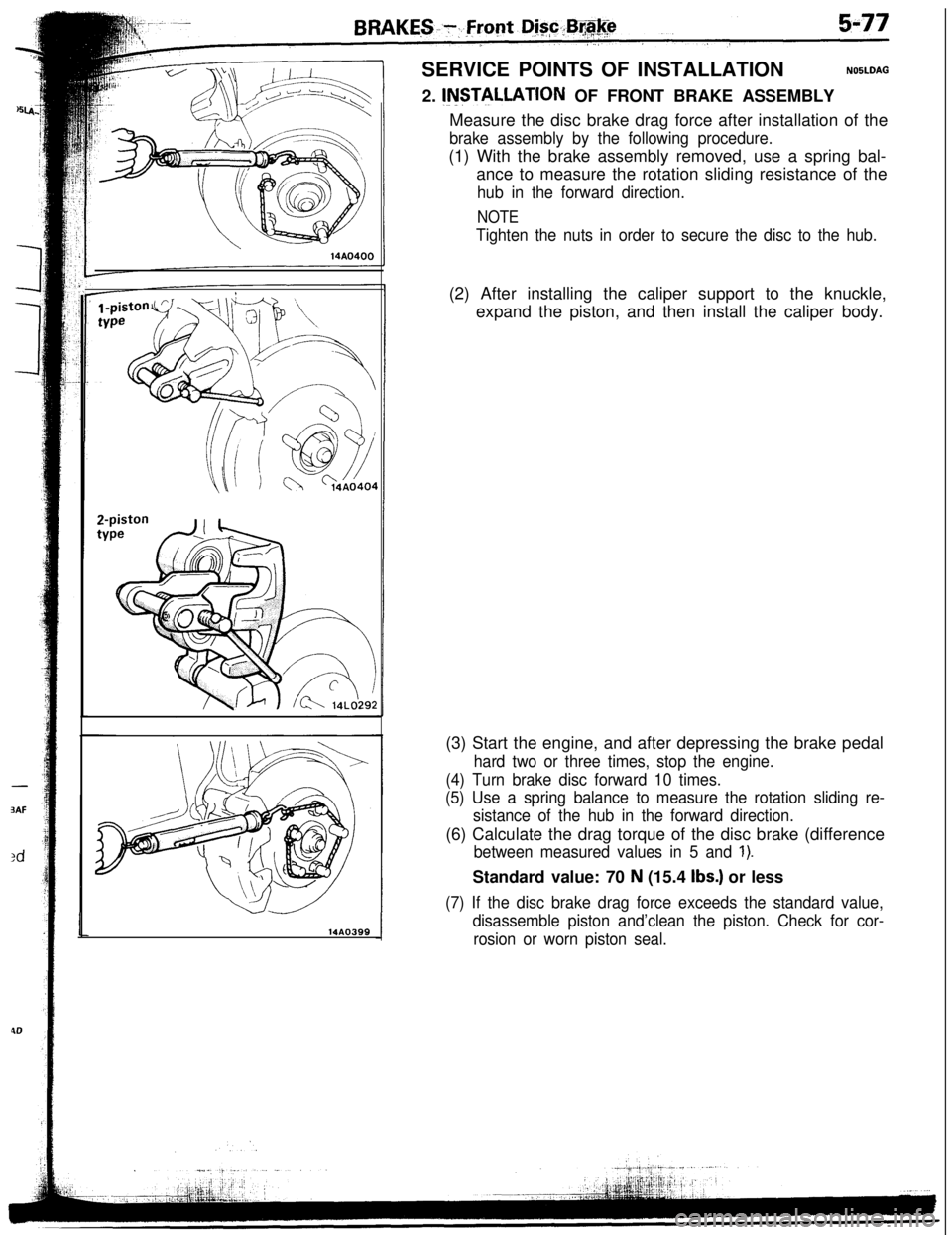

:dSERVICE POINTS OF INSTALLATION

NOBLDAG2.

INSTILLATION OF FRONT BRAKE ASSEMBLY

14AO399Measure the disc brake drag force after installation of the

brake assembly by the following procedure.(1) With the brake assembly removed, use a spring bal-

ance to measure the rotation sliding resistance of the

hub in the forward direction.

NOTE

Tighten the nuts in order to secure the disc to the hub.(2) After installing the caliper support to the knuckle,

expand the piston, and then install the caliper body.

(3) Start the engine, and after depressing the brake pedal

hard two or three times, stop the engine.

(4) Turn brake disc forward 10 times.

(5) Use a spring balance to measure the rotation sliding re-

sistance of the hub in the forward direction.(6) Calculate the drag torque of the disc brake (difference

between measured values in 5 and 1).Standard value: 70

N (15.4 Ibs.) or less

(7) If the disc brake drag force exceeds the standard value,

disassemble piston and’clean the piston. Check for cor-

rosion or worn piston seal.

Page 29 of 57

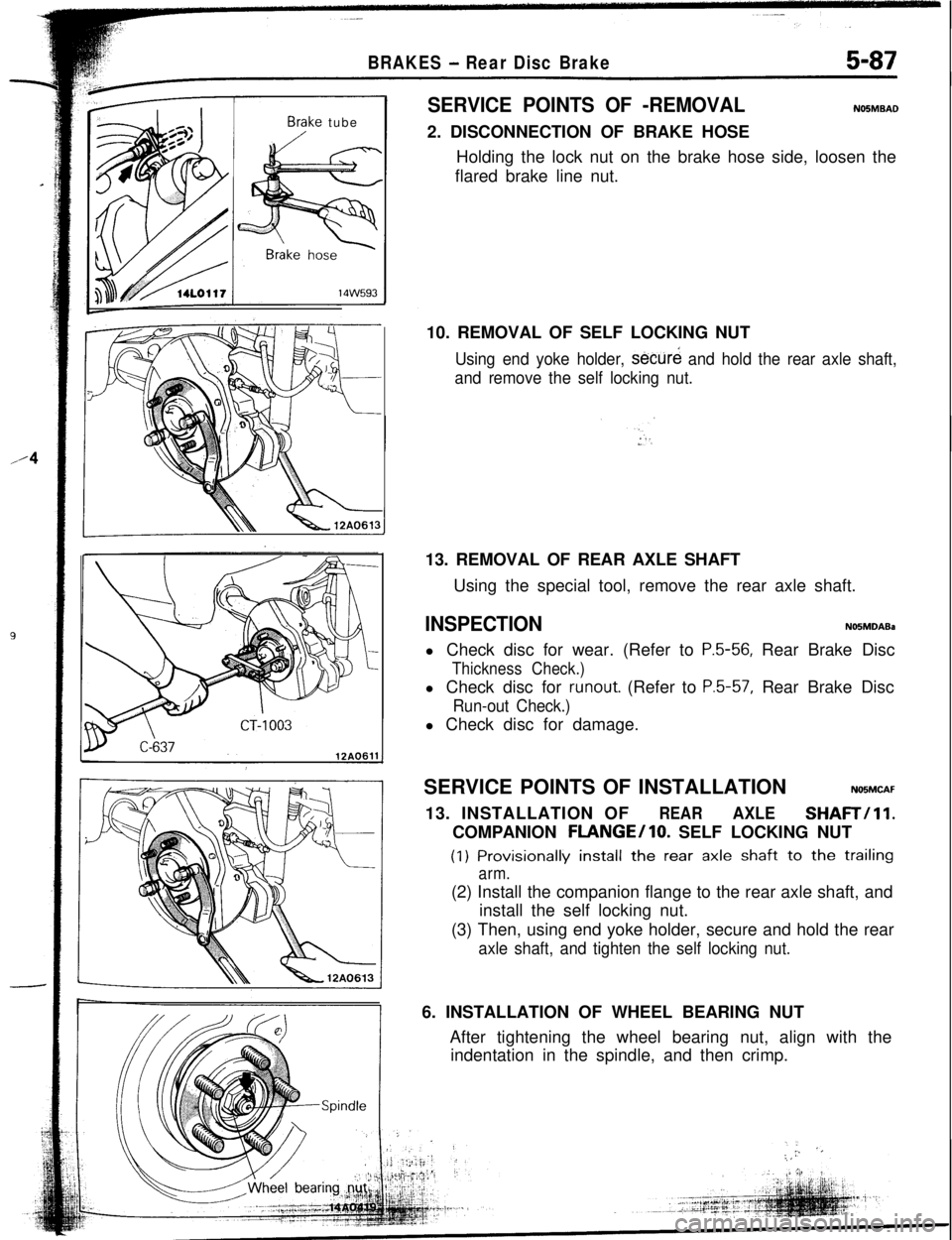

Brake tubeSERVICE POINTS OF -REMOVALNO5MBAD2. DISCONNECTION OF BRAKE HOSE

Holding the lock nut on the brake hose side, loosen the

flared brake line nut.

BRAKES - Rear Disc Brake5-8710. REMOVAL OF SELF LOCKING NUT

Using end yoke holder, secure and hold the rear axle shaft,

and remove the self locking nut.13. REMOVAL OF REAR AXLE SHAFT

Using the special tool, remove the rear axle shaft.

INSPECTIONNOSMDABal Check disc for wear. (Refer to

P.5-56, Rear Brake Disc

Thickness Check.)l Check disc for

runout. (Refer to P.5-57, Rear Brake Disc

Run-out Check.)l Check disc for damage.

SERVICE POINTS OF INSTALLATION

NOBMCAF13. INSTALLATION OF

REARAXLESHAFTill.COMPANION

FLANGE/lo. SELF LOCKING NUT(1)

Provisionally install the rear axle shaft to the trailing

arm.(2) Install the companion flange to the rear axle shaft, and

install the self locking nut.

(3) Then, using end yoke holder, secure and hold the rear

axle shaft, and tighten the self locking nut.6. INSTALLATION OF WHEEL BEARING NUT

After tightening the wheel bearing nut, align with the

indentation in the spindle, and then crimp.

:. ‘.:,,

Page 55 of 57

I

23-74BODY - Aero Parts

\18AQ245

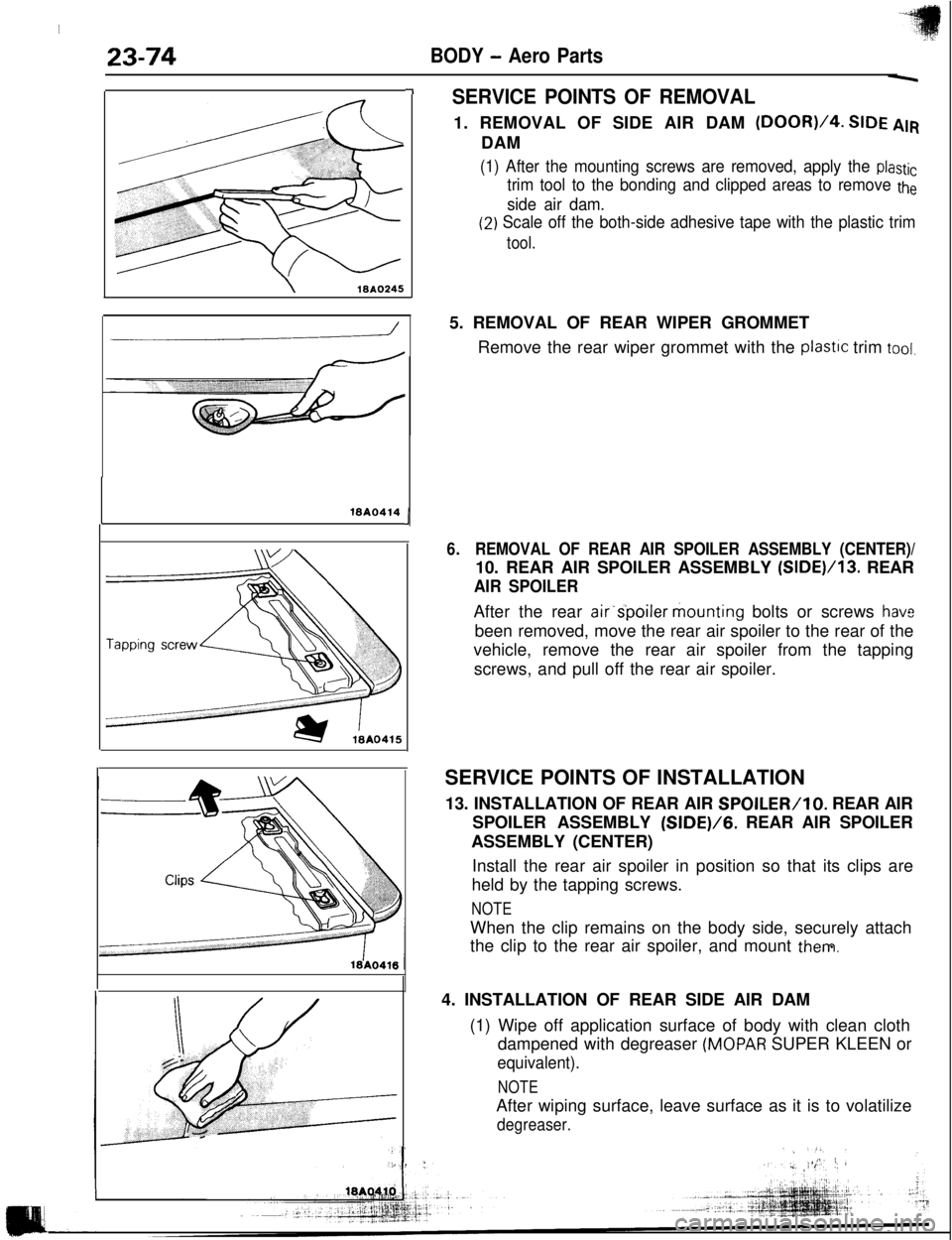

-ISERVICE POINTS OF REMOVAL1. REMOVAL OF SIDE AIR DAM

(DOOR)/4. SIDE AIRDAM

(1) After the mounting screws are removed, apply the plastic

trim tool to the bonding and clipped areas to remove the

side air dam.

(2) Scale off the both-side adhesive tape with the plastic trim

tool.

16AQ414J5. REMOVAL OF REAR WIPER GROMMET

Remove the rear wiper grommet with the

plastlc trim tool.

6.REMOVAL OF REAR AIR SPOILER ASSEMBLY (CENTER)/10. REAR AIR SPOILER ASSEMBLY (SIDE)/13. REAR

AIR SPOILERAfter the rear air’s’poiler mounting bolts or screws

hav2been removed, move the rear air spoiler to the rear of the

vehicle, remove the rear air spoiler from the tapping

screws, and pull off the rear air spoiler.

SERVICE POINTS OF INSTALLATION

13. INSTALLATION OF REAR AIR

SPOILER/lo. REAR AIR

SPOILER ASSEMBLY (SIDE)/G. REAR AIR SPOILER

ASSEMBLY (CENTER)

Install the rear air spoiler in position so that its clips are

held by the tapping screws.

NOTEWhen the clip remains on the body side, securely attach

the clip to the rear air spoiler, and mount

them.4. INSTALLATION OF REAR SIDE AIR DAM

(1) Wipe off application surface of body with clean cloth

dampened with degreaser

(MOPAR SUPER KLEEN or

equivalent).

NOTEAfter wiping surface, leave surface as it is to volatilize

degreaser.