torque MITSUBISHI ECLIPSE 1993 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1993, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1993Pages: 57, PDF Size: 4.18 MB

Page 3 of 57

BRAKES

SERVICE AND PARKINGCONTENTS

ANTI-LOCK BRAKING SYSTEM

TROUBLESHOOTING.........................9

BRAKE BOOSTER..............................

71

BRAKE LINE....................................73

BRAKE PEDAL..................................

63ELECTRONIC CONTROL UNIT

G-SENSOR

PARKING BRAKES.............................103

REAR DISC BRAKE............................

65SERVICE ADJUSTMENT PROCEDURES

..a 47

ABS Power Relay Check....................

62

Bleeding.......................................50Brake Booster Operating

Inspection.......49Brake Fluid Level Sensor Check...........

48Brake Pedal Inspection and Adjustment

...

47Check Valve Operation Check..............

49Flat Battery Remedy.........................

62Front Disc Brake Pad Check and

Replacement..................................51Front Disc Brake Rotor Inspection.........

53Inspection of Hydraulic Unit.................

59Measurement of Wheel Speed Sensor

Output Voltage................................

57Parking Brake Lever Stroke Check.........

48Parking Brake Switch Check................

49Proportioning Valve Function Test..........

50Rear Brake Disc Run-out Check............

57Rear Brake Disc Run-out Correction.......

57Rear Brake Disc Thickness Check..........

56Rear Disc Brake Pad Check and

Replacement..................................55Run-out Check................................

54Run-out Correction...........................

54

Thickness Check..............................55SPECIAL TOOLS...............................

6SPECIFICATIONS...............................

2General Specifications........................

2

Lubricants.....................................5

Service Specifications........................4Torque Specifications..................

.:....4TROUBLESHOOTING..........................

7

WHEEL SPEED SENSOR

95

CAUTION

When servicing brake assemblies or components, do not create dust by sanding, grinding or by cleaning

brake

parts with a dry brush or with compressed air. A WATER DAMPENED CLOTH SHOULD BE USED.

Many brake components contain asbestos fibers which can become air-borne if dust is.created duringservice operations. Breathing dust which contains asbestos fibers can cause serious bodily harm.

Page 6 of 57

-

5-4BRAKES- Specifications

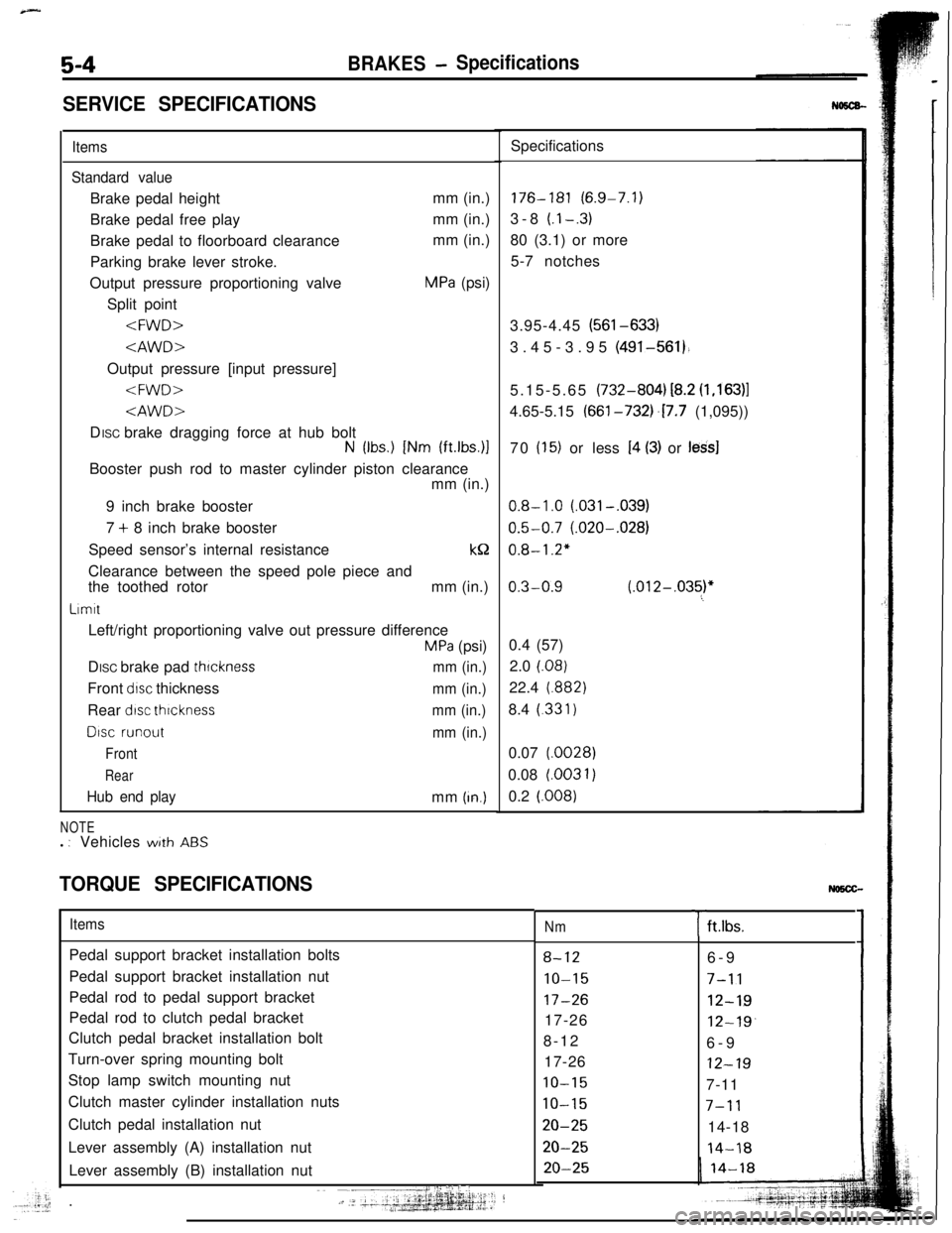

SERVICE SPECIFICATIONS

Items

Standard valueBrake pedal heightmm (in.)

Brake pedal free playmm (in.)

Brake pedal to floorboard clearancemm (in.)

Parking brake lever stroke.

Output pressure proportioning valve

MPa (psi)

Split point

N (Ibs.) [Nm (ft.lbs.)lBooster push rod to master cylinder piston clearance

mm (in.)

9 inch brake booster

7 + 8 inch brake booster

Speed sensor’s internal resistancek&

Clearance between the speed pole piece and

the toothed rotormm (in.)

LrmttLeft/right proportioning valve out pressure difference

MPa (psi)

DISC brake pad

thrcknessmm (in.)Front

drsc thicknessmm (in.)Rear

dtsc thrcknessmm (in.)

DISC runout

mm (in.)

Front

Rear

Hub end playmm (In.)

NOTEl : Vehicleswith ABS

TORQUE SPECIFICATIONSSpecifications176-181 (6.9-7.1)

3-8

(.l-.3)80 (3.1) or more

5-7 notches

3.95-4.45 (561-633)

3.45-3.95 (491-561).

5.15-5.65 (732-804) i8.2

(1,163)14.65-5.15 (661-732j.17.7 (1,095))

70

(15) or less I4 (3) or less]

0.8-1.0 (.031-,039)

0.5-0.7 (.020-.028)

0.8-1.2"

0.3-0.9 (.012-,035)"60.4 (57)

2.0

(.08)22.4

(.882)8.4

(.331)0.07

(.0028)0.08 l.0031)

0.2

(.008)

ItemsPedal support bracket installation bolts

Pedal support bracket installation nut

Pedal rod to pedal support bracket

Pedal rod to clutch pedal bracket

Clutch pedal bracket installation bolt

Turn-over spring mounting bolt

Stop lamp switch mounting nut

Clutch master cylinder installation nuts

Clutch pedal installation nut

Lever assembly (A) installation nut

Lever assembly (B) installation nut

I:: ::I .:‘i j ,:~~ -__j.-, .‘- ‘+‘+gg&p.~j:;.;1--?.+.k

Nm

8-12

IO-15

17-2617-26

8-12

17-26

10-15

10-15

20-25

20-25

20-25

Tft.lbs.

6-9

7-11

12-19

12-19.6-9

12-197-11

7-1114-18

14-18

Page 11 of 57

guiisur

dd

lght

clidc

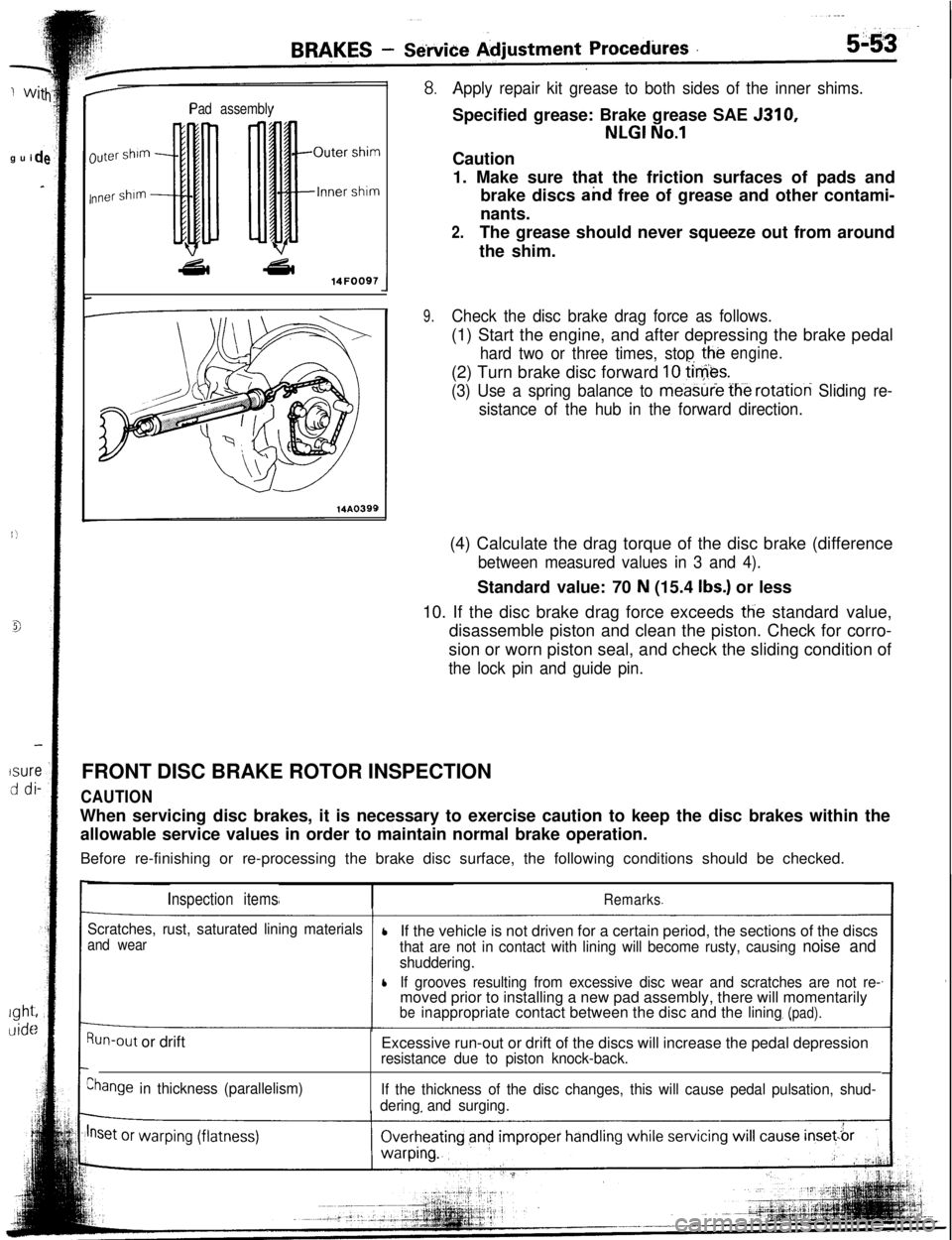

Pad assembly

luter shim

nner shim

43l a14FOO97

14A0399

Apply repair kit grease to both sides of the inner shims.Specified grease: Brake grease SAE 5310,

NLGI No.1Caution

1. Make sure that the friction surfaces of pads and

brake discs and free of grease and other contami-

nants.

2.The grease should never squeeze out from around

the shim.

9.Check the disc brake drag force as follows.(1) Start the engine, and after depressing the brake pedal

hard two or three times, stop the(2) Turn brake disc forward

10 tie&.

engine.

(3) Use a spring balance to meastiie fh-e rotation Sliding re-

sistance of the hub in the forward direction.(4) Calculate the drag torque of the disc brake (difference

between measured values in 3 and 4).Standard value: 70

N (15.4 Ibs.) or less

10. If the disc brake drag force exceeds

tlie standard value,

disassemble piston and clean the piston. Check for corro-

sion or worn piston seal, and check the sliding condition of

the lock pin and guide pin.FRONT DISC BRAKE ROTOR INSPECTION

CAUTIONWhen servicing disc brakes, it is necessary to exercise caution to keep the disc brakes within the

allowable service values in order to maintain normal brake operation.

Before re-finishing or re-processing the brake disc surface, the following conditions should be checked.

Inspection itemsRemarks

Scratches, rust, saturated lining materials

and wearlIf the vehicle is not driven for a certain period, the sections of the discsthat are not in contact with lining will become rusty, causing noise and

shuddering.

lIf grooves resulting from excessive disc wear and scratches are not re-moved prior to installing a new pad assembly, there will momentarily

beinappropriatecontact between the disc and thelining(pad).

Run-out or drift

Ehange in thickness (parallelism)Excessive run-out or drift of the discs will increase the pedal depression

resistance due to piston knock-back.

If the thickness of the disc changes, this will cause pedal pulsation, shud-

deringand surging.

Page 19 of 57

-

3AF

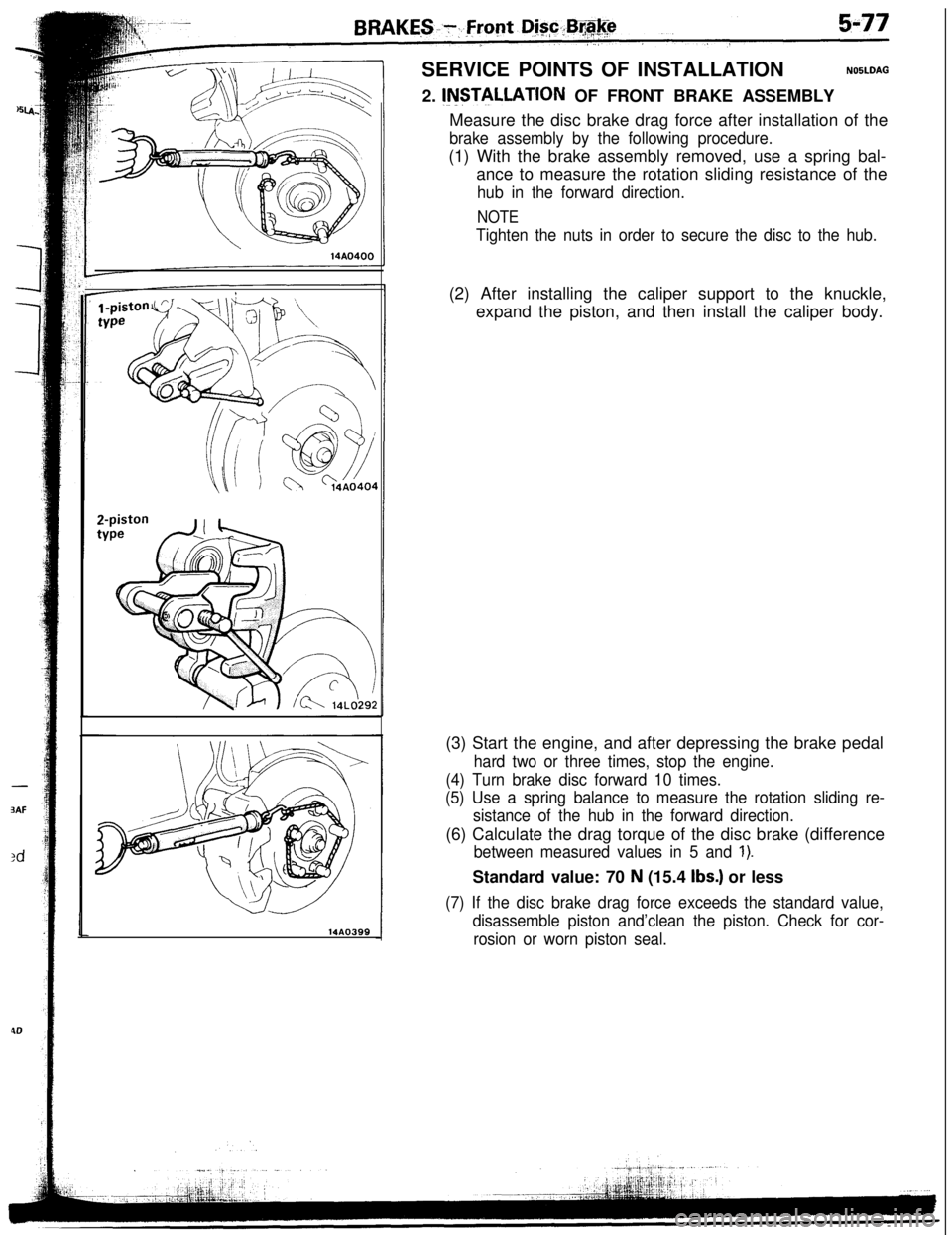

:dSERVICE POINTS OF INSTALLATION

NOBLDAG2.

INSTILLATION OF FRONT BRAKE ASSEMBLY

14AO399Measure the disc brake drag force after installation of the

brake assembly by the following procedure.(1) With the brake assembly removed, use a spring bal-

ance to measure the rotation sliding resistance of the

hub in the forward direction.

NOTE

Tighten the nuts in order to secure the disc to the hub.(2) After installing the caliper support to the knuckle,

expand the piston, and then install the caliper body.

(3) Start the engine, and after depressing the brake pedal

hard two or three times, stop the engine.

(4) Turn brake disc forward 10 times.

(5) Use a spring balance to measure the rotation sliding re-

sistance of the hub in the forward direction.(6) Calculate the drag torque of the disc brake (difference

between measured values in 5 and 1).Standard value: 70

N (15.4 Ibs.) or less

(7) If the disc brake drag force exceeds the standard value,

disassemble piston and’clean the piston. Check for cor-

rosion or worn piston seal.

Page 33 of 57

BODY

CONTENTS

,I

i

1AEROPARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

; CENTRAL DOOR LOCKING SYSTEM . . . . . . . . . . .68

’DOORASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

DOOR GLASS AND REGULATOR................

64

DOOR HANDLE AND LATCH.....................67QUARTER WINDOWGLASS..

...............

..i..59

REAR BUMPER........................................41

REARSEAT.........................................;..93

SEATBELT.............................................

94

SERVICE ADJUSTMENT PROCEDURES........30

Door Adjustment....................................31

Door Glass Adjustment............................31

Door Inside Handle Play Check...................31

Door Outside Handle Play Check................31

Floor PanInspection..............................

32

Fuel Filler Door Adjustment.......................30

Hood Adjustment...................................30

Liftgate Adjustment.................................30

Water Test...........................................

32

SPECIAL TOOLS....................*..........c......

5

SPECIFICATIONS.....................................2

General Specifications...........................;..2

Lubricants.............................................5

Sealants and Adhesives...........................5

Service Specifications..............................3

Torque Specifications..............................3

SUNROOF...............................................

77

TRIMS....................................................

85

TROUBLESHOOTING................................6

WINDOWGLASS.....................................52

WINDSHIELD...........................................56

DOORMIRROR........................................

70

DOOR

MOULDING AND

DRIP LINE WEATHERSTRIP........................

70

DOORRUNCHANNEL...............................

69

DOOR TRIM AND WATERPROOF FILM........

63

ELECTRIC REMOTE CONTROLLED

MIRRORSWITCH.....................................

71

FENDER..................................................

49

FLOORCONSOLE....................................

84

FRONTBUMPER......................................37

FRONTSEAT...........................................90

FUEL TANK FILLER DOOR.........................

36

GARNISHES............................................45

HEADLINING...........................................89

HOOD....................................................

33

INSTRUMENTPANEL.,..............................

79

Lll=l’GATE...............................................

35

LIFTGATE WINDOW GLASS......................60

LOOSEPANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

MOULDING.............................................

46

POWERWINDOW....................................65

N23AA--

Page 50 of 57

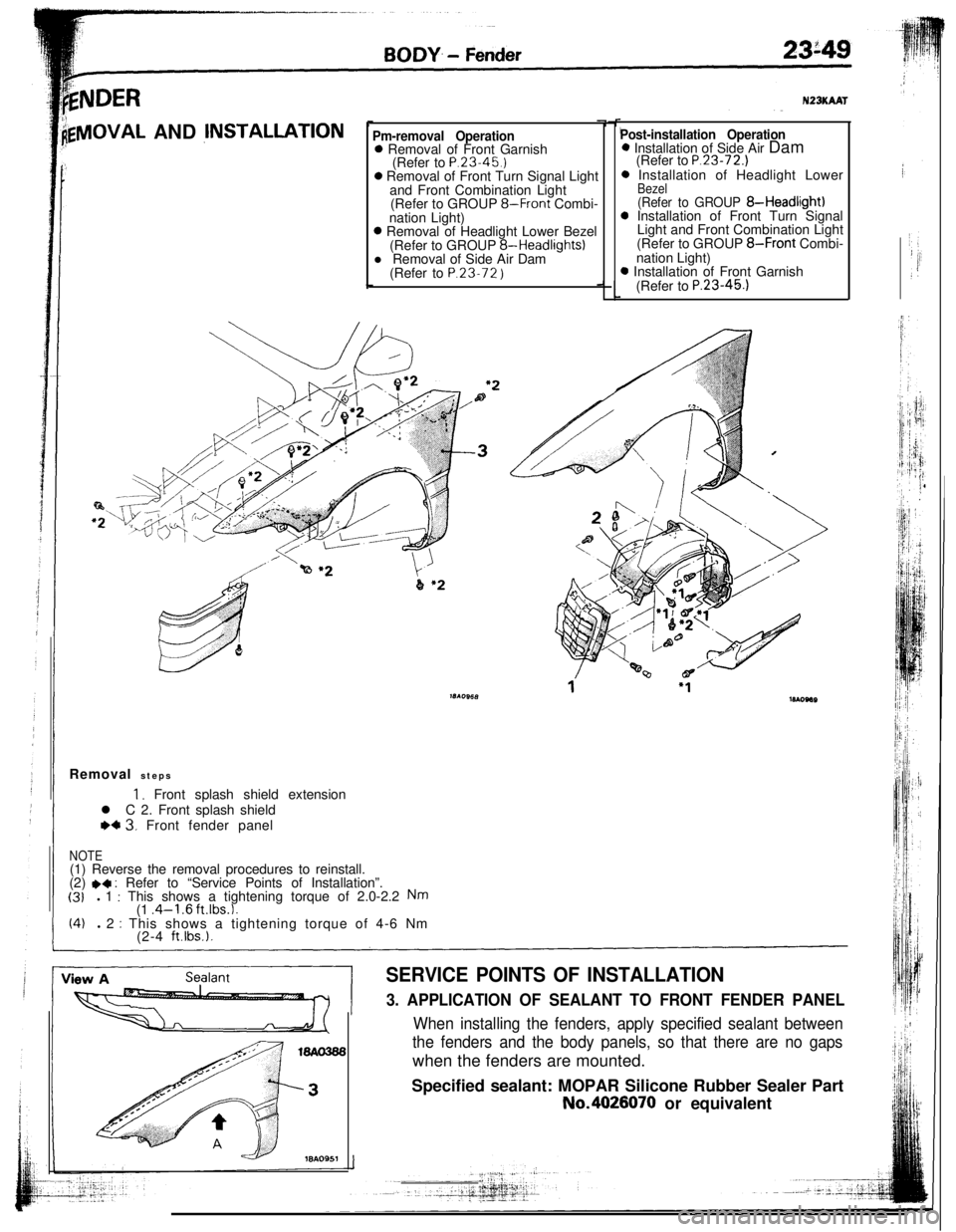

kNDER

lgVlOVAL AND jNSTALLATIONPm-removal Operation0 Removal of Front Garnish

(Refer to P.23.45.)0 Removal of Front Turn Signal Light

and Front Combination Light

(Refer to GROUP

8-Front Combi-

nation Light)0 Removal of Headlight Lower Bezel

(Refer to GROUP 8-Headlights)

l Removal of Side Air Dam

(Refer to P.23.72

)

N23KAAT

Post-installation Operation0 Installation of Side Air Dam

(Refer to

P.23-72.)0 Installation of Headlight Lower

Bezel(Refer to GROUP 8-Headlight)0 Installation of Front Turn Signal

Light and Front Combination Light

(Refer to GROUP

8-Front Combi-

nation Light)0 Installation of Front Garnish

(Refer to

P.23-45.1Removal steps

1, Front splash shield extension

l C 2. Front splash shield

WC 3. Front fender panel

NOTE(1) Reverse the removal procedures to reinstall.

(2)

.4 : Refer to “Service Points of Installation”.(31l 1 : This shows a tightening torque of 2.0-2.2 Nm(1 .4-l .6 ft.lbs.1.(4)l 2 : This shows a tightening torque of 4-6 Nm

(2-4 ft.lbs.).

SERVICE POINTS OF INSTALLATION

3. APPLICATION OF SEALANT TO FRONT FENDER PANEL

When installing the fenders, apply specified sealant between

the fenders and the body panels, so that there are no gapswhen the fenders are mounted.

Specified sealant: MOPAR Silicone Rubber Sealer PartNo.4026070 or equivalent