ESP MITSUBISHI ENDEAVOR 2004 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2004, Model line: ENDEAVOR, Model: MITSUBISHI ENDEAVOR 2004Pages: 3870, PDF Size: 98.47 MB

Page 268 of 3870

with a new one if a problem is found.

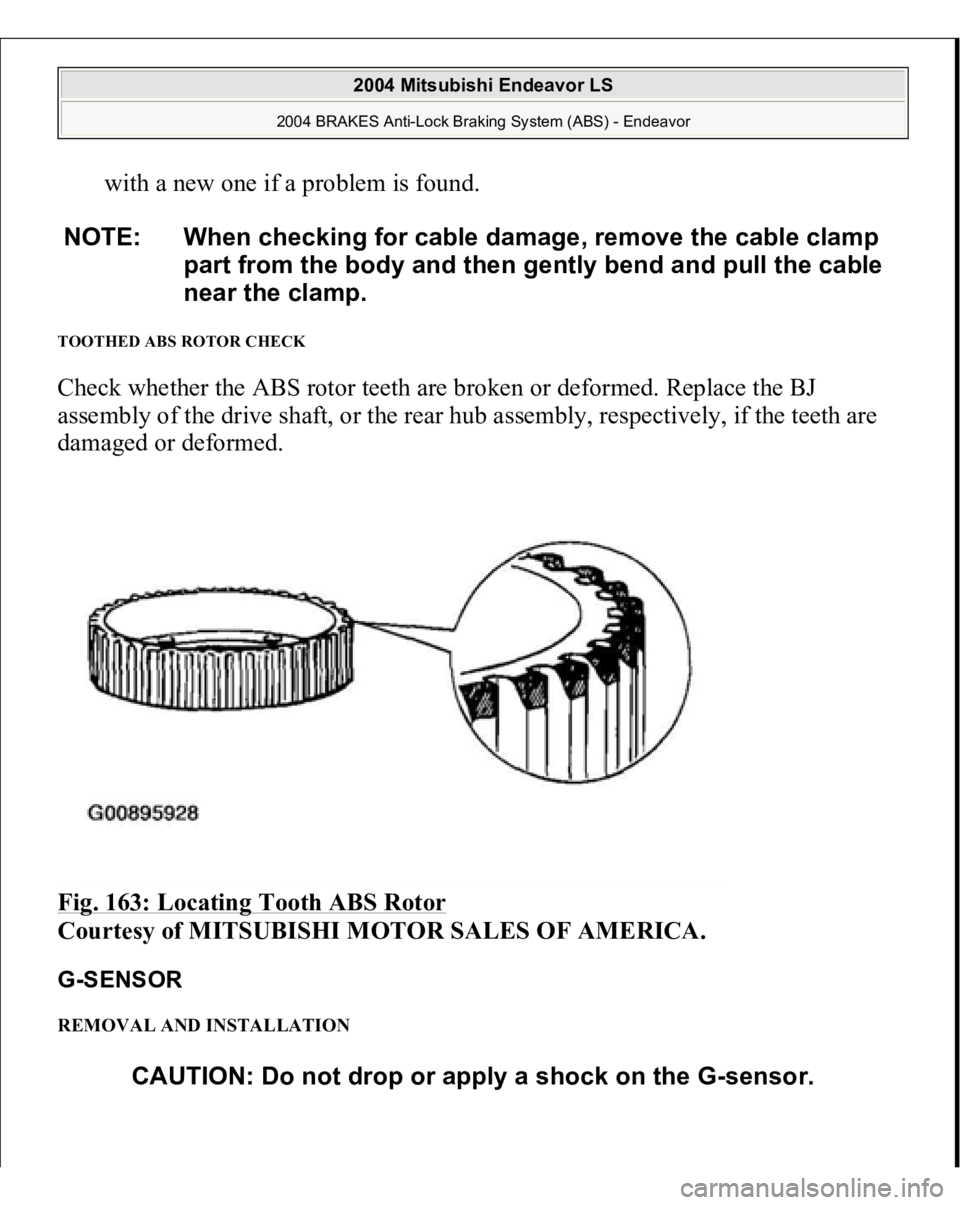

TOOTHED ABS ROTOR CHECK Check whether the ABS rotor teeth are broken or deformed. Replace the BJ

assembly of the drive shaft, or the rear hub assembly, respectively, if the teeth are

damaged or deformed.

Fig. 163: Locating Tooth ABS Rotor

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

G-SENSOR REMOVAL AND INSTALLATION NOTE: When checking for cable damage, remove the cable clamp

part from the body and then gently bend and pull the cable

near the clamp.

CAUTION: Do not drop or apply a shock on the G-sensor.

2004 Mitsubishi Endeavor LS

2004 BRAKES Anti-Lock Braking System (ABS) - Endeavor

Page 525 of 3870

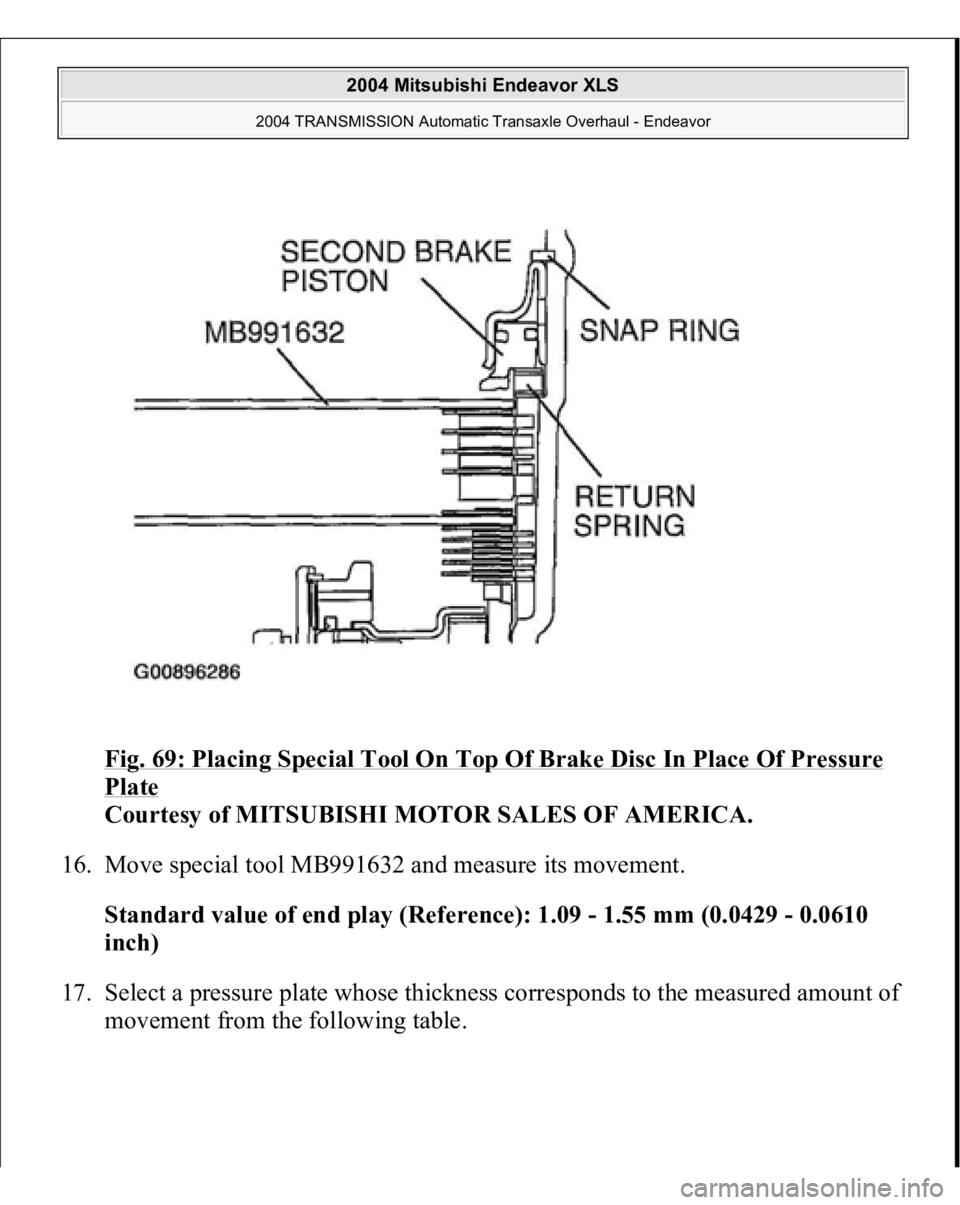

Fig. 69: Placing Special Tool On Top Of Brake Disc In Place Of Pressure Plate

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

16. Move special tool MB991632 and measure its movement.

Standard value of end play (Reference): 1.09 - 1.55 mm (0.0429 - 0.0610

inch)

17. Select a pressure plate whose thickness corresponds to the measured amount of

movement from the followin

g table.

2004 Mitsubishi Endeavor XLS

2004 TRANSMISSION Automatic Transaxle Overhaul - Endeavor

Page 529 of 3870

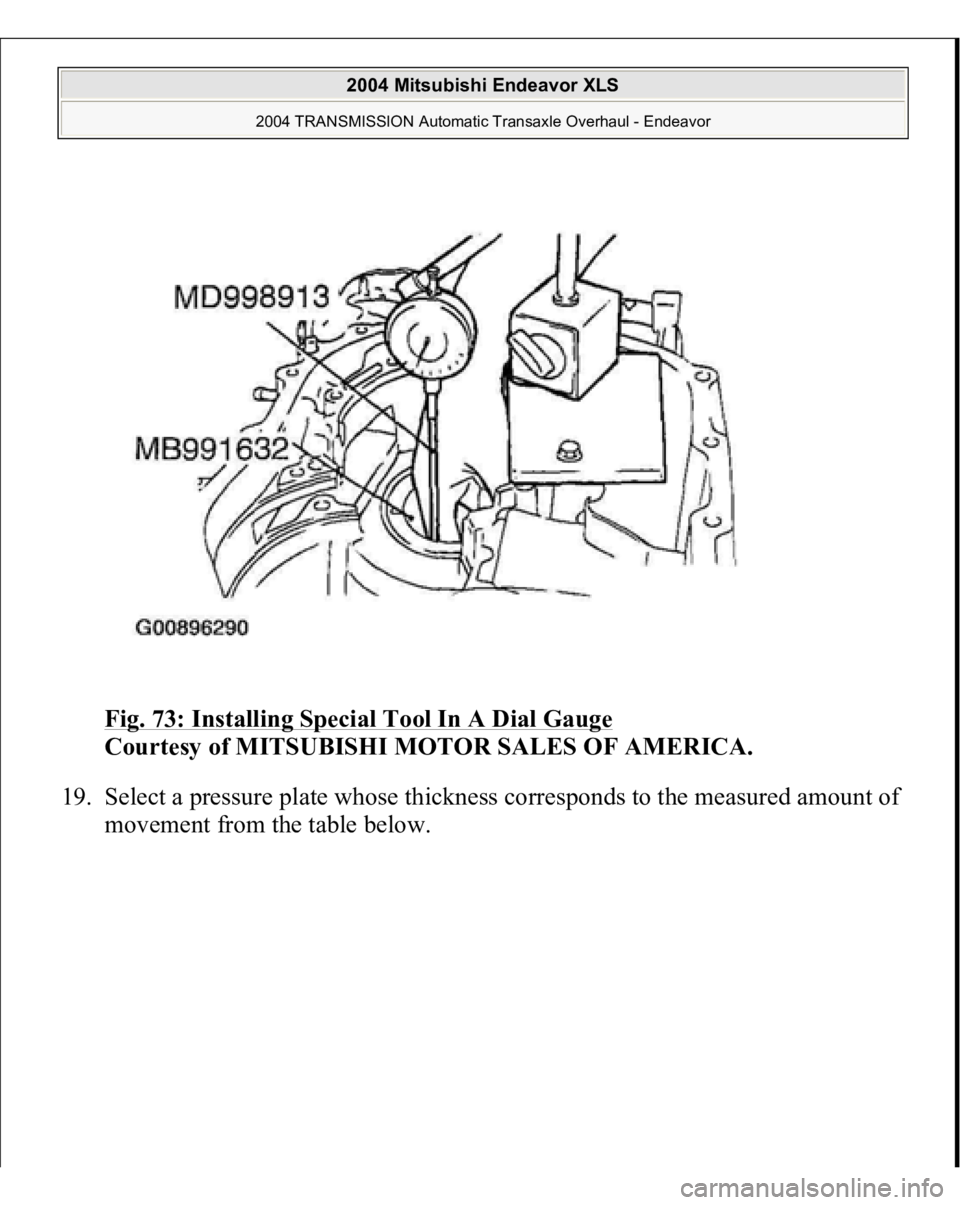

Fig. 73: Installing Special Tool In A Dial Gauge

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

19. Select a pressure plate whose thickness corresponds to the measured amount of

movement from the table below.

2004 Mitsubishi Endeavor XLS

2004 TRANSMISSION Automatic Transaxle Overhaul - Endeavor

Page 558 of 3870

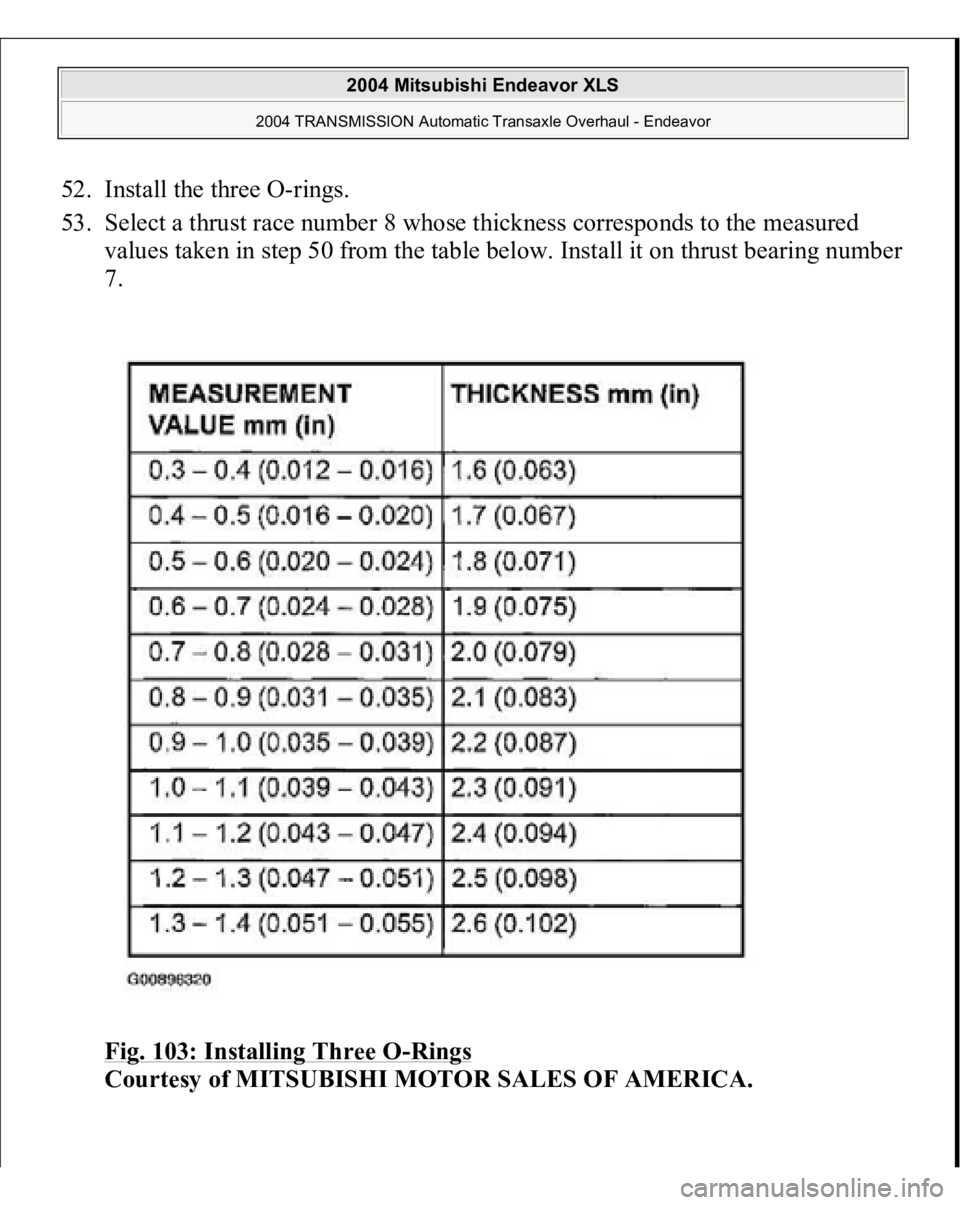

52. Install the three O-rings.

53. Select a thrust race number 8 whose thickness corresponds to the measured

values taken in step 50 from the table below. Install it on thrust bearing number

7.

Fig. 103: Installing Three O

-Rings

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

2004 Mitsubishi Endeavor XLS

2004 TRANSMISSION Automatic Transaxle Overhaul - Endeavor

Page 567 of 3870

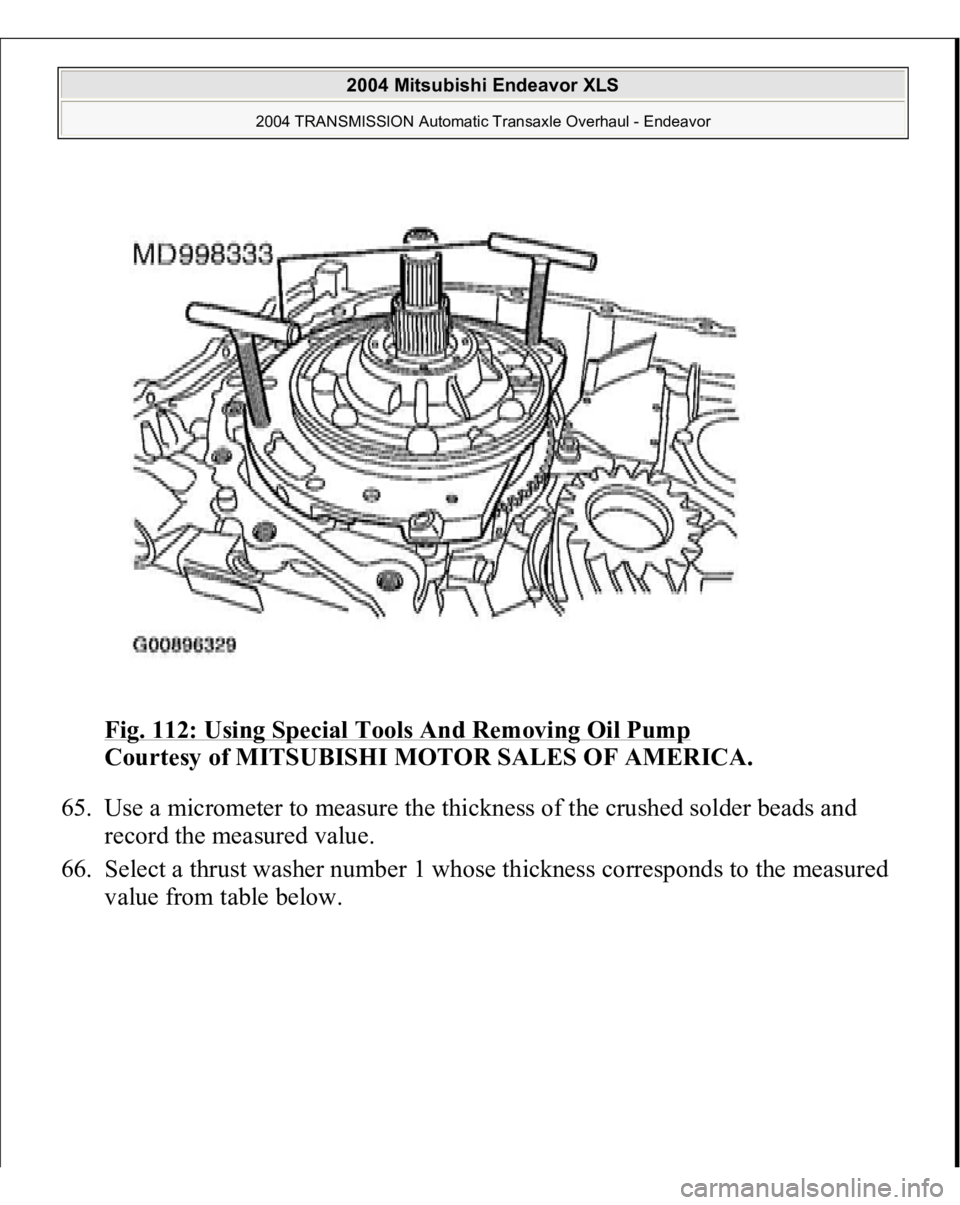

Fig. 112: Using Special Tools And Removing Oil Pump

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

65. Use a micrometer to measure the thickness of the crushed solder beads and

record the measured value.

66. Select a thrust washer number 1 whose thickness corresponds to the measured

value from table below.

2004 Mitsubishi Endeavor XLS

2004 TRANSMISSION Automatic Transaxle Overhaul - Endeavor

Page 578 of 3870

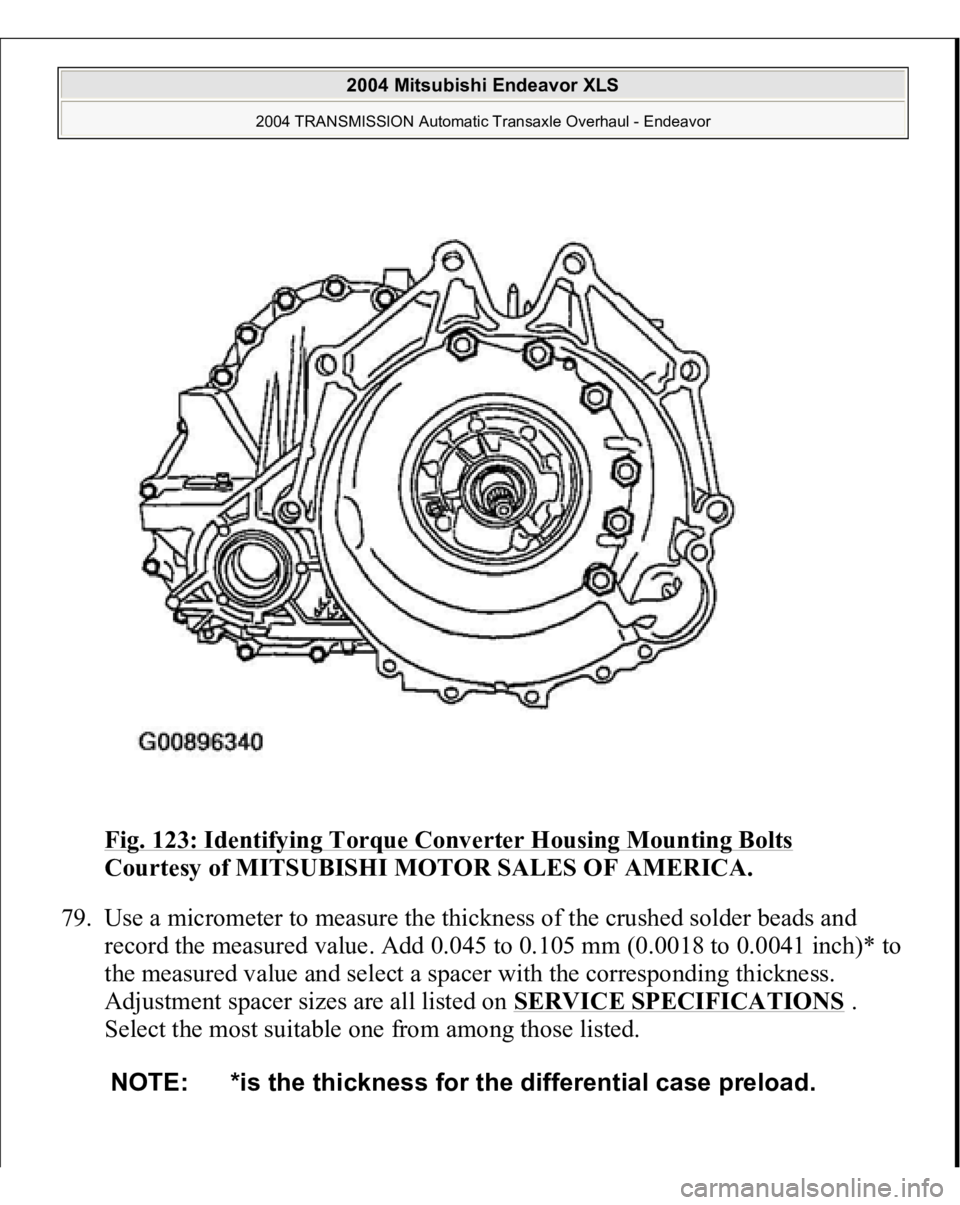

Fig. 123: Identifying Torque Converter Housing Mounting Bolts

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

79. Use a micrometer to measure the thickness of the crushed solder beads and

record the measured value. Add 0.045 to 0.105 mm (0.0018 to 0.0041 inch)* to

the measured value and select a spacer with the corresponding thickness.

Adjustment spacer sizes are all listed on SERVICE SPECIFICATIONS

.

Select the most suitable one from among those listed.

NOTE: *is the thickness for the differential case preload.

2004 Mitsubishi Endeavor XLS

2004 TRANSMISSION Automatic Transaxle Overhaul - Endeavor

Page 692 of 3870

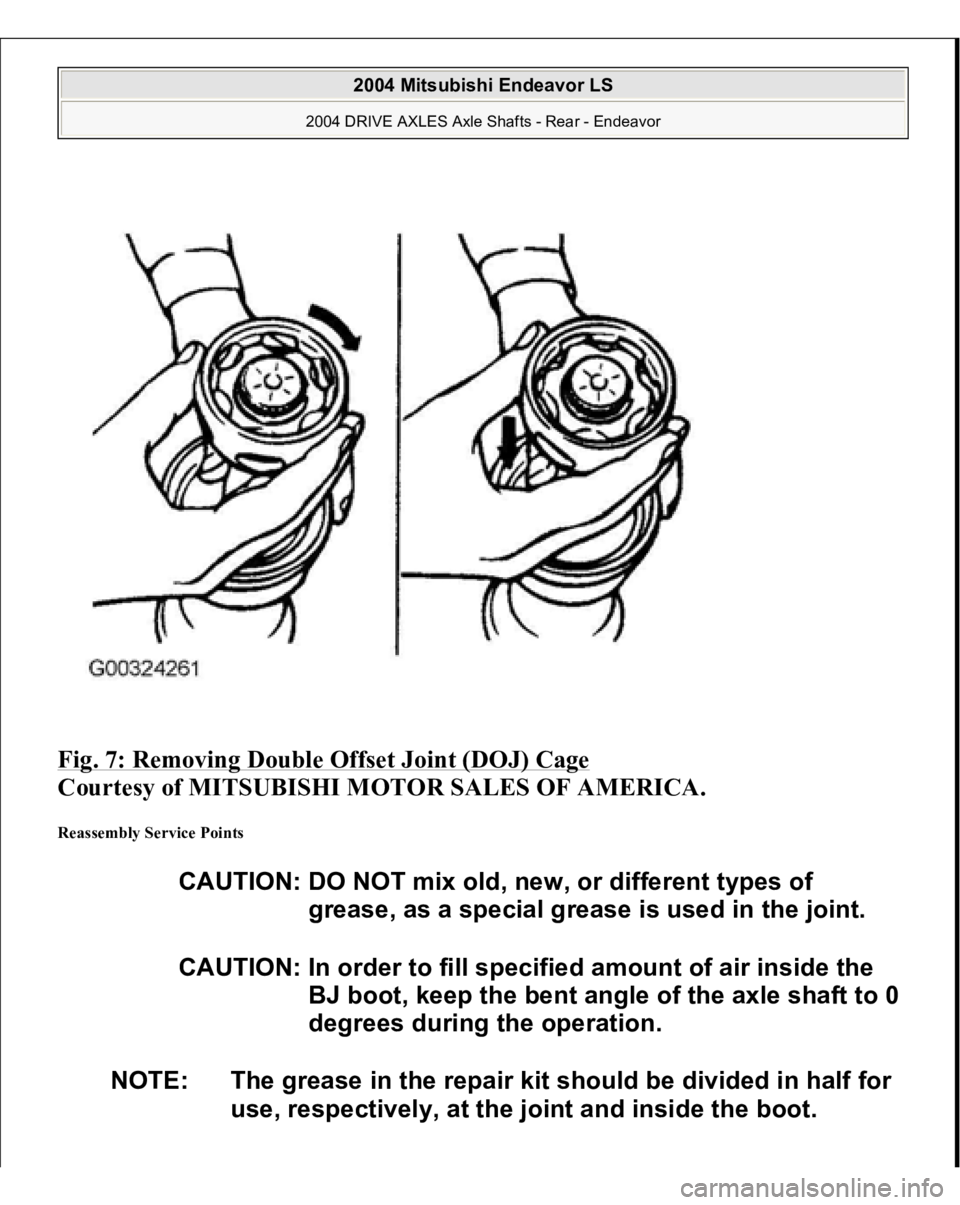

Fig. 7: Removing Double Offset Joint (DOJ) Cage

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

Reassembly Service Points

CAUTION: DO NOT mix old, new, or different types of

grease, as a special grease is used in the joint.

CAUTION: In order to fill specified amount of air inside the

BJ boot, keep the bent angle of the axle shaft to 0

degrees during the operation.

NOTE: The grease in the repair kit should be divided in half for

use, respectively, at the joint and inside the boot.

2004 Mitsubishi Endeavor LS

2004 DRIVE AXLES Axle Shafts - Rear - Endeavor

Page 697 of 3870

2. Remove the battery from the vehicle.

3. Inspect battery carrier for damage caused by loss of acid from the battery. If

acid damage is present, it is necessary to clean area with a solution of clean

warm water and baking soda. Scrub area with a stiff bristle brush. Wipe clean

with a cloth moistened with ammonia or baking soda in water.

4. Clean the battery, especially the top with same solutions as described in step 3.

5. Inspect the battery case and cover for cracks. If cracks are present, battery must

be replaced.

6. Clean the battery post with a suitable battery post cleaning tool.

7. Clean the inside surfaces of the terminal clamps with a suitable battery

terminal cleaning tool. Replace damaged or frayed cables and broken terminal

clamps.

8. Install the battery in the vehicle.

9. Connect the positive and negative cables to the battery in the order of mention.

10. Tighten the clamp nut securely. BATTERY CHARGING Battery electrolyte temperature may temporarily be allowed to rise to 55°C (131°F).

Increase of electrolyte temperature above 55°C (131°F) is harmful to the battery,

causing deformation of battery cell, decrease in life of battery, etc.

case is cracked or leaking to protect hands from

the electrolyte. A suitable pair of rubber gloves

(not the household type) should be worn when

removing battery by hand.

WARNING:When batteries are being charged, an explosive gas

forms beneath the cover of each cell. Do not smoke

near batteries on charge or which have recently

been charged. Do not break live circuits at the

terminals of the batteries on charge. A spark will

occur where the live circuit is broken. Keep all open

flames away from the battery.

2004 Mitsubishi Endeavor Limited 2004 ELECTRICAL Battery - Endeavor

Page 983 of 3870

pressed. If the values measured at the time correspond to those in the table below, the resistance values are correct.

2004 Mitsubishi Endeavor LS

2004 BODY & ACCESSORIES Auto, Cruise Control System - Endeavor

Page 1068 of 3870

2 .

3. Turn the ignition switch to the ON position and select BELT TENSION

MEASUREMENT from the menu screen on Scan Tool (MB991958).

4. Hold Microphone (part of Belt Drive Meter Set) (MB991668) near the center

of the drive belt between the pulleys away from the rear surface of the belt and

perpendicular to the belt (no more then 15 degrees in either direction). See Fi

g.

3 and Fig. 4

.

5. Gently tap the middle of the belt between the pulleys with your finger, and

check that the vibration frequency of the belt is within specification. See Fig. 3

and Fig. 4

. See DRIVE BELT ADJUSTMENT SPECIFICATIONS

table.

CAUTION: Temperature of the surface of the belt should be

as close possible to underhood temperature.

CAUTION: DO NOT let contaminants such as water or oil get

onto the microphone. If strong gusts of wind

blow against the microphone or if there are any

loud sources of noise nearby, the values

measured by the microphone may not

correspond to actual values. DO NOT take

measurement while engine is running.

2004 Mitsubishi Endeavor Limited

2004 ENGINE COOLING Specifications & Drive Belt Routing - Endeavor