ESP MITSUBISHI ENDEAVOR 2004 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2004, Model line: ENDEAVOR, Model: MITSUBISHI ENDEAVOR 2004Pages: 3870, PDF Size: 98.47 MB

Page 1097 of 3870

SOLENOIDS & SOLENOID VALVES SOLENOIDS & SOLENOID VALVES LOCATION Photo Sensor

Top front center of dash.Fig. 58

.

Right Bank Heated Oxygen Sensor

(Front)

On inlet of right catalytic

converter.Fig. 42

.

Right Bank Heated Oxygen Sensor

(Rear)

On outlet of right catalytic

converter.Fig. 54

.

Seat Slide Sensor

Under left front seat. See Fig. 68

.

Side Impact Sensor (Left)

At base of left "B" pillar. See Fig. 69

.

Side Impact Sensor (Right)

At base of right "B" pillar. See Fig.

69 .

Steering Wheel Sensor

On steering column. See Fig. 57

.

Throttle Position Sensor

On throttle body assembly.Fig. 44

.

Tire Pressure Sensor (4)

Inside tire. (integral to TPMS

transmitter). See Fig. 65

.

Transmission Fluid Temperature

Sensor

In A/T control solenoid valve

assembly.Fig. 56

.

Wheel Speed Sensor (Left/Right Front)

At respective front wheel. See Fig. 66

.

Wheel Speed Sensor (Left/Right Rear)

At respective rear wheel. See Fig. 70

.

Component

Location

ABS Solenoid Valve

Right rear of engine compartment.Fig.

71 .

A/T Control Solenoid Valve Assembly

Connector

Left side of engine compartment. See

Fig. 56

.

Evaporative Emission Purge Solenoid

Center rear of engine

compartment.Fig. 72

.

Evaporative Emission Ventilation

Solenoid

Near fuel tank, on evaporative

emission canister. See Fig. 75

.

Exhaust Gas Recirculation Valve

Left side of engine compartment.Fig.

73 .

Injector 2, 4, 6 (B-29, B-03, B-04)

Top of engine.Fig. 78

.

2004 Mitsubishi Endeavor LS

2004 MITSUBISHI Endeavor

Page 1302 of 3870

cleaned regularly and kept separate from personal clothing. Where there is a risk of eye contact, eye protection should be worn i.e.

chemical goggles or face shields. In addition, an eye wash facility should be

provided. Obtain First Aid treatment immediately for open cuts and wounds. Wash regularly with soap and water to ensure all oil is removed, especially

before meals (skin cleansers and nail brushes will help). After cleaning, apply

lotion, etc., containing lanolin to replace natural skin oils is advised. Do not use gasoline, kerosene, diesel fuel, gas oil, thinner or solvents for

cleaning skin. Apply barrier creams before each work period to help clean the skin after

work. If skin disorders develop, obtain medical advice immediately.

SPECIAL TOOLS Fig. 1: Identifying Special Tool

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

ON-VEHICLE SERVICE ENGINE OIL CHECK 1. Pull out the oil dipstick slowly and check that the oil level is within the marks

on the oil dipstick.

2. Check that the oil is not excessively dirty, that there is no coolant or gasoline

mixed in, and that it is sufficientl

y thick and sli

ppery.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Lubrication - Endeavor

Page 1461 of 3870

Fig. 134: Installing Connecting Rod Cap Nu

t

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

INSPECTION PISTON Replace the piston if scratches or seizure is evident on its surfaces (especially the

thrust surface). Replace the piston if it is cracked. PISTON PIN 1. Insert the piston pin into the piston pin hole with a thumb. You should feel a

slight resistance. Replace the piston pin if it can be easily inserted or there is

excessive play.

2. The piston and piston pin must be replaced as an assembly. PISTON RING 1. Check the piston ring for damage, excessive wear, and breakage. Replace if

defects are evident. If the piston has been replaced with a new one, the piston

rings must also be replaced with new ones.

2. Check for clearance between the piston ring and ring groove. If the limit is

exceeded, replace the ring or piston, or both.

Standard Value:

Number 1: 0.03 - 0.07 mm (0.0012 - 0.0027 inch)

Number 2: 0.02 - 0.06 mm (0.0008 - 0.0023 inch)

Limit: 0.1 mm (0.003 inch)

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1501 of 3870

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA

.

2. Connect scan tool MB991958 to the data link connector.

3. Turn the ignition switch to the "ON" and select scan tool MB991958 "Belt

Tension Measurement" from the menu screen.

4. Hold special tool MB991668 (microphone) to the middle of the drive belt

between the pulleys (at the place indicated by the arrow), about 10 - 20 mm

(0.4 - 0.8 inch) away from the rear surface of the belt and so that it is

perpendicular to the belt (within an angle of +/-15 degree angle).

5. Gently tap the middle of the belt between the pulleys (the place indicated by

the arrow) with your finger as shown in the illustration, and check that the

vibration fre

quenc

y of the belt is within the stan

dard value.

CAUTION:

The temperature of the surface of the belt

should be as close as possible to underhood

temperature. Do not let an

y contaminants such as water or

oil get onto the microphone.

If strong gusts of wind blow against the

microphone or if there are any loud sources

of noise nearby, the values measured by the

microphone may not correspond to actual

values. If the microphone is touching the belt while

the measurement is being made, the values

measured by the microphone may not

correspond to actual values. Do not take the measurement while the

vehicle's engine is running.

2004 Mitsubishi Endeavor Limited

2004 ENGINE Engine - Endeavor

Page 1511 of 3870

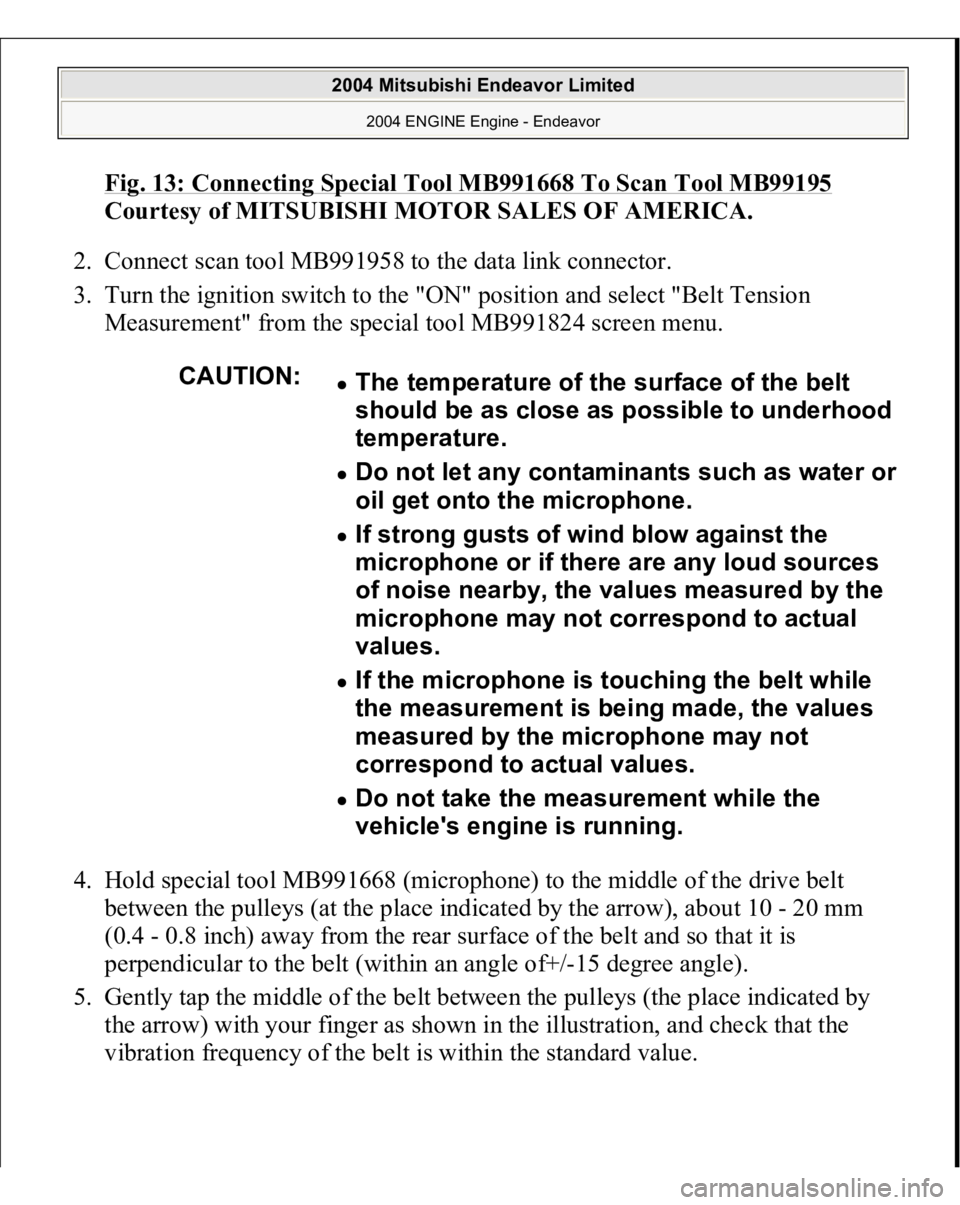

Fig. 13: Connecting Special Tool MB991668 To Scan Tool MB99195

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

2. Connect scan tool MB991958 to the data link connector.

3. Turn the ignition switch to the "ON" position and select "Belt Tension

Measurement" from the special tool MB991824 screen menu.

4. Hold special tool MB991668 (microphone) to the middle of the drive belt

between the pulleys (at the place indicated by the arrow), about 10 - 20 mm

(0.4 - 0.8 inch) away from the rear surface of the belt and so that it is

perpendicular to the belt (within an angle of+/-15 degree angle).

5. Gently tap the middle of the belt between the pulleys (the place indicated by

the arrow) with your finger as shown in the illustration, and check that the

vibration frequency of the belt is within the stan

dard value.

CAUTION:

The temperature of the surface of the belt

should be as close as possible to underhood

temperature. Do not let any contaminants such as water or

oil get onto the microphone. If strong gusts of wind blow against the

microphone or if there are any loud sources

of noise nearby, the values measured by the

microphone may not correspond to actual

values. If the microphone is touching the belt while

the measurement is being made, the values

measured by the microphone may not

correspond to actual values. Do not take the measurement while the

vehicle's engine is running.

2004 Mitsubishi Endeavor Limited

2004 ENGINE Engine - Endeavor

Page 1531 of 3870

the vacuum gauge reading.

Idle speed: 680+/-100 r/min

Minimum limit: 60 kPa (18 in Hg)

LASH ADJUSTER CHECK If an abnormal noise (chattering noise) suspected to be caused by malfunction of the

lash adjuster is produced immediately after starting the engine and does not

disappear, perform the following check.

1. Start the engine.

2. Check if the abnormal noise produced immediately after starting the engine,

changes with the change in the engine speed.

If the abnormal noise is not produced immediately after starting the engine or it

does not change with the engine speed, the lash adjuster is not the cause for the

noise.

Therefore, investigate other causes. The abnormal noise is probably caused by

some other parts than the engine proper if it does not change with the engine

speed. (In this case, the lash adjuster is in good condition.)NOTE: An abnormal noise due to malfunction of the lash adjuster

is produced immediately after starting the engine and

changes with the engine speed, irrespective of the engine

load. If, the abnormal noise is not produced immediately

after starting the engine or does not change with the engine

speed, or it changes with the engine load, the lash adjuster

is not the cause for the abnormal noise.

NOTE: When the lash adjuster is malfunctioning, the abnormal

noise is rarely eliminated by continuing the warming-up of

the engine at idle speed.

However, the abnormal noise may disappear only when

seizure is caused by oil sludge in the engine whose oil is

not maintained properly.

2004 Mitsubishi Endeavor Limited

2004 ENGINE Engine - Endeavor

Page 1774 of 3870

7. Does vehicle have an antenna which extend? If not eliminate this step.

If there is noise, the following causes can be considered.

8. If due to vehicle noise: It may not be possible to prevent noise if the signal is

weak.

9. If due to external noise: In almost all cases, prevention on the receiver side is

not possible. Weak signals especially are susceptible to interference.

If there is more noise than on radios in other vehicles, find out the noise condition

and the name and frequency of the receiving stations from the owner, and consult

with the radio manufacturer's service center. INSPECTION PROCEDURE 10: Sound mixed with Noise, Only at Night (AM). The following can be considered as possible causes of noise appearing only at

night.

1. It is significantly easier to receive long-distance signals at night. This means

that even stations that are received without a problem during the day may

experience problems at night. Remember that the weaker station is more

susceptible to interference. The appearance of a beat sound may occur in the

evening. A beat sound is created when two signals close in frequency interfere

with each other. A common sign of this type of interference is a repetitious

high-pitched sound that may over power the desired radio station. This sound is

generated not only by sound signals but electrical waves as well.

2. The changing system may also be a source of noise. When diagnosing radio

noise, do not over look the possibility of a problem with the vehicles generator. DIAGNOSIS

STEP 1. Check the vehicles lighting system.

Q: Does the noise disappear when the vehicles headlights are turned

"OFF"?

YES: Go to Ste

p 2.

2004 Mitsubishi Endeavor LS

2004 BODY & ACCESSORIES Radio With Tape Player & Cd Player - Endeavor

Page 1888 of 3870

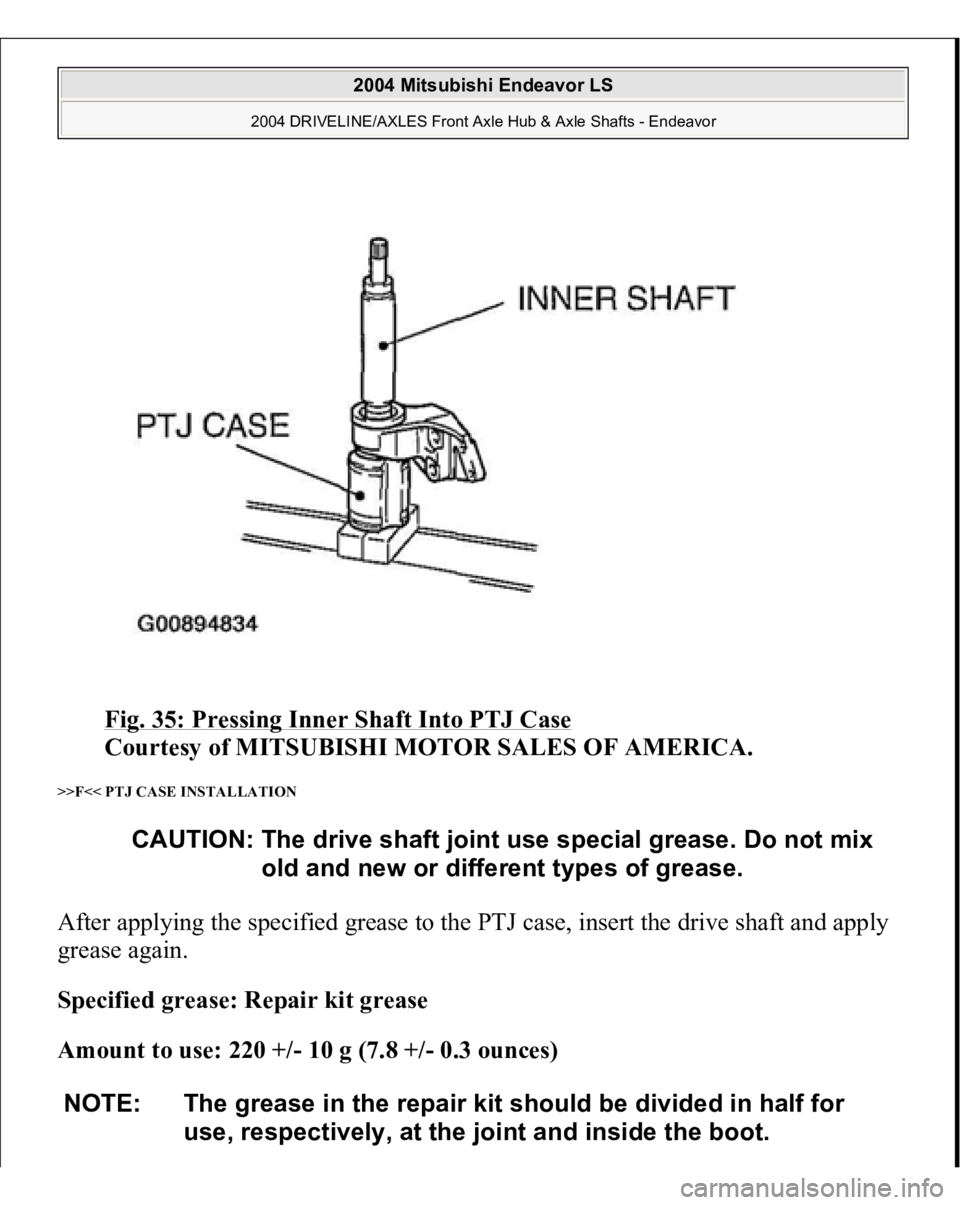

Fig. 35: Pressing Inner Shaft Into PTJ Case

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

>>F<< PTJ CASE INSTALLATION After applying the specified grease to the PTJ case, insert the drive shaft and apply

grease again.

Specified grease: Repair kit grease

Amount to use: 220 +/- 10 g (7.8 +/- 0.3 ounces)

CAUTION: The drive shaft joint use special grease. Do not mix

old and new or different types of grease.

NOTE: The grease in the repair kit should be divided in half for

use, respectively, at the joint and inside the boot.

2004 Mitsubishi Endeavor LS

2004 DRIVELINE/AXLES Front Axle Hub & Axle Shafts - Endeavor

Page 1897 of 3870

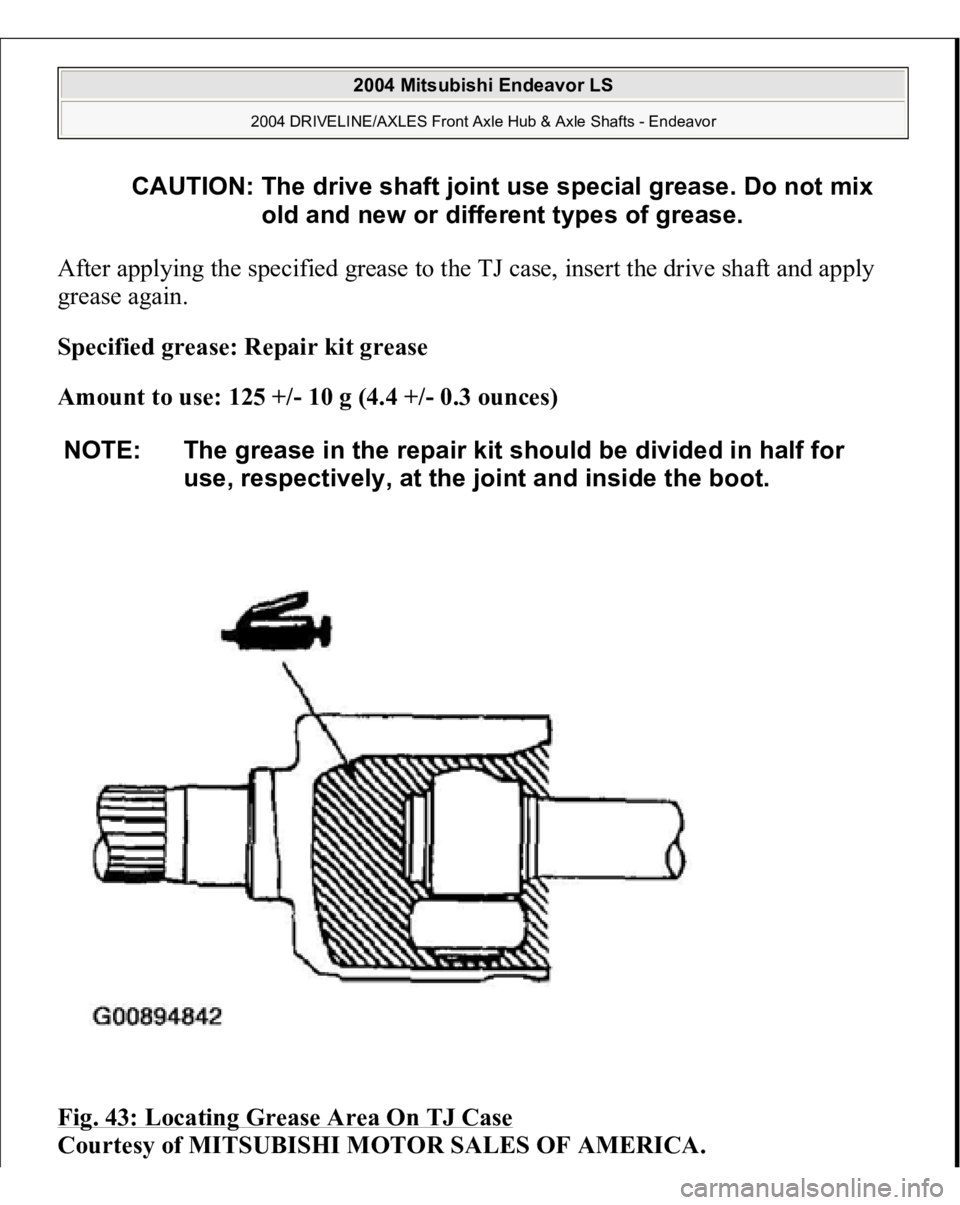

After applying the specified grease to the TJ case, insert the drive shaft and apply

grease again.

Specified grease: Repair kit grease

Amount to use: 125 +/- 10 g (4.4 +/- 0.3 ounces)

Fig. 43: Locating Grease Area On TJ Case

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

CAUTION: The drive shaft joint use special grease. Do not mix

old and new or different types of grease.

NOTE: The grease in the repair kit should be divided in half for

use, respectively, at the joint and inside the boot.

2004 Mitsubishi Endeavor LS

2004 DRIVELINE/AXLES Front Axle Hub & Axle Shafts - Endeavor

Page 1926 of 3870

A. Wipe off grease from the spider assembly and the inside of the TJ case. Clean

the spider assembly if water or foreign material is present.

B. Wipe off grease from the shaft spline. When reusing the TJ boot or the BJ boot,

wrap plastic tape around the shaft spline to avoid damaging the boot. Reassembly Service Points (All-Wheel Drive) A. Wrap plastic tape around the shaft spline. Install small DOJ boot band and DOJ

boot. Then install the small TJ boot band and TJ boot.

B. Set the DOJ boot bands at the specified distance in order to adjust the amount

of air inside the DOJ boot. See Fig. 12

. Then tighten the small and large DOJ

boot bands.

C. Apply the specified grease furnished in the repair kit to the spider assembly

between the spider axle and the roller. Install the spider assembly to the shaft

from the direction of the spline chamfered side. See Fig. 13

.

D. After applying the specified grease to the TJ case, insert the axle shaft and

apply grease again.

E. Set the TJ boot bands at the specified distance in order to adjust the amount of

air inside the TJ boot. See Fig. 14

. Then tighten the small and large TJ boot

bands.

CAUTION: The axle shaft joint uses special grease. DO NOT

mix old, new, or different types of grease. If the

spider assembly has been cleaned, take special

care to apply the specified grease.

CAUTION: The axle shaft joint uses special grease. DO NOT

mix old, new, or different types of grease. If the

spider assembly has been cleaned, take special

care to apply the specified grease.

NOTE: The grease in the repair kit should be divided in half for

use, respectively, at the joint and inside the boot.

2004 Mitsubishi Endeavor LS

2004 DRIVE AXLES Axle Shafts - Front - Endeavor