MITSUBISHI ENDEAVOR 2004 Service Owners Manual

ENDEAVOR 2004

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57105/w960_57105-0.png

MITSUBISHI ENDEAVOR 2004 Service Owners Manual

Page 1350 of 3870

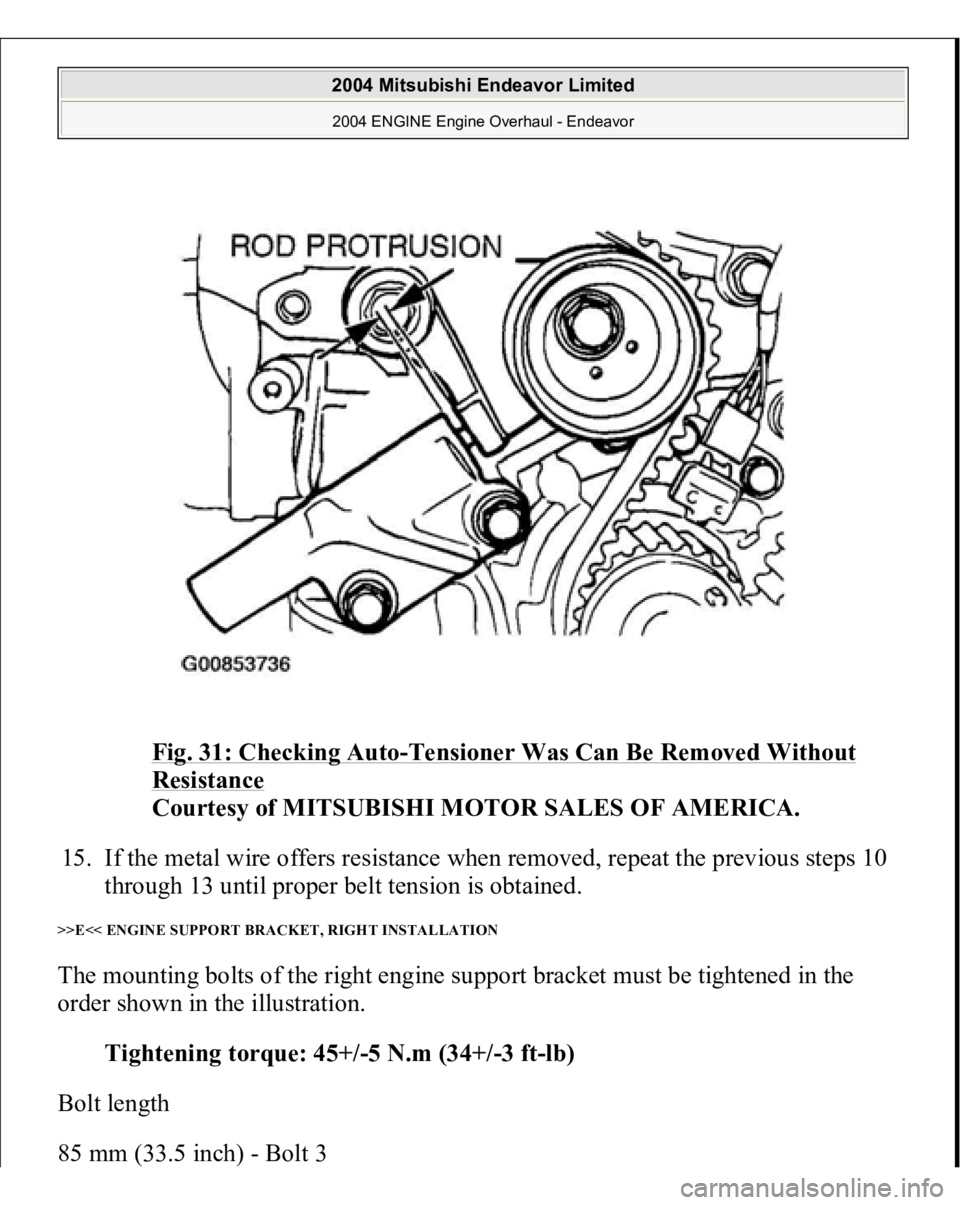

Fig. 31: Checking Auto

-Tensioner Was Can Be Removed Without

Resistance

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

15. If the metal wire offers resistance when removed, repeat the previous steps 10

through 13 until proper belt tension is obtained.

>>E<< ENGINE SUPPORT BRACKET, RIGHT INSTALLATION The mounting bolts of the right engine support bracket must be tightened in the

order shown in the illustration.

Tightening torque: 45+/-5 N.m (34+/-3 ft-lb)

Bolt length

85 mm

(33.5 inch

) - Bolt

3

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1354 of 3870

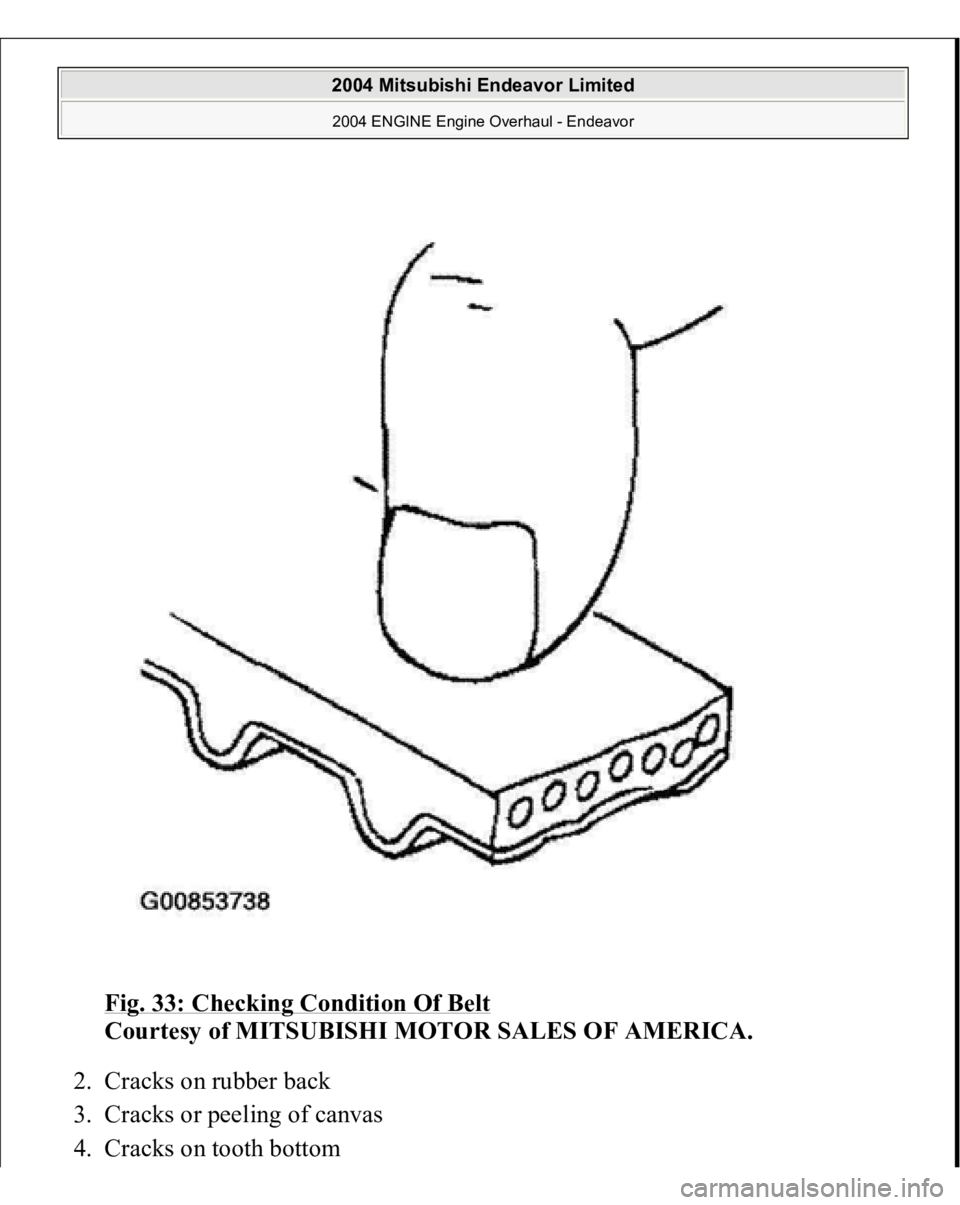

Fig. 33: Checking Condition Of Belt

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

2. Cracks on rubber back

3. Cracks or peeling of canvas

4. Cracks on tooth bottom

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1358 of 3870

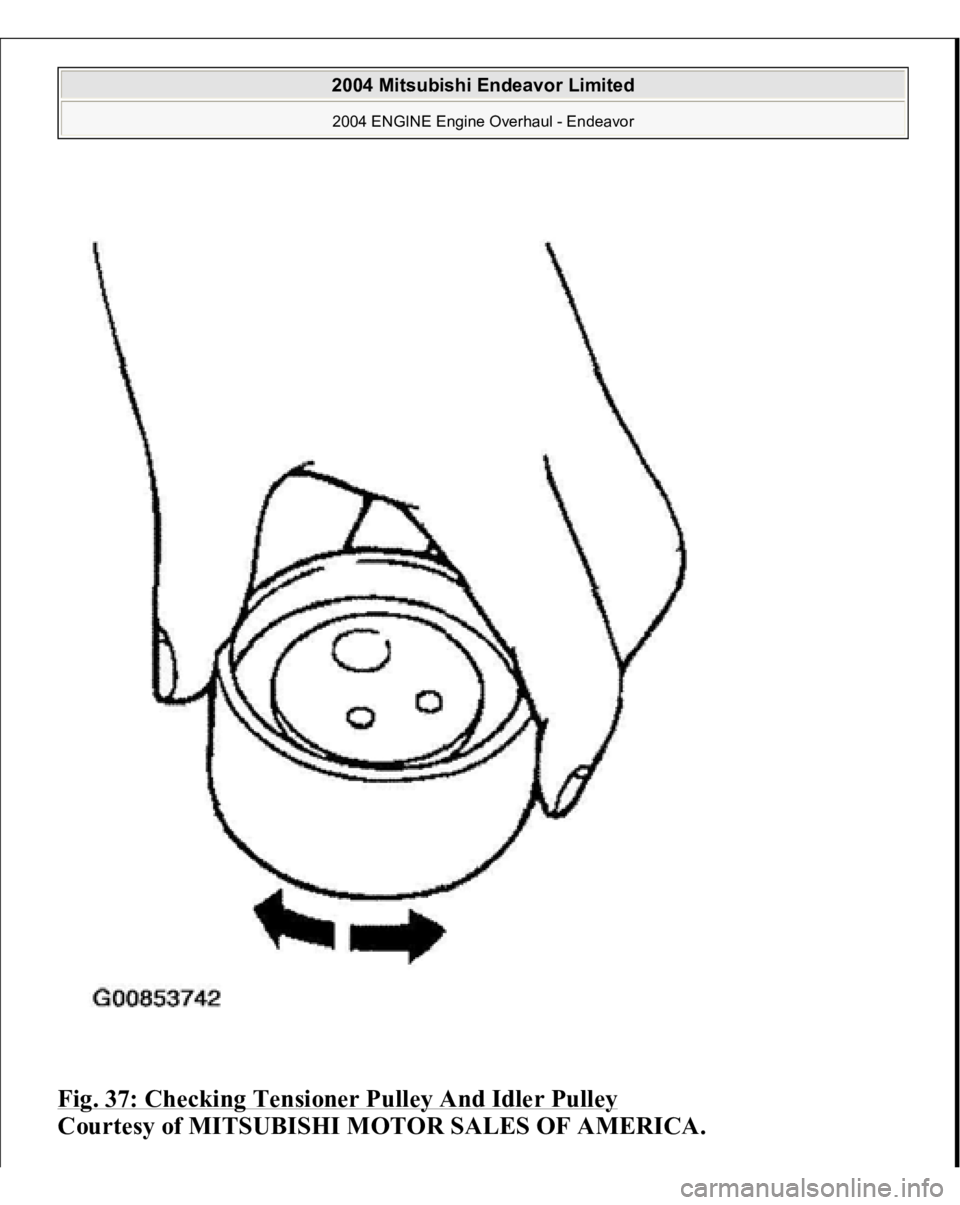

Fig. 37: Checking Tensioner Pulley And Idler Pulley

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1359 of 3870

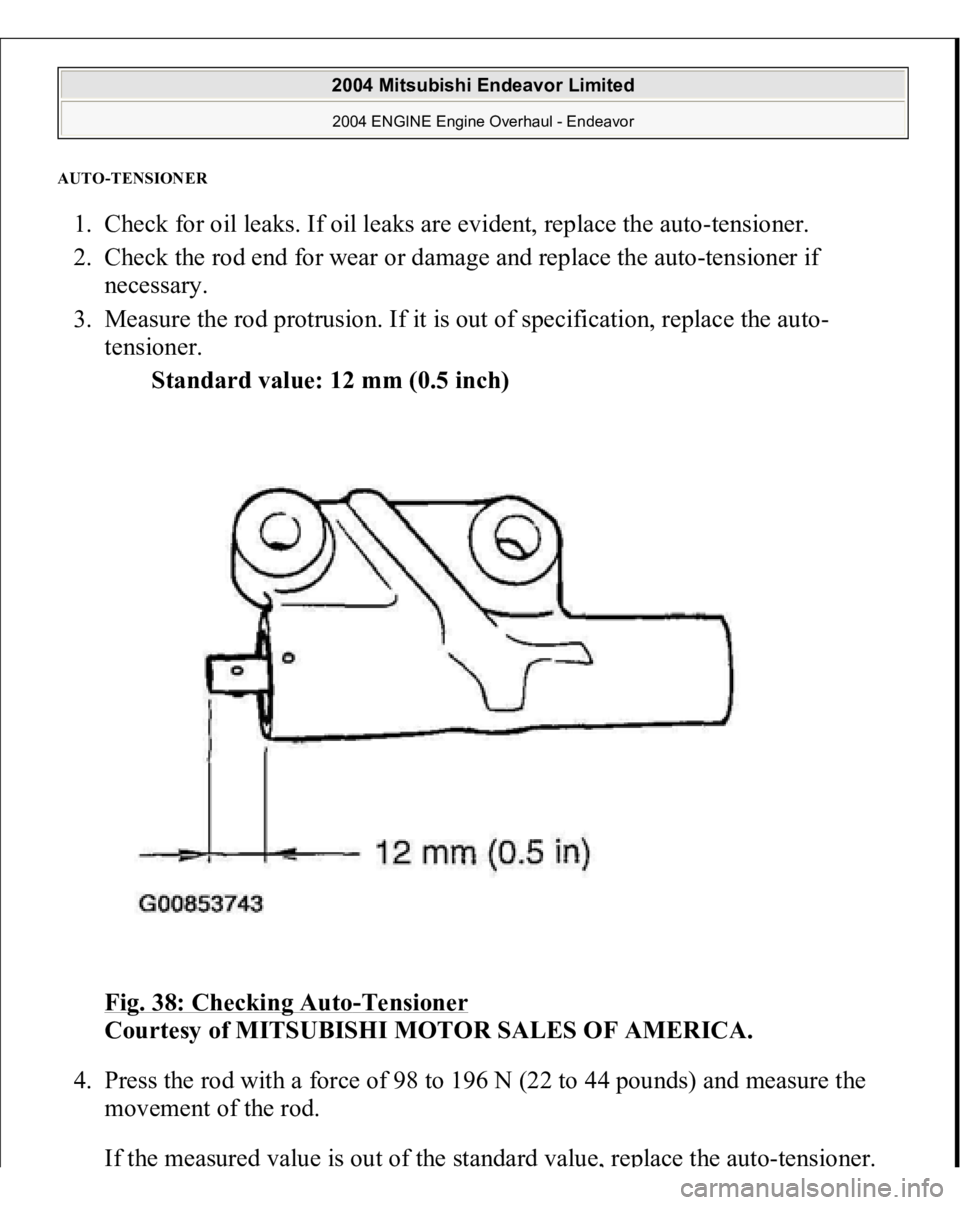

AUT

O-TENSIONE

R

1. Check for oil leaks. If oil leaks are evident, replace the auto-tensioner.

2. Check the rod end for wear or damage and replace the auto-tensioner if

necessary.

3. Measure the rod protrusion. If it is out of specification, replace the auto-

tensioner.

Standard value: 12 mm (0.5 inch)

Fig. 38: Checking Auto

-Tensioner

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

4. Press the rod with a force of 98 to 196 N (22 to 44 pounds) and measure the

movement of the rod.

If the measured value is out of the standard value

, re

place the auto-tensioner.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1364 of 3870

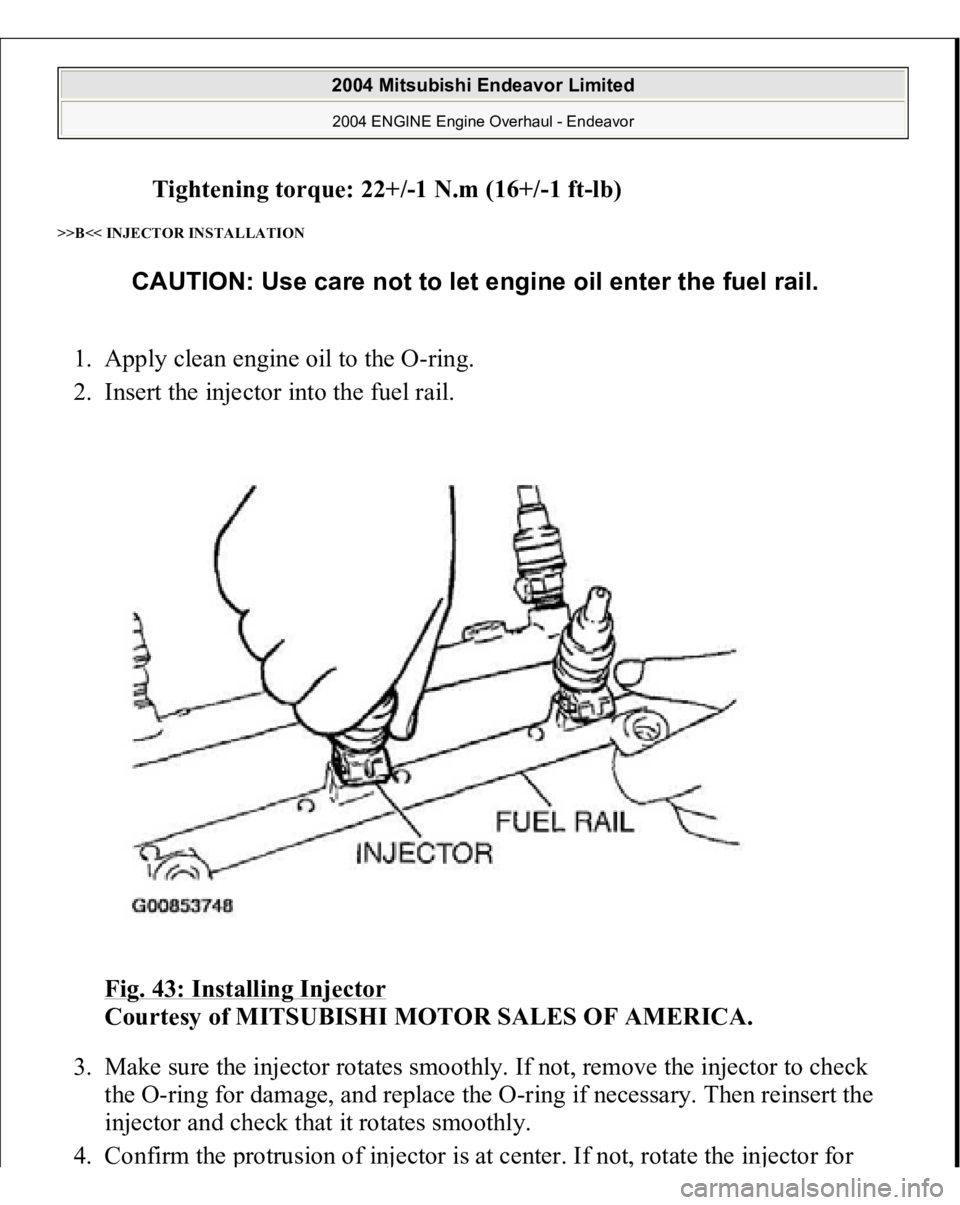

Tightening torque: 22+/-1 N.m (16+/-1 ft-lb)

>>B<< INJECTOR INSTALLATION 1. Apply clean engine oil to the O-ring.

2. Insert the injector into the fuel rail.

Fig. 43: Installing Injector

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

3. Make sure the injector rotates smoothly. If not, remove the injector to check

the O-ring for damage, and replace the O-ring if necessary. Then reinsert the

injector and check that it rotates smoothly.

4. Confirm the

protrusion of in

jector is at center. I

f not

, rotate the in

jector fo

r

CAUTION: Use care not to let engine oil enter the fuel rail.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1365 of 3870

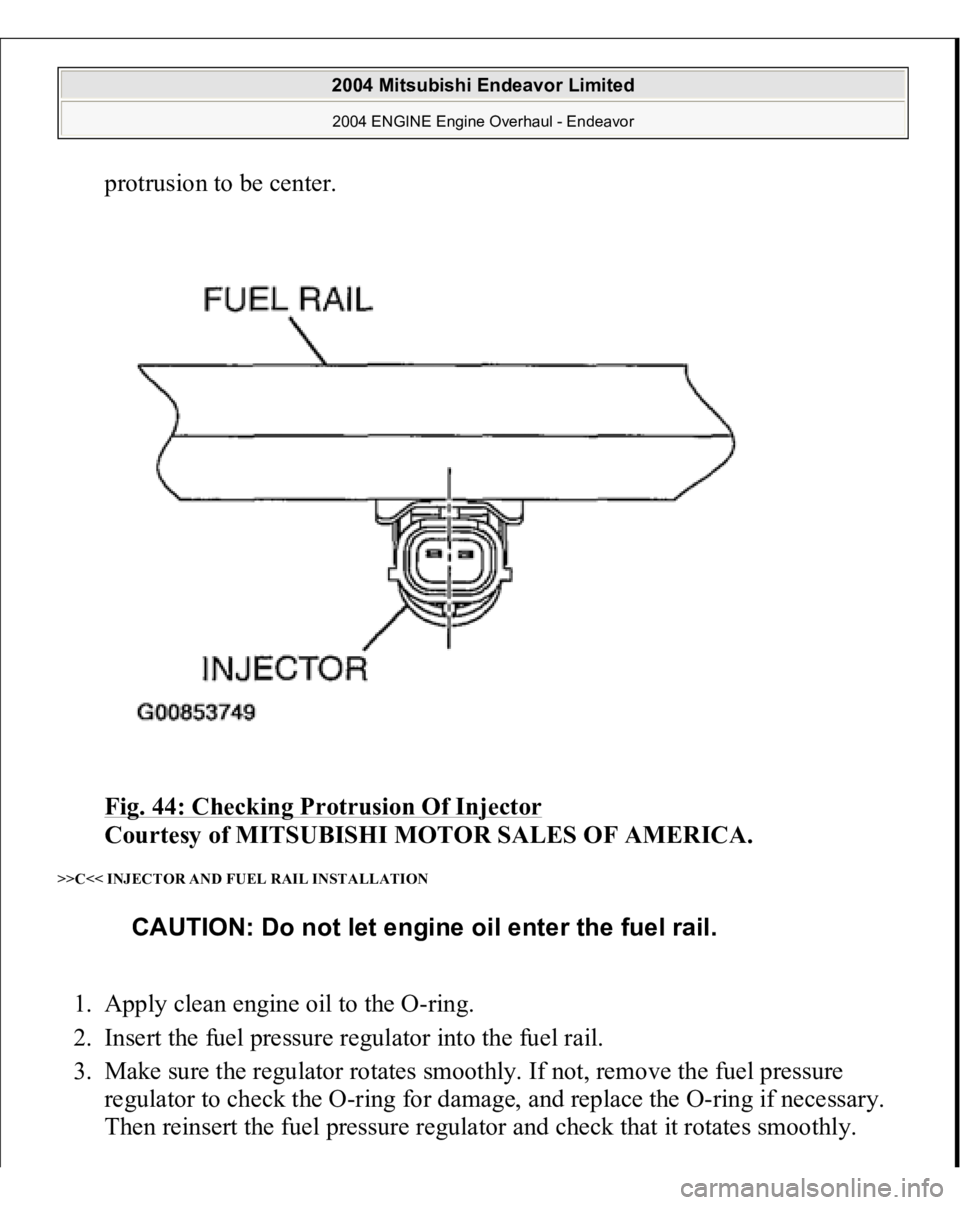

protrusion to be center.

Fig. 44: Checking Protrusion Of Injector

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

>>C<< INJECTOR AND FUEL RAIL INSTALLATION 1. Apply clean engine oil to the O-ring.

2. Insert the fuel pressure regulator into the fuel rail.

3. Make sure the regulator rotates smoothly. If not, remove the fuel pressure

regulator to check the O-ring for damage, and replace the O-ring if necessary.

Then reinsert the fuel pressure regulator and chec

k that it rotates smoothly.

CAUTION: Do not let engine oil enter the fuel rail.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1369 of 3870

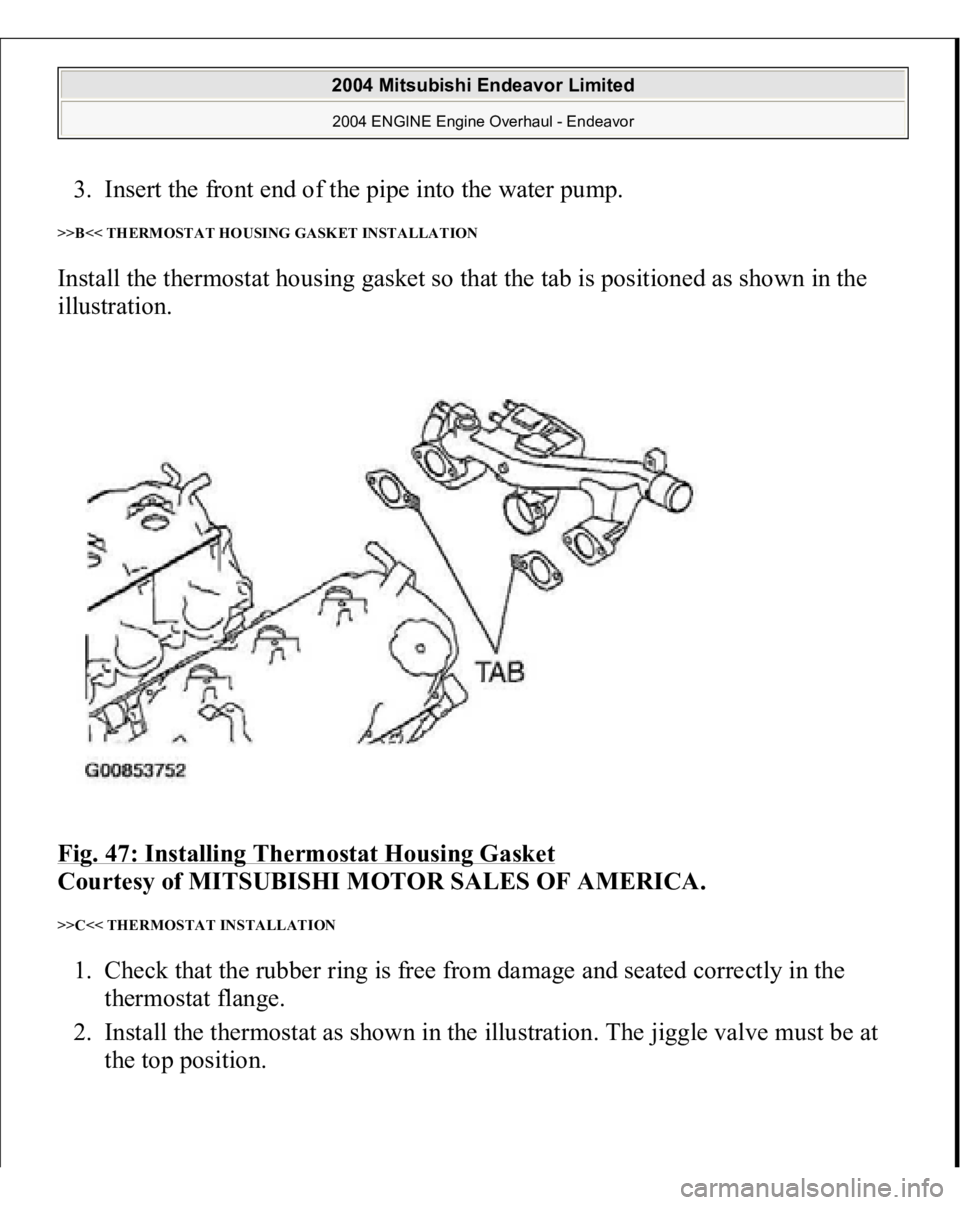

3. Insert the front end of the pipe into the water pump. >>B<< THERMOSTAT HOUSING GASKET INSTALLATION Install the thermostat housing gasket so that the tab is positioned as shown in the

illustration.

Fig. 47: Installing Thermostat Housing Gasket

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

>>C<< THERMOSTAT INSTALLATION 1. Check that the rubber ring is free from damage and seated correctly in the

thermostat flange.

2. Install the thermostat as shown in the illustration. The jiggle valve must be at

the to

p position.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1378 of 3870

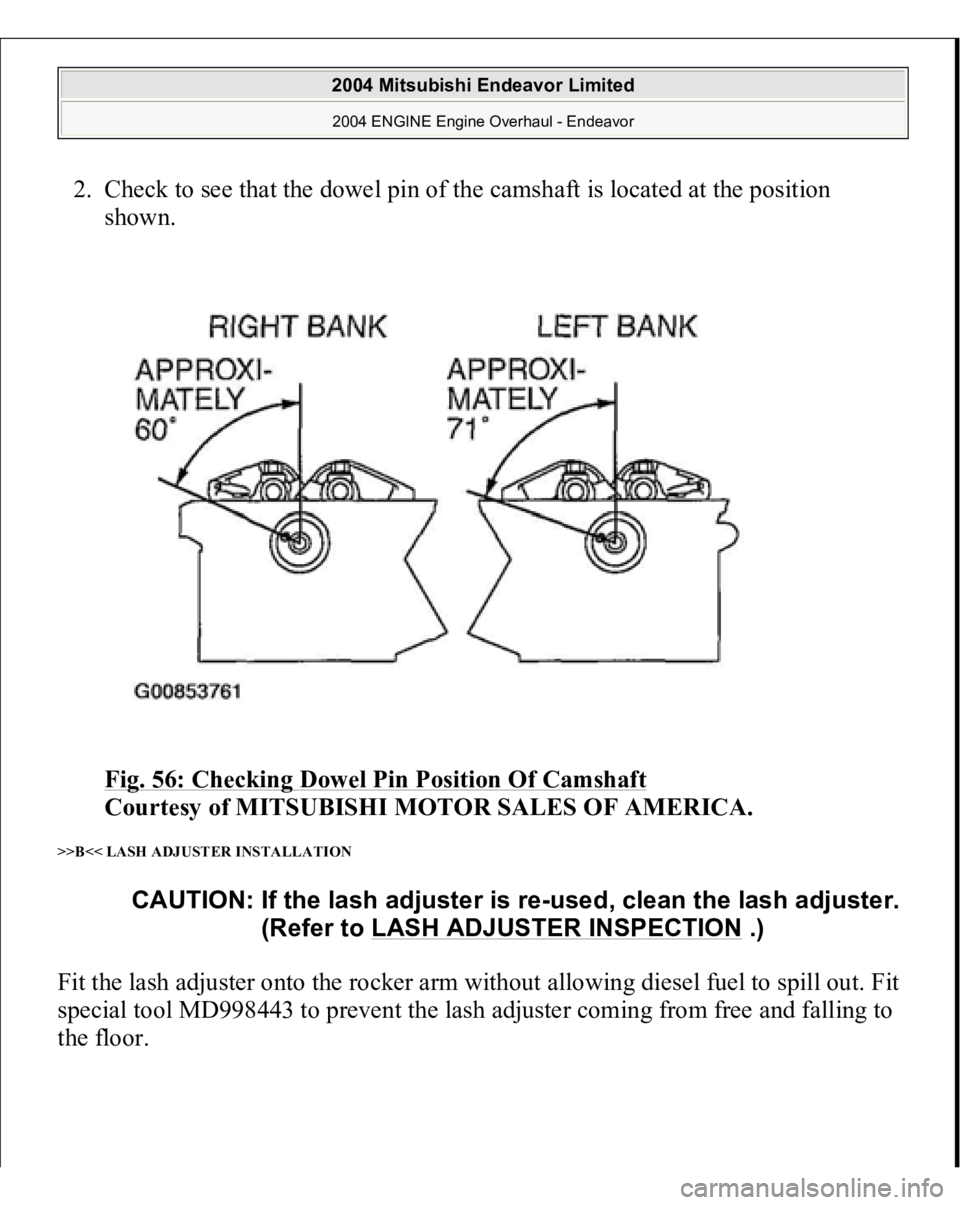

2. Check to see that the dowel pin of the camshaft is located at the position

shown.

Fig. 56: Checking Dowel Pin Position Of Camshaft

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

>>B<< LASH ADJUSTER INSTALLATION Fit the lash adjuster onto the rocker arm without allowing diesel fuel to spill out. Fit

special tool MD998443 to prevent the lash adjuster coming from free and falling to

the floor.

CAUTION: If the lash adjuster is re-used, clean the lash adjuster.

(Refer to LASH ADJUSTER INSPECTION

.)

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1382 of 3870

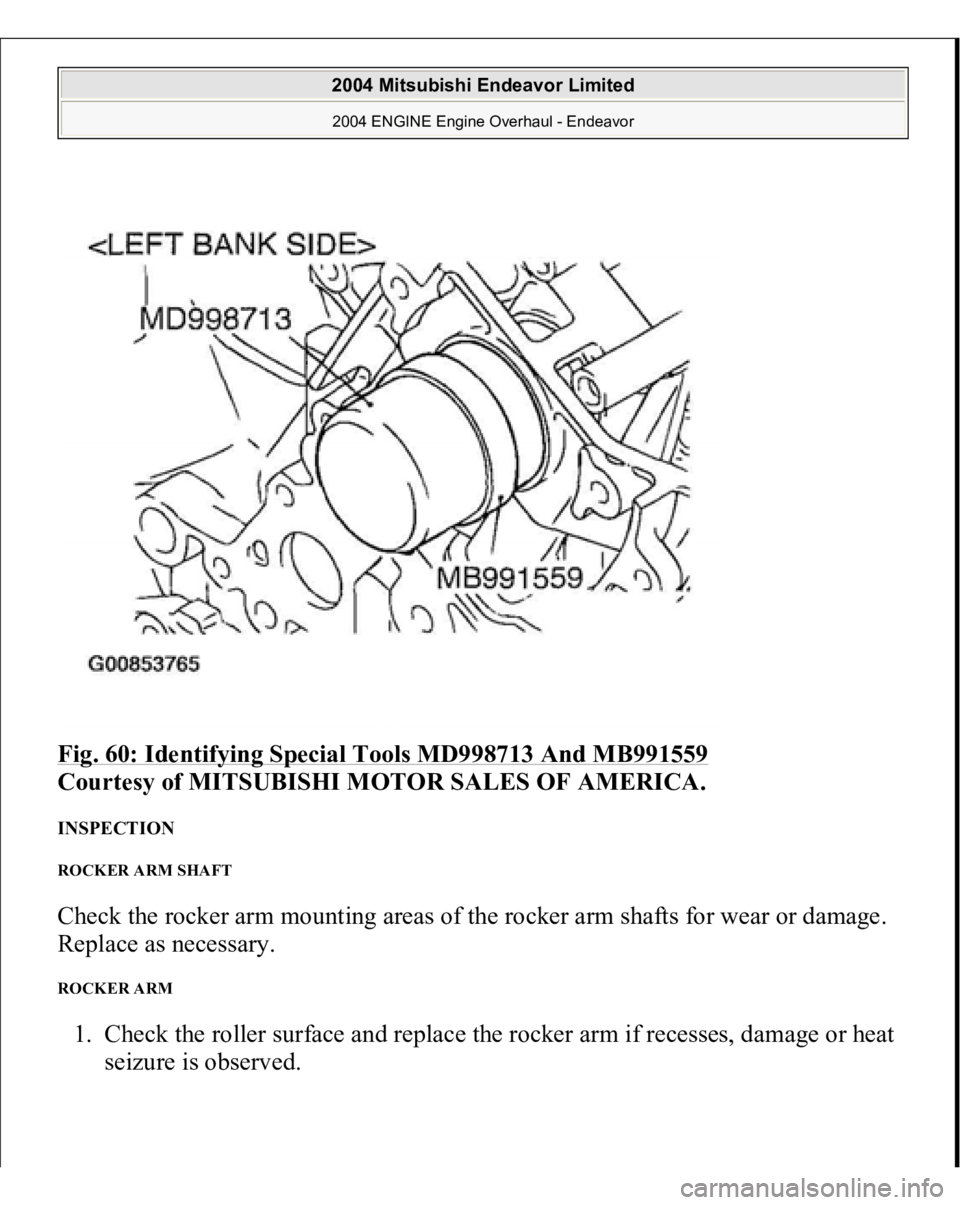

Fig. 60: Identifying Special Tools MD998713 And MB991559

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

INSPECTION ROCKER ARM SHAFT Check the rocker arm mounting areas of the rocker arm shafts for wear or damage.

Replace as necessary. ROCKER ARM 1. Check the roller surface and replace the rocker arm if recesses, damage or heat

seizure is observed.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1383 of 3870

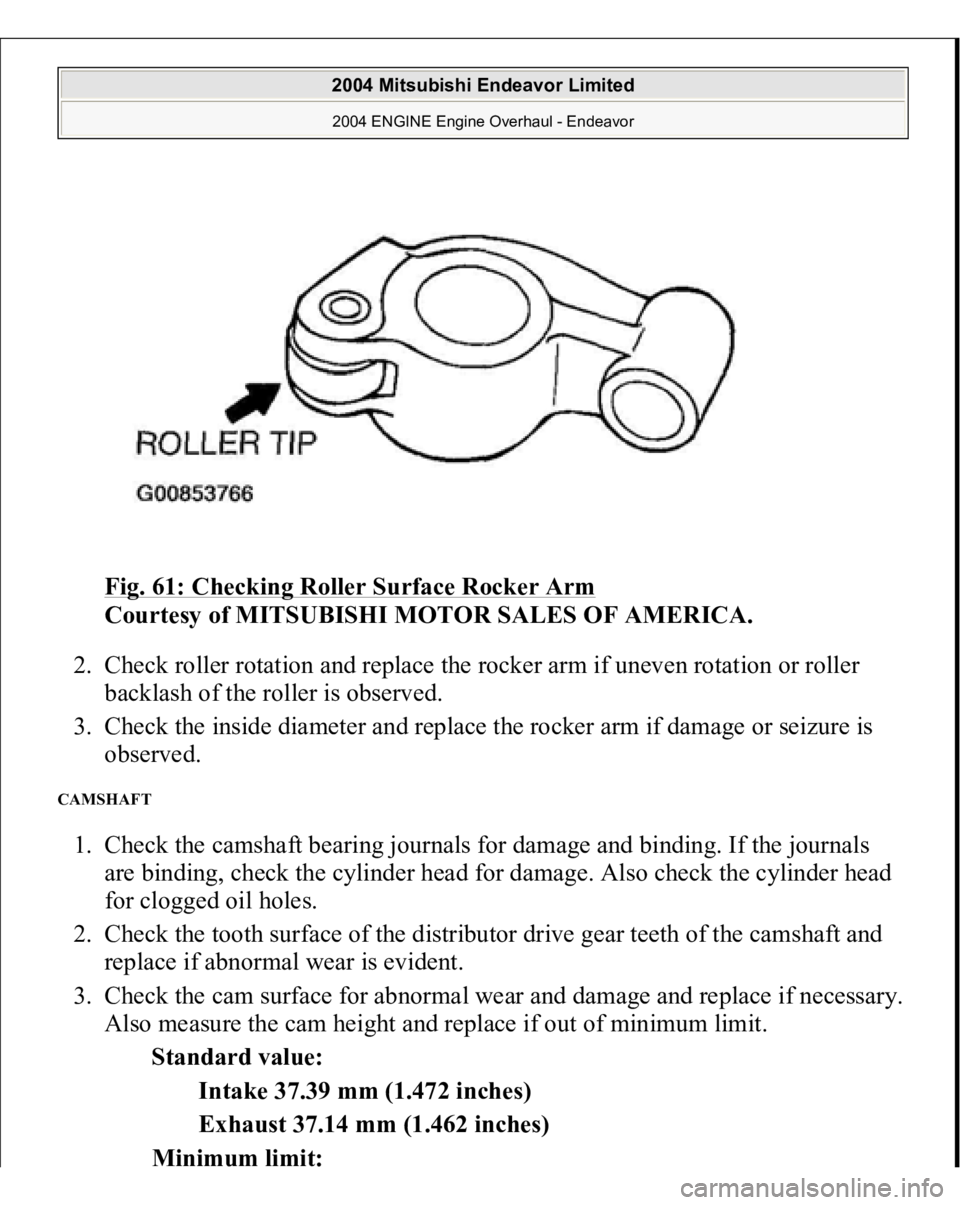

Fig. 61: Checking Roller Surface Rocker Arm

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

2. Check roller rotation and replace the rocker arm if uneven rotation or roller

backlash of the roller is observed.

3. Check the inside diameter and replace the rocker arm if damage or seizure is

observed.

CAMSHAFT 1. Check the camshaft bearing journals for damage and binding. If the journals

are binding, check the cylinder head for damage. Also check the cylinder head

for clogged oil holes.

2. Check the tooth surface of the distributor drive gear teeth of the camshaft and

replace if abnormal wear is evident.

3. Check the cam surface for abnormal wear and damage and replace if necessary.

Also measure the cam height and replace if out of minimum limit.

Standard value:

Intake 37.39 mm (1.472 inches)

Exhaust 37.14 mm (1.462 inches)

Minimum limit:

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor