cover MITSUBISHI ENDEAVOR 2004 Service Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2004, Model line: ENDEAVOR, Model: MITSUBISHI ENDEAVOR 2004Pages: 3870, PDF Size: 98.47 MB

Page 1518 of 3870

(Ignition Timing Check)

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

3. Set up a timing light.

4. Start the engine and run it at idle.

5. Check that the idle speed is approximately 680 r/min.

6. Select scan tool MB991958 actuator test "item number 17".

7. Check that basic ignition timing is within the standard value.

Standard value: 5° BTDC +/-3°

8. If the basic ignition timing is not within the standard value, check the

following items:

Diagnostic output Timing belt cover and crankshaft position sensor installation conditions Crankshaft sensing blade condition

9. Press the clear key on scan tool MB991958 (select forced drive stop mode),

and cancel the actuator test.

10. Check that the actual ignition timing is at the standard value.

Standard value: Approximately 10° BTDC

CURB IDLE SPEED CHECK Required Special Tool:

CAUTION: If the actuator test is not canceled, the forced

drive will continue for 27 minutes. Driving in this

state could lead to engine failure.

NOTE: Ignition timing fluctuates about+/-7° Before T op Dead

Center, even under normal operating condition.

NOTE: It is automatically further advanced by about 5° to 10°

Before Top Dead Center at higher altitudes.

2004 Mitsubishi Endeavor Limited

2004 ENGINE Engine - Endeavor

Page 1526 of 3870

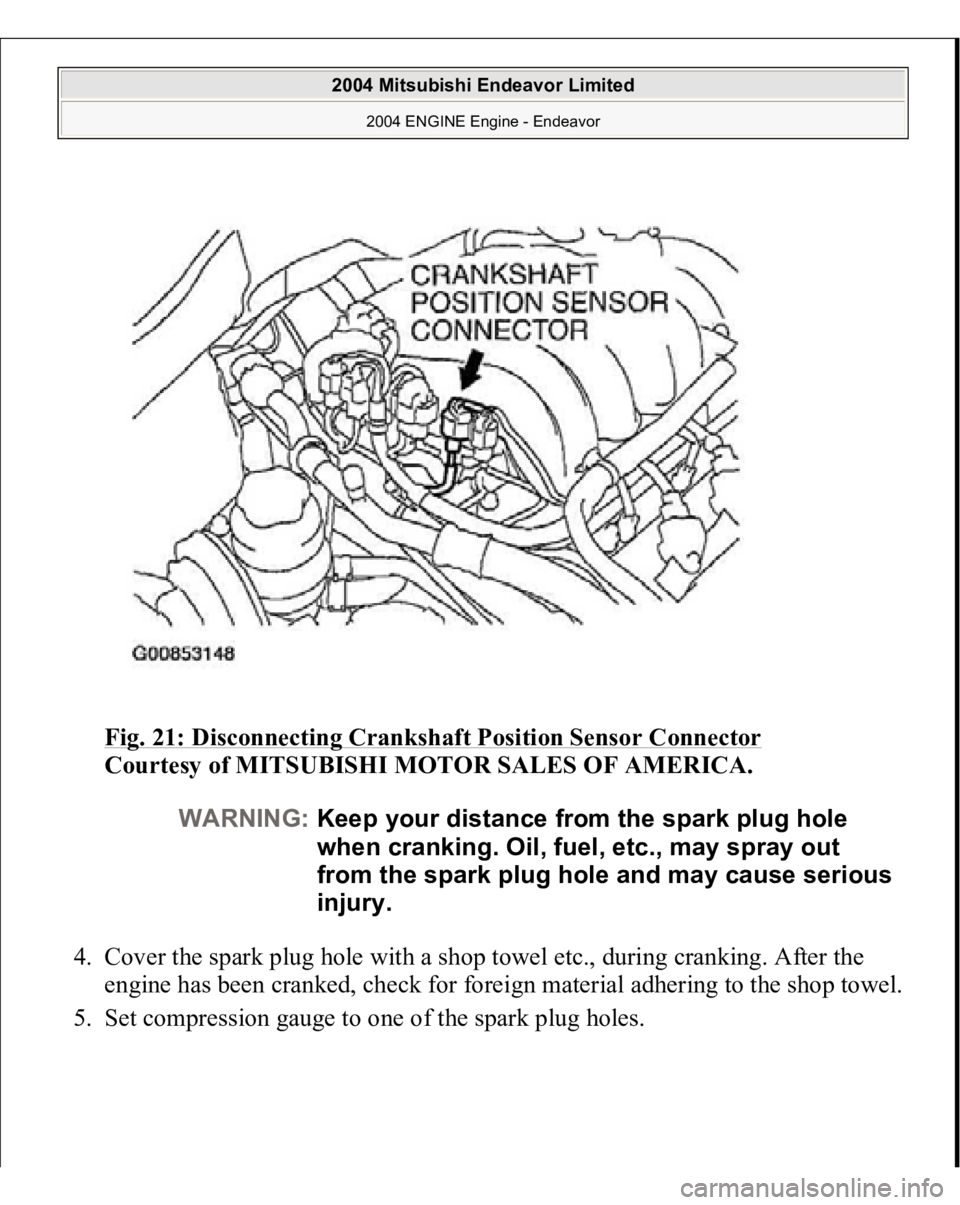

Fig. 21: Disconnecting Crankshaft Position Sensor Connector

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

4. Cover the spark plug hole with a shop towel etc., during cranking. After the

engine has been cranked, check for foreign material adhering to the shop towel.

5. Set compression gauge to one of the spark plug holes.

WARNING:Keep your distance from the spark plug hole

when cranking. Oil, fuel, etc., may spray out

from the spark plug hole and may cause serious

injury.

2004 Mitsubishi Endeavor Limited

2004 ENGINE Engine - Endeavor

Page 1554 of 3870

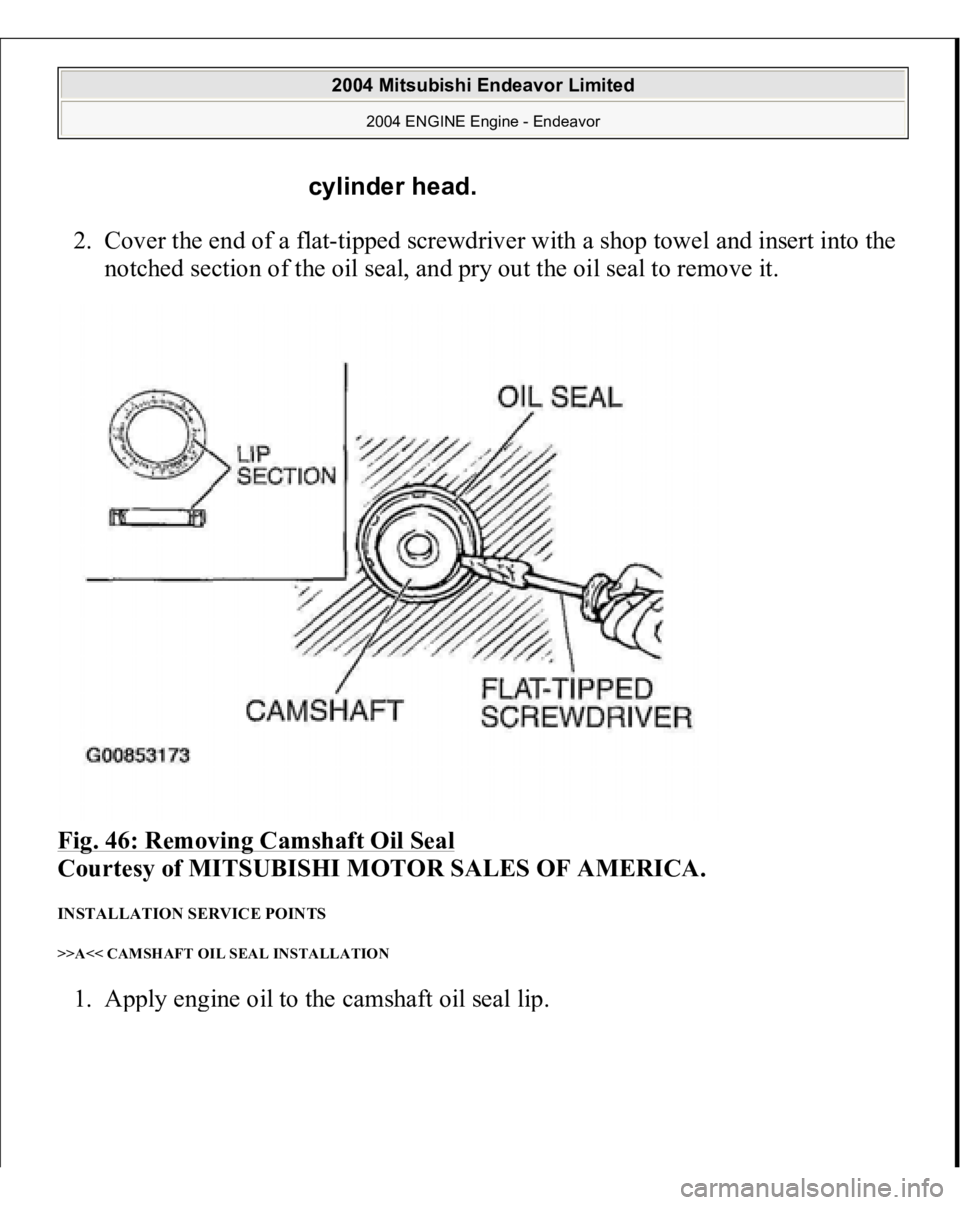

2. Cover the end of a flat-tipped screwdriver with a shop towel and insert into the

notched section of the oil seal, and pry out the oil seal to remove it.

Fig. 46: Removing Camshaft Oil Seal

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

INSTALLATION SERVICE POINTS >>A<< CAMSHAFT OIL SEAL INSTALLATION 1. A

pply en

gine oil to the camshaft oil seal li

p.

cylinder head.

2004 Mitsubishi Endeavor Limited

2004 ENGINE Engine - Endeavor

Page 1565 of 3870

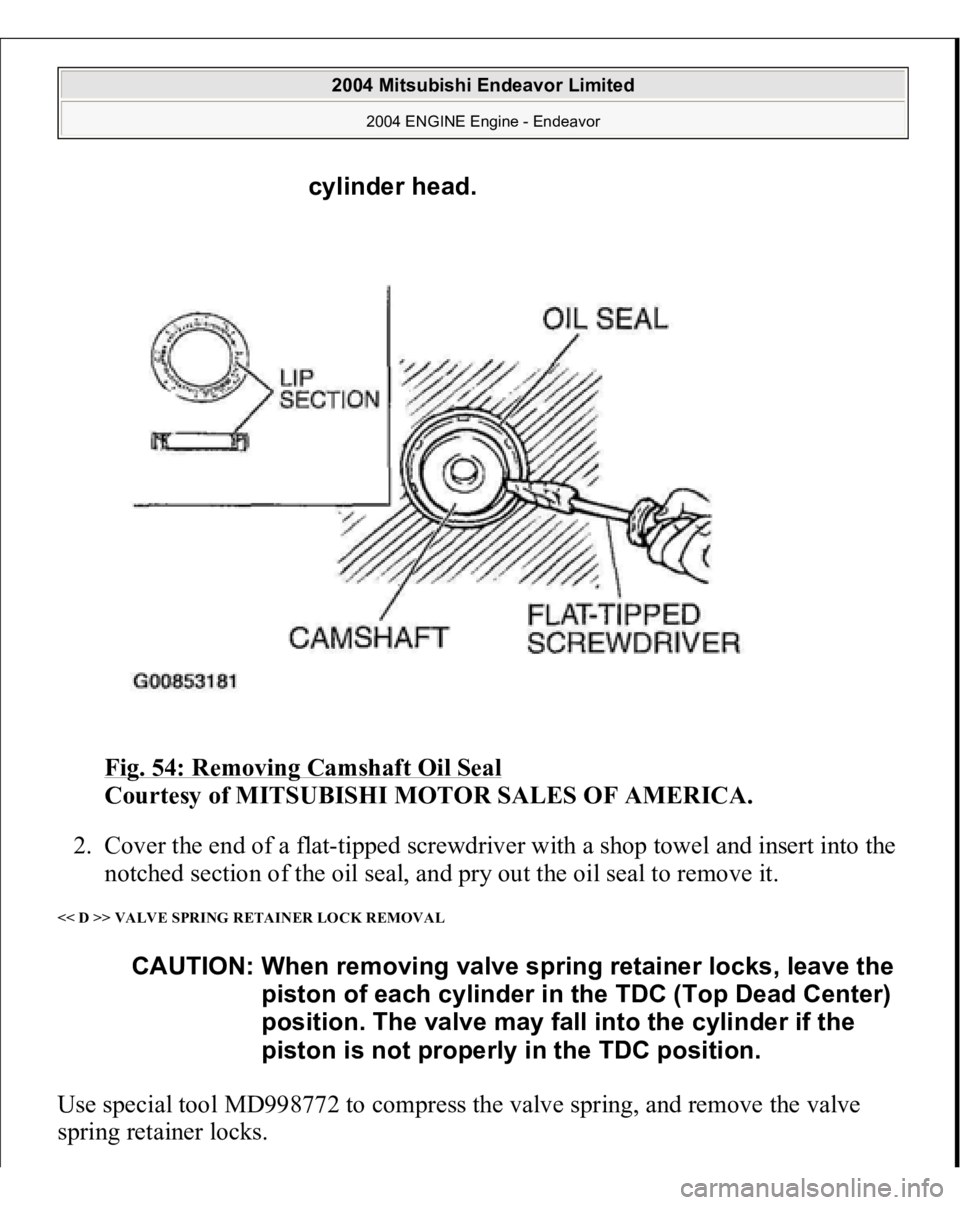

Fig. 54: Removing Camshaft Oil Seal

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

2. Cover the end of a flat-tipped screwdriver with a shop towel and insert into the

notched section of the oil seal, and pry out the oil seal to remove it.

<< D >> VALVE SPRING RETAINER LOCK REMOVAL Use special tool MD998772 to compress the valve spring, and remove the valve

sprin

g retainer locks.

cylinder head.

CAUTION: When removing valve spring retainer locks, leave the

piston of each cylinder in the TDC (Top Dead Center)

position. The valve may fall into the cylinder if the

piston is not properly in the TDC position.

2004 Mitsubishi Endeavor Limited

2004 ENGINE Engine - Endeavor

Page 1610 of 3870

4. Install the auto-tensioner to the engine.

>>B<< TIMING BELT INSTALLATION 1. Align the timing marks on the camshaft sprockets with those on the rocker

cover and the timing mark on the crankshaft sprocket with that on the engine

block as shown in the illustration.

CAUTION: Do not remove the setting pin from the auto-

tensioner.

CAUTION: The camshaft sprocket (right bank) can turn

easily due to the spring force applied, so be

careful not to get your fingers caught.

2004 Mitsubishi Endeavor Limited

2004 ENGINE Engine - Endeavor

Page 1890 of 3870

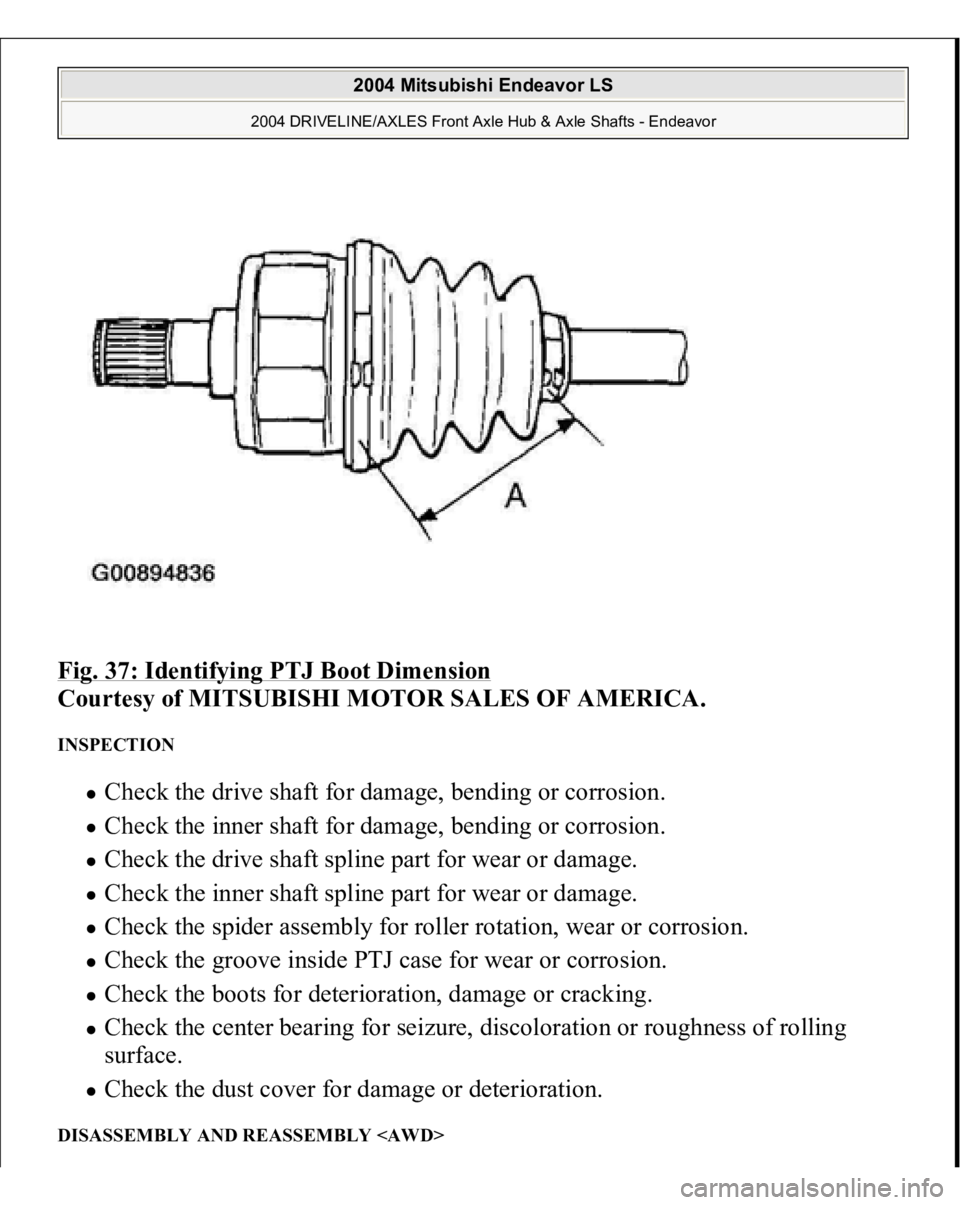

Fig. 37: Identifying PTJ Boot Dimension

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

INSPECTION

Check the drive shaft for damage, bending or corrosion. Check the inner shaft for damage, bending or corrosion. Check the drive shaft spline part for wear or damage. Check the inner shaft spline part for wear or damage. Check the spider assembly for roller rotation, wear or corrosion. Check the groove inside PTJ case for wear or corrosion. Check the boots for deterioration, damage or cracking. Check the center bearing for seizure, discoloration or roughness of rolling

surface. Check the dust cover for damage or deterioration.

DISASSEMBLY AND REASSEMBLY

2004 Mitsubishi Endeavor LS

2004 DRIVELINE/AXLES Front Axle Hub & Axle Shafts - Endeavor

Page 1915 of 3870

AXLE SHAFTS Removal & Installation For removal and installation of axle shafts, see Fig. 4

. NOTE: Before removing axle shaft, remove front cover and side

under cover, and drain automatic transmission and transfer

fluids. Then remove front exhaust pipe and transfer heat

protector.

2004 Mitsubishi Endeavor LS

2004 DRIVE AXLES Axle Shafts - Front - Endeavor

Page 1953 of 3870

Fig. 11: Adjusting Camber

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

3. Tighten the nuts to 305 +/- 25 N.m (225 +/- 18 ft-lb).

4. Recheck the camber.

LOWER ARM BALL JOINT END PLAY CHECK 1. Raise the vehicle.

2. Move the lower arm up and down with your hands to check for an excessive

play in the axial direction of the ball joint. If there is an excessive play, replace

the lower arm assembly. BALL JOINT DUST COVER CHECK 1. Press the dust cover with your finger to check that there are no cracks or

damage in the dust cover.

2. If the dust cover is cracked or damaged, replace the lower arm assembly. STRUT ASSEMBLY REMOVAL AND INSTALLATION

NOTE: If the dust cover is cracked or damaged, it is possible

that there may also be damage to the ball joint.

2004 Mitsubishi Endeavor LS 2004 SUSPENSION Front - Endeavor

Page 1965 of 3870

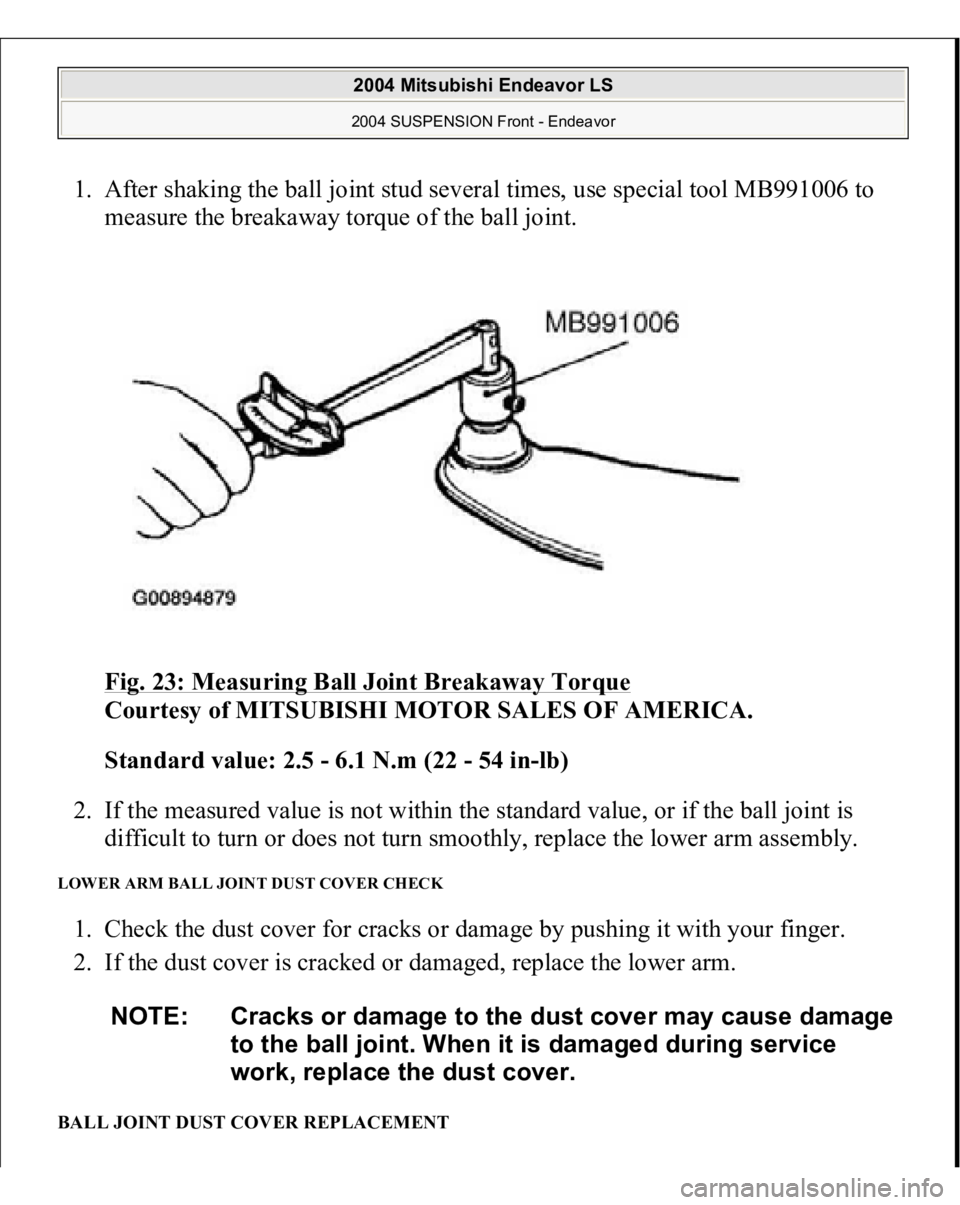

1. After shaking the ball joint stud several times, use special tool MB991006 to

measure the breakaway torque of the ball joint.

Fig. 23: Measuring Ball Joint Breakaway Torque

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

Standard value: 2.5 - 6.1 N.m (22 - 54 in-lb)

2. If the measured value is not within the standard value, or if the ball joint is

difficult to turn or does not turn smoothly, replace the lower arm assembly.

LOWER ARM BALL JOINT DUST COVER CHECK 1. Check the dust cover for cracks or damage by pushing it with your finger.

2. If the dust cover is cracked or damaged, replace the lower arm. BALL JOINT DUST COVER REPLACEMENT

NOTE: Cracks or damage to the dust cover may cause damage

to the ball joint. When it is damaged during service

work, replace the dust cover.

2004 Mitsubishi Endeavor LS 2004 SUSPENSION Front - Endeavor

Page 1966 of 3870

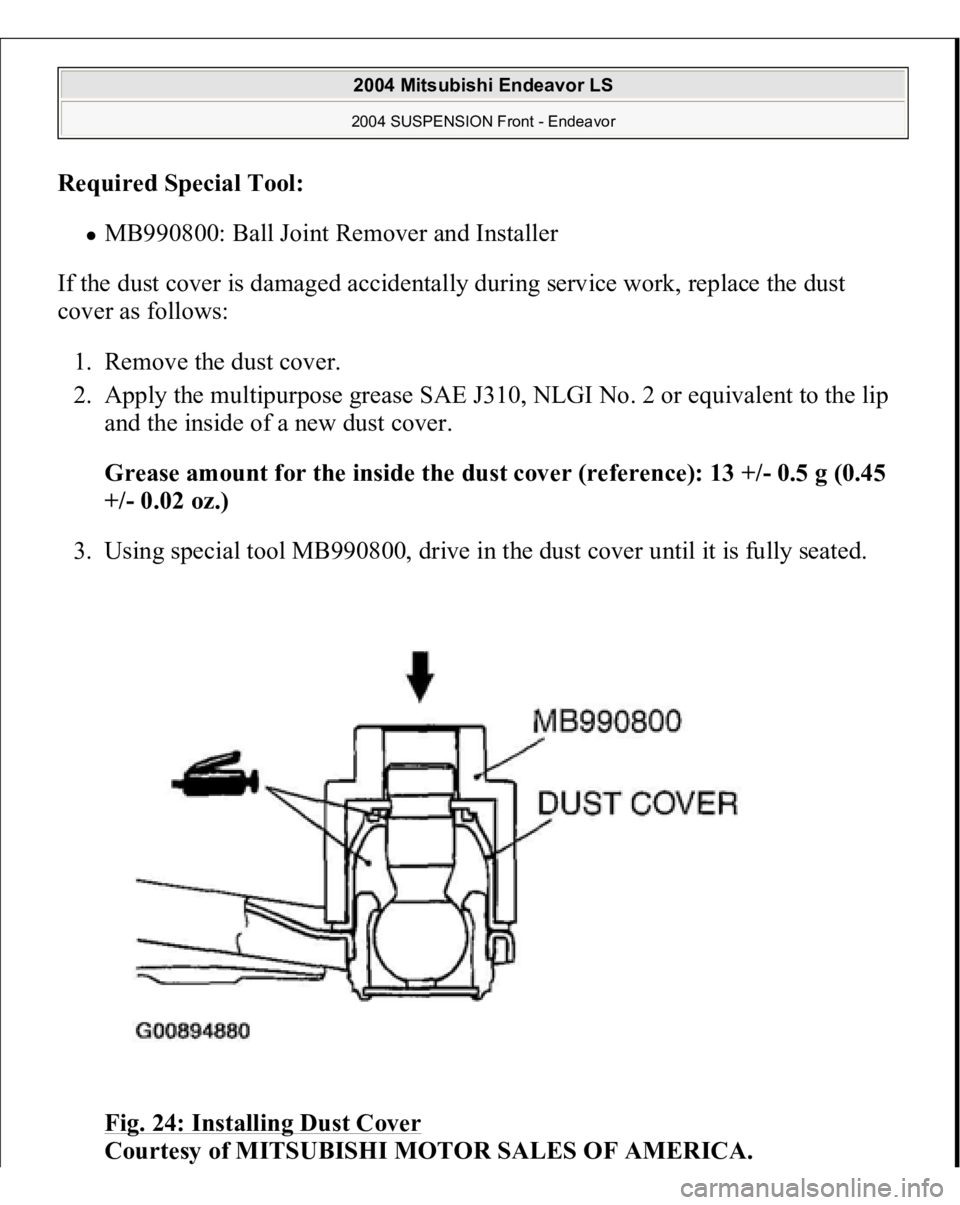

Required Special Tool

:

MB990800: Ball Joint Remover and Installer

If the dust cover is damaged accidentally during service work, replace the dust

cover as follows:

1. Remove the dust cover.

2. Apply the multipurpose grease SAE J310, NLGI No. 2 or equivalent to the lip

and the inside of a new dust cover.

Grease amount for the inside the dust cover (reference): 13 +/- 0.5 g (0.45

+/- 0.02 oz.)

3. Using special tool MB990800, drive in the dust cover until it is fully seated.

Fig. 24: Installing Dust Cover

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

2004 Mitsubishi Endeavor LS 2004 SUSPENSION Front - Endeavor