Rear suspension MITSUBISHI ENDEAVOR 2004 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2004, Model line: ENDEAVOR, Model: MITSUBISHI ENDEAVOR 2004Pages: 3870, PDF Size: 98.47 MB

Page 252 of 3870

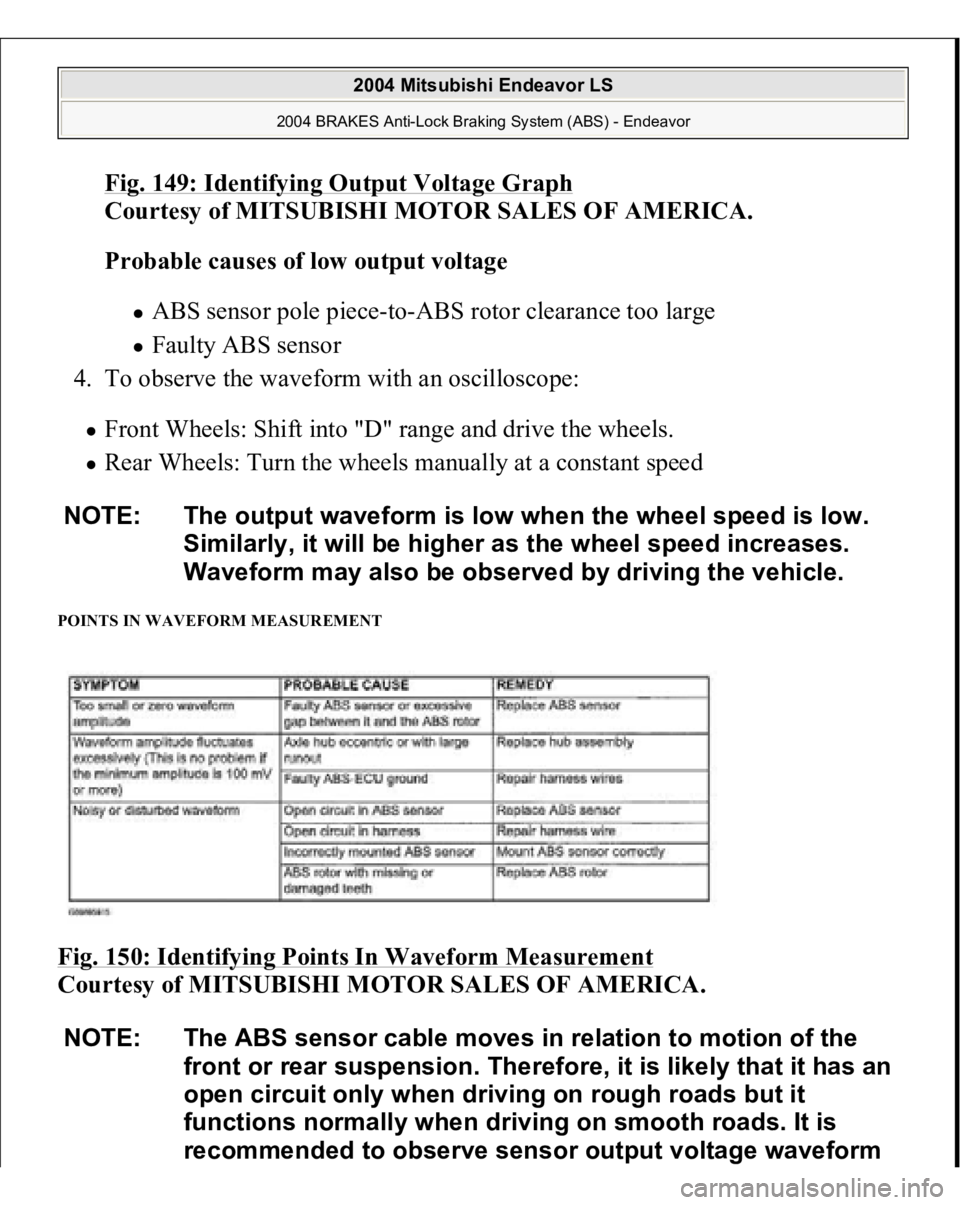

Fig. 149: Identifying Output Voltage Grap

h

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

Probable causes of low output voltage

ABS sensor pole piece-to-ABS rotor clearance too large Faulty ABS sensor

4. To observe the waveform with an oscilloscope:

Front Wheels: Shift into "D" range and drive the wheels. Rear Wheels: Turn the wheels manually at a constant speed

POINTS IN WAVEFORM MEASUREMENT Fig. 150: Identifying Points In Waveform Measurement

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA. NOTE: The output waveform is low when the wheel speed is low.

Similarly, it will be higher as the wheel speed increases.

Waveform may also be observed by driving the vehicle.

NOTE: The ABS sensor cable moves in relation to motion of the

front or rear suspension. Therefore, it is likely that it has an

open circuit only when driving on rough roads but it

functions normally when driving on smooth roads. It is

recommended to observe sensor output voltage waveform

2004 Mitsubishi Endeavor LS

2004 BRAKES Anti-Lock Braking System (ABS) - Endeavor

Page 1877 of 3870

Required Special Tools:

MB991248 or MD998801: Inner Shaft Remover MB990810: Side Bearing Puller MB990930: Installer Adapter MB990932: Installer Adapter MB990934: Installer Adapter MB990938: Bar (snap-in type) MB990890: Rear Suspension Bushing Base MB991172: Inner Shaft Installer Base

LUBRICATION POINTS

(RESIN BOOT) REPLACEMENT

.

2004 Mitsubishi Endeavor LS

2004 DRIVELINE/AXLES Front Axle Hub & Axle Shafts - Endeavor

Page 1934 of 3870

the direction of the spline chamfered side. See Fig. 13

.

C. Using Bar (Snap-In Type) (MB990938) and Installer Adapter (MB990932),

press-fit the center bearing into the center bearing bracket. See Fig. 18

.

D. Apply the specified great (from the repair kit) to the rear surface of all dust

seals. Using Rear Suspension Bushing Base (MB990890), Bar (Snap-In type)

(MB990838), and Installer Adapter (MB990934), press the dust seals into the

center bearing bracket until they are flush with each other. See Fig. 19 . Apply

repair kit grease to the lip of each dust seal.

E. Using Inner Shaft Installer Base (MB991172), hold the center bearing inner

race, and then press-in the inner shaft. See Fig. 20

. Apply repair kit grease to

the inner shaft spline, then press-fit it into the PTJ case.

F. After applying the specified grease to the PTJ case, insert the axle shaft and

apply grease again.

G. Set the PTJ boot bands at the specified distance to adjust the amount of air

inside the PTJ joint, and then tighten the small and large PTJ boot bands. See

Fi

g. 12

. CAUTION: When applying grease, make sure that it does not

adhere to anything outside the lip.

NOTE: When press-fitting the inner shaft into the PTJ case,

apply a thin coat of repair kit grease to the dust seal

outer lip part and the outside edge of the PTJ axial part.

CAUTION: The axle shaft joint uses special grease. DO NOT

mix old, new, or different types of grease.

NOTE: The grease in the repair kit should be divided in half for

use, respectively, at the joint and inside the boot.

2004 Mitsubishi Endeavor LS

2004 DRIVE AXLES Axle Shafts - Front - Endeavor

Page 1946 of 3870

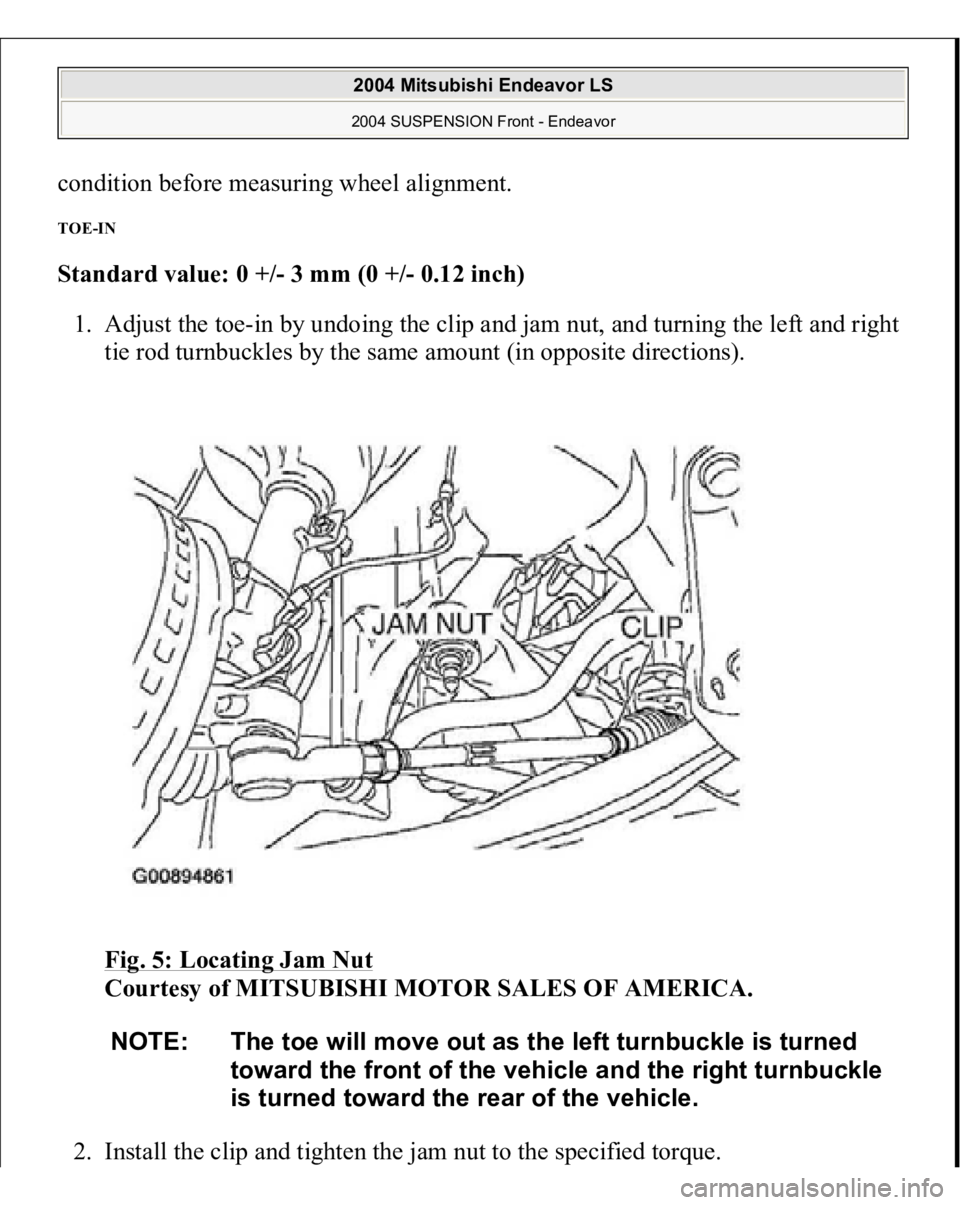

condition before measuring wheel alignment. TOE-IN Standard value: 0 +/- 3 mm (0 +/- 0.12 inch)

1. Adjust the toe-in by undoing the clip and jam nut, and turning the left and right

tie rod turnbuckles by the same amount (in opposite directions).

Fig. 5: Locating Jam Nut

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

2. Install the cli

p and ti

ghten the

jam nut to the s

pecified tor

que.

NOTE: The toe will move out as the left turnbuckle is turned

toward the front of the vehicle and the right turnbuckle

is turned toward the rear of the vehicle.

2004 Mitsubishi Endeavor LS 2004 SUSPENSION Front - Endeavor

Page 1967 of 3870

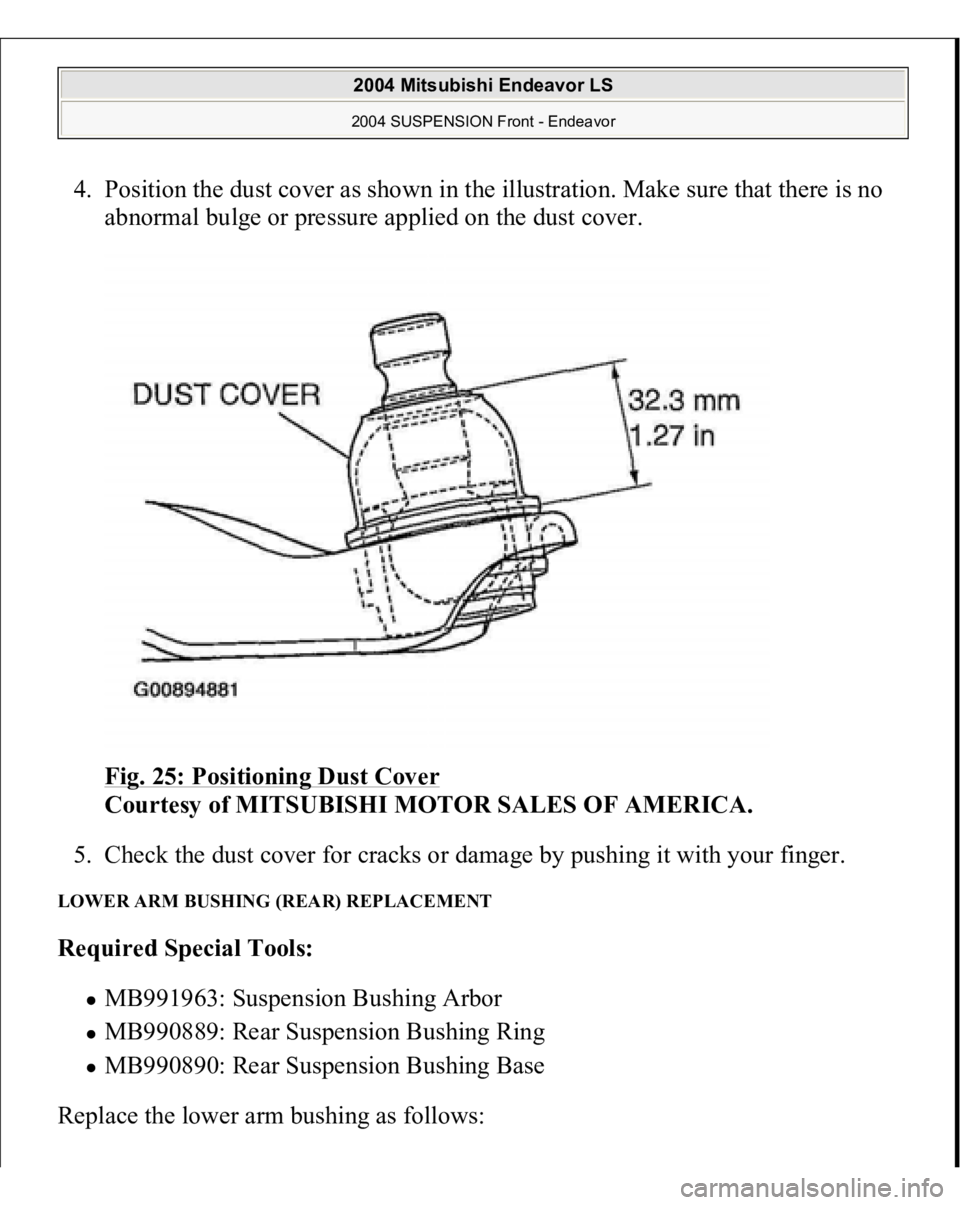

4. Position the dust cover as shown in the illustration. Make sure that there is no

abnormal bulge or pressure applied on the dust cover.

Fig. 25: Positioning Dust Cover

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

5. Check the dust cover for cracks or damage by pushing it with your finger.

LOWER ARM BUSHING (REAR) REPLACEMENT Required Special Tools:

MB991963: Suspension Bushing Arbor MB990889: Rear Suspension Bushing Ring MB990890: Rear Suspension Bushing Base

Replace the lower arm bushin

g as follows:

2004 Mitsubishi Endeavor LS 2004 SUSPENSION Front - Endeavor

Page 1979 of 3870

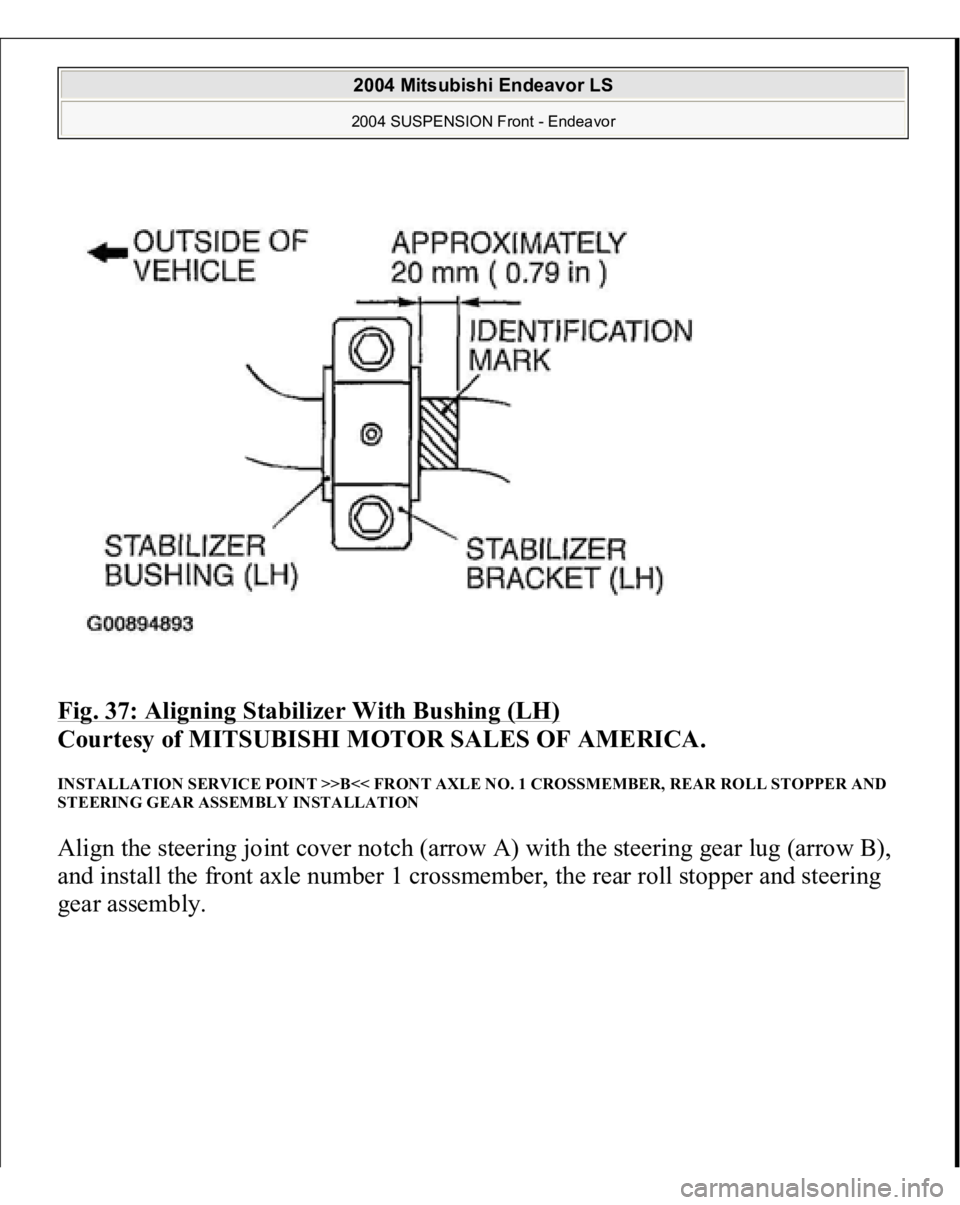

Fig. 37: Aligning Stabilizer With Bushing (LH)

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

INSTALLATION SERVICE POINT >>B<< FRONT AXLE NO. 1 CROSSMEMBER, REAR ROLL STOPPER AND

STEERING GEAR ASSEMBLY INSTALLATION Align the steering joint cover notch (arrow A) with the steering gear lug (arrow B),

and install the front axle number 1 crossmember, the rear roll stopper and steering

gear assembly.

2004 Mitsubishi Endeavor LS 2004 SUSPENSION Front - Endeavor

Page 2925 of 3870

2004 SUSPENSION

Rear Axle < AWD > - Endeavor

GENERAL DESCRIPTION The rear axle has the following features.

The wheel bearing incorporates a unit ball bearing (double-row angular contact

ball bearing) for reduced friction. The rear wheel hub assembly combines the hub, wheel bearing, housing, and

oil seal in a single unit for fewer parts, better durability, improved assembly

precision, and better structural organization. The drive shaft has BJ-DOJ constant velocity joints. ABS rotor for wheel speed detection is press-fitted onto the drive shaft in

vehicles with ABS.

CONSTRUCTION DIAGRAM NOTE:

BJ: Birfield Joint DOJ: Double Offset Joint

2004 Mitsubishi Endeavor LS

2004 SUSPENSION Rear Axle < AWD > - Endeavor

2004 Mitsubishi Endeavor LS

2004 SUSPENSION Rear Axle < AWD > - Endeavor

Page 2926 of 3870

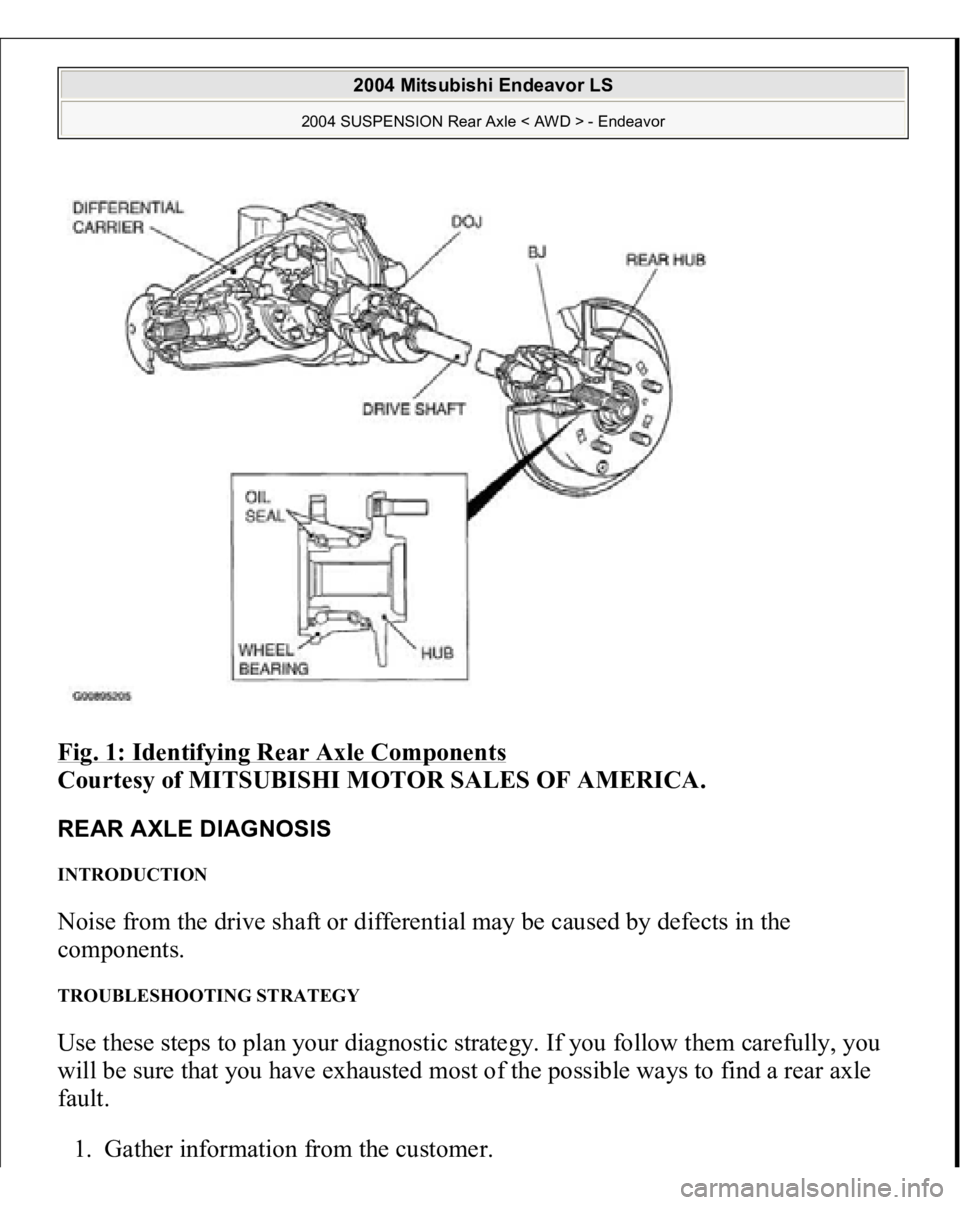

Fig. 1: Identifying Rear Axle Components

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

REAR AXLE DIAGNOSIS INTRODUCTION Noise from the drive shaft or differential may be caused by defects in the

components. TROUBLESHOOTING STRATEGY Use these steps to plan your diagnostic strategy. If you follow them carefully, you

will be sure that you have exhausted most of the possible ways to find a rear axle

fault.

1. Gather information from the customer.

2004 Mitsubishi Endeavor LS

2004 SUSPENSION Rear Axle < AWD > - Endeavor

Page 2927 of 3870

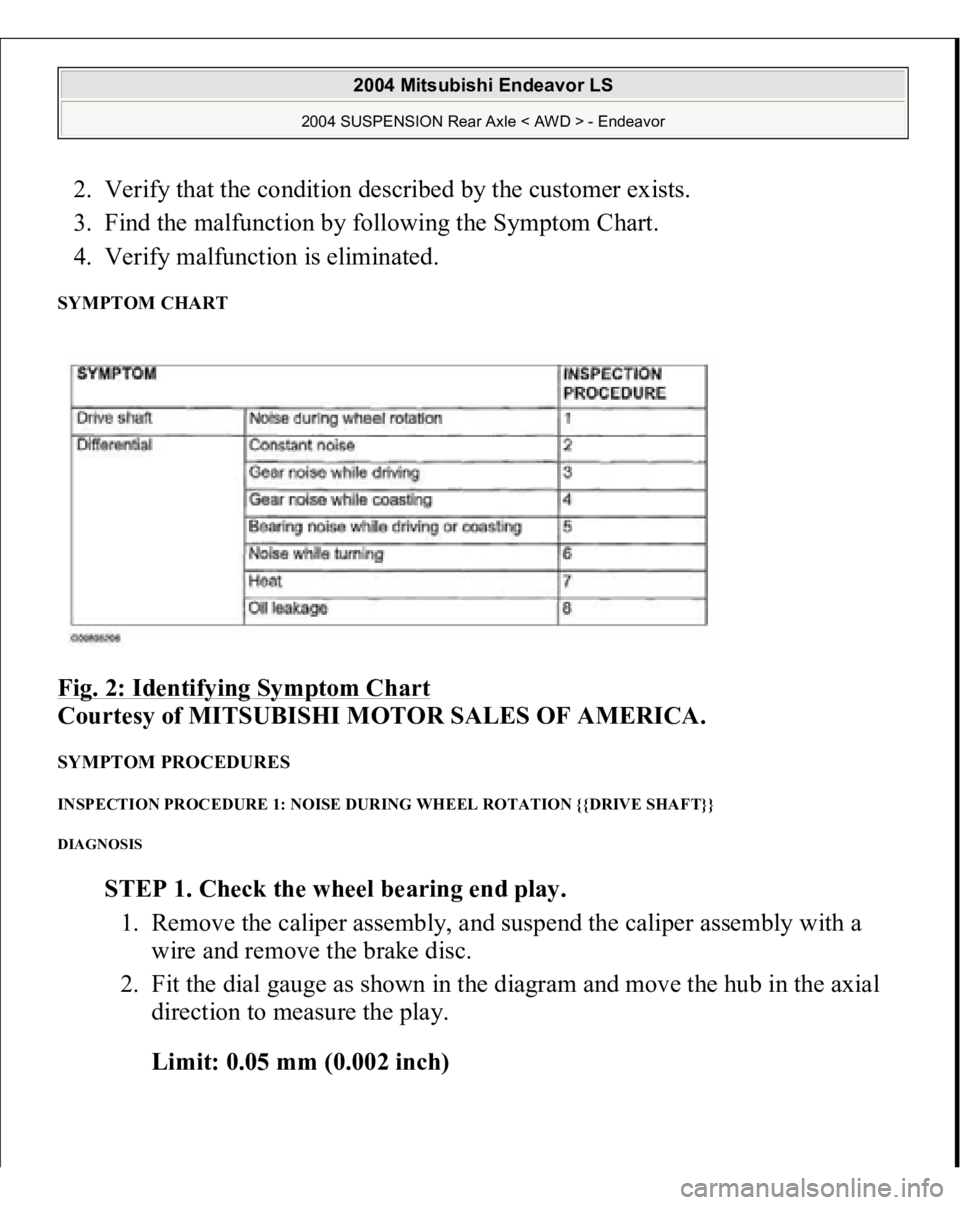

2. Verify that the condition described by the customer exists.

3. Find the malfunction by following the Symptom Chart.

4. Verify malfunction is eliminated. SYMPTOM CHART Fig. 2: Identifying Symptom Chart

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

SYMPTOM PROCEDURES INSPECTION PROCEDURE 1: NOISE DURING WHEEL ROTATION {{DRIVE SHAFT}} DIAGNOSIS

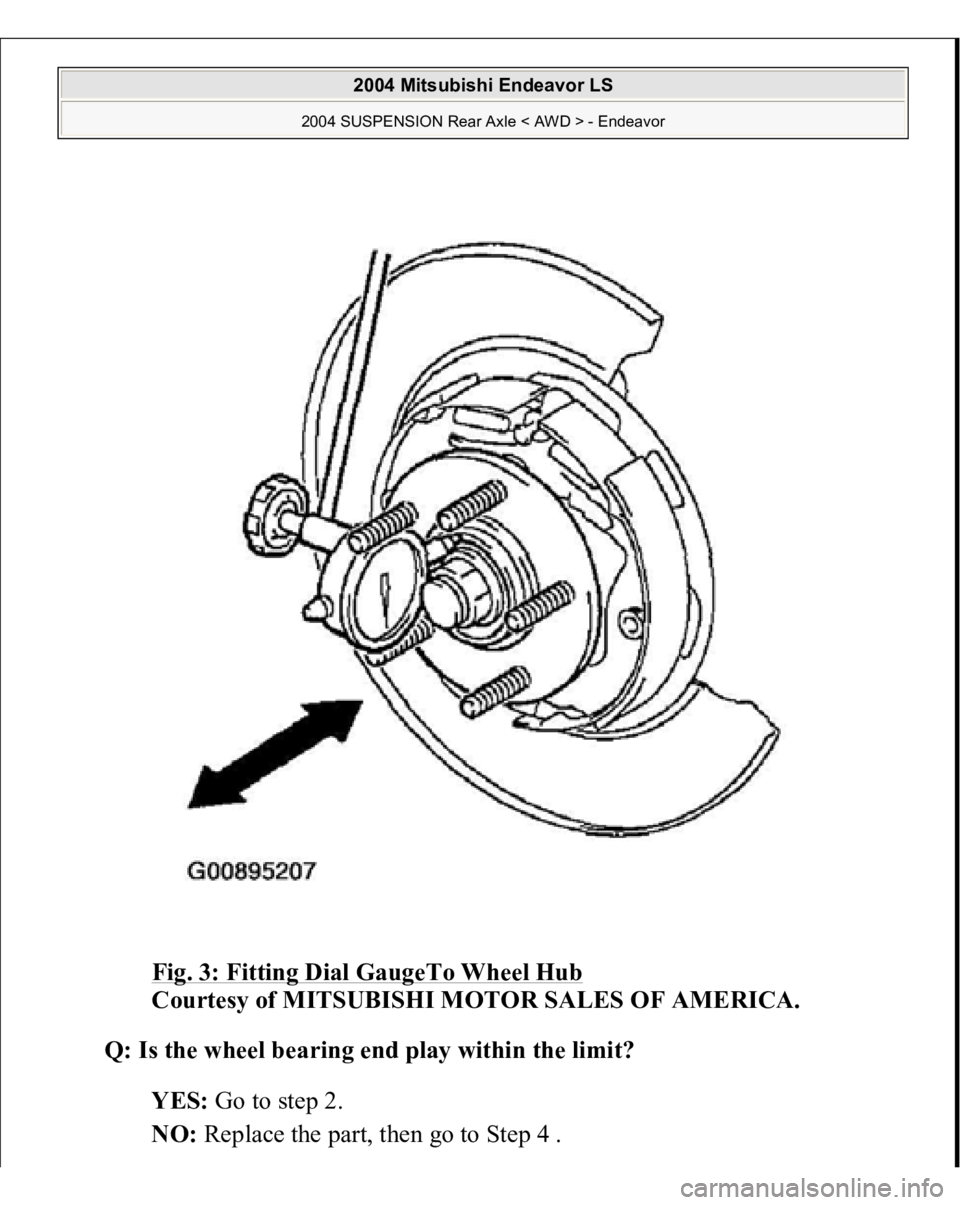

STEP 1. Check the wheel bearing end play.

1. Remove the caliper assembly, and suspend the caliper assembly with a

wire and remove the brake disc.

2. Fit the dial gauge as shown in the diagram and move the hub in the axial

direction to measure the play.

Limit: 0.05 mm (0.002 inch)

2004 Mitsubishi Endeavor LS

2004 SUSPENSION Rear Axle < AWD > - Endeavor

Page 2928 of 3870

Fig. 3: Fitting Dial GaugeTo Wheel Hub

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

Q: Is the wheel bearing end play within the limit?

YES: Go to step 2.

NO: Re

place the

part, then

go to Ste

p 4 .

2004 Mitsubishi Endeavor LS

2004 SUSPENSION Rear Axle < AWD > - Endeavor