check engine light MITSUBISHI ENDEAVOR 2004 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2004, Model line: ENDEAVOR, Model: MITSUBISHI ENDEAVOR 2004Pages: 3870, PDF Size: 98.47 MB

Page 4 of 3870

LONG STOPPING DISTANCES ON LOOSE ROAD SURFACESWhen braking on loose surfaces like snow-covered or gravel roads, the stopping

distance can be longer for an ABS-equipped vehicle than the stopping distance for a

vehicle with a conventional brake system. SHOCK AT STARTING CHECK Shock may be felt when the brake pedal is lightly pressed while driving at a low

speed. This is a normal characteristic because the ABS system operation check is

carried out when vehicle speed is 8 km/h (5 mph) or less. ANTI-LOCK BRAKING SYSTEM (ABS) DIAGNOSIS INTRODUCTION TO ANTI-LOCK BRAKING SYSTEM DIAGNOSIS The anti-lock braking system (ABS) operates differently from conventional brake

systems. These differences include sounds, sensations, and vehicle performance that

owners and service technicians who are not familiar with ABS may not be used to.

Some operational characteristics may seem to be malfunctions, but they are simply

signs of normal ABS operation. When diagnosing the ABS system, keep these

operational characteristics in mind. Inform the owner of the kind of performance

characteristics to expect from an ABS-equipped vehicle. ABS DIAGNOSTIC TROUBLE CODE DETECTION CONDITIONS ABS diagnostic trouble codes (ABS DTCs) are set under different conditions,

depending on the malfunction detected. Most ABS DTCs will only be set during

vehicle operation. Some ABS DTCs will also be set during the ABS self-check

immediately after the engine is started.

When you check if an ABS DTC will be displayed again after the DTC has been

erased, you should duplicate the ABS DTC set conditions. Depending on the

detection timing and set conditions for the specific ABS DTC, you must either drive

the vehicle or turn the engine off and restart it. To set the proper conditions for that

DTC again, refer to ABS DTC SET CONDITIONS

for each ABS DTC that you

are trying to reset.

ABS DIAGNOSTIC TROUBLESHOOTING STRATEGY

2004 Mitsubishi Endeavor LS

2004 BRAKES Anti-Lock Braking System (ABS) - Endeavor

Page 255 of 3870

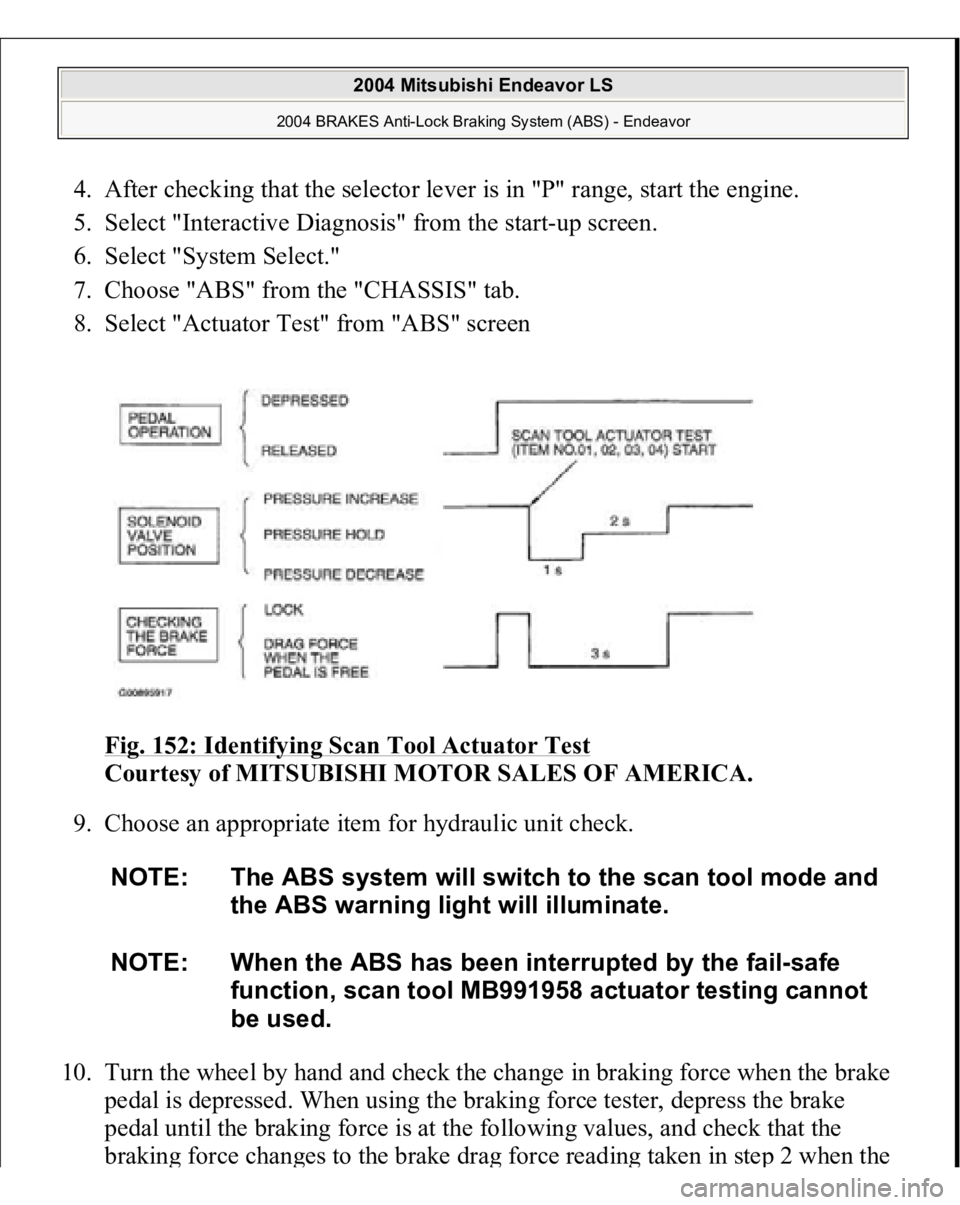

4. After checking that the selector lever is in "P" range, start the engine.

5. Select "Interactive Diagnosis" from the start-up screen.

6. Select "System Select."

7. Choose "ABS" from the "CHASSIS" tab.

8. Select "Actuator Test" from "ABS" screen

Fig. 152: Identifying Scan Tool Actuator Test

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

9. Choose an appropriate item for hydraulic unit check.

10. Turn the wheel by hand and check the change in braking force when the brake

pedal is depressed. When using the braking force tester, depress the brake

pedal until the braking force is at the following values, and check that the

brakin

g force chan

ges to the brake dra

g force readin

g taken in ste

p 2 when the

NOTE: The ABS system will switch to the scan tool mode and

the ABS warning light will illuminate.

NOTE: When the ABS has been interrupted by the fail-safe

function, scan tool MB991958 actuator testing cannot

be used.

2004 Mitsubishi Endeavor LS

2004 BRAKES Anti-Lock Braking System (ABS) - Endeavor

Page 732 of 3870

2. If the brake pedal play is not within the standard value, check the following,

and adjust or replace if necessary:

Excessive play between the brake pedal and the clevis pin, or between the

clevis pin and the brake booster operating rod Brake pedal height Installation position of the stop light switch, etc.

CLEARANCE BETWEEN BRAKE PEDAL AND DASH PANEL 1. Turn up the carpet, etc. under the brake pedal.

2. Start the engine, depress the brake pedal with approximately 500 N (112

pounds) of force, and measure the clearance between the brake pedal and the

dash panel.

Standard value: 110 mm (4.33 inches) or more [From the surface of dash

panel to the face of

pedal

pad]

2004 Mitsubishi Endeavor LS

2004 BRAKES Basic Brake System - Endeavor

Page 1271 of 3870

For belt tension, see ADJUSTMENTS

.

TROUBLE SHOOTING 1. Is battery in good condition?

If Yes, then go to next step. If No, then charge or replace battery.

2. Is generator drive belt in good condition? If Yes, then go to next step. If No, then adjust belt tension or replace belt.

3. Does the generator malfunction light come on when the ignition switch is

turned on? If Yes, then go to next step. If No:

Check the ignition switch.

Check for burnt-out generator malfunction light.

Check the generator.

Check the generator malfunction light-related circuits.

4. Does the generator malfunction light go out after starting the engine? If Yes, then go to next step. If No, check the generator.

5. Is an oscilloscope available? If Yes, then go to next step. If No, then go to step 7 .

6. Does the oscilloscope show a normal wave pattern? If Yes, then go to next step. If No, then check the generator.

7. Turn the engine on and idle at 2500 RPM. Turn the headlights on with the

High Beams on. Be sure that there is voltage between generator terminal B and

the positive battery terminal of 0.5V or less. Check that the voltage between

the negative batter

y terminal and

generator bod

y is 0.5V or less. Are the

2004 Mitsubishi Endeavor Limited

2004 STARTING & CHARGING SYSTEMS Generators & Regulators - Endeavor

Page 1274 of 3870

4. Connect a clamp-type DC test ammeter with a range of 0-150A to the

generator B terminal output wire.

5. Connect a digital-type voltmeter between the generator B terminal and the

positive battery terminal. (Connect the positive lead of the voltmeter to the B

terminal, and then connect the negative lead of the voltmeter to the positive

battery cable.)

6. Reconnect the negative battery cable.

7. Connect an engine tachometer or scan tool MB991958.

8. Leave the hood open.

9. Start the engine.

10. With the engine running at 2500 RPM, turn the headlights and other lights on

and off to adjust the generator load so that the value displayed on the ammeter

is slightly above 30A. Read the voltmeter. Voltage reading at or below limit

value means voltage drop between generator and batter is OK. There should be

a maximum voltage of 0.3V.

11. If the value displayed on the voltmeter is above the limit value, there is

probably a malfunction in the generator output wire. Check the wiring between

the

generator B terminal and the

positive batter

y terminal

(includin

g fusible

NOTE: The way of disconnecting the generator output wire and

of connecting the ammeter is possibly not found the

problem that the output current is dropping due to the

insufficient connection between terminal B and the

output wire.

NOTE: When the generator output is high and the value

displayed on the ammeter does not decrease to 30A,

set the value to 40A. Read the value displayed on the

voltmeter at this time. In the case the limit value

becomes maximum 0.4V. Adjust the engine speed by

gradually decreasing it until the value displayed on the

ammeter is 30A. Take a reading of the value displayed

on the voltmeter at this time

2004 Mitsubishi Endeavor Limited

2004 STARTING & CHARGING SYSTEMS Generators & Regulators - Endeavor

Page 1278 of 3870

11. Immediately after setting the headlights to high beam and turning the heater

blower switch to the highest position, increase the engine speed to 2,500 RPM

and read the maximum current output value displayed on the ammeter. Limit

value: 70 percent of nominal current output.

12. The reading on the ammeter should be above the limit value. If the reading is

below the limit value and the generator output wire is normal, remove the

generator from the engine and check the generator.

13. Run the engine at idle speed after the test.

14. Turn the ignition switch to the LOCK (OFF) position.

15. Disconnect the engine tachometer or scan tool MB991958.

16. Disconnect the negative battery cable.

17. Disconnect the ammeter and voltmeter.

18. Connect the negative battery cable.

19. Run the engine for 10 minutes at an idle. REGULATED VOLTAGE TEST Required special tools:

MB991958: Scan Tool MUT

-III Sub Assembly.

NOTE: The current output value will depend on the electrical

load and the temperature of the generator body.

NOTE: If the electrical load is small while testing, the specified

level of current may not be output even though the

generator is normal. In such cases, increase the

electrical load by leaving the headlights turned on for

some time to discharge the battery or by using the

lighting system in another vehicle, and then test again.

NOTE: The specified level of current also may not be output if

the temperature of the generator body or the ambient

temperature is too high. In such cases, cool the

generator and then test again.

2004 Mitsubishi Endeavor Limited

2004 STARTING & CHARGING SYSTEMS Generators & Regulators - Endeavor

Page 1280 of 3870

Generator installation. Check to be sure that the battery installed in the vehicle is fully charged. Generator drive belt tension. Fusible link. Abnormal noise from the generator while the engine is running.

2. Turn the ignition switch to the LOCK (OFF) position.

3. Disconnect the negative battery cable.

4. Use the special tool (Generator Harness Connector: MB991519) to connect a

digital-type voltmeter between the generator S terminal and ground. (Connect

the positive lead of the voltmeter to the S terminal, and then connect the

negative lead of the voltmeter to a secure ground or to the negative battery

terminal.)

5. Connect a clamp-type DC test ammeter with a range of 0-150A to the

generator B terminal output wire.

6. Reconnect the negative battery cable.

7. Connect an engine tachometer, or scan tool MB991958.

8. Turn the ignition switch to the ON position and check that the reading on the

voltmeter is equal to the battery positive voltage.

9. Check to be sure that all lights and accessories are off.

10. Start the engine.

11. Increase the engine speed to 2,500 RPM

12. Read the value displayed on the voltmeter when the current output by the

generator becomes 10A or less.

13. If the voltage reading conforms to the value in the voltage regulation table,

then the voltage regulator is operating normally. If the voltage is outside the

standard value, there is a malfunction of the volta

ge re

gulator or the

generator.

NOTE: If the voltage is 0V, the cause is probably an open

circuit in the wire or fusible link between the generator

S terminal and the battery positive terminal or

malfunctioning voltmeter.

2004 Mitsubishi Endeavor Limited

2004 STARTING & CHARGING SYSTEMS Generators & Regulators - Endeavor

Page 1281 of 3870

See REGULATOR VOLTAGE SPECIFICATIONS TABLE

.

14. After the test, lower the engine speed to idle.

15. Turn the ignition switch to the LOCK (OFF) position.

16. Disconnect the engine tachometer or scan tool MB991958.

17. Disconnect the negative battery cable.

18. Disconnect the ammeter and voltmeter.

19. Connect the negative battery cable.

20. Run the engine for 10 minutes at an idle.

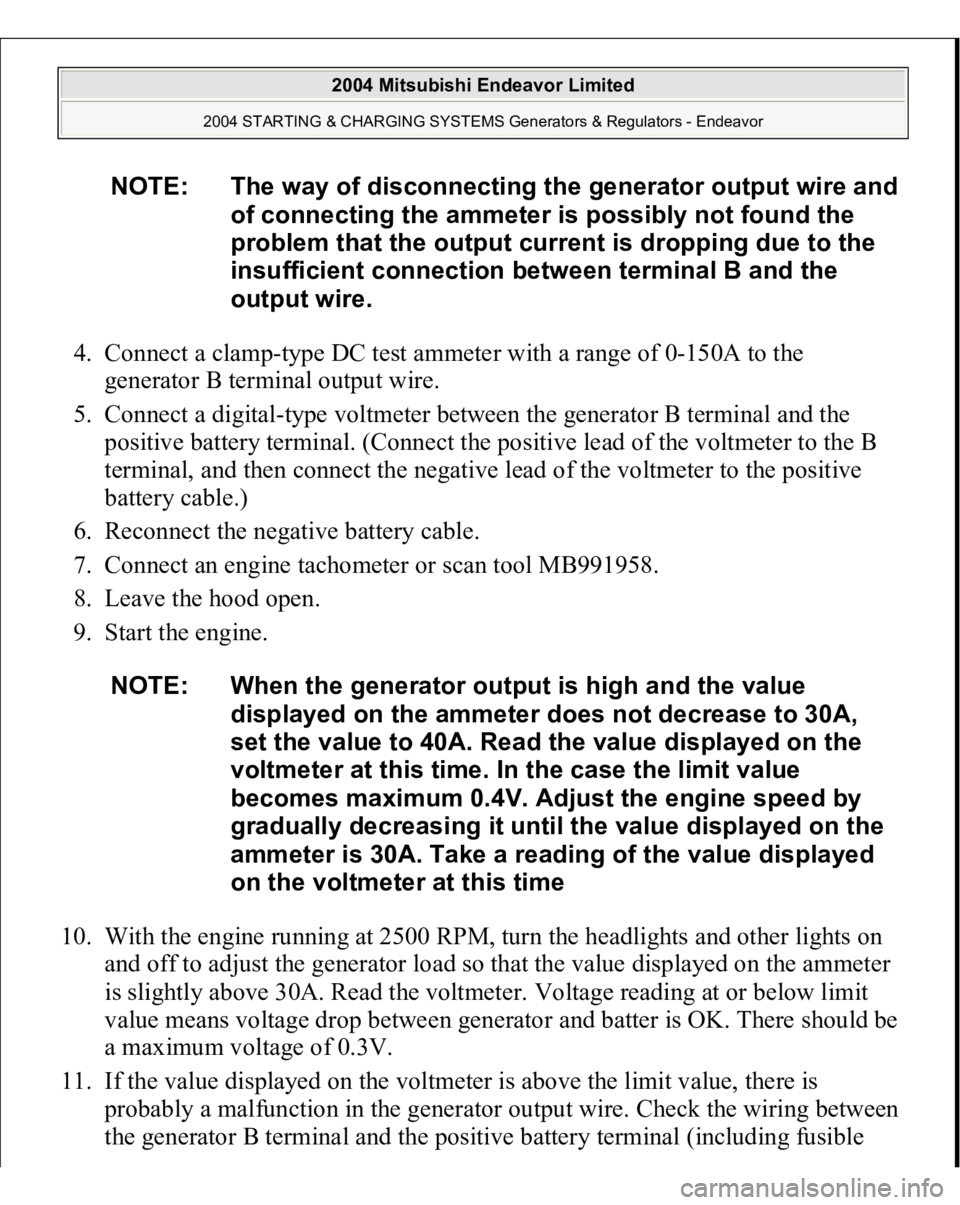

REGULATOR VOLTAGE SPECIFICATIONS

WAVE PATTERN CHECK USING AN OSCILLOSCOPE Abnormal Waveforms The size of the waveform patterns can differ greatly, depending on the adjustment

of the variable knob on the oscilloscope. See Fig. 6

.

Identification of abnormal waveforms is easier when there is a large output current

(regulator is not operating). Waveforms can be observed when the headlights are

illuminated.

Check the conditions of the generator malfunction light (illuminated/not

illuminated

) also, and carr

y out a total check.

Ambient Temp. °F (°C)

Voltage

Terminal S-4 (-20)

14.2-15.4

68 (20)

13.9-14.9

140 (60)

13.4-14.5

176 (80)

13.1-14.2

2004 Mitsubishi Endeavor Limited

2004 STARTING & CHARGING SYSTEMS Generators & Regulators - Endeavor

Page 1461 of 3870

Fig. 134: Installing Connecting Rod Cap Nu

t

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

INSPECTION PISTON Replace the piston if scratches or seizure is evident on its surfaces (especially the

thrust surface). Replace the piston if it is cracked. PISTON PIN 1. Insert the piston pin into the piston pin hole with a thumb. You should feel a

slight resistance. Replace the piston pin if it can be easily inserted or there is

excessive play.

2. The piston and piston pin must be replaced as an assembly. PISTON RING 1. Check the piston ring for damage, excessive wear, and breakage. Replace if

defects are evident. If the piston has been replaced with a new one, the piston

rings must also be replaced with new ones.

2. Check for clearance between the piston ring and ring groove. If the limit is

exceeded, replace the ring or piston, or both.

Standard Value:

Number 1: 0.03 - 0.07 mm (0.0012 - 0.0027 inch)

Number 2: 0.02 - 0.06 mm (0.0008 - 0.0023 inch)

Limit: 0.1 mm (0.003 inch)

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1516 of 3870

Required Special Tool

:

MB991958: Scan Tool (MUT-III Sub Assembly)

MB991824: V.C.I. MB991827: MUT-III USB Cable MB991910: MUT-III Main Harness A

1. Before checks set the vehicle in the following condition:

Engine coolant temperature: 80 - 95°C (176 - 203°F) Lights and all accessories: OFF Transaxle: P range

2. Connect scan tool MB991958 to the data link connec

tor.

NOTE: Vehicles for Canada, the headlight, taillight, etc. remain

lit even when the lighting switch is in "OFF" position

but this is no problem for checks.

CAUTION: To prevent damage to scan tool MB991958,

always turn the ignition switch to the

"LOCK" (OFF) position before connecting or

disconnecting scan tool MB991958.

2004 Mitsubishi Endeavor Limited

2004 ENGINE Engine - Endeavor