fuel pressure MITSUBISHI ENDEAVOR 2004 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2004, Model line: ENDEAVOR, Model: MITSUBISHI ENDEAVOR 2004Pages: 3870, PDF Size: 98.47 MB

Page 1096 of 3870

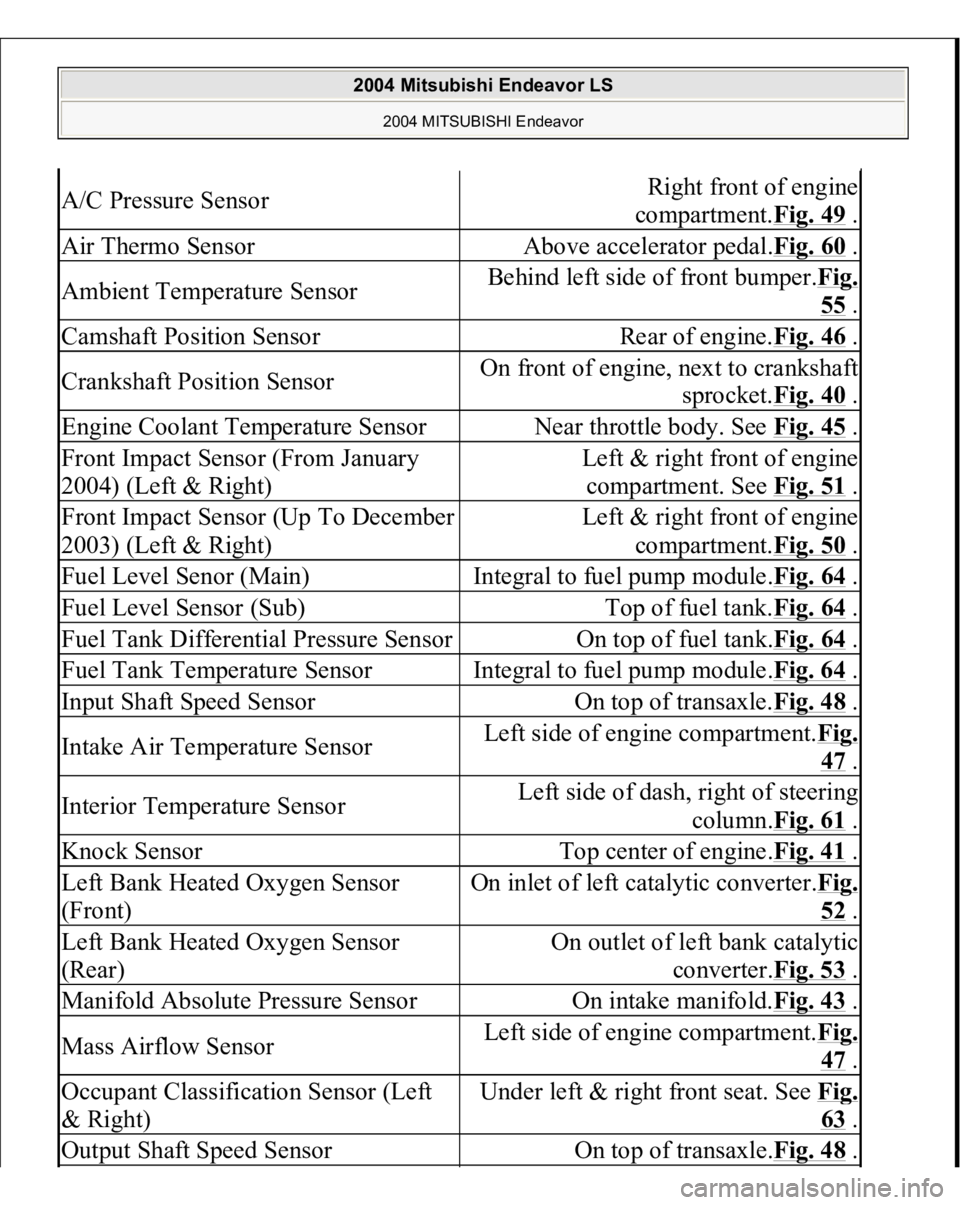

A/C Pressure Sensor

Right front of engine

compartment.Fig. 49

.

Air Thermo Sensor

Above accelerator pedal.Fig. 60

.

Ambient Temperature Sensor

Behind left side of front bumper.Fig.

55 .

Camshaft Position Sensor

Rear of engine.Fig. 46

.

Crankshaft Position Sensor

On front of engine, next to crankshaft

sprocket.Fig. 40

.

Engine Coolant Temperature Sensor

Near throttle body. See Fig. 45

.

Front Impact Sensor (From January

2004) (Left & Right)

Left & right front of engine

compartment. See Fig. 51

.

Front Impact Sensor (Up To December

2003) (Left & Right)

Left & right front of engine

compartment.Fig. 50

.

Fuel Level Senor (Main)

Integral to fuel pump module.Fig. 64

.

Fuel Level Sensor (Sub)

Top of fuel tank.Fig. 64

.

Fuel Tank Differential Pressure Sensor

On top of fuel tank.Fig. 64

.

Fuel Tank Temperature Sensor

Integral to fuel pump module.Fig. 64

.

Input Shaft Speed Sensor

On top of transaxle.Fig. 48

.

Intake Air Temperature Sensor

Left side of engine compartment.Fi

g.

47 .

Interior Temperature Sensor

Left side of dash, right of steering

column.Fig. 61

.

Knock Sensor

Top center of engine.Fig. 41

.

Left Bank Heated Oxygen Sensor

(Front)

On inlet of left catalytic converter.Fi

g.

52 .

Left Bank Heated Oxygen Sensor

(Rear)

On outlet of left bank catalytic

converter.Fig. 53

.

Manifold Absolute Pressure Sensor

On intake manifold.Fig. 43

.

Mass Airflow Sensor

Left side of engine compartment.Fi

g.

47 .

Occupant Classification Sensor (Left

& Right)

Under left & right front seat. See Fi

g.

63 .

Output Shaft Speed Sensor

On top of transaxle.Fig. 48

.

2004 Mitsubishi Endeavor LS

2004 MITSUBISHI Endeavor

Page 1097 of 3870

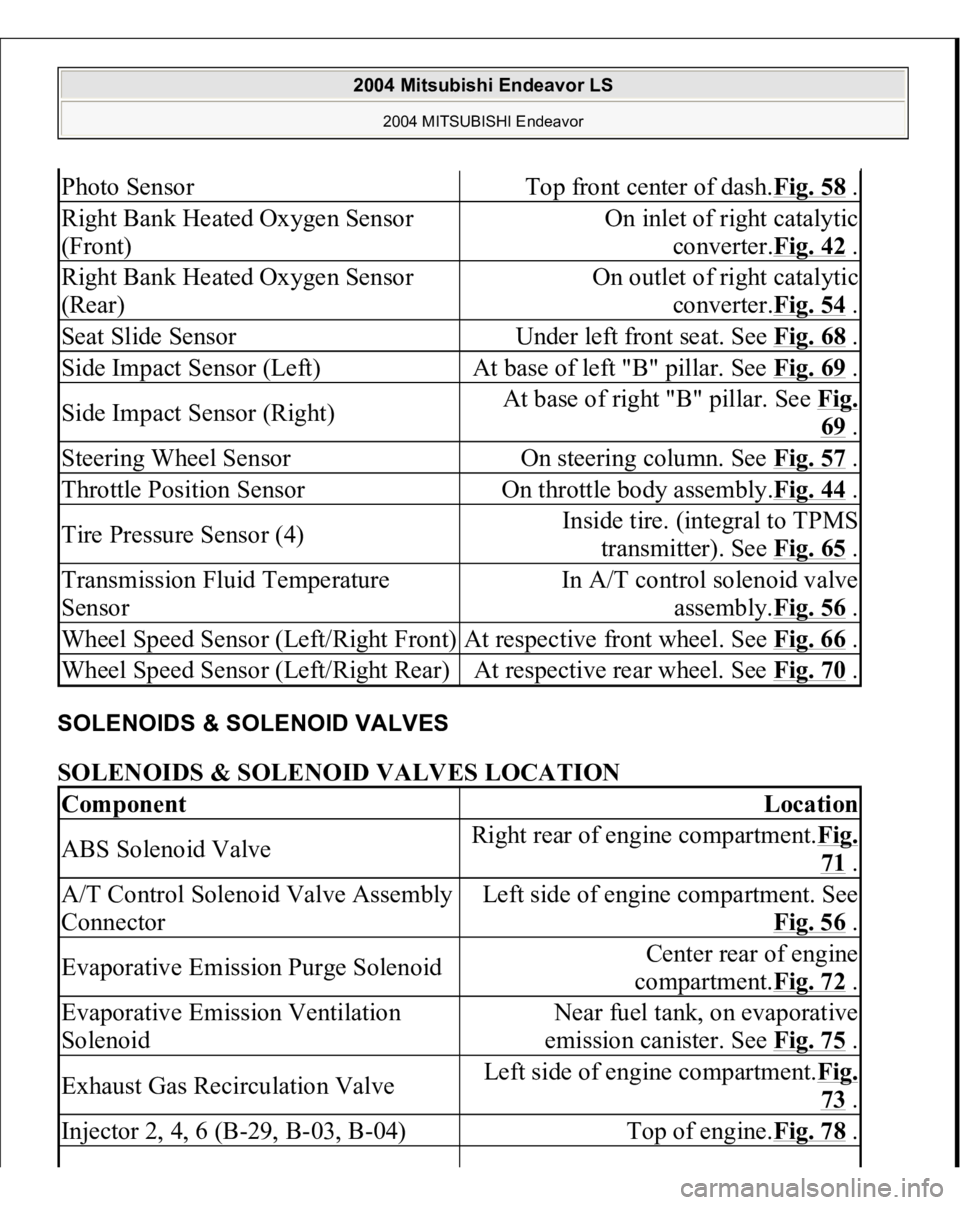

SOLENOIDS & SOLENOID VALVES SOLENOIDS & SOLENOID VALVES LOCATION Photo Sensor

Top front center of dash.Fig. 58

.

Right Bank Heated Oxygen Sensor

(Front)

On inlet of right catalytic

converter.Fig. 42

.

Right Bank Heated Oxygen Sensor

(Rear)

On outlet of right catalytic

converter.Fig. 54

.

Seat Slide Sensor

Under left front seat. See Fig. 68

.

Side Impact Sensor (Left)

At base of left "B" pillar. See Fig. 69

.

Side Impact Sensor (Right)

At base of right "B" pillar. See Fig.

69 .

Steering Wheel Sensor

On steering column. See Fig. 57

.

Throttle Position Sensor

On throttle body assembly.Fig. 44

.

Tire Pressure Sensor (4)

Inside tire. (integral to TPMS

transmitter). See Fig. 65

.

Transmission Fluid Temperature

Sensor

In A/T control solenoid valve

assembly.Fig. 56

.

Wheel Speed Sensor (Left/Right Front)

At respective front wheel. See Fig. 66

.

Wheel Speed Sensor (Left/Right Rear)

At respective rear wheel. See Fig. 70

.

Component

Location

ABS Solenoid Valve

Right rear of engine compartment.Fig.

71 .

A/T Control Solenoid Valve Assembly

Connector

Left side of engine compartment. See

Fig. 56

.

Evaporative Emission Purge Solenoid

Center rear of engine

compartment.Fig. 72

.

Evaporative Emission Ventilation

Solenoid

Near fuel tank, on evaporative

emission canister. See Fig. 75

.

Exhaust Gas Recirculation Valve

Left side of engine compartment.Fig.

73 .

Injector 2, 4, 6 (B-29, B-03, B-04)

Top of engine.Fig. 78

.

2004 Mitsubishi Endeavor LS

2004 MITSUBISHI Endeavor

Page 1365 of 3870

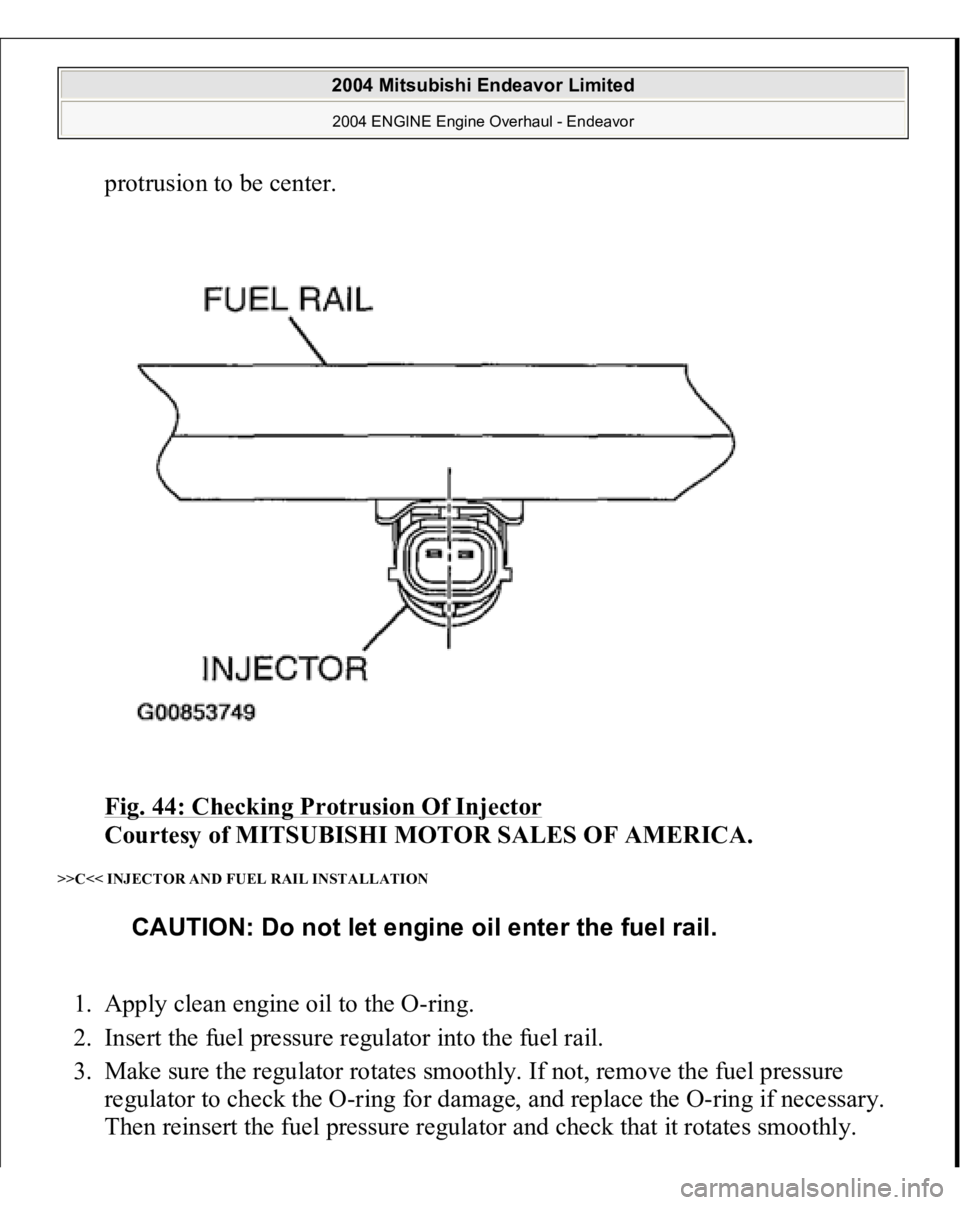

protrusion to be center.

Fig. 44: Checking Protrusion Of Injector

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

>>C<< INJECTOR AND FUEL RAIL INSTALLATION 1. Apply clean engine oil to the O-ring.

2. Insert the fuel pressure regulator into the fuel rail.

3. Make sure the regulator rotates smoothly. If not, remove the fuel pressure

regulator to check the O-ring for damage, and replace the O-ring if necessary.

Then reinsert the fuel pressure regulator and chec

k that it rotates smoothly.

CAUTION: Do not let engine oil enter the fuel rail.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1387 of 3870

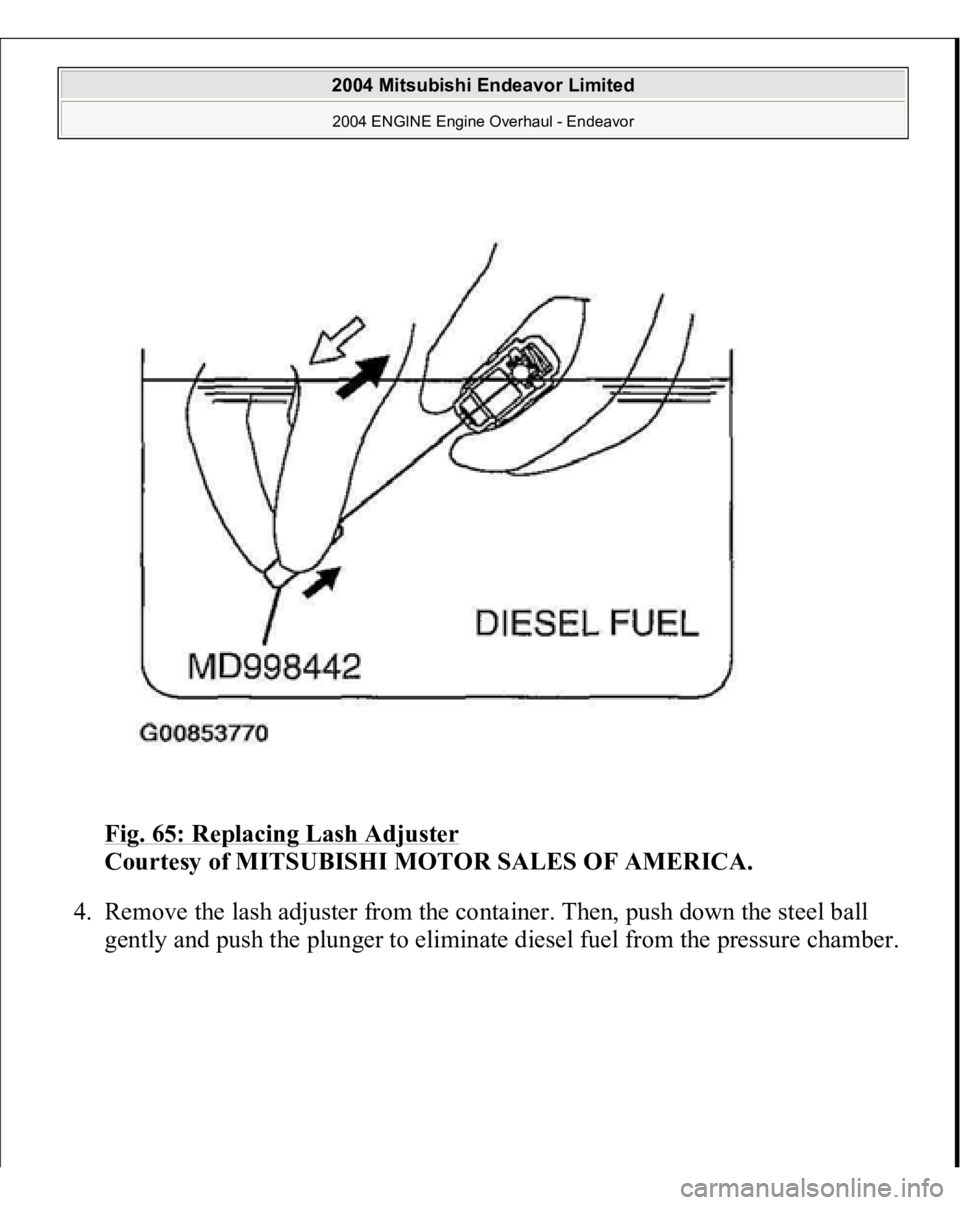

Fig. 65: Replacing Lash Adjuster

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

4. Remove the lash adjuster from the container. Then, push down the steel ball

gentl

y and

push the

plun

ger to eliminate diesel fuel from the

pressure chamber.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1388 of 3870

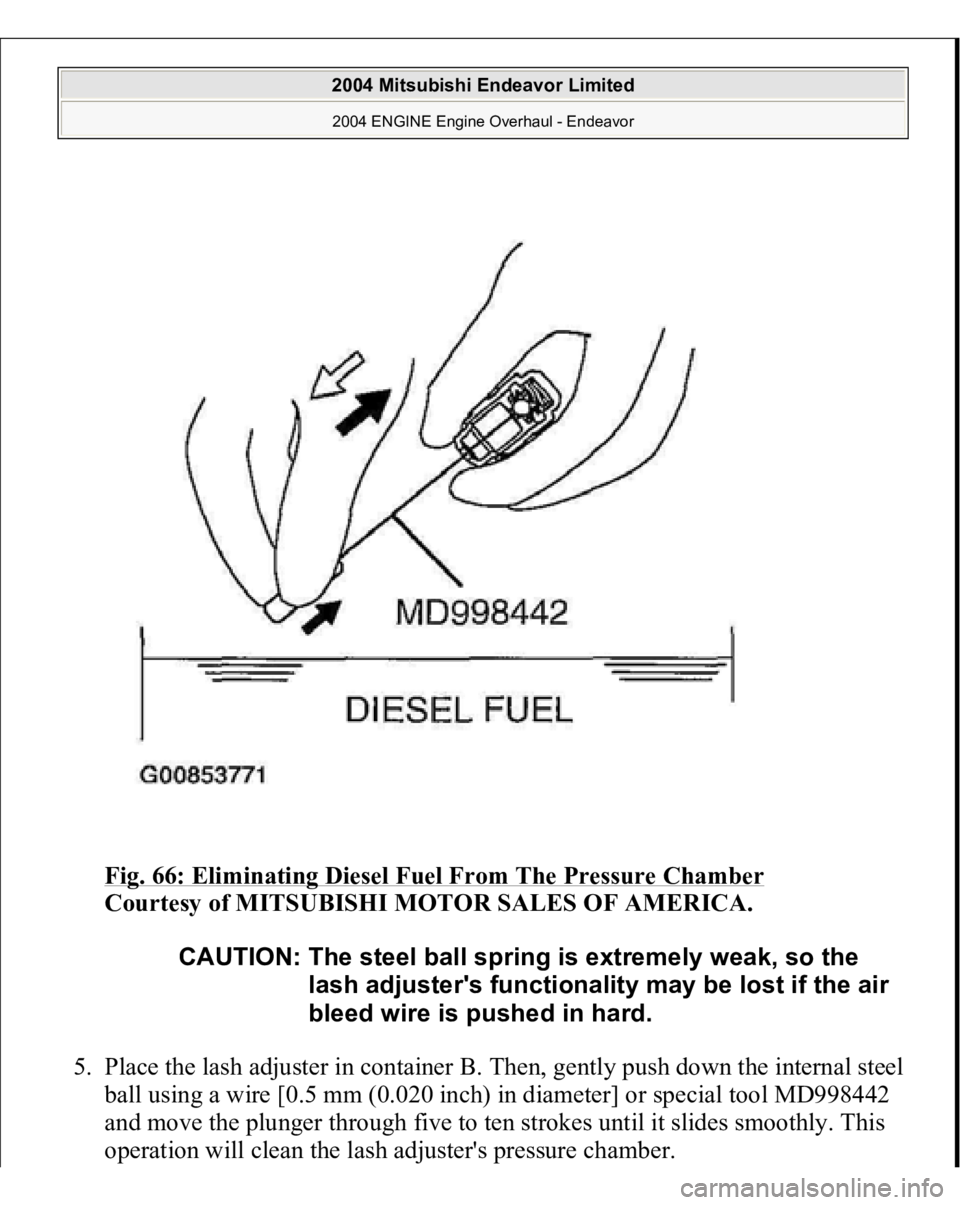

Fig. 66: Eliminating Diesel Fuel From The Pressure Chamber

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

5. Place the lash adjuster in container B. Then, gently push down the internal steel

ball using a wire [0.5 mm (0.020 inch) in diameter] or special tool MD998442

and move the plunger through five to ten strokes until it slides smoothly. This

o

peration will clean the lash ad

juster's

pressure chamber.

CAUTION: The steel ball spring is extremely weak, so the

lash adjuster's functionality may be lost if the air

bleed wire is pushed in hard.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1389 of 3870

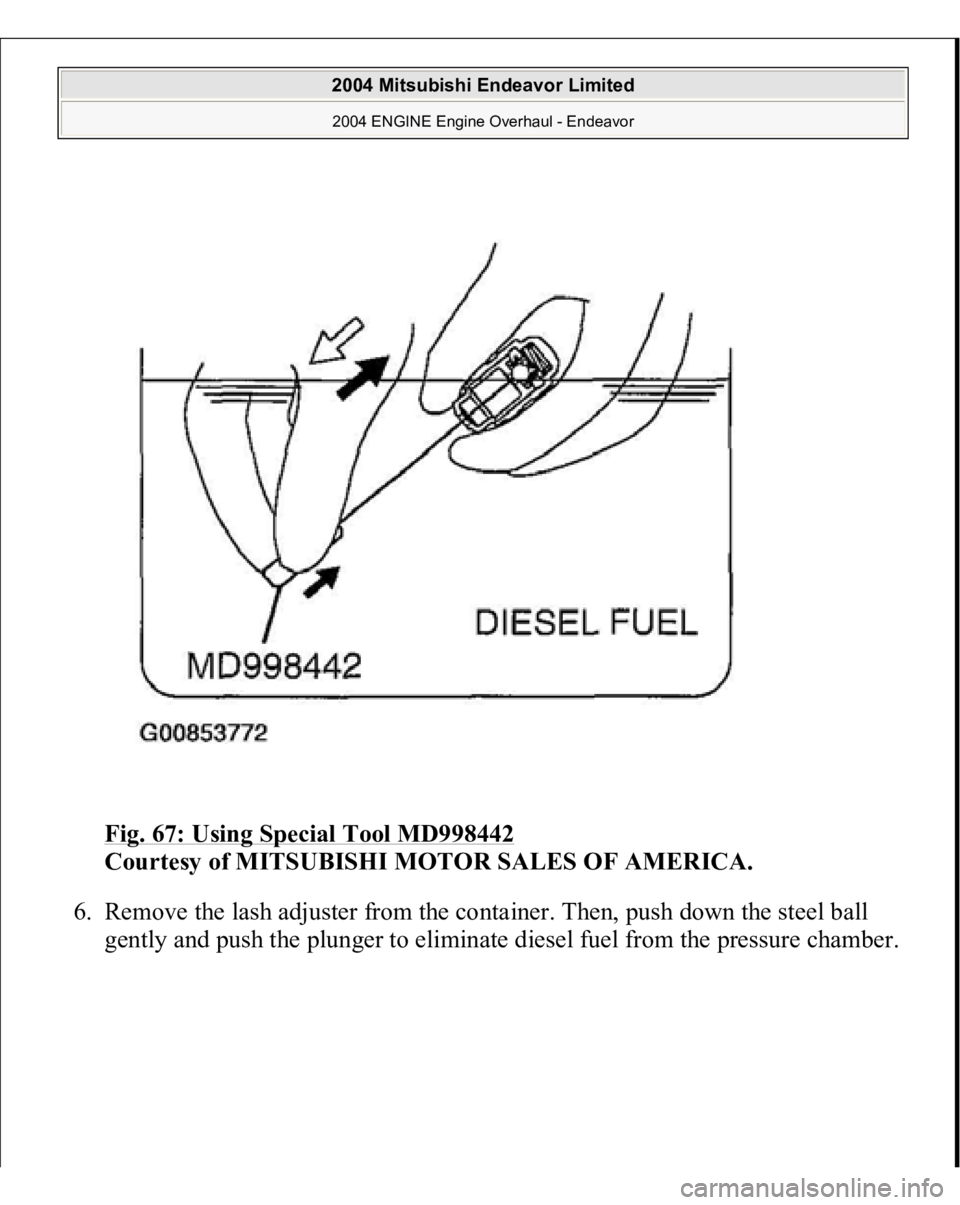

Fig. 67: Using Special Tool MD998442

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

6. Remove the lash adjuster from the container. Then, push down the steel ball

gentl

y and

push the

plun

ger to eliminate diesel fuel from the

pressure chamber.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1390 of 3870

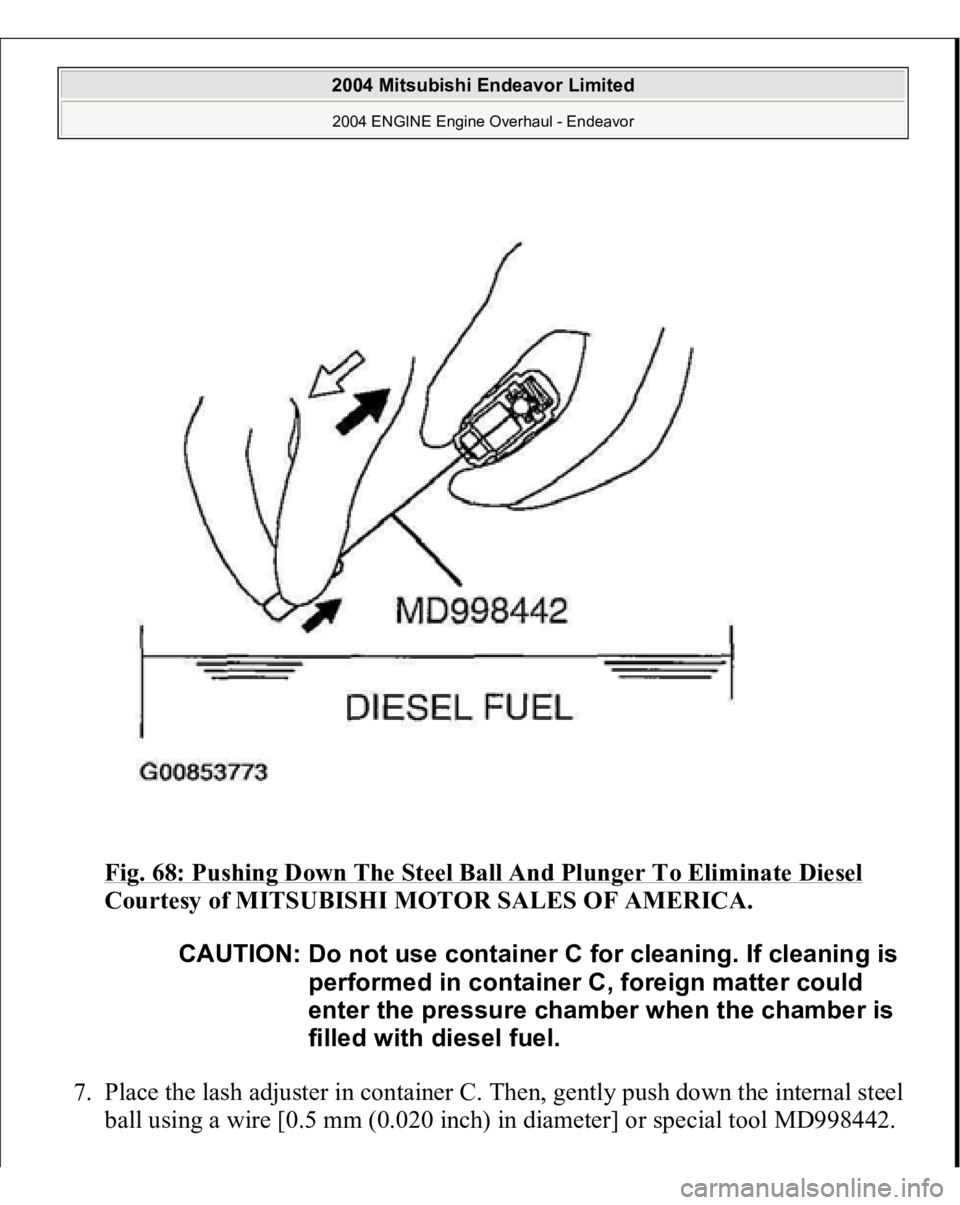

Fig. 68: Pushing Down The Steel Ball And Plunger To Eliminate Diesel

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

7. Place the lash adjuster in container C. Then, gently push down the internal steel

ball using a wire [0.5 mm (0.020 inch) in diameter] or special tool MD998442.

CAUTION: Do not use container C for cleanin

g. If cleanin

g is

performed in container C, foreign matter could

enter the pressure chamber when the chamber is

filled with diesel fuel.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1391 of 3870

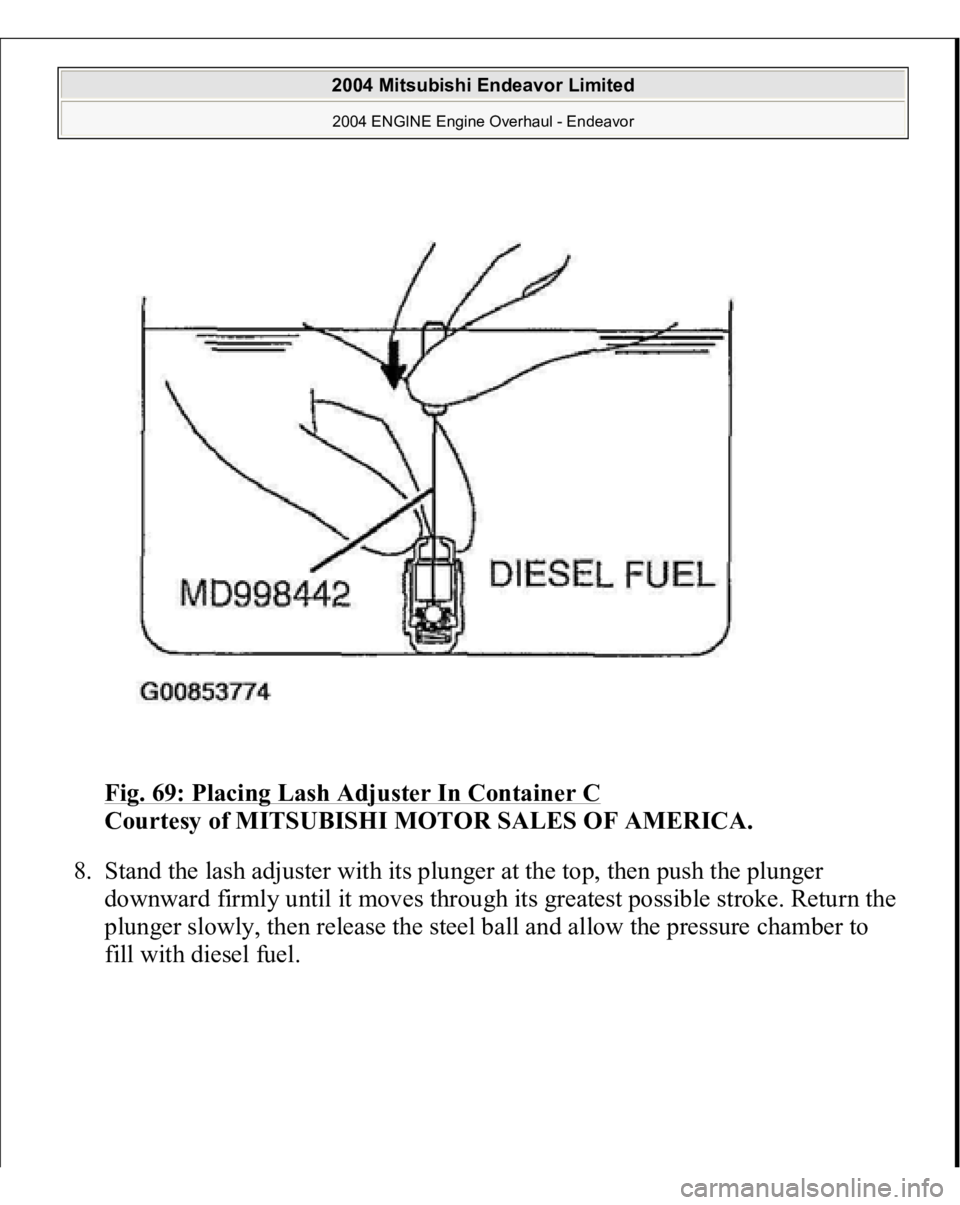

Fig. 69: Placing Lash Adjuster In Container C

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

8. Stand the lash adjuster with its plunger at the top, then push the plunger

downward firmly until it moves through its greatest possible stroke. Return the

plunger slowly, then release the steel ball and allow the pressure chamber to

fill with diesel fuel.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1524 of 3870

Mixture Check)

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

3. Check that the basic ignition timing is within the standard value.

Standard value: 5° BTDC+/-3°

4. Start the engine and increase the engine speed to 2,500 r/min for 2 minutes.

5. Set the CO, HC tester.

6. Check the CO contents and the HC contents at idle.

Standard value:

CO contents: 0.5% or less

HC contents: 100 ppm or less

7. If the CO and HC contents do not remain inside the standard value, check the

following items:

Diagnostic output Closed-loop control (When the closed-loop control is carried out normally, the

output signal of the heated oxygen sensor changes between 0 - 400 mV and

600 - 1,000 mV at idle.) Fuel pressures Injector Ignition coil, spark plug EGR system and EGR valve leak Evaporative emission system Compression pressure

COMPRESSION PRESSURE CHECK Re

quired S

pecial Tool

:

NOTE: Replace the catalytic converter when the CO and HC

contents do not remain inside the standard value, even

though the result of the inspection is normal for all items.

2004 Mitsubishi Endeavor Limited

2004 ENGINE Engine - Endeavor

Page 1539 of 3870

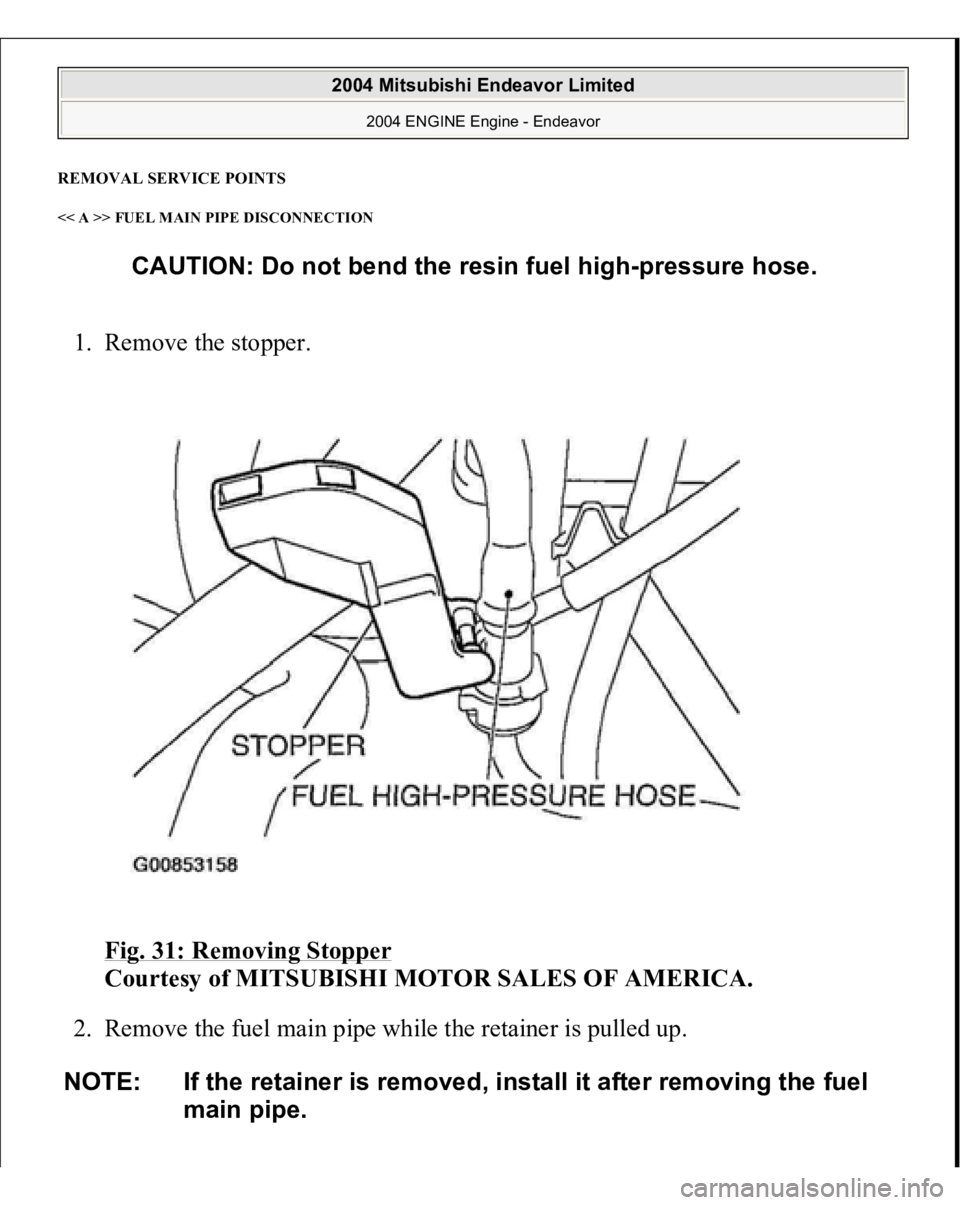

REMOVAL SERVICE POINTS << A >> FUEL MAIN PIPE DISCONNECTION 1. Remove the stopper.

Fig. 31: Removing Stopper

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

2. Remove the fuel main pipe while the retainer is pulled up.

CAUTION: Do not bend the resin fuel high-pressure hose.

NOTE: If the retainer is removed, install it after removing the fuel

main pipe.

2004 Mitsubishi Endeavor Limited

2004 ENGINE Engine - Endeavor